Stratasys idea series mojo 3d printer

The Stratasys Mojo Desktop 3D Printer

THE STRATASYS

Bring your Big Ideas to Life

Give your design team a little Mojo with proven Fused Deposition Modeling (FDM) technology and the Mojo 3D Printer. It's as simple to use as an inkjet printer, yet powerful enough to meet the highest 3D printing standards

View Video Request Demo

- Overview

- Key Features

- Advantages

- Materials

- Specifications

- Request a Quote

Discover the Magic of Mojo

The Mojo 3D Printer from Stratasys brings affordable, professional 3D printing to your design process. Powered by FDM technology, you can trust the Mojo to empower your design creativity. Whether you’re testing for form, fit or function, Mojo works easily with your CAD software- bringing your ideas to life with just the push of a button.

Explore the Stratasys Mo by watching the video

Affordable, Professional 3D Printing

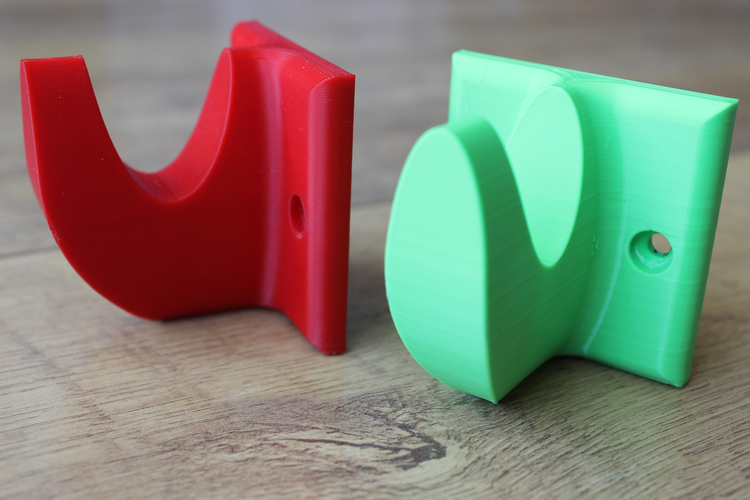

The Mojo 3D Printer allows you to print professional grade 3D models in ABSplus thermoplastic – at a price lower than other professional 3D printers. Using Stratasys’ Fused Desposition Modeling (FDM) technology , the Mojo achieves excellent accuracy and function, all in one compact unit.

Discover the Magic of Mojo

With the simplicity of a typical inkjet printer, the Mojo makes the transition from 2D to 3D a smooth one. With intuitive 3D Print Wizard Software, easily replaceable material cartridges, and simple post-processing, the Mojo 3D printing process is guaranteed to enhance your application.

An All-In-One Solution

Printer Bundle includes everything you need to start desktop 3D printing:

· The Mojo 3D Printer

· Print Wizard/Control Panel

Software

· WaveWash 55 Cleaning System

· Ivory ABSplus model material

· Support Material

· Ecoworks Tablets

· Modeling bases and more

The Mojo is ideal for printing 3D models that help determine form, fit, and function- everything from ergonomics to design verification. When it’s time to test your concepts, Mojo produces durable ABSplus 3D models that will stand up to testing in their intended environment

When it’s time to test your concepts, Mojo produces durable ABSplus 3D models that will stand up to testing in their intended environment

SHOP ABSPLUS

Bring Your Ideas to Life

The Mojo from Stratasys is ideal for 3D printing models that help determine form, fit, and function- everything from ergonomics to design verification.

Print models with ABSplus, production-grade thermoplastic that provides your print with durability and a high-quality finish.

Simple Yet Powerful

As one of the smallest industrial 3D printers, the Mojo is the perfect desktop solution for quick prototype prints in both small or large office spaces. The system works as easily as a traditional inkjet printer yet powerful enough to meet and exceed 3D printing standards. Included software allows for real-time status updates and estimated print times allowing your design team to print their ideas efficiently.

Easy to Use

Everything you need to start printing is straight out of the box. Set up is fast and easy- you can be printing your first 3D model in less than an hour.

Set up is fast and easy- you can be printing your first 3D model in less than an hour.

With the WaveWash 55 Support Cleaning System, removing support material is easy. Featuring a stainless steel carafe, the device dissolves soluble support material quickly and quietly.

