How much is a 3d food printer

Top food 3D printers available this year

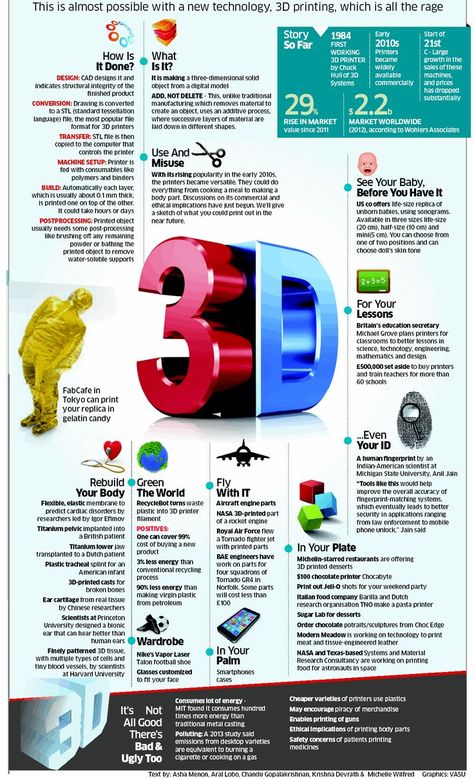

What is food 3D printing?

Although it may sound like something from a sci-fi movie, food 3D printers do actually exist. Edible 3D printing is becoming more and more popular not only for professionals but also for personal use. That said, how does food 3D printing work? To what extent is it similar to standard 3D printing?

