Creality ender 3 pro 3d printer filament types

What Filaments Can Be Used On A Creality Ender-3 3D Printer?

What Filaments Can Be Used On A Creality Ender-3 3D Printer?

2020-07-23 09:11:11

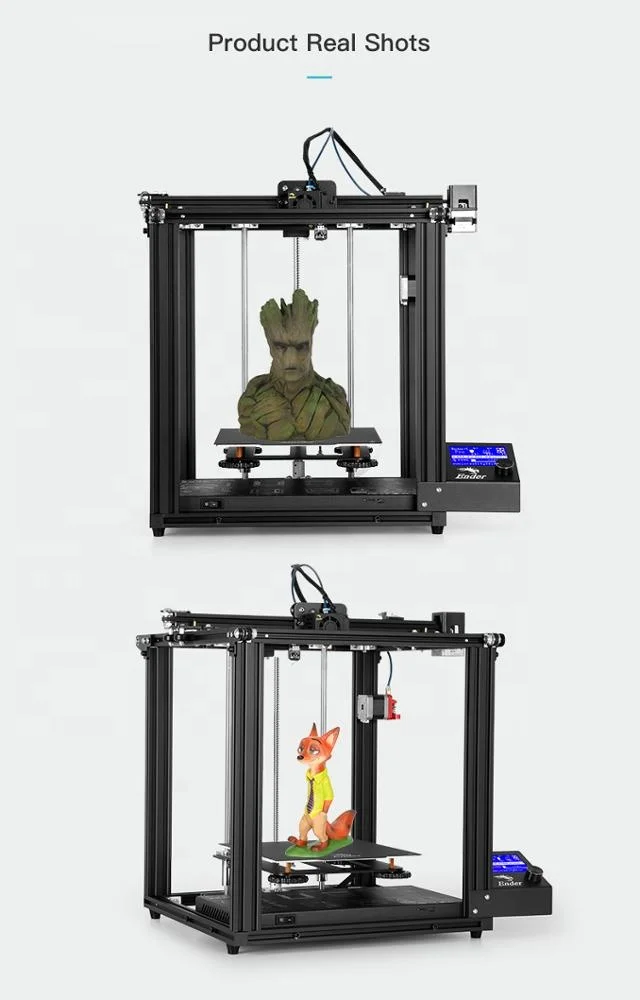

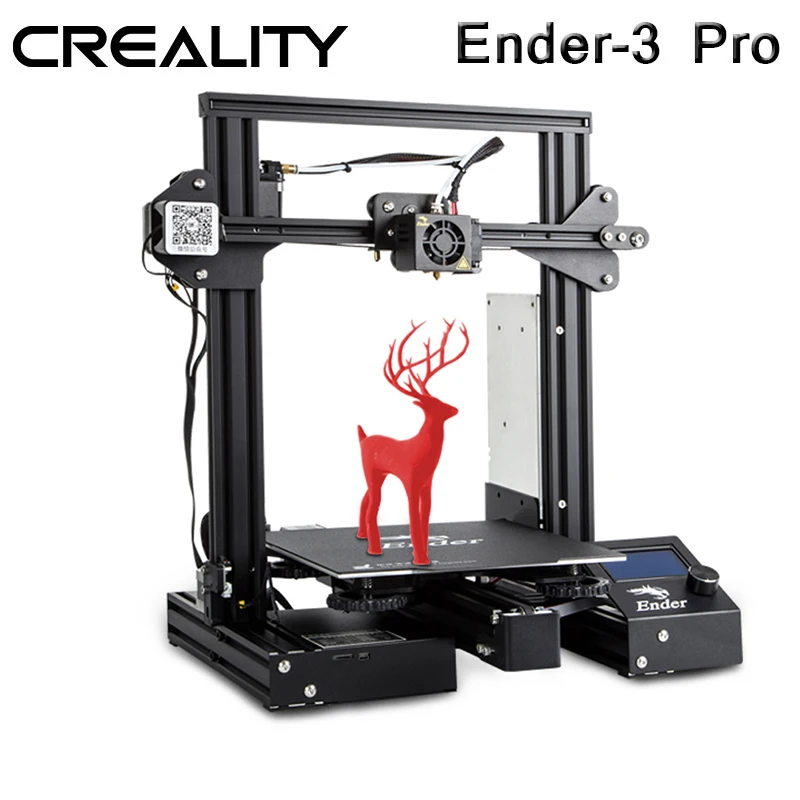

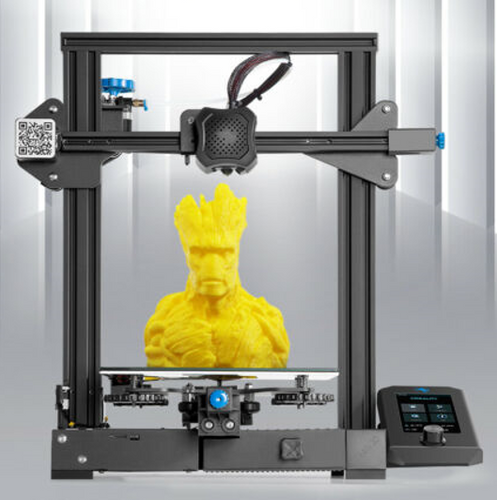

Creality Ender-3 3d printer has always been praised as the best-pick-up for 3D printing hobbyists due to its reliability and affordability. Since its release, Creality Ender-3 3d printer has achieved amazing sales records, a total annual shipment of 100,000 pieces.

With conclusions drawn from audiences, Creality Ender-3 3D Printer is an extraordinary 3D printer when you take the sub-$200 price tag into consideration.

Though it is actually a budget 3D printer, Creality Ender-3 3d printer can achieve performance comparable to many high-end machines in the market. For instance, the wide material compatibility will make it more versatile than its peer machine.

Before we probe into its filament compatibility and print performance, we would like to gain some understanding about its components which will affect the performance of various filaments.

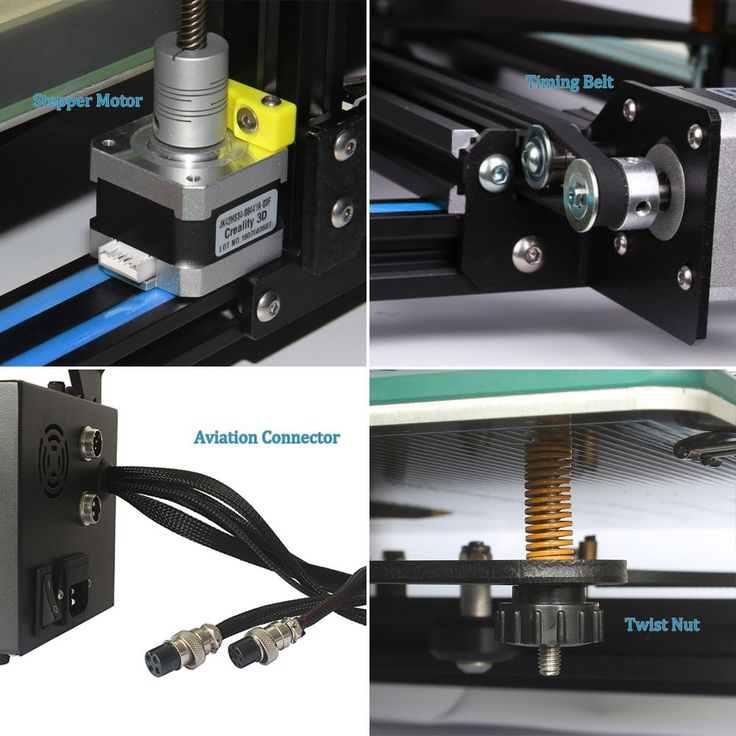

What Impacts Material Compatibility?

Hot end: Creality Ender-3 3d printer has a reliable hot-end which easily reach up to 280°C. However, as it is not an all-metal hot-end, so the temperature is limited to 240°C because of the use of PTFE tubing and the quality of the components it's made of. Otherwise, Creality Ender-3 3d printer is supposed to quite versatile in printing with a variety of plastics, such as PLA, ABS, TPU, and even PETG.

Nozzle: The standard 0.4-mm brass nozzle made use of on the Creality Ender-3 3d printer will certainly give you superb printing performance with a wide range of filaments. You can't make use of unpleasant materials, though, because those would certainly eat through the brass very swiftly.

Heated bed: The Creality Ender-3 3d printer has an integrated heated bed that can reach temperature up to 110 ° C, which will allow you to print with products susceptible to bending, such as ABS.

Supportive Filaments on Ender-3 3D Printer

PLA

Polylactic Acid, commonly referred to as PLA, is among the most popular products used in desktop 3D printing. Because it can be printed at a reduced temperature and does not require a heated bed, it is the default filament of selection for many extrusion-based 3D printers.

PLA is an excellent first product to utilize as you are learning about 3D printing because it is very easy to print, extremely inexpensive, as well as creates components that can be made use of for a variety of applications.

It is also among the most environmentally friendly filaments on the market today. Derived from crops such as corn and sugarcane, PLA is renewable and most notably biodegradable. As a bonus offer, this likewise allows the plastic to produce a sweet aroma during printing.

As a bonus offer, this likewise allows the plastic to produce a sweet aroma during printing.

PLA Printing Settings:

Printing temperature: 180-230 ° C. Normally, the specific printing temperature depends on the brand of PLA.