Materials

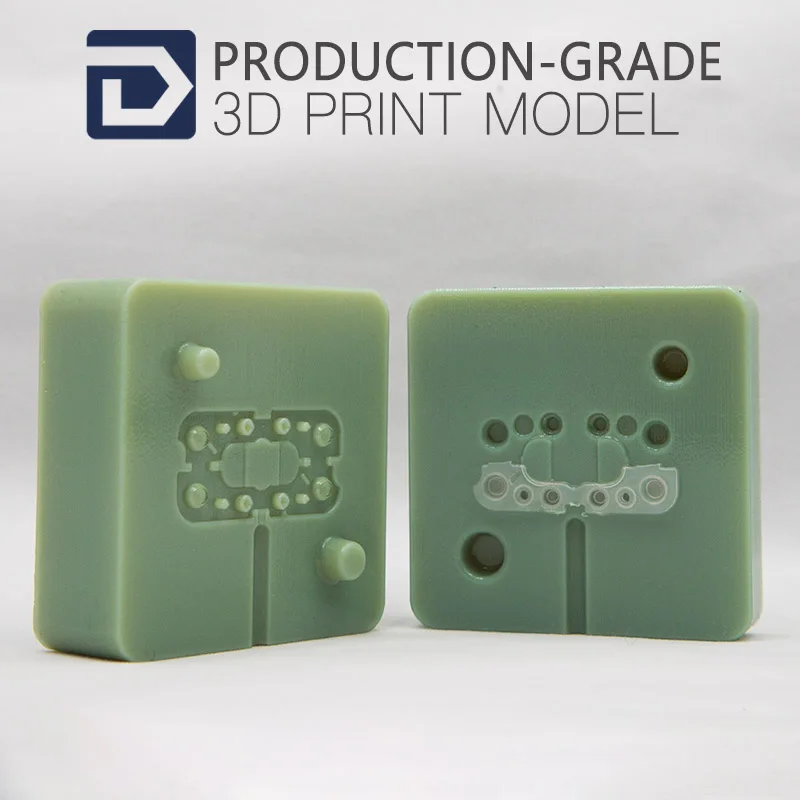

ABSplus

Production-grade thermoplastic ideal for conceptual modeling, prototyping and end-use parts. Get a high-quality finish with matching durability