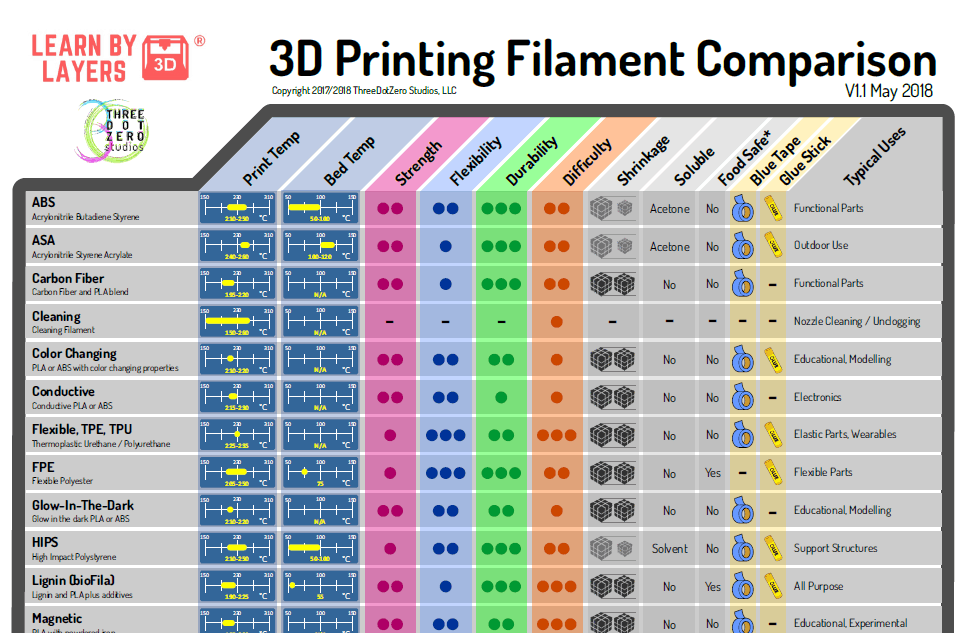

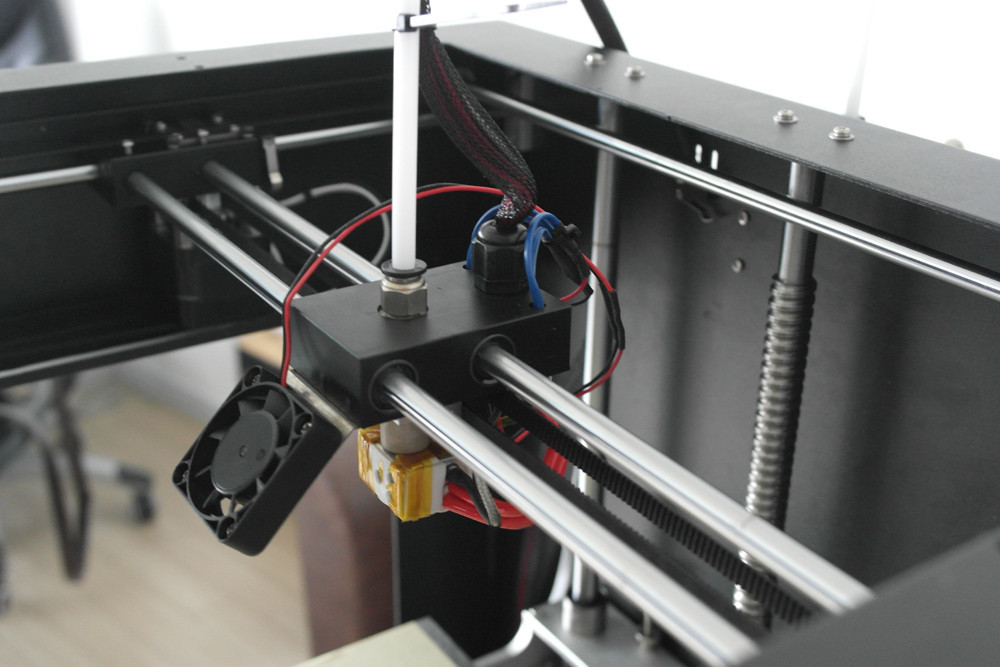

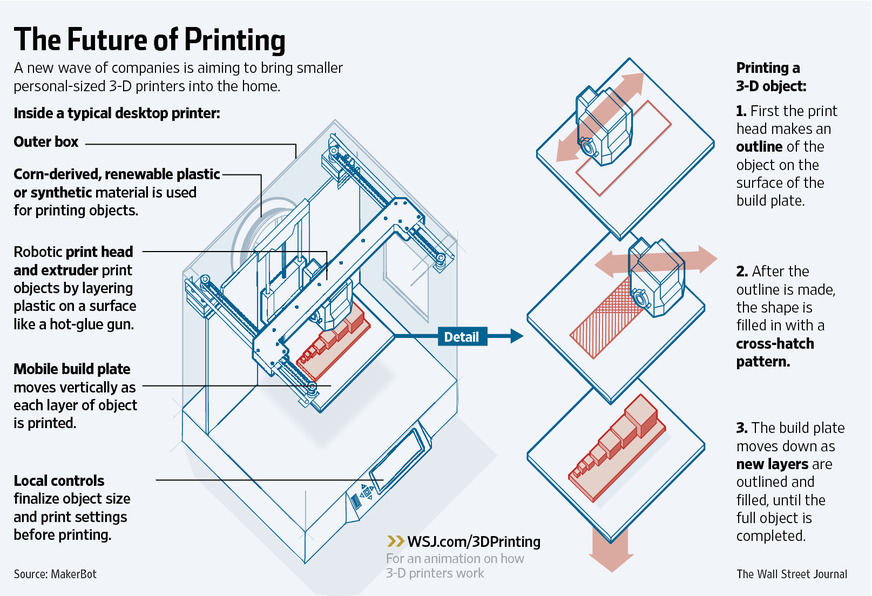

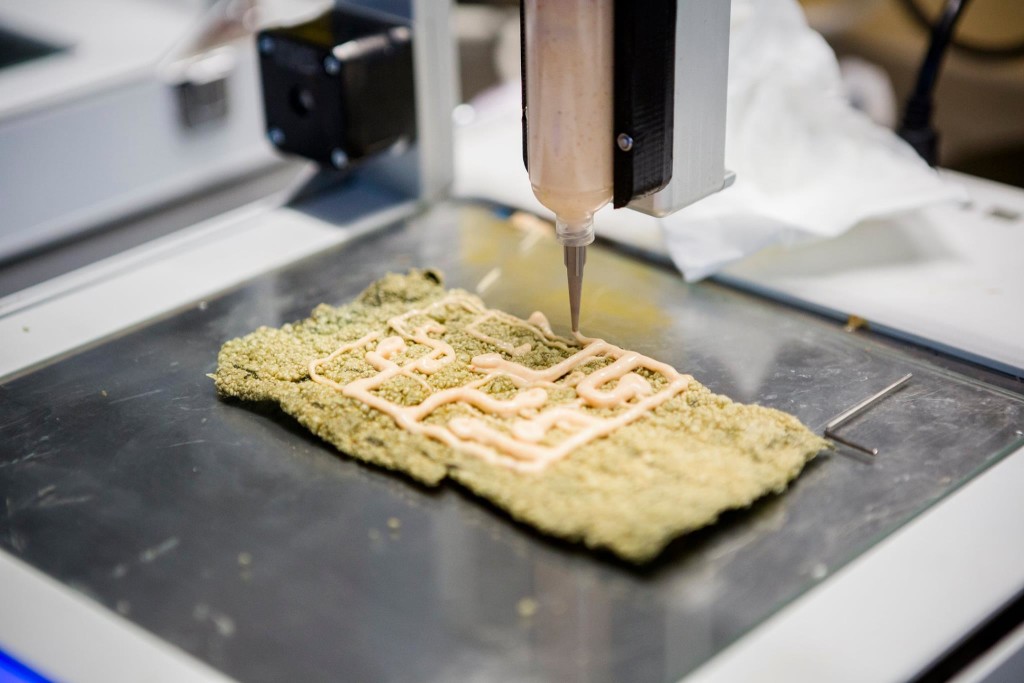

Most food 3D printers use extrusion 3D printing technology, much like regular desktop FFF (FDM) 3D printers. Instead of using plastic material, though, food 3D printers use paste-type ingredients. The most common ingredients are chocolate, pancake batter, and cream, although there are many other possibilities (even pizza!). They are 3D printed layer after layer, generally through a syringe-like extruder.

