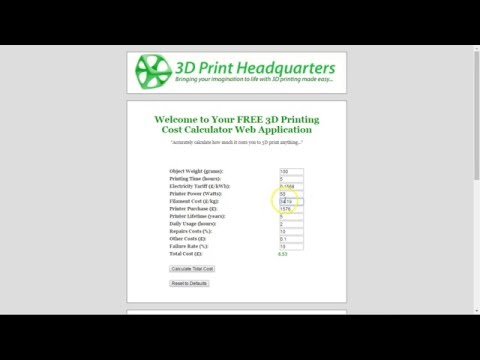

3D printing material cost calculator

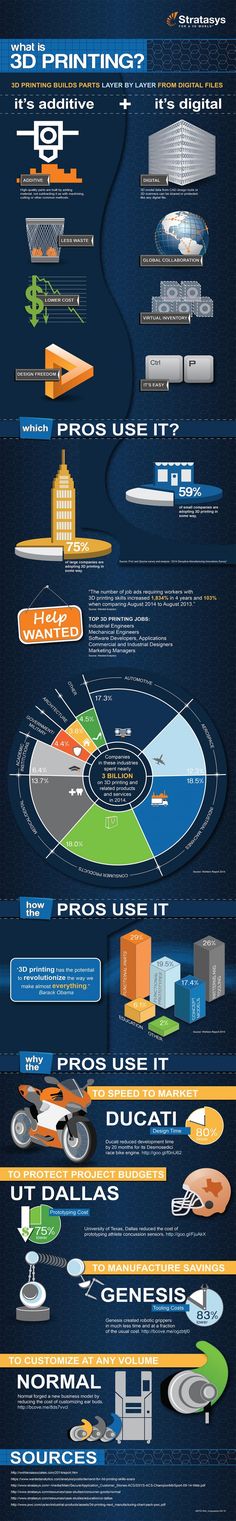

The Best 3D Printing Pricing Calculator — MakerOS

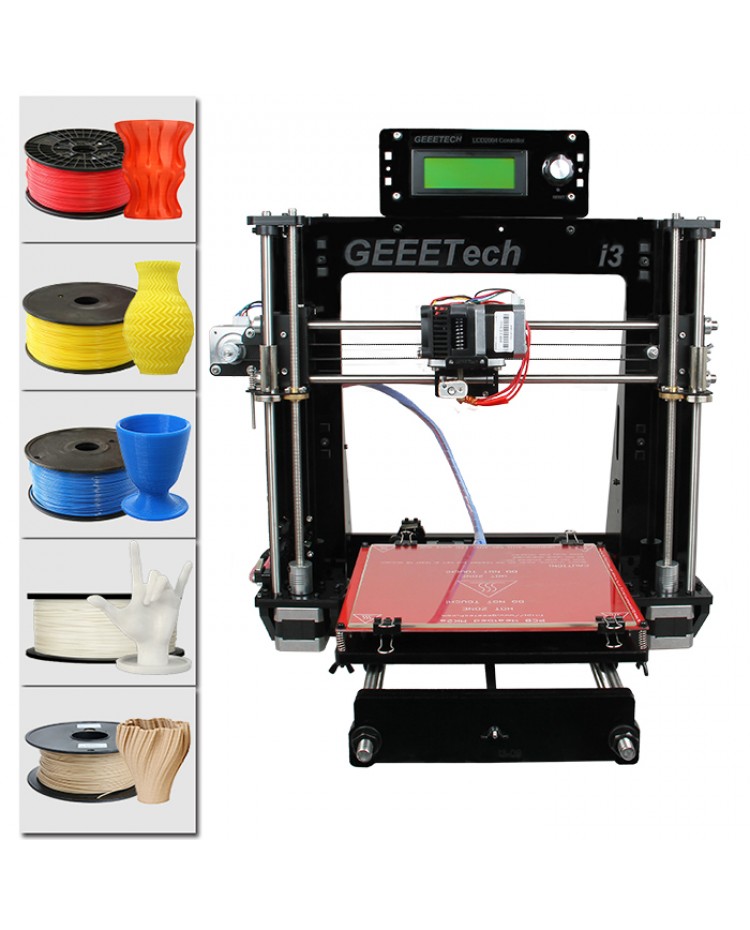

If you are an FDM 3D Printing Shop

Material

Material Density - this is important to know, and if you don’t know you can easily find it with a Google search. Every filament manufacturer will have that information.

