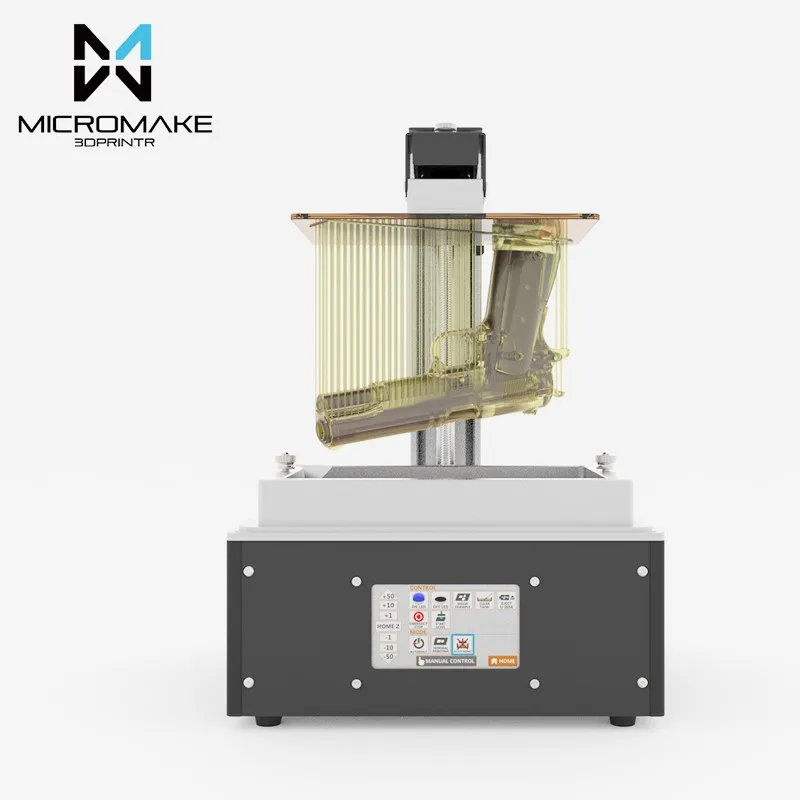

Sla 3d printer large build volume

Large Resin 3D Printers: Buyer's Guide 2022 (Affordable & Commercial)

For some, size matters – and a normal-sized resin 3D printer just won’t cut it. For you size kings and queens, bigger is better, and you shouldn’t have to compromise on your quest for the biggest resin 3D printer around.

And with resin printing becoming more affordable than ever before, buying a large resin 3D printer vs outsourcing larger resin prints to a service has never been more cost-effective.

Why Buy a Large Resin 3D Printer?

First, by keeping prototyping in-house you retain full control, you can prototype as fast as your printer will print, and you still don’t have to compromise on size.

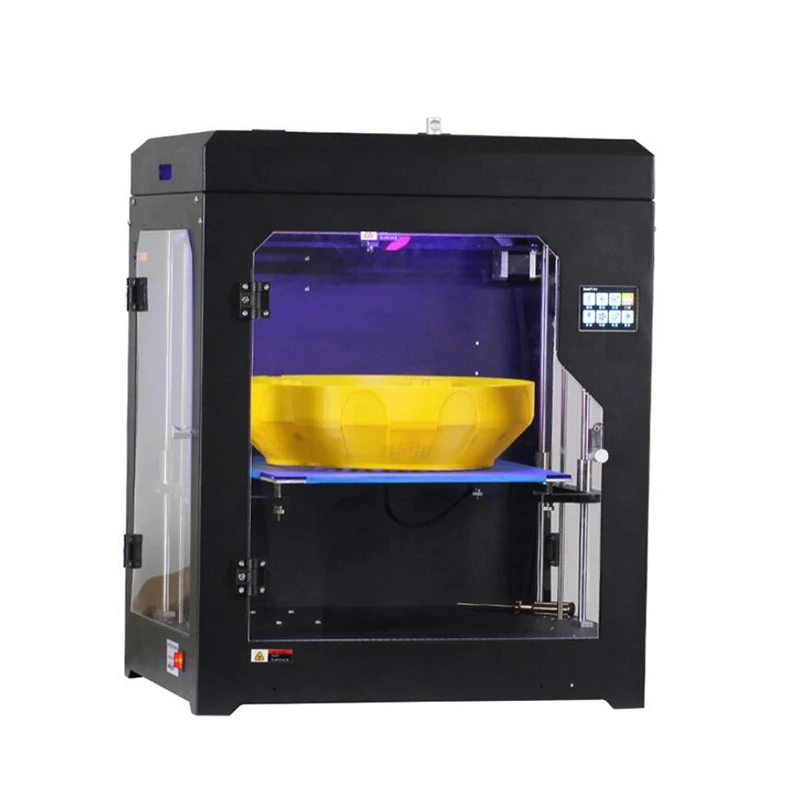

Resin printers typically have smaller build volumes than their FDM counterparts, focusing instead on outrageous quality and incredibly smooth surface finishes. However, this creates problems when you want to prototype larger parts, such as helmets or tools and equipment. With a large resin 3D printer, you’re free to print human-sized resin parts that can be tested right away.

And even if you’re a hobbyist looking to print large cosplay pieces or other parts, some large format resin 3D printers have become so affordable that you can even get in on the action at home.

We have therefore picked our recommendations for the best build volume format resin 3D printers, in both more affordable and commercial and industrial price ranges and specs, so you can pick the ideal printer for you.

The Best Large Resin 3D Printer Reviews

3DSourced is reader-supported. When you buy through links on our site, we may earn an affiliate commission. Learn more

Affordable Large Resin Printers

1. Elegoo Saturn

- Price: Check price at Elegoo store here / Available at Amazon here

- Large resin 3D printer build volume: 192 x 120 x 200 mm

The Elegoo Saturn packs a powerful punch with its 8.9-inch 4K monochrome LCD, offering fast (2-3 seconds per layer) printing — a 60% improvement on Elegoo’s cheaper Mars Pro, and with upgraded stellar quality.

The build volume is far larger than most entry-level large resin 3D printers at 192 x 120 x 200 mm, and while this isn’t large enough for printing tools prototypes like spades, for example, you can still print most normal-sized resin parts here. And for smaller resin prints like casts for jewelry, small prototypes, or fun home projects, you can fit many within each print run.

The upgraded Z-axis moves more precisely and accurately – and you’ll see the differences as it churns out delightful resin prints. The printer contains 54 LEDs to accurately print and solidify resin more uniformly than ever before. It’s also built to need less frequent leveling – saving you hassle – and the Elegoo Saturn is known for great adhesion when printing.

2. Anycubic Photon M3 Max

- Price: Check latest price at Anycubic here / Amazon here

- Build Volume: 298 x 164 x 300 mm

- XY Resolution: 46 microns

- Minimum Layer Height: 0.

01 mm

01 mm - Speed: 60 mm/h

The latest in Anycubic’s long line of budget-friendly resin 3D printers, the Photon M3 Max is the manufacturer’s first venture into super-sized build volume territory. And, with a generous 298 x, 164 x 300 mm build volume – plenty for all those bigger resin projects you’ve put off due to size constraints – it does so with a splash.

A 13.6″ 7K LCD delivers a dizzying 6480 x 3600 pixels, which, when put to the test, offer a 46 micron XY resolution, a feat worth recognizing given the build volume. That sufficient detail to bring out armor and weapon details on tiny figures and minis, or craft intricate and patterned. jewelry

Elsewhere, Anycubic has weaved some welcome ease-of-use features. An automatic smart resin filling system sees a resin bottle mounted on the machine. It automatically tops up the vat as required, almost guaranteeing uninterrupted printing for even the largest prints. Elsewhere there’s a replaceable screen protector and solid adhesion courtesy of a checkerboard build plate.

Elsewhere there’s a replaceable screen protector and solid adhesion courtesy of a checkerboard build plate.

So, why opt for the Anycubic Photon M3 Max over the Phrozen Sonic Mega 8K? For one thing, price. The Mega 8K costs more than twice as much, which is illustrative of Anycubic’s knack for shipping out quality machines with sensible corner cutting (mainly plastic-heavy construction) at reasonable prices.

Where the extra money goes is clear: the Mega 8K is faster, offers better print detail, and provides a large build volume. But, for makers needing an XL printer at a reasonable price and one capable of delivering feature-rich and detailed prints, the Anycubic Photon M3 Max is a great compromise and the top budget large SLA printer pick.

