Flexion 3d printer

Flexion Extruder: Take a Lower-Performing 3D Printer to the Industrial Level - 3DPrint.com

Like many other 3D printing enthusiasts, you may have experienced challenges in using flexible 3D printing filament. Numerous filaments on the market promise strength and flexibility but at the same time present difficulty in making complex parts, causing issues with temperature, clogging, adhesion, and more. We’ve covered the pros and cons you may run into with these materials previously, leaving it up to you to weigh out which benefits work best for you—even if you are running into some tricky areas.

Now, a rather interesting combination has been brought to our attention via Diabase Engineering, a new 3D printing startup co-founded by Stephen Heston—the inventor of NinjaFlex filament. Bringing his expertise and knowledge regarding issues that arise with filaments to a new product, he and his team at Diabase created an extruder that works well with flexible materials, but not only that—promises to imbue your desktop 3D printer with industrial qualities; in fact, ‘low-performance’ hardware may suddenly become much more versatile and reliable, according to Diabase.

With the Flexion Extruder kit, those at the desktop level should be able to look forward to an exciting upgrade meant to solve numerous issues that the Diabase team saw plaguing the 3D printing space. The Flexion processes more rigid materials than other extruders, and employs a low-friction, low-clearance barrel to convert stepper motor torque and melt pressure with minimal loss.

With these features, the Flexion offers the much-desired speed 3D printing operator desire, along with greater precision and control; in fact, you can look forward to watching the Flexion extrude materials like 60 ShoreA urethanes—described to be as soft as the eraser of a pencil.

“This is the most precise, effective, and absolutely gorgeous upgrade I have done to a printer so far,” said Patrick Bishop of PB3D Creations.

Offering three configurations, the Flexion can be dropped in to nearly any 3D printer, with two of the configurations being made to retrofit MakerBot Replicator 2x printers quickly. The third configuration is also compatible with E3D’s well known v6 hotend.

The third configuration is also compatible with E3D’s well known v6 hotend.