LEARN MORE

Build Tray Size | Build Tray Size12.7 x 12.7 x 12.7 cm [5 x 5 x 5 in] |

Layer Thickness | Layer Thickness0.17 mm [0.007 in] |

Printing Material | Printing MaterialP430 ABSplus |

Support Material | Support MaterialSR-30 Soluble |

Workstation Compatibility | Workstation CompatibilityWindows 7+ |

Printer Size | Printer Size63 x 45 x 53 cm [25 x 18 x 21 in] |

Printer Weight | Printer Weight60 lbs [27 kg] |

Mojo 3D Printer Review 2022

4. 2

2

See Price

| Printing Area | 127mm x 127mm x 127mm |

| Layer Resolution | 170 microns |

| Supported Filament | ABS, Support Material |

| Connectivity | USB |

| Extruders | 2 (ABS/Support) |

| Weight | 60 lbs |

Table of ContentsShow

Design and Features

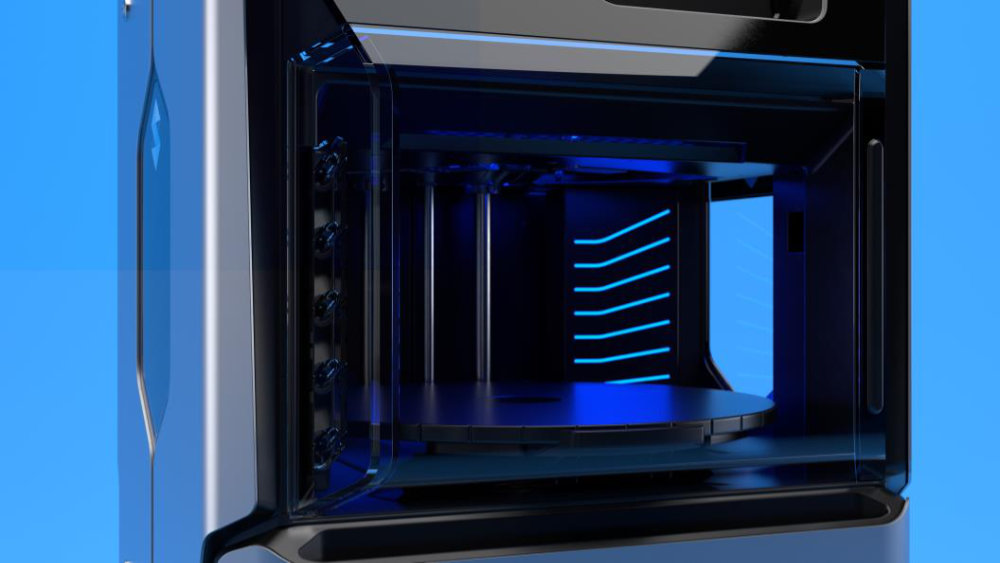

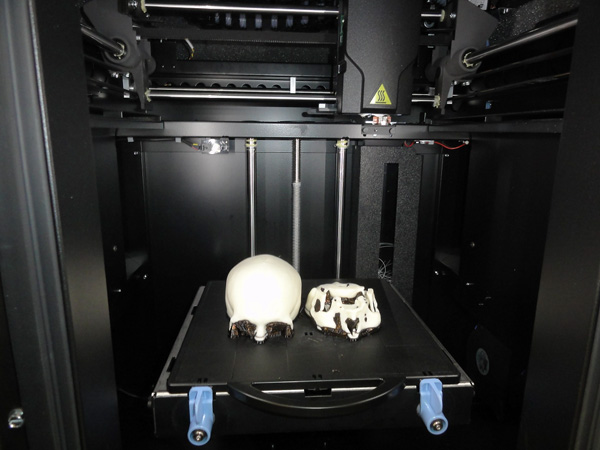

Opening the top cover and peering into the belly of the Mojo reveals a professionally engineered machine that even the most stringent designer will find satisfying. The smart positioning of various parts (including the inner brackets for the filament), the quality of said parts, and the clean look of the innards point towards the caliber of the printer in contention here. The configuration is a thing of beauty.

The two-shade gray color of the casing is on the drab side but has the benefit of smooth contours and an uncluttered look. The printing area feels contained and ordered hinting at Stratasys aim to provide an intuitive, easy to use printer free of the tinkering and messiness synonymous with barebones hobbyist alternatives. The Mojo wouldn’t be out of place within the hustle and bustle of a fast-paced professional design studio or prototyping workshop.

The printing area feels contained and ordered hinting at Stratasys aim to provide an intuitive, easy to use printer free of the tinkering and messiness synonymous with barebones hobbyist alternatives. The Mojo wouldn’t be out of place within the hustle and bustle of a fast-paced professional design studio or prototyping workshop.

The design itself is centered on a fully-enclosed heat regulated chamber supported by a full metal frame and plastic outer casing with a reasonable footprint weighing in at a total of 60 lbs. The heated chamber is vital here because the Mojo only supports ABS filament and as any versed maker will know, temperature and humidity regulation is a core concern when printing with ABS, which is prone to warping.

Although the printer has a dual extruder setup that uses Fused Deposition Modeling technology, it differs quite radically from what we’ve come to expect from this duality. Typically, you’d expect two types of filament or at least two different colors of PLA or ABS, but with the Mojo, one extruder is used for ABS, while the other extrudes SR-30 soluble support material. The focus on supports is incredibly important in the systematic quality of the prints.

The focus on supports is incredibly important in the systematic quality of the prints.

Stratasys has made it so that the Mojo doesn’t just use any run of the mill open source ABS either. The Mojo uses what is termed ABSplus, which is a production-grade thermoplastic that more or less mimics the durability of bonafide production parts with the added benefit of working in unison with the support material to print intricate recesses, cavities, and overhangs.

As you’ve probably guessed, Stratasys ships ABSplus in a proprietary filament cartridge coined the QuickPack Print Engine with a capacity of 80 cubic inches available in nine different colors. Not only does the Print Engine contain the ABS, but also a disposable snap-in print head that is ostensibly as easy to switch out as a cartridge on a standard inkjet printer. The new print head with every spool is not just for ease of use, but to keep part quality.

Additionally, a chip is fitted into each Print Engine that communicates to the printer how much filament is left so the printer won’t trigger prints it can’t complete, and each cartridge is foil-wrapped to keep the ABS from going brittle. The Print Engine design is one-time use.

The Print Engine design is one-time use.

