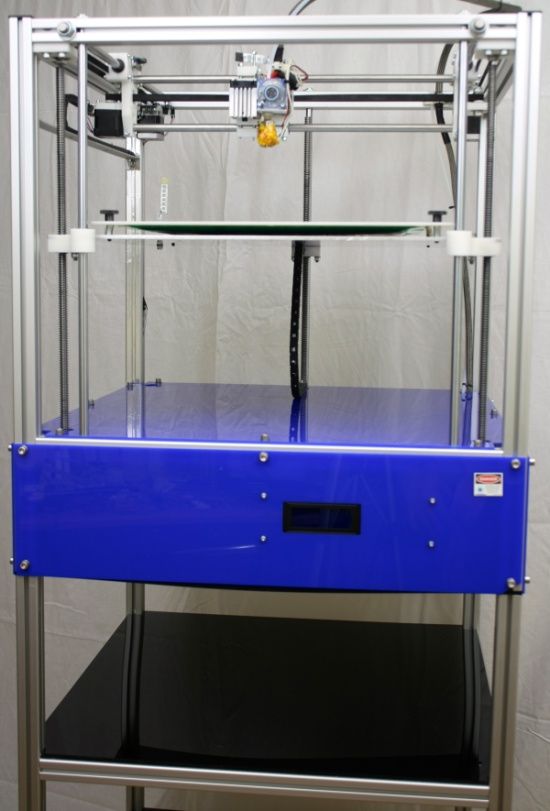

Roboze one 400 3d printer

Your Guide to the Roboze One +400

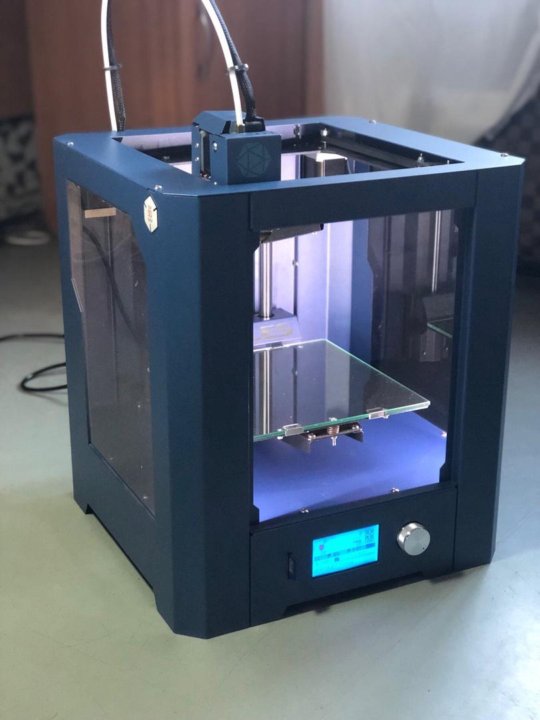

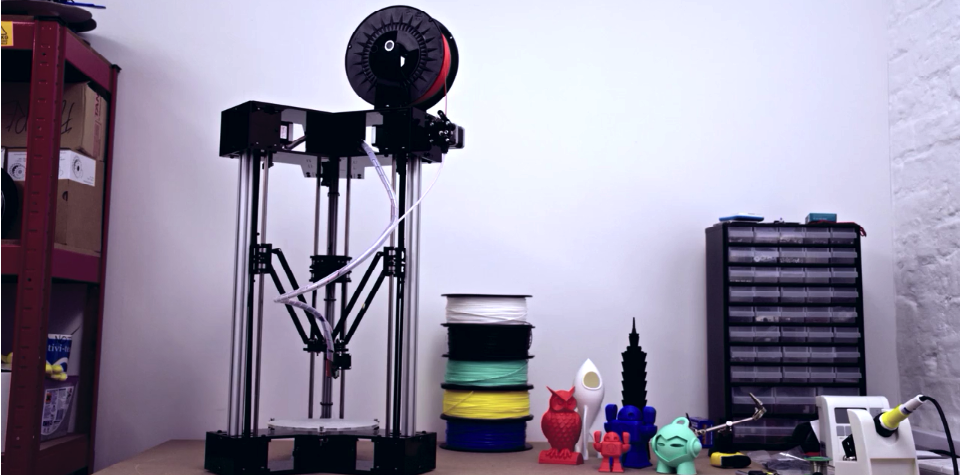

Engineers and designers, a word of warning: Whatever benchmark you have in your head for what the ultimate industrial desktop 3D printer looks and performs like, scrap it, because the Roboze One + 400 blows it away. But before we get into why that is the case, let’s discuss who the One + 400 is for, since Roboze also manufacture the regular One model.