Hotbed temperature: PLA does not always require a heated bed, however, benefits dramatically from having on. Having a heated bed will certainly decrease the possibilities of warping. A modest 20-60 ° C helps a lot. If the temperature goes any higher, the PLA at the bottom layers might deform.

Bed adhesion: The build plate on Ender-3 provides a superb bed attachment for PLA. But for a smoother bottom surface, glass is a much better option. When utilizing glass, hairspray, or glue stick function the best. They provide your prints a good hold on the bed.

Print speed: PLA has no concerns as speed is taken into consideration. A basic recommended speed of 60 mm/s functions excellent, balancing high quality with printing time.

Retraction: PLA is a stiffer material, as well as thus it can be easily tuned. As the Ender 3 has a Bowden style setup, retraction settings are much higher. We only need to consider 2 factors here.

Retraction range: 5 mm

Retraction speed: 45 mm/sec

Part-cooling fan: This should be on. PLA is a drippy product, so it requires to be effectively cooled.

ABS

ABS (Acrylonitrile Butadiene Styrene) has a long background in the 3D printing community. This material was among the first plastics to be made use of with industrial 3D printers.

Many years later, ABS is still an incredibly popular material owing to its affordability and its excellent mechanical prosperities. ABS is known for its toughness and impact resistance, permitting users to print sturdy parts that will hold up to additional usage and wear.

LEGO building plates are made from ABS for the same reason! ABS likewise has a higher glass transition temperature, which implies ABS can endure much higher temperatures before it starts to deform. This makes ABS a great selection for outside or high-temperature applications.

This makes ABS a great selection for outside or high-temperature applications.

When printing with ABS, please make sure to use an open space with great ventilation, as the material has a great tendency to have some smell. ABS likewise often tends to contract quite a bit as it cools, so regulating the temperature level of your print area and the part inside can have significant advantages.

ABS Printing Settings:

Printing temperature: ABS

Requires to be printed at a higher temperature than PLA. A printing temperature of 230°C is a great beginning factor. Although the printing temperature varies from different brands of filaments, the optimal temperatures vary from 210-250°C.

Hotbed temperature: ABS does not easily get warped, yet a heated bed does a good work of preventing this. A bed temperature level of 80-110°C should be really helpful. Since the Creality Ender-3 3d printer is capable of getting to such temperature levels, ABS is a wind to print.

Bed adhesion: ABS needs some adhesion. Otherwise, you might find the corners of your prints lifted up. A border or a raft will help in lowering the bending of the parts. Furthermore, you ought to also be using a glue stick or ABS slurry for better adhesion.

Print speed: The print speed for PLA doesn't have much difference from ABS. Printing at 60 mm/s works well for ABS too. You run the risk of layer bond as well as layer splitting if you print at any kind of higher speed.

Retraction: Same values as for PLA.

Retraction distance: 5 mm

Retraction speed: 45 mm/sec

Part-cooling fan: ABS likes to be cooled down gradually. If it's cooled instantly, it might warp, or have higher possibilities of layer splitting.

PETG

PETG is a Glycol Modified variation of Polyethylene Terephthalate (PET), which is commonly utilized to make water bottles. It is a semi-rigid material with great impact resistance, but it has a slightly softer surface that makes it prone to wear.

The material likewise benefits from great thermal conductivity, allowing the plastic to cool down efficiently with almost minimal warpage. There are a number of variations of this material in the market including PETG, PETE, and PETT.

PETG Printing Settings:

Printing temperature: The best printing temperature for PETG is at 220-250°C. Many PETG manufacturers have actually optimized their PETG filament so that it can be printed at a temperature lower than 240 ° C.

Hotbed temperature: The very first layers should be a little high. It assists with adhesion and also minimizes warping. A bed temperature for PETG is supposed to be set at 50-75°C.

Bed adhesion: You should utilize a releasing agent on a glass surface for PETG. Otherwise, you'll be having a chunk of glass in addition to your part. PETG adheres extremely well to blue painter's tape. Hairspray and gluestick also function well.

Print speed: PETG prints well at around 50-60 mm/s. With greater speeds, it will sacrifice print quality. There could also be under-extrusion issues. Therefore, you should print at 25-30 mm/s, also, for much better high quality.

With greater speeds, it will sacrifice print quality. There could also be under-extrusion issues. Therefore, you should print at 25-30 mm/s, also, for much better high quality.

Retraction: This can get more difficult, and nobody wants stringing or blobs on their prints. PETG needs greater retraction than PLA, but printing at too high speed might result in nozzle clogging.

Retraction range: Start with a 5 mm distance, and rise in 0.2 mm increments. The max is 7 mm.

Retraction rates: A beginning speed of 40 mm/s with 5 mm/s increments to call it in.

Part-cooling fan: Keep the part-cooling fan on, as it will certainly provide you very in-depth prints and aid you with decreased stringing as well as blobs. If you want a stronger part, you can also choose to turn off the fan.

First layer height: PETG shouldn't be squeezed on the bed. It should lay down smoothly, and hence the layer height of the first layer should be approximately 0.32 mm. It prevents the build-up of material on the nozzle, which would introduce blobs and strings.

TPU

Thermoplastic Polyurethane (TPU) is a flexible, abrasion-resistant polycarbonate. It's being utilized in a variety of producing procedures for both customers as well as commercial usage. In specific blends, it can end up being really soft, yet TPU product offers numerous benefits as well as functions. 3D printed parts with TPU are durable, and have the ability to endure ambient temperature up to 80°C.

Print temperature: TPU prints well at a temperature between 210°C and also 230°C.

Hotbed temperature: A heated bed isn't required, as TPU doesn't shrink or warp like other materials. Nevertheless, if you desire, you can restrict it to 60°C.

Bed adhesion: Blue painter's tape works simply great. You can additionally use a raft or a border, but they're not crucial.

Print speed: TPU is a flexible material, as well as printing it quickly will certainly lead to issues, like the filament obtaining wound up in the extruder gear. The suggested maximum speed is about 25-30 mm/s.

Retraction: Keep retraction settings as low as possible. Higher values of retraction will lead to filament winding up in the extruder.

Retraction Distance: 3 mm must do it to start. Increase the value by 0.2 mm at a time if you still have stringing issues.

Retraction rates: 25-30 mm/s.

Part-cooling fan: Leave the part-cooling fan on. This will certainly help in the energetic air conditioning of layers as well as likewise stop any kind of stringing or balls, thus boosting print quality.

What Filaments Can Be Used On A Creality Ender-3 3D Printer?

Subscribe to Our Newsletter

Creality is a leading 3D printer manufacturer dedicated to developing the FDM/resin 3D printer, 3D printer filament, and maker related products. Subscribe to learn more.

Thanks for subscribing

Social Media

Ender 3 Filament Guide, What Filaments Can Ender 3 Use? - 3D Printing & Laser Cutting

Getting to know how to use your printer starts with learning about the different filaments you can work with. This Ender 3 filament guide will help you decide which type works with the popular Ender 3 3D printer and about some of the most efficient ways to feed filaments. There are many types of filaments compatible with the Ender 3; find out which one works best for your next project.

This Ender 3 filament guide will help you decide which type works with the popular Ender 3 3D printer and about some of the most efficient ways to feed filaments. There are many types of filaments compatible with the Ender 3; find out which one works best for your next project.

What is an Ender 3 3D Printer?