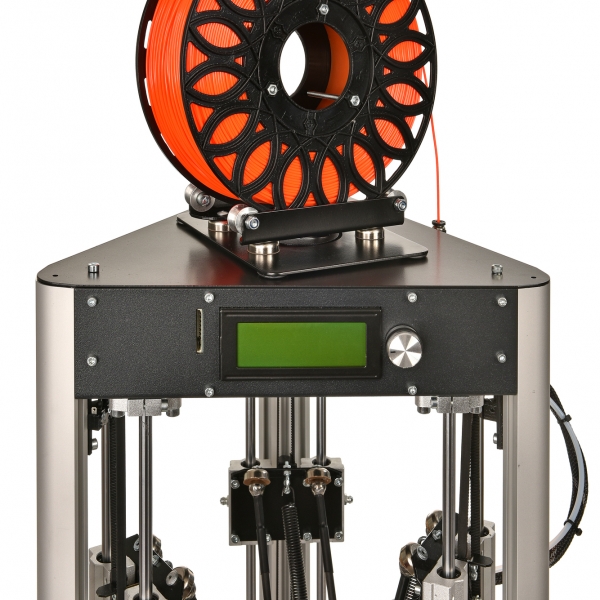

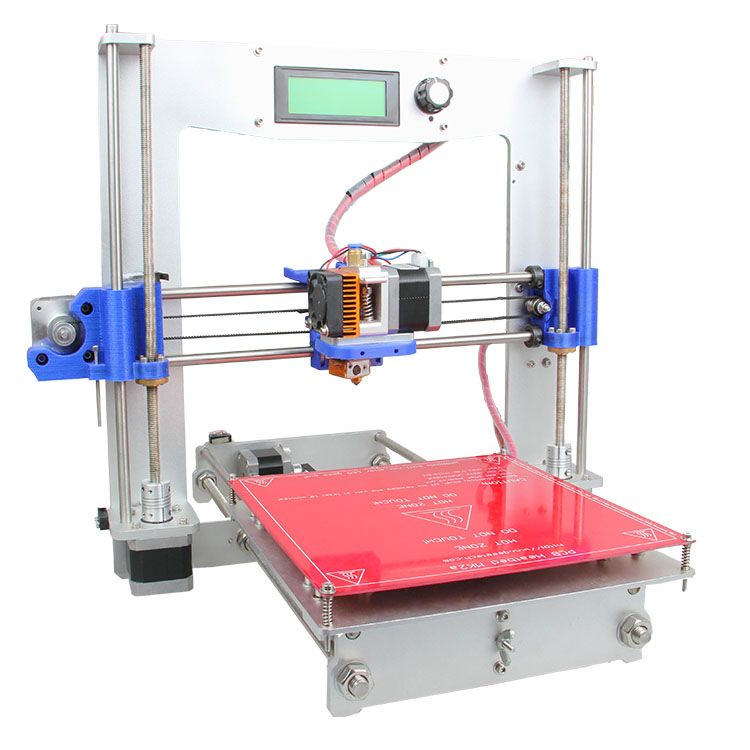

“E3D makes a fantastic hotend,” said Austin Reid of Diabase Engineering. “We’re excited to combine the precision of the Flexion drive unit with the high temperature capability and extended reach of the v6 hotend. This setup will be especially useful for RepRap and other DIY printers.”

Diabase, upon receiving funding for 3D printing innovations, was able to release the Flexion Extruder kit in April, marking their debut.

“We collaborated with NinjaTek on the extruder development and continue to work with them on materials testing,” Stephen Heston told 3DPrint.com. “We have received local technology grants and investment for several other longer-term projects related to deposition technology.”

The company reports good sales growth with the extruder kit so far, and has received good 3D printing product reviews, including a recent one from Makers Muse as Angus gave an extensive report. The product caught his eye as he sees many users having difficulty with flexible filaments. He remarks on the nice packaging, complete with four nozzles ranging from .2 to .5 mm, and all the upgrade parts you will need. Assembly took Angus less than one hour.

The product caught his eye as he sees many users having difficulty with flexible filaments. He remarks on the nice packaging, complete with four nozzles ranging from .2 to .5 mm, and all the upgrade parts you will need. Assembly took Angus less than one hour.

“It was printing almost straightaway, which is awesome,” said Angus at Makers Muse.

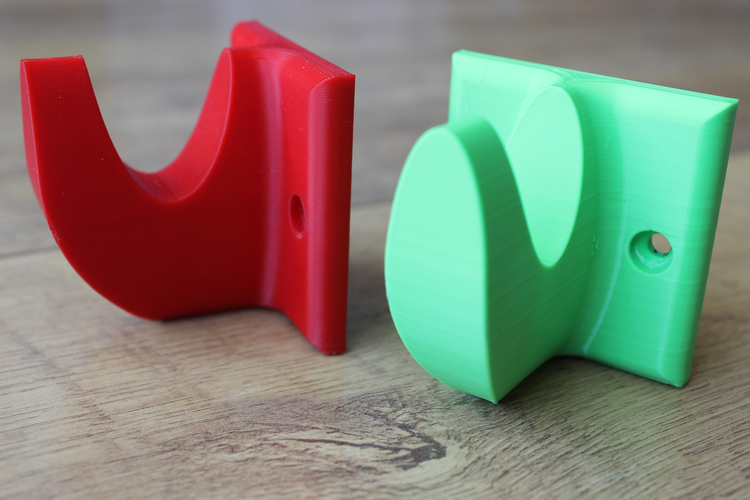

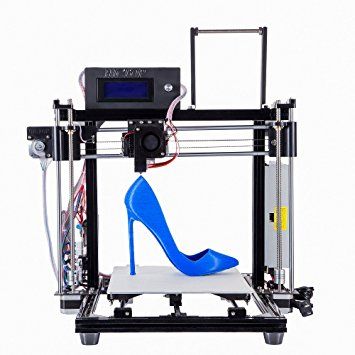

The Extruder kit, as displayed in the review by Makers Muse.

He goes on to explain that this extruder handles flexible materials so well because it is fully supported from the feeder gear to the hotend, as well as being constructed with fixed tension, offering less pressure for flexible materials. Pointing out that the Flexion also has four different tension steps, this may be another key element to its success in printing with a variety of materials. Angus was extremely impressed with his PLA print, indicating no issues with infill at all. Next, using a flexible and ‘really soft’ TPU, the reviewer had success after increasing the temperature, slowing the speed, and modifying some other settings as well—and then even going so far as to print the ubiquitous octopus.

“If you’re serious about taking your 3D printer to the next level, the Flexion Extruder is a no-brainer,” concluded Angus.

The enthusiastic reviewer reported that he would now be using the Flexion all the time, and even when printing with PLA.

