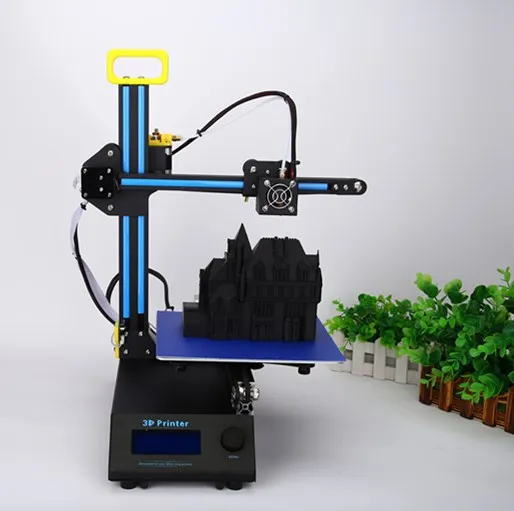

Rapid one 3d printer

dddrop RAPID ONE | Fully Configurable 3D Printer

- New Design

- Print Head

- Sizable Frame

- Room Control

- Bed Leveling

- Water Cooling

New Design

The dddrop 3D printers followed one design line for a few product generations. With the ddddrop RAPID ONE we decided to redesign our machine and give it a brand new look and feel: An industrial appearance that fits the capabilities alongside clean lines and aesthetics.

Learn More

Print Head Configuration

Each print material requires a different print configuration to achieve the perfect 3D print. Our 3D printer specialists will advise you on putting together the right configuration for you.

Learn More

Sizable Frame

What differentiates the dddrop RAPID ONE from other 3D printers is its sizable frame. You can determine the dimensions of the build volume, assuming a minimum size of 300 x 300 x 300 mm, scalable in X, Y and Z directions.

Learn More

Room Control

The RAPID ONE has a closed print cabin, with fans in the rear wall and optional HEPA-filters. The print cabin can turn into a heated chamber in various methods depending on the application and requirements.

Learn More

Advanced Bed Leveling

Leveling the print bed has never been this simple. The RAPID ONE print head is equipped with a leveling sensor which automatically adjusts the distance between the print head and printing bed; resulting in a perfect first layer.

Learn More

Water Cooling

Temperature control plays an important role in the print head as well. By means of a regulated liquid-cooling system, the print head temperature can be adjusted accurately. This will result in high-quality 3D prints.

Learn More

PRINT HEAD CONFIGURATION

Our engineers, at the dddrop research and development department, have created something special. We wanted to show how reliable 3D printing is, so we decided to implement it in our own product. The new print head utilizes 3D printed parts which provide us with design freedom and flexibility. The print head houses many new capabilities and features unlike any dddrop print head before.

The new print head utilizes 3D printed parts which provide us with design freedom and flexibility. The print head houses many new capabilities and features unlike any dddrop print head before.

Print heads can be exchanged in less than a minute to ensure the printer is always ready for the next project.

Back

Print Head configuration

Our engineers, at the dddrop research and development department, have created something special. We wanted to show how reliable 3D printing is, so we decided to put in use in our own product. The new print head utilizes 3D printed parts which provide us with design freedom and flexibility. The print head houses many new capabilities and features unlike any dddrop print head before.

Print heads can be exchanged in less than a minute to ensure the printer is always ready for the next project.

SIZABLE FRAME

All 3D printers in the market come in fixed shapes and sizes, which limits the machines to certain build volumes. We decided to tackle this limitation by allowing our customers to choose the build volume suitable for them. The new generation of dddrop 3D printers will feature new sizable frame constructions that will allow you to choose which build volume is ideal your requirements. The RAPID ONE is specifically designed to allow changes to frame size along the X, Y and Z axis without significantly extending production and delivery time. The new clever implementation of supporting beams and structural pillars allows you to free your creativity from limits using a 3D printer tailored to your needs.

We decided to tackle this limitation by allowing our customers to choose the build volume suitable for them. The new generation of dddrop 3D printers will feature new sizable frame constructions that will allow you to choose which build volume is ideal your requirements. The RAPID ONE is specifically designed to allow changes to frame size along the X, Y and Z axis without significantly extending production and delivery time. The new clever implementation of supporting beams and structural pillars allows you to free your creativity from limits using a 3D printer tailored to your needs.