Machine

Machine Lifetime Hours - this is how long is the machine going to last while operating. Some manufacturers may actually have this listed for their machines. Another way to look at this is how long will it take until you to replace this machine, whether it becomes obsolete or you replace it with something new (assume no scrap value).

Maintenance & Service Cost per year - the cost for the service plan. Also, all of the consumables that go into the machine over the year, such as blue painter’s tape for printing surfaces, really anything that goes into the cost of the machine you want to compensate for with this number.

Fabricated Material

How long to fabricate 1 cubic centimeter of material? In minutes - it’s important to understand the rate at which your machine can print. It is not necessary to calculate the warm up time, the time it takes to heat up the nozzle or bed. There are two ways to do this. Take a 1 cubic centimeter cube, go into your slicer, and it will give you a time estimate for how long it will print. But a more accurate and correct way to do this is to actually time it with a stopwatch to see how it will take to print a 1 cubic centimeter cube from the first extrusion to the print stopping. If you need a cube, download it here. This is an average number and is meant to be a baseline. Different machine movements move differently and your mileage may vary.

How much can be deposited in 1 hr? In grams - this is our material deposition rate per hour.

Facility

Monthly Rent - the rent for wherever you’re working out of. If you’re working from home, include either your mortgage or your monthly rent, whether it’s your apartment or your home.

If you’re working from home, include either your mortgage or your monthly rent, whether it’s your apartment or your home.

Monthly Utilities - include any cost to support your print job. Everything that goes into the operation of the facility itself.

Humans

Time on setup & teardown for the job in minutes - when you want to do a print job for a client, how long does it take for you to validate the files, slice them, get them to the machines, tear them down and remove supports? Give yourself more time than you think you need. You need to give yourself a realistic average and padding of time in this calculation. If you underestimate this input, you’ll be losing a lot of money and time.

Software/Service

What are you spending on different software to run your business? Solidworks license, your general inventory management system, ERP, etc.

All Other Services - is all of your auxiliary software services that you’re using, such as the cost to host your website, other web services like email, and the cost of MakerOS.

Calculated Costs ($/hr)

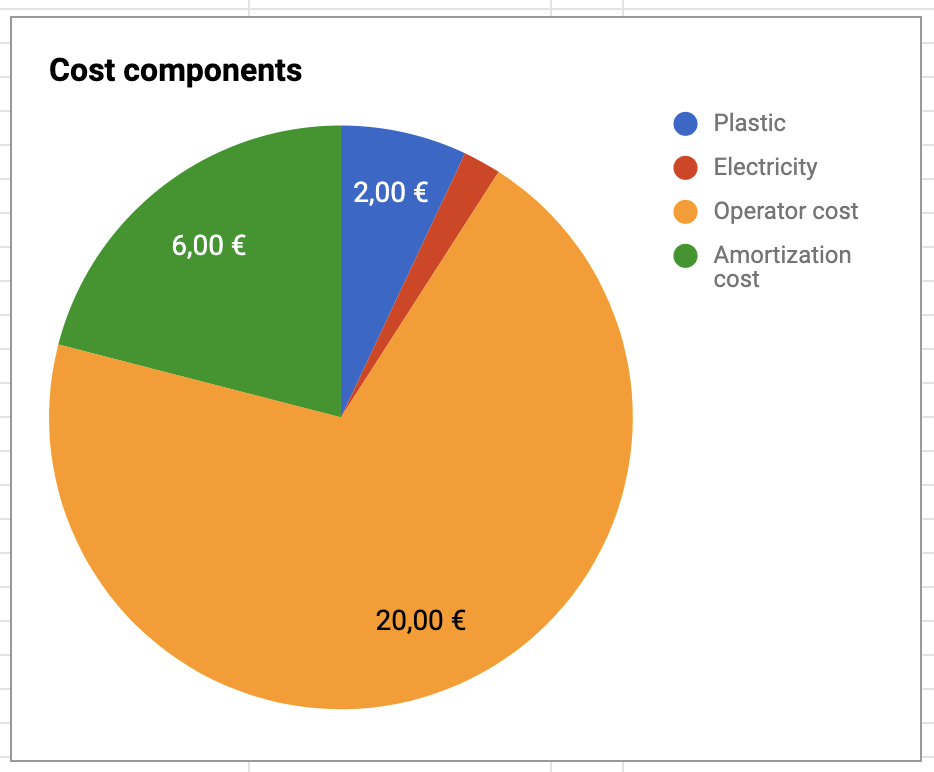

Here you will notice that the printing of the material and the machine depreciation are by far the lowest cost onto the business. The true costs are your rent, your software, and human time.