Beginning at $149, you can order the Flexion kits directly from Diabase. What are your thoughts on this new product? Discuss further over in the Diabase 3D Printing Extruder Kits forum over at 3DPB.com.

Stay up-to-date on all the latest news from the 3D printing industry and receive information and offers from third party vendors.

Tagged with: 3D printing extruder • colorado • Diabase Engineering • flexible 3d printing filament • Flexion Extruder kit • Makers Muse 3D printing product reviews • ninjaflex • NinjaTek • PB3D Creations • PLA 3D printing filament • TPU

Please enable JavaScript to view the comments powered by Disqus.

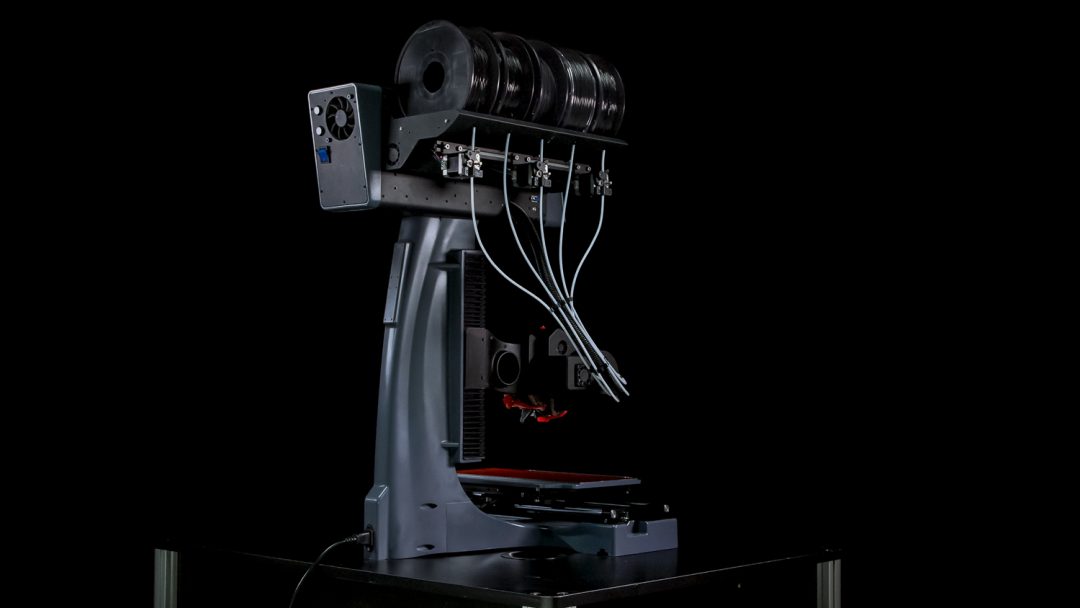

Dual Flexion Flexible Filament Extruder Kit

Flexion

- $24900

Default Title - Sold Out Quantity

- Info

- Why buy from us?

- Shipping

- Price Guarantee

Flexible filament extruder retrofit kit for dual-extruder direct-drive machines, such as Flashforge Creator, Monoprice Dual, or Powerspec Ultra. The Flexion extruder will allow full-speed printing of ultra-flexible filaments. The precision machined components allow your printer to push on filament harder, achieve high pressure in the nozzle, and control feed rates very closely. The self-cleaning drive will keep your long prints from failing due to a clogged drive. Works will with Ninjaflex, Filaflex, flexible PLA, TPU, TPE, ultra-flexible filament down to 50 Shore A, and all the standard rigid filaments like ABS and PLA.

Works will with Ninjaflex, Filaflex, flexible PLA, TPU, TPE, ultra-flexible filament down to 50 Shore A, and all the standard rigid filaments like ABS and PLA.

This kit requires you to disassemble your printer’s extruder and reinstall this upgrade.

*Fits all of the most common dual extruder printers – Flashforge Creator Pro, Powerspec Ultra, QiDi Tech, Malyan M180, Wanhao Duplicator 4s, CTC, etc.

