3D printed switch cover

▷ switch cover plates 3d models 【 STLFinder 】

Wall switch cover plates

thingiverse

Cover plates for Decora-style wall switches and outlets.

Light Switch Cover Plates

thingiverse

Modified my original model to create single, double switch and blank plate combos. Printed face down on glass with a skirt. sanded with 230 - 600 wet-dry paper for smooth finish. ... could and probably should be primed and painted as infill can be...

light switch cover plates

thingiverse

i printed in glow-in-the dark filament because nobody needs to find a light switch when there is enough light to see the switch.

f3d's included, edit/hack it up any way you want.

do not ask/comment for printing recommendations, you should be...

Decora Light Switch Cover Plates

thingiverse

single, double and triple Decroa Light Switch Cover Plates based off of my earlier plates https://www.thingiverse.com/thing:3339401 made by request. I don't have these types of plates in my house but found some dimensional drawings with a google...

DEADPOOL and Punisher Light Switch cover plates

thingiverse

Kids will love these! Big kids too! ... Instructions Printed @ . 3 layer height, with touching plate support

3 layer height, with touching plate support

Harley Auxiliary Accessory Switch Housing: Cover Plates for Switch or LED

thingiverse

The official name is "Auxiliary Accessory Switch Housing Kit" It has locations for three switches and comes with two blanks, assuming you're installing at least one switch. Cool. I lost one of the blanks, and the hole has been covered with black...

switch-cover

thingiverse

super easy switch cover

Switch Cover

thingiverse

Switch Cover in Viking Theme

Switch Cover

thingiverse

This is a switch cover.

switch cover

thingiverse

Switch cover found online and printed. ... Covers one side.

Switch cover

thingiverse

Switch cover for isolation, shower switch , extractor fan prevents switch from being turned off by accident

Switch cover

thingiverse

Cover for normalised switch, with 3 cable passages.

Switch Cover

thingiverse

This are some Switch Cover for the Overhead from my Airbus 320 Home-Sim

Switch Cover

prusaprinters

This are some Switch Cover for the Overhead from my Airbus 320 Home-Sim Category: Tools

Switch cover

thingiverse

Switch Cover www. ebay.de/itm/281070682449 Spannung : 250V / Wechselspannung Schaltleistung: max 750W ohmsche Last Einbaumaß : 19,5 x 13 mm Snap in Montage Steckkontakte 4,5mm screw: 2,0mm 67mm x 39mm x 6mm

ebay.de/itm/281070682449 Spannung : 250V / Wechselspannung Schaltleistung: max 750W ohmsche Last Einbaumaß : 19,5 x 13 mm Snap in Montage Steckkontakte 4,5mm screw: 2,0mm 67mm x 39mm x 6mm

Switch Cover

thingiverse

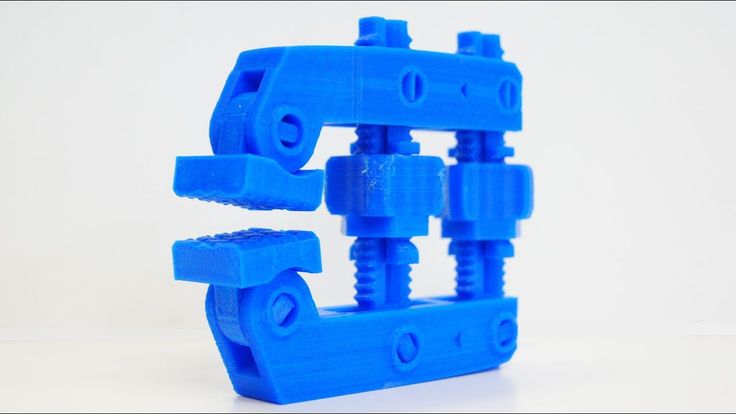

Here is a cover for power switches, like they used in multi sockets and other aplications. ... You'll also need: - spring (torsion) - 1x screw M3 x 22 mm (inbus) - 1x nut M3 - 4x countersunk screw (or double faced adhesive tape)

Switch Cover

thingiverse

Cover a mechanical stitch so that it can be flush mounted on enclosure. ... You can find switch here. https://www.amazon. com/Support-Guitar-Effect-Switch-Bypass/dp/B012CF1ASQ/ref=sr_1_2?dchild=1&keywords=3PDT&qid=1613407268&sr=8-2

com/Support-Guitar-Effect-Switch-Bypass/dp/B012CF1ASQ/ref=sr_1_2?dchild=1&keywords=3PDT&qid=1613407268&sr=8-2

Switch Cover

thingiverse

This is a simple cover that screws over a standard North American light switch to help prevent accidentally turning the switch off or on. Unless the screws are very short, replacement screws shouldn't be necessary - just unscrew the screws holding...