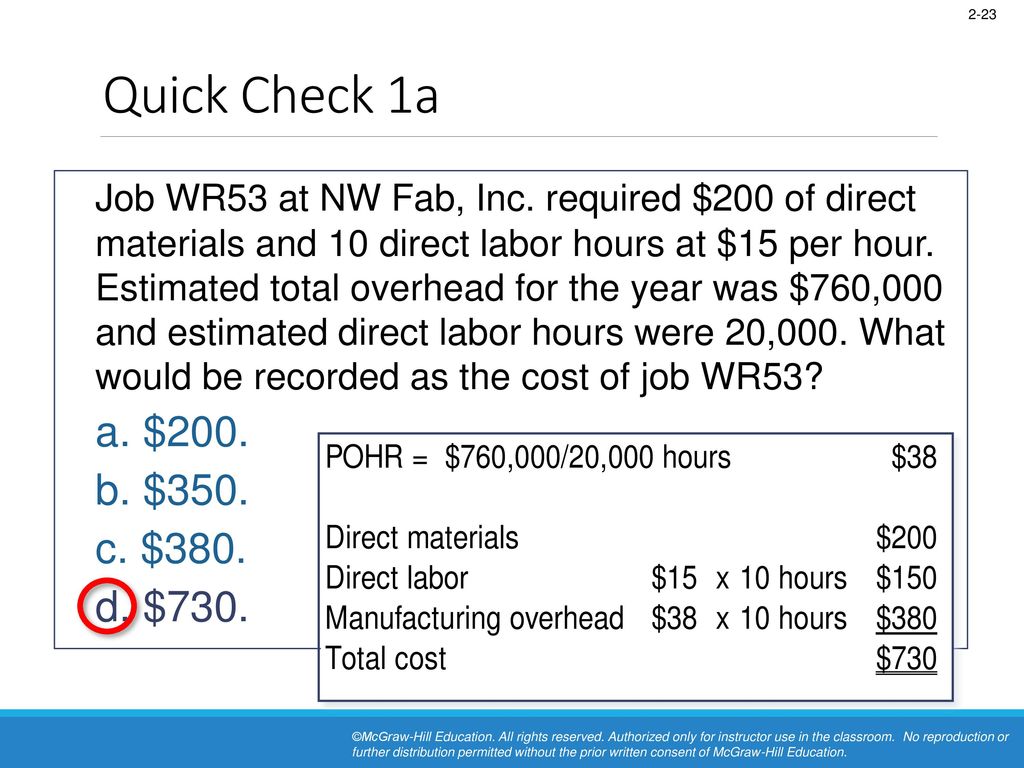

What does it cost to fabricate the purchased material?

How long to fabricate all grams (hrs) - this is the time in hours it will take to use all of the material in the spool.

Cost to fabricate all material - when you take the totally hour cost and multiply that by how long it takes to fabricate all grams.

How many jobs projected per unit? - this is an average. We need to understand on average how many jobs are there within a 1kg spool (the unit). To do that, look at the last 10 print jobs you’ve done for clients and average how much material was used. A print job can be more than one print, there can be multiple parts that go on the printing bed.

The Total Cost to fabricate all material - this line adds up the lines “Cost to fabricate all material” and “Added cost of human time” and you must get more than this dollar amount out of that spool in order to be profitable. 3) - the printed density of the printed part (loose powder vs sintered powder).

3) - the printed density of the printed part (loose powder vs sintered powder).

Machine

Machine Cost - this will be significantly more than an FDM machine

Fabricated Material

Machine Startup and Cooldown (mins) - you’ll have to look up or test your machine to find the inputs for this sections. As an example for now, we’ll use an EOS FORMIGA P110 as our benchmark example machine. With the EOS machine it should take roughly two hours to heat up and cool down.

Startup and Cooldown Cost - we get this number from taking the machine startup and cooldown time, and multiplying it by the Total Machine Time Cost per hour.

Layer Print Time (seconds) - it should take 15 seconds per layer.

Layer Height - with our EOS machine, it should be 0.1 mm.

Time to print 10x10x10mm cube(mins) - what we really want to know is how long will it take in pure print time to print 10 mm in the Z direction.

Material and print time cost for cube calculating - the price of the material which is $0.06 per gram and the time of 25 minutes to print the cube, which gives us $10.57 in this case.