Please note, the QiDi and CTC stock extruders are NOT compatible, so you will not be able to mix your stock and Flexion extruder. Also for QiDi, the temperature sensor location is moved and will read 10-15° low, so turn your print temperatures down.

| Weight | .25 lbs | |

|---|---|---|

| Dimensions | 3 x 4 x 1 in | |

| Works with | Flashforge Creator, Monoprice Dual, Wanhao 4S, Powerspec Ultra, and many others (see support pages) | |

| Includes |

|

Price match guarantee:

We work very hard to ensure that we offer the absolute best prices online for all of our printers including Tevo 3D printer kits. If you find another online store that offers a lower price than us on Tevo 3D printers for sale, please let us know and we will refund your original payment for the difference. Read More

30 day price assurance guarantee:

We want you to feel confident that you are getting the absolute best price for the product. If you find that our own website has a lower price for the same item you have ordered within 30 days of your purchase date, we will refund the difference! Read More

Full manufacturer direct warranty:

We are an authorized dealer for all our products and comes with the full manufacturer warranty.

Tax free (except California and Nevada):

The price you see is the price you pay but because we operate in California and Nevada we must charge tax in California and Nevada.

Safe & secure online ordering:

We are certified Level 1 PCI DSS compliant. What this means is that we meet all the requirements defined by the Payment Card Industry Security Standards Council. For additional information on PCI Compliance, visit the PCI Compliance Guide website. We also accept payment via Pay Pal, a leader in secure online payment processing.

Best customer service:

We strive to offer the best customer service we can. If you have any questions please let us know by phone or email.

Exclusive deals:

We appreciate each and every customer that comes to our store. We know you have a lot of choices when it comes to your 3D printing purchase. That's why we'd like to show our appreciation by periodically sending out exclusive coupons and deals to our past customers!

Order Confirmation:

As soon as you place your order you will receive an order confirmation e-mail. This means that we have received your order in our system and pre-authorized your credit card for the purchase. As soon as we receive your order we automatically reach out to our suppliers to confirm that it is in stock and available for immediate shipment. If your item is on backorder or unavailable we will void the pre-authorization and reach out to you via e-mail. If your item(s) are available for immediate shipment (within 5 business days) we will process the charges and submit the order for shipment.

This means that we have received your order in our system and pre-authorized your credit card for the purchase. As soon as we receive your order we automatically reach out to our suppliers to confirm that it is in stock and available for immediate shipment. If your item is on backorder or unavailable we will void the pre-authorization and reach out to you via e-mail. If your item(s) are available for immediate shipment (within 5 business days) we will process the charges and submit the order for shipment.

Order Shipment:

If your order is in stock and we process the charges to your credit card, it will ship within five business days from the date of your order. We will send you tracking information within 24 hours of your order leaving the warehouse to the e-mail address you provide when checking out. If you do not receive tracking information from us within six business days of your order feel free to follow up with us at [email protected]

Domestic Shipping:

We do not ship to P. O. Box.

O. Box.

International Shipping:

Please contact us for international shipping rates

We work very hard to ensure that we offer the absolute best prices online for all of our printers including Tevo 3D printer kits. If you find another online store that offers a lower price than us on Tevo 3D printers for sale, please let us know. We want you to feel confident when you buy a Tevo 3D printer or any of our other printers that you are getting the absolute best price for the product.

To request your partial refund simply e-mail us a link to the same product on our website, or on our competitors’ website and we will process the credit accordingly.

Our 100% Price Guarantee has some limitations:

- You must purchase the item from our website before requesting your Price Match Guarantee

- Promotions such as rebates and buy one, get one free offers are not eligible

- The item must be in stock on the competitors website

- The competitor must be an online store, they may not have a retail location

- The item must ship from the same country.

- The website cannot be a discounter or auction website (ie; eBay, overstock, etc..)

- The competitor must be an Authorized Retailer for the product in question

- The Price Match Guarantee includes the item price and the shipping charges, it excludes sales tax or any customs and duties

Info▼

Flexible filament extruder retrofit kit for dual-extruder direct-drive machines, such as Flashforge Creator, Monoprice Dual, or Powerspec Ultra. The Flexion extruder will allow full-speed printing of ultra-flexible filaments. The precision machined components allow your printer to push on filament harder, achieve high pressure in the nozzle, and control feed rates very closely. The self-cleaning drive will keep your long prints from failing due to a clogged drive. Works will with Ninjaflex, Filaflex, flexible PLA, TPU, TPE, ultra-flexible filament down to 50 Shore A, and all the standard rigid filaments like ABS and PLA.

This kit requires you to disassemble your printer’s extruder and reinstall this upgrade.

*Fits all of the most common dual extruder printers – Flashforge Creator Pro, Powerspec Ultra, QiDi Tech, Malyan M180, Wanhao Duplicator 4s, CTC, etc.