To get a better overview of this niche, we have put together a comprehensive list of food 3D printers on the market. This selection is based on available food 3D printers under $6,000. We also mention a few other food customization solutions, including coffee 3D printing, food ornament 3D printing, and 3D printing food molds.

Bon appétit!

Best food 3D printers available on the market

| Brand | Product | Build size | Country | Price Approximate starting prices based on supplier-provided information and public data. Prices may vary by region, over time and do not include additional products or services (taxes, shipping, accessories, training, installation, …). | |

|---|---|---|---|---|---|

| Micromake | Food 3D printer | 100 × 100 × 15 mm3.94 × 3.94 × 0.59 in | – | $ 9991 015 €886 £148,907 ¥ | Contact |

| Choc Edge | Choc Creator V2.0 Plus | 180 × 180 × 40 mm7.09 × 7.09 × 1.57 in | – | $ 2,6832 727 €2,380 £399,929 ¥ | Quote |

| ZMorph | VX | 250 × 235 × 165 mm9. 84 × 9.25 × 6.5 in 84 × 9.25 × 6.5 in | – | $ 2,7992 845 €2,483 £417,208 ¥ | Quote |

| byFlow | Focus | 208 × 228 × 150 mm8.19 × 8.98 × 5.91 in | – | $ 3,6303 300 €3,220 £541,073 ¥ | Quote |

| Natural Machines | Foodini | 250 × 165 × 120 mm9.84 × 6.5 × 4.72 in | – | $ 4,0004 066 €3,548 £596,224 ¥ | Quote |

| Mmuse | Chocolate 3D printer | 160 × 120 × 150 mm6.3 × 4.72 × 5.91 in | – | $ 5,4995 590 €4,878 £819,659 ¥ | Quote |

Expand to see more specs

The products in the table are ranked by price (low to high).

| Brand | Product | Build size | Country | Price Approximate starting prices based on supplier-provided information and public data. Prices may vary by region, over time and do not include additional products or services (taxes, shipping, accessories, training, installation, …). | |

|---|---|---|---|---|---|

| Micromake | Food 3D printer | 100 × 100 × 15 mm3. 94 × 3.94 × 0.59 in 94 × 3.94 × 0.59 in | – | $ 9991 015 €886 £148,907 ¥ | Contact manufacturer |

| Choc Edge | Choc Creator V2.0 Plus | 180 × 180 × 40 mm7.09 × 7.09 × 1.57 in | – | $ 2,6832 727 €2,380 £399,929 ¥ | Get a quote |

| ZMorph | VX | 250 × 235 × 165 mm9.84 × 9.25 × 6.5 in | – | $ 2,7992 845 €2,483 £417,208 ¥ | Get a quote |

| byFlow | Focus | 208 × 228 × 150 mm8.19 × 8.98 × 5.91 in | – | $ 3,6303 300 €3,220 £541,073 ¥ | Get a quote |

| Natural Machines | Foodini | 250 × 165 × 120 mm9.84 × 6.5 × 4.72 in | – | $ 4,0004 066 €3,548 £596,224 ¥ | Get a quote |

| Mmuse | Chocolate 3D printer | 160 × 120 × 150 mm6.3 × 4.72 × 5.91 in | – | $ 5,4995 590 €4,878 £819,659 ¥ | Get a quote |

Pros and cons of food 3D printing

Benefits of 3D printing food

Time-saving

Edible 3D printing can be less time-consuming than traditional cooking. Indeed, users can launch a food 3D print and move on to other activities. Once the food 3D print is launched, there is no more need for manual operation.

Indeed, users can launch a food 3D print and move on to other activities. Once the food 3D print is launched, there is no more need for manual operation.

Customization

Food 3D printing enables users to customize their food according to special events or simply to their mood. It can vary from writing a name on a birthday cake to 3D printing a heart-shaped pancake, for instance.

Creativity

Edible 3D printing enables cooking aficionados to unleash even more creativity in the kitchen. Users can imagine and actually create intricate designs. Amazing 3D-printed food artwork already exists!

3D printed food art by Marijn Roovers. Source: Marijn RooversLimits to food 3D printers

Type of food

Not just any sort of food can be 3D printed. The food must be in the form of a paste, such as cream or mashed potatoes.

Partial cookingThe 3D printing process doesn’t encompass every step of a meal’s preparation. For instance, food 3D printers cannot bake a cake or sprinkle oregano over a pizza.

For instance, food 3D printers cannot bake a cake or sprinkle oregano over a pizza.

Price

Food 3D printers are a bit expensive, generally in a price range between $1,000 and $5,000 (although there are exceptions).

Risk of failure

Just like with any other type of 3D printing, food 3D prints can be unsuccessful – too bad if it’s a birthday cake!

Food 3D printers: overview

The byFlow Focus is a compact food 3D printer made by byFlow, a Dutch 3D printing company specialized in edible 3D printing. This food 3D printer targets mostly professionals in the bakery industry.

The Focus works with refillable cartridges containing any kind of paste-type food to create customized meals. Furthermore, users have the possibility to access downloadable recipes.

Contact manufacturer Get a quote Add to comparison

The Choc Edge Choc Creator is a chocolate 3D printer targeting mostly professionals in chocolate and confectionery industries.