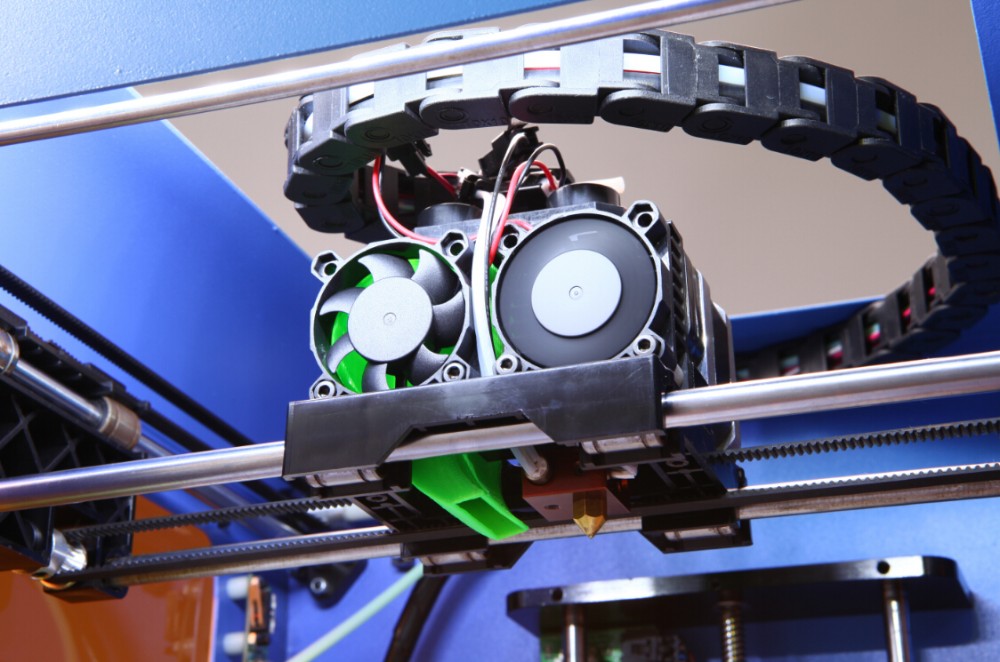

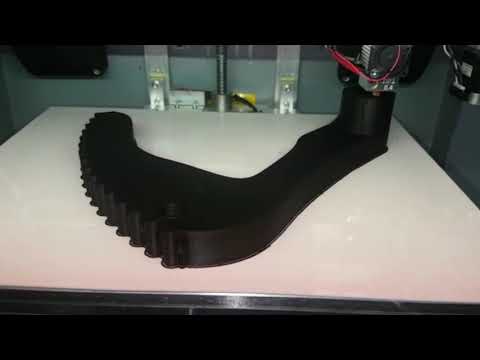

The Roboze One + 400 is for engineering and manufacturing applications, where there is a clear limitation to product and part design due to the standard range of thermoplastics / filaments available, such as ABS, PLA and Nylon. The Roboze One + 400 can 3D print with a much wider range of materials than the regular One model, and most other 3D printers, because it has dual extruders that can reach an operating temperature of over 400 °C, and because it has a heated build plate that can reach a temperature of 150 °C. Crucially, this means that you can print with PEEK (Polyether ether ketone), a high-performance material that is widely used in engineering and manufacturing applications.

The Ultimate Industrial Desktop 3D Printer?

With the ability to print with PEEK, thanks to dual extruders that can reach an operating temperature of over 400 °C, the Roboze One + 400 offers something that other industrial-grade desktop 3D printers do not. However, it is far from a one-trick pony, as we have duly found out after testing it ourselves.

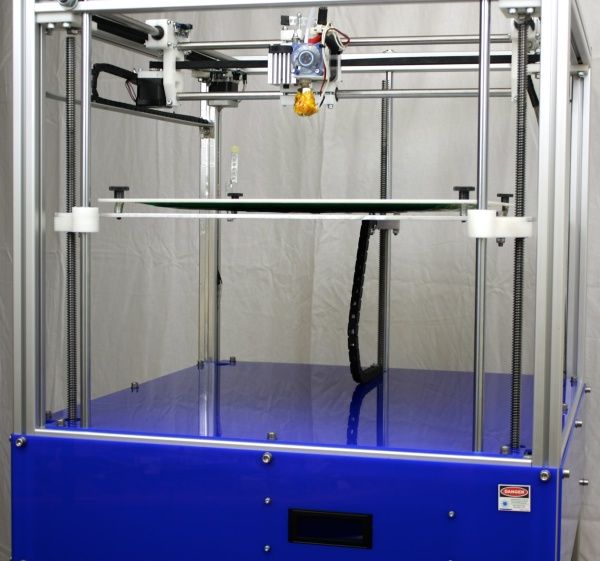

We have found the Roboze One + 400 to be extremely accurate and precise, not to mention extremely reliable and consistent, across hours of operation. It even offers a build volume that satisfies larger projects, and it has some of the highest quality mechatronics we have seen in any 3D printer, full stop.

But enough of the praise, already – let’s get into the features that make this 3D printer the machine it is, and the selling points that are going to sway you to invest in one for your workshop.

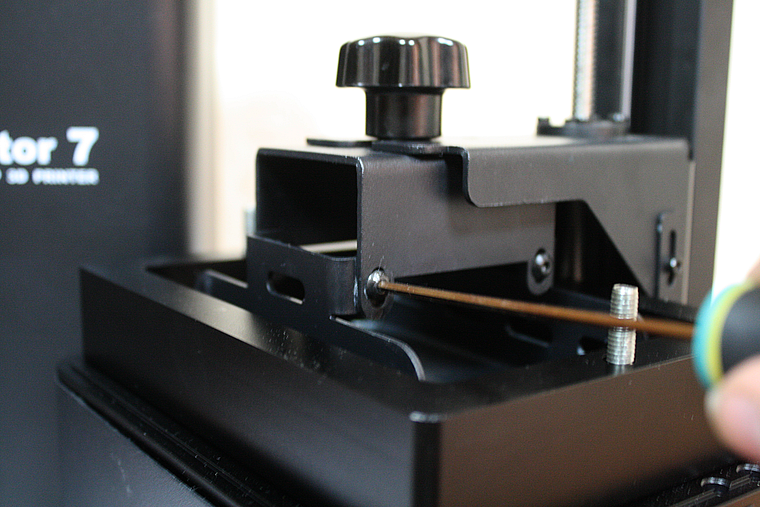

Patented Technology

One of the key reasons that the Roboze One + 400 has epic accuracy and consistency, is that it has no belts. Belts, for what it’s worth, are used in almost all desktop 3D printers to move things. Roboze has done away with this, by creating a new beltless system. This patented mechatronic movement is a work of art – it incorporates a counterbalanced pair of stainless steel helical racks with a pinion, for fluid motion, and as a by-product of this, it eradicates the dilation and contraction issues you may face with a ‘belted’ 3D printer. The result? More uptime, better consistency, and a more enjoyable 3D printing experience.

Belts, for what it’s worth, are used in almost all desktop 3D printers to move things. Roboze has done away with this, by creating a new beltless system. This patented mechatronic movement is a work of art – it incorporates a counterbalanced pair of stainless steel helical racks with a pinion, for fluid motion, and as a by-product of this, it eradicates the dilation and contraction issues you may face with a ‘belted’ 3D printer. The result? More uptime, better consistency, and a more enjoyable 3D printing experience.

It is quite clear when you cast gaze at this patented system, that a huge amount of research and engineering time went into it. It really is that good. But that’s not all – the Roboze One + 400 also has a C7 spindle ball screw on the Z axis with a flexible motor coupling for the absorption of vibration, for perfect resolution between layers, and every single component in the printer has been expertly CNC machined. So, in a nutshell, this is one 3D printer that has been built to perform, and to last.

Now, let’s move onto barebone specifications. The Roboze One + 400 can print at a layer height (resolution) of 50-200 microns with a precision accuracy of 0.05mm, and it has a 200 mm x 200 mm x 200 mm (xyz) build volume. The recommended print speed is 50 mm/s however you can turn that up to 80 mm/s with select filaments. It uses open source software, it has a 3.5″ touchscreen interface, and you can send files to print over USB or SD card. The only thing it misses out on is Wi-Fi.

12 Technical Materials – Limitless Applications

How far can we talk about the One + 400 without mentioning its extruders that can exceed 400 °C? Not very. And we’ve tried, really. But when a 3D printer is, by its very nature, defined by what it can print, you can’t knock us, or Roboze, who proudly state that this printer can print with 12 technical materials, to suit a wide range of engineering and design applications.