Please note, the QiDi and CTC stock extruders are NOT compatible, so you will not be able to mix your stock and Flexion extruder. Also for QiDi, the temperature sensor location is moved and will read 10-15° low, so turn your print temperatures down.

| Weight | .25 lbs | |

|---|---|---|

| Dimensions | 3 x 4 x 1 in | |

| Works with | Flashforge Creator, Monoprice Dual, Wanhao 4S, Powerspec Ultra, and many others (see support pages) | |

| Includes |

|

Why buy from us?▼

Price match guarantee:

We work very hard to ensure that we offer the absolute best prices online for all of our printers including Tevo 3D printer kits. If you find another online store that offers a lower price than us on Tevo 3D printers for sale, please let us know and we will refund your original payment for the difference. Read More

30 day price assurance guarantee:

We want you to feel confident that you are getting the absolute best price for the product. If you find that our own website has a lower price for the same item you have ordered within 30 days of your purchase date, we will refund the difference! Read More

If you find that our own website has a lower price for the same item you have ordered within 30 days of your purchase date, we will refund the difference! Read More

Full manufacturer direct warranty:

We are an authorized dealer for all our products and comes with the full manufacturer warranty.

Tax free (except California and Nevada):

The price you see is the price you pay but because we operate in California and Nevada we must charge tax in California and Nevada.

Safe & secure online ordering:

We are certified Level 1 PCI DSS compliant. What this means is that we meet all the requirements defined by the Payment Card Industry Security Standards Council. For additional information on PCI Compliance, visit the PCI Compliance Guide website. We also accept payment via Pay Pal, a leader in secure online payment processing.

Best customer service:

We strive to offer the best customer service we can. If you have any questions please let us know by phone or email.

Exclusive deals:

We appreciate each and every customer that comes to our store. We know you have a lot of choices when it comes to your 3D printing purchase. That's why we'd like to show our appreciation by periodically sending out exclusive coupons and deals to our past customers!

Shipping▼

Order Confirmation:

As soon as you place your order you will receive an order confirmation e-mail. This means that we have received your order in our system and pre-authorized your credit card for the purchase. As soon as we receive your order we automatically reach out to our suppliers to confirm that it is in stock and available for immediate shipment. If your item is on backorder or unavailable we will void the pre-authorization and reach out to you via e-mail. If your item(s) are available for immediate shipment (within 5 business days) we will process the charges and submit the order for shipment.

Order Shipment:

If your order is in stock and we process the charges to your credit card, it will ship within five business days from the date of your order. We will send you tracking information within 24 hours of your order leaving the warehouse to the e-mail address you provide when checking out. If you do not receive tracking information from us within six business days of your order feel free to follow up with us at [email protected]

Domestic Shipping:

We do not ship to P.O. Box.

International Shipping:

Please contact us for international shipping rates

Price Guarantee▼

We work very hard to ensure that we offer the absolute best prices online for all of our printers including Tevo 3D printer kits. If you find another online store that offers a lower price than us on Tevo 3D printers for sale, please let us know. We want you to feel confident when you buy a Tevo 3D printer or any of our other printers that you are getting the absolute best price for the product.

We want you to feel confident when you buy a Tevo 3D printer or any of our other printers that you are getting the absolute best price for the product.

To request your partial refund simply e-mail us a link to the same product on our website, or on our competitors’ website and we will process the credit accordingly.

Our 100% Price Guarantee has some limitations:

- You must purchase the item from our website before requesting your Price Match Guarantee

- Promotions such as rebates and buy one, get one free offers are not eligible

- The item must be in stock on the competitors website

- The competitor must be an online store, they may not have a retail location

- The item must ship from the same country.

- The website cannot be a discounter or auction website (ie; eBay, overstock, etc..)

- The competitor must be an Authorized Retailer for the product in question

- The Price Match Guarantee includes the item price and the shipping charges, it excludes sales tax or any customs and duties

Flexible TPU plastic for printing on a 3D printer in Moscow: 1.

75 mm, weight 1 kg

75 mm, weight 1 kg Learn more

Only high-quality products

Learn more

Subscribe to newsletter

Be the first to know about discounts!

