How 3d printing changed the world

6 Ways 3D Printing will Change the World

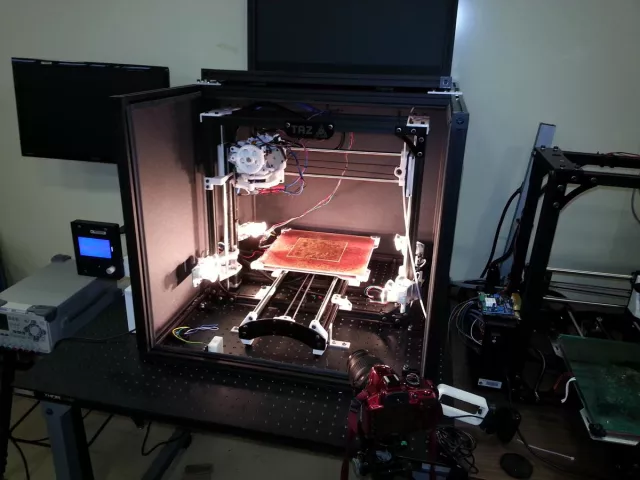

3D printing, or additive manufacturing, may not be making headlines like it was in 2013, but rest assured, the technology’s only been spreading and advancing over the past four years. The implications of 3D printing design are vast, and the technology has the potential to revolutionize our society.

Here are a few of the ways that 3D printing will change the industry, the economy, and the culture in the years to come.

1. Production will Take a Turn Towards the Local

Since the 1980s, corporate outsourcing has been a significant force driving change in the manufacturing industry. Large corporations often reduce costs by setting up factories in multiple companies to manufacture each sub-component of their end product.

With 3D printing, a company could manufacture a whole car in one place. 3D printing only requires a few employees, so labor laws will be less of a game-changer than they are with traditional manufacturing and its large labor forces. As the technology improves, it’ll become cheaper and more accessible for companies to manufacture their product close to home.

This would mean significant economic restructuring for China and other countries whose economies depend on being able to provide a cheap labor pool for manufacturing. They’ll have to find new forms of economic value-production to maintain their GDP.

If you’re looking to manufacture your invention locally with 3D printing, you’ll need to start with a CAD model and prototype. We can help with that. Contact us, and we’ll connect you with the best designers and 3D printers on the web to get your product out there.

2. The Medical World Will be Turned Upside-Down

From surgery to prosthetics to medications, 3D printing has the power to revolutionize the world of medicine.

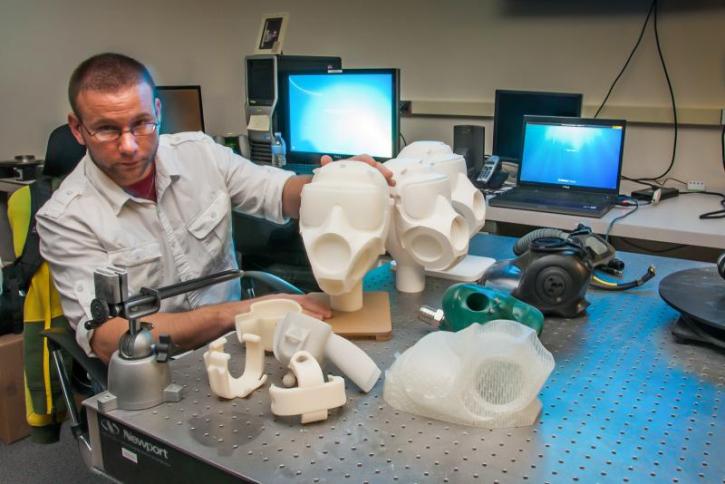

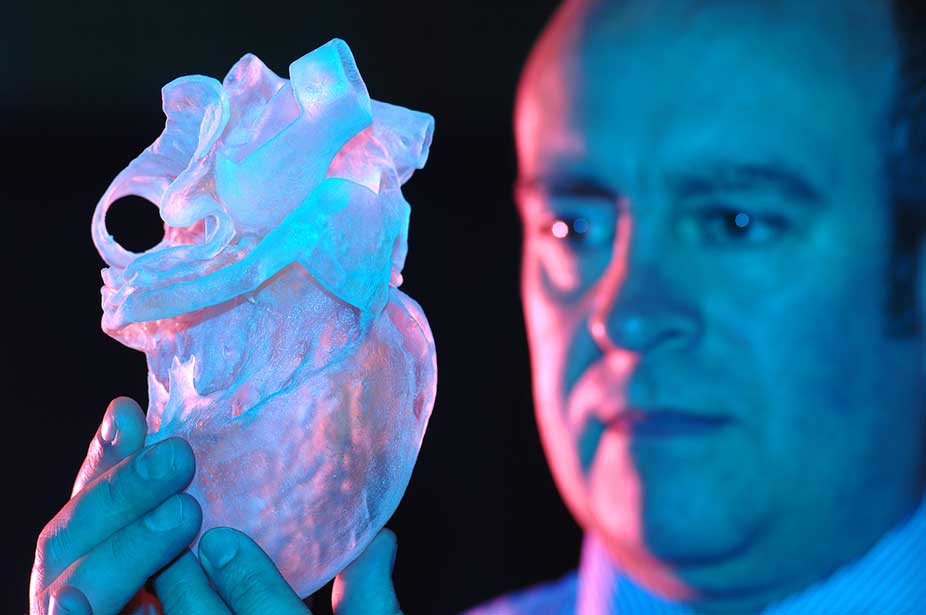

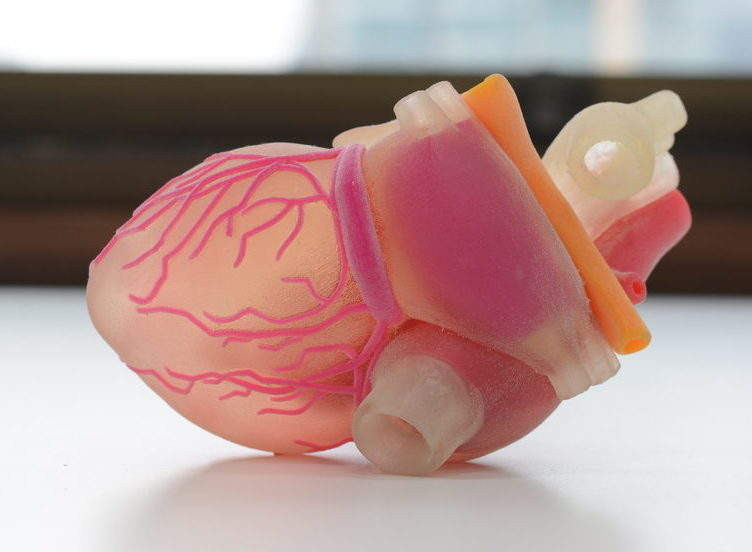

3D printing is already being used for prosthetics. Research firm Not Impossible Labs is already using the technology to print prosthetics for amputees in war-torn regions at a total cost of under $100. 3D printing could make prosthetics cheaper for everyone, changing the lives of amputees worldwide. 3D printing is also being used for surgery, with replicas of hearts and organs being used to help surgeons prep.

3D printing could make prosthetics cheaper for everyone, changing the lives of amputees worldwide. 3D printing is also being used for surgery, with replicas of hearts and organs being used to help surgeons prep.

Bioprinting, 3D printing that uses “ink” made of human cells and tissue, is making massive strides. Many tech and medical experts believe that 3D-printed internal organs will be in use for surgery by the year 2025. 3D printing has already been used to repair damaged bone and cartilage, with surgeons using the technology in 2014 to repair a man’s face after a road accident.

3D printed pills are already a reality, with Spiritam, a 3D printed anti-seizure medication, patented in 2015. 3D printed pills could be a cheap and practical way to make lifesaving drugs available worldwide.