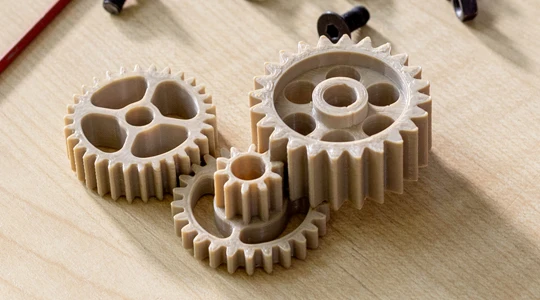

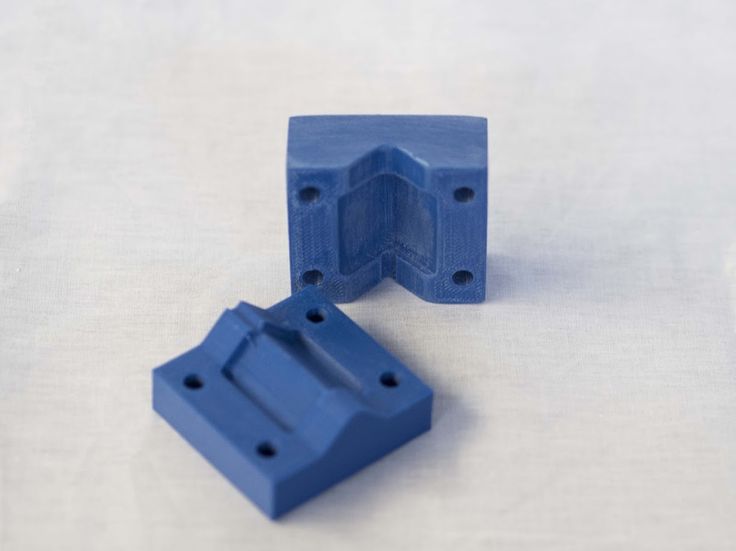

Perhaps the most impressive application, is metal replacement. Techno-polymer plastics have come a long way over the last twenty years, and it is now possible to create plastic parts that are as strong as metal, with impressive thermal performance to match. Carbonium is one such techno-polymer created by Roboze that offers this. Another important application is rapid production. The One + 400 has excellent print speed that’s suitable for small-series production.

Techno-polymer plastics have come a long way over the last twenty years, and it is now possible to create plastic parts that are as strong as metal, with impressive thermal performance to match. Carbonium is one such techno-polymer created by Roboze that offers this. Another important application is rapid production. The One + 400 has excellent print speed that’s suitable for small-series production.

Here’s everything you need to know about those materials:

Ultra:Prints at 200 – 210 °C with a bed temperature of 40 °C. Offers the definition and print speed of PLA, with the durability of ABS.

Strong:Prints at 240 °C with a bed temperature of 90 °C. This is an ABS-based material with special fillers for additional strength.

Functional:Prints at 220 °C with a bed temperature of 60 °C. This is a PolyAmide with good strength, flexibility and chemical resistance.

Flex:Prints at 215 – 225 °C with a bed temperature of 60 °C. This material mimics rubber, or silicone, with high wear resistance.

This material mimics rubber, or silicone, with high wear resistance.

Prints at 285 – 310 °C with a bed temperature of 110 °C. This is a polycarbonate filament that’s completely transparent.

PC/ABS:Prints at 270 °C with a bed temperature of 110 °C. Has the thermal properties of PC with the mechanical properties of ABS.

PMMA:Prints at 285 – 310 °C with a bed temperature of 110 °C. This is acrylic glass, or Plexiglass as it is often referred to.

Carbonium:Prints at 250 °C with a bed temperature of 100 °C. This is a polyamide with 40 per cent chopped carbon fibre.

PEI:Prints at 290 – 330 °C with a bed temperature of 150 °C. A polymer that’s self-extinguishing with good mechanical properties.

PVA:Prints at 180 – 190 °C with a bed temperature of 40 °C. This is a water-soluble support material, for printing with Ultra.

Prints at 245 °C with a bed temperature of 90 °C. This is a D’Limonene-soluble support material, for printing with Strong.

PEEK:Prints at 330 – 380 °C with a bed temperature of 130 °C. This is a chemically inert material with outstanding heat resistance.

Here’s an interesting video testing PEEK’s thermal inertia:

To find out more about the Roboze One + 400, check out our product page, or visit the official Roboze website.

[maxbutton id=”1″]

Roboze One + 400 Xtreme Archives

Posted on

In today’s 3D Printing News Briefs, we’re talking about new products and materials, an industry event, 3D printed electronics, and education. 3Doodler announced a new product, and Essentium will be showcasing two new materials at RAPID + TCT. The 4th annual AM Cluster of Ohio conference is coming up in July, and nScrypt is microdispensing 50um dots for 3D printed electronics. Finally, Penn State University is investing in Roboze technology.

The 4th annual AM Cluster of Ohio conference is coming up in July, and nScrypt is microdispensing 50um dots for 3D printed electronics. Finally, Penn State University is investing in Roboze technology.

3Doodler Introduces New 3D Build & Play

At the New York Toy Fair, February 22-25 at Manhattan’s Jacob Javits Center, 3Doodler will be showcasing its latest device – the 3D Build & Play, perfect for preschoolers and kindergartners to use. The pen was designed for users as young as four years old, and introduces growing children to 3D printing technology in a way that promotes cognitive and fine motor skills development, hands-on learning, story telling, and three-dimensional thinking. The 3D Build & Play is kid-safe, extruding low-heat, BPA-free, non-toxic, biodegradable plastic, and comes with a story-based Activity Guide so parents and kids can create together. Currently available for pre-order, 3D Build & Play will have an MSRP of $29.99, and major retailers, like Amazon, are also expected to carry the product in Q2 2020. Visit 3Doodler in Booth #2771 at the New York Toy Fair to learn more.

Visit 3Doodler in Booth #2771 at the New York Toy Fair to learn more.

“3D Build & Play brings the creative fun of our Start pen without the learning curve for the youngest users. The system we have developed, that lets kids crank and create in 3D, is a major benefit for parents looking to improve their children’s basic motor skills. The included molds make it easy to create 3D objects by simply filling and popping them out. There’s nothing on the market today that makes 3D creation this simple or fast for young creators,” said 3Doodler’s CEO Daniel Cowen.