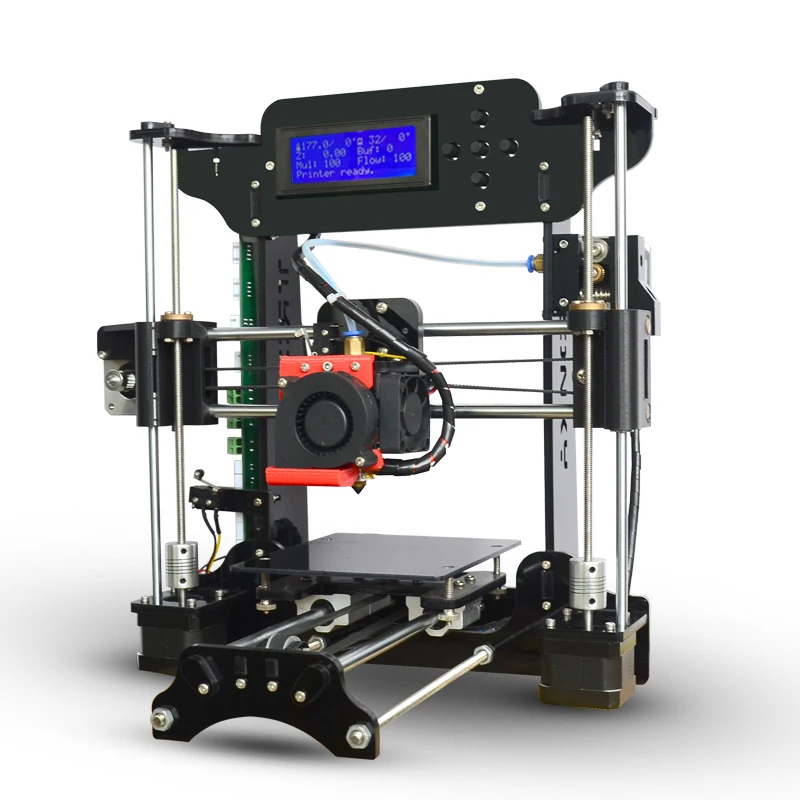

TPU plastic Description Parameters

for printing and

for post-processing Physical

mechanical characteristics

Material: TPU - thermoplastic polyurethane

Thermoplastic polyurethane (TPU) is a modern polymer material based on polyesters. The elasticity of printed products is the main property that determines the use of this plastic.

Press parameters:

Print temperature: 175-190 ° C

Table temperature: 50 ° C

Table cover: clean glass, glue BF-2, glue for 3D printing

speed speed prints: 15-20 mm/s.

Cooling: is recommended to be printed using efficient, annular airflow.

Density: 1.25 g/cm3

Features of TPU plastic and handling:

- Elasticity is the main property that determines the application.

- High resistance to deformation in both compression and tension.

- High strength, very soft. Shore hardness 75A

- No smell when printed.

- Excellent intercoat adhesion.

- The print speed is slow.

- Resistant to most solvents, fats, oils. Relative resistance to gasoline.

- Machining is very difficult due to the specific properties of the plastic.

- Wide operating temperature range.

- Bar accuracy ± 0.05 mm (reduced geometry tolerance).

- The FDM extruder head needs to be modified to eliminate gaps and cavities in the path of the bar from the feed gear to the hot zone of the print head. The use of bowden tube extruders is difficult due to the very low hardness of the material.

- Machining of TPU plastic products is difficult.

- Chemical treatment not applicable.

Thermoplastic polyurethane (TPU) is a unique material, one of the most sought after polymeric materials. Operational and chemical properties have provided this material with a wide distribution in all industries with high requirements for the quality of materials.

Thermoplastic polyurethane (TPU) combines wear resistance, lightness and elasticity, the ability to not change its color during its use. The material is resistant to low temperatures. rupture and aggressive environments, adheres well to the surface, restores shape when deformed, is able to perfectly resist punctures, has slip resistance.

TPU plastic is the first flexible, Flex-plastic in the line of plastics produced by the Moscow FDplast plant. Possessing excellent structural and technological properties, thermoplastic polyurethane is used in various industries, ranging from winding power cables, use in the development of the design of the bottom of shoes, the manufacture of protective accessories for electronic devices, and ending with a decorative overlay in the car interior.

Information on the properties of plastics and printing requirements can be found in the booklet "Flex for 3D printing FDplast".

Plastic storage

3D printing plastic must be stored in a dry place. Moisture and dampness greatly affect the filament, as a result, the plastic deteriorates, it becomes impossible to print from such plastic. There are no problems with the storage of plastic, it is practically not affected by the normal humidity of the ambient air. However, in order to obtain an ideal printing result, it is advisable to store the filament in a dry place, with silica gel.

