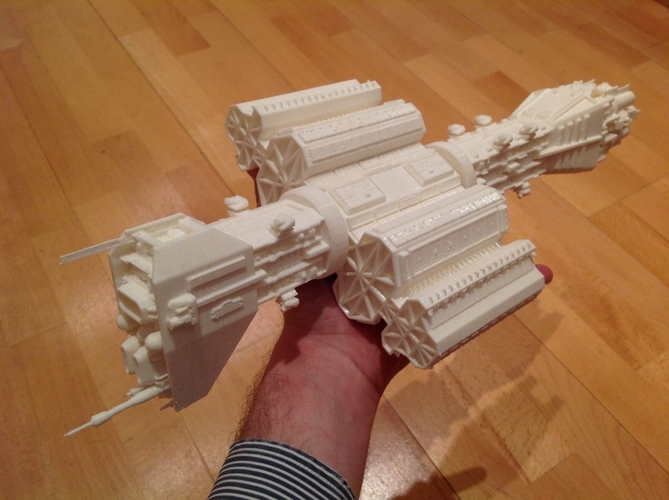

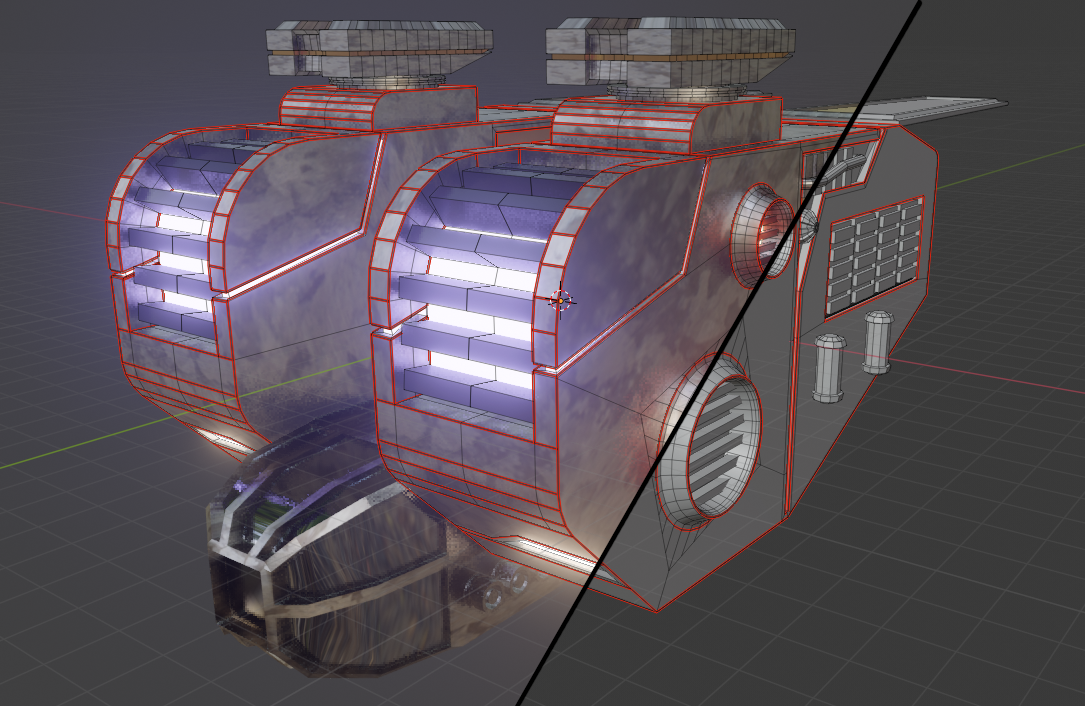

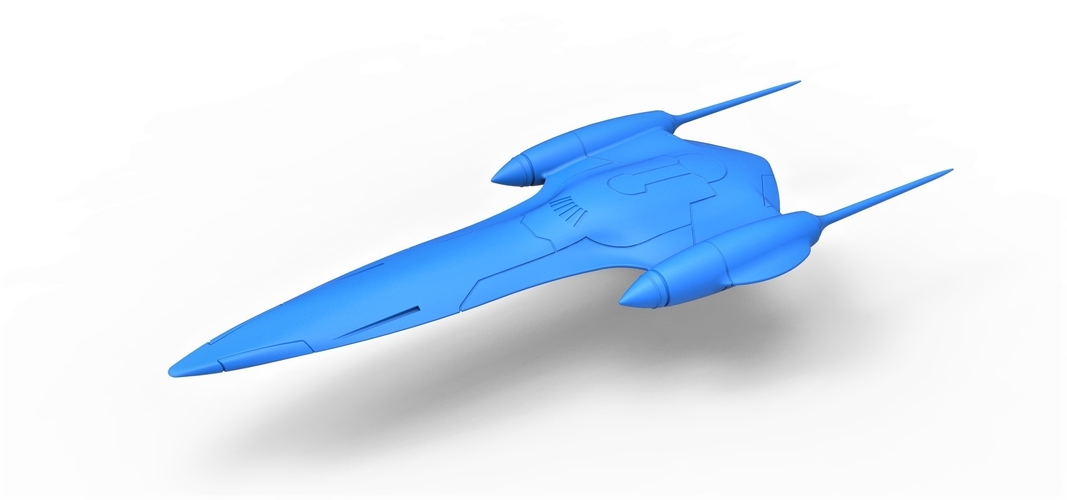

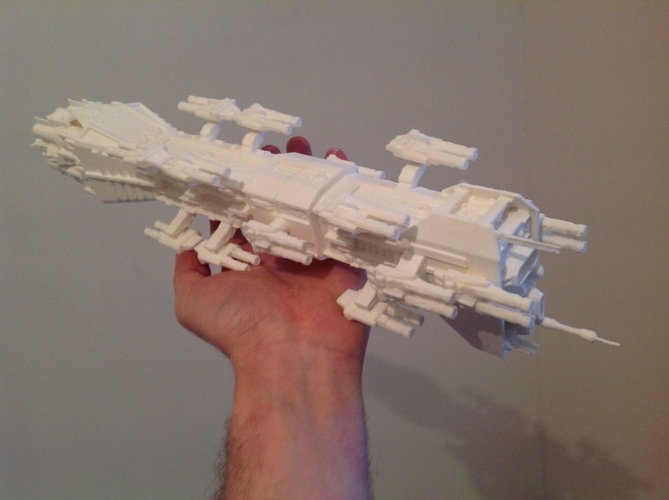

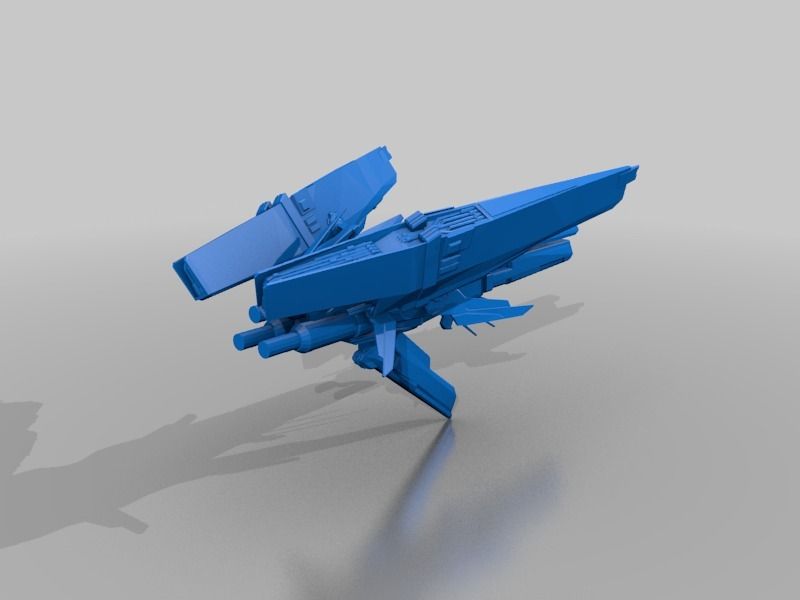

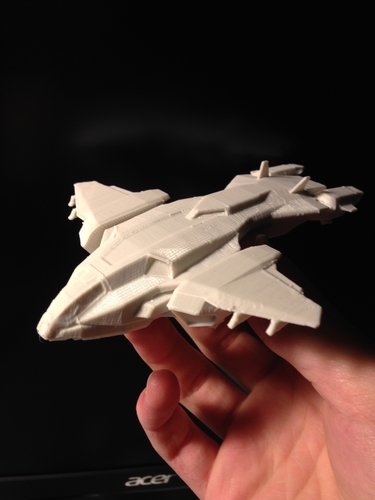

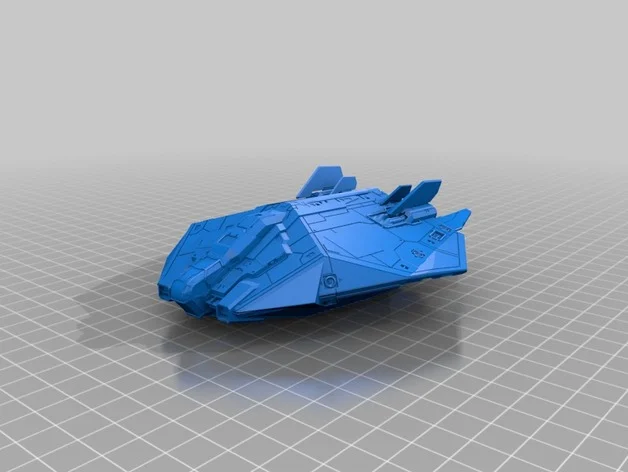