Switch Cover

thingiverse

This is a cover I made for a rocker switch in my car so I wouldn't accidentally turn my AUX Lights on. The switch is a standard rocker switch thats lights up. Print Settings Printer Brand: MakerBot . ..

..

Switch Cover

thingiverse

A cover I made to protect the main power switch on my 3D printer and prevent anyone from turning it off by accident. Mounting holes are 3 mm. The cover is screwed to the base using two M3 screws that is treaded into the plastic. ... Print Settings...

switch cover

thingiverse

Explanation : The design of the switch cover was designed by applying it to the switch cover, which is an interior item, using a sculptured kite pattern. You can also download this file from the link below. (3D상상포털) Everyone please come and...

Switch cover

thingiverse

to prevent turn on/ off by accident, fit for clipsal switch case at 87 x 87mm

Switch Cover

thingiverse

Addon for http://www. thingiverse.com/thing:1596485 Holes for: 2* 20mm circular switches (http://www.aliexpress.com/item/12V-DC-LED-Lighted-Dot-Illuminated-Round-Rocker-Switch-Button-3Pin-ON-OFF-Toggle-SPST-Car/32636899209.html) 1 27mm12 switch...

thingiverse.com/thing:1596485 Holes for: 2* 20mm circular switches (http://www.aliexpress.com/item/12V-DC-LED-Lighted-Dot-Illuminated-Round-Rocker-Switch-Button-3Pin-ON-OFF-Toggle-SPST-Car/32636899209.html) 1 27mm12 switch...

Switch Cover

thingiverse

These decor electrical switch plates were printed with ColorFabb Copperfill PLA. I had hoped to add a patina but had some issues with partial melting of the plastic matrix, as shown on the test swatch. ... Left on their own to the open air environment...

Cover for switch cover

cults3d

Hello, printers I propose this cover for Legrand switches. ... Contact me: lahbib. [email protected] pay for a coffee via PayPal https://www.paypal.me/LahbibAissa Thank you and have a good print!

[email protected] pay for a coffee via PayPal https://www.paypal.me/LahbibAissa Thank you and have a good print!

Labrador Switch Plates

thingiverse

just some more switch covers ill take requests

Electrical Switch Plates

grabcad

Decorative electrical switch plate covers suitable for single, double, triple and quad gang decor rocker switch and/or receptacles.

Polaris RZR Switch Plates

thingiverse

. ..I was able to take the outline of the pieces I needed and generate new items. I added some additional touches by respacing the switches, adding raised separators between each switch ,and a border around the outer perimeter with recessed screw holes.

..I was able to take the outline of the pieces I needed and generate new items. I added some additional touches by respacing the switches, adding raised separators between each switch ,and a border around the outer perimeter with recessed screw holes.

CNC Limit Switch Plates

thingiverse

Simple plates or bases to fit limit switches to a generic CNC machine. For Z and X axes print 2 to make a sandwich. The Y axes plate fits into the recess in the carriage. The Y axes plate may require supports. I attached the plates with double sided...

MGB Switch Blanking Plates

thingiverse

Plates to fit into unused rectangular switch holes in the MGB center console. Designed for and test fitted on a 1973 car. There are three options included:

- Blank plate to fill the hole (replacement for factory part)

- Blank plate but with a...

Designed for and test fitted on a 1973 car. There are three options included:

- Blank plate to fill the hole (replacement for factory part)

- Blank plate but with a...

3D Printed Water Pump Switch Cover

Welcome to the eighth entry in November’s Medium Mod Contest. One Medium Mod will be published in every Email Alert in November. At the end of the month, we’ll hold a reader vote to determine November’s winner. Click here to submit a mod to the Mod Contest.