In addition, Choc Edge develops three apps, CHOC DRAW, MIX & MATCH and CHOC TEXT, to help users to draw and write on their chocolate 3D prints. A slicing software, ChocPrint, is also available.

Contact manufacturer Get a quote Add to comparison

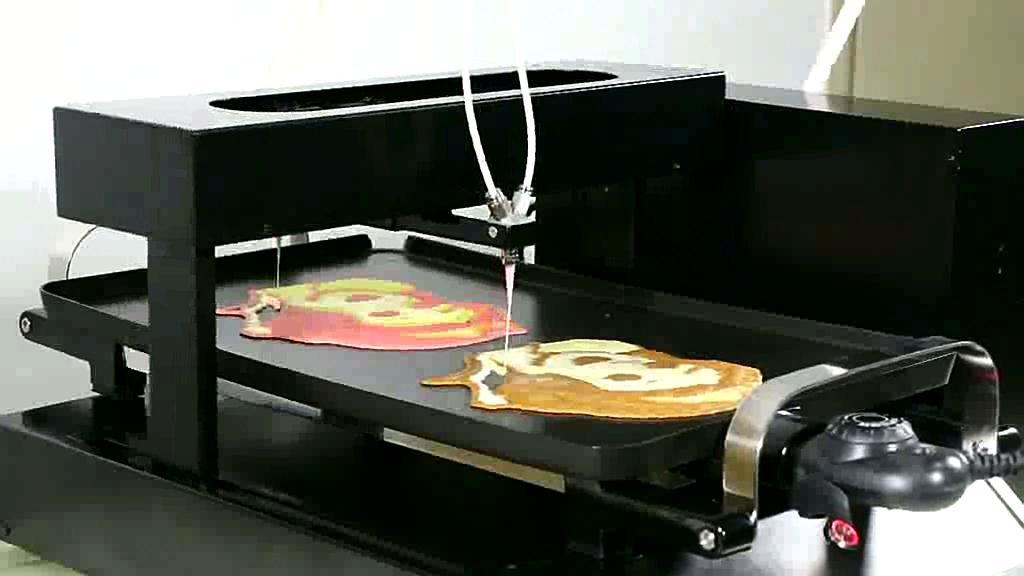

The Micromake Food 3D printer can 3D print all kinds of paste-type ingredients, such as tomato sauce, chocolate sauce, and salad sauce. Also, the removable heated build plate is able to bake ingredients such as pancake batter.

Contact manufacturer Add to comparison

The Mmuse Chocolate 3D printer is a closed-framed chocolate 3D printer made by Muse, a manufacturer from China. This 3D printer uses chocolate beans as consumables: they melt in the extruder, just as with regular FFF/FDM 3D printing.

Contact manufacturer Get a quote Add to comparison

The Natural Machines Foodini is a 3D printer able to 3D print all kinds of paste-type food. Users can fill the Foodini’s capsules with any type of paste food they wish.

Users can fill the Foodini’s capsules with any type of paste food they wish.

Furthermore, if users choose a specific Foodini recipe, the 3D printer gives instructions on which ingredients to insert into the capsules.

Contact manufacturer Get a quote Add to comparison

Thanks to its thick-paste extruder, the ZMorph VX can 3D print ceramics as well as food!

This multifunctional 3D printer is indeed able 3D print with chocolate, cookie dough, cream cheese, frosting and more.

In addition to paste extrusion, the VX is features CNC milling and laser engraving capabilities.

Contact manufacturer Get a quote Add to comparison

Special mention: Cakewalk

- Materials: chocolate, meringue, royal icing, ketchup, guacamole, cream cheese, butter, mashed vegetables, Swiss butter cream

- Price:

- During KS campaign: €49 to €89

- After KS = €119

Cakewalk 3D is a precise and practical extruder that converts your desktop 3D printer into a food printer. The screw-in extruder is designed to be easily installed on any type of Cartesian 3D printer. All parts are food-safe and easily washable in your dishwasher.

The screw-in extruder is designed to be easily installed on any type of Cartesian 3D printer. All parts are food-safe and easily washable in your dishwasher.

To adapt Cakewalk 3D to your printer, you just need to 3D print 3 or 4 pieces of support in plastic. Disassembling your plastic extruder, screwing in the support parts, and connecting the motor to your card takes less than 30 min. The extruder then works with your usual slicer.

Cakewalk3D Kickstarter campaign

Edible 3D printing: who is it for?

Restaurants and bakeries

Edible 3D printing is indeed very useful for professionals in the food industry. 3D printed food can be attractive to new customers seeking different food experiences. A restaurant serving 3D-printed food, the Food Ink. pop-up store already exists.

Industrial food production

In the industrial food production sector, edible 3D printing allows manufacturers to vary their product ranges with new creations. Furthermore, food 3D printers can achieve a high level of precision. Barilla, an Italian food company, 3D prints some of its pasta products.

Furthermore, food 3D printers can achieve a high level of precision. Barilla, an Italian food company, 3D prints some of its pasta products.