Support Equipment Cost - this includes the cost of the special vacuum you need for the machine, and this vacuum can be up to $4K to $6K, along with a cleaning station or breakout station, which is another several thousand dollars. So for our EOS FORMIGA P110 support equipment should be about $15,000.

Max packing density % - the more dense your print is, the more likely you are to run into defects, so use 10% as the max packing density.

Grams printed per hour - this is the most important number to know in this whole Fabricated Material section.

>>> What if I have multiple machines? <<<

If you have two SLS machines (the exact same model) and both machines require the same supporting equipment, then just divide the Support Equipment Cost by two. Ultimately we’re trying to get the cost to print with just one machine.

Ultimately we’re trying to get the cost to print with just one machine.

Facility

Monthly Rent - the rent for wherever you’re working out of. If you’re working from home, include either your mortgage or your monthly rent, whether it’s your apartment or your home.

Monthly Utilities - include any cost to support your print job. Everything that goes into the operation of the facility itself.

Humans

Time on setup & teardown for the job in minutes - how long does it take your team to prep the build? When you want to do a print job for a client, how long does it take for you to validate the files, slice them, get them to the machines, tear them down and remove supports? Give yourself more time than you think you need. You need to give yourself a realistic average and padding of time in this calculation. If you underestimate this input, you’ll be losing a lot of money and time. This should take longer for an SLS machine than an FDM machine. An SLS machine requires a bit more finesse.

An SLS machine requires a bit more finesse.

Software/Service

What are you spending on different software to run your business? Solidworks license, your general inventory management system, ERP, etc.

All Other Services - is all of your auxiliary software services that you’re using, such as the cost to host your website, other web services like email, and the cost of MakerOS.

>>> What if I have multiple software for each line? <<<

Similarly to having multiple machines, then divide costs by however many software or services you’re using. With Software/Services, it’s not entirely necessary to do this, but it certainly is a good exercise to do to understand the economies of scale for a business.

Calculated Costs

Total Hourly Cost - this is significantly more for SLS than it is for FDM - approximately 4X more. However, it is significantly faster to print with an SLS printer.

What does it cost to fabricate the purchased material?

How long to fabricate all grams (hrs) - this is where we see that it is much faster to print with an SLS machine than it is with an FDM machine.

How many jobs projected per unit - this is an average

Added cost of machine procedures - this is how many jobs project per unit multiplied by the cost to startup and cool down your machine.

What should you charge?

Markup up your margins - compared to an FDM machine, having an SLS machine can be extremely profitable, even though an SLS machine is very expensive. So increase your margins even more because of economies of scale and also mainly because of jobs you can fit in the machine. So increase it to 100%, 125%, even 175%. If you charge 50%, you’re basically undercutting the margin.

Job Minimum Price for 1hr Print

Total minimum you should charge - this takes the Total Hourly Cost, The Added Human Time, and your Markup retail price per hour.

MakerOS is an all-in-one collaboration platform for 3D printing service bureaus to improve workflows with their clients and get projects done. Our software is a solution for 3D printing businesses to win more clients, reduce churn, increase machine utilization, and scale at a comfortable pace. We were founded by a team that previously ran several 3D printing businesses. Our expertise is how we put together this pricing calculator.