Essentium’s New Materials for High-Temperature Applications

At RAPID + TCT 2020 in Anaheim this spring, 3D printing solutions provider Essentium will introduce new ULTEM AM9085F and ABS materials for high-temperature industrial AM applications. These high-performance materials, which will be showcased on the company’s High Speed Extrusion platform at the event, provide high strength and have excellent resistance to heat and chemicals at high temperatures, so they can be used for applications in the aerospace, automotive, industrial, and medical industries.

These high-performance materials, which will be showcased on the company’s High Speed Extrusion platform at the event, provide high strength and have excellent resistance to heat and chemicals at high temperatures, so they can be used for applications in the aerospace, automotive, industrial, and medical industries.

According to a survey commissioned by Essentium, 51% of executives believe that the high cost of materials is a major obstacle when it comes to adopting 3D printing for large-scale production purposes. The new ULTEM AM9085F and ABS materials were created to give manufacturers a more cost-effective solution when compared to expensive closed-system materials. Learn more at Essentium’s Booth #3400 at RAPID + TCT in Anaheim, CA, April 20-23, 2020.

4th Annual Additive Manufacturing Cluster of Ohio Conference

The Additive Manufacturing Cluster of Ohio, powered by organizations such as America Makes and the Youngstown Business Incubator, has announced that its 4th annual conference will take place this summer in Cleveland. Cluster members work together to create a supply chain of interconnected institutions and businesses to advance regional growth in 3D printing. This conference, to be held on Thursday, July 30, at the Embassy Suites by Hilton Cleveland Rockside, will be the first cluster event of 2020, and will give Ohio manufacturers of multiple business models and sizes perspectives on available opportunities for adopting 3D printing into their process chain over the next five years.

Cluster members work together to create a supply chain of interconnected institutions and businesses to advance regional growth in 3D printing. This conference, to be held on Thursday, July 30, at the Embassy Suites by Hilton Cleveland Rockside, will be the first cluster event of 2020, and will give Ohio manufacturers of multiple business models and sizes perspectives on available opportunities for adopting 3D printing into their process chain over the next five years.

The website states, “The program will look at similarities and differences across several selected manufacturer types and will identify strategies ranging from low to high risk. Attendees will leave with actionable strategies and information about regional resources to help them remain competitive in the evolving manufacturing landscape.”

nScrypt Working with 3D Printed Electronics

Orlando company nScrypt is working with precision microdispensing, an additive method of dispensing pastes, inks, and other fluid materials, to create adhesive dots with volumetric control, in the 50 micron range, for 3D printed electronics and flexible hybrid electronics (FHE). Microdispensing gets much closer to the substrate surface when compared to methods like jetting, and the closer the nozzle is to the surface, the finer the features of the 3D printed parts. The team used the nScrypt SmartPump, a silicone adhesive, a conical pen tip, and Heraeus SAC305-8XM8-D Type IX solder paste, and tested the consistency and repeatability of ~50µm Type IX solder and adhesive dots.

These tests showed a consistent average dot diameter of 51.24 microns, with a 6.42 micron (13%) standard deviation. These results support the fabrication of 3D printed electronics through the use of direct digital manufacturing (DDM), which allows printing to both planar substrates and the non-planar world of Printed Circuit Structures, which prints the housing or structure of an electronic device as well as placing the electronics conformally. In the future, the team plans to conduct a larger solder and adhesive dot study, in order to test required downtime, long-term reliability, and the frequency of clogging.

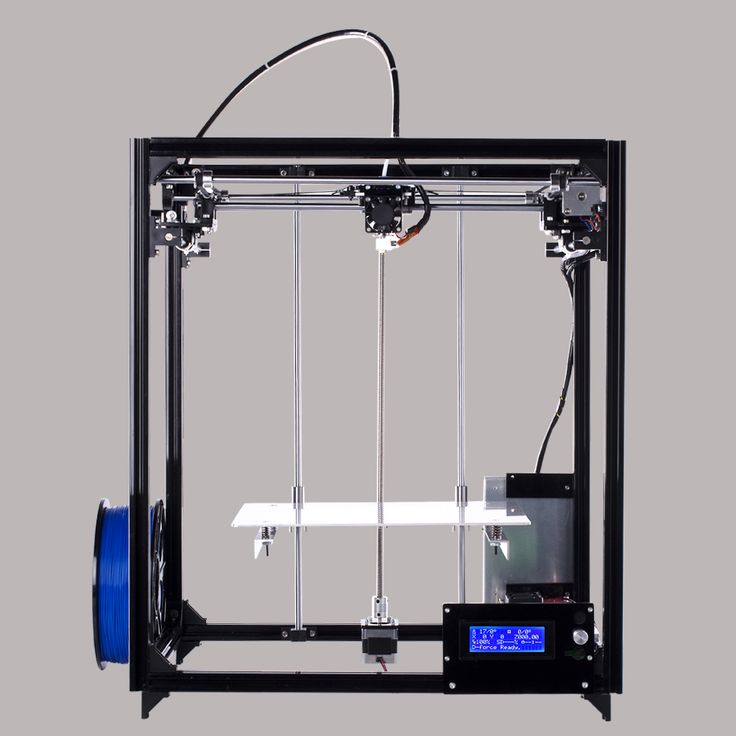

Penn State University Invests in Roboze Technology

Penn State, a 3D printing leader through its Center for Innovative Materials Processing through Direct Digital Deposition (CIMP-3D), has invested in a new FFF solution in order to expand its AM capabilities. The ROBOZE One+400 Xtreme 3D printer, which was designed to create high performing, functional finished parts in advanced composite materials, will help the university increase its development of high performance plastics for 3D printing, and will be housed in the Department of Chemical Engineering. Students will be able to test out new polymers on the system, and develop new formulations to provide 3D printed parts with multi-functionality. These parts will be used to advance research in applications like chemical reactors.

“ROBOZE One+400 Xtreme will be used to examine novel polymers to help to fundamentally understand the 3D printing process and as a tool to enable custom equipment more cost effectively than can be obtained with machining metals while also allowing for designs not possible with traditional manufacture.

The ROBOZE One+400 Xtreme will allow Penn State to leverage its expertise in materials science, engineering and characterization to enable new solutions to problems through additive manufacturing,” said Professor Bryan D. Vogt from the Department of Chemical Engineering.

“The ability to use custom filaments and control the print processing was a critical factor in selecting ROBOZE. The flexibility allowed by ROBOZE along with its excellent printing capabilities is well aligned with the discovery-oriented research mission of the university to expand knowledge and its application. Moverover, our prior 3D printer had issues printing high temperature engineering plastics like PEEK with severe deformation of the structure generally observed. After challenges with printing PEEK with standard belt driven systems, the novel direct drive approach with the ROBOZE was an added bonus.”