Food 3D printing at home

Food 3D printers are also adapted for personal use. They allow for more creativity in the kitchen with food customization.

What food can be 3D printed?

Ingredients

Virtually any type of fresh food can be 3D printed as long as it’s a paste, or “purée”. For instance, ingredients could be:

- Chocolate, candy and sugars

- Pancake batter or cookie dough

- Dairy products

- Pasta, wheats and grains

- Fruits and vegetables

Even pizza can be partly 3D printed! However, users will have to sprinkle their favorite toppings manually.

3D printed pizza by Beehex. Source: BeehexFood 3D models

To 3D print food, we can let our imagination take over. Users indeed have the opportunity to create their own food 3D models with special CAD software. However, it is also possible to directly download any 3D model on dedicated STL file websites.

Users indeed have the opportunity to create their own food 3D models with special CAD software. However, it is also possible to directly download any 3D model on dedicated STL file websites.

How much does a food 3D printer cost?

Food 3D printer price

There are various price points for food 3D printers. Prices can depend on the food 3D printer’s build volume and/or on the variety of 3D printable ingredients it is compatible with.

In general, the minimum price for a food 3D printer is around $1,000 (although the PancakeBot is available for under $400). However, prices may decrease in the future, just as they have for regular extrusion (FFF/FDM) 3D printers.

Other promising food 3D printing applications

Here are a few industries where food 3D printing is already beneficial.

Sustainable food

Food 3D printing could be a part of the answer to the world hunger crisis. Indeed, some food 3D printers use hydrocolloids as a consumable.

Indeed, some food 3D printers use hydrocolloids as a consumable.

This chemical, gel-like substance can mimic food. 3D printed meals with hydrocolloids could also include sustainable ingredients, such as algae.

Medical

As explained above, certain food 3D printers use hydrocolloids to create different shapes and textures for meals. Also, like the EU’s PERFORMANCE program is proving, it can be very useful to make softer meals for people with chewing or digestion problems, especially elders.

In addition, medicine can be presented in the shape of yummy food, instead of pills or powder.

Army

The US Army is carrying out scientific research to provide personalized food for their soldiers.

According to Lauren Oleksyk, a food technologist leading the team at the Army’s Natick research center, a sensor installed in soldiers’ bodies could detect their specific dietary needs. This sensor would be interfaced with a food 3D printer, to produce customized meals.

Aerospace: NASA food 3D printer

Beehex, an American startup, has received a grant from NASA to develop a food 3D printer.

Indeed, the aerospace agency aims to allow astronauts to produce their own food during long-term space missions to go to Mars!

3D printed food ecosystem

Food ornament 3D printers

Coffee 3D printers: 3D printing on coffee

There seems to be no connection between the portrait of the Mona Lisa and coffee. However, thanks to coffee 3D printers, it is possible to see the beautiful smiling lady in a cup of coffee. Indeed, a combination between 3D printing and inkjet printing technologies allows these machines to draw images on top of any foam-covered beverage.

As such, the Ripple Maker, a coffee 3D printer made by Ripples, can help users print “their own selfies, favorite quotes, or special messages and images on their drinks”. Another existing coffee printer is the Lixian 3D CafeMaker.

Cake ornament 3D printers

Bakery industry professionals also use 3D printers to adorn cakes or pastries. Thanks to edible sheets of paper and ink, any kind of image (including photos) can be 3D printed to decorate cakes.

Food extruders

If users already have an FFF 3D printer at home, another solution exists to 3D print food: food extruders. These tools generally feature universal compatibilities with regular extrusion 3D printers. Some of them, such as the Structur3D Discov3ry, allow 3D print with non-only edible food and clay, silicone, etc. An open-source extruder, the BotBQ Extruder, can 3D print raw meat – a good fit for your future barbecue!

3D printed food molds

3D printers can also 3D print very useful tools for food production: this is the case of 3D printed food molds. Users can create their own molds and print them in 3D to customize cakes, for example.

Users can create their own molds and print them in 3D to customize cakes, for example.

Conclusion

Food 3D printers are suitable for professional, industrial, and personal use-cases. Only paste-type ingredients are printable, but a wide range of food – from pizzas to cakes – can be created. As 3D-printed food can be customized according to users’ needs, it can be helpful in many fields, such as medicine.

3D printed food may also represent a hope for the world hunger crisis in the future. What food 3D printers are still missing is the ability to actually cook or bake. That is why cooking robots could be more and more popular in the future.

The 10 Best Food 3D Printers 2022 (All Price Ranges!)

They’re here, and shaking up how we view and prepare food. Food 3D printers are usually hybrid FDM 3D printers that print food pastes rather than plastic filaments, printing delicious chocolate, jam or toffee layer-by-layer to create a custom dessert or savory dish based on your design.

Want to 3D print a model of your face in chocolate? Or print your company’s brand in biscuit to send to potential clients? You can do it all with food 3D printers.

Our ranking below features some of the best 3D printers for printing food, and compares them on accuracy, speed, variety of food types you can 3D printer, and more.