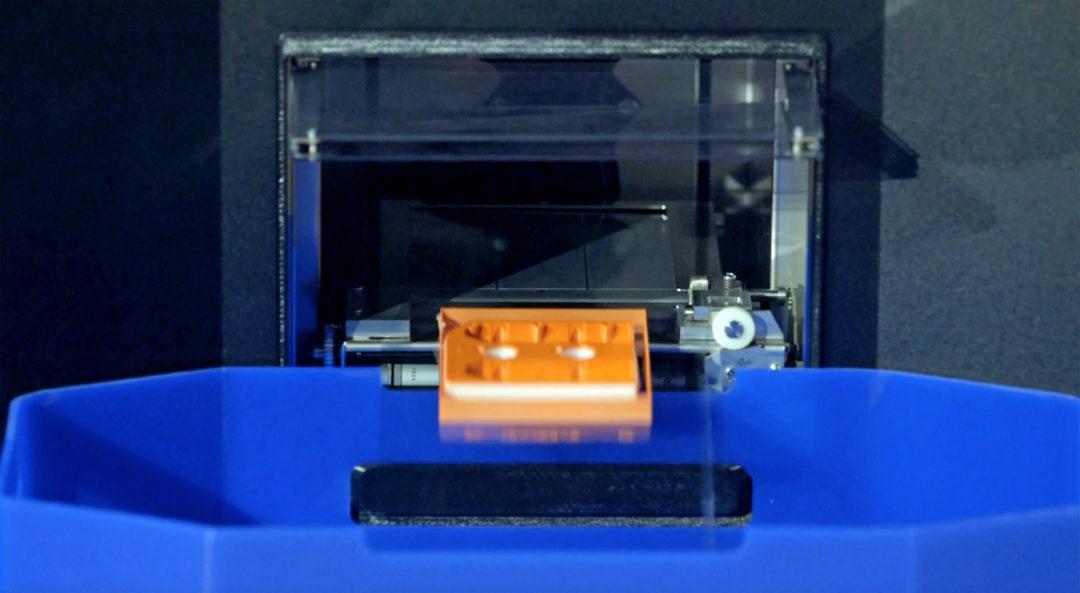

Going back to the support material, Stratasys also ships each Mojo with a WaveWash 5S support cleaning system, which is none other than a bin for cleaning off supports. Just add in an Ecoworks tablet (a dissolving detergent provided by Stratasys), a splash of tap water, turn on the cleaner and it will set the right temperature and amount of swirling to remove the supports without damaging the ABS print.

The Mojo has a comparatively small build area of 127mm x 127mm x 127mm, and the printing process sticks to the tried and trusted Cartesian configuration. The limited size is at odds with the price of the printer, but the truth is that for the majority of prototypes the available surface is more than sufficient. The printer steps up when it comes to the quality of the prints to counterbalance the limited space as we’ll see below.

The Mojo only prints at one layer resolution of 0.17 mm or 170 microns, with only one print speed available. The idea here is to provide detailed prints at every turn at the detriment of a quick test lower resolution print although it isn’t uncommon to see professional grade 3D printers with resolutions as high as 20 microns. Given that Stratasys is flogging the Mojo as a prototyping machine, the attention to detail makes sense but might irk users who desire a little more flexibility.

The idea here is to provide detailed prints at every turn at the detriment of a quick test lower resolution print although it isn’t uncommon to see professional grade 3D printers with resolutions as high as 20 microns. Given that Stratasys is flogging the Mojo as a prototyping machine, the attention to detail makes sense but might irk users who desire a little more flexibility.

The attention to detail also carries over to practicality with features like a set of internal brushes that clean the nozzles and collection bins that pick up any of the excess filament removed by the brushes. In the same vein, the front door has a locking mechanism to ensure the chamber remains at a uniform heat while printing.

As for software, the Mojo comes with the Stratasys Print Wizard utility that resembles a streamlined slicing application that’s intuitive and incredibly easy to use. The Wizard does most of the hard work by scaling STL files to fit the printer, queuing prints if the parts are too large for the build area, and communicates directly with the printer. The only real hands-on aspect is setting up the support style (basic, spare, surround) and orientation, which we found self-explanatory and easy to navigate.

The only real hands-on aspect is setting up the support style (basic, spare, surround) and orientation, which we found self-explanatory and easy to navigate.

We understand that Stratasys is banking on most of the heavy design work being completed in CAD software which is then carried over to Print Wizard for conversion then printing.

Connectivity wise, the Mojo is limited to a USB connection via a PC running Windows 7 or Windows 8.

Assembly

The Mojo ships with the printer itself, one QuickPack Print Engine cartridge of ABSplus and one of SR-30 support material, WaveWash 55 support cleaning system, 24 Ecoworks tablets, a modeling base (read build plate), USB cable, power cord, and official documentation.

For an all-in-one, pre-assembled configuration, two large styrofoam supports on the top and bottom adequately protect the printer. It ships as is with the filament in the brackets and the startup kit sitting on the build plate alongside boxes for the cleaning system. It’s all very minimal in keeping with the functional ethos of the Mojo.

It’s all very minimal in keeping with the functional ethos of the Mojo.

The setup is among the most straightforward we’ve ever encountered. Not only was installing the handful of parts a doddle, but the instructions were concise. We had to remove the cable ties holding the Print Engine cartridges in place, remove the packaging, place them back into the brackets, hook up the print head to the extruder, fit the cleaning brushes inside the chamber by merely putting them on a set on spindles, and finally snap on the modelling plate to the build area. It all took no more than 20 minutes.

The printer auto-calibrates so there’s no wasting time leveling the bed by toying with a set of screws and a piece of leveling paper. From here, we plugged in the power cord, connected the USB cable, and hit the ‘’on’’ button.