Back

SIZABLE FRAME

The RAPID ONE features a closed print cabin with temperature control. This allows isolation of the print process from the environment which eliminates temperature variability that affect print quality. The two fans in the back allow greater circulation and an optional HEPA-filter eliminates smells and harmful gasses resulting from melting certain plastics.

Temperature of materials and equipment is extremely important in the process of high-quality additive manufacturing, so we decided to take a step into the future with liquid cooling. This technique allows maintaining temperatures and cooling the print head more efficiently, which provides better control over temperature fluctuation and ultimately lead to significantly better quality prints.

This technique allows maintaining temperatures and cooling the print head more efficiently, which provides better control over temperature fluctuation and ultimately lead to significantly better quality prints.

The new system consists of two elements that work hand in hand to level print bed accurately and efficiently: First, an assembly of stepper motors connected to 3 robust leveling rods that position the print bed at the correct height. Second, the print head is equipped with a single point bed leveling touch sensor that measures the tolerance of the print bed as well as the alignment by sampling the position of different points on the print glass.

Specifications Table

| Production method | Made to order. Tailored to your needs. |

| Sizable Frame | Min. 300 x 300 x 300 mm Sizable in X – Y and Z direction |

| Print head (Configure yourself) | Easily interchangeable Water cooled Active 3D print cooling Bed leveling sensor |

| Print nozzle configuration | 0. 2 mm – 0.4 mm – 0.6 mm – 0.8 mm – 1.0 mm 2 mm – 0.4 mm – 0.6 mm – 0.8 mm – 1.0 mm |

| Print bed | Interchangeable Heated 3-point bed leveling |

| Integrated base cabinet | Filament dryer |

| Filament Diameter | 1.75 mm |

| Printable Materials | PLA, PET-G, ABS, PP, PC, PA, flexible & fiber filled |

| User Interface | 7 inch LCD Touchscreen |

| Slicing | Autoslicing & Simplify3D |

Simply, leave your contact information and we will make sure to contact you as soon as possible and discover together which dddrop fits you.

Get a Quote

Rapid 3D Inc.

About Us

3D Printing Services

Custom Printer Manufacturer

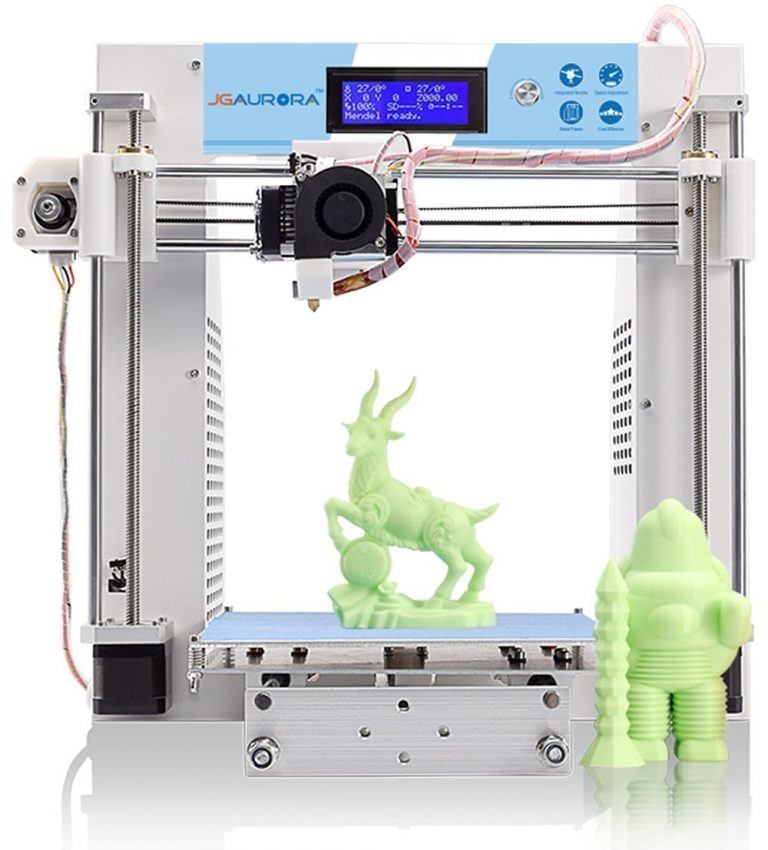

3D Printing Services

We specialize in 3D printing any model that you may have, click below for a quote.