That said, if you have the extra funds, then the Phrozen Sonic Mega 8K is a substantially better machine. It has a much more versatile set of features that are better suited to serious prototyping, batch printing Dungeons & Dragons, or other tabletop miniatures to fuel a small business or workshop, and other big resin 3D printer projects.

3. Phrozen Sonic Mega 8K

- Price: $2199 — Available at Phrozen here

- Build Volume: 330 x 185 x 400 mm

- XY Resolution: 43 microns

- Minimum Layer Height: 0.01 mm

- Speed: 70 mm/h

The Phrozen Sonic Mega 8K is not just one of the largest resin printers on the market, but also widely regarded as one of the best thanks to a careful balance of relative affordability, features, and the pristine detail offered by its 8K resolution LCD.

The star of the show is, of course, the 330 x 185 x 400 mm build volume, the most generously sized you’ll find among consumer-grade printers this side of Pluto. While we could stop there, the Phrozen Sonic Mega 8K has plenty more strings to its resiny bow.

The 15″ 8K LCD is a thing of beauty and manages to deliver superb print quality while avoiding the unusual downgrade in detail and feature richness usually associated with supersizing the build volume. 8K means pixels for days – 7680 x 4320, if we’re being exact.

8K means pixels for days – 7680 x 4320, if we’re being exact.

All these desirable features allow the Phrozen Sonic Mega 8K to reach an XY resolution of 43 microns, which is astounding for such a chunky machine. Few other large resin 3D printers come close to delivering this level of detail in large-scale models and parts.

As Phrozen puts it:

‘You can now have both size and quality in one print, at the same time.’

Elsewhere, there are a few other notable mentions. The Phrozen Sonic Mega 8K ships pre-leveled, so no messing around with the tough task of calibrating a huge build plate before you can start printing.

Curing away at 70 mm/h, the Phrozen Sonic Mega 8K makes quick work of prints, too, which should help with large prints that already take a long time to complete.

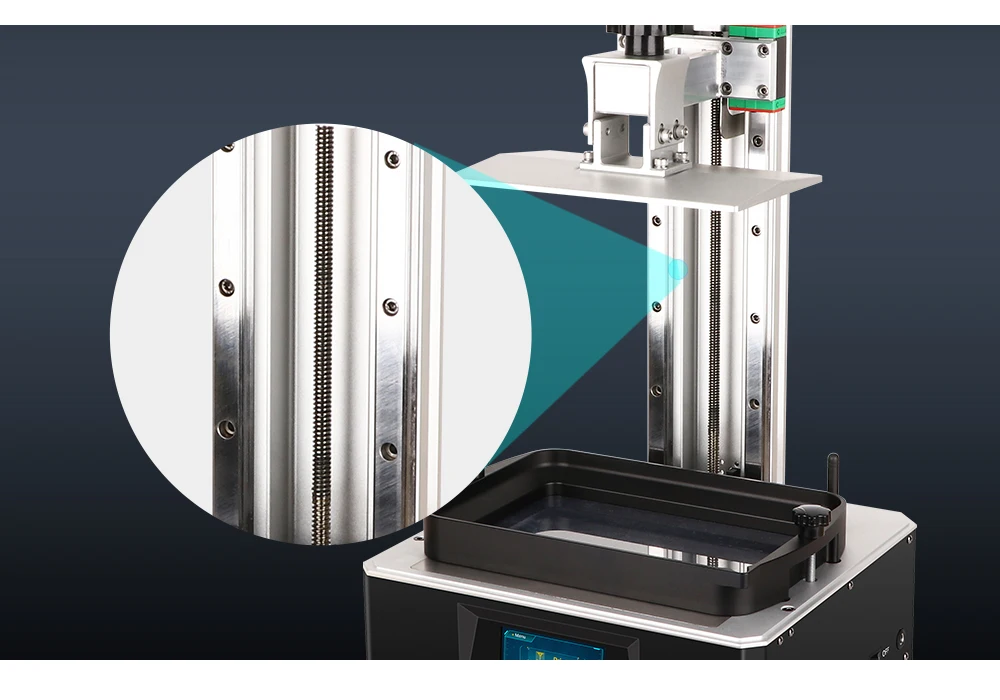

It also features a dual linear rail and ball screw design for extra stability even in the upper reaches of the massive build volume. And lastly, the full metal exterior adds strength and durability but also mixes in a welcome touch of flair.

Priced at $2,200, the Phrozen Sonic Mega 8K requires a substantial investment, which makes it a good pick for serious amateur makers with deep pockets, and small businesses looking for a reliable workhorse with plenty of printing capacity.

- A cheaper alternative: Phrozen Mighty 4K for $599

Professional large resin 3D printers

4. Peopoly Phenom L

- Price: $2,499 — Available at Matterhackers here

- Print volume: 345 x 197 x 400 mm

You can even then choose to upgrade and go further and buy the Phenom L, an even larger resin 3D printer for an extra $500. Resolution falls to 90um, but print volume explodes to 345 x 194 x 400 mm — it’s gigantic!

You can easily print prototype helmets, tools, and other larger resin prototypes in this large-format resin build area.

4.5 – Peopoly Phenom Prime

- Price: $1899 — Available at Matterhackers here

- Build Volume: 276 x 155 x 400 mm

- XY Resolution: 51 microns

- Minimum Layer Height: 0.

01 mm

01 mm - Speed: 60 mm/h

Since 2017, Peopoly has wowed 3D printer enthusiasts by delivering some of the roomiest, large-scale 3D printers, chiefly embodied by the Phenom range. Half a decade later, Peopoly has booted much of the original line-up to the technological graveyard to make room for its most sophisticated Phenom yet, the Peopoly Phenom Prime.

Both a spiritual successor and a logical evolution for the range, the Phenom Prime retains all of what we liked about the original but levels up the offering with modern features and niceties to make it faster and more precise.

It features a massive 276 x 155 x 400 mm build volume – same as on the Phenom – so no major changes there. Where things get interesting is the inclusion of a 5.5K (read 5448 x 3064 pixels) LCD that bumps up the XY resolution to a sharp 51 microns, a massive leap over the original’s 72 microns.

Unlike the original Phenom’s RGB LCD, the Prime features a monochrome screen. Par for the course in modern printers, but a welcome change that increases panel lifespan by up to three times. The monochrome panel also boasts a higher light transmission rate or permeability, which results in much faster curing and a 70% reduction in exposure time. In other words, much speedier printing – a 100% increase according to Peopoly.

Par for the course in modern printers, but a welcome change that increases panel lifespan by up to three times. The monochrome panel also boasts a higher light transmission rate or permeability, which results in much faster curing and a 70% reduction in exposure time. In other words, much speedier printing – a 100% increase according to Peopoly.

Elsewhere, the Phenom Prime has an improved cooling system to handle the heat produced by such a large machine. It’s also quieter, something that anyone who dabbled with the original will relish, given its reputation for blaring the decibels in full swing.

Who would benefit most from the Phenom Prime? First and foremost, anyone that owns a Phenom and will make the most of the Prime’s sleek new upgrades. Second, for us, the Phenom Prime slots in as an excellent option for a small workshop that needs more capacity and printing pep than the more budget-oriented printers like Anycubic Photon M3 Max.

5. Formlabs Form 3L

- Price: $10,999 — Available at Dynamism here

- Build volume: 335 x 200 x 300 mm

Designed specifically for large-scale resin part production, the Formlabs 3L build on Formlabs is already stellar reputation and brings it to the big leagues.

It uses the same Formlabs technology as on the Form 3, with two precision LPUs (Light Processing Units) for fantastic precision and consistency throughout, and Formlabs stress that this indeed is the ideal solution to save your business money by no longer outsourcing your prototyping and fabrication.

Numerous case studies show helmets printed in exquisite detail, shovel prototypes (though even with the printer’s large build area, it required three parts), nozzles, and even high-resolution full-size Teenage Mutant Ninja Turtle models — if you’re a design studio or uber-wealthy superfan.

It’s easier to use than most commercial large resin 3D printers, and seeks to minimize hassle and the steep learning curve across the board — such as by offering automatic resin dispensing, simplifying the entire slicing and software workflow, and with the delightfully intuitive 5.5-inch full-color touchscreen.