Chris Cameron, Draper, Utah

3D Printed Water Pump Switch Cover

2020 Ford F-350

2020 Alaskan 7-foot

I was driving off-road and took a break to check the road ahead and heard the water pump going in my camper. That surprised me so I immediately went in to check it out.

I found that the cordless blinds had fallen down and bumped the water pump switch and faucet on. They are right next to each other.

The sink had a lot of water in it by this point and was splashing around. Luckily I happened to stop and catch it before it was a full-blown disaster. This drove me to find a solution which led me to get a 3D printer to solve it.

Luckily I happened to stop and catch it before it was a full-blown disaster. This drove me to find a solution which led me to get a 3D printer to solve it.

I looked online at lots of solutions for a switch cover. None really looked great or fit my current switch. I decided I needed to make my own and I had read about 3D printers.

After learning a CAD software program I got to work designing a solution and running test prints.

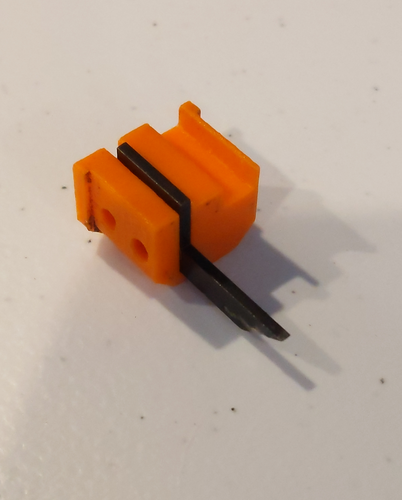

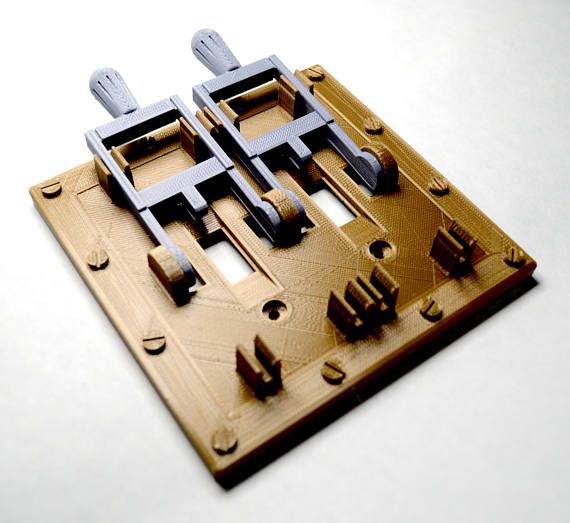

The first prototype (pictured above) didn’t provide enough protection for the switch since the blinds or something could still bump it from above.

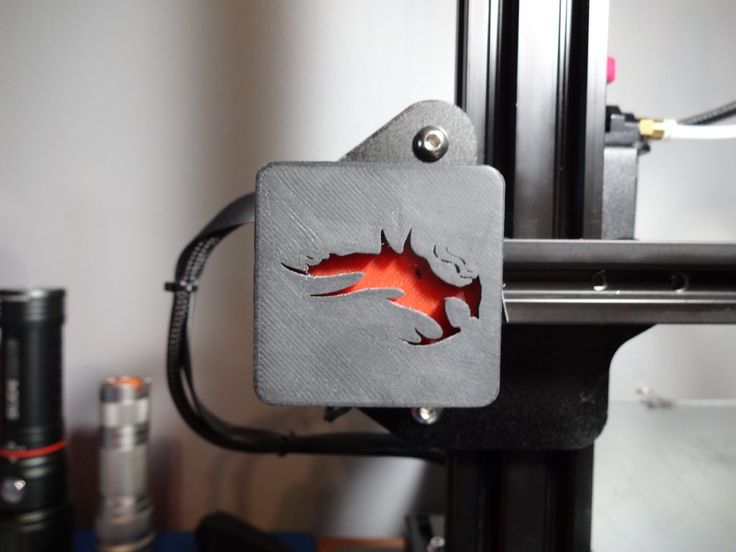

A later iteration (pictured above) was better for covering it, however, I couldn’t see whether the switch was on or off from a quick glance. Part of putting the top down on an Alaskan camper is that I need to make sure the switch is off.

The final iteration (pictured above) had a window opening on the side so I could easily see the switch status.