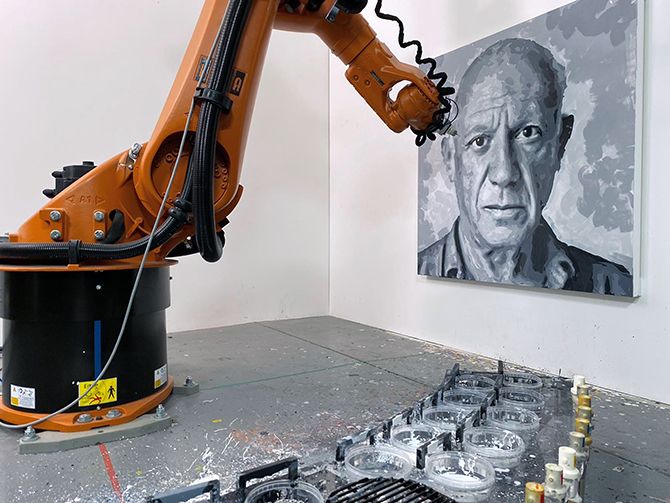

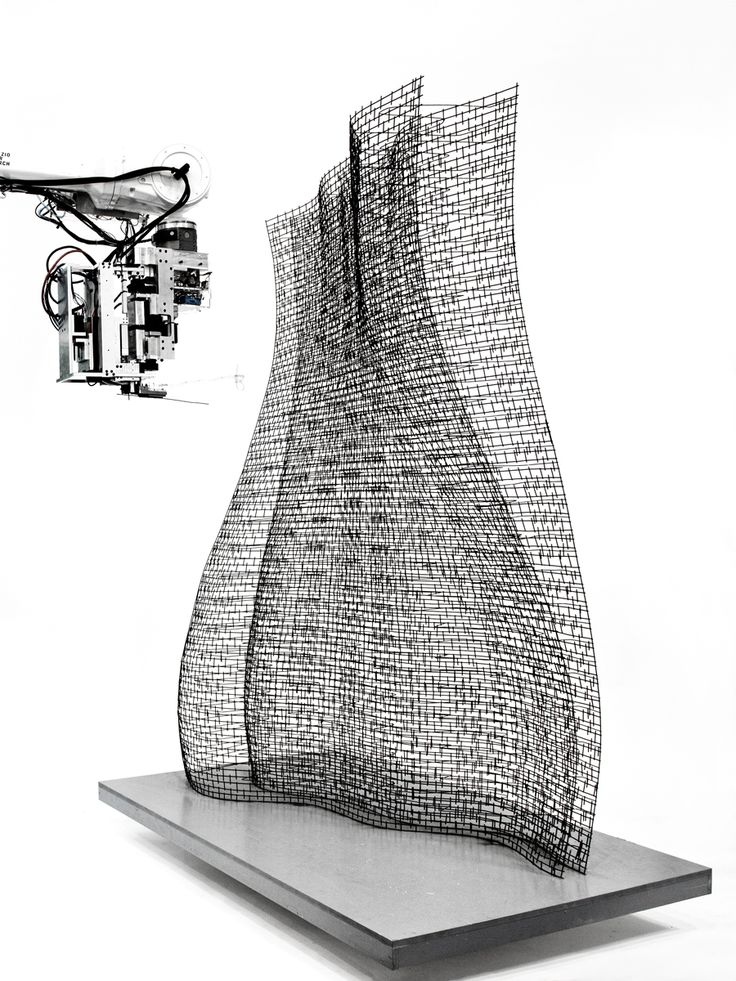

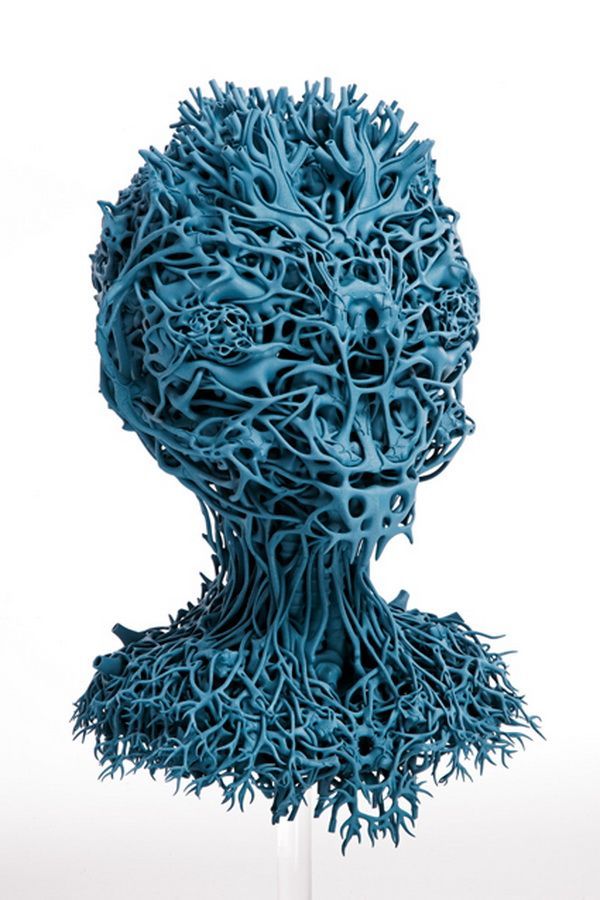

3. 3D Printing will Spark a Creative Renaissance

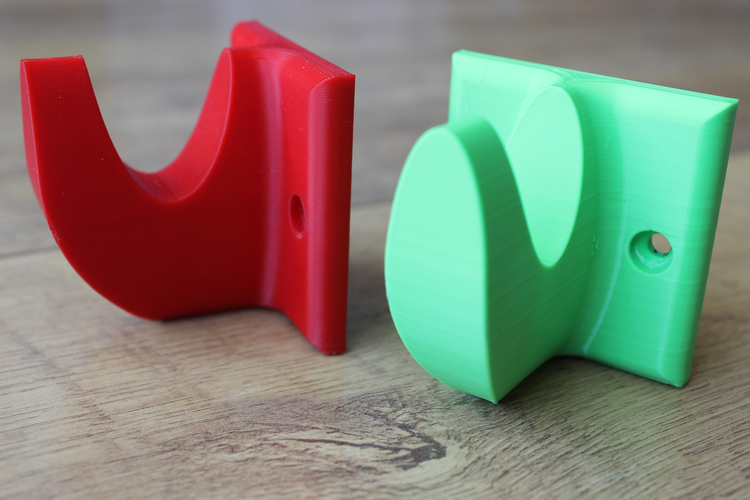

As 3D printing becomes more and more common, it’ll become more accessible and easier for inventors and creatives to turn their ideas into realities. 3D printing already makes it far easier for inventors to produce prototypes. In the future, the manufacturing process could be carried out by 3D printing as well. In a few decades, we might see the store shelves packed with a variety of 3D printed products that today would be unimaginable.

3D printing already makes it far easier for inventors to produce prototypes. In the future, the manufacturing process could be carried out by 3D printing as well. In a few decades, we might see the store shelves packed with a variety of 3D printed products that today would be unimaginable.

Are you an inventor trying to bring your product to the market? Contact Cad Crowd, and we’ll set you up with a 3D printing expert to help you produce your prototype.

4. 3D Printing Could Help Solve the Housing Crisis

Housing prices are skyrocketing across the West. Far fewer young people can afford to buy homes than their parents, and many people have difficulty even affording rent. 3D printing could help address that. A Chinese company called Winsun offers 3D houses built entirely out of recycled materials, which cost less than $5000 to produce. Their process uses “ink” made from fiberglass, steel, cement, binder, and recycled rubble. They’ve already built housing in China, have recently expanded to Saudi Arabia, and plan on expanding to twenty other countries over the next few years. 3D printing allows home builders to save on transportation costs, building materials, and labor costs. The cities of the future may be built through 3D printing!

3D printing allows home builders to save on transportation costs, building materials, and labor costs. The cities of the future may be built through 3D printing!

5. New Kinds of Crime Will Emerge

When 3D printers become a household item, digital piracy may spread from the media world to the general marketplace. Why buy an iPhone when you can buy some metal, plastic, and silicone “ink” for far less and print one yourself? This level of precision is well beyond the capability of the average 3D printer today, but that may no longer be the case in ten or twenty years. The digital pirates of the future may be sharing CAD files rather than media torrents.

3D printing will complicate gun registration. 3D-printed firearms are already a reality and will only improve in performance and practicality as time goes on. How will state governments regulate the sale and traffic of firearms when anybody with a modem and printer can make their own?

This could be a problem across the black market. If 3D printing medications become a reality, expect 3D printed illegal drugs to follow on their heels.

If 3D printing medications become a reality, expect 3D printed illegal drugs to follow on their heels.

This may sound bleak, but luckily, there’s a major upside to 3D printing that could help offset the dangers…

6. 3D Printing Could Save the Environment

3D printing will make it easier to produce goods locally, which dramatically reduces fuel costs. Faster production of goods may help curb the use of fossil fuels, perhaps even preventing the worst excesses of climate change.

With 3D printing, we’ll be able to step up our recycling game. Plastics, metals, and paper will become the “ink” used by printers, a process that uses less energy than conventional recycling.

Additionally, by its very nature, 3D printing produces less waste than conventional manufacturing. 3D printing is known as additive manufacturing, where an object is created by adding layer after layer of material to a previously empty space. Traditional manufacturing is a subtractive process, where the manufacturer starts with a block of material and carves away at it to produce the product. The latter produces far more waste, which will be eliminated by switching to 3D printing.

The latter produces far more waste, which will be eliminated by switching to 3D printing.

Finally, 3D printing can help study the process of environmental degradation. Researchers at the University of Sydney have produced a 3D model of the Great Barrier Reefs to help model how these natural structures are being impacted by climate change. This could be used to support the reefs recover from bleaching and storms.

Want to be part of the 3D printing revolution? Get in touch for your free consultation and we’ll connect you with the best modelers and 3D printing freelancers on the web!

How 3D Printing is Changing the World (Infographic)

Copied link!

January 8, 2019

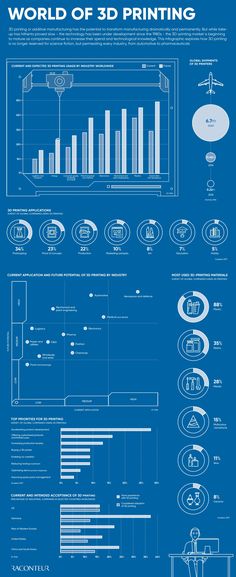

Across the globe, various 3D printing materials are being sourced to feed the growing demand for 3D-printed parts and objects.

3D printing continues to make waves in a huge range of industries from healthcare to art to science. Although 3D printing feels intensely futuristic, initial versions of this technology date back to the 1980s. The early days consisted of many rejections and failures since patents and inventions often failed to get the funding necessary to take off.