If you’re running a 3D printer farm you can manage them all via the cloud, and you can also make use of Formlabs’ wide resin selection: standard, engineering, flexible, tough and durable, dental or medical, and even jewelry casting resins — you can make almost anything for any industry use with the Form 3L.

6. Photocentric Liquid Crystal Magna

- Price: $15,000+

- Print volume: 510 x 280 x 350 mm

British company Photocentric make some of the highest resolution LCD printers around for industry, with the LC Magna designed for precise dental and product design prototyping at large scales and sizes.

It’s super-fast, large, and accurate, with Photocentric’s own resins helping keep costs lower over the long term. Photocentric also manufactures a wash module for washing prints and a curing module for curing prints that require this, and the LC Magna has been used to prototype and manufacture glasses, dental models, models figurines, and even motorbike engines.

The 4K 137-micron display delivers accuracy over the entire build area, using the benefits of anti-aliasing, and uses Photocentric’s patented blow-peel technologies to prevent some of the negative effects of large resin build areas coming into play.

Overall, it’s costly but offers key benefits as a big resin 3D printer in large-scale industry and prototyping.

Buyer’s Guide – Things to Consider When Buying a Large Resin 3D Printer

Build Volume

When considering what large format resin printer to buy, build volume is, unsurprisingly, one of the largest considerations. What size you need depends entirely on your plans.

For most amateur makers looking to print cosplay props, highly detailed figures in batches, and larger decorative pieces, a build volume around 300 x 150 x 300 mm should be sufficient.

It’s easy to get carried away by the big numbers and buy a printer with far more capacity than you’ll ever need, but it’s also worth opting for something a little larger than your needs for a sprinkling of future-proofing. Your ambitions and project may change over time, and it’s advisable to have a bit of leeway to work with should that happen.

LCD and Pixel Count

Avoid RGB LCDs at all costs. The technology is now outdated: it’s slower and has a shorter lifespan. Instead, choose a large resin 3D printer with a monochrome LCD – a must-have in our book.

It’s worth noting that the larger the LCD (and, by extension, build volume), the more pixels have to stretch and expand to cover the entire plate effectively. The fewer pixels, the less detail a printer can produce.

This means that LCDs with a higher resolution are a must-have for larger printers. We’d recommend at least 4K, but don’t hesitate to pivot to printers pushing 5K and even 7K/8K LCDs if your budget allows it.

XY Resolution

XY resolution determines the level of accuracy a printer can produce, the amount of detail, the quality of the surface finish, and how well it will render features.

Larger build volumes used to mean a downgrade to XY resolution, but nowadays, it’s possible to buy large format printers with excellent resolution.

Anything around 50 microns should serve the large majority of makers, but if you want that extra bit of detail, opt for printers with a lower XY resolution.

Build Quality and Stability

Managing movement in large format resin printers is vital if you want uniform fine details and precision throughout your prints. Look to printers with solid metal frames to improve durability, dual linear rails, and sturdy covers/shrouds/hinged doors.

Look to printers with solid metal frames to improve durability, dual linear rails, and sturdy covers/shrouds/hinged doors.

You may find that these tend to peter out as the price drops, but so does the build volume, which somewhat cuts down on their utility. In other words, don’t be put off by budget large format resin 3D printers that don’t have all the fancy features of the pricier XL alternatives.

Print Speed

Though it’s easy to be drawn in by the pull of blisteringly fast print speeds, these tend to signal a theoretical maximum. Though they embellish and help with marketing efforts, these numbers are rarely reached, especially if you want high-detail prints.

But, if you plan to use a resin printer as a daily go-to machine for batch printing, more speed certainly makes a tangible difference to print times. 60 mm/h is becoming somewhat of a standard for most large resin 3D printers and represents a good starting point for most makers.

Price

Though specifications, features, and print quality play a major role in the buying process, none wields as much weight as price. Price will likely be the most crucial decider of what printer you end up buying.

Price will likely be the most crucial decider of what printer you end up buying.

For a modestly-sized but still comparatively large resin printer, expect to pay around $500 at best. Manufacturers like Anycubic and Elegoo have done well to cut the price on these entry-level machines, and the value proposition has never been better.

For mid-range machines with plenty of capacity, we’re nearing $1000. The Anycubic and Phrozen ranges are great options in this price portion.

From here, prices surge to thousands of dollars for large resin 3D printers with the biggest build volumes and features. These tend to be reserved for business and professional workshops with the budget to spare.

Large Resin 3D Printer FAQs

What Resin Printer Has the Biggest Build Plate?

The consumer-grade resin 3D printer with the biggest plate is currently the Phrozen Sonic Mega 8K. Phrozen’s flagship large format SLA printer features a 15″ 8K LCD, 330 x 185 mm build plate for a total build volume of 330 x 185 x 400 mm.

Jumping up in price, we have Peopoly Phenom XX, which has a 23.8″ 4K LCD and 527 × 296 x 550 mm build volume. It’s priced at $7,500, positioning it firmly in the professional portion of the resin 3D printer market as one of the largest SLA printers available.

How Big Can a Resin Printer Print?

A resin 3D printer can print as big as its build volume allows. For instance, the Anycubic Photon M3 Max has a 300 x 164 x 298 mm build volume, meaning you could print a solid cube of that size on the printer.

What Is the Biggest Anycubic Resin Printer?

The biggest resin 3D printer from Anycubic is the Anycubic Photon M3 Max, the largest of the manufacturer’s recently launched M3 series printers. It has a build volume of 300 x 164 x 298 mm, which positions it as a large format resin 3D printer.

Further reading:

- The best resin 3D printers

- DIY SLA 3D printers you can build yourself

- The best large 3D printer (FDM and other technologies)

- Best 3D printers for small businesses

- Top professional 3D printers

- 500x500x500mm 3D printers

- Best wash and cure stations

Top-Notch Equipment with Big Build Volume

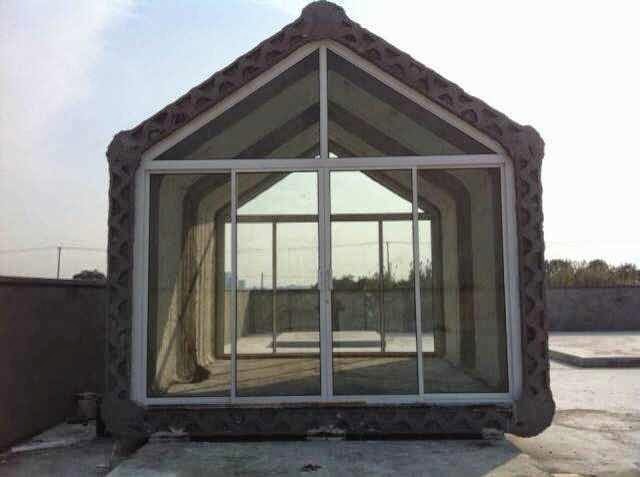

Veterans of additive manufacturing know that the first 3D printing technology to appear was stereolithography — it was as far back as 1986. Since then, there’ve been developed plenty of other methods like FDM and SLS; on the other hand, the popularity of stereolithography technology drastically increased when resin 3D printers became much more affordable and advanced. As a result, now the market offers a variety of options for printing in photosensitive resins, with multiple smart features and build volumes for different purposes.

Since then, there’ve been developed plenty of other methods like FDM and SLS; on the other hand, the popularity of stereolithography technology drastically increased when resin 3D printers became much more affordable and advanced. As a result, now the market offers a variety of options for printing in photosensitive resins, with multiple smart features and build volumes for different purposes.

Credit: allthat3d.com

This is Top 3D Shop, and in this article, we are going to tell you about large resin 3D printers. Read on to learn about the most notable models and their peculiarities, as well as the applications of SLA printing and the criteria to be taken into account when choosing such equipment.

What is a large resin 3D printer?