I needed a digital caliper to precisely measure the switch surface and model the cover. I wanted a very custom and precise fit for the final cover, including using the existing screws. I was able to accomplish this with the digital calipers. This tool typically costs hundreds of dollars, however, I found one with excellent reviews for around $40.

I wanted a very custom and precise fit for the final cover, including using the existing screws. I was able to accomplish this with the digital calipers. This tool typically costs hundreds of dollars, however, I found one with excellent reviews for around $40.

There are many CAD software options, including one that can be used in a web browser. Originally, I majored in graphic design prior to switching to computer science, so I had exposure to 3D modeling.

This helped lower the learning curve on the CAD software. However, watching beginner tutorials on YouTube should allow someone to make simple models fairly quickly.

There are two steps to getting the object from the digital world and into the physical. First I had to design the object model and then I had to “slice” the model. The 3D printer company provides slicer software (PrusaSlicer) that creates a printable version of the object.

Above: The Prusa I3 MK3S+ arrived with a bag of gummy bears!

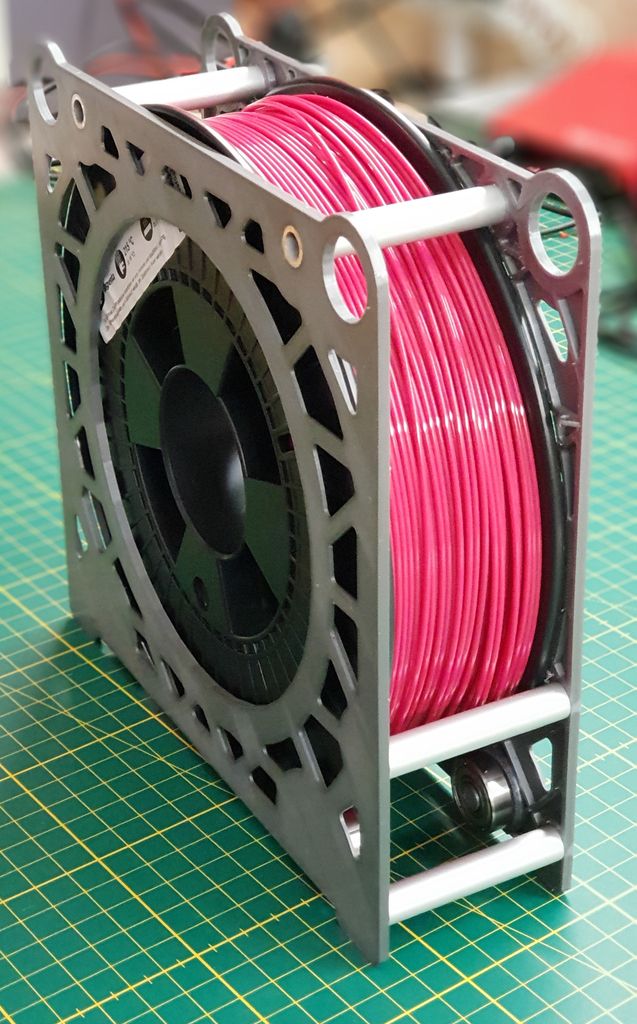

The 3D printer I settled on is the Prusa I3 MK3S+. It comes from the Czech Republic. It cost about $1K plus shipping. With the plastic filaments, it came in around $1.3K. It even came with a bag of gummy bears to snack on while you learn how to get it running. They actually run a farm of 3D printers which print parts for their 3D printers. It’s really a neat process.

It comes from the Czech Republic. It cost about $1K plus shipping. With the plastic filaments, it came in around $1.3K. It even came with a bag of gummy bears to snack on while you learn how to get it running. They actually run a farm of 3D printers which print parts for their 3D printers. It’s really a neat process.

I used free 3D modeling software and then spent a lot of time learning it and designing the mod. There are also many freely available 3D printable models available to search and print from the Internet.

Prusa 3D also provides a downloadable library of community-contributed models. For instance, I found a model that someone designed which is a hook that goes into the awning rail on my Fiamma awning. This works great for hanging a shade tarp off the awning and staking it to the ground.

I have plans on making more 3D printed mods for my camper. Off the top of my head are some clips to hold a garbage bag inside the cabinet door and probably some little bins that custom fit the drawers so things aren’t a mess after driving.