The early days consisted of many rejections and failures since patents and inventions often failed to get the funding necessary to take off.

Today, it’s a sophisticated process that has gained popularity for its speed and relatively low cost. It’s particularly promising for smaller companies that can take advantage of quick manufacturing at a lower price to compete with bigger companies. 3D printing is, quite literally, changing the world, print by print.

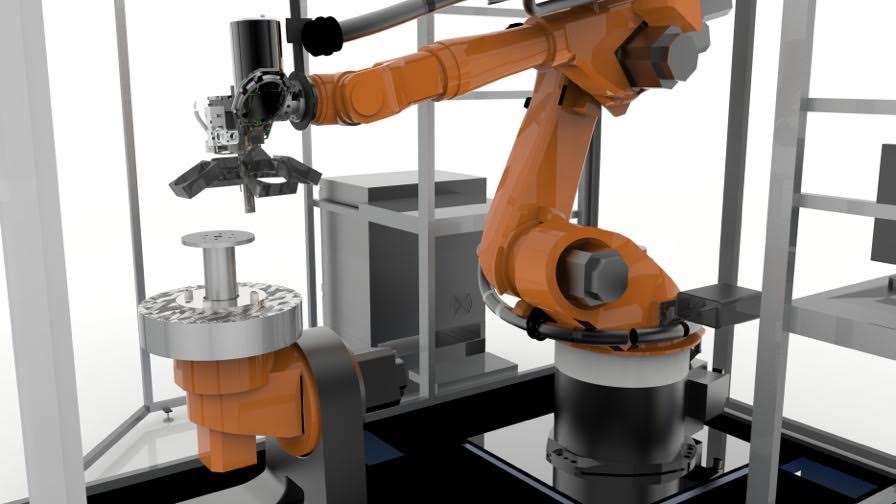

Manufacturers like HP® are leading the way with revolutionary 3D printing technologies, such as the HP Metal Jet industrial printer, which help to vastly increase production volumes and expedite time to market.

View our below infographic for more details on how 3D printing is advancing in commercial and educational applications, and also its environmental impact and e-waste.

3D printing history overview

Before diving into the impact this unique technology is making today, it’s important to understand where it all started. The idea of 3D printing was powered by a desire for “rapid prototyping devices” that companies tried to patent in the early 1980s. Companies needed a faster way to get their products to market because traditional manufacturing was a slow, cumbersome obstacle.

The idea of 3D printing was powered by a desire for “rapid prototyping devices” that companies tried to patent in the early 1980s. Companies needed a faster way to get their products to market because traditional manufacturing was a slow, cumbersome obstacle.

The story of 3D printing begins with Dr. Hideo Kodama who tried and failed to patent a resin curing system in Japan. Yet another patent failure for a rapid prototyping device that cured liquid monomers into solids happened in France in 1984. Luckily, these early failures simply paved the way for eventual success.

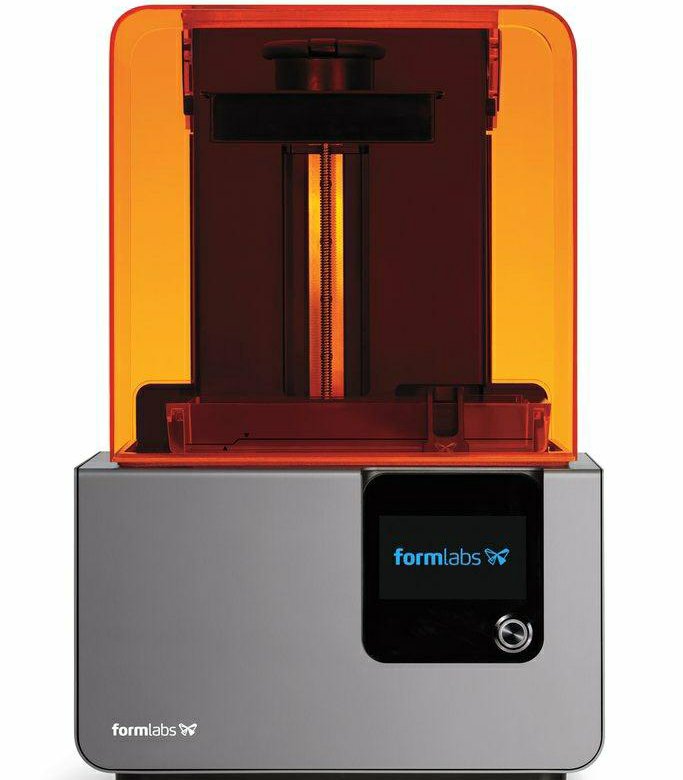

1984 was a pivotal year for 3D printing where the tables finally turned. A tabletop manufacturer by the name of Charles “Chuck” Hall became frustrated with the painstaking process of creating customized parts. He suggested curing photosensitive resin into a part, layer by layer. He called this process “stereolithography.” And finally, in 1986, a patent was issued for this technology.

In 1988, another 3D printing method was brought to the mainstream called selective laser sintering (SLS). University of Texas undergrad Carl Deckard invented SLS and filed a patent, naming his creation “Betsy.”

University of Texas undergrad Carl Deckard invented SLS and filed a patent, naming his creation “Betsy.”

Selective laser sintering is more complex than other types of 3D printing methods. It involves powdered polymers fused together with a laser, layer by layer. The object then undergoes a final curing and decaking process.

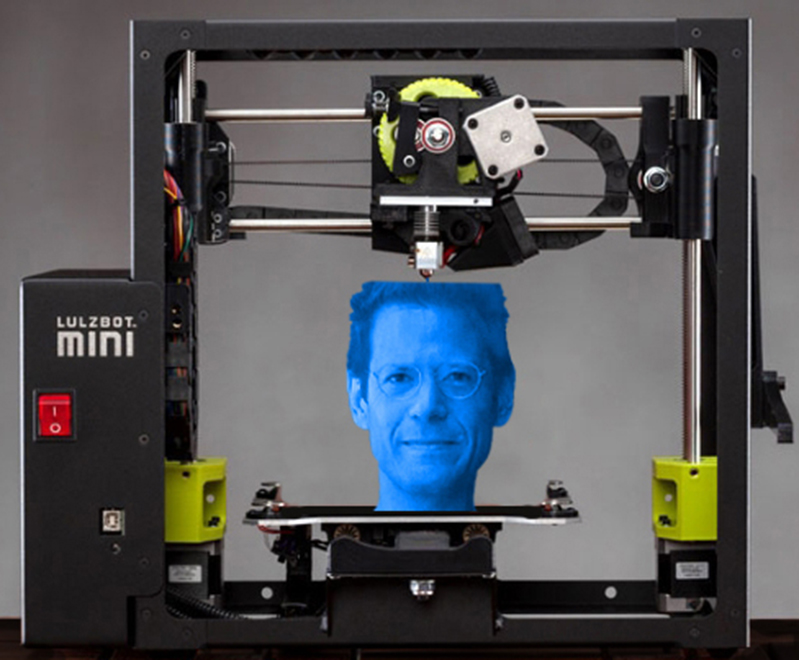

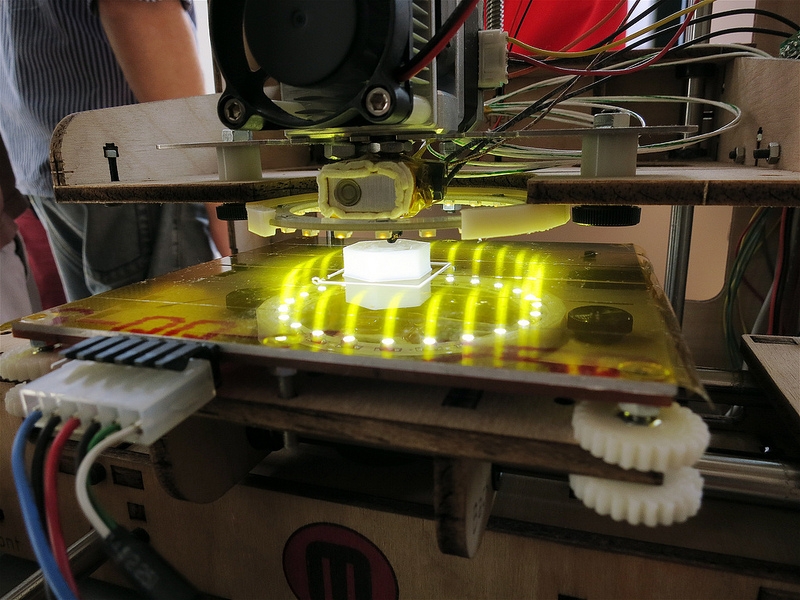

Fused deposition modeling (FDM) was invented most recently and is the most common 3D printing process used today. It’s a type of additive 3D printing characterized by very thin layers, added one on top of another until the part is created.

3D printing impacts

As you might imagine, 3D printing has transformed the world and it’s nowhere near reaching its full potential. Many companies, universities, and industries are benefiting from 3D printing.

What are the environmental impacts of 3D printing?

Thanks to 3D printing, production can benefit the environment in several ways:

- 3D-printed products are up to 50% lighter than those produced with standard methods, meaning they require less energy to transport

- In manufacturing, 3D printers use only the amount of material necessary for the product, reducing overall waste

- Some 3D printers only accept recycled materials

- It’s not all good news: One study found that 3D printers utilizing heat or lasers use 50 to 100 times more electricity than traditional production methods

What are the commercial impacts of 3D printing?