Discuss these stories and other 3D printing topics at 3DPrintBoard.com or share your thoughts in the Facebook comments below.

The post 3D Printing News Briefs: February 21, 2020 appeared first on 3DPrint.com | The Voice of 3D Printing / Additive Manufacturing.

Posted on

Roboze, a leader in functional 3D printed prototypes produced in industrial materials like PEEK, CarbonPA, and ULTEM AM9085F, manufactures 3D printers that can handle high-performance, high temperature polymers, such as SABIC’s LEXAN EXL AMHI240F. Now, the company is getting extreme with FFF 3D printing, with an announcement about the new desktop production 3D printing series it will debut at next week’s formnext in Frankfurt.

“The new Xtreme solutions, is the result of intense work by the entire Roboze team, that has allowed us today to create a new line of systems capable of meeting the most extreme needs of our customers, offering greater versatility in the materials and accuracy of the prints as well as better performance,” said Alessio Lorusso, CEO & Founder of Roboze.

“We have rewritten the history of 3D printing and the Formnext 2018 represents the best showcase to tell the story.”

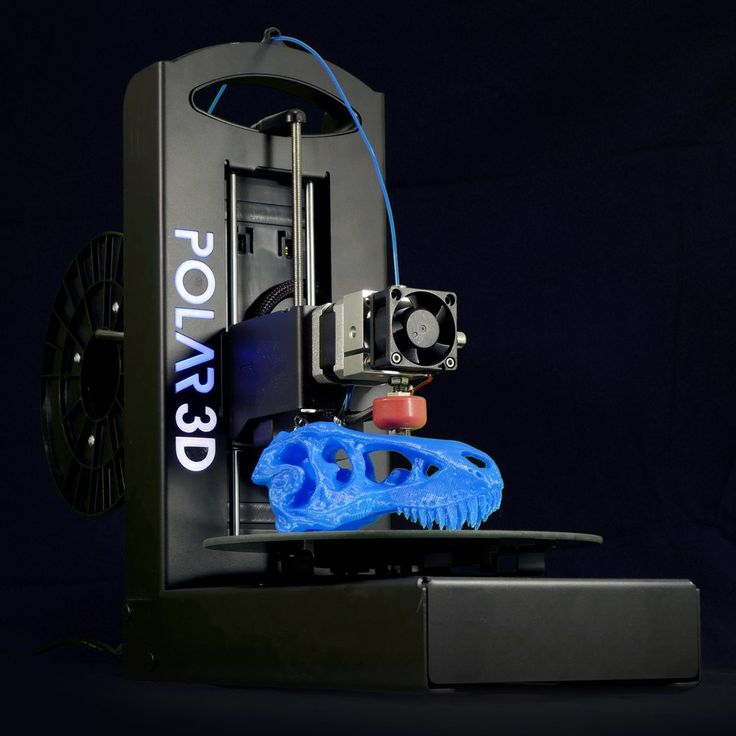

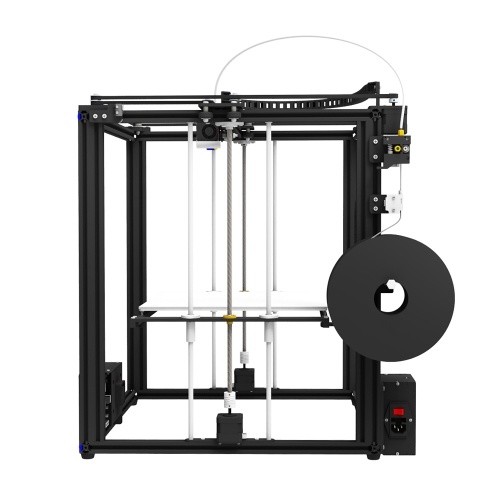

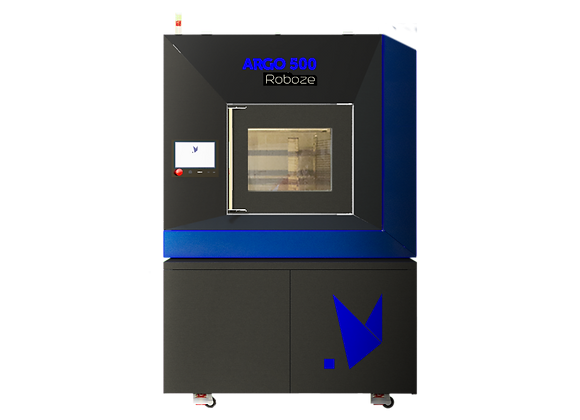

The new Xtreme 3D printer series, made up of the Roboze One Xtreme and Roboze One + 400 Xtreme, will strengthen the company’s PEEK and CARBON PEEK solutions for FFF 3D printing, bringing users closer to true additive production.

Roboze has become a major manufacturing player thanks to its innovative technology, like the Beltless System that allows operators from around the world to 3D print both finished parts and prototypes with 25-micron mechanical tolerances, which all but guarantees repeatability and, as the company puts it, “immediate economic advantages.”

But this new Xtreme series launch is an even bigger deal for the company, as it sets up a point of contact between the production ARGO 500 3D printer and its desktop One and One + 400 systems.

Rocco Maggialetti, head of the mechanical design of Roboze, explained, “The strong collaboration between all the members of Roboze’s R & D team has allowed us to design this new system that improves the previous one, guaranteeing longer useful life of the machine.

”

The newly designed covers for the Xtreme 3D printers are made of sheet metal, and designed to lower maintenance on the machines while also improving their robustness. In addition to providing a more elegant aesthetic, this new feature also makes the Roboze Xtreme series extremely quiet.

The Roboze One Xtreme and Roboze One + 400 Xtreme 3D printers were built by Roboze engineers who changed up the status quo in order to offer extremely versatile and accurate 3D printing solutions. The series feature a new, advanced sensor system, which includes an endstop aimed at leveling the semi-automatic plan, WiFi and USB connections, motor encoders for closed loop control that monitor the printing process, and optical endstop/touchless, which promises less maintenance because it decreases typical issues.

The Beltless System on this new 3D printer series has also evolved from the original, and features racks machined with chemical nickel plating. This lowers the contact friction between the rack and pinion for faster print speed, and also increases the resistance to wear and corrosion.

The Xtreme series also includes a Cabinet Support System (SSC), which is meant for unloading machine vibrations and controlling material temperatures, as well as storing coils so they’re not exposed to atmospheric agents. Just like with the ARGO 500 and the Roboze One + 400, these new 3D printers also house a Vacuum Box for vacuum generation, which provides greater first-layer flatness and print surface adhesion for faster 3D printing.