Printing

The print quality was nothing short of perfect. Within the space of the seven days we had access to the Mojo, not once did it fail, print blemishes, imperfections, or layering issues. The prints were of the highest quality, systematically. Speed wise, the Mojo isn’t the fastest, but this does mean through and through quality with every print. The support system worked well to ensure each job had the right foundations to come out flawless every time.

The prints were of the highest quality, systematically. Speed wise, the Mojo isn’t the fastest, but this does mean through and through quality with every print. The support system worked well to ensure each job had the right foundations to come out flawless every time.

The small things also made the printing experience that much better. For one, Print Wizard gave spot on estimates for print timings, even providing an exact time for when a project would be finished that it hit without fail. The bins that collect excess filament on the nozzles are excellent for keeping the chamber clean.

Equally, from powering up the Mojo to starting a print job, we are talking less than 15 minutes, and this includes initializing, diagnostics, and heating the chamber. The Mojo is by any standard quick to get going.

The absence of any lingering ABS odor is a nice departure from open-plan 3D printers where you’ll need to crack open a window to be able to breathe comfortably. It’s also inexplicably silent to the point that at times we had to check that it was still printing.

The WaveWash 55 worked well although it does take time to complete a cleaning cycle that can vary from two to five hours depending on the print job in question.

Support

Unfortunately, the Mojo is no longer in production, so any assistance is vendor specific beyond Stratasys offering user guides, videos, and a customer support contact on its website. The Mojo ships with a one-year warranty as standard. The company also still sells the proprietary Print Engine filament.

Verdict

With the Mojo 3D printer, manufacturer Stratasys isn’t holding back: we have here a professional grade device with all the precision, versatility, reliability, and a price tag to match. A hobbyist will shy away at the approximately $10,000 price tag, but professionals will find an affordable printer that gives competitor models with similar qualitative results a run for their money. In other words, for those with a budget to match, they will be hard pressed to find much wrong with the Mojo.

In other words, for those with a budget to match, they will be hard pressed to find much wrong with the Mojo.

Our only real criticism is the ongoing cost of operation; the cartridge design which incorporates a new print head with every Print Engine cartridge doesn’t come cheap. Heavy usage racks up quite the bill sentencing the Mojo to prototyping designers with the financial backing from a profitable company to keep the printer running.

On the flip side, print head failure is the number one cause of issues with 3D printing, and by extension, poor quality prints. In light of this, the additional price does equate to peace of mind and assured printing success.

Stratasys Desktop 3D Printer Review

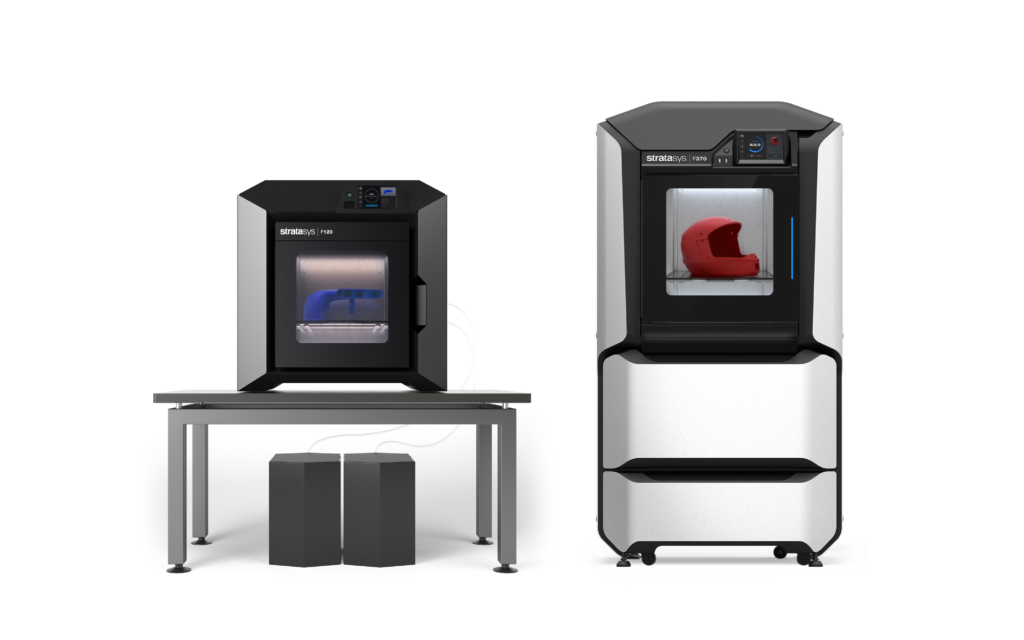

We're starting another review of 3D printers from trusted manufacturers, and this time we're talking about Stratasys desktop models. This article will describe three devices for three-dimensional printing - Mojo, PrintSE and uPrint SE Plus.