3D printing helps companies differentiate their businesses in terms of quality, speed, and customization. 93% of companies that use 3D printing reduce time-to-market which means that companies can enjoy a faster turnaround from concept to product launch.

93% of companies that use 3D printing reduce time-to-market which means that companies can enjoy a faster turnaround from concept to product launch.

This is especially important for smaller companies who need to quickly bring in revenue after spending capital developing a product. This quick turnaround allows these small businesses to compete with larger ones.

In addition, 3D printing limits overhead costs, requires less labor than traditional manufacturing methods, and boosts overall production efficiency. If a product goes to market and needs a replacement part, there is no bottleneck or slowdown. You can simply print and replace the component.

Prototyping (55%), production (43%) and proof-of-concept models (41%) are the three most popular 3D printing applications in 2018. 3D printing delivers a competitive advantage for forward-thinking companies.

HP® is leading the way in commercial 3D metal printing with the HP Metal Jet. This revolutionary 3D printer is the first industrial-scale metal printer to hit the market. It allows manufacturers in numerous industries to produce high volumes of parts, making them up to 50 times more productive.

It allows manufacturers in numerous industries to produce high volumes of parts, making them up to 50 times more productive.

What are the automotive and aviation industry impacts of 3D printing?

Both the automotive and aviation industry benefit from 3D printing because this method of manufacturing means that parts can be lighter, less expensive to transport, and easily tweaked via additional parts or replacement parts post-production.

As an example, Ford has used 3D printing over the last few decades and printed more than 500,000 auto parts. This has saved the company billions of dollars and millions of hours of labor. Typically the prototype process takes anywhere from 4 to 5 months and costs the company around $500,000. But a 3D printout of a prototype takes less time and costs just a few thousand.

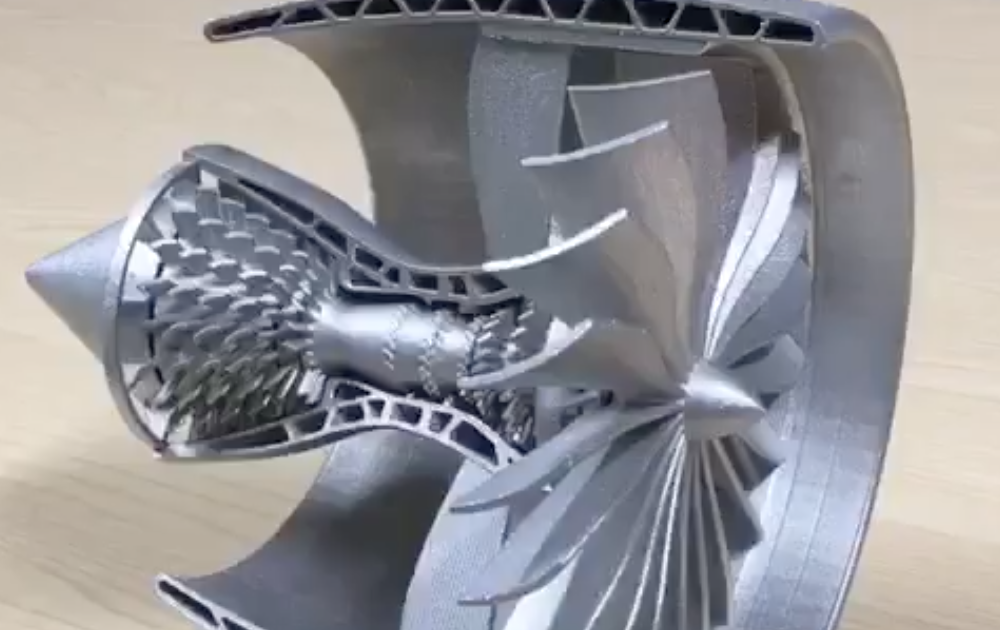

Manufacturers are also using 3D printing to develop aircraft. GE, for instance, used 3D printing to create a new turboprop engine called the GE Catalyst. Engine designers combined 855 separate parts into just 12 using 3D printing which means the engine weight is 5% less and improves fuel consumption by 1%. While these may seem like incremental improvements, they make a huge difference across large fleets.

While these may seem like incremental improvements, they make a huge difference across large fleets.

What are the healthcare impacts of 3D printing?

The healthcare industry benefits from 3D printing which can be used for bioprinting to create organs for transplant patients.

Labs have also been leveraging 3D printing to create prosthetics that cost under $100; much cheaper than traditionally-made prosthetics.

While it sounds like science fiction, there have been many real-life examples where medical 3D printing has proven its worth. A mouse with 3D-printed ovaries gave birth to healthy pups, for example. And scientists are still looking at its potential to ameliorate other medical issues.

What are the educational impacts of 3D printing?

Thanks to 3D printing, children are now learning about:

- 3D design

- Computer-aided design (CAD): using computers to create, modify, analyze, or optimize design

- Programming

- Manufacturing processes

- 3D printing can be used to produce tactile models for teaching purposes

- 3D printing has been used to create Braille picture books for blind or low-vision students

Takeaways: 3D printing into the future

Although 3D printing uses significant amounts of electricity, still 3D-printed products are up to 50% lighter than those produced with standard methods, meaning they require less energy to transport.

In manufacturing, 3D printers use only the amount of material necessary for the product, reducing overall waste. HP® is leading the path with the HP Metal Jet and other technology ready to help businesses grow faster and better.

Learn more about 3D printers, including HP®'s industrial metal printer and how 3D printers work on HP® Tech Takes.

Infographic sources:

- 3D Insider; The Environmental Impact of 3D Printing

- 3D Print Headquarters; Bioprinting: Creating Human Organs Using 3D Printing

- 3D Printing Industry; Half Million 3D Printers Sold in 2017

- 3D Printing Media; 10 Ways 3D Printing is Positively Impacting the World

- All3DP; 10 Ways 3D Printing Supports the Blind

- CB Insights; From Construction to Art, Here are 25 Industries that 3D Printing Could Disrupt

- Fabbaloo; What are the Environmental Impacts of 3D Printing

- Forbes; 7 Amazing Real World Examples of 3D Printing in 2018

- Forbes; The State of 3D Printing, 2018

- Hongkiat; 9 Ways 3D Printing is Changing the World

- HP; Metal 3D Printing

- i.

materialize; 8 Interesting Facts About 3D Printing

materialize; 8 Interesting Facts About 3D Printing - My 3D Concepts; Moving Toward Eco-Friendly Manufacturing

- Tech Guided; 63 Ways 3D Printing is Changing the World

Popular HP Printers:

Disclosure: Our site may get a share of revenue from the sale of the products featured on this page.

How 3D printing has changed the world of fashion

Almost everyone has heard about 3D printing for several years now. Every day there is news about houses, clothes, food and even human organs created with this technology.

The idea that clothes can be printed instead of sewn has been on the minds of the fashion industry for a long time. Of course, this method of production has a lot of useful advantages over the traditional one. While others are only dreaming, the fashion industry is moving forward in this matter by leaps and bounds. Which of the stars have already tried out unique new technologies and why they were delighted with them, further in the review.

How it all began

Stages of 3D printing of dresses.

The main disadvantage of 3D printed clothing has always been inconvenience in everyday use. A similar disadvantage was caused by the lack of suitable materials for this. This terribly slowed down the development of these technologies in the fashion world. To date, this obstacle has already been overcome and the designer is even creating underwear using 3D printing.

Designers even manage to make underwear using 3D printing.

Dutch designer Iris van Herpen is a pioneer in the fashion printing industry. More than ten years ago, she presented her first creation at the International Fashion Week in Amsterdam. Van Herpen created a snow-white top called "Crystallization" using 3D technology. It was printed from polyamide.

It was printed from polyamide.

The process of turning liquid into crystals gave its name to the design creation. Iris got inspiration from him and created her masterpiece. The product caused an unprecedented sensation. All eminent designers instantly turned their eyes to innovative technologies.

After Iris van Herpen, all designers are 3D printed.

A dizzying development

Designers of the world's leading fashion houses began to embody their most daring fantasies in 3D models. Of course, because the unique technology allows you to create clothes without seams! Recently, ideas have been spreading more and more actively that it is time to take 3D printing of clothes outside the world of haute couture. It's time for mass production. The only drawback, which, however, will, as they promise, be eliminated soon is that not everyone can afford such things.

Everything is good in these outfits, except for the price.

The first star to walk a 3D dress

One of the first dresses worn by a world-class star was created for the beautiful Dita Von Teese. The luxurious outfit was 3D printed and lavishly embellished with Swarovski crystals. Flexibility was provided to him by several thousand mobile connections. In how to put on and take off this dress, it was no different from the usual.

Dita Von Teese in a 3D dress.

Has the future arrived?

Unique clothes for unique women! Just a few weeks after Dita, eccentric star Lady Gaga tried on a chic 3D dress. She stated that she will never stop surprising her fans, because her show is a mixture of music, performance and cutting-edge innovative technologies.

Lady Gaga in a 3D dress.

After such a triumph, fashion designers were unstoppable! 3D technology has taken over the catwalks around the world. Fashion designers competed among themselves not only for those who would create a unique design, but also for those whose outfit would be more comfortable. After all, the most important thing is that 3D printing leaves the world of haute couture. To do this, you need to prove that clothes not only look impressive, practical to use, but also comfortable in everyday life. Also, the question of price does not lose its relevance.