Quote

Engineering Services

Custom Printer Manufacturer

3D Printing Services

Need a model or looking for engineering services, click below to see how we can help you out!

Get in touch

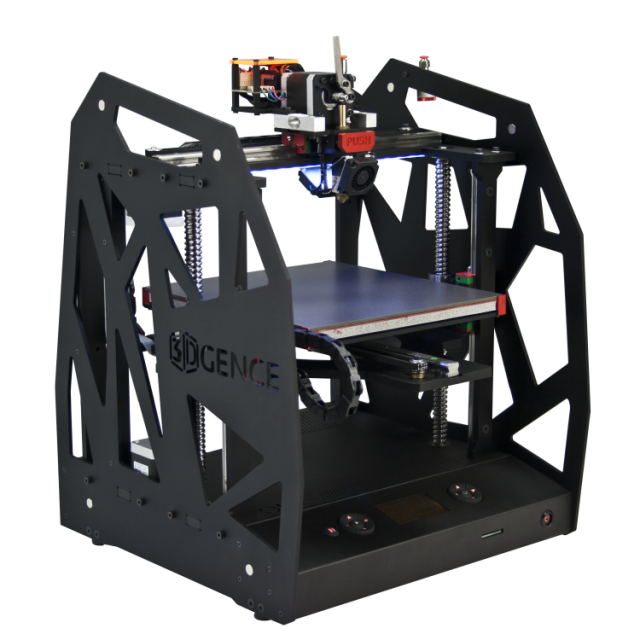

Custom Printer Manufacturer

Custom Printer Manufacturer

Custom Printer Manufacturer

Can't find a printer you want, we can help! Click below to get started!

Get started

Photo Gallery

Meet the Team

Tony Vander Pas

Travis Vander Pas

Travis Vander Pas

President & CEO

Click here for more info.

Travis Vander Pas

Travis Vander Pas

Travis Vander Pas

Co-President & CTO

Click here for more info.

Our Partner

Reviews

the world's fastest and most accurate resin 3D printer・Cults

HITRY, a team of innovators in 3D printing since 2014, recently announced the launch of Rocket 1, the world's first DCLF (Digital Continuous Liquid) 3D printer. Forming). Learn more here: https://comingsoon.higizmos.com/rocket1.

Learn more here: https://comingsoon.higizmos.com/rocket1.

Rocket 1 is capable of printing at 260 mm/h, which is 20 to 60 times faster than traditional resin printers.

This is the highest speed achievable for a 3D printer. In the future, the printing speed may reach 1000mm/h! Instead of waiting for hours, you can now complete your project in minutes!

This exciting new product from HITRY sets a new standard in 3D printing with DCLF (Digital Continuous Liquid Forming) technology, which combines 35µm ultra-high XY resolution, DLP ultra-durability and stereolithography top-down surface curing.

The key to DCLF's continuous fluid molding is a self-developed photosensitive resin.

In addition to nanomaterials to help quickly level the resin, our photosensitive resin also contains components that enhance the polymerization oxygen barrier, which increases the uncured layer in contact with oxygen, the dead zone, from zero to ten microns to tens of microns and hundreds of microns for ultra-high resolution results. . Thus, the top-down surface can be leveled quickly without changing the curing properties of the resin or using a scoop to achieve incredibly high print speeds.

. Thus, the top-down surface can be leveled quickly without changing the curing properties of the resin or using a scoop to achieve incredibly high print speeds.

In addition to the fastest print speed, Rocket 1 also has the highest XY accuracy to date. This printer can easily create intricate parts and holes as small as 0.2mm, allowing liquids and gases to pass freely - exactly the kind of precision required by researchers who use complex models to study.

Top-down printing also protects prints from gravitational and peeling forces, allowing high-transparency printing. Rocket 1 prints as transparently as glass. You can even use it to print a pair of glasses for yourself. Thanks to the top-down design, it is easy to print flexible models, such as shoe lasts. Models printed by Rocket 1 need very few or no supports, saving a lot of time in post-processing.