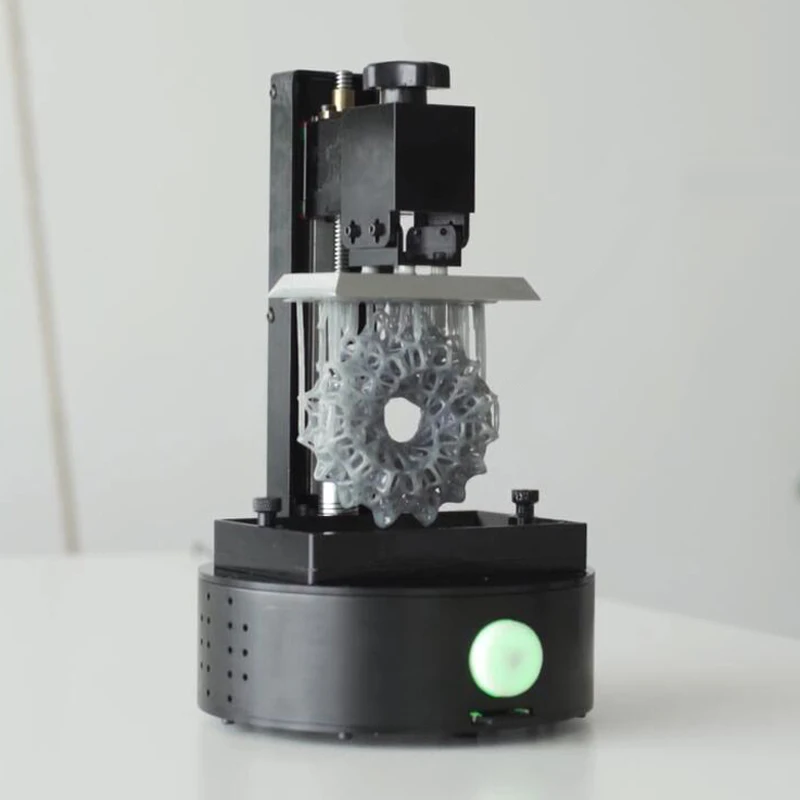

Before we get to discussing specific models and their pros and cons, let’s have a brief look at the technology called vat photopolymerization. As the name suggests, it’s the process of turning a liquid polymer into a solid object under UV light exposure. Vat polymerization comes in three main types which are SLA, DLP, and LCD (or MSLA).

Vat polymerization comes in three main types which are SLA, DLP, and LCD (or MSLA).

We’ve already mentioned that the first 3D printing technology was SLA (Stereolithography Apparatus) invented and patented by Chuck Hull in 1986. Like the other vat polymerization technologies, this one cures photosensitive resin, layer by layer, to print a 3D object. The difference lies in the source of UV light used for polymerization. SLA employs the UV laser to “draw” each layer of the future model. The method provides high quality prints but the downside of that is the trade-off in speed.

(Sometimes resin 3D printing in general can be referred to as SLA 3D printing, although it may cause ambiguity.)

Credit: burkhartdental.com

DLP (Digital Light Processing) technology uses a digital light projector screen as a light source. This technology gives you a significant gain in speed, as a whole layer is cured all at once. On the other hand, classic SLA printers can feature higher resolution compared to those using a projector.

The newest type of vat polymerization technology is called LCD (which stands for Liquid Crystal Display). It’s pretty similar to DLP, but instead of a projector it uses an LCD as a mask for the light coming from an array of UV LEDs.

Credit: phrozen3d.com

As was already mentioned, the popularity of resin 3D printers is growing rapidly as they are becoming more advanced and user-friendly, and definitely less pricey. First these devices were used for printing small objects requiring high accuracy and flawlessly smooth surfaces, like in jewelry. But some users wanted to have bigger prints without compromising on quality. So eventually, resin 3D printers acquired bigger build volumes, and now we can speak of a great number of large resin 3D printers that entered the market.

Uses of a large resin 3D printer

Resin 3D printing with its precision, time-saving, and the opportunity of using a great variety of materials with different characteristics, is highly recommended for use in many sectors like jewelry, healthcare, engineering, aerospace, automotive, robotics, education, and more. This technology helps to create complex finely-detailed models which would be difficult to produce using traditional methods. Let’s look at some examples.

This technology helps to create complex finely-detailed models which would be difficult to produce using traditional methods. Let’s look at some examples.

Medical and dental tools

Healthcare is one of the industries that benefit most from resin 3D printing. The variety of applications is numerous: from producing medical tools, which, being made of special medical resins, are biocompatible and can be sterilized in a usual way, to making organ models that help doctors make surgery preparations. In dentistry, special dental resins are utilized to produce models of crowns and bridges, surgical guides, splints and retainers with incredible accuracy.

Credit: instituteofdigitaldentistry.com

Gifts and toys / miniatures

Resin 3D printing technology has already been highly appreciated by hobbyists looking for a simple way of making miniatures and customized figures. Toy and gift industries also greatly benefit from employing 3D printing in manufacturing. One more interesting application of the technology in the toy industry is repairing toys and creating spare parts for them.

One more interesting application of the technology in the toy industry is repairing toys and creating spare parts for them.

Credit: facfox.com

Education and entertainment

As the resin 3D printing industry grows, educational institutes are starting to use it for research and education purposes. Both students and professors utilize 3D printers for a variety of purposes like printing visual AIDS or models for their projects. In some colleges, professors make use of 3D printers while telling the students about additive manufacturing technology. There are a lot of sites that offer huge selections of free 3D printing models for entertainment and educational purposes.

Credit: 3dstartpoint.com

The best large resin 3D printers: affordable, commercial and industrial

A wide variety of large format resin 3D printers can be divided into three categories, let’s call them affordable, commercial, and industrial devices. Printers relating to the first category are the best choice for home use, as they are quite affordable and not very big in size. They can also be used for the needs of small businesses, and would be perfect in the field of education. The category of commercial printers is aimed at small and medium-sized businesses, but some consumers can also become interested in buying such a device, especially if they are planning on printing some huge ambitious projects, like, for instance, certain elements for cosplay costumes. Commercial large-scale resin 3D printers normally have more spacious build volumes than devices from the category of affordable printers. And, last but not least, industrial printers with their impressively high performance and no less impressive price are mostly targeted at large manufacturing companies with high production volumes.

They can also be used for the needs of small businesses, and would be perfect in the field of education. The category of commercial printers is aimed at small and medium-sized businesses, but some consumers can also become interested in buying such a device, especially if they are planning on printing some huge ambitious projects, like, for instance, certain elements for cosplay costumes. Commercial large-scale resin 3D printers normally have more spacious build volumes than devices from the category of affordable printers. And, last but not least, industrial printers with their impressively high performance and no less impressive price are mostly targeted at large manufacturing companies with high production volumes.

Affordable

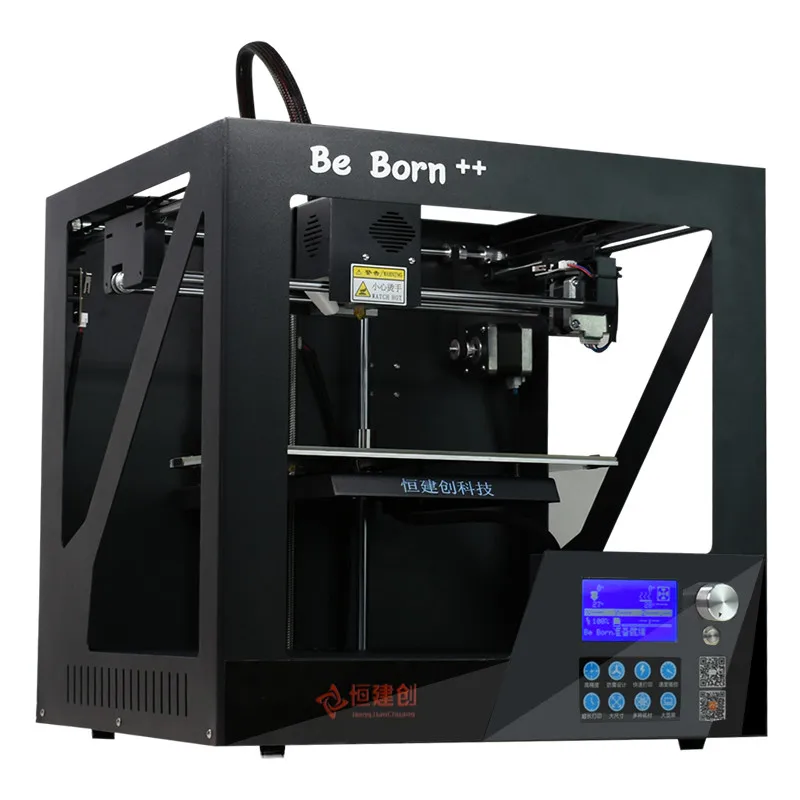

Anycubic Photon Mono X 3D printer

The Anycubic Photon Mono X is a high-speed LCD resin 3D printer. It boasts a 4K resolution panel which allows for high accuracy of printing with a single layer depth not exceeding 0.01 mm. The printing speed is impressive — it takes only 1–2 seconds to print a layer. The Photon Mono X features a spacious build volume of 192х120х245 mm. Built-in safety functions are helpful if you are planning to use the printer at home with kids. The Photon Mono X offers a number of convenience features, such as Wi-Fi and remote control. All this makes the Anycubic Photon Mono X one of the best large format resin 3D printers in its price range.