Designers' dream to mass-produce these clothes.

Now these clothes are not as expensive as just a couple of years ago. Designers and fashion designers have done a good job of making 3D printed clothing more accessible. They are stimulated in this not only by unlimited possibilities for fantasy and self-expression.

They are stimulated in this not only by unlimited possibilities for fantasy and self-expression.

A great flight of fancy and an endless source of inspiration for fashion designers.

The fact is that additive technologies are incredible opportunities in the field of environmentally friendly production. It will also reduce the costs of the enterprise and their waste in the future. So mass production of printed clothing is a reality that is not far off. In the meantime, you can buy author's models for quite affordable money. The future is closer than it seems...

Web flexibility already achieved.

While some designers are concerned about innovative technologies, others are creating outfits for the cinema. Read our other article on who dresses Oscar-winning movie characters and why the top 7 costume designers are famous.

How 3D printing changes the world / Sudo Null IT News

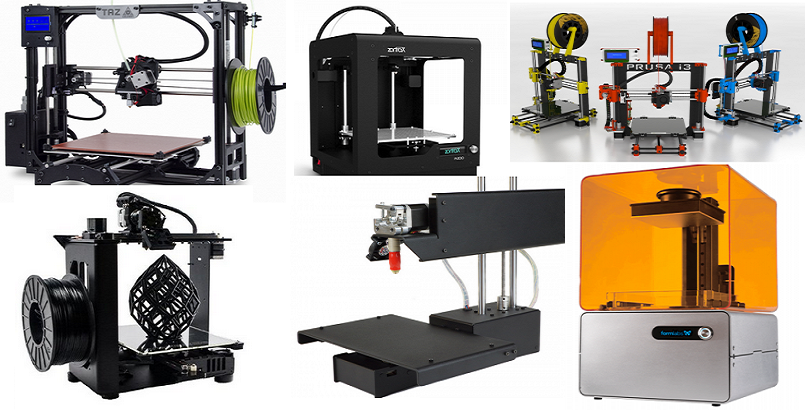

A new era of technological revolution According to the CONTEXT research group, the 500,000th 3D printer was shipped in 2015, and by 2017, about a million devices had been sold. 3D printing is already being introduced as a manufacturing technology. For example, in 2016 company

General Electric began selling aircraft engines with 3D printed fuel injectors. Atlas-5 rockets with parts printed with the same technology were launched into space. Brands Under Armor and New Balance launched small batches of partially 3D printed athletic shoes, while Organovo launched commercial bioprinting of human kidney tissue. So far, this is just the foundation. Throughout the history of mankind, there have been many technological revolutions, each of which went through three phases. 9 comes first0091 "conceptualization" when visions and ideas are formed that determine the future path. Then "realization" , during which previously seemingly impossible plans begin to be partially realized. And the third phase - "mass commercialization" , when enterprises master the production and application of new technology.

Then "realization" , during which previously seemingly impossible plans begin to be partially realized. And the third phase - "mass commercialization" , when enterprises master the production and application of new technology.

And what phase is 3D printing in? The use of a 3D printer to turn a digital file into a physical object is already widespread. For example, in such areas as engineering, law, economics, business, geography and art. There is already debate about the implications of exchanging digital objects over the Internet to print them out immediately on a printer (let's say a firearm). Clearly, we are far from the day when personal 3D printers put an end to capitalism by placing production in the hands of the majority. However, there is no doubt that the 3D printing revolution has reached its second phase, implementation.

By this time, enough methods have been invented to make solid objects by printing them in many thin successive layers. In fact, the most common 3D printing technologies have been around for decades.

In fact, the most common 3D printing technologies have been around for decades.

Although the technology continues to evolve, I will assume that the last revolutionary phase - mass commercialization - is about ten years away. The pioneers of 3D printing are already using it to make a wide variety of things. However, this market is still niche and limited in commercial applications. In particular, these are companies that are engaged in small-scale, piece production or goods that cannot be manufactured using traditional methods.

Notwithstanding the above, we must remember that ten years ago, no industry sector reported selling products entirely or partially made with a 3D printer. So what is happening now is impressive. As 3D printing techniques evolve and new ones emerge, and old processes become faster and cheaper, we can expect 3D printing to move closer to a mass commercialization phase in the late 2020s or early 2030s. Innovators in the field plan to take advantage of the technology long before that.

3D printing technology

How does 3D printing work? To a large extent, it is an evolution of 2D printing, already used ubiquitously in offices and homes.

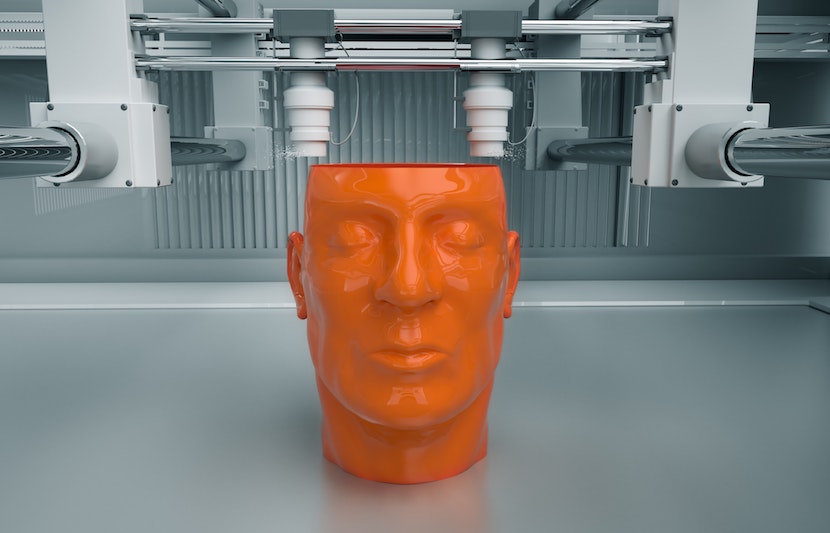

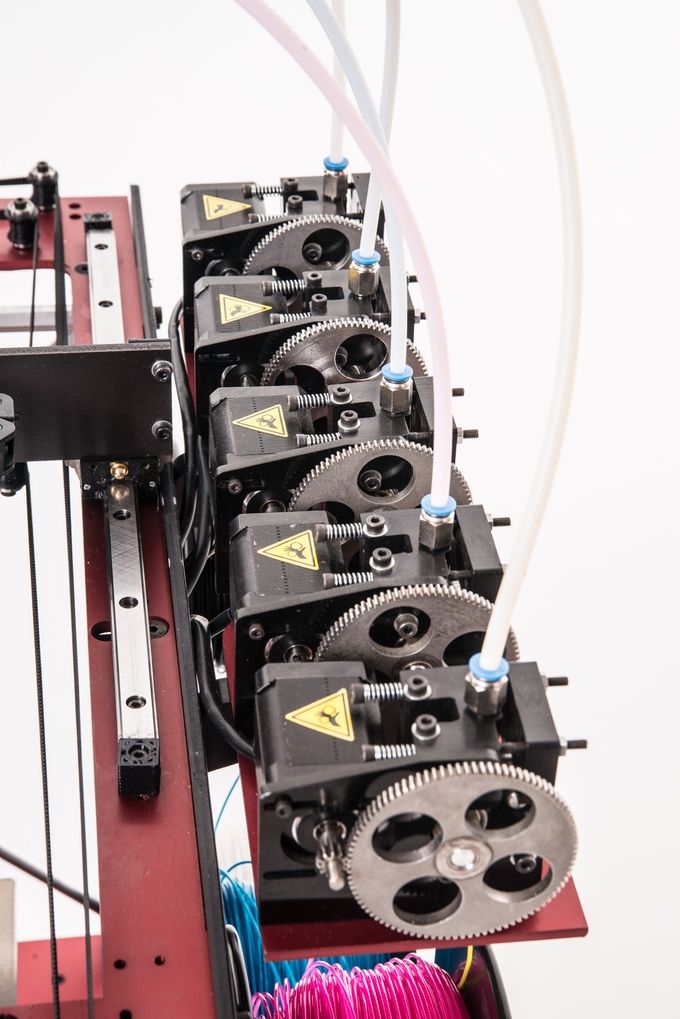

Most of us are familiar with inkjet or laser printers that allow you to print documents or photos. They create them by controlling the application of ink or toner to the surface of a sheet of paper. Similarly, 3D printers produce objects by controlling the placement and adhesion of successive layers of "building material" in 3D space. For this reason, 3D printing is also known as Additive Layer Manufacturing (ALM) or "additive manufacturing" ( AP or AM - Additive Manufacturing).

To print an object on this printer, you need a digital model on your computer. It can be created using a computer-aided design (CAD) application or other 3D modeling software. Also, a digital model can be captured by scanning a real object with a 3D scanner and processing with CAD or other programs.

The model must then be run through yet another "slicing" program that will cut the digital object into multiple cross-sectional layers - typically about 0.1mm thick. These digital ribbons are sent to a 3D printer, which makes them one on top of the other until a real object is formed.