Roboze 3D printers are certainly impressive, thanks in large part to the versatility of materials they can handle. Many of these were developed specifically to add enhancements to parts with properties not dissimilar from metals. In addition to its Xtreme desktop production 3D printer series, Roboze is also introducing several new materials at formnext 2018.

Carbon PP is the first, and is good for use in automotive applications, because it promises the same high performance of PP (polypropylene), combined with the advantages of carbon fiber.

“Carbon PP’s carbon fiber provides a 25% resistance increase level compared to PP. The addition of specially selected carbon fibers improves the mechanical properties of the material and increases its HDT maintaining its properties even at a higher temperature than that of PEEK,” said Maria Luisa Geramo , PhD, Head of Applications – Roboze R&D Material Engineer.

According to Roboze, its new PP has excellent electrical insulating properties and high resistance against abrasion, chemical agents, and shock, and “represents the most commodities polymer primarily used in applications for objects of common use and automotive components,” while its new Glass PA – a polyamide loaded with glass spheres – is a good electrical insulator, and ensures high dimensional stability because it has lower moisture absorption and increased mechanical properties when compared to standard polyamide.

Carbon PEEK, which has excellent mechanical properties and thermal stability, is already used with the company’s ARGO 500 production 3D printer, and is the only new material that’s available for use solely on the Roboze One + 400 Xtreme.

Come see all of Roboze’s new 3D printing materials and solutions at next week’s formnext – visit the company at booth C78 in Hall 3.1.

Discuss this news and other 3D printing topics at 3DPrintBoard.com or share your thoughts below.

ROBOZE 3D printers

Application

Application

Professional

Industrial

Personal

Commercial

3D printer type

3D printer type

Tabletop

Food

Professional

For home

Chocolate

Jewelry

Russian

Reprap

Dental

Full color

Industrial

Not expensive

Medical

For training

Material type

Material type

Plastic

606

Metal

50

Photopolymer

245

Other

144

Manufacturer

Manufacturer

3D Systems

84

PICASO 3D

8

Stratasys Ltd

38

Leapfrog BV

6

EnvisionTEC

51

Myriwell

4

3D-Experts

3

PrintBox3D

4

FELIXrobotics

11

Solidoodle

8

WANHAO

32

ROKIT

5

SeeMeCNC

4

mUVe 3D LLC

1

RepRapPro

5

Formlabs

9

Afinia

1

Airwolf 3D

6

Type A Machines

2

iRapid

1

RoBo 3D Printer

3

Mixshop Inc

4

IonCoreLtd

1

Old World Laboratories

1

XYZprinting

13

Panowin Technologies Co. , Ltd.

, Ltd.

2

MiiCraft

7

Portabee 3D Printer

2

Zeepro

1

Pirate 3D

1

Qualup SAS

2

BEETHEFIRST

3

Heacent

2

Robot Factory

2

Kuhling&Kuhling

1

3Dfactories

3

Tangible Engineering USA Corporation

1

DWS Lab

1

Sedgwick

2

3DJoy

4

Futura Elettronica

1

Makible Ltd

2

ALT Design

1

Active 3D

2

Trinitylabs

1

Sumpod Ltd.

4

Brahma3

1

Hyrel 3D

5

Omni3D

4

BCN3D Technologies

7

Boots Industries

2

ORD Solutions

2

Ironvault

1

2PrintBeta

3

Unique Design

3

Hot Proceed

1

3DD Plas

2

York3dPrinters

1

Code-P

4

Deezmaker

3

Ruian Maitian Network Technology Co

2

CB-Printer

1

Print Technologies Pty Ltd.

5

MaukCC

1

Choc Edge Ltd

2

Shenzhen WeisTek Co.,Ltd

5

Delta Tower

2

Tegelbeckers Ltd

1

Deltaprinter

1

MindKits

1

Robot Co, Ltd

1

Romscraj

2

Fabmaker

1

Peerbhai Robotic

1

Sintermask GmbH

1

KL Services Group Inc

1

Fochif Mechatronics Technology Co. , Ltd

, Ltd

4

Teil3

1

Maker's Tool Works, LLC.

2

Gaminu

1

re:3D

1

inDimension3

4

Acuity Design

1

Essential Dynamics

1

Isis3D

1

Velleman

1

Kentstrapper

4

Blue Eagle Labs

1

Gubbels Engineering

2

Zortrax

8

3dBotic

1

MakerGear, LLC

1

Jelwek

1

it is 3D

2

Cablysa Systems, S. L.

L.

3

Ac123Dc

1

E3D Online

1

Hydraraptor

1

MakerBot Industries, LLC

8

Delta Micro Factory Corporation

3

Ultimaker B.V.

11

Solidscape Inc.

8

MBot3D

4

B9Creations

4

Jinhua Flashforge Technology Co., Ltd

26

Tinkerine Studio Ltd

3

Aleph Objects Inc.

4

DeltaMaker

1

Reprap Austria

3

IC3D LLC.

1

Ultibots, LLC.

2

Intelligent Machine Inc.

1

Metamaquina

1

Shenzhen Mootooh Engineering Co., Ltd.

1

Multitec GmbH

3

German RepRap GmbH

3

Sharebot

17

Nova 3D

1

QU-BD Inc.

4

RDMCU

1

Full Spectrum Laser LLC

1

PieceMaker Technologies

1

Printbot, Inc.

7

Terawatt Industries

1

botObjects

1

Lunavast

2

Maker Farm

3

NWRepRap

1

eMotion Tech

1

Printed Worlds

1

Reprapsource

1

Twelvepro Co

1

Replicator Warehouse

1

Stellamove Inc.

1

Make Mendel

6

Rapide 3D

2

Makealo

1

Crew Ltd.

1

Open cube

1

3D Kits

1

Coombes Solutions Ltd.

1

SHARK Limited Partnership

1

Smartfriendz

1

3D Monster

1

Kikai Labs

2

THY3D

1

Tantillus

1

RepRap Diffusion

1

QSQM International Co.

1

Tumaker

1

Makism 3D Corp.

3

3dBotZ

1

ZMorph 3d

1

Eckertech Inc.

1

Imec Proto

6

miniFactory Oy Ltd

1

printMATE 3D

1

CMET Inc.

5

Arcam AB

6

3Geometry Manufacturing Systems Pvt Ltd

8

Electro Optical Systems

15

Trump Precision Machinery Co. , Ltd

, Ltd

4

Wuhan Binhu Mechanical & Electrical Co., Ltd.

11

Optomec Inc.

1

Shaanxi Hengtong Intelligent Machine Co., Ltd.