I even printed up some more switch covers and sold them to fellow Alaskan Camper owners just to help cover the cost. It isn’t a moneymaker since it’s so niche, but I am glad to help other owners avoid a disaster.

The 3D switch cover has been excellent! It prevents accidental bumping of the water pump.

It took me 15-hours to complete this modification and cost me $1,300; the cost of the 3D printer and supplies. In my opinion, the skill level of this modification is hard.

Disclaimer: The modifications above are submitted by Truck Camper Magazine readers. It is your responsibility to make sure that any do-it-yourself modification project you undertake is safe, effective, and legal for your situation.

Enter Your Mods Now!

If you’d like to enter a modification you’ve done on your truck camper, click here. You can enter as many mods as you want, at any time. Good luck mod makers!

Related Items:AlaskanMods, Latest

Towards a brighter future with 3D printed lights

The Dutch company Yuugn creates lights for office buildings, commercial spaces and schools using 3D printing, with a focus on sustainability and environmental friendliness.

Several times a day we turn on the light with the flick of a switch, regardless of the huge amount of energy consumed by each light bulb.

Yuugn, a subsidiary of the Lichtdivisie brand, designs and manufactures environmentally friendly luminaires to meet every need and specification. Yuugn is a name derived from the Japanese word for "to be one with nature" and the company follows this philosophy with the BCN3D Sigma D25 3D printers, using biodegradable materials to minimize hazardous waste.

“As a company, we feel responsible for the production of environmentally friendly products in order to reduce the environmental pollution that occurs with traditional production methods” . – Louise Cisneros, Yuugn Marketing Manager.

Sustainable manufacturing with 3D printing

Yuugn's headquarters in the Netherlands house three Sigma D25 3D printers used for both prototyping and end-use parts.

Let's look at an example of 3D printed lights:

In bright metallic purple, the body of the Downlight swirl luminaire, which is installed in ceilings to direct light downwards. The swirl light ring, which is already a design item, is also 3D printed, and thanks to the really good quality of the finish, it looks impressive. This product uses carbon fiber reinforced biodegradable PLA that is durable and high temperature resistant, two vital considerations in the lighting industry.

The side covers of the ZIP module 60 LED luminaire, decorated with the brand logo, were also created for end use using the BCN3D Sigma D25 3D printer. These parts are also printed with PLA using carbon fiber.

Because each product requested by customers is different, customization is key for Yuugn. Going from idea to Stratos software to print gives the team the freedom to be flexible. Through 3D printing, Yuugn provides its customers with products that are fully compatible and tailored to the specific needs of their projects.

How does Yuugn manage to be sustainable in the market?

The ability to 3D print in duplicate was paramount in deciding whether to purchase a manufacturing method that could lower their carbon footprint.

“Duplicate mode gives you two 3D printers for the price of one!” . – Martijn Broekhuis, CEO of Yuugn.

IDEX technology in the Sigma D25 saves time and money by rapidly prototyping the individual products required by each customer, while the local production capability contributes to a more environmentally friendly product.

“I would recommend BCN3D 3D printers to any company that wants to experiment with cleaner production methods.” - Martijn Brookhuis, CEO of Yuugn.

The Yuugn team has a strong interest in researching the most environmentally friendly materials. The 3D printing process allows the team to use organic compounds and biodegradable materials made from renewable resources. They are currently investigating recycled materials, in particular those created from PET bottles, which have a soft texture and various colors that can be combined with printed parts for an efficient process and a high quality end product.

So what's next for Yuugn? The company hopes to continue exploring new environmentally friendly materials and one day use solar energy as a direct way to source power. The combination of values that Yuugn cares deeply about, along with 3D printing as the tool that enables them to do so, allows the company to set the standard for other manufacturers hoping to make a difference in the world's environment.

How do 3D printing standards improve the performance of Olympic athletes?

You are here

Home

Some of the Olympic cycling teams competing in Tokyo made extensive use of 3D scanners and 3D printers to customize equipment and fit bike parts to the exact requirements of the athletes. The teams used 3D printers to make new bike handlebars and chains, avoiding the use of expensive tooling/moulds.

Application of 3D printing to assist athletes outside of the Tokyo Olympics

To be fair, 3D printing advances are also being applied to other sports disciplines. For athletes competing in the upcoming Paralympic Games, for example, 3D printing offers an effective way to create lighter and more aerodynamic prostheses, as well as wheelchairs.