3D Printing Tips

More >>

Download

Presentation. Plastic for 3D printing FDplast

Booklet. Plastic for 3D printing FDplast

Do you need a pipe? Call us and we will help you!

Send an order to the Plant's e-mail and our managers will contact you as soon as possible!

Update form

Contacts

Moscow plant FDplast

Office in Moscow

Construction sites

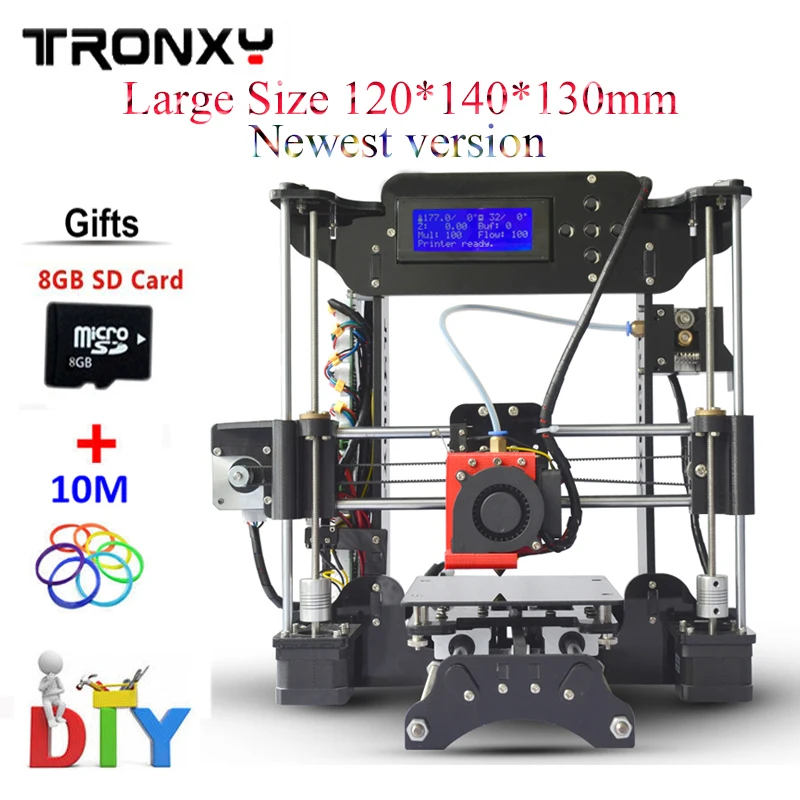

Trying out a flexible magnetic table for a 3d printer

3DPrintStory 3D printing process Trying a flexible magnetic table for a 3d printer - advantages and disadvantages

Hello everyone. Some time ago I became the owner of a magnetic table. I have long wanted to try it, but upon arrival of the package, there was not enough time to install it, and why, when the native glass did an excellent job with its functions. But I really wanted to get away from the regular one for the simple reason that in the design of my table a heating plate was tightly glued to the glass. And in order to remove the printed product from the table, one had to wait for it to cool completely, after which, working abundantly with a spatula, scrape it off. This is not very convenient, especially if 3d printing is on stream. Not only is it inconvenient, it takes a lot of time.

Some time ago I became the owner of a magnetic table. I have long wanted to try it, but upon arrival of the package, there was not enough time to install it, and why, when the native glass did an excellent job with its functions. But I really wanted to get away from the regular one for the simple reason that in the design of my table a heating plate was tightly glued to the glass. And in order to remove the printed product from the table, one had to wait for it to cool completely, after which, working abundantly with a spatula, scrape it off. This is not very convenient, especially if 3d printing is on stream. Not only is it inconvenient, it takes a lot of time.

In general, in this article I will share my experience and testing of the magnetic table. Let's discuss which plastics he is friends with and which he is not. And does its presence make life easier for us, as owners of 3d printers.

What is a flexible table? In my case, this is a heating plate to which glass is glued, on which, in turn, a magnetic coating is already glued. The end of this sandwich is the mat on which we will print. Please note that the Internet offers sets of a magnetic base and a mat without glass and a plate heater. In this case, all you need to do is stick the base to the glass and start using.