9

Matsuura Machinery Corporation

1

ExOne Company, LLC

6

Concept Laser GmbH

9

Instrument Tech Co, Ltd

7

UnionTech

8

Renishaw plc

2

D-MEC Ltd.

3

Realizer GmbH

5

SLM Solutions GmbH

5

Fabriconic LLC

3

Mark Forged

8

Keyence Corporation

2

SYS + ENG

1

Lithoz GmbH

1

DWS s.r.l.

12

Beijing TierTime Technology Co. Ltd

17

Carima

3

Mcor Technologies Ltd.

3

Asiga

11

Rapid Shape GmbH

14

solido ltd.

1

Blueprinter ApS

1

Kevvox Pte Ltd.

2

JER Education Technology Co., Ltd

1

Azuma Engineering Machinery Inc.

2

Space Monkey

1

Trimaker

1

Most Fun

1

Iniciativas 3D

1

IdeaLab 3d

1

MendBot Labs

Bonsai Lab

2

MakerDreams

1

i3Dbot Co. , Ltd

, Ltd

2

Natural Machines

1

Cyrus3D

ITALYmaker

Something3D

Cagelli Distribution

E Crew Vis

BigRep GmbH

2

Voxeljet Technology GmbH

5

Sciaky Inc.

Mankati

4

F&B rapid production

3

3DQuality

17

Workshop Churyumov

2

Unimix

2

Center for Additive Technologies

3

ENNOVA

1

Exclusive Solutions

2

Magnum

5

SHEKLA

1

D-Force

3

BigRep

4

Roland

1

Alphabet 3D

2

MAKEX

1

3D Master Kit

7

Shining 3D

25

3NOVATICA

3

AVS Robotics

1

IMPRINTA

11

Createbot

5

AIO Robotics

1

RK-3D

1

SPETSAVIA

3

3DiY

14

Wonwall

1

Apium Additive Technologies

3

3DSUN

1

Cheap3D

1

3rd

1

EGL3D

1

Creality 3D

42

UNIMATECH

2

VolgoBot

3

ZVER 3D

3

Zenith

2

MicroFactory

1

Hewlett Packard

2

Shenzhen Anet Technology Co Ltd

15

MASS PORTAL SIA

11

Cyberon

2

PHOTOCENTRIC

2

TotalZ

11

3dcon

2

Raise3D

6

OOO RUSSIAN ENGINEER

1

Vortex-3D

5

Flying bear

11

Print3D

5

ROBOINO

1

SoloPrint

1

Fun Distribution

1

Alekmaker

2

Cronos

2

TEVO 3D

9

3D printers from China

2

ZAV 3D printer

4

Epo3d

1

FLSUN 3D

3

WINBO

19

PROTOTYPE

1

UNIZ TECHNOLOGY

2

W2P Engineering GmbH

4

MAESTRO

1

Pi 3D printer

1

Shenzhen Tronxy Technology Co

23

Kelandi

1

Geeetech

21

3DCeram

2

Omaker

1

Builder 3D Printers

6

Creatable Labs

1

ROBOZE

3

Desktop Metal

1

Sintratec

2

CreatBot

10

ANYCUBIC

29

3dlaboratorio

2

OOO SPC "Lasers and Equipment"

2

Prusa Research

6

Prismlab

3

ivilol

2

Geralkom-3D

7

EqMex

1

Tsar3D

2

Zhuhai CTC Electronic Co. , Ltd

, Ltd

3

Shenzhen Aurora Technology Co., Ltd

6

Monoprice

1

Shenzhen Salon Technologies Co., Ltd.

1

Shenzhen Sundystar Technology Co., Ltd

2

Shenzhen Easythreed Technology Co., Ltd

1

WOW Innovation Technology Co., Ltd.

2

Jinhua Xingzhe 3D Technology Co., Ltd

1

Shenzhen Zhongxin Microscience Software Co., Ltd.

1

Shenzhen Yaying Trading Co. , Ltd

, Ltd

5

Z Bolt Co.

2

Anisoprint

1

Shanghai 3D ARTEL Science and Technology Co.

3

FABERANT 3D printers

1

Self-assembly 3D printers

4

Z Rapid Tech

21

Zonestar

13

3DGence

3

BLB Industries

1

Hard Light

1

Stereotech

2

TPM3D

7

Artillery

4

Phrozen Tech Co. , Ltd.

, Ltd.

8

INDIGO 3D

1

Aconity3d

6

OR Laser

3

Farsoon Technologies

5

QIDI Technology

11

Shenzhen Twotrees Technology Co., Ltd.

7

Mingda

18

Elegoo

14

Longer

9

Sunhockey

2

DUPAS3D

1

Kelant

5

Voxelab

3

DIYMARIA

1

VSHAPER

CREASEE

CNC Barcenas

5

Vistar

11

Kingroon

1

IdeaFormer

3

F2 Innovations

3

Sindoh

8

Eplus3D

8

Print Technology

Print Technology

Plastic Jet Printing (PJP)

8

MultiJet Modeling (MJM) Technology

1

SLA printing technology

Sterolithography (SLA) technology

2

Film Transfer Imaging (FTI)

MultiJet Printing (MJP)

20

Multi-Jet Modeling (MJM) Technology

2

Stereolithography (SLA)

115

Selective Laser Sintering (SLS)

65

Direct Metal Sintering (DMS)

6

Granular

5

Fused deposition modeling (FDM/FFF)

962

DoD/SCP Technology

6

PolyJet 3D printing Technology

19

The EnvisionTEC 3D-Bioplotter 3D printing technique

2

Direct Light Projection (DLP)

31

Photopolymerization

Digital Light Projection (DLP)

5

Digital Light Processing (DLP)

64

Additive Layer Manufacturing (ALM)

2

Laser Stereolithography (LSLA)

1

Direct Light Processing (DLP)

1

Electron Beam Melting (EBM)

6

Laser welding CLAD

6

Laser sintering (LS)

4

Layer by layer manufacturing (LOM)

5

Selective laser melting (SLM)

31

Laser Engineered Net Shaping (LENS)

1

Direct Metal Laser Sintering (DMLS)

11

Laser metal melting (LC)

10

Direct Metal Tooling (DMT)

7

Solid Creation System (SCS)

3

Ultrasonic Additive Manufacturing (UAM)

3

Composite Filament Fabrication (CFF)

1

Drop on Demand (DOD)

1

Lithography Ceramic Manufacturing

1

Melted and Extruded Modeling (MEM)

7

Drop-On-Demand (DOD)

Sliding Separation Process (SSP)

9

Smooth Curvature Printing (SCP)

2

Plastic Sheet Lamination (PSL)

1

Selective Heat Sintering (SHS)

1

ColorJet Printing (CJP)

7

Micro-SLA

1

DLP-SLA

3

WDM (Layer Waxing)

2

SLA-sla

Direct Metal Printing (DMP)

7

HP Multi Jet Fusion technology

2

3D Daylight Polymer Printing (DPP)

2

Smart-Positioning-System Technology (SPS)

2

LCD Stereolithography

62

UV LED DLP

4

Single Pass Jetting (SPJ)

1

Atomic Diffusion Additive Manufacturing (ADAM)

1

bioprinting

3

Powder Binder Jetting (PBJ)

10

Reset Filters

The new Roboze One+400 3D printer works with PEEK, ULTEM and other materials

Some products will produce a boy, others a girl. Do you think so too? Many future parents do not bother whether they will have a boy or a girl - as they say, the main thing is that the child is healthy. But there are also those who ...