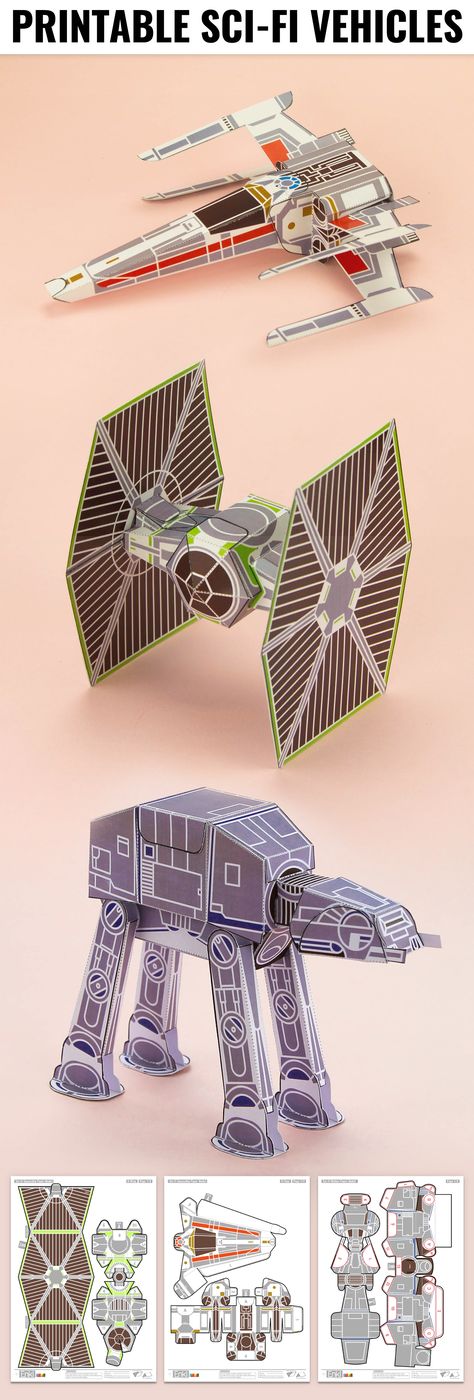

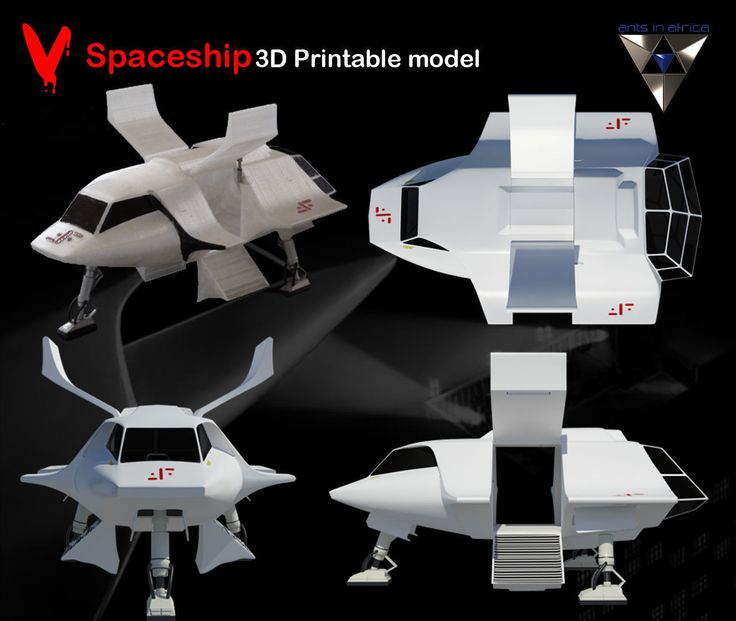

3D printed spaceship models

Spaceship best 3D printing models・Cults

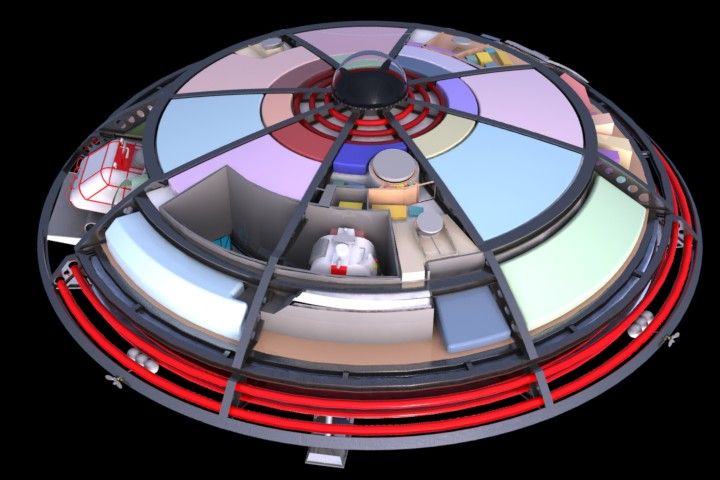

UFO With Lid and Twist-Off Base

€2.89

my first attack ship

€0.81

1 cube challenge fighter ship

€0.81