The Photon Mono X features a spacious build volume of 192х120х245 mm. Built-in safety functions are helpful if you are planning to use the printer at home with kids. The Photon Mono X offers a number of convenience features, such as Wi-Fi and remote control. All this makes the Anycubic Photon Mono X one of the best large format resin 3D printers in its price range.

Credit: @leandro_benignoart / Instagram

Pros

- high printing speed

- great resolution

- Wi-Fi connectivity

- strong brushed aluminum panel

- built-in safety functions

Cons

- rather expensive

- some users complain of the software performance

Phrozen Sonic Mighty 4K resin 3D printer

The Phrozen Sonic Mighty 4K offers one of the largest build volumes in its price range — 200x125 x220 mm. The machine is designed for printing one big model or multiple smaller parts in one batch. A 9.3-inch 4K monochrome LCD screen offers excellent printing quality alongside the high speed. The printer is equipped with a 5-inch touchscreen for navigation and settings configuring. The device is compatible with the free Chitubox slicer optimized to work with resin 3D printers. The Phrozen Sonic Mighty 4K would become a good choice both for commercial and home use. The printer is widely used in dentistry.

A 9.3-inch 4K monochrome LCD screen offers excellent printing quality alongside the high speed. The printer is equipped with a 5-inch touchscreen for navigation and settings configuring. The device is compatible with the free Chitubox slicer optimized to work with resin 3D printers. The Phrozen Sonic Mighty 4K would become a good choice both for commercial and home use. The printer is widely used in dentistry.

Credit: printablescenery.com

Pros

- high printing speed

- excellent print quality

- large build volume for its class

- easy operation

Cons

- resin vat is not easy to fit

- small touchscreen

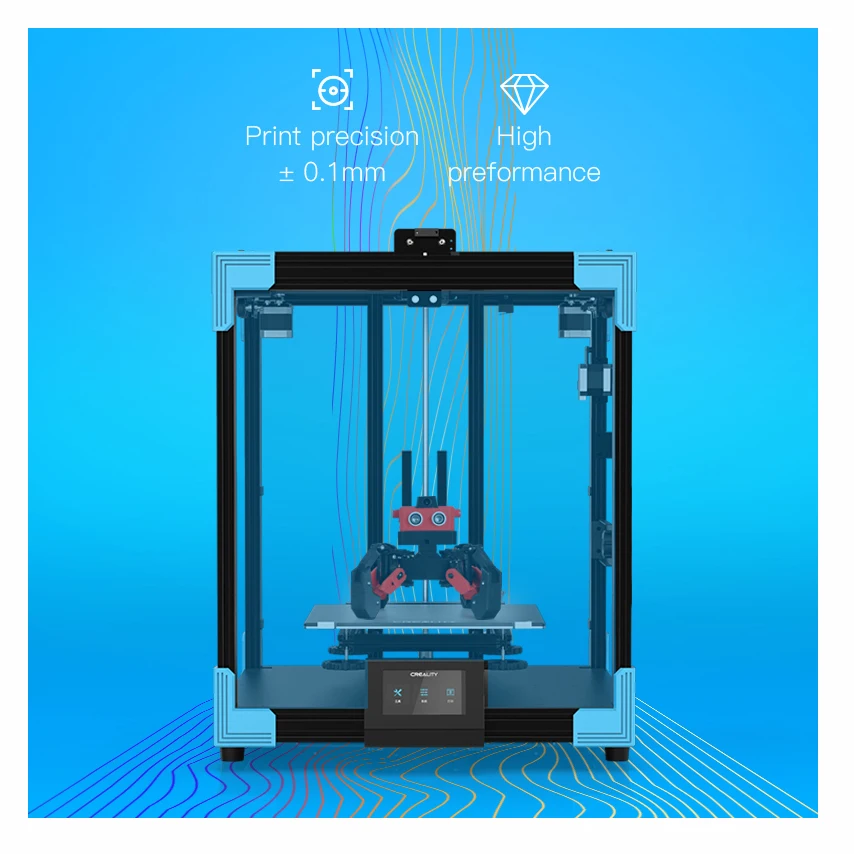

Creality LD-006 3D printer

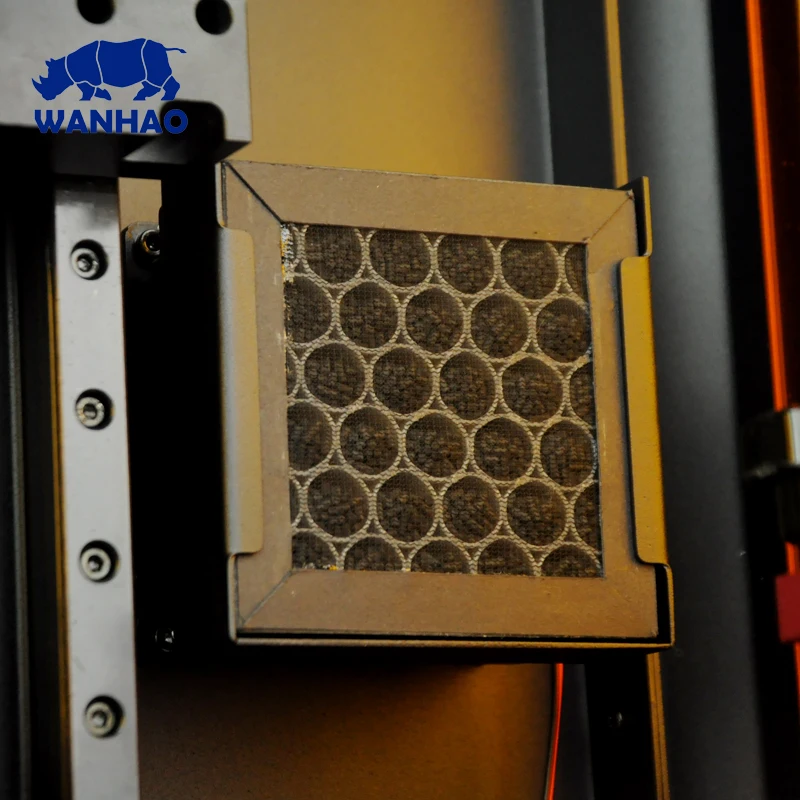

Like most large volume resin 3D printers in this segment, the Creality LD-006 is based on LCD technology. The device features a new 8.9-inch monochrome LCD screen with 4K resolution. The build volume is decent enough — 192x120x250 mm. The Creality LD-006 boasts a renewed vat which adds to the user’s convenience. The vat has a liquid level line which helps to control the resin expenditure, and special stands to prevent the FEP film from being damaged. The LD-006 has a built-in air filtering system, which seems to be pretty useful when working with resins that are characterized by strong odor.

The Creality LD-006 boasts a renewed vat which adds to the user’s convenience. The vat has a liquid level line which helps to control the resin expenditure, and special stands to prevent the FEP film from being damaged. The LD-006 has a built-in air filtering system, which seems to be pretty useful when working with resins that are characterized by strong odor.

Credit: fabbaloo.com

Pros

- high resolution and print quality

- convenient vat

- built-in air filtration system

- great touchscreen

Cons

- no Wi-Fi connection

- a bit pricey

Uniz IBEE 3D printer

The Uniz IBEE is a multi-purpose desktop LCD 3D printer of medium size. It offers an 8.9-inch 4K monochrome LCD screen and the build volume of 192x120x200 mm. Its new optical system employs a collimated light source, providing the 1000:1 contrast ratio. The device has a wide range of connectivity options including Wi-Fi, and comes with the proprietary powerful and user-friendly software, which makes the Uniz IBEE a win-win choice for beginners.