For athletes competing in the upcoming Paralympic Games, for example, 3D printing offers an effective way to create lighter and more aerodynamic prostheses, as well as wheelchairs.

Chevrolet is now actively outfitting its INDYCAR and NASCAR race cars with 3D printed parts including oil tanks, intake manifolds and fuel tank caps. The company uses this technology both at the stage of prototyping and at the stage of final production. London-based Cavendish Imaging is using the technology to produce protective masks that allow athletes with facial injuries (such as a broken nose/cheekbone) to continue playing. Using special software, the company 3D-scans the athlete's face and creates a model, on the basis of which the individual protective mask is printed.

This innovation reduces the athlete's downtime associated with injury and prevents further injury while healing. The company's masks have already been worn by several professional football and rugby players, including former Chelsea Football Club captain John Terry and footballer Sergio Ramos. Most bicycle helmets are made of foam, which is not completely safe when dropped. HEXR has created a new type of helmet in polyamide 11 (PA 11). The product is made by 3D printing to provide maximum personalization through 3D scanning of the shape of the head and thus increase protection.

Most bicycle helmets are made of foam, which is not completely safe when dropped. HEXR has created a new type of helmet in polyamide 11 (PA 11). The product is made by 3D printing to provide maximum personalization through 3D scanning of the shape of the head and thus increase protection.

Another sport supported by the 3D printing industry is surfing. The French startup Wyve is already developing surfboards using this technology, which allows you to create personalized products with an original translucent design. The company produces boards from recycled plastic waste, offering the end user a reliable solution with optimal performance. An original way to combine sustainability and innovation in one project. 3D printing of sports shoes may soon be on the stream. More and more sporting goods manufacturers including Adidas, Nike and Reebok are using the technology in question. A prime example is the Adidas 4D Fusion sneakers. The reason for the growth in the use of 3D printing in this area is again the possibility of personalization. 3D technologies can be used to scan a consumer's foot, develop a 3D model, and print in record time. The result is footwear adapted to the morphology, needs and style of the consumer. When it comes to ski boots, skiers often have to choose between high performance and comfort: boots that are too loose, yet more comfortable, can't provide the level of control they need. Using the latest 3D printing technology, Tailored Fits has developed ski boots that combine comfort and performance. Thanks to 3D scanning technology, Tailored Fits can 3D print the inside of the boot to suit any individual, providing a direct transfer of energy. And the buckle-free design ensures free circulation, helping you feel the slopes and keep your toes cool.

3D technologies can be used to scan a consumer's foot, develop a 3D model, and print in record time. The result is footwear adapted to the morphology, needs and style of the consumer. When it comes to ski boots, skiers often have to choose between high performance and comfort: boots that are too loose, yet more comfortable, can't provide the level of control they need. Using the latest 3D printing technology, Tailored Fits has developed ski boots that combine comfort and performance. Thanks to 3D scanning technology, Tailored Fits can 3D print the inside of the boot to suit any individual, providing a direct transfer of energy. And the buckle-free design ensures free circulation, helping you feel the slopes and keep your toes cool.

The value of 3D printing standards

In a nutshell, in the world of sports today, 3D printers are being used to make a variety of objects that improve the performance of athletes: from sneakers and ski boots to surfboards and parts for racing cars. This technology additionally comes to the rescue in case of accidents and injuries.

This technology additionally comes to the rescue in case of accidents and injuries.

International standards have played a decisive role in ensuring the reliability, efficiency and safety of 3D printers and related device components, as well as consumables used in advanced equipment in this category. A number of technical committees and subcommittees make a significant contribution to standardization work. For example, ISO / IEC STK 1, a joint technical committee of the International Electrical Commission (IEC; IEC) and the International Organization for Standardization (ISO; ISO), develops standards on the topic of 3D printing and 3D scanning , including the fundamental standards that form the basis of new documents.

In addition, a number of IEC technical committees and subcommittees are working to determine the feasibility of preparation, development and harmonization of international standards on electrical and electronic components installed inside 3D printers. Relevant parts and components include, but are not limited to, switches and relays covered by IEC/TC 17 (Switching and control gear) and TC 121 (Switching and control gear and low voltage assemblies) technical committees.