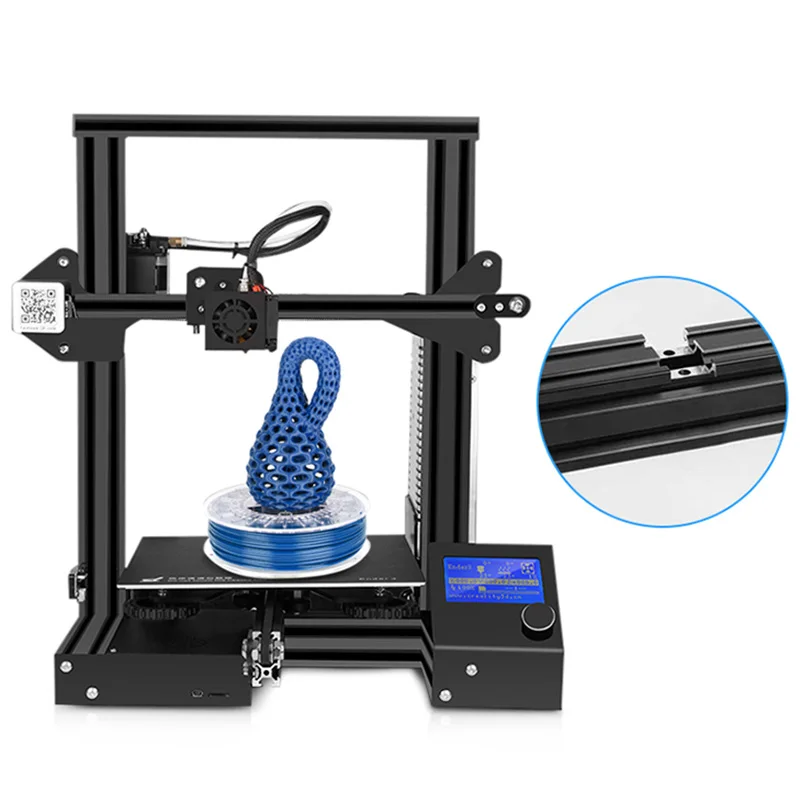

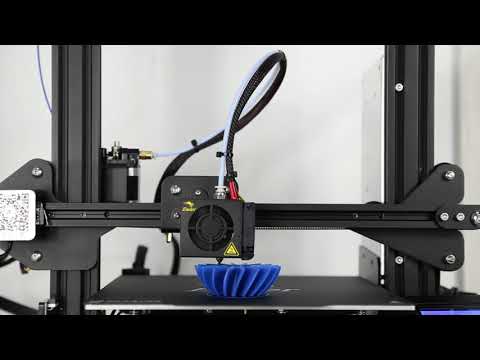

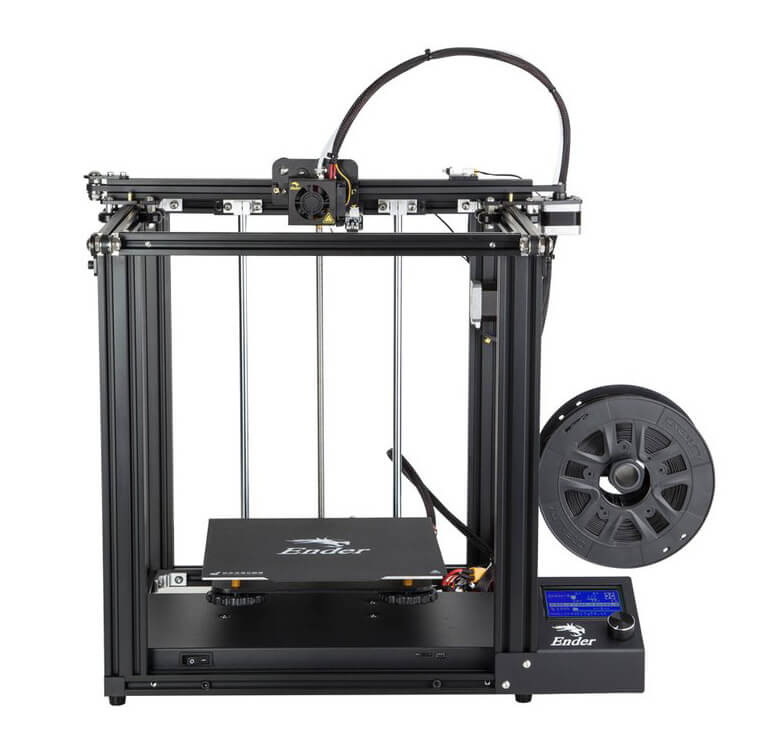

The Ender 3 3D printer is one of the most in-demand printers these days. It’s easy to use, easy to set up and has good features that fit beginners and professional hobbyists alike. The Ender 3 is a high-precision printer designed to quickly heat up for perfect filament material delivery. It has resume printing features that let you get back to where you left off after a power interruption.

- Dimensions: 8.7 x 8.7 x 9.8 inches, 17.64 pounds

- Power Supply: with a branded power supply

- Circuitry: industrial-grade circuit

- Ender 3 Max Temp/Ender 3 Max Bed Temp: 240 degrees Celsius

- Heating Time: 5 minutes to reach 110 degrees Celsius

- Extruder Type: plastic MK8

- Supported File Formats: OBJ and STL

- Compatible Materials: 1.

75 mm filaments TPU, PLA, and ABS

75 mm filaments TPU, PLA, and ABS - Ender 3 Print Speed: 180mm/second

- Ender 3 Bed Temperature: 110 degrees Celsius

- Special Features: resume printing, enhanced extruder, upgraded wheels, V-shape design

- Release Date: March 27, 2018

- Warranty: 1-year warranty on major parts, 3 months for the extruder kit

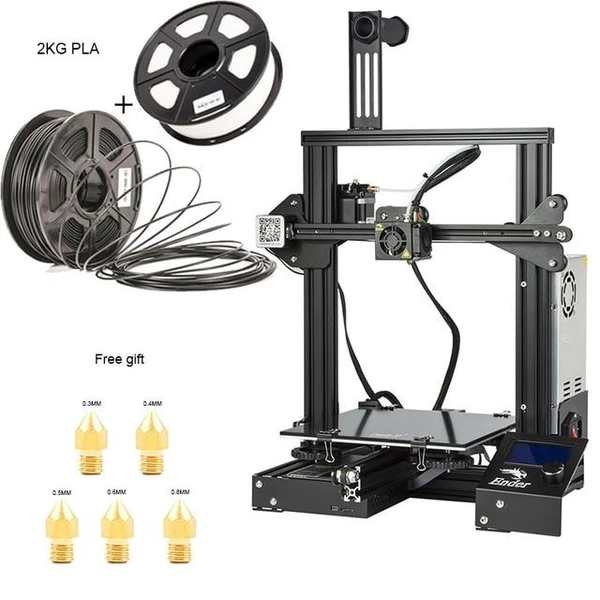

The Ender 3 is a part of Creality’s Ender 3D printer series. A newer version of this printer is the Ender 3 Pro with an updated extruder system, magnetic hotbed, MeanWell power supply, and other enhanced features.

What is a filament in a 3D printer?

Filaments in 3D printers are plastics or polymers (also called thermoplastics) which melt when heat is applied. Compared to other types of plastics that burn when exposed to heat, filaments only change shape so these can be molded and shaped into different forms.

Related: How to Change Filament on Ender 3 3D Printer

Filaments are fed through a heating unit found in the extruder assembly of the 3D printer. The heating unit heats the filament until it melts and afterward squirts it through a metal nozzle. The extruder moves and follows a path that’s programmed in a 3D file. The 3D object is created using the melted filament one layer at a time.

The heating unit heats the filament until it melts and afterward squirts it through a metal nozzle. The extruder moves and follows a path that’s programmed in a 3D file. The 3D object is created using the melted filament one layer at a time.

Most basic 3D printers have one extruder, like the Ender 3 but others have dual-extruders that can print anything in many colors or use different kinds of filaments.

Interested: https://makemendel.com/petg-vs-pla/

What filaments can Ender 3 use?

Ender 3 is one of the most versatile 3D printers as it can work with almost any type of filaments to create all kinds of projects. Here are the most popular types of filaments

PLA (polylactic acid)

PLA is the most common printing filament and is the most recommended one for the Ender 3. Printing with PLA is the easiest, less stressful, and brings the most fun! The Ender 3 was made for PLA printing. Take note of the following Ender 3 PLA settings:

- Temp Range for Extruder: 190 to 220 degrees Celsius

- Printing Speeds: 60 mm per second

- Retraction Speeds: 45 mm per second

- Retraction Distance: 5 mm

- Cooling Needed: yes

- Available Colors: different colors

- Available Sizes: FDM 3D printing sizes are 1.

75 to 2.85 mm

- Special Features: does not need a heating bed, should use a glass plate, low melting temperatures, hard to recycle but biodegradable

- Where to Buy: you can buy from many online suppliers

All these basic filament specs are followed by the Creality Ender 3. The temp of the Ender 3 nozzle tip is just the right range to work with PLA. You’ll notice that compared to other filaments, PLA does not require a heated bed. PLA can easily work with a bed with regular temperature but not a very cold printing bed. The Ender 3 has a heated bed but is flexible as you can turn the feature off if you’re working with PLA filaments. This is why there is no PLA bed temperature Ender 3 settings.

The Ender 3 plate may seem perfect but it also has its disadvantages. It creates an uneven underside which is why it’s best to use a glass plate when working with PLA so that the underside of the item is smooth like a mirror. Most users spray the glass plate with a bit of hairspray to improve its adhesiveness.

PLA comes in many types and sizes. The best PLA for Ender 3 type depends on the temperature range so be sure that the type you’re working with fits the temperature range of the printer. All PLA filaments need cooling which is why a print should be provided with an even airflow. The fan located near the extruder helps cool the print to create top-quality print results. It’s important to remove or open the printer casing (if you have one) to allow airflow to cool the print. Problems may arise if you overlook good airflow.

A common problem of poor airflow is clogging as PLA filaments have very low melting points. An enclosed printer can trap heat inside the housing which can heat the gears and increase the temp of the extruder component. The filament can wrap around the gear and become trapped; you need to take your 3D printer in for repair and costly cleaning.

As we mentioned, the Ender 3 is optimized to work with PLA and thus, there are always new files available for download. Recent files for PLA projects include topics like filament cooling and ventilation. Follow PLA print settings and PLA filament settings to ensure the best results.

Recent files for PLA projects include topics like filament cooling and ventilation. Follow PLA print settings and PLA filament settings to ensure the best results.

Read: https://makemendel.com/ender3-vs-ender3-pro/

ABS (acrylonitrile-butadiene-styrene copolymer)

ABS is another common filament material in 3D printing and is a popular choice for Creality Ender 3 filament. Acrylonitrile-butadiene styrene was the very first consumer-available filament for 3D printers. But the fascination for ABS was short-lived as pretty soon, users found many disadvantages. ABS requires the user to stick all the important filament parameters because if these are overlooked, problems may arise such as crooked printing or problems with filament extrusion. Check out these Ender 3 ABS settings:

- Temp Range for Extruder: 230 degrees Celsius

- Temp Range for Bed: 80 to 100 degrees Celsius

- Plate Adhesion Support: yes, very important

- Printing Speeds: 60 mm per second

- Retraction Speeds: 45 mm per second

- Retraction Distance: 5 mm

- Cooling Needed: no

- Available Colors: different colors available

- Available Sizes: 1.