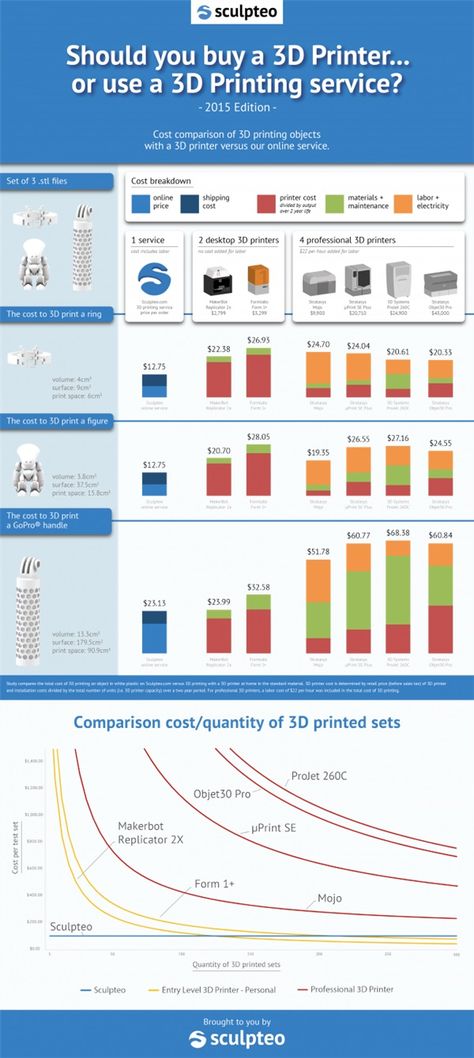

Online 3D Print Cost Calculator

Here is a 3D print cost calculator. Good for 3D print e-shop owners or casual 3D printer users. It may happen that colleagues, friends, or relatives may ask you to 3D print something for them. And they may insist to reward you by paying cash to cover the cost of the material, but there is more to it. This online calculator will help you to estimate the costs involved in creating a 3D printed object taking into consideration various factors.

Disclaimer: If you decide to start selling models, please make sure that they are licensed appropriately. It should be Creative Commons – Attribution. If not sure, please contact the designer.

It should be Creative Commons – Attribution. If not sure, please contact the designer.

To get the final cost of a printed part all fields should be filled in.

Filament/Resin Cost

3D printed object weight (g)

Cost of the material ($)

(Price of a spool/bottle)

Material on a spool/in a bottle (g)

(500/750/1000g)

Material Cost Result:

(Please complete the whole table)

3D Printer Cost

Price of the machine ($)

3D printer life expectancy (h)

(Ranges from 300-3000h, average 1500h)*

Total hours spent on a print (h)

3D Printer Cost Result:

(Please complete the whole table)

Labour Cost

Hourly Rate ($)

Hours spent to set up a 3D printer (h)

(0.1-0.2 hours or 0 if none)**

Hours spent on post-processing (h)

(0 if none)

Hours spent on slicer settings customization (h)

(0.25-1 hour or 0 if none)***

Labour Cost Result:

(Please complete the whole table)

Additional Charges ($)

(Model, electricity, etc. or 0 if none)****

or 0 if none)****

Total ($):

Example Calculations of the Popular 3D Models

We placed some of the popular models’ 3D printing details into our calculator and this is what came out (Considering that the cost of the filament spool is $20, 3D printer is $300 and the labor hourly rate is $20p/h):

– 3DBenchy – $0.51 (only material and printer costs) – $3.51 (with 10 min 3D printer set up cost, and a $1 tip for the designer)

– Flexi Rex – $0.68 (only material and printer costs) – $5.68 (with 10 min 3D printer set up, 10 min slicer settings configuration, and a $1 tip for the designer)

– Dog The Gardener – $4.32 (only material and printer costs) – $ 9.32 (with 10 min 3D printer set up, 10 min supports manual placement, and a $1 tip for the designer)

* Price of the Machine – For How Long Will a 3D Printer Last?

Price of the machine ($) – We would recommend adding up all maintenance costs to the price of the machine. Let’s say a 3D printer costs $300 and a new PTFE tube is $5 plus labor $20p/h, then the new price of the machine is 325$. And so on.

And so on.

The same steps should be considered for the resin 3D printers with LCD technology. In order to calculate resin printing cost properly, it is important to take into account the live expectancy of LCD screen. Such screens last for 2-3 years on average, and will need replacing, which may result in the expenditure of $200-500, depending on the brand. However, some manufacturers started offering free warrantee for between 500 and 2,000-hour life span.

This ranges between 300-3000h, with an average of 1500h – Any 3D printer costs money, and over time it ends its life cycle, after that it either gets thrown away or is disassembled for scrap. This metric is quite difficult to estimate precisely as it depends on many factors like the brand and model of the 3D printer, techy level of the owner (maintenance), quality of 3D printing materials, etc. So this “average 1500h” number is our approximate assessment that we came to after researching various sources of information together with our own experience with desktop 3D printers.

– Minor repairs. Most of 3D printers are very easy to fix (nozzles, belts, PTFE tubes, etc.). If the owner manages to fix small issues and even implements a few upgrades, then the 3D printer may last much longer. (Read the real experience of upgrading 3 years old Original Prusa i3 MK2.5S) We would recommend adding up all maintenance costs to the price of the machine.

– If you have had a 3D printer for a specific duration, you could place the number of total working hours instead.

** Time spent to set up a 3D printer?

0.1-0.2 hours or 0 if none – The first thoughts that come to our minds are the following: is it an automatic or manual bed levelling system? Is the material has bed adhesion issues? In short: how long it will take to start 3D printing successfully (the first layer check).