The end of this sandwich is the mat on which we will print. Please note that the Internet offers sets of a magnetic base and a mat without glass and a plate heater. In this case, all you need to do is stick the base to the glass and start using.

Let's start by setting up the table. But the first thing we will do is dismantle the old one. For this operation, we do not need any tool. Just unscrew the nuts from the legs of the table and lift it up, pulling it out of the mounting holes. We turn the table, turn off the plug. We take a new table and place it on the supporting structure. Plug the plug back in. After that, we install the springs on the legs, tighten them with nuts to make it easier for ourselves to level the table. I recommend tightening the nuts about the same distance.

Done. Now you can start calibrating. Let's first unscrew the adjustment screw as far as possible so that the nozzle does not rest against the soft surface of the table, as I assume that it can be very easily damaged. First you need to set the approximately 0 home position of the extruder, and then go directly to the alignment, when set to 0, the nozzle should be slightly pressed against the table.

First you need to set the approximately 0 home position of the extruder, and then go directly to the alignment, when set to 0, the nozzle should be slightly pressed against the table.

Turn off the stepper motors and use a piece of paper to level the table. The procedure is very simple - we move the extruder from one corner to another and see that in all corners the piece of paper between the nozzle and the table moves with little effort. Once the table is relatively level, finer calibration can be started during 3d printing. For the first run, it is best to choose a model with a large area of the first layer, during the printing of which we will have time to set everything up. The setting principle is as follows. The extruded thread should lay down slightly flattened and the width of the line in all corners of the table should be the same. If so, then your table is calibrated correctly.

We finish with the calibration and proceed directly to testing. We will print from PLA, ABS and PETG. Of course, you can’t count on ABS, since the maximum recommended heating temperature for such magnetic tables for 3d printing is 80 degrees. Above this temperature, the table begins to lose its magnetic properties and the mat no longer adheres so well to the substrate.

We will print from PLA, ABS and PETG. Of course, you can’t count on ABS, since the maximum recommended heating temperature for such magnetic tables for 3d printing is 80 degrees. Above this temperature, the table begins to lose its magnetic properties and the mat no longer adheres so well to the substrate.

First test. PLA on a cold table.

As you can see, the cube moved away from the table quite easily. I will even say more - he moved away from the table too easily. It was like he didn't hold up at all. Upon closer inspection, it can be seen that some corners are slightly bent. Not critical, but true.

Now let's set the table temperature to 70 degrees and see what happens. With these 3d print settings, the part is already much more difficult to remove from the table. And the corners are no longer bent.

Let's take a larger part to confirm the possibility of 3d printing PLA on a magnetic table.

No problems found again. The bottom of the part turned out to be flat, with minor deformations. The corners are not bent.

The bottom of the part turned out to be flat, with minor deformations. The corners are not bent.

Conclusion - printing PLA plastic on this magnetic table is definitely worth it.

Moving on to the next article.

ABS printing on a magnetic flexible table

ABS plastic I won't even try to print on a cold table. Let's set a maximum of 80 degrees and start the 3d printing process. The cube was printed without coming off during printing. This is good, but I am sure that if you take the part a little bit larger, the table will no longer cope with it.

Let's take something bigger for the experiment. For example, our test block. As expected, during printing, the bar began to bend towards the center. Moreover, it was not the bar that began to come off, but the magnetic mat, which began to rise at the corners of the bar.

After finishing printing, I was very surprised when I realized that it was not the mat that was raised during 3d printing, but it seemed that the magnetic backing had peeled off the table.

Conclusion - I strongly do not recommend printing with ABS plastic on this magnetic table. I think that with similar materials with a high degree of shrinkage.

Let's move on to the last item on our list.

Printing with PETG plastic on a magnetic flexible table

Let's try printing with PETG plastic and see what happens. We run our test cube for 3d printing at a table temperature of 70 degrees and get a decent result.

The cube stuck well enough to the table, the corners are not bent. Basically, as expected, PETG would work great for this magnetic mat as it is a low shrinkage material.

Now let's move on to the main question that most likely arose in your head - what about the reliability and durability of such a table? You can answer as follows: it depends on how carefully you use it. I can only add that on the website of one European manufacturer of such sets of magnetic carpets and pads, the user is immediately offered to order a set of one pad and 5 rugs, and this is a reason to think.

3, 0.4, 0.5 mm orifice

3, 0.4, 0.5 mm orifice 3, 0.4, 0.5 mm orifice

3, 0.4, 0.5 mm orifice