75 to 2.85 mm

75 to 2.85 mm - Special Features: 100% recyclable, warps when it’s solidifying, contracts when the material cools, requires an adhesive bed, slow printing speeds

- Where to Buy: available in different sizes and colors online

You can use the Ender 3 to print Ender 3 ABS projects however, you must consider fine-tuning your printer. You need to access the printer’s main menu, adjust the temperature of the extruder and bed and make sure that everything is in the right setting before you start printing.

Compared to PLA, ABS is recyclable and 3D printer manufacturers are introducing new mini-extrusion equipment to create new filaments from old ABS materials. Although this ABS recycling equipment is expensive, you’ll save a lot of money in the long run as you can recycle your waste and prints.

This filament material needs to be hot printed at 230 degrees Celsius. Most experts say that you should work near the maximum temperature value of 250 degrees Celsius to get the best results. There is a thing called the “warping effect” in ABS. This phenomenon is present when the ABS print is starting to solidify as the hardened and brittle filament material starts to cool. Parts of the print may bend because of imbalanced internal stress.

There is a thing called the “warping effect” in ABS. This phenomenon is present when the ABS print is starting to solidify as the hardened and brittle filament material starts to cool. Parts of the print may bend because of imbalanced internal stress.

In printing ABS on Ender 3, you can avoid the warping effect by using a heated bed. However, you must be careful when you reach 100 degrees Celsius as this means that the table is very hot (boiling). You should always use thermal-resistant gloves when handling a hot printing bed.

The print should adhere to the table to prevent slipping while printing. An adhesive head can also give you a good bonding surface. You should give ABS time to print. You must wait till your printer is at the right temperature before you print and you must also wait until the print gradually cools to avoid internal stress.

A heated bed will cool the print very evenly so the results will not look crooked. Don’t switch on your fan so cooling happens gradually and efficiently.

PETG (polyethylene terephthalate variant)

PETG is a regular PET variant and is used to make water bottles and drink bottles. PETG has the combined properties of ABS and PLA and therefore printing is easier and more precise compared to using PLA or ABS alone.

- Temp Range/Ender 3 Temperature Settings: 230 to 250 degrees Celsius

- Bed Temp Range: 110 degrees Celsius for the first layers. Layers higher than 5 mm will need 70 degrees Celsius

- Plate Adhesion: needed but use a release agent

- Printing Speeds: 60 mm per second

- Retraction Speeds: minimum of 40 mm per second

- Retraction Distance: 5 to 7 mm

- Cooling Needed: yes

- Available Colors: available in many colors

- Available Sizes: 1.75 to 2.85 mm

- Special Features: needs a very hot print, will warp, use a loose base layer, higher printing speeds

- Where to Buy: Available in online stores and shops

PETG is one of the common Ender 3 filament types. To use PETG, your printer must work up to 250 degrees Celsius but lately, new PETG filaments can be used at 240 degrees Celsius. This temperature range can be handled by the Ender 3 3D printer. Just like ABS, PETG can warp but not as extensively as ABS. Therefore it’s a must to let the base layers stick very well and everything should be straight using a hot, adjustable printing bed. When the base layers are ready, you can reduce the temperature without encountering further problems.

To use PETG, your printer must work up to 250 degrees Celsius but lately, new PETG filaments can be used at 240 degrees Celsius. This temperature range can be handled by the Ender 3 3D printer. Just like ABS, PETG can warp but not as extensively as ABS. Therefore it’s a must to let the base layers stick very well and everything should be straight using a hot, adjustable printing bed. When the base layers are ready, you can reduce the temperature without encountering further problems.

You can’t just place a PETG print on a heating table. You must use an efficient adhesive layer made of painter’s tape (the blue tape) and a small amount of hairspray. As you print, the solid part of the PETG material will adhere to this layer very securely but can be easily removed when the project is complete.

Printing speeds using PETG vary. You can go for a 60 mm per second speed if you don’t want to add pressure on the outer section of the print. You can reduce speeds up to 30 mm per second to get the best results. This may delay printing time but you won’t have to worry about wasting your filament because of poor printing results.

This may delay printing time but you won’t have to worry about wasting your filament because of poor printing results.

You can’t discuss PETG filament without mentioning retraction. Because you need to use high temperatures to work with PETG, the material can drip and turn into threads. This will also cool down very quickly so pulling back can create a drop from the hot end. This can block the printing. It’s best to determine the right retraction for every project you do use PETG filament.

Use a good cooling system. When the fan is on, you can see the details of your prints. But with the fan turned off, the layers will bond better. So consider a balance when applying air to your PETG project. Use a base layer when you’re printing. You should place the base layer very loosely so the melted material won’t glide to the heating plate and press the project down. Remember, steady the base layer first before reducing printing distance and temperatures.

TPU (thermoplastic polyurethane)

Soft, workable rubber; these are words to describe TPU or thermoplastic urethane. This filament material allows hobbyists to make rubber toys, gaskets, and many kinds of components. TPU requires careful adherence to its operating temperatures and printer conditions. Overlooking these can lead to the deformity of your prints. TPU is considered one of the best filaments for Ender 3.

This filament material allows hobbyists to make rubber toys, gaskets, and many kinds of components. TPU requires careful adherence to its operating temperatures and printer conditions. Overlooking these can lead to the deformity of your prints. TPU is considered one of the best filaments for Ender 3.

- Temp Range: 220 to 240 degrees Celsius

- Temp of Printing Bed: 40 to 60 degrees Celsius

- Printing Speeds: up to 30 mm per second

- Retraction Speeds: up to 30 mm per second

- Retraction Distance: minimal

- Cooling Needed: yes

- Available Colors: all colors available

- Available Sizes: 1.75 to 2.85 mm

- Special Features: elongation up to 750%, waterproof, oil and grease resistant, alkali resistant, dissolves in acids or alcohol, should start as dry, will attract water (hygroscopic property), store in a dry container with silica gel or salt, available in soft/semisoft, medium and hard versions, high melting temperature, will not warp

- Where to Buy: available in most online 3D printer filament stores

TPU has a high heat resistance and is impossible to rework. Therefore, you should adjust your 3D printer correctly before you start working. This filament is waterproof when the project is complete. It’s resistant to grease, oil, and alkali but can be vulnerable when exposed to acids and alcohol.

Therefore, you should adjust your 3D printer correctly before you start working. This filament is waterproof when the project is complete. It’s resistant to grease, oil, and alkali but can be vulnerable when exposed to acids and alcohol.

Unused TPU filaments should be kept in a very dry container as the raw material is hygroscopic. When TPU is soaked, the results will develop bubbles. It’s best to place the TPU inside an airtight container. Place silica gel inside to keep away moisture.

You can buy TPU in three kinds: soft or semisoft, medium and hard. Soft TPU is for low-load products. This is the most elastic type and with the lowest breaking-elongation value of 550%. Medium TPU is very common and has the regular properties of rubber.

Related: TPU Filaments for 3D Printing Guide

TPU has one of the highest melting temps but can be handled by the Ender 3. There’s no need to apply heat on the print bed as this filament doesn’t warp. You can also use a warm 60 degrees Celsius plate. Use painter’s tape and a small amount of hairspray to enhance its adhesion properties. You must power on your cooling fan when printing with TPU.

Use painter’s tape and a small amount of hairspray to enhance its adhesion properties. You must power on your cooling fan when printing with TPU.

HIPS (High Impact Polystyrene)

HIPS is foamed rubber and is one of the special Creality Ender 3 filament types in 3D printing. You can’t use the Ender 3 to print with HIPS as this comes with only one printing head. You need a printer with a dual-extruder to print the support and the product using two types of filament.

- Temp Range: up to 230 degrees Celsius

- Temp Range of Plate: at least 100 degrees Celsius

- Adhesion: Yes

- Printing Speeds: up to 60 mm per second, the slower the better

- Retraction Speeds: 45 mm per second

- Retraction Distance: 5 mm

- Cooling Needed: no

- Available Colors: available in different colors

- Available Sizes: from 1.75 to 3 mm

- Special Features: inexpensive, low resolution, stiffer, resistant to abrasion, less warping, lightweight, demands high processing

- Where to Buy: available in most thermoplastic filament stores online

HIPS is used to print simple objects. However, it is a low-resolution material and thus, you can’t print fine details on it. It is stiff, resistant to abrasion, and will not warp so much. HIPS has great mechanical properties but is very lightweight.

However, it is a low-resolution material and thus, you can’t print fine details on it. It is stiff, resistant to abrasion, and will not warp so much. HIPS has great mechanical properties but is very lightweight.

HIPS needs a high-temperature 3D printer like the Ender 3. It also needs a heated plate. This filament needs a plain printing plate but not bare metal as it can stick to it like glue. The best one is glass but make sure to use painter’s tape and some hairspray. Always print with no fans as this material needs to cool down slowly.

Related: comparison between HIPS vs PVA

PVA (polyvinyl alcohol)

PVA is a highly specialized filament and is only used by professionals. It is water-soluble so it’s not as popular. Ender 3 is not made for PVA filaments as it is a single-extruder type of printer.

Moldlay Wax Filament

Moldlay is a popular wax type of filament. It is very costly but it has a very low density which makes it economical to use.

- Temp Range: 170 to 180 degrees Celsius

- Printing Speed: 35 to 100 m per second

- Available Colors: available in many colors

- Available Sizes: 17.