Let's just say that the above printer models are designed for home use, but they also belong to the category of professional printers that can help in creating a high-quality layout or even a prototype of a part. The manufacturing company claims that such models were created for creative people and for customers who are looking for the perfect balance of price and quality. Well, let's see if this is actually the case.

The manufacturing company claims that such models were created for creative people and for customers who are looking for the perfect balance of price and quality. Well, let's see if this is actually the case.

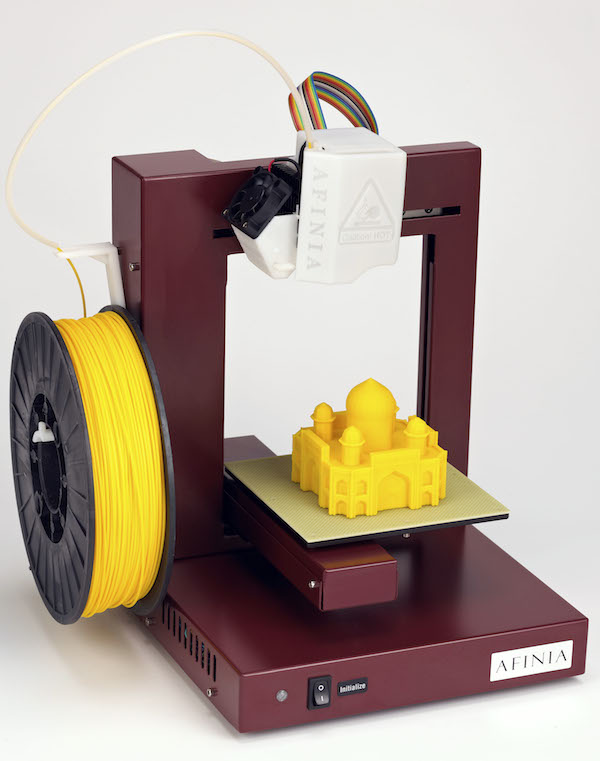

The Mojo 3D printer is a budget model due to its affordability. As a company representative writes: "This printer is so perfect that it could print itself." The device is based on FDM technology. As a consumable, you can use ABS thermoplastic or plain plastic. Includes:

- Printer

- Some consumable

- Control Panel and Printer Software

- A system for removing excess plastic from a model called WaveFlash

This kit can only be obtained if you purchase the device from an authorized dealer who has a direct relationship with the Stratasys manufacturer.

To create CAD files, you can use either the original software or download any popular program. The advantages of the Mojo 3D printer include high quality workmanship and printing speed - the device copes with the reconstruction of a medium-sized model in an hour. Working with a 3D printer is no more difficult than with an ordinary inkjet printer. The manufacturer advises using PrintWizard, a program that is one of the simplest among existing analogues.

Working with a 3D printer is no more difficult than with an ordinary inkjet printer. The manufacturer advises using PrintWizard, a program that is one of the simplest among existing analogues.

Another advantage of this printer model are Quick Pack Print Engines - these are the highest quality parts that can be easily replaced, like an inkjet printer cartridge. As for the WaveWash system, it also has a lot of advantages. The system allows you to quickly and easily remove excess consumables from the finished model. It should be noted here that the Mojo 3D printer can use SST printing technology when the object is recreated with the support of soluble materials.

Model specifications:

- Printable area 127x127x127 mm

- Layer thickness min. 0.17 mm

- The exact name of the consumable is ABS Plus P430

- Prints in one color

- Compatible with Windows7/XP

- Weight 26 kg

- The cost of this model may be different, but most dealers put a price tag around $ 9900

The next model in the Stratasys 3D printer line is the uPrint SE

uPrint SE is also a personal device, but offers more features than Mojo. This model of a 3D printer is the dream of a modern designer, engineer or teacher. The device is ideal for those who are engaged in three-dimensional modeling. The printer is based on FDM technology, and the same ABS-Plus thermoplastic is used as a consumable. This allows the use of uPrint SE in the field of prototyping - a full-fledged and durable object will appear before the user. What the buyer will receive in the kit:

This model of a 3D printer is the dream of a modern designer, engineer or teacher. The device is ideal for those who are engaged in three-dimensional modeling. The printer is based on FDM technology, and the same ABS-Plus thermoplastic is used as a consumable. This allows the use of uPrint SE in the field of prototyping - a full-fledged and durable object will appear before the user. What the buyer will receive in the kit:

- uPrint SE 3D Printer

- ABS-Plus consumable

- Catalyst EX Software

- WaveWash waste plastic cleaning system

As for thermoplastic, this consumable allows you to recreate durable objects. Plastic in a semi-liquid state passes through a special tube, tending to the head, which prints the loaded model with high accuracy. The Catalyst EX software converts the CAD file by taking into account all supporting structures. As for the WaveWash system, we have already talked about it. I would like to add that the printer is able to work independently, that is, without the help of an operator or user. You can leave the device overnight, and in the morning the printed object will be ready.