3D model in CURA-a popular open-source cutting program

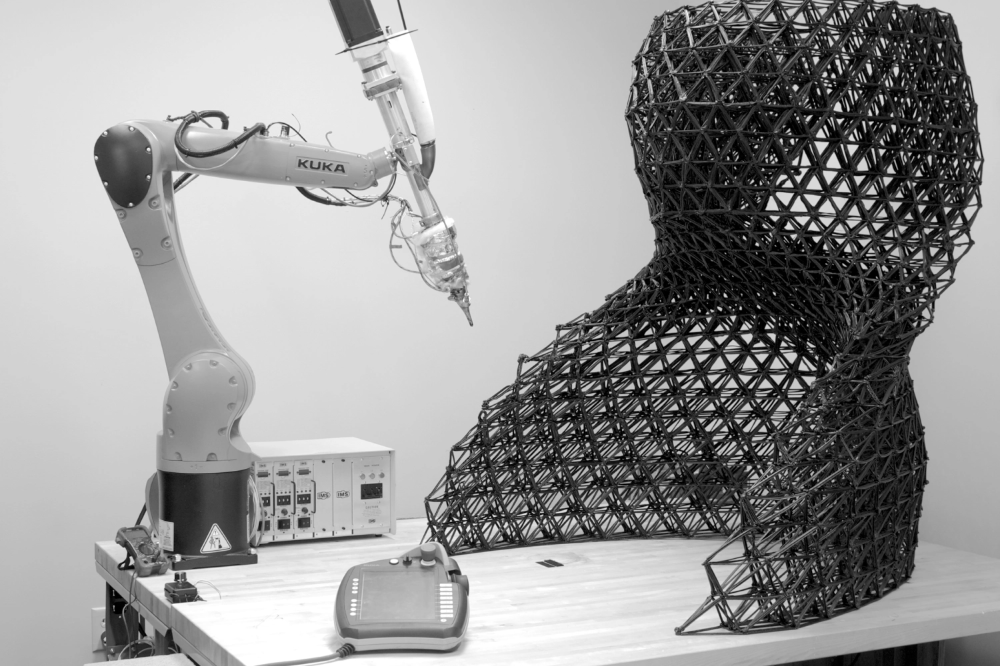

30 9000 TO 3D 3D-3D 2 draws an object one layer at a time, depending on the technology it's built on. There are many 3D printing methods and they can be divided into 4 categories. 3D printing is used for prototyping, mold making, digital direct manufacturing and custom manufacturing. Suppliers of 3D printing hardware, software and materials are already serving the needs of various market sectors. And now we will look at these areas of application to understand how 3D printing technology is developing. Most often, 3D printers are used for rapid prototyping (RP - Rapid Prototyping). Functional prototypes and concepts were created before the advent of 3D printers using laborious methods and tools. Therefore, their production often takes many days, weeks or even months, and the cost is thousands or tens of thousands of dollars. 3D printers can create concepts and functional prototypes in days or even hours, and at a fraction of the cost of traditional fabrication methods. Examples from this industry include concept cars for Formula 1. In addition to saving time and money, printing prototypes allows improved products to be brought to market as designs typically go through many iterations. 3D printing technology in color in various materials and metals continues to evolve, so the range and quality of products, including their components that can be quickly prototyped, continues to increase. So the company Nano Dimension demonstrated a desktop 3D printer - DragonFly 2020 , which can produce functional PCB prototypes. This equipment uses inkjet technology to output highly conductive "nano-ink" and can produce multi-layer boards, including all connections between layers. At a time when many companies wait days or weeks to get a prototype board from an outside vendor, the machine will print it in a matter of hours. In addition to prototypes, 3D printers are used to make molds and other fixtures for manufacturing equipment. A mold is needed in order to cast metals or plastics in it. Like prototypes, molds have traditionally been made by hand. Therefore, the use of 3D printers can save time and money for large manufacturers. For example, by using Stratasys' Fortus printers, Lyon-based automotive giant Volvo Trucks has reduced the time it takes to manufacture some engine components from 36 days to 2. In August 2016, the American Oak Ridge National Laboratory 3D printed a 5.34 x 1.34 x 0.46 m trimming and drilling tool for Boeing. It is used in the construction of passenger aircraft, and was printed from carbon fiber reinforced plastic in about 30 hours. Previously, the production of such a part would take three months. As Boeing's Leo Christodoulou explained, “Additive manufacturing tools like the wing trim tool will save energy, time, labor and manufacturing costs. Another promising application is the production of molds used for casting metals. 3D printers are capable of producing the required shapes, as well as any additional rods needed to be placed inside them. The process is carried out by applying thin layers of foundry sand, which are held together with a binder. The resulting 3D printed mold is sent to the foundry, where molten metal is poured into it to produce the finished product. ExOne is one of the companies specializing in the production of 3D printers for additive manufacturing using foundry sand. By 3D printing molds and foundry sand cores, manufacturers can not only save time and reduce costs, but also improve accuracy and mold more complex parts, the company says. This is because 3D-printed shapes and rods do not require post-processing, which could damage them. 3D printers can also be used to make molds for injection molding plastic parts. Bi-Link , based in Bloomingdale, Illinois, 3D prints low-volume injection molds. It manufactures parts for electronics and medical device manufacturers around the world. The ProJet 3500 HD Max printer from 3D Systems creates a form in hours instead of weeks. As Director of Research and Development Frank Sieberna said: “Customers are delighted with this service. Previously, you had to wait two or three weeks to get just the tools - not to mention the test parts. The ProJet 3500 HD Max can produce four different designs for a single customer in six days, shipping 10-12 parts per iteration overnight. Some companies are building machines that can print objects from wax (or wax substitutes) to create investment casting molds. The wax object is 3D printed, then molded around it using a material such as plaster. After the form is heated, as a result of which the wax “burns out” and flows down. Molten metal or other liquid material is then poured into the mold to create the finished product. The use of 3D printers to create wax models is quite common in the jewelry industry and other industries that specialize in complex and expensive items. Like injection molds, wax samples are consumable because the process of creating the finished product causes them to break. In several niche markets, 3D printers are already being used to produce finished industrial components and even consumer products. This development is referred to as "Direct Digital Manufacturing" (DDM - Direct Digital Manufacturing) and is becoming increasingly popular, for example, in aviation. Other DDM industries include automotive, medical, jewelry, and footwear. One of the leading pioneers is Nike. According to COO Eric Sprank, the company "has made a number of breakthroughs in design and manufacturing through 3D printing that will enable the creation of an entirely new custom shoe cushioning system." To this end, Nike is building an "Advanced Product Creation Center" covering approximately 11,000 square meters to house 3D printing and other design and manufacturing technologies. It is quite possible that in the future everything will be made using a 3D printer, including even human organs. This is most noticeable in dentistry: wax models, orthodontic applications, fittings, surgical guides and veneer models are now 3D printed. In addition to creating inorganic prostheses, there are "bioprinters" that build up human tissue by laying down layers of living cells. In addition to bioprinting tissues outside the body, bioprinting on the body or inside a wound is already under development. It involves printing layers of cultured cells directly onto the wound or even inside using keyhole surgery techniques. When such technology becomes advanced enough, the patient simply needs to insert an instrument into the wound, which will remove the damaged cells and replace them with new ones. These instruments will even be able to heal the wound caused by their introduction. In parallel with the growth of industrial 3D printing, there is an increase in individual production. These are all situations when an entrepreneur prints his own things on a 3D printer, bypassing the launch of production at a remote factory. In addition to the growing number of personal machines, there is a growing number of free and paid 3D models that can be downloaded for printing. On resource Thingiverse hosts over a million free models - some of them can be customized to the user's requirements. It is possible that the provision of such content will become the foundation for mass personal production, as it will eliminate the need for creative and engineering skills. Currently, personal and professional 3D printers are limited in their ability to use thermoplastics or composites, as well as photopolymer resins. Therefore, the range and quality of products that can be manufactured on such equipment remain low. At the same time, an increasing number of cloud-based 3D printing services, such as Shapeways and i.materialise allow anyone to upload a 3D object to be printed on industrial equipment. If the majority of people start making the products they need on their own, this will have a serious impact on many industries. Parts companies are already wary of the threat of mass-produced personal items. The representatives of the transport and logistics sectors are afraid of the same, because this will change the demand for their services. In 2014, the IBM Institute for Business Value published a report highlighting four futures for custom manufacturing. And now we will briefly get acquainted with it. My guess is that consumer involvement in 3D printing will grow as technology improves, but at a slower pace. There are different segments of the 3D printing market, and they are at different stages of development. The very first 3D printers began to make prototypes in the late 1980s, and the use of printing to create molds did not begin until a few years after that. Long before the early 2000s, the first finished products and works of art printed using this technology appeared. Finally, customization only became possible in 2007 with the introduction of the first "open source" 3D printers that private individuals could afford. I estimate that half of all prototypes will be 3D printed by 2025. However, 3D printing is not the only rapid prototyping technology. There are cases where traditional methods are better suited for prototyping. It is inconceivable that inventors would stop sculpting things out of clay, wood, paper, metal, and everything else that is available in their kitchens, studios, labs, workshops, and sheds. In terms of 3D printing of molds and manufacturing tools, this market currently lags behind rapid prototyping, but will very soon become the mainstay of additive manufacturing. I assume that it will take at least a decade to saturate it. After talking with manufacturers of industrial 3D printers, I was convinced of this. In most industries, 3D printing of molds and other tools represents the biggest market opportunity. In digital direct manufacturing, this is just starting to happen, although it is currently a very niche activity. However, in the next ten years or so, many industries, primarily aerospace, automotive, healthcare, fashion, footwear and designer goods, will use 3D printing as one of their core manufacturing technologies. This will allow you to create completely new types of products and attract media attention. And even so, in 10 or 20 years, the vast majority of objects in our lives will still be produced by traditional methods. Likewise, for decades to come personal items will be a niche market in both the 3D printing industry and global manufacturing. It can be argued that home production will not be the driving force behind the 3D printing revolution - and many in the industry agree. However, I will look forward to 3D printers in 9$9 that will be able to make small plastic items based on a model sent from a tablet or smartphone. Like the Internet revolution that preceded it, 3D printing is enabling companies and individuals to achieve the previously impossible. And the reason is not only in the creation of prototypes and old things in new ways. It does so in line with new business models. Let's outline these key benefits. With traditional methods, single and small batch production is expensive and often prohibitive. Jay Leno, who enjoys collecting cars, is already using 3D printing for one-off production. As an example, when a rare EcoJet concept car needed to have some broken air vents replaced, it contacted 3D Systems . The company scanned the broken parts, digitally repaired them using a CAD program, and sent the resulting data to service provider Quickparts . There, the new vents were 3D printed from a lightweight, fiber-filled nylon material called DuraForm HST. The result is a reliable replacement part with a better strength-to-weight ratio than the original. 