Rocket 1 creates its pieces with very fine detail and each piece can fit perfectly with only 0.05mm gap on one side which is much better than most 3D printers and the model comes out smooth and flawless as a piece, cast under pressure. Rocket 1 offers 8 types of photosensitive resins that cover all industries as well as a variety of applications, and it can start printing immediately with just 300g of resin.

Rocket 1 offers 8 types of photosensitive resins that cover all industries as well as a variety of applications, and it can start printing immediately with just 300g of resin.

With powerful DCLF technology, the Rocket 1 is capable of printing solid 8CM cube models. In addition, Rocket 1 is intuitive and easy to use. No alignment or professional experience required. Just plug it in and start typing. Because light is projected from the top of the machine down onto the surface of the resin and cures it, Rocket 1 has no vulnerable parts such as LCD screens or release films, so no maintenance is required, saving you time and money.

With maximum speed and ultra-high resolution DCLF technology, the HITRY Rocket 1 is ushering in a new era of 3D printing, offering powerful, convenient, quality printing experiences for everyone. HITRY Rocket 1 is coming to Kickstarter soon. Limited special offers start at $599. Learn more here: https://comingsoon.higizmos.com/rocket1.

Rocket 1 is looking for KOLs to help with the first hands-on review. Selected reviewers will receive Rocket 1 for testing and evaluation. Please contact [email protected] if you are interested. Read more here: https://comingsoon.higizmos.com/rocket1

Selected reviewers will receive Rocket 1 for testing and evaluation. Please contact [email protected] if you are interested. Read more here: https://comingsoon.higizmos.com/rocket1

This page has been translated using machine translation. Suggest the best translation

Rocket 1 is the world's fastest resin 3D printer

HITRY is a high-tech company founded in 2014 that integrates 3D printing product development, maintenance, processing services and equipment sales.

For years, HITRY has striven to increase print speed without sacrificing resolution or accuracy. These efforts culminate in Rocket 1's patented Digital Continuous Liquid Forming (DCLF) technology. This revolutionary new technology delivers superior prints with incredible detail at an affordable price. The basis of DCLF technology is the dead zone. The dead zone is the thin liquid interface of the uncured resin between the oxygen and the curing zone. The light passes through the dead zone and turns the resin below it into a hard part. During the curing process, the resin continues to flow onto the curable part, maintaining a constant liquid layer, hence the curable part is less prone to sinking.

During the curing process, the resin continues to flow onto the curable part, maintaining a constant liquid layer, hence the curable part is less prone to sinking.

The world's fastest consumer resin 3D printer, the Rocket 1, can print at 380mm/hr. Rocket 1 is not only fast, but also prints with outstanding accuracy. With 0.035mm XY resolution and 0.001mm Z resolution, Rocket 1 prints every pixel quickly and accurately, leaving surfaces exceptionally smooth and perfect.

Rocket 1 can print complex pattern structures with 0.2 mm internal pores and a smooth surface through which liquids and gases can freely flow.

Rocket 1 projects light from the top of the device down onto the surface of the resin and cures it so no replacement screen or removable films are required. This means less waste and less energy consumption. This 3D printer is industrial quality, durable, reliable and stable with an expected lifespan of over 18,000 hours.

Rocket 1 Resin Reservoir holds 3. 7 kg of resin and can hold large models. However, you don't have to worry about resin loss. HITRY has developed a resin-insoluble filling liquid that is non-toxic, reusable and inexpensive. With this tank filling liquid, you can finish your print with only 300g of resin left.

7 kg of resin and can hold large models. However, you don't have to worry about resin loss. HITRY has developed a resin-insoluble filling liquid that is non-toxic, reusable and inexpensive. With this tank filling liquid, you can finish your print with only 300g of resin left.

Rocket 1 currently offers 8 different types of resins, giving you more options for different applications. The nanomaterials in HITRY resins cause the resin to flow into the dead zone and level out quickly, greatly reducing print times.

Another key feature of the Rocket 1 is top-down printing. Unlike bottom-up printing, top-down printing immerses the curing model in resin instead of pulling it up to avoid the effects of gravity and peel forces. Rocket 1's top-down print design ensures models print with little or no support, saving a lot of time in post-processing.

Rocket 1 is pre-calibrated and ready to use right out of the box. No installation steps are required, making it a true plug-and-play device.