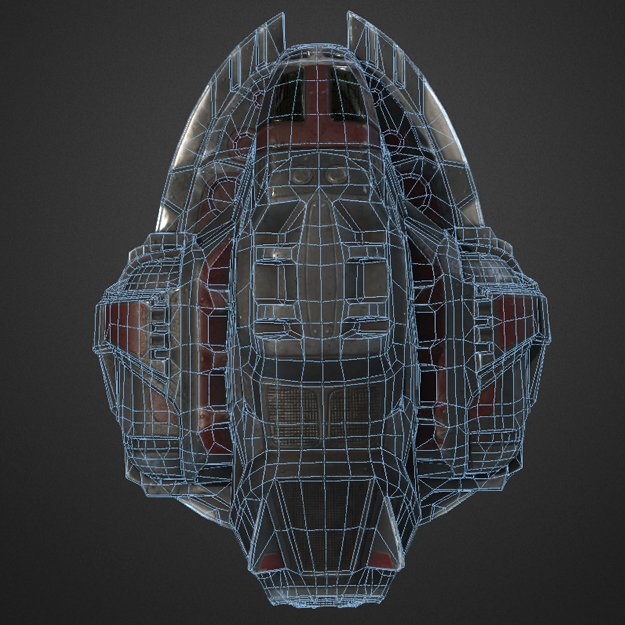

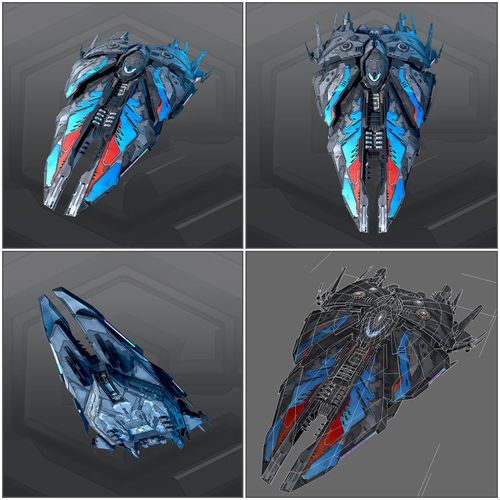

Spaceship concept

€1

ARP-Madore 608-333 deep sky object 3D software analysis

€2.50

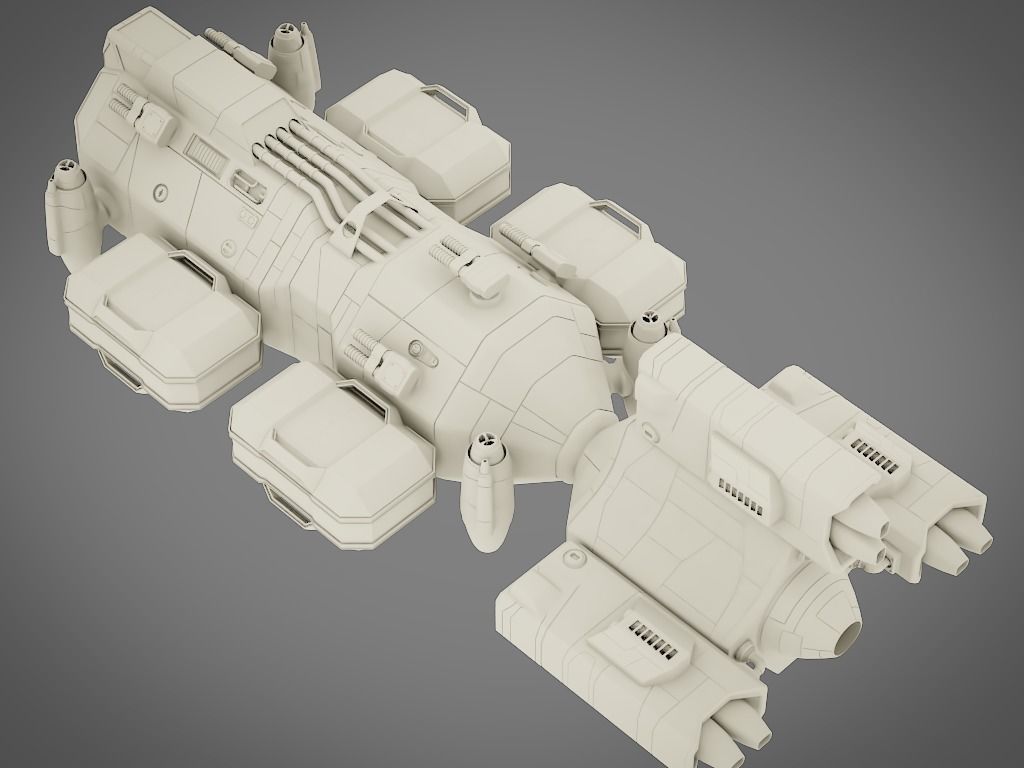

Spatha Class ESCORT SHIP

€2.87

Low resolution Pillar of creation James Webb deep sky object 3D software analysis