3D printing is being used to make props for TV shows, movies and theatrical productions. With this technology, SpaceX is printing the engine chambers of the Crew Dragon spacecraft, and NASA has printed about 70 parts for the rover. In addition to facilitating the small-scale production of identical items, 3D printing allows products to be customized according to the tastes of the buyer and his physical needs. For example, company Robot Bike Co. uses technology to build a custom R160 mountain bike frame. It is created from carbon fiber passing between titanium ridges, which are printed on Renishaw 3D printers . On the Robotbike.co website, the buyer enters his height, leg size and arm span, which allows him to get a frame individually for him. The R160 is a great example of a real product that combines 3D printed parts with other standard components. This makes it possible to offer a product according to individual requests in an economical way. Another key benefit of 3D printing is that it removes the limitations of traditional manufacturing methods. While a designer can come up with any design for a product, if its components cannot be molded, machined, and assembled, the product will never hit the market. And in the “brave new world” of 3D printing, you can create things that were previously impossible to make. For example, such a printer can produce a chain or necklace made up of links that do not have breaks and therefore will never come apart. The TransFIORmers motorcycle racing team used a Renishaw metal 3D printer to produce a new, optimized suspension design. The original version was handcrafted from steel, and at the same time, twelve parts were required for assembly, which must be welded together. But with the help of 3D printing, the team was able to combine the structure into a single titanium component that required no assembly, resulting in a 40% weight reduction, a critical feature for racing. Using plastic or polymer materials, some printers can create working, pre-assembled, composite mechanisms such as a gearbox. Traditionally, the production of multi-component products includes a final assembly step. But when things are printed on a 3D printer, this is not necessary. In addition to improving product performance, 3D printing will enable many more people to become manufacturers. This is because the cost of prototypes and production tools will no longer be prohibitive, so 3D printing is making small-scale production increasingly viable. But more importantly, the availability of 3D printing services will allow almost any talented artist or designer to find a market for their creations. Today it is very difficult for an individual or even a small company to bring a product to market, let alone globally. One of the few exceptions is book publishing, where an author can create and distribute a print-on-demand product. Similarly, 3D printing allows individual designers to bring products to market without investing in equipment and prefabricated copies. For example, more than 8 thousand designers have already opened online stores on the site of a 3D printing service provider - Shapeways . As an example, consider the store of the famous bot creator Kidmechano. His creation is Modibot, which is an ever-expanding line of 3D printed action figures with an articulated design. You can compare Modibot with Lego or Transformers. Kidmechano uses the Shapeways platform to sell over 400 different ModiBot figures and accessories, including armor and weapons. Prices start at a few dollars, and when an order is placed, Shapeways prints whatever is required, sending the finished product to the customer, and Kidmechano his share of the proceeds. In addition to enabling small-scale production, cost-effectiveness and democratization of market access, 3D printing will facilitate the storage and transportation of digital objects. This means that in the future there will be two options for sending a parcel. The first is to send the physical product by courier or mail, and the second is to transfer the digital file over the Internet for 3D printing on site by the recipient. Many people regularly post texts, photos and videos on the Internet, and thanks to 3D printing, digital objects will soon be added to social networks. Thus, by making digital storage and transport possible, 3D printing will do to things what computers and the Internet have already done to store and transmit information. In some industries, digital object storage is already starting to make a difference. For example, most dentists have traditionally had to store huge amounts of plaster casts taken from patients' mouths. In addition to the benefits mentioned above, 3D printing saves materials for manufacturers, which is especially important for sustainable development. Today, factories begin production with a block of metal or other raw material and then cut it: lathe it, file it, drill it, or otherwise, to form the final product. In contrast, 3D printing is an additive activity that takes as much material as the finished product. Therefore, we get significant savings in raw materials if we make things using this technology. In addition, 3D printed products can have an internal structure optimized to use the minimum amount of materials. For example, plastic or metal parts printed on printers can be produced with internal cavities or an open grid - something that is almost impossible to achieve using most traditional technologies. Again, this results in material savings as well as lighter parts, which, for example, will reduce the fuel consumption of aircraft and other vehicles. 3D printing could be the cornerstone of the future transition to Local Digital Manufacturing (LDM). Today, most of the production is carried out in factories remote from their customers. As a result, huge amounts of oil and other resources are being spent on storage and transportation. Given declining natural resource stocks and climate action within a decade or two, these modes of transportation and storage may not be feasible or culturally appropriate. Thus, environmental protection may be a force to stimulate the mass adoption of 3D printing to facilitate the production of goods in local industries. Like any new technology, 3D printing can have both negative and positive effects. For example, there are fears that its further development will reduce jobs. And this is quite possible for some professions. Especially for those who produce prototypes, molds and tools using traditional methods. It is possible that employment in countries that prepare products for export will decline as the technology is absorbed by local industries. In his 2013 State of the Union address, President Obama cited 3D printing as a technology that "has the potential to revolutionize everything we do" and thereby bring jobs back from Asia back to the US. In other words, the global economic impact of the development of 3D printing has been recognized at the government level as one of the largest economies in the world. Obviously, 3D printing will also help create new jobs. It will be a long time before we can 3D print finished products without the help of a skilled technician. Some industries could also benefit from the spread of 3D printing. Last but not least, the logistics sector is already aware of these opportunities. For example, in July 2014, in Publication 9U.S. Postal Service 0091 noted that the service provider could "benefit enormously" from the spread of 3D printing due to the expected increase in small package deliveries. In particular, it was predicted that the technology could lead to an increase in the income of the local parcel delivery service by 486 million dollars a year. The forecast was based on the assumption that most 3D printed goods will be made in local service bureaus, from where they will need to be delivered to people's homes. In addition to the impact on employment, there are two other problems: infringement of intellectual property rights and the use of 3D printing for criminal purposes. Even more disturbing, it is already possible to 3D print firearms. Currently, a $230 personal 3D printer can only make a disposable plastic gun. But when the ability to print from metal becomes affordable, we will have serious problems. The latest minefield with 3D printing and personal effects is health and safety. Today, almost all the products we buy meet certain standards and are tested. However, manufacturers are responsible for any accidents and injuries that may occur as a result of their failure or malfunction. But who will be responsible if, for example, a child downloads a free toy from the site, prints it out and gives it to the younger one - and he swallows a piece broken off from it and suffocates? Will the fault lie with the person who developed the object; the site through which it was published, the manufacturer of the 3D printer, the supplier of the consumables, or the parent that allowed it? Now there is no answer to this question. The 3D printing revolution, like any other technological revolution, is the product of action, energy and the vision of those people who are brave enough to make it happen. Over the past few years, I have had the pleasure of interviewing many of the pioneers of 3D printing. And since my goal is to capture your imagination and not focus on details and technical details, so I asked them the fundamental question: “Why did you choose this particular technology?”. One of the first people I spoke to was Anssi Mustonen , the head of the Finnish 3D printing and design company AMD-TEC .

The same model printed by the Ultimaker 9000 9000 Two

There are also printers that use concrete, ceramic paste or clay.

There are also printers that use concrete, ceramic paste or clay.  There are many types of powder adhesion based on various materials. These include nylon, wax, bronze, stainless steel, cobalt chromium and titanium.

There are many types of powder adhesion based on various materials. These include nylon, wax, bronze, stainless steel, cobalt chromium and titanium.

Market and application

Rapid Prototyping

This includes concepts and functional prototypes. Concepts are simple, non-functional "drafts" of product design (such as a bottle without a removable cap) and are intended to allow artists to recreate their ideas in a physical format. Functional prototypes, on the other hand, are more complex and allow you to evaluate the form, fit, and function of each part of a product before putting it into production.

This includes concepts and functional prototypes. Concepts are simple, non-functional "drafts" of product design (such as a bottle without a removable cap) and are intended to allow artists to recreate their ideas in a physical format. Functional prototypes, on the other hand, are more complex and allow you to evaluate the form, fit, and function of each part of a product before putting it into production.  For example, thermos maker Thermos uses Stratasys 3D printers to produce prototypes in hours, not days, at a fifth of the cost of production from an external supplier. Because designers can now “create as many prototypes as needed,” the company has been able to fine-tune product features such as lid retention and ease of pouring.