5 to 2.85 mm

5 to 2.85 mm - Special Features: needs a casting material, needs low temperatures, easy to use

- Where to Buy: available from online suppliers

It takes time to learn how to print with wax but once you got the hang of it, printing is a snap. It needs casting material to create the best prints. The casting core must be completely melted and then cleaned and cooled down.

You must store unused Moldlay wax in a cool dry place like a refrigerator. Wax has high adhesive strength so there’s no need to worry about adhesion to the plate.

Metal Filaments

A hot end nozzle is required to handle metal filaments. The best type is chrome-plated printer nozzles as chrome can withstand extreme heat and any hard particles found in the filament. Printing parameters for metal filaments are the same as ABS and the best PLA settings.

- Temp Range: 201 degrees Celsius

- Temp Range for Heating Bed: 60 degrees Celsius

- Printing Speeds: 30 to 60 mm per second

- Available Colors: available in many colors

- Available Sizes: 1.

75 to 2.85 mm

75 to 2.85 mm - Special Features: robust, maybe sanded, can have a glossy finish

- Where to Buy: available in suppliers online

Wood Filaments

You need to adjust the Ender 3 or any 3D printer before working with wood as it is very abrasive and can ruin your nozzle. Wood filaments are cheap, very economical and prints like PLA.

- Temp Range: 180 to 220 degrees Celsius

- Printing Speeds: 60 mm per second

- Retraction Speeds: 45 mm per second

- Retraction Distance: 5 mm

- Cooling Needed: yes

- Available Colors: different colors

- Available Sizes: FDM 3D printing sizes are 1.75 to 2.85 mm

How to feed filaments in Ender 3?

To feed filaments to the Ender 3 follow these instructions:

- Go to the Menu and the Nozzle settings to heat the nozzle. This is also where to adjust the Ender 3 bed temperature PLA filaments.

- When the printer hotend has achieved the right temperature, press the extruder level to release the filament.

Remove any remaining filament and spool.

Remove any remaining filament and spool. - Take the end of the filament material and thread it in one of the holes at the filament spool.

- Insert the new filament into the extruder.

- If there is old material, purge it from the system through the menu options.

- The printer will automatically feed the new material through the nozzle. You must repeat this many times so that any old filament can detach from the tip of the nozzle.

This Ender 3 filament guide will help you use different materials and find the best PLA filament for Ender 3 3D printers as well as other filament types. Ender 3 is an open-source printer. Improve your printing experience by using different kinds of filaments and share with the community.

Contents

- 1 What is an Ender 3 3D Printer?

- 2 What is a filament in a 3D printer?

- 3 What filaments can Ender 3 use?

- 3.1 PLA (polylactic acid)

- 3.2 ABS (acrylonitrile-butadiene-styrene copolymer)

- 3.

3 PETG (polyethylene terephthalate variant)

3 PETG (polyethylene terephthalate variant) - 3.4 TPU (thermoplastic polyurethane)

- 3.5 HIPS (High Impact Polystyrene)

- 3.6 PVA (polyvinyl alcohol)

- 3.7 Moldlay Wax Filament

- 3.8 Metal Filaments

- 3.9 Wood Filaments

- 4 How to feed filaments in Ender 3?

Differences between Creality Ender 3 (Pro) and Ender 3 V2

3DPrintStory Reviews Differences between Creality Ender 3 (Pro) and Ender 3 V2

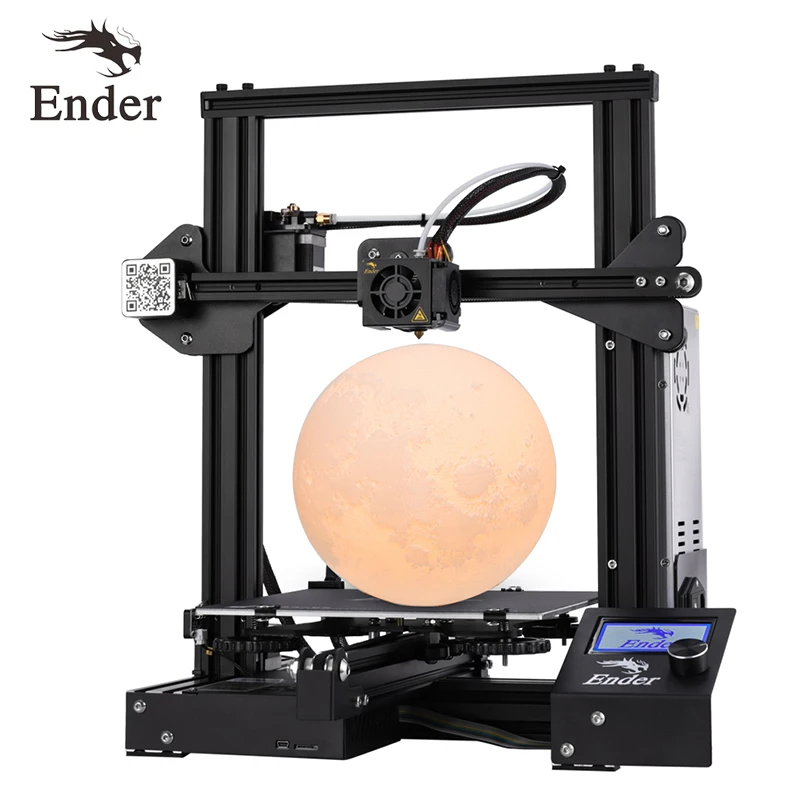

When it comes to budget 3D printers, the Creality Ender 3 is second to none - with the exception of later iterations released by a Chinese 3D printer manufacturer.

And given the huge popularity of this model, Creality has tried its hand at several upgraded versions of it, including the Ender 3 Pro, the Ender-3X and - the latest in the Ender 3 saga - the Ender 3 V2.

Announced in 2020, the Ender 3 V2 is very similar to its predecessors, with a few exceptions that give the 3 V2 the highest price of all, $269 at press time. It hasn't been released yet, but we've put together all the specs Creality has given us so you can get an idea of what to expect.

The big question is, is the Creality Ender 3 Pro or Ender 3 V2 worth the extra money, or is the Ender 3 still a firm favorite? This is what we will try to answer in this article.

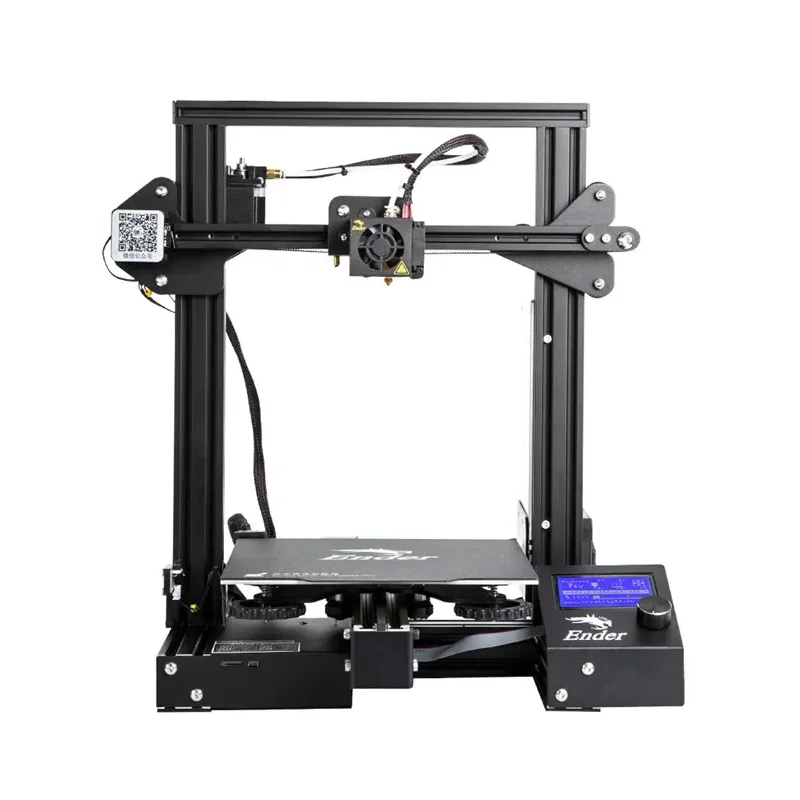

Creality Ender 3

There are a number of features that make the original Creality Ender 3 the most popular 3d printer on the market. And aside from the specs this model offers, one of the Ender 3's biggest selling points is its vast community. Since the model is no longer a novelty, it has a huge number of owners and an incredible amount of information about it on the Internet, not to mention the enthusiasm of users who are happy to help if you have any problems.

In addition, the Ender 3 offers a working volume of 220 x 220 x 250 mm, a BuildTak-like heated bed, print resume mode. These attributes are often missing from even more expensive 3D printers, and the Ender 3 delivers this for around $200.

These attributes are often missing from even more expensive 3D printers, and the Ender 3 delivers this for around $200.

We experimented with PLA, PETG, ABS, flexible and exotic plastics and the Creality Ender 3 successfully printed all of these materials.

This 3D printer is easy to assemble, and although manual calibration is required, the oversized table leveling knobs make the process quite convenient.

Creality Ender 3's most egregious problem is the foundation that causes the entire 3D printer to wobble. The manufacturer seems to have addressed this issue by creating a slightly more stable frame for the Ender 3 Pro. Other than that, the Creality Ender 3 is nothing more to blame, especially considering how much (or rather how little) it costs.