3DSourced is reader-supported. When you buy through links on our site, we may earn an affiliate commission. Learn more

The Best Delta 3D printers and where to buy them

| Name | Max Build Volume (mm) | Speed (mm/s) | Price | Where to buy for best price |

|---|---|---|---|---|

| Monoprice Mini Delta | 110 x 110 x 120 | 150 mm/s | $179 | Amazon here |

| FLSUN Q5 | 200 x 200 x 200 | 150-300 mm/s | $260 | Amazon here |

| He3D K280 Delta | 280 x 280 x 600 | 150 mm/s | $320 | Amazon here |

| FLSUN QQ-S | 255 x 255 x 360 | 300 mm/s | $379 | Amazon here |

| Frankensbox FX-800 | 150 x 150 x 175 | 150 mm/s | $299 | Amazon here |

| Monoprice Delta Pro | 270 x 270 x 300 | 150 mm/s | $699 | Amazon here |

| WASP Delta 2040 PRO Turbo | 200 x 200 x 400 | 500-600 mm/s | $3,400 | Amazon here |

- We’ve also written a feature story on 3D printed food.

- We also have a more specific ranking on the best chocolate 3D printers.

What is a Food 3D Printer?

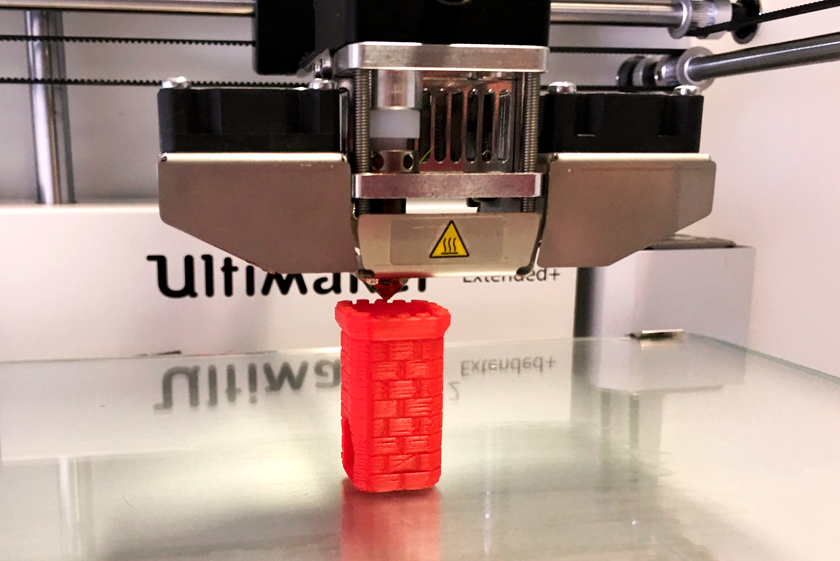

Typical FDM 3D printing involves a 3D printer’s extruder depositing melted plastic filament along the dimensions specified in the STL file. It’s somewhat similar to icing a cake in that regard, but when you’ve completed one layer the next layer is then deposited on top of that existing layer.

3D printed food will have a layered appearance as FDM parts do — if you look hard you’ll see the tiny layers at slightly jagged angles like the steps on a pyramid, or a spring being pressed together.

With the icing a cake analogy, now assume that instead of icing, you can do the same action but with any edible food type. Chocolate, toffee, sugar, jam and savory flavors like tomato sauce / paste and cheese. Instead of being limited in the shapes you can make by the type of cake tin you use, you can now create incredibly intricate structures by perfectly depositing each part of food exactly where it is supposed to be. A 3D printed chocolate. You can see the layers on the side that have been printed on top of each other.

Food 3D printers are similar to FDM 3D printers — one printer on our list is a modified FDM printer — they deposit food instead of plastic filament in exactly the same way. This allows them to be more precise and accurate that any human could be, and also means that menial food jobs in restaurants and kitchens can be automated, saving time and energy.

What’s more, since you only extrude the exact amount of food you need, this makes for more efficient use of food, saving both money and the environment! This is a key and reoccurring theme in additive manufacturing.

Food 3D printers are gradually making their way into STEM education as a novel and fun new way of teaching both 3D printing skills and about what we eat. Food 3D printers for kids are also a great way of family bonding while creating something delicious to eat after, as well as by small businesses who want a new way of creating custom, up-market chocolates and other treats.

Benefits of a food 3D printer

- Better for the environment. 3D printed food materials can be created from alternative proteins like algae, leaves, and even insects, which are ground into a paste ready to be 3D printed. These ingredients otherwise would not be used, and are a form of protein and nutrients which may be key to future diets.

- Increased food customization. Though everybody’s food is already arguably customized, it isn’t to the level that food 3D printers offer. Not only can you create and pick the exact ingredients you want, but you can also create custom shapes and geographies that you want your food to occupy. Want a rabbit-shaped chocolate bar? Or an emoji-shaped burger? Easy. 3D printers conquer conquer the first three dimensions for you, saving you the fourth dimension — time.

- Saves time & stress. 3D food printers can automate the boring and repetitive kitchen tasks for you so you don’t need to do them.

Simple tasks such as presentation and laying out of ingredients can be done by the food printer, and if you are creating food from pastes then you don’t need to chop those ingredients up yourself.