Free

NGC 1433 Hubble deep sky object 3D software analysis

€2

Rocket by Play Conveyor

€3.03 -50% €1. 51

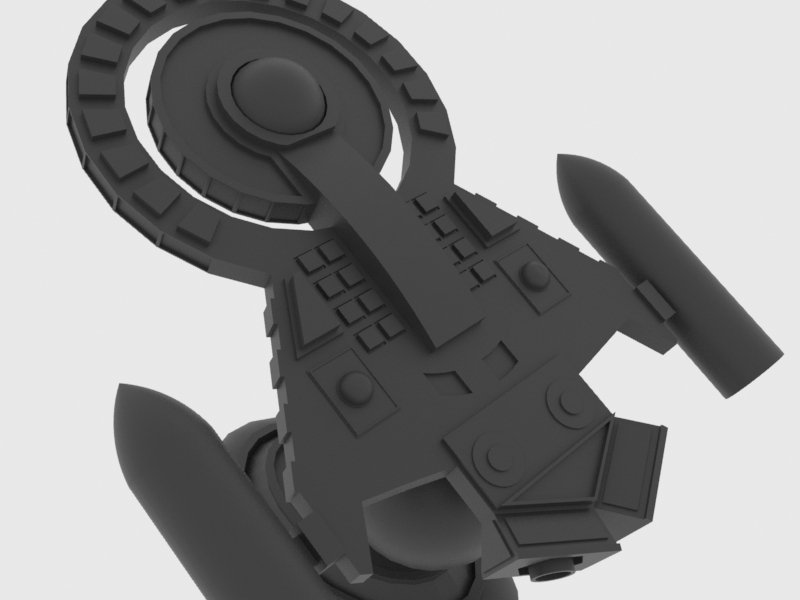

Enterprice Keyring

€0.50

Aetherium 3 Starship - Searchable upload

Free

Sentinel class FRC SOLID Non-RC

Free

FASA Romulan V-11 Stormbird: Star Trek starship parts kit expansion #25

Free

Spaceship 004

€6.61

Spaceship 003

€3.33

FASA Klingon Non-combatants: Star Trek starship parts kit expansion #24

Free

Spaceship concept

€2

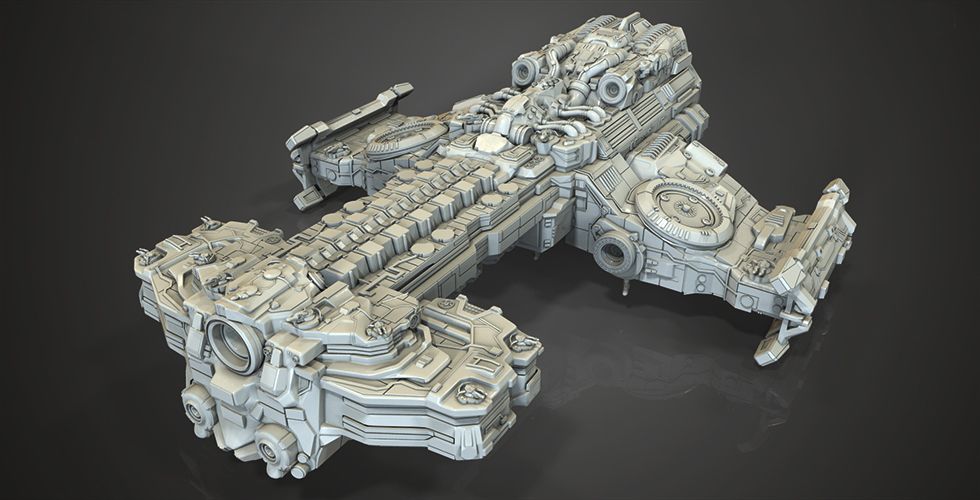

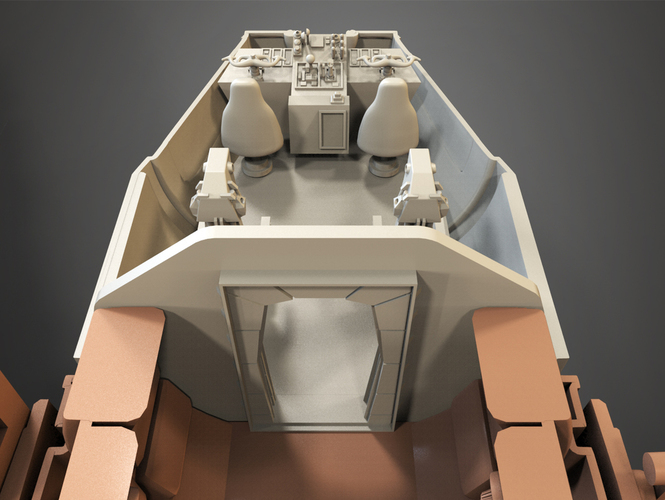

Hasta Cruiser

€5.16

Sci-Fi Cyberpunk temples Dark

€50.48

Sci-Fi dark Cyberpunk Shogun Towers 4 Kitbash

€25. 24

24

Sci-Fi dark Cyberpunk Shogun 2 Kitbash

€25.24

Sci-Fi dark Cyberpunk temples With ship 2 Kitbash

€20.65

Sci-Fi dark Cyberpunk temples With ship Kitbash

€25.24

Sci-Fi dark Cyberpunk Mass Halls Kitbash

€20.65

Sci-Fi dark Cyberpunk Tower Kitbash

€24.09

Sci-Fi dark Cyberpunk temples 3 Kitbash

€19.51

Super Deformed Pegasus Whitebase SCV 70 Spaceship

€7

Flying saucer

€1.27

Experimental Space Plane XN-1

Free

Space Ship Coockie Cutter

€1. 10

10

Sci-Fi dark Cyberpunk temples 2 Kitbash

€28.68

Skylark sounding rocket

Free

Soyuz-FG rocket

Free

Sci-Fi dark Cyberpunk temples Kitbash

€25.24

Sci-Fi dark Platforms 8 Monoliths

€25.24

Sci-Fi dark Platforms 6 Monoliths

€17.21

Sci-Fi dark Platforms 3 Monoliths

€18.36

Sci-Fi dark Platforms 2 Monoliths

€10.33

Sci-Fi dark Platforms 13

€9.18

Sci-Fi dark Platforms 12

€9.18

Sci-Fi dark Platforms ship version 2

€9. 18

18

Sci-Fi dark Platforms Ship

€8.03

COMPLETE BUNDLE - SPACESHIP / INDUSTRIAL BASES - 40MM 32MM 25MM

€3.49

Sci-Fi dark Platforms 10

€10.33

Sci-Fi dark Platforms 9

€13.77

Sci-Fi dark Platforms Decepticon base

€18.36

SPACESHIP / INDUSTRIAL BASES 40MM 32MM 25MM PART5

€0.99

Sci-Fi dark Lord Platforms Base kitbash

€19.51

3d Print Spaceships - Etsy.de

Etsy is no longer supporting older versions of your web browser in order to ensure that user data remains secure. Please update to the latest version.

Take full advantage of our site features by enabling JavaScript.

Find something memorable, join a community doing good.

(688 relevant results)

3D printing and space: the most important

1. The use of additive technologies in the manufacture of spacecraft parts.

The use of additive technologies in the manufacture of spacecraft parts.

3D printing is actively used in the aerospace industry for the manufacture of prototypes, engine parts and tooling. Its use allows the manufacturer to reduce the cost of products, improve their performance, and significantly reduce the time of manufacture of individual products. All major companies involved in aerospace production are turning to additive technologies in one way or another.