All in all, the Creality Ender 3 is a great option for beginners or producers on a budget. While this 3D printer has its drawbacks, the affordability makes it a worthwhile investment. Unlike other budget options in this price range, the Creality Ender 3 is ready for high quality 3D printing right out of the box.

Here are the detailed specs of the original Creality Ender 3:

- Technology: FDM

- Year: 2019

- Build: semi-assembled

- Manufacturer: Creality

- Thread diameter: 903 903 900

- Compatible materials: PLA, ABS, PETG, TPU

- Accuracy: 0.1 mm

- Layer height: 0.1 mm

- Feeding system: Bowden

- Extruder type: single nozzle

- Nozzle size: 0.4 mm

- Max. 3D print volume: 220 x 220 x 250 mm

- Max. extruder temperature: 255 ° C

- Max. heated bed temperature: 110 °C

- Max. print speed: 180mm/s

- Closed print chamber: No

- Table calibration: manual

- Print bed: heated

- Display: LCD screen

- Connectivity: SD card, USB stick

- Integrated Camera: No

- 3D Print Recovery: Yes

- Recommended slicer: Cura, Simplify3D

- Operating system: Windows, Mac

- File types: STL, OBJ

- Frame dimensions: 475 x 470 x 620 mm

- Weight: 7.

8 kg

8 kg Believe it or not, the Ender 3 Pro isn't all that different from its hugely popular predecessor.

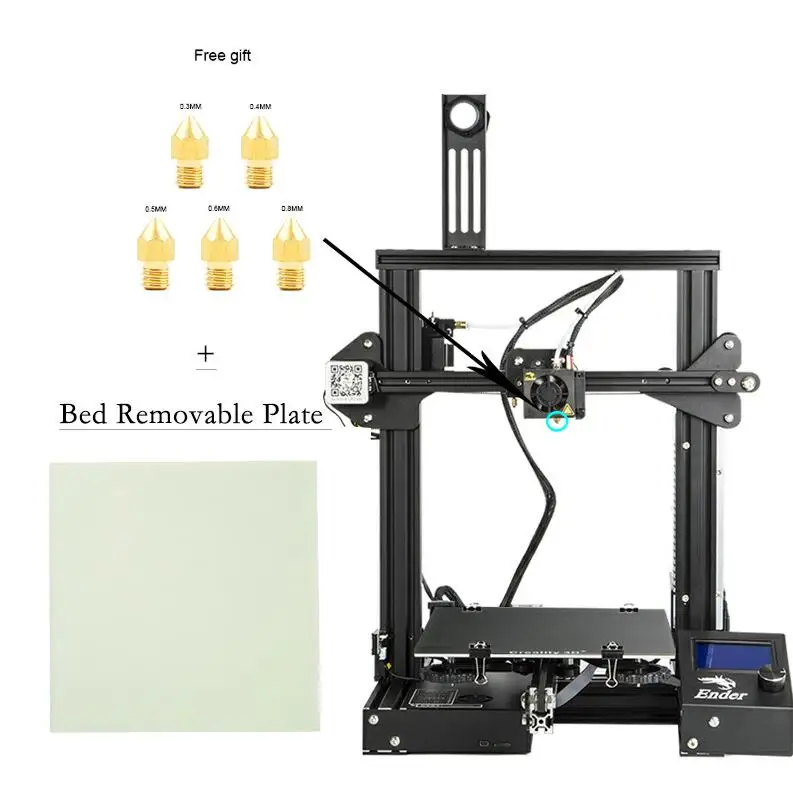

First, the Ender 3 Pro has been redesigned with a stronger 40×40 aluminum profile for the Y-axis base. Perhaps the most important upgrade in terms of 3D print quality.

Another aspect that makes the Ender 3 Pro great is the updated Meanwell power supply, which is thinner, quieter, and better in every way than the version featured on the original Ender 3.

part of the base of the 3D printer, making it vulnerable to falling pieces of filament. On the Ender 3 Pro, the manufacturer placed this fan at the bottom of the 3D printer. While the new placement of this fan effectively keeps the board free of plastic, we remain a bit skeptical about how much airflow under the 3D printer's base is sufficient.

Finally, Creality 3D has also added a magnetic table to the Ender 3 Pro build plate. This sheet is removable and flexible, making it easy to remove finished parts from the work surface.

It has a textured surface that should theoretically improve adhesion for all fiber types, eliminating the need for tape, glue, and hairspray.

It has a textured surface that should theoretically improve adhesion for all fiber types, eliminating the need for tape, glue, and hairspray. Otherwise, the Creality Ender 3 Pro has the same workspace, design, and general features as the original Ender 3.

With the above improvements, you'll have to spend a little more on the Creality Ender 3 Pro. Its retail price is 259US dollars.

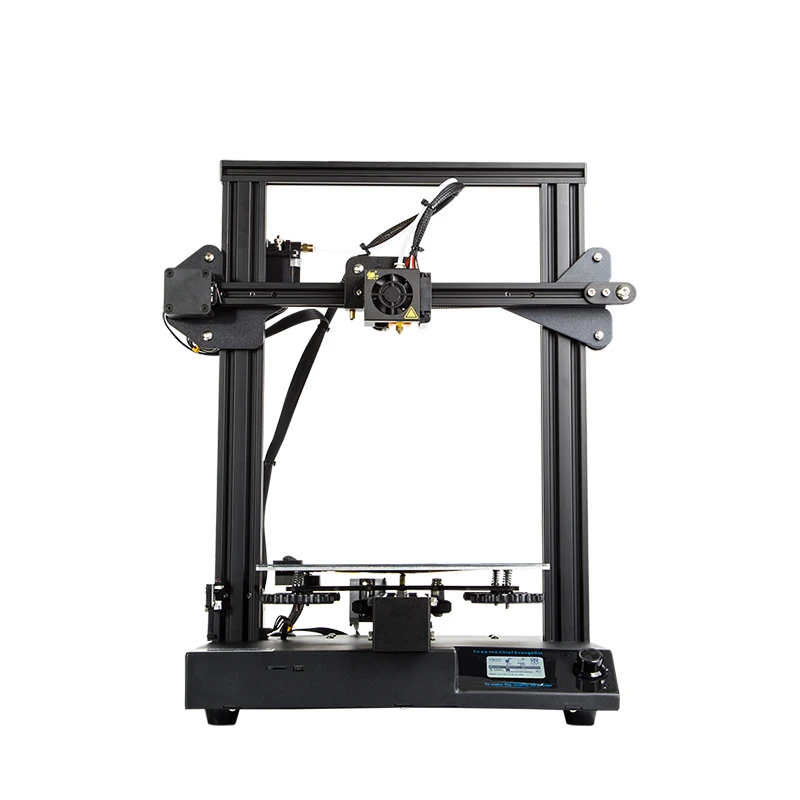

Creality Ender 3 V2

And here we come to Creality's latest (and perhaps most serious?) iteration of Ender 3: Ender 3 V2.

It's hard to tell if this is the best (or worst) option - again, the 3D printer hasn't been released yet, though it's available for pre-order and we haven't had a chance to review it yet. - we can make some guesses based on the specs and details that Creality has released so far.

Like the original Ender 3, the V2 provides a print volume of 220 x 220 x 250mm and can also print with PLA, ABS, TPU and PETG materials.

But there are some important differences, namely: the table is made of tempered carborundum glass.

This is perhaps the most notable of all the novelties. This is a welcome change from the Ender 3 Pro Magnetic Desk.

This is perhaps the most notable of all the novelties. This is a welcome change from the Ender 3 Pro Magnetic Desk. The printing table is mounted on an aluminum plate. Because of the improved overall adhesion of the material, this flatter surface is said to allow easier removal of finished 3D models. 9The 0005

V2 also features a beautiful HD color screen instead of the old LCD character display. As with older style displays, the color screen is still navigated using the control wheel.

It also boasts an upgraded 32-bit "silent" motherboard of its own design. Creality says it prints at 50 decibels, which is comparable to a quiet suburb or conversation at home. And it has a MeanWell brand power supply that heats up quickly and allows users to choose between 115V or 230V supply voltage.

Some other upgrades and tweaks are a toolbox built into the base of the 3D printer where you can store things like nozzles, needles, pliers and other tools, the ability to resume printing after a power outage, an XY axis tensioner.

Finally, Creality has added two adjustable X and Y tensioners to extend the life of the belts.

However, again, despite some welcome changes, the main specifications of the Ender 3 V2 are the same as the original Ender 3.

What is the best buy?

All of this information above is helpful, but which model is right for you? The answer depends on several factors: your budget, how much you value novelty, and how much effort you want to put into 3D printing. Without a doubt, the original Ender 3 still offers the best value for money. If you already own Ender 3, we would suggest simply upgrading it to get the same features. For example, replace the printing table.

But if you don't already have Ender 3, you need to decide if the improvements and extra features in V2 are worth the extra cost. For example, the carborundum glass print bed, while great, is easily purchased separately and upgrades the existing Ender 3. Other features such as the color screen and toolbox are nice features, but they don't change the game in terms of 3D print quality.

and even ease of use.

and even ease of use. As for the V2's tensioners and material loading rotary knob, they're handy, but since the model isn't available yet, it's hard to say if they'll work as advertised and how useful they'll be.