You can leave the device overnight, and in the morning the printed object will be ready.

Please pay attention to the technical characteristics of the device:

- Print area 203x152x152 mm

- Layer thickness 0.254 mm

- Compatible with Windows XP/7

- Print speed 15 cubic centimeters per hour

- Weight 72 kg

- Cost about $21,000

The next desktop printer model that we will talk about in this review is the uPrint SE Plus

model As the professionals say: “The path from an idea to a completed project should be as short as possible.” This 3D printer can become a reliable assistant to a designer, engineer or 3D modeling specialist. If you have a 3D printing device, you can provide ready-made prototype models. This, in turn, allows you to organize a demonstration of a product prototype or help a designer or customer evaluate the appearance of a product. Also, this device is perfect for creating a pilot series of parts, which will then be put into production.

In general, the scope of the uPrint SE Plus 3D printer is quite extensive. Let's take a closer look at what this device is. Complete with the printer, the buyer will receive:

- Consumables

- Catalyst EX Software

- WaveWash waste plastic cleaning system

You can read about the cleaning system and software in the description of the uPrint SE printer. So how is the Plus model different from its non-plus sibling? First, the uPrint SE Plus printer is capable of printing in nine colors. Secondly, it has a large printable area. In fact, this model has a lot in common with its brother, and it is intended for those who just want to increase the printable area a little.

Specifications:

- Printed using thermoplastic ABS-PLus

- Print area 203x203x152 mm

- Print thickness 0.254 mm

- Compatible with Windows XP/7

- Weight 76 kg

- Cost about $23,000

Stay tuned for updates on our website.

Review prepared for 3dtoday.ru

Link to source: 3D printers today.