Also, was a nozzle change involved (f/e for a 0.2mm thinner or 0.8mm thicker nozzle)? Nozzle changing and recalibration may take another 15-30 min. Unless u have a specific 3D printer ready.![]()

*** Time spent for slicer settings customization?

0.25-1 hour or 0 if none – Some 3D printing jobs, especially those that require supports, may require tunning in a slicer software. Customized support placement may be a lengthy process. Slicer settings optimization is an important skill. The same model may take much fewer hours to print and use less material if tuned well or used known techniques as a vase mode 3D printing or hollowing (no infill).

**** Extra – Electricity, Tips for Designers, etc.

Model, electricity, etc. or 0 if none – Any extra charge that may occur.

– Is a 3D model acquired for free? In some cases, it is possible to leave a tip for a designer.

– Electricity – an important metric for 3D printer farms but not for the casual printing jobs.

– Design printability. Does the design need adjustment to make it 3D printable? For example, a lion’s tail or the hands’ fingers may need to be made thicker for FDM 3D printers. If yes, then the hourly rate for such customized design jobs may vary greatly.

If yes, then the hourly rate for such customized design jobs may vary greatly.

We hope this 3D print calculator will help you to get an idea of the costs involved. Please do not hesitate to leave a comment below if your think some metrics should be included.

Online calculator for calculating the cost of 3D (3D) printing

You are here

Home » Our services

How to calculate the cost of 3D printing

- load the model in STL format into the calculator;

- get a cost estimate and recommendations;

- change the print settings or leave the default;

- if you are ready to order 3D printing on a 3d printer, click the "Order printing" button, fill in the contact details and send an application.

test model used for illustration purposes. To calculate your model, download it. The calculation takes place automatically.

Load STL file?Click the "Load" button and select the 3d model file. This is an STL file, such as 3dmodel.stl. The calculator will automatically calculate the cost immediately. You can go directly to the calculation below or change the 3D printing settings

Characteristics of the model, recommendations and cost of 3D printing

Volume, cm 3 : - Area cm 2 : - Dimensions, mm: - Plastic consumption, cm3: - Plastic consumption, gr: -

Recommendations: -

Preliminary cost of printing: -

Set your own 3D printing settings? Press if no special print settings are required, rather than the default settings*optimum settings for price/performance ratio). The default settings are marked with *.

Select material:? This is the material that will be used for 3D printing.

Simply put, ABS is suitable for gears, housings and similar technical details, PLA is suitable for figurines and souvenirs, for the rest, see the material comparison table in the FAQ section.

Simply put, ABS is suitable for gears, housings and similar technical details, PLA is suitable for figurines and souvenirs, for the rest, see the material comparison table in the FAQ section. ABS*ABS is strong and durable, suitable for printing housings, gears and stressed parts. We print by default.

PLAPLA has low print shrinkage, prints small fragments well, can print overhanging elements. Also, since PLA is made from corn, it can be used in food production

PET-GPET-G is stronger than ABS, less shrinkage, chemically resistant. This plastic has excellent interlaminar adhesion. Food grade plastic

CarbonCarbon is a nylon with carbon added. Very durable and wear-resistant, has low shrinkage and deformation during printing. In addition, after printing, the parts have a rough surface, on which the layering is not visible.

FlexFlex is an excellent rubber-like material. Unlike its TPU (polyurethane) counterpart, it is chemically resistant to engine oil and gasoline, and can be used as gaskets and flexible hoses in the automotive industry

PhotopolymerPhotopolymer resin is indispensable for printing small and precise details. Advantages: layer thickness up to 1 micron, no layers visible, possibility of printing transparent models, coloring before printing with coloring pigments

Advantages: layer thickness up to 1 micron, no layers visible, possibility of printing transparent models, coloring before printing with coloring pigments

ABS-Like loaded and durable parts. Together with ultra-high precision printing, it is indispensable for printing small gears and machine parts

Select filling density:? This parameter characterizes how much the part will be filled with plastic. Often it is not necessary to completely fill the part, partial filling can be used to save plastic

10%

20%*

33%

50%

100%

Select layer thickness (height):? This parameter characterizes the quality. The thinner the layer thickness, the better the printing will be, but the longer the printing time and its cost

0.05mm

0.1mm

0.15mm

0.2mm

0.25mm*

Print order

test model

Hold the left mouse button to rotate the model

Use the middle mouse button or Shift and the left mouse button to zoom

Use Alt and left mouse button to move the model

Order printing

The print operator will receive a request with a 3D model and selected print characteristics and will contact you.