After all, if you want a car with all sorts of bells and whistles and don't mind paying extra for it (and you're a fan of new stuff and don't worry about the model not standing the test of time), the Creality Ender 3 V2 is your guy. But if you're happy with the best deal and don't mind upgrading your 3D printer as you go, then go for the Ender 3.

setup, refinement and firmware update process

Creality Ender 3 Pro is a budget Chinese 3D printer. The device became the company's bestseller, with 200,000 models sold in 2018. The equipment prints blanks using FDM technology.

Creality Ender 3 Pro Review

Creality Ender 3 Pro comes in DIY format: the user needs to assemble the frame and connect all the necessary nodes. Each detail is marked, beginners will not have difficulty.

The model comes with a user manual detailing the assembly steps.

The model comes with a user manual detailing the assembly steps. Creality Ender 3 Pro is an upgraded version of the popular Creality Ender 3. There are three main differences between the printers.

- Mechanical data. The Pro version uses a 40×40 aluminum profile to create a rigid Y-axis extrusion. This measure improves print stability. Improved guide wheels are installed, which improve the stability of work.

- There are rubberized feet at the bottom of the case. This allows you to reduce the noise level during operation. The printer is securely fixed to the surface, which reduces vibration.

- Brand new magnetic printing surface. The C-Mag magnetic backing is removable and flexible, it allows you to quickly unstick the printout from the desktop after the printer has finished working. The panel is textured, the first layer adheres well - this is important for detailed processing.

The frame of Creality Ender 3 Pro is made of aluminum profiles.

This adds rigidity and strength to the device. One screw is mounted on the left, it is responsible for the functioning of the Z axis. The model has a large heated table, which allows you to process several types of plastic.

This adds rigidity and strength to the device. One screw is mounted on the left, it is responsible for the functioning of the Z axis. The model has a large heated table, which allows you to process several types of plastic. The print chamber measures 220 x 220 x 250 mm and is suitable for medium size workpieces. It is equipped with a small monochrome LCD display and a rotary switch to control and monitor the printing process.

Chamber fully open. This is a good option for those who would like to get acquainted with the principle of operation of the extruder and consider the mechanism of 3D printing.

Description

The Creality Ender 3 Pro 3D Printer is a Chinese design that incorporates advanced concepts and precision printing requirements. Works using standard Cura software. The slicer is distinguished by a multifunctional menu in which each setting item is signed. The user can choose the necessary characteristics independently.

Equipped with Meanwell power supply for stable operation and high performance.

This part allows you to achieve a constant supply of electricity from the network to the device.

This part allows you to achieve a constant supply of electricity from the network to the device. Aluminum V-rails ensure smooth and silent movement of the extruder along the axes. Wear-resistant rollers are installed, sliding freely during operation.

Advantages and disadvantages of

Creality Ender 3 Pro has the following advantages.

- Magnetic work surface.

There is a magnetic sticker on the platen. It provides better adhesion than glue or a textured surface. This property is especially important for working out the first layer. It is detailed and smooth.

The finished model can be removed effortlessly. It is enough to pry it with a spatula, it will move away from the surface itself.

- Patented extruder MK-10.

New technology reduces clogging and improves extrusion.

- Fast heating of the platform surface.

Platform warms up to 110°C in 5 minutes. This is facilitated by the updated UL power supply system: the device works without interruption.

- Ability to resume operation after an emergency shutdown.

If the 3D printer has a power failure or a filament supply failure while the 3D printer is running, the user will be able to resume work from the point they left off. The device saves progress, to continue printing, you need to select the appropriate item in the menu on the external display.

- Y-axis mounting slots are CNC machined.

They provide precise positioning and a high level of workpiece processing.

- Simple calibration.

There is a large nut under the platen. To manually calibrate the level of the table, it is necessary to rotate it in the desired direction and monitor the position of the working platform.

- Narrow filament channel.

The user can work with flexible threads.

- Modernizable.

To improve print quality, control overheating of the extruder and fine-tune the unit is upgradeable.

- Equipped with USB and Micro SD card slots.

The user can download projects created in the slicer directly to the device, start work through the monochrome display installed on the external part.

- Compact.

The volume of the print chamber allows you to work with medium-sized workpieces. But at the same time, the device does not take up much space on the desktop.

The Creality Ender 3 Pro also has a few drawbacks.

- Magnetic base not suitable for all materials.

- Adhesion aids may be required to improve adhesion.

- The Autodesk Kickstarter test system showed that fine flow control in the printer is poorly implemented. The device cannot print objects with high detail. If there are spikes on the surface, then in the workpiece they may be of irregular shape.

- Z alignment does not work correctly. This negatively affects the development of layers.

- Fragile filament causes problems during operation.

It is damaged and processed incorrectly, the finished model is different from the one that was created in the slicer.

It is damaged and processed incorrectly, the finished model is different from the one that was created in the slicer.

Help! Creality Ender 3 Pro belongs to the budget class of 3D printing equipment. It has become an improved version of its predecessor.

Creality Ender 3 Pro

The device is supplied as follows.

- 3D printer disassembled;

- hex wrench set;

- power cable;

- PLA for proof printing;

- spatula and wire cutters;

- SD card and USB adapter for SD card;

- nozzle cleaning wire;

- replacement nozzle;

- fixing kit;

- cable tie kit;

- screwdriver;

- user manual in Russian;

- warranty card.

The manual describes in detail how to build a DIY printer. For the convenience of users, there are color codes and inscriptions that help to assemble the device. Experienced assembly will take 10 minutes, beginners - about 30 minutes or an hour.

Print quality and product examples

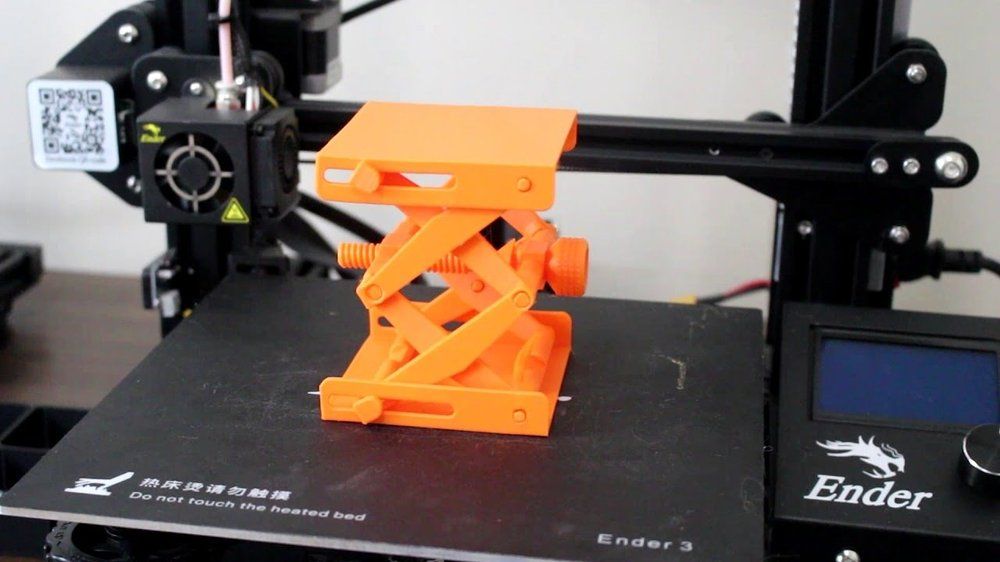

The manufacturer suggests that you start with a test print. A three-dimensional model of a dog is supplied as a sample.

The workpiece is fuzzy. Eyebrows and eyes lack detail, the user will have to manually clean up the flaws of the printer.

Piglet also failed. The left side is covered with potholes, a notch appeared between the ears. The ears are processed in different ways, the patch is without details, lubricated.

During the printing process, the problem of filament breakage may occur, as users write about in the reviews. An example is a model of a toy boat.

The device could not print the top part. The preparation was left unfinished.

A set of simple geometric products, the printer prints well after correcting the shortcomings in the settings. The surface is smooth, the filament is fed evenly without interruption.

With correct adjustments and correction of defects in the positioning of the table, printed models come out clear.

Details of its structure are visible on the body of the dragon: scales and fangs are printed, all spikes are of different lengths and are at different levels.

Geometric patterns print well after adjusting the extruder. The layers are uniform, without gaps.

WOOD prints parts with moving parts.

An Autodesk Kickstarter issue occurs during printing of spikes. On the turtle on the right, this is clearly visible: filament threads are visible on the surface, there is not enough smoothness and clarity.

The gaps in the man's body are made hollow, as it was created in the slicer. There are no filament threads and fuzzy printed edges. An identical problem occurred when printing a figure with spiers.

Tips came out fuzzy. They are of different heights and thicknesses. The lower part is processed without significant remarks.

What types of plastic does he use?

Creality Ender 3 Pro can print on the following plastics:

- ABS;

- TPU;

- WOOD;

- PLA;

- PETG.

The platform warms up to 110 °C, which allows you to work with different types of plastic.

Upgrade

You can upgrade yourself to improve print accuracy, improve user experience, and eliminate minor imperfections.

- Extruder replacement.

The plastic filament feeder is unstable. This leads to defects during printing, the printer does not print details, makes the layers fuzzy. The plastic mechanism backlash, before work, the screw must be tightened tightly. Due to the constant control of the screw, the pressure roller may jam, which will lead to uneven processing of the layers.