Mostly 3D printed engine parts. Thus, the American company Aerojet Rocketdyne has signed a contract for 1.6 billion dollars for the production of the RS-25 rocket engine, some of the parts for which will be made on a 3D printer. Production of a single part by traditional methods could take half a year - 3D printing allowed Aerojet Rocketdyne to reduce time and costs, significantly speed up the prototype production process. In addition, the company successfully uses additive technologies in other projects.

Another US company, Rocket Lab, is building New Zealand's first orbital launch station. It is from there that it is planned to launch the world's first rocket, the oxygen-hydrocarbon engine of which is completely printed on a 3D printer.

The list would be incomplete without businessman and designer Elon Musk. His company SpaceX has successfully tested 3D-printed SuperDraco engines to be used in the Dragon spacecraft and is also working on the Raptor Rocket propulsion system.

Other industrial giants didn't stop at engines. Blue Origin used over 400 3D printed parts on New Sheppard's first flight in June 2015.

And Boeing has contracted Oxford Performance Materials, a leading additive manufacturing specialist, to produce 600 3D printed parts for the new Starliner space taxis.

Additive technologies are also used in promising projects of the near future. NASA is using advanced techniques in preparing for a Mars mission: 3D printing is already being used to create prototypes, manufacture parts in space, and even make engine parts for a future ship that will go to Mars.

The Russian aerospace industry is also beginning to introduce 3D printing. For these purposes, the Roscosmos Corporation has received a unique domestic 3D printer Router 3131 with a large print field. He will create elements of spacecraft.

2. The use of 3D printing in the production of satellites and devices.

Another direction in the aerospace industry, which we decided to consider separately, is additive technologies in the production of satellites. Unlike a rocket, the cost of a satellite is significantly lower, but it can also be reduced by paying attention to innovative technologies.

Aerospace giant Boeing has done just that by using 3D printing to produce modular satellites. Now one device costs, on average, 150 million dollars - this price is due not only to the high-tech component, but also to the significant cost of the labor force involved in production. When using 3D printers, the cost and production time of satellites are significantly reduced.

Small start-ups and research projects have more modest goals, but 3D printing helps them too. A team of researchers at Northwestern Nazarene University in Idaho awaits the launch of their 3D-printed MakerSat satellite, the first in the state, into space. The dimensions of the device are only 10x10x11.35 cm, and it is created from available polymers for 3D printing (ABS, ULTEM and nylon).