Download model STL

Read more

- Maximum file size: 120 MB .

- Allowed file types: stl .

Telephone

Order comment

Data

Add filesAdd new file

More details

- Maximum file size: 100 MB .

- Allowed file types: stl obj .

FDM thermoplastic 3D printing:

-

Eco-friendly PLA strength detail smoothness flexibility environmental

2923 rub/cm 3 bottles and children's toys.

Due to the peculiarities of the material (detailing, printing "on weight") figurines, souvenirs and various decorative elements are well obtained from it. Well processed and smoothed. Order printing

-

Popular ABS strength detail smoothness flexibility environmental

2919 rub/cm 3 Print order

Excellent price-quality ratio, made from oil.

Well suited for printing cases, instruments, automotive components, gears and mechanisms, elastic and strong. Excellent mechanical and chemical processing. Order print

-

Durable PET-G strength detail Smoothness Environmental friendliness

3923 rub/cm 3 Order PECH

In PET-G.

Excellent interlayer adhesion, due to which parts from this plastic will be stronger than ABS. In addition, PET-G is chemical resistant and can be used in food production (common plastic bottles are made from PET). Order printing

Excellent interlayer adhesion, due to which parts from this plastic will be stronger than ABS. In addition, PET-G is chemical resistant and can be used in food production (common plastic bottles are made from PET). Order printing 69 RUR/cm 3 Print order

Carbon is a nylon with added carbon. Thanks to this combination, carbon has the super strength of nylon, but is spared its disadvantage - strong shrinkage. Carbon also has an amazing property: the surface of the part after printing is rough without visible layering, like other plastics. Therefore, it can be used not only for printing heavy-duty and loaded products, but also for decorative elements. Order print

You must have JavaScript enabled to use this form.

Order

Phone

Service type - Not specified -3D printing3D scanning3D modelingother

Choice of plastic - Not Specified -ABS/PLAPET-GCarbonFlexFotopolimerABS-Like

Upload drawing or 3d model File formats: obj, stl, max, doc, pdf, jpg, png, step, 3ds, zip, rar. The maximum file size is 120 MB. In the description, describe the terms of reference and the details of the task.

The maximum file size is 120 MB. In the description, describe the terms of reference and the details of the task.

Add new file

Read more

- Maximum file size: 120 MB .

- Allowed file types: obj stl max doc pdf jpg png step 3ds zip rar .

Notes

Many potential customers of our company who are considering our professional services think that 3D printing cost of is very high today. They say that new expensive equipment, not the cheapest materials and unique technology, which is not available on every corner, lead to an automatic increase in the cost of the service provided, which has only recently begun to be popular in our country. But such reasoning goes against the fundamental concept and philosophy of our company. From the first day of opening, we set ourselves the goal of bringing 3D printing technologies to the masses, making them the maximum available for everyone. And, in our opinion, on this path we have managed to achieve great success. 3D printing cost calculator , posted on the official website of our company, will help you make sure of this.

And, in our opinion, on this path we have managed to achieve great success. 3D printing cost calculator , posted on the official website of our company, will help you make sure of this.

The development of appropriate software has been one of the top priorities of our skilled programmers. We wanted to demonstrate to potential customers that 3D printing can be quite affordable in its final price. And the best way to do this is by providing the opportunity to conduct your own calculations according to individual parameters, available to each visitor to our site. To take advantage of 3D printing cost calculator , you do not have to contact our managers, go through the registration procedure on the site or send your contact information anywhere. Just go to the site, go to a special page and take step-by-step actions, the end result of which will be to get the result you need in the form of the price of the ordered service.

How exactly is the calculation of the cost of 3D printing in the calculator on our website? This procedure boils down to making three basic steps .

- Download model

You will need a file of a three-dimensional model of the object, which you want to print by ordering the appropriate service from our company. The file must be in STL format, which is optimal both for the printing procedure itself and for carrying out the necessary calculations.

- 3D printing settings

These are advanced steps for specifying individual print process parameters. In particular, here you can determine the material of the printed object, the filling density of the object and the thickness of the printed layer. Each of these parameters, set in the corresponding windows of the online 3D printing cost calculator, will largely determine the quality of the final result. This is especially important for the thickness (height) parameter of the walls of the printed part, which will be the better, the thicker and stronger its underlying layer will be.