Simple tasks such as presentation and laying out of ingredients can be done by the food printer, and if you are creating food from pastes then you don’t need to chop those ingredients up yourself.

The Best Food 3D Printer

We have created our list of the best 3D food printers based on a number of criteria. These include price-performance ratio, speed, amount of materials available, print volume, among others.

Note: this article is not intended to be objective fact, and is based on opinions. This content is independent and features no paid or sponsored content, but we have included links where you can buy a food 3D printer, which we receive commissions on.

1. WiiBoox Sweetin — Food 3D Printer For Kids

- Country based: China

- Food 3D printer cost: $1,599 — Available on Amazon here

- Maximum food printing area: 90 x 90 x 70 mm

- Food 3D printing speed: 15 – 70 mm/s

- Accuracy: 100 microns

The WiiBoox Sweetin is sold as the easy to operate, accessible food printer perfect for families at home together. The printer itself comes with a number of models to print out, and you’re free to unleash your creativity by designing or downloading your own STL files to print. It’s super simple to use: just load your design onto the supplied USB and print away!

The printer itself comes with a number of models to print out, and you’re free to unleash your creativity by designing or downloading your own STL files to print. It’s super simple to use: just load your design onto the supplied USB and print away!

The Chinese company bring their extensive 3D printing and scanning expertise to food 3D printing. They also sell an LCD 3D printer, an upmarket dual extruder 3D printer, as well as a range of 3D scanners.

The WiiBoox 3D food printer works by preheating the chocolate filament packs (or other food filament type), setting the temperature and speed you want to print at, and then it’s ready to start! You can change the print speed based on how accurate you want your 3D printed chocolate piece to be. Comments on Amazon recommend that you leave any 3D printed chocolate model for at least 10 minutes before removing it however to ensure it has cooled down and solidified.

The WiiBoox Sweetin is accurate with 100 micron precision so any cakes you decorate or chocolate food you 3D print will look crisp and smooth. Unlike some of the other food 3D printers on this list, the WiiBoox Sweetin appears to only use a 0.6mm diameter nozzle, and though it comes with their own 3D slicer you can also set it up to use Cura.

Unlike some of the other food 3D printers on this list, the WiiBoox Sweetin appears to only use a 0.6mm diameter nozzle, and though it comes with their own 3D slicer you can also set it up to use Cura.

Overall, it’s a low price food 3D printer with good reliability and is easy to use. We recommend it as a great food 3D printer for kids and families to enjoy spending time together cooking and having fun, and creating delicious chocolates and sweets at the same time.The WiiBoox Sweetin printing Albert Einstein in white chocolate.

2. FoodBot S2

- Food printer price: $2,100 — Available on 3DPrintersOnlineStore here

- Max print volume: 150 x 150 x 73 mm

- Food print speed: 15 – 70 mm/s

- Accuracy: 100 microns

A versatile food 3D printer, the FoodBot S2 can print chocolate, biscuit, jam, cheese, mashed potatoes, toffee and more! You can change the speed between 15 and 70 mm/s based on the accuracy and intricacy of your print, and alter the temperature based on your preferences.

What stands out however is how great the printer itself looks — if Apple ever made a 3D printer, this is how I imagine it would look. The design is futuristic, elegant and modern; it really adds a sci-fi feel to any kitchen. The 5.2 inch touchscreen and sleek UI add to this atmosphere.

As for accuracy, you’ll have no problem creating detailed food 3D prints with its 100 micron precision, with the ability to use nozzles ranging from 0.3 to 1.5 mm based on your needs. It comes with its own free 3D software to slice and prepare prints, and prints via either USB or SD card.

FoodBot stress how hygienic their S2 food printer is. The actual food filament never touches the printer, as it comes in disposable plastic dispenser tubes and is extruded straight through the nozzle. This makes keeping the printer clean and safe very easy, as there are no innards to clean, just the nozzle. Overall, it’s an impressive and easy to use food 3D printer with a wide variety of materials and uses.

3. Zmorph Fab (with Thick Paste Extruder Add-on)

- Price: $3,999 — Available at Matterhackers here / Available on 3DPrima Europe here

- Maximum print volume: 235 x 250 x 165 mm

- Thick paste extruder available here

Most people know of the Zmorph Fab as a workhorse 3D printer, drawing praise for its reliability, toughness and grit. It’s also known for being unbelievable versatile — it can be converted from a 3D printer into either a CNC mill or a laser engraver!

Now in addition to this, if you buy Zmorph’s thick paste extruder you can also print in chocolate, nutella, cookie dough and a few other food 3D printer filaments too. It prints pastes in a similar way to how it prints plastic filaments, so you benefit from the Zmorph Fab’s 50 micron layer resolution and excellent stability.Thick paste extruder add-on sold by Zmorph allows for chocolate 3D printing.

All the technology developed for the Zmorph Fab that makes it one of the best 3D printers around also works perfectly to make it a great food 3D printer. The accuracy, reliability and stability all apply in food 3D printing, and the Zmorph VX therefore is the perfect 3D printer for those who want a printer that can do it all. It’s ideal if you’ve been looking for both a food 3D printer and standard FDM 3D printer, but don’t want to buy two printers.