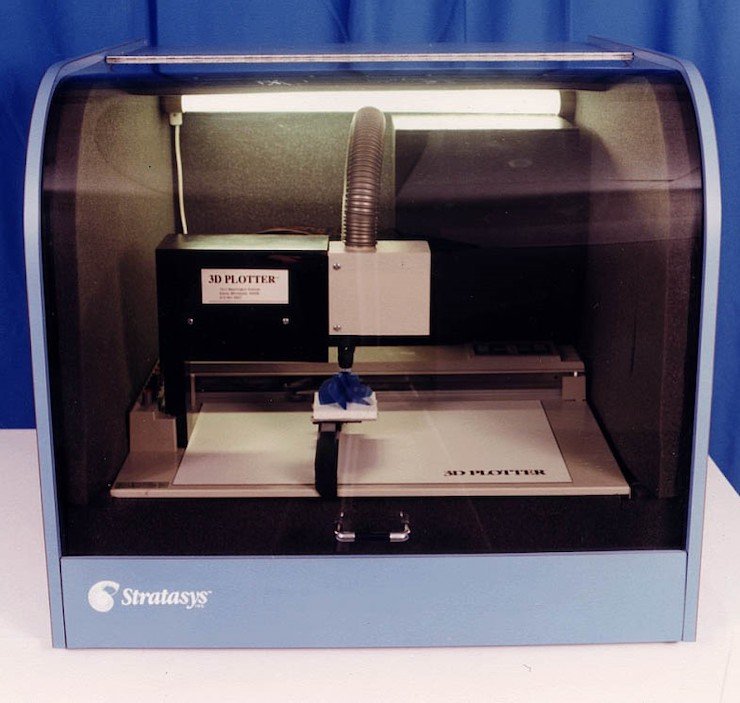

Stratasys Inc. - 3D printers and systems

| Stratasys Inc. USA. GEO-NDT LLC supplies 3D printers manufactured by Stratasys in Russia. Anything you can imagine, Stratasys Inc. can build! Stratasys Inc. provides a wide range of services including custom manufacturing, low cost 3D printers and high performance 3D manufacturing systems. For 2009Stratasys ranks #1 in the world in terms of total units sold. The growing popularity of Stratasys machines is explained by such qualities as a large selection of modeling materials, a reliable design, a wide range of models and an affordable price. In 1988, Stratasys invented and patented FDM (Fused Deposition Modeling) technology. This method marked the beginning of the development and formation of the company. In early 2010, Stratasys entered into an agreement with HP. Under the agreement, Stratasys designs and manufactures an exclusive line of 3D printers based on FDM technology for HP. In one year, HP will begin a phased rollout of mechanical design (MCAD) 3d printers to select country markets with the right to expand the distribution of 3d printers globally. Rapid prototyping technologies are currently in demand by both large industrial companies and small businesses. Systems Stratasys Inc. used by manufacturers to create models and prototypes to assist in the design process of a new product. And they are becoming widely used for low volume finished products. Systems range from low cost desktop 3D printers to large production systems for direct digital manufacturing. Stratasys Inc. units. are actively used by the world's leading manufacturers in the automotive, aviation, medical, radio-electronic industries, manufacturers of household appliances, helping to significantly reduce the time required to update the product range and ensuring competitive success. These are the leading companies in their industries: Boeing, Lochheed Martin, Raytheon, Toyota, Volkswagen, BMW AG, Cummins-Allison, Honda, Harley-Davidson, Sony, Panasonic, Hewlett Packard, Xerox, IBM, Canon, Lexmark, Texas Instruments, Bosch, Lego, etc. If you want to order and buy a 3D printer of the Idea, Design and Production series, please call the numbers listed in the "contacts" section of our website. |

|

|

Stratasys Inc. USA.

USA.

GEO-NDT LLC supplies 3D printers manufactured by Stratasys in Russia.

Anything you can imagine, Stratasys Inc. can build!

Stratasys Inc. provides a wide range of services including custom manufacturing, low cost 3D printers and high performance 3D manufacturing systems. For 2009, Stratasys ranks #1 in the world in terms of total units sold. The growing popularity of Stratasys machines is explained by such qualities as a large selection of modeling materials, a reliable design, a wide range of models and an affordable price.

In 1988, Stratasys invented and patented FDM (Fused Deposition Modeling) technology. This method marked the beginning of the development and formation of the company. Stratasys continues to use FDM to this day. In 2003, FDM ranked #1 in sales among other rapid prototyping technologies. Stratasys uses FDM technology in its Dimension 3D Printers and Fortus 3D Production Systems lines, which are designed for direct digital manufacturing and precision rapid prototyping. The company also operates the RedEye On Demand manufacturing service, producing on-demand parts. In 2007, Stratasys supplied 44% of the world's 3D manufacturing systems turnover, becoming the market leader for the sixth year in a row.

The company also operates the RedEye On Demand manufacturing service, producing on-demand parts. In 2007, Stratasys supplied 44% of the world's 3D manufacturing systems turnover, becoming the market leader for the sixth year in a row.

In early 2010, Stratasys entered into an agreement with HP. Under the agreement, Stratasys designs and manufactures an exclusive line of 3D printers based on FDM technology for HP. In one year, HP will begin a phased rollout of mechanical design (MCAD) 3d printers to select country markets with the right to expand the distribution of 3d printers globally.

Rapid prototyping technologies are currently in demand by both large industrial companies and small businesses.

Systems Stratasys Inc. used by manufacturers to create models and prototypes to assist in the design process of a new product. And they are becoming widely used for low volume finished products. Systems range from low cost desktop 3D printers to large production systems for direct digital manufacturing.

Stratasys continues to use FDM to this day. In 2003, FDM ranked #1 in sales among other rapid prototyping technologies. Stratasys uses FDM technology in its Dimension 3D Printers and Fortus 3D Production Systems lines, which are designed for direct digital manufacturing and precision rapid prototyping. The company also operates the RedEye On Demand manufacturing service, producing on-demand parts. In 2007, Stratasys supplied 44% of the world's 3D manufacturing systems turnover, becoming the market leader for the sixth year in a row.

Stratasys continues to use FDM to this day. In 2003, FDM ranked #1 in sales among other rapid prototyping technologies. Stratasys uses FDM technology in its Dimension 3D Printers and Fortus 3D Production Systems lines, which are designed for direct digital manufacturing and precision rapid prototyping. The company also operates the RedEye On Demand manufacturing service, producing on-demand parts. In 2007, Stratasys supplied 44% of the world's 3D manufacturing systems turnover, becoming the market leader for the sixth year in a row.

And if you need an even larger product, it is enough to “grow” its parts, and then glue it together. Combined with powerful control software and hardware, this increases productivity, accuracy, repeatability and reliability.

And if you need an even larger product, it is enough to “grow” its parts, and then glue it together. Combined with powerful control software and hardware, this increases productivity, accuracy, repeatability and reliability.  There is no need to wait for anything - the parts can be released from the support material immediately after the completion of the building process.

There is no need to wait for anything - the parts can be released from the support material immediately after the completion of the building process.  ..

..  The system has many flexible settings for specific tasks, and is able to print assembled parts of different colors.

The system has many flexible settings for specific tasks, and is able to print assembled parts of different colors.  The thickness of one printed layer is only 0.178 mm.

The thickness of one printed layer is only 0.178 mm.