Please note that the defined parameters are already set by default, and you will have to change them as you wish in manual mode. As for the settings shown, they are suitable for the vast majority of our customers and their orders. We are talking about the use of reliable ABS plastic, a 20% filling density of the printed object, as well as a layer thickness of 0.25 millimeters. If these parameters suit you, you can safely skip the second paragraph and proceed to the third step of using the 3D printing cost calculator.

As for the settings shown, they are suitable for the vast majority of our customers and their orders. We are talking about the use of reliable ABS plastic, a 20% filling density of the printed object, as well as a layer thickness of 0.25 millimeters. If these parameters suit you, you can safely skip the second paragraph and proceed to the third step of using the 3D printing cost calculator.

- Get result

When you upload the correct 3D model file, our calculator will quickly make the necessary calculations and then display the price on your screen. At the same time, the main characteristics of the printed object will be calculated and visually indicated, and recommendations will be provided regarding the possible need to change the order parameters in order to achieve a better result. Online calculation of the cost of 3D printing in the calculator starts immediately after you upload a three-dimensional model. But when changing the parameters from the second step, the calculation is repeated, giving the corrected result.

Is the amount received through the steps described final and irrevocable? No. The print cost calculator is designed to indicate for you the approximate price of the ordered service, which can change in one direction or another when placing an order directly together with the manager of our company. But you will already know what cost to expect in order to get the result you need. We guarantee that the final price prescribed in the contract, if it differs from the one calculated in the calculator, then only by a minimum value.

The fourth step of is filling in the contact information in the appropriate fields on our website, as well as sending an application for your 3D model and individually defined characteristics of the printing process to our company's operators. Of course, you will proceed to this step only if the cost of 3D printing given by the online calculator suits you.

3D Printing Cost Calculator

Although I posted the link in the discussion of the parallel topic of comrade 3D_MPL (Cost of 3D printing. Calculator for calculating from 3D-MPL), I thought it would be better to make a separate post to get feedback.

Calculator for calculating from 3D-MPL), I thought it would be better to make a separate post to get feedback.

So please make constructive (!) suggestions. I will answer any questions on the topic.

.

So.

Again and again the question arises of how to calculate the payment of your labor as correctly as possible. Although some of the details seem simple, they often require a lot of brain effort, which MUST be paid. Well, the time spent too.

.

Some people think that it is enough to take into account the weight of the part - I think this method is simply fundamentally wrong, because, for example, printing a vase / box with a 1mm nozzle and a 0.6mm layer will be faster than printing some highly detailed bracket in a car or a souvenir with a 0.2mm nozzle and a 0.05mm layer. So, with the same weight, the time can be many times (tens of times) longer! Yes, and draw a different bracket, you must be able to!

Moreover, we want our many hours of work to be adequately paid.

A typical example from my practice is a teapot handle.

The detail is shapeless, you don't know how to approach it in order to draw it. The result - 7 hours of modeling, 4 hours of printing, an hour of post-processing, 57 (total!) Grams of plastic. And now, imagine, a customer comes to you, 'Why is it so expensive??? It's only 57 grams!!!'. And you lost a whole day (work shift).

.

So, I think that the main resource that should be paid for is time!

.

And here is the table itself.

Link to Yandex Disk: https://yadi.sk/i/oy1r3v_dA-8E1w

.

By the way, I update the table from time to time! I recently discovered an inaccuracy in the calculation of the cost of the material, corrected it. So follow the link and check it out.

.

Some characteristics:

Time is written conveniently - in hours and minutes.

Modeling and post-processing cost per hour.

The weight and cost of the coil are written separately - no need to calculate the cost of a kilogram (for lazy people).

The so-called 'difficulty factor' is missing from the table. The complexity itself will be formed from: modeling time (mostly), printing time (necessary detailing), post-processing time (picking out supports from hard-to-reach places, painting, etc.).

Substitute the values that are convenient for you. I don't insist on these. Columns 'Prices' and 'Costs'.

The white numbers in the 'Total' column are reference numbers, just for convenience.

Depreciation is calculated from the time of direct operation of the printer (more work - more wear). I take half a dollar.

The price of the first part differs from the subsequent ones only by taking into account the simulation time.

The maximum power of the printer is taken - all the same, pennies come out.

Currency - rubles. You can change to yours.

When writing the price for a reel, you must also consider the shipping cost! (In our outback, the delivery of one coil is 500 rubles!) I can add the 'delivery' item for convenience, if you want.