Credit: uniz.com

Pros

- great quality of printing

- decent build volume

- rich connectivity options

- easy to use

Cons

- changing the vat film requires a lot of time

Commercial

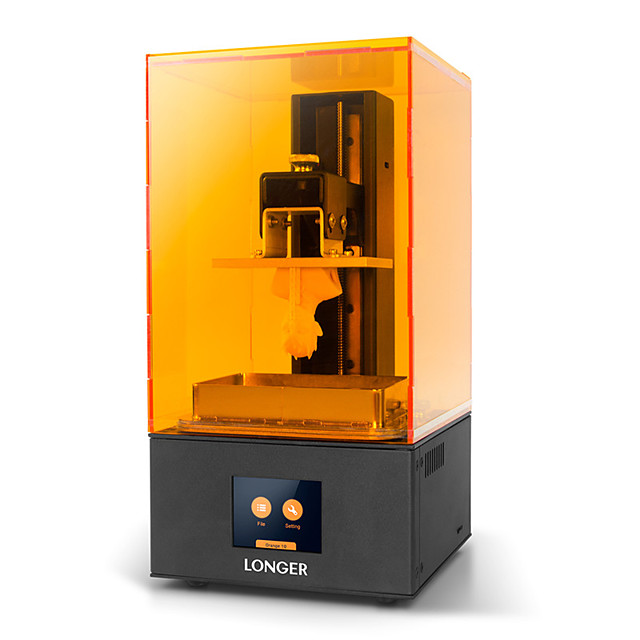

Phrozen Sonic MEGA 8K resin 3D printer

The Phrozen Sonic MEGA 8K stands out among other large resin 3D printers as it provides both stunning print quality and one of the largest print volumes on the market. Its 15-inch 8K mono LCD panel allows you to print at 43-micron resolution, which gives you almost twice more detailed prints than most competitors can offer. The Sonic MEGA 8K comes with a pre-calibrated build plate, which means your printer is ready for use right out of the box. The device has a full-metal exterior and its more than competitive price makes it the best choice for those seeking for really large and highly detailed prints.

Credit: reddit. com

com

Pros

- excellent print quality

- huge build volume

- pre-calibrated build plate

- great value for money

Cons

- rather slow printing speed

Uniz Slash 2 Pro 3D printer

The Uniz Slash 2 Pro is an upgraded version of the popular Slash 3D printer. Its liquid cooling system together with the intelligent heat management provides fast curing time which results in high printing speed. The printer uses LCD 3D printing technology and is equipped with a 4K LCD screen. The build volume is 192x120x400 mm, which is quite enough for most projects. The Uniz Slash 2 Pro sports a durable resin vat with the automatic level control.

Credit: uniz.com

Pros

- extremely fast printing speed

- large build volume

- high printing accuracy

- quite affordable

- durable resin vat

- powerful and user-friendly software

Cons

- no touchscreen for the printer control

Phrozen Sonic XL 4K resin 3D printer

The Phrozen Sonic XL 4K is a large format resin 3D printer specially designed for the dental industry, although it perfectly suits the needs of jewelry production, prototyping, and other industries requiring high-accuracy printing. It features a monochrome LCD matrix with a resolution of 3840x2160 and a pretty large print area. One of the advantages of the Sonic XL 4K is the support of various types of resins by different manufacturers. The optical system of the device has been improved compared to the previous models. The Phrozen Sonic XL 4K also has a more powerful ParaLED® 3.0 module which provides an even layer thickness over the entire area of the build plate.

It features a monochrome LCD matrix with a resolution of 3840x2160 and a pretty large print area. One of the advantages of the Sonic XL 4K is the support of various types of resins by different manufacturers. The optical system of the device has been improved compared to the previous models. The Phrozen Sonic XL 4K also has a more powerful ParaLED® 3.0 module which provides an even layer thickness over the entire area of the build plate.

Credit: reddit.com

Pros

- fast printing speed

- large build volume

- fine precision

- compatibility with various resin types

- a lot of connectivity options

Cons

- no warranty for the building platform and the LCD screen

EPAX X156 3D printer

With a 345x194x400 mm build volume, the EPAX X156 is one of the largest resin 3D printers in the market. The printer features a 15.6-inch 4K RGB screen which is less durable and requires more time to cure the layers, compared to monochrome screens. The good news is that in the case of the EPAX X156 it doesn’t seem much of a problem as the manufacturer provides the opportunity to upgrade the device with a smaller but more durable 4K monochrome screen with the same resolution and a 4 times faster printing speed.

The good news is that in the case of the EPAX X156 it doesn’t seem much of a problem as the manufacturer provides the opportunity to upgrade the device with a smaller but more durable 4K monochrome screen with the same resolution and a 4 times faster printing speed.

Credit: reddit.com

Pros

- super large build volume

- fine precision and great surface finish

- factory-leveled printing plate

- large metal resin vat

Cons

- small touchscreen (3.5 inches)

- RGB LCD screen is less durable and features a slower printing speed (although can be upgraded to monochrome)

Formlabs Form 3 / 3L

Credit: formlabs.com

The Formlabs Company has developed a completely new proprietary printing technology called LFS (Low Force Stereolithography) for its Form 3/3L models. This technology, based on SLA, ensures edge-to-edge consistency of the print quality. The major difference between the two models is the build volume, which is 145x145x185 mm for the Form 3 and 335x200x300 mm for the Form 3L. Both printers can work with various resin types which increases their versatility and allows their use in different industries.

The major difference between the two models is the build volume, which is 145x145x185 mm for the Form 3 and 335x200x300 mm for the Form 3L. Both printers can work with various resin types which increases their versatility and allows their use in different industries.

Credit: formlabs.com

Pros

- large build volume (for the 3L model)

- high printing speed

- very user-friendly, allows fully automatic one-click printing

- works with a great number of various resin types

Cons

- support structure is required for every build

- some users reported problems with dust inside the laser unit

Peopoly Phenom Prime

Credit: peopoly.net

The Peopoly Phenom Prime is a large resin LCD 3D printer featuring a great monochrome 12.5-inch 5.5K screen, which allows printing with a resolution of 51 microns. The device boasts a huge 276x155x400 mm build volume. The Phenom Prime has an improved cooling system compared to its predecessor, the Phenom model.

The Phenom Prime has an improved cooling system compared to its predecessor, the Phenom model.

Credit: peopoly.net

Pros

- one of the biggest resin 3D printers

- monochrome high resolution LCD screen

- supports various resin types

Cons

- loud printing process

Industrial

Industrial large resin 3D printers are to meet special requirements, one of them being definitely an extremely high printing speed. None of the existing technologies is capable of providing such speed level. The growing demands for high-speed 3D printing have led to developing such ultra-fast printing technologies as CLIP and LSPc. Let’s see what’s so special about them.

Nexa3D vs Carbon3D

The CLIP (Continuous Liquid Interface Production) technology was developed by the Carbon 3D Company. Like with SLA technology, the models are printed layer by layer, but you don’t have to wait for each layer to be cured, since the technology harnesses oxygen as an inhibiting agent. This allows for printing speed 25–100 times higher than that of any other existing 3D printing technology. Such an approach not only decreases production time, but also removes the layering effect in the print structure. The CLIP technology is presented by two models: Carbon M1 and Carbon M2 with build volumes of 144х81х330 and 190х118х326 mm respectively. These models can not be called affordable, but they quickly caught the attention of big companies like Adidas, Ford, and others. These companies highly appraised the advantages of high-speed and at the same time low-cost production, compared to traditional manufacturing.

Credit: YouTube

Credit: 3dbeginners.com

The LSPc (Lubricant Sublayer Photocuring) technology by the Nexa3D Company uses a similar principle to CLIP, being different in some features. Nexa3D produces two models based on LSPc technology – NXE400 with a print volume of up to 16 liters and the 7-liter NXE200. These models are suitable for both industrial prototyping and small-volume manufacturing. The LSPc printers are equipped with replaceable resin cartridges, so you don’t have to refill the vat during the printing process. Nexa3D printers can work with a great number of different materials, which makes them suitable for use in the aerospace and car industries, consumer goods, electronic equipment, and many other fields.

Credit: nexa3d.com

The main advantage of the ultra-fast printing technologies is an extremely high printing speed which gives the user absolutely new experience in 3D printing. However, such devices are highly expensive and sometimes the manufacturers don’t even sell them to consumers, which makes such printers completely unsuitable for home use and even for small businesses. Still, they can be a great choice for large manufacturing enterprises affiliated with large production volumes.

How to choose a good large resin 3D printer

When it comes to choosing a large resin 3D printer among the numerous solutions offered by manufacturers, one can feel a little bit frustrated as the choice is too vast and not always obvious. Besides, each user usually has special requirements in mind, thus what’s essential for one person can be of no importance for another. We’ve already given you the list of the models worth considering, and now let’s name the key features that’ll help you find the best large resin 3D printer that you’ll be fully content with.