For example, thermos maker Thermos uses Stratasys 3D printers to produce prototypes in hours, not days, at a fifth of the cost of production from an external supplier. Because designers can now “create as many prototypes as needed,” the company has been able to fine-tune product features such as lid retention and ease of pouring.

Molds and other manufacturing tools

They are also part of our strategy to apply 3D printing technology to manufacturing areas.”

They are also part of our strategy to apply 3D printing technology to manufacturing areas.”

Core molded from ExOne 3D printer  Such molds typically cost tens of thousands of dollars and are traditionally made of aluminum. Technically, a 3D printer can already make aluminum die casting molds using metal powder. But nowadays printers make such molds from resin using photopolymerization. Plastic molds are not as durable as their aluminum counterparts. But they are cheaper, faster to produce, and can be used to make up to 200 plastic parts before replacement is needed.

Such molds typically cost tens of thousands of dollars and are traditionally made of aluminum. Technically, a 3D printer can already make aluminum die casting molds using metal powder. But nowadays printers make such molds from resin using photopolymerization. Plastic molds are not as durable as their aluminum counterparts. But they are cheaper, faster to produce, and can be used to make up to 200 plastic parts before replacement is needed.  ”

”

Digital Direct Manufacturing

Airbus and Boeing are installing tens of thousands of 3D printed components for their aircraft.

Airbus and Boeing are installing tens of thousands of 3D printed components for their aircraft.  Such technology could revolutionize the medical field, for example by cutting the queues in organ donation. Company Bioprinting pioneer Organovo already sells printed liver and kidney tissue for use in drug testing.

Such technology could revolutionize the medical field, for example by cutting the queues in organ donation. Company Bioprinting pioneer Organovo already sells printed liver and kidney tissue for use in drug testing.

Individual production

There are already several hundred professional 3D printers on the market starting at $230.

There are already several hundred professional 3D printers on the market starting at $230.  It is likely that access to such a service – rather than the sale of personal 3D printers – will be the driving force behind the DIY revolution over the next five to ten years.

It is likely that access to such a service – rather than the sale of personal 3D printers – will be the driving force behind the DIY revolution over the next five to ten years.

This means that over the next few decades, we will gradually move from a “quiet revolution” to a “manufacturing revolution” and then to a “consumer rethinking”.

This means that over the next few decades, we will gradually move from a “quiet revolution” to a “manufacturing revolution” and then to a “consumer rethinking”.

The development of the 3D printing industry

Currently, no more than 10% of the 3D printing industry's revenue comes from the sale of personal printers. Many of these machines are sold to companies rather than individuals. But this does not mean that the sale of personal equipment for home use does not represent a market opportunity.

Currently, no more than 10% of the 3D printing industry's revenue comes from the sale of personal printers. Many of these machines are sold to companies rather than individuals. But this does not mean that the sale of personal equipment for home use does not represent a market opportunity.

Making new products in new ways

Single and small batch production

When things are printed on a printer, there is practically no difference in cost per unit - that is, it does not matter if 1, 100 or 1000 copies are required, since there are no costs for tools and workers. Therefore, in many situations where a few hundred or fewer components are needed, 3D printing will be the most economical way. It is for this reason that 3D printing is so widely used in rapid prototyping and is increasingly used in the production of molds and other tools.

When things are printed on a printer, there is practically no difference in cost per unit - that is, it does not matter if 1, 100 or 1000 copies are required, since there are no costs for tools and workers. Therefore, in many situations where a few hundred or fewer components are needed, 3D printing will be the most economical way. It is for this reason that 3D printing is so widely used in rapid prototyping and is increasingly used in the production of molds and other tools.

Customization and personalization

I am sure that over time, many companies will realize the potential of "custom-made" by 3D printing certain parts.

I am sure that over time, many companies will realize the potential of "custom-made" by 3D printing certain parts.

Design and build optimization

Free access to the market

For example, residents of the UK can order a printed book through Amazon and receive a book printed in the corporation's warehouse within eight hours. This innovation allows authors to sell books without pre-printing and distribution.

For example, residents of the UK can order a printed book through Amazon and receive a book printed in the corporation's warehouse within eight hours. This innovation allows authors to sell books without pre-printing and distribution.

Digital storage and transportation

Although they were only used once, there was no way to predict if they would be needed in the future, which led to archives with boxes and cabinets littered with plaster models. But now dentists are moving to digital technologies: 3D scanners and 3D printers are replacing alginate molds and plaster casting. This allows you to save impressions of the patient's oral cavity in digital form, for future 3D printing if necessary.

Although they were only used once, there was no way to predict if they would be needed in the future, which led to archives with boxes and cabinets littered with plaster models. But now dentists are moving to digital technologies: 3D scanners and 3D printers are replacing alginate molds and plaster casting. This allows you to save impressions of the patient's oral cavity in digital form, for future 3D printing if necessary.

Material savings and environmental impacts

Difficulties can be overcome!

As technology spreads, new jobs will emerge, and such employment will be evenly distributed across the region—not typical of the industrial revolutions of the past.

As technology spreads, new jobs will emerge, and such employment will be evenly distributed across the region—not typical of the industrial revolutions of the past.  It is already possible to use consumer equipment to scan an object, such as a model of Mickey Mouse, and then print a plastic copy of it. Similar to the impact that mp3 music and the internet have had on the music industry, 3D printing can impact intellectual property rights.

It is already possible to use consumer equipment to scan an object, such as a model of Mickey Mouse, and then print a plastic copy of it. Similar to the impact that mp3 music and the internet have had on the music industry, 3D printing can impact intellectual property rights.  And pretty soon, we won't be able to ignore it.

And pretty soon, we won't be able to ignore it.

In the world of pioneers

“We live in a hectic world, but with this technology, we can deliver quality service to our customers,” Anssi said. As for prototypes: I don't have time to code and send orders to external vendors for details. 3D printing is not the only way to fabricate, but it is faster at creating complex shapes and configurations than traditional methods.”

Konstantin Ivanov , co-founder and CEO of 3DPrintus.ru , told me how technology allows us to offer new types of products and services:

“3D printing provides solutions that are at the intersection of manufacturing and the digital technologies of the Internet. Our customers have discovered an easy way to create and produce just about anything. I'm sure the main advantage for them is the ability to use a simple interface to get their product."

Gary Miller , Managing Director of 3D Print Bureau Print Services in the UK, told a similar story, albeit with caution in the forecasts:

“We use 3D printing because it’s faster: faster lead times and almost any geometry is available! I started with the Objet printer over ten years ago when there was only one material. Years have passed, and now there are about 2 thousand materials for printing.Just imagine where we will be in ten years! True, no matter how much raw material you have, you need to transfer it to reliable hands. You need experience in your industry to understand where this technology is suitable, and where it will only increase the cost. I used to be skeptical that 3D printing would move into manufacturing, but in the first half of 2016 we saw progress and an increase in orders. It's great to see how 3D printing develops and new materials emerge."

One of the most interesting conversations was with John Cobb , EVP Corporate Affairs of 3D printing giant Stratasys in the US. Shortly after starting the conversation, John focused on the technology's potential to redesign and distribute products:

“In 3D printing, there is a lot of focus on adapting it to traditional manufacturing processes. The fundamentals of design are changing, allowing for a change in the way products are made and then methods of distribution.Imagine there is a problem with the plumbing. You take a picture of it with your smartphone and send it to the Home Depot And after an hour or two, you assemble the pipeline - replacing a non-standard part. It may take another five years, but we are already moving in this direction.”

Miranda Bastins , director of Belgian 3D printing service i.materialise , focused on new market opportunities from a different perspective:

“3D printing helps to create a world where products meet our expectations or individual style, and where everyone has the opportunity to own something unique. Things not only better meet the needs and interests of consumers, but it also becomes possible to sell their own goods to others. For example, a jewelry designer might propose a new ring to a global audience and test the demand for the design. If there are no orders, this is no longer a problem (printing only on demand) - and if there are, then the rings will be printed, delivered to the customer, and the creator will receive his share of the proceeds.

Lucy Beard , founder of Feetz , also recognizes the potential of 3D printing to create "better fit" products. Feetz is a "digital shoemaker" that uses 3D printers to make custom shoes. As Lucy told me:

“This technology is changing the way we produce and consume things. We can make personalized products with fewer resources, and it will be much easier to recycle them.”

Mark Saunders is Director of the Global Solutions Centers at Renishaw , a 3D printer manufacturer. He also focused on the opportunities the technology offers manufacturers:

“More and more companies are looking to use the potential of 3D printing to improve product performance, making it more efficient and better adapted to the application. The unique ability to create complex geometries from high-quality materials opens up huge potential for innovation in both product design and business models.We expect additive manufacturing to play a key role in further developing processes and improving products.”

Finally, Sylvain Premont , founder of iMakr 3D printer shops and 3D content website My Mini Factory , noted how technology unleashes the imagination:

we will be able to invent, design and manufacture almost everything - in the shortest possible time and at a low cost. You will also be able to download content that is ready to print and easily adaptable to your own needs. The next generation will ask their parents: How did you get along without a 3D printer before?

A new frontier

As you can see from the interview, 3D printing continues to generate interest among its pioneers. And many large manufacturers using traditional technologies are already changing direction towards this technology.

Nobody can predict the future of 3D printing. However, there is good reason to believe that the technology will have a drastic impact on many manufacturing sectors.