Do you think so too? Many future parents do not bother whether they will have a boy or a girl - as they say, the main thing is that the child is healthy. But there are also those who ...

How does IIS work and what is it? Many smart people do not accumulate money, but make it work and multiply. In recent years, it has become unprofitable to make a deposit, because interest ...

How does a windfinder work? Are there devices to help nurses find veins to give an IV? — Similar devices exist. Technology of operation of a venom detector ...

How pre-5G from MegaFon works Mobile operator MegaFon has recently launched a new pre-5G option, which can significantly increase the speed of mobile Internet. Telling…

She works in the library… Sounds boring? But in fact, in the temple of books there is so much magic that you never dreamed of. For example, a Kemerovo resident Sofya Poddubskaya, one of the employees of the State ...

For example, a Kemerovo resident Sofya Poddubskaya, one of the employees of the State ...

Telegram does not work Messenger users report that it does not open. Also, some cannot upload photos and videos, or send messages.The post Te …

VPN does not work on iPhone. What to do Some foreign services, such as Netflix, have ceased operations in Russia and restricted access for users of our country to their content ... Whatsapp. Messages were not received or sent, …

What is blockchain and how does it work Blockchain technology, like cryptocurrencies based on it, is traditionally surrounded by an aura of inaccessibility. Although the principles of the blockchain are quite simple even …

Subway does not work in Kharkov Subway does not work in Kharkov, power went out in some areas. It is reported by RIA Novosti with reference to local publications. …

It is reported by RIA Novosti with reference to local publications. …

TASS: air defense works over Donetsk A TASS correspondent reports that an air defense system is working over Donetsk. According to the mayor of the city Alexei Kulemzin, which he published in Telegram ...

Air defense works over Belgorod again The operational headquarters of the Belgorod region reported that an air defense system (AD) is working over the territory of the region. Residents of the regional center …

What works at night in Stavropol? If you've been waking up at night with a toothache or wishing your friends happy birthdays, then you're familiar with the fussy search for the right place that works in …

Morata: "I don't understand how VAR works" Atlético Madrid striker Alvaro Morata was left confused by the refereeing of yesterday's Spanish Championship match against Rayo Vallecano.

Syrian air defense works in the vicinity of Damascus Syrian air defense systems reflect an air strike in the sky over Damascus and its environs, the Ikhbariya news agency reports on October 21. According to …

What is 3D printing and how does a 3D printer work? A lot has changed since then, and today 3D printers are showing amazing results and allowing you to create everything you can imagine - from children ...

Tiny TV Introduced - And It Works! American startups have launched the TinyTV Mini, one of the smallest TVs in the world. Unfortunately, he does not broadcast on-air channels, …

The Mostbet website is not working, what should I do? Currently, you can find dozens of sites of various bookmakers on the Internet. The player can place bets at any bookmaker, g …

WhatsApp has been down for more than an hour Failures are observed around the world. Some users are unable to send a message, others notice problems connecting to the server.1650 The City Attorney sued a construction company to impose an obligation to commission elevator equipment in an apartment building. In press …

Some users are unable to send a message, others notice problems connecting to the server.1650 The City Attorney sued a construction company to impose an obligation to commission elevator equipment in an apartment building. In press …

An air defense system is working in the sky over Kherson An air defense system is supposedly working in the sky over Kherson, four powerful explosions thundered. This was reported by a correspondent of RIA Novosti from the …

Explosions are heard in Zaporozhye and air defense is working Explosions and the operation of air defense systems are heard in the city of Zaporozhye, which is under the control of the terrorist Kyiv regime. About it 12…

Elevator has not been operating in a ten-story building in Kursk for a year The city prosecutor filed a lawsuit against a construction company to impose an obligation to commission elevator equipment in an apartment building. In press …

In press …

Why is the Bryansk Sports Palace still not working? As it turned out, the Palace is really idle: they don't go in for hockey, figure skating, and they don't go skating on days off. …

A palliative service has been operating in Orel for several years. She provides free assistance to patients in serious condition. They provide the necessary equipment to families who are faced with a terrible diagnosis …

Seven explosions thundered in Belgorod: air defense is working The Russian air defense system destroyed seven missiles in the sky over Belgorod, RIA Novosti reports.

Alfa Romeo is working on an exclusive supercar 9

Hotspot mode on iPhone 14 does not work. What to do A month and a half ago, Apple introduced a new line of iPhone 14 Apart from the almost complete lack of differences between the basic versions . ..

..

Wink is working on a content extension program The press service reminded that the video service is developing as a multi-format digital platform, a complementary digital platform is already presented there, as well as in ...

Apple is working on a new operating system SiriOS will compete with HongmengOS for IoT systems. At the beginning of the month, insiders reported on the preparation of a new Huawei operating system. And …

Grulyov about Zakharyan: “He is working on himself. Well done!" Vyacheslav Grulev shared his opinion on the game and work in training of his teammate and midfielder of the Russian national team Arsen Zakharyan. …

How many Russians are working in Kazakhstan today? Since the start of mobilization, thousands of Russians of working age have left for a neighboring country. In what areas can they find their application? …

In what areas can they find their application? …

Sony working with Naughty Dog on 'favorite franchise' Sony's new in-house development team is working with Naughty Dog to develop a game based on 'favorite franchise'. Earlier this week, the headquarters of #MYVMESTE 9 is working in the Bryansk region during the …1650 In the Center for Culture and Leisure in the village of Glinishchevo, Bryansk District, the work of the #MYVMESTE headquarters continues to help the mobilized and their families, story ...

Kursk deputy Yevgeny Maslov works in the DPR personal videos and photos from the territory of the 4th district of Kursk. - ...

How the brain works when you decide to help someone Researchers from the Karolinska Institute in Sweden have shown that the same system in the brain that allows us to avoid danger is also activated when “n .