Build volume

The build volume or the printing area defines the maximum size of your future project. The larger the build volume – the larger laser sword you can print. But if you are not that ambitious and gonna print something of a smaller size, you may not restrict your choice by this parameter. Besides, larger build volume usually means bigger size of the printer itself. It also requires more consumables.

LED array

LED array, or LED matrix, is used in LCD 3D printers as the light source to cure the printed layers. Manufacturers develop different optical systems trying to get the consistent lighting possible on the entire build plate, as it directly affects the print quality.

Production speed

DLP and LCD printers generally have a faster production speed than SLA models. Monochrome LCD matrix provides much higher printing speed than a color one, as the latter absorbs more light and the layers are cured more slowly. It’s up to you, whether you need really speedy printing or better save a little money.

Resolution and precision

Important parameters that define how similar your print will be to the original. Resolution and precision are often regarded as synonyms; but nevertheless these two words are close in their meanings, there's a certain difference. Resolution can be defined as the X-Y dimensions (horizontal resolution) and layer thickness in micrometers (vertical resolution). The less the layer thickness is, the higher resolution your printer has, which results in smoother and more detailed prints. Precision rather refers to the consistency of the printer, in other words, it shows if it is capable of providing expected results in every print. If you need fine-detailed prints, then resolution is a crucial thing for you. But don’t forget that higher resolution always means slower printing speed.

Stability

The quality of your prints depends to a great extent on how stable your printer is, if there’s any undesired wobbling during the printing process. To ensure the stability, all the printers in our list are equipped with double linear Z-axis rails to move the build platform up and down. You can also make some steps to improve your device’s stability. First put it on a sturdy, heavyweight surface. Then put a foam or rubber pad under the printer to absorb vibrations. You can also reduce printing speed if this option is not very important for you.

Credit: all3dp.com

Print bed adhesion

It sometimes happens that your prints don’t stick to the print bed, but rather to the FEP film or to the resin vat. It means that the first layer of your project has poor adhesion to the build plate. To stop this, you should make sure you have enough bottom layers and the bottom layer has enough time to harden. You can use PTFE spray on your FEP film and let it dry to create a lubricant preventing the resin from sticking to the resin vat.

Economical

When one is choosing a large resin 3D printer, price can become an important factor as such machines, although becoming more affordable, still cost a lot. If you don’t want to spend extra money, you’d better check all the features to decide what you’re ready to pay for. Such parameters as high printing speed and extreme resolution make the device more expensive, but one can always find a reasonable compromise depending on their needs. Another important thing to keep in mind is consumables. Some printers allow using different types of resins produced by third-party manufacturers, which is great, as you can always choose the best option that suits your budget.

Conclusion

Large resin 3D printers are becoming more and more popular. As the technology’s developing rapidly, such machines have entered a lot of various industries, where they successfully meet the goal of high-speed precise printing at a relatively low cost. The vast variety of different resin types, offered by manufacturers, allows for use of resin 3D printers in almost any industry, when one wants to get a finely detailed object with a flawlessly smooth surface, be it dentistry, jewel industry, aircrafting, or even shoes manufacturing, like this famous Adidas 4DFWD model with 3D printed midsoles.

Credit: adidas.com

It’s not only businesses that benefit from the technology of resin 3D printing, but also consumers, as the market of affordable resin 3D printers is growing really fast. So, if you want to purchase the best large resin 3D printer, we do hope that this article will answer your questions and help you make the right choice.

How to create models that are larger than the print volume of a 3D printer

Don't have a large format 3D printer yet? When evaluating the capabilities of a compact desktop 3D printer, do not limit yourself to print volume. Many objects, like your smartphone or a bridge over a river, are made up of many individual components. Therefore, splitting the model into smaller parts that can be aligned after printing is a great solution for 3D printing large objects that do not fit on the platform.

Also, splitting the model can be a great way to get a high quality result, even if the whole model fits on the platform. This makes sense when multiple or opposing surfaces must be free from support structures, when the model has complex ledges, or contains cavities where liquid polymer can remain.

3D printing of various parts opens up new possibilities, for example, the creation of prefabricated structures from various materials or the combination of rigid and flexible parts to simulate the overmolding method.

When choosing a gluing method, it is necessary first of all to take into account the required degree of strength of the glued joints, which depends on the purpose of the models:

-

chemical: use adhesive on artwork, scale models, and complex shapes that are not intended for functional use and should not be impacted;

-

Mechanical: Provide threaded holes or sockets for attaching parts that require a secure mechanical connection, or repeatedly detaching and attaching components as needed.

This tutorial focuses on building large, prefabricated 3D stereolithographic (SLA) printed models with chemically bonded components. Read on to learn all the steps in this process, from model separation to post-processing for a professional finish.

Formlabs Form 3L is the first affordable, easy-to-use large format 3D printer optimized for reliable production of industrial-quality models. The Form 3L stereolithographic 3D printer features a huge print volume of 30 x 33.5 x 20 cm and unrivaled cost-effectiveness.

Meet the Form 3L

We recommend two ways to separate models: adding features to the design that will allow the parts to fit together, or separating the model with straight lines, which will require them to fit together properly during the bonding process.

Regardless of which method you choose, if you have a lot of parts, it's helpful to add a unique identifier (letters/numbers) for each one to make assembly easier.

![]()

Use CAD software to split a 3D model and add basic centering components such as slots, pins, slots, notches, and tabs, or more complex features such as dovetails and slots to match model folds.

Adding centering components to the design makes it easier to assemble parts.

Ideally, these components should make it easier to align and assemble parts, but can cause problems if they differ even slightly from your 3D models, preventing perfect centering. Therefore, it is best to use centering components only when the printer can print parts with accurate dimensions that are not subject to deformation.

Splitting a 3D model along straight lines requires less effort than adding components to center. There are also fewer problems when using this separation method if the parts are slightly deformed or differ in size.

Adding IDs for each part makes the assembly process easier.

On the other hand, parts separated by straight lines can be time-consuming to assemble, as each part must be manually centered and ensured that they all remain in the correct position until the adhesive is completely dry.

By default, when printing on a stereolithographic 3D printer, solid models without voids are obtained. Depending on the design, different requirements may apply to the manufacture of large items. In such cases, 3D printing the outer shell or converting the structure into a hollow is a great way to save a lot of material and time. When printing hollow models on a stereolithographic 3D printer, be sure to add ventilation holes to avoid creating cavities filled with air and pressurized resin.

SAMPLE PART

Experience Formlabs print quality firsthand. We will send a free sample of the printed model directly to your office.

Request a free print sample

Converting a model design to a hollow saves a lot of time and material because the printer only needs to print the outer shell.

Learn more about how to save materials and time by hollowing out 3D models.

Depending on the size of the details and the purpose of the model, we recommend three mounting methods:

| Epoxy glue (5-30 min) | cyanoacrylate (CCA, Supercollah) | Resin | |||||

|---|---|---|---|---|---|---|---|

| Square. | Large | Small/Medium | Small | ||||

| Paintable | Yes | Yes | Yes | 9006 7Yes | 9006 70072Medium | Low | Low |

For large parts and maximum adhesion, use 5-30 minute dry epoxy. It takes longer to dry than other adhesives, allowing you to fit large 3D printed parts but slows down the assembly process. Most 5-minute epoxy adhesives stop changing shape in as little as five minutes and cure by about 75% in less than an hour.

For large parts and maximum adhesion we recommend using epoxy adhesive.

The next option is cyanoacrylate (CA or superglue), which quickly forms a strong bond, ideal for small to medium sized parts. Thoroughly clean the part before applying CA to the surface, because contaminants adversely affect the quality of the connection. CA has a moderate impact strength, but is not recommended for models that require high strength.

For small models, you can simply use liquid resin from a stereolithographic 3D printer. Pour a small amount of resin into a tray from a bottle or cartridge, pick it up with a pipette or syringe, and place it on the surface to be bonded. Connect the parts and wipe off excess resin that may spill around the edges. Aim a 5mW (405µm wavelength) UV laser pointer at the contact area to cure the resin and bond the parts.

This method produces a chemical bond similar to 3D stereolithography printing, but is only suitable for bonding small surfaces as a low power light pointer cannot penetrate the model deep enough to create a strong bond.