High performance satellite developer Millennium Space Systems recently announced the completion of a pre-production model of the ALTAIR series, which is now being prepared for launch into space. The new technologies used in the design of the satellite will make new space missions possible. For example, 3D printing will save on the cost of sending parts into space and reduce the time it takes to prepare and conduct missions.

Russian scientists also excelled. In 2016, the Tomsk-TPU-120 small satellite was developed at the Tomsk Polytechnic University. When creating the device, scientists and students of Tomsk Polytechnic University used additive technologies - the frame and most of the components are printed on a 3D printer. On March 31, 2016, the 3D satellite left the Earth and settled in orbit.

On March 31, 2016, the 3D satellite left the Earth and settled in orbit.

Juno flew even further. The NASA space station with that name entered Jupiter's orbit in the summer of 2016. This event is also important for 3D printing, as Juno became the first spacecraft with 3D printed parts - titanium waveguide elements manufactured by Lockheed Martin.

3. Space 3D printers.

Astronauts in orbit often cannot provide themselves with everything they need and have to wait for cargo that arrives at the International Space Station (ISS) during scheduled flights. Unfortunately, during this time the crew is not insured against accidents or breakdowns of important systems. 3D printing experiments in space offer the potential to print needed parts if any parts fail in space. This is very important for future flights to Mars and other planets: for a long time, the colonists will not be able to receive help from Earth. Therefore, in the forthcoming expeditions, it is extremely important to use all available opportunities for the manufacture of products on board ships and space stations.

Such experiments have been carried out on the ISS since 2014. It was then that the Zero G 3D printer manufactured by Made in Space was delivered to the American segment of the station. The first print took place on November 24, 2014 and marked a new era in the development of 3D technologies. The printed object was a part of the printer itself, the faceplate of the printhead, symbolizing the ability to one day print a 3D printer in space on a 3D printer. In 2016, another Made in Space printer called the Additive Manufacturing Facility (AMF) was delivered to the ISS.

Since then, print trials on the ISS have taken place regularly. One of the latest ideas was an innovative plan by the Canadian company 3D4MD, which involved printing medical devices, such as splints or surgical instruments, on the ISS. To create devices such as custom splints for broken fingers, 3D4MD's developers could use, for example, measurements taken during the preparation of spacesuits and create a model on Earth. The 3D model can then be sent to the ISS, where the tire will be 3D printed.

The 3D model can then be sent to the ISS, where the tire will be 3D printed.

Roskosmos is also developing a similar project. An experiment called "3D printing" should confirm the possibility of using a 3D printer in the absence of gravity. This device was created within the walls of the Tomsk Polytechnic Institute and agreed with the engineers of RSC Energia. The printer will go to the ISS in 2018.

Not being able to conduct experiments in space, other powers organize experiments on the ground. A development team from China recently successfully tested the first 3D printer designed for weightless conditions. Many difficult tests were carried out in the French city of Bordeaux.

4. 3D bioprinting in space.

It is known that in outer space there is electromagnetic and radiation radiation that has a detrimental effect on biological tissues. In order for the astronaut to be able to endure all the hardships of the flight, the protection of the ship alone is not enough - it is necessary to think about high-quality medical care. And if it does not help, then it’s about replacing any organs.

And if it does not help, then it’s about replacing any organs.

That is why the Russian United Rocket and Space Corporation (ORSC) agreed on an experiment to use a 3D bioprinter on the International Space Station (ISS). Its developer was the Russian laboratory 3D Bioprinting Solutionsspecializing in bioprinting technologies. Scientists hope that the magnetic bioprinter will make it possible to create tissues and organs in space. It is expected that the device will be delivered to the ISS by 2018.

There are no analogues of the Russian project abroad yet.

5. Construction of structures using building 3D printing.

One of the most basic problems in the construction of buildings on extraterrestrial objects is the limited amount or lack of building material. The only available raw materials that do not need to be transported from our planet are local geological rocks. It is not surprising that scientists are solving the problem of using them in the construction of buildings.

For example, engineers at Northwestern University in the US have found a way to use quality materials in situations where resources are limited. We are talking about the process of additive manufacturing from special materials that mimic the lunar and Martian regolith. These are strong and elastic materials that are produced using powdered substances that resemble rocks from the surface of the Moon and Mars.

It is likely that this technology will be used in the colonization of Mars. Due to extreme temperatures and high radiation on the surface of the "red planet", the first colonizers will need reliable shelters. NASA experts propose using 3D printing to create a "dome" of ice from the surface of Mars, covered with a transparent membrane of fluoroplast-40. One of the main advantages of a water-based dwelling is that such walls protect from cosmic radiation, but do not prevent the penetration of light - this creates some comfort. In addition, when choosing materials, other criteria were taken into account - their strength and reliability, the ability to withstand the difficult conditions of Mars.

The European Space Agency (ESA) is working in the same direction and has already achieved some results. Scientists from the Austrian University of Applied Sciences in Wiener Neustadt managed to 3D print a small needle and a corner wall from JSC-Mars-1A material, which mimics Martian soil.

In addition to serious research, there are quite unexpected projects. So, experts from the ESA we mentioned thought about saving the souls of the first lunar colonists and planned to build a temple on the moon using 3D printing. This building, poetically named Temple of Eternal Light, will be located in the center of a residential complex for the first lunar settlers and will combine a prayer place and an observatory. The designers believe that the temples on the moon will revive the lost connection between mankind and the cosmos.

However, according to Vyacheslav Bobin, head of the Center for the Study of Natural Substances at the Institute for the Integrated Exploration of the Subsoil of the Russian Academy of Sciences, the construction of settlements on the Moon is not such a fantastic prospect as you might think. A new Russian lunar exploration program could provide the conditions for building a base using 3D printing. If Russian researchers manage to identify a suitable location for the colony, Bobin believes a 3D printer could be used to construct buildings later on.