Users experiencing this issue are advised to replace the filament feed mechanism before use. A compact self-printing version is suitable: it can be used with a standard roller, a feed gear and a spring with the ability to adjust the clamping force.

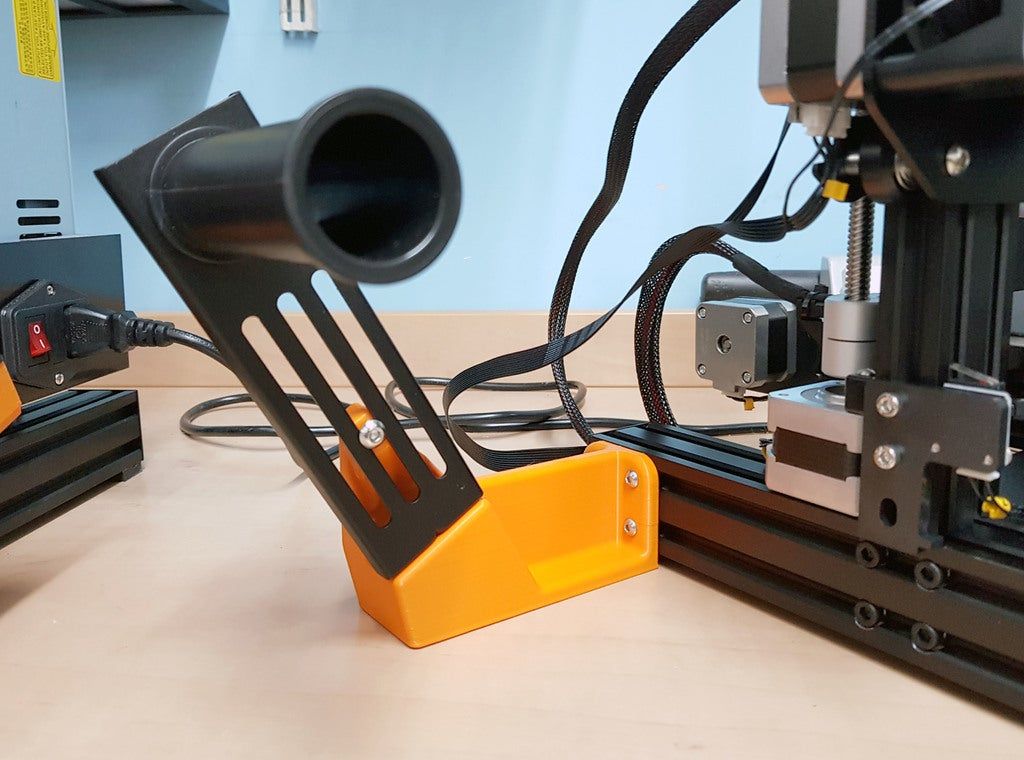

- Cooling system

One of the common problems with Creality printers is the poor performance of the cooling system.

If this deficiency is not corrected, the print quality will deteriorate. The thermal barrier overheats, the plastic softens, the extruder does not process all the necessary zones.

If this deficiency is not corrected, the print quality will deteriorate. The thermal barrier overheats, the plastic softens, the extruder does not process all the necessary zones. Fans must be replaced immediately to avoid overheating and defects in finished blanks. They should be 40 x 40 x 20 mm in size and with a potential of 24 V. A powerful cooling system is necessary to work with PLA plastic.

It is also recommended to replace the cooling system of the board. If it overheats during operation, the drivers may stop working, defects are found on the blanks during printing. A suitable fan model is with dimensions of 70 × 70 × 15 mm. For installation, you must first print a new cover with a suitable size or increase the airflow hole.

It is also recommended to install a dust filter. It is not included in the kit. It can be printed on a printer or purchased at a store.

Initial setup and preparation instructions

Creality Ender 3 Pro - DIY model.

The user needs to assemble it himself and prepare it for work. To do this, the kit includes a Russian-language user manual. It describes the process of assembling the equipment step by step and with illustrations.

The user needs to assemble it himself and prepare it for work. To do this, the kit includes a Russian-language user manual. It describes the process of assembling the equipment step by step and with illustrations. - Mounting the axle guides.

Before you start screwing in the vertical guides, you need to check the play on the table rollers. Tighten the eccentrics with the key from the kit, do not press them hard, so as not to accelerate wear.

Insert the rails into the lower part of the frame, screw into the end with a pair of screws M 5 × 45. To do this, use the hexagon that is included in the kit. It is important to observe the distance from the edge of the rail to the frame hole, as indicated in the instructions.

- Shield and power supply assembly.

To mount the shield, take the screws M 5 × 8 from the kit. Screw the display obliquely into the end part of the profile. The power supply is fixed with M 4 × 20 screws to the vertical rails.

- Installation of the limit switch on the axle.

Take a small fee from the Z-limit package. It is screwed with plastic guides to the necessary protrusions. Screw the board, connect with a wire marked "Z" to the control unit.

- Installing the motor on the axle.

The motor to frame mount is made of durable plastic and is already attached to the motor. The task of the user is to screw it to the frame and connect it to the designated wire. After that, you need to insert the trapezoidal screw into the coupling and tighten it.

- X-axis assembly.

The X-axis is supplied almost completely assembled. It is necessary to fix the guide, on which then install the carriage with the hotend. There are holes on the body plates through which you need to tighten the screws to secure the rail. Finally install the fitting for the extruder.

- Carriage installation with hot end.

Take a plate with three rollers, a pair of screws M 4 × 16 and a carriage with a hot end, which must be adjusted after installation on the rail. Tighten the screws so that the carriage does not wobble, but do not compress them too much.

- Install the belt on the X-axis.

In order for the carriage with the hot end to move along the axis, you need to mount the belt. The kit comes with a part of the required length, copper plates are installed at the ends. Pass it through the holes indicated in the instructions, on the other hand, install the tensioner. Fix the belt in the carriage by inserting the aglet into the slot.

- Installing the tensioner on the X-axis belt.

This is the last stage of the X-axis assembly. Insert the tensioner from the end of the guide, slightly tension the belt without creating maximum tension. Secure the tensioner with swivel T-nuts - they are inserted into the channel and tightened with screws.

Do not screw them in to the limit.

Do not screw them in to the limit. - Installing the X-axis on vertical rails.

For installation, slide the axle onto the vertical guides. Loosen the axial fasteners so that the screw enters the trapezium. They should move slightly. Lower the axle.

- Top bar fixing.

Take the remaining rail and 4 screws M 5 × 25, screw them in and install the end caps on the end of the rails.

- Mounting the spool holder.

Attach the metal holder with screws to the location indicated in the instructions.

- Wire connection.

All connectors and wires are marked, some of them are connected during the assembly of the printer. Complexity may arise at the stage of connecting the screen. The connector is on the right when looking at the device from the side of the board.

It remains to connect the motor connectors on the X axis, the limit switch on the X axis and the extruder.

The printer will be ready for use after calibration.

The printer will be ready for use after calibration. The height of the table must be adjusted before use. If it is not set, the printing process will not start or will fail.

Check the setting of the Z-axis limit switch, set it in such a position that the limit switch is pressed when the X-beam is lowered. The nozzle should not rest against the table; a small margin should be left in the springs to adjust the height. This is necessary so that the nozzle does not rest against the table during calibration.

Turn on the printer, select the "AutoHome" item in the menu, the carriages will move to the zero mark. Turn on the heating of the extruder to 200° and the table to 50°. After everything warms up, start adjusting.

Disable steppers in the menu (select "Disable steppers"). This allows you to adjust the position of the carriages along the X and Y axis manually. The Z axis does not need to be touched, it is already at the required point. Move the carriage with your hands over the entire surface of the table, starting from the corners.

Raise and lower the table with rollers installed from below. It is necessary to ensure that the nozzle touches the table at all points butt.

Raise and lower the table with rollers installed from below. It is necessary to ensure that the nozzle touches the table at all points butt. Firmware for Creality Ender 3 Pro

In order for the 3D printer to work correctly, the user needs to install an updated firmware version. You can download the required Marlin software here. Before you start, you also need to install the Arduino IDE to edit the firmware. You can download from the official website by following the link.

Attention! Choose the latest version of the Arduino IDE as older ones may not work with the updated Marlin.

- Go to the "Marlin" folder, open the Marlin.ino file through the Arduino IDE program.

- A field for editing printer settings opens.

- Go to "Configuration.h".

- Search for "Ender 3 Pro".

- Uncomment the initialization line (remove "//" before the device name).

- Uncomment the "define DISABLE BOOT" line.

This will speed up the boot process of the device by disabling the splash screen on the screen.

This will speed up the boot process of the device by disabling the splash screen on the screen. - Change the printer name in the "define USER_PRINTER_NAME" field. Uncomment and type "Ender 3 Pro".

- Automatic calibration settings do not need to be changed.

- Go to "Tools", select "Sanguino" in the "Board" field, replace the programmer with Arduino as ISP. Click on Download Bootloader. Wait for the process to complete.

- Restart printer.

Creality Ender 3 Pro is ready to go.

Conclusion

The Creality Ender 3 Pro is a budget open chamber 3D printer. It is equipped with the possibility of additional changes: the user can install a new extruder, dust filter and replace the cooling system with a more powerful one.

- The model is completed with a magnetic table. This increases adhesion and makes it easy to remove finished products with a spatula.

- The front panel has a monochrome display and a switch to control the printing process.

Learn more