Note. Protective equipment must be worn when working with polymers, including proper eye protection and gloves.

Download PDF

Don't have time to read the article now? Download it in PDF format.

Download as PDF

After assembling the model, it's time to move on to post-processing. This step includes geometric correction of the model to provide a smooth surface that matches the original 3D model, and aesthetic finishing to obtain a uniformly colored surface.

Depending on the precision of the printer and the size of the printed parts, there will almost always be slight voids or mismatches at the contact points. Automotive sealant (e.g. Bondo 907) adheres well to polymers, therefore, to eliminate such inconsistencies, it is recommended to apply it in a thin layer on the surface. Lightly sand the surface after each coat has dried to bring the model to its final shape.

Sealing models with automotive sealant (red area in image) will help eliminate small gaps and inconsistencies between parts.

Sanding helps remove traces of support structures and remaining inconsistencies in the model. Gently start sanding the surface with 150-grit sandpaper to remove traces of support structures and smooth edges where parts meet. Once the surface is smooth, sand it wet using 320 grit sandpaper to remove any remaining layer lines. Sand the surface in random motions so as not to leave marks. In most cases, these two methods will produce a fairly smooth surface, but you can continue to increase the grit of the sandpaper up to 2 times and, after wetting it, sand the entire model until the surface is reasonably smooth.

Power sanding is great for large flat surfaces, but can ruin fine details. Grinding of small models is recommended to be done by hand, and for large ones, a combination of manual and mechanical grinding is recommended.

Machining large parts with mechanical and manual grinding saves a lot of time. Power sanding is great for large, flat surfaces, but can ruin the fine details, sharp corners, and subtle contours that are typical of stereolithography. As a result of mechanical grinding, a lot of dust is also generated, so before starting processing, it is necessary to prepare the working area.

Note. The use of power tools requires full attention and the use of protective equipment.

The surface can be damaged very quickly without even realizing it, just by leaving the sander without moving.

When finished sanding the model, rinse it in soapy water to remove dust and debris and dry thoroughly before proceeding to the last step.

The primer helps the paint adhere to the surface and can indicate areas where additional sanding is needed or removal of traces of supports that you may have missed. The Universal Matte Gray Plastic Primer shows these spots exceptionally well. For best results, apply it to the surface in several thin coats. Sand critical areas and reapply a thin coat of primer. Repeat this process until the entire surface of the model is level.

Note. Use protective equipment during priming and painting, including a respirator to protect against paint fumes.

All-purpose matt gray primer for plastics is exceptionally good at showing fine details and helping to identify areas that need to be sanded down.

Find out more about sanding and priming in our detailed guide.

When painting with multiple colors, protect the model with a temporary coat. First, plan the order in which you will paint the model, depending on the color, transparency, and size of the area of a certain color. Start with small details so that fewer of them can be protected when painting with the main color. Apply painter's tape to the edges and corners. To quickly cover large areas, attach sheets of paper to them. Ribbon guides (laser cut) can also be useful for creating straight lines, circles and complex shapes.

When it comes to masking, figuring out the correct order is your first priority. In our case, the parts were first painted silver and the sections that would remain silver on the final part were then covered with painter's tape to hide them from the next l

painting. In our case, we first painted the parts silver and put masking tape on the areas that should remain silver in the finished model so that they do not get paint of a different color.

As with primer, several thin coats of paint should be applied for optimal results rather than one thick coat. Most spray paints will achieve the best color in warm and slightly damp conditions in the absence of wind. In this case, you must always follow the manufacturer's recommendations, which can be given on the paint container or in the technical documentation.

Consider the time the paint needs to dry: Allow layers to settle before applying the same color and allow the paint to dry completely before applying a new color.

The area where we applied masking tape is still silver.

Become an expert in painting 3D models with our detailed guide

Already wondering what your finished model will look like?

"Sorry sir, that R2-D2 over there is in excellent condition and not expensive."

Formlabs optics designer Adrien Tanner created this R2-D2 model from 105 parts printed on a Formlabs stereolithographic 3D printer. It even has working electronics borrowed from the Form 2 printer - a galvanometer drive for sound reproduction, a cartridge dispenser for lamps, and a Z-axis drive for dome rotation. 9The 0003

Form 3L is the first large format 30 x 33.5 x 20 cm 3D printer for producing massive industrial quality models.

Reduce order processing time when outsourcing or manual work when assembling large-scale 3D models. Now you can print large 3D models in their entirety on the Form 3L, the first affordable large format SLA printer.

Want to see how stereolithographic parts work? Explore our resources to learn more about stereolithographic resins, or request a free sample to evaluate print quality for yourself.

Request a free print sample

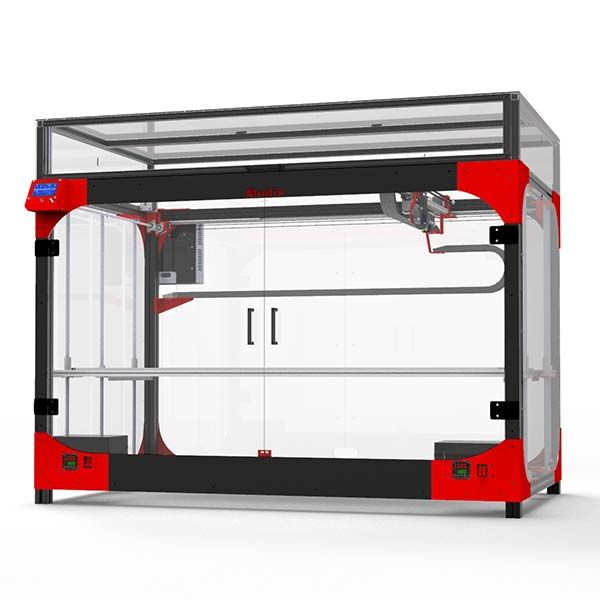

Admaflex 300

Admaflex 300OVERVIEW

Admaflex 300

Introducing the unique Additive Plant capable of print with ceramics and metals in large sizes . Optimized for the production of silicate shells and cores for precision casting.

Request a quote

Large build chamber volume

The Admaflex 300 is an extremely stable production equipment concept capable of handling a wide range of feedstock viscosities. The printer comes standard with assembly volume 200x200x300 mm. It is designed to meet the needs of customers using Admaflex technology as an alternative to investment casting technology.

Patented material feed system

The Admaflex 300 has a integrated high volume handling system with automatic controlled dosing that allows you to provide 3D printing of large products. The printer is designed to work efficiently with high viscosity materials such as ceramic mortars. This provides high reliability and speed for high throughput continuous production. This innovative system also makes efficient use of raw materials by reusing excess material.

Advantages:

-

Ability to produce large components

-

Clean workplace

-

Zero waste

-

Fast and easy switching between materials

- High flow

Modular concept

The Admaflex 300 is a modular additive plant that allows all future developments such as multi-material printing to be implemented. The client is also asked to select the build chamber resolution and volume that suits your needs.

Advantages:

Open platform

The Admaflex 300 is an open system that gives the full control over the printing process. The software has the ability to customize settings, allowing full control not only before but also during the printing process. This opens up the possibility of using different materials and gives you the freedom to develop your own solutions. A standard feature of our software is “multi-part printing”, which allows the to control the projector settings on every layer.

Advantages:

Optional Print Control System

Job Quality Monitoring is a great feature to keep track of the entire print process. This software and hardware complex controls temperature, humidity and film usage. This complex has a system with two cameras for real-time video tracking and frame-by-frame recording. This allows the user, for example, to partially stop printing a defective product in order to ensure successful completion of the remaining parts.

Advantages

ADMAFLEX 300 TECHNICAL DATA

| Technology | DLP |

| Build chamber dimensions (X,Y,Z) | 200 x 200 x 300 mm (80 µm) 200 x 160 x 300 mm (62.5 µm) 160 x 128 x 300 mm (50 µm) 100 x 89 x 300 mm (35 µm) *Optional Z-axis up to 500 mm |

| Layer thickness | 10 - 200 µm |

| Build speed | Up to 300 layers per hour |

| Printer dimensions | 1282 x 1900 x 1000 mm |

| The weight | 500 kg |

| Required ambient temperature | 22 +/- 2°C |

| Required ambient humidity | < 40% |

| Connectors | Ethernet, USB |

| Food | 110 / 230V |

| Compatible files | SLC, STL |

| End product density | Technical Ceramics > 98. |