A new Russian lunar exploration program could provide the conditions for building a base using 3D printing. If Russian researchers manage to identify a suitable location for the colony, Bobin believes a 3D printer could be used to construct buildings later on.

That's not all the exciting news about space 3D printing. What can you say, for example, about 3D-printed rocket fuel or the use of 3D technologies in the development of a unique space suit for the first participants in a Martian mission?

Read even more up-to-date information in our special section "Space" and don't forget to congratulate your family and friends on Cosmonautics Day!

REC Wiki » Who makes money on 3D printing and how

Ready to make money with direct hands and a 3D printer? Okay, but before diving head first into the business, it would be nice to understand exactly how 3D printing is changing the face of the industries around us in order to find its niche. Let's watch.

Let's watch.

The market is growing

From Bugatti to Adidas, 3D printing is making its way into one industry after another, influencing not only design processes but also manufacturing processes. Even the pandemic did not stop the development of the additive market. The situation turned out to be twofold: on the one hand, many manufacturers of 3D printers and consumables suffered losses due to reduced demand, but already bounced back in 2021, as more and more enterprises began to resort to localized additive manufacturing of components due to problems with global logistics . It's time to join the trend and row money with a shovel. A shovel, by the way, can also be printed.

The main applications of 3D printing technologies are prototyping and additive manufacturing. As a prototyping tool, 3D printing helps speed up the development and refinement of products, and as an additive manufacturing tool, it allows you to make final products. Prototyping with 3D printing greatly accelerates the work of designers, providing low-cost, functional prototypes for enterprises of all sizes. In manufacturing, 3D printing is used for mass customization, on-demand production, and even distributed production.

In manufacturing, 3D printing is used for mass customization, on-demand production, and even distributed production.

3D printing is everywhere you look

As the subtitle suggests, there is no hiding from 3D printing, it is already everywhere. On the other hand, adoption rates vary from industry to industry. 65% of the use of additive technologies is in engineers working on the creation of new industrial and consumer products.

Example: Three-quarters of American and German automotive companies, including BMW, Ford, Volkswagen, Audi, Porsche, Mercedez-Benz and General Motors, are already actively using 3D printing technologies in the mass production of tooling, parts and spare parts. But the matter is not limited to cars alone: medicine, the service industry, architects, artists, and so on and so forth have picked up an additive fever. And what do they do, you ask? Now let's show.

Construction

3D printing is a new word in construction. "Office of the Future" is a demonstration project in Dubai carried out by the Chinese company WinSun in 2016. Six meters high, thirty-six long, twelve meters wide, plus 50% savings on labor. For everything about everything, including decoration and landscaping - seventeen days. The emirs have big plans: the same Saudi Arabia intends to build one and a half million houses to solve the housing crisis, actively attracting developers of construction 3D printers. It is understandable, because the salaries of local builders are high, and the economy should be economical.

Six meters high, thirty-six long, twelve meters wide, plus 50% savings on labor. For everything about everything, including decoration and landscaping - seventeen days. The emirs have big plans: the same Saudi Arabia intends to build one and a half million houses to solve the housing crisis, actively attracting developers of construction 3D printers. It is understandable, because the salaries of local builders are high, and the economy should be economical.

The Dubai 3D printing office was just one of the first wake-up calls, and now, six years later, construction 3D printing is being mainstreamed by companies such as ICON, Apis Cor, COBOD, AMT-Spetsavia. The illustration above shows a series of low-income homes built by Texas-based ICON in their native Austin. The houses are small, only thirty-seven square meters each, but are equipped with a bedroom, a living room, a fully equipped kitchen and a bathroom.

And this is one of the projects of the Russian company 3D4art: a pavilion with a 3D printed concrete cat was erected on a private plot in Yaroslavl and serves as a summer kitchen. 3D4art uses 3D printers developed by the local company AMT-Spetsavia, which is also engaged in construction, in parallel with the production of additive technology. Now AMT-Spetsavia is busy building a whole 3D-printed village, in total it is planned to build twelve houses according to individual projects.

3D4art uses 3D printers developed by the local company AMT-Spetsavia, which is also engaged in construction, in parallel with the production of additive technology. Now AMT-Spetsavia is busy building a whole 3D-printed village, in total it is planned to build twelve houses according to individual projects.

“From a hardware point of view, a construction 3D printer is not much different from conventional 3D printing with molten plastic. These are the same CNC machines, only construction 3D printers are larger. However, they allow realizing any architect's fantasy: the printer doesn't care what to print - a simple rectangular building or a house with curved facades, turrets and columns. And to automate the process as much as possible, thanks to which the time for construction is reduced by one and a half times compared to the traditional one,” said Alexander Maslov, General Director of AMT-Spetsavia.

Tissue engineering and organs

No one has yet learned how to print working livers, but the process is underway. For example, Prellis Biologics is working on methods for 3D printing of functional organs, including hearts, livers, kidneys and lungs, and the Russian company 3D Bioprinting Solutions has already conducted several bioprinting experiments in space.

For example, Prellis Biologics is working on methods for 3D printing of functional organs, including hearts, livers, kidneys and lungs, and the Russian company 3D Bioprinting Solutions has already conducted several bioprinting experiments in space.

Even if the technology is not yet ready for 3D printing of organs for transplantation, it is already useful, allowing the growth of living tissue samples for toxicological research in the development of new pharmaceuticals, as well as research in the treatment of various dangerous diseases, such as cancer.

Cars and motorcycles

Finding and buying a four-wheeled classic is not that difficult, if you have the money. It is more difficult to bring the often rusty collection of no longer produced parts up to standard. Mercedes has found a simple solution by offering owners of older cars, including the legendary 300 SL coupe, 3D printed parts. Ride for health.

The Russian studio Box3D went in a slightly different direction, customizing cars and motorcycles. In some cases, the company immediately prints parts on 3D printers using durable composites, such as REC X-Line filaments, in others, it prints master models from PETG, from which matrices are removed, and carbon or fiberglass parts are made from matrices. The illustration above is one example. This is a custom motorcycle Giotto 31 based on Harley-Davidson V-Rod. All plastic parts are printed in PETG with fiberglass reinforcement.

In some cases, the company immediately prints parts on 3D printers using durable composites, such as REC X-Line filaments, in others, it prints master models from PETG, from which matrices are removed, and carbon or fiberglass parts are made from matrices. The illustration above is one example. This is a custom motorcycle Giotto 31 based on Harley-Davidson V-Rod. All plastic parts are printed in PETG with fiberglass reinforcement.

And this is a very extreme example from the USA - the Czinger C21 hypercar with a structure made of carbon fiber and 3D-printed titanium parts made using selective laser metal powder fusion (SLM) technology. The machine is equipped with a hybrid power plant based on a turbocharged V-engine with a capacity of 925 hp. With. with the main drive to the rear wheels and auxiliary to the front. From zero to one hundred kilometers per hour Czinger C21 accelerates in just 1.9 seconds. Last year, the prototype set a new lap record at Laguna Seca and improved the previous best time set by the McLaren Senna by a full two seconds. The company plans to produce just eighty of these cars, costing about $1.7 million each.

The company plans to produce just eighty of these cars, costing about $1.7 million each.

Shoes and fashion in general

Sooner or later the day will come when you will put on freshly printed underpants in the morning. Think this is a joke? Maybe. However, the same Adidas brand is already actively pursuing the idea of mass distributed additive manufacturing of shoes. Each has its own size, its own shape, its own color, and even at the place of residence. The company has already released several sneaker models with comfortable and resilient 3D printed soles made on Carbon's high-speed photopolymer 3D printers.

Bicycles

This is the Arc Bicycle, a 3D printed bicycle designed by Delft University of Technology students and manufactured by MX3D. And the uncle on a bicycle is the Minister of Economy of the Kingdom of the Netherlands Henk Kamp, who tested the novelty at the Innovation Expo in Amsterdam. It's a well-known fact: the Dutch love 3D printers and bicycles. Especially when 3D printers are printing bicycles, for the perfect synergy. The frame of this two-wheeled vehicle was printed by an industrial multi-axis robotic arm that fuses metal wire.

Especially when 3D printers are printing bicycles, for the perfect synergy. The frame of this two-wheeled vehicle was printed by an industrial multi-axis robotic arm that fuses metal wire.

And this e-bike has a carbon fiber composite frame, but also 3D printed. Such bikes are produced under the Kimoa brand, founded by the famous racing driver Fernando Alonso. The production is carried out by the Californian company Arevo, which has developed a special 3D printer: an additive system prints a combination of thermoplastics and continuous reinforcing fibers.

Instead of a thermal block, a laser emitter is responsible for melting the polymer, and immediately after application, the melt and the reinforcing thread are pressed by a roller, increasing the isotropy. Thanks to the multi-axis positioning system, the reinforcing threads can be overlapped, and the high power-to-weight ratio of the system makes it possible to work even with refractory structural thermoplastics such as polyetheretherketone (PEEK).

Food

Who wants a delicious cake? Only cakes are not simple, but made according to intricate 3D printed forms. These sweets were invented by a former Ukrainian architect, and now a confectioner Dinara Kasko. The unusual shape of the cake was obtained using a silicone mold made from a 3D printed master model. With 3D modeling in Grasshopper 3D, Dinara was helped by a friend, Ukrainian artist Andrey Pavlov, who is engaged in general and architectural design.

Fashion

Let's get back to our clothes. Dutch designer Anouk Wipprecht knows the safest way to ride the subway. This 3D-printed "spider" outfit not only flatters the figure, but can tear apart anyone who will unravel their hands. We have warned you. But there are other options: go to the store in such a dress, elegantly lean on the counter and ask: “How much?” Discount guaranteed.

And now to space

When someone enthusiastically mentions "space technology", they mean 3D printing. Seriously. We have already mentioned 3D Bioprinting Solutions, but NASA has long appreciated the possibilities of 3D printing, operating the second FDM 3D printer on board the ISS and even funding the development of 3D printers for printing in outer space. The Russian "space" polymer 3D printer (pictured above) is due to leave for the ISS on June 3, 2022.

Seriously. We have already mentioned 3D Bioprinting Solutions, but NASA has long appreciated the possibilities of 3D printing, operating the second FDM 3D printer on board the ISS and even funding the development of 3D printers for printing in outer space. The Russian "space" polymer 3D printer (pictured above) is due to leave for the ISS on June 3, 2022.

SpaceX's rockets and spacecraft are powered by 3D printed engines, and California-based startup Relativity Space is already gearing up to launch the first 3D printed orbital launch vehicle.

Relativity Space relies on at least two 3D printing technologies: for example, engines are manufactured using selective laser sintering technology using industrial 3D printers from the German company Electro Optical Systems (EOS GmbH), and fuel tanks are printed by an additive system of our own design - a robotic complex Stargate on hybrid technology of laser-plasma deposition of welding wire. Through the use of robotic manipulators, the system is easily scaled up, allowing you to create large-sized products.

The first flight of an experimental Terran 1 rocket with a payload mock-up is scheduled for June 2022. The company estimates the cost of one launch at twelve million dollars, and the production time for serial samples is only two months.

Architecture

And I'm walking, walking on… a 3D printed bridge. Not so unexpected: 3D printed bridges have been built in Spain, the Netherlands and China. These are all reinforced concrete structures, although there are also plastic ones, but the engineers of the already mentioned Dutch company MXD3 designed an all-metal steel bridge.

The bridge was installed in the center of Amsterdam in the summer of 2021. The opening ceremony turned out to be quite funny: Her Majesty Queen Maxima deigned to press the big green button, thereby graciously giving the red ribbon to be torn to pieces by a robot-manipulator armed with scissors. Why such an honor fell to the robot is quite understandable: the robots did the bulk of the physical work, armed with welding machines.