The accuracy, reliability and stability all apply in food 3D printing, and the Zmorph VX therefore is the perfect 3D printer for those who want a printer that can do it all. It’s ideal if you’ve been looking for both a food 3D printer and standard FDM 3D printer, but don’t want to buy two printers.

It is worth noting however that Zmorph do not certify that the printer’s food prints are edible or take any accountability for that. The add-on is therefore more of a fun extra to have fun at home with your family, but not for those looking to sell chocolate 3D prints or to use it in a restaurant. The printer was not built with food 3D printing strictly in mind, but it is a fun add-on for $250.

4. Createbot 3D Food Printer

- Price: $2,115 — Available on 3DPrintersOnlineStore here

- Max food 3D print size: 150 x 150 x 100 mm

- Speed: 20 – 30 mm/s

- Precision: 100 microns

There are definite similarities between the Createbot and Foodbot printers, in size, speed, price and appearance. One key difference however is that the Createbot food 3D printer comes in three different colors: Champagne Gold, Simple Silver and Rose Gold. All three options portray a stylish, expensive-looking machine.

One key difference however is that the Createbot food 3D printer comes in three different colors: Champagne Gold, Simple Silver and Rose Gold. All three options portray a stylish, expensive-looking machine.

It can print many of the same ingredients as the Foodbot S2 3D printer, including chocolate, biscuit, red and green bean paste, lotus seed paste, and other foods. The actual print speed depends on the material used: it is recommended to use 20 mm/s for chocolate printing, and 30 mm/s for other materials.

A cool feature with the Createbot is the ability to operate the printer from your laptop, tablet or smartphone. You can also carefully control the printer’s temperature to ensure prints retain their nutrition and print with the right consistency. Import your 3D printer model into Repetier-Host 3D slicer, slice it, and you’re ready to go!

5. Mmuse Delta Food 3D Printer

- Price: $1,140 — Available on 3DPrintersOnlineStore here

- Maximum print volume: 100 x 100 x 100 mm

- Speed: 150 – 300 mm/s

The only delta 3D printer on our list, the Mmuse delta brings the advantages of high printing speeds associated with these types of 3D printer to the food sector. Whereas some other food printers max out at around 70 mm/s, Mmuse claim the delta food 3D printer can print between 150 and 300 mm/s — depending on the quality of print and type.

Whereas some other food printers max out at around 70 mm/s, Mmuse claim the delta food 3D printer can print between 150 and 300 mm/s — depending on the quality of print and type.

It can print materials including chocolate, pancake, candy and tomato sauce, so you have the option of either sweet or savory. Unlike most delta printers it isn’t a DIY 3D printer, instead coming fully assembled and ready to print — saving time and effort. It’s also lighter than most of the other food 3D printers, at a very manageable 5kg.

Rather than offer a wide variety of nozzle sizes, the Mmuse delta sticks with the standard FDM 3D printer nozzle diameter of 0.4mm. It’s more of a fun food 3D printer for kids to enjoy and play with than an industrial food printer for restaurants. Don’t expect pinpoint accuracy and Michelin-level food presentation, but you can definitely still enjoy creating fun food prints of your favorite kids’ TV characters and other fun 3D printed food projects.

6. Foodbot D2 — Dual extruder food 3D printer

- Price: $5,999 — Available on 3DPrintersOnlineStore here

- Maximum print volume: 80 x 150 x 100 mm

- Print speed: 25 – 50 mm/s

- Precision: 100 microns

An upgrade on the Foodbot S2 that also features in our ranking, this extraordinary machine not only can print intricate food structures, but can print them with two materials concurrently!

The dual heads mean you can print either two different colors of the same food material, or two different materials. So you could create your own design in part toffee and part chocolate, or any other combination you want. Additionally, the 3.5 inch touchscreen and ergonomic UX makes food printing a breeze.

So you could create your own design in part toffee and part chocolate, or any other combination you want. Additionally, the 3.5 inch touchscreen and ergonomic UX makes food printing a breeze.

This second print head is very useful in commercial business opportunities such as creating custom edible brand logos that need to be in two different colors or materials. Custom cake decorations, intricate chocolate pieces, mini portrait pieces and busts, and general personalized gifts are made easy with the Foodbot D2.

Both the D2 and S2 food printers have solid, sheet metal frames which aid stability, accuracy and precision food 3D printing. The D2 prints at between 25 and 50 mm/s dependent on the material printed, and can be converted to use nozzles varying from 0.4mm to 1.5mm. It’s heavier however, at around 25kg — so keep this in mind if you need something very portable.

7. Mmuse Touchscreen

- Country based: China

- Food 3D printer price: $5,700 — Available on 3DPrintersOnlineStore here

- Print volume: 160 x 120 x 150 mm

Another chocolate 3D printer, the Mmuse is a food 3D printer that looks like something out of the matrix. It’s futuristic and beautiful, selling itself as a chocolate making experience, not just a 3D printer. It’s fast too, able to print between 30 and 60 mm/s of delicious 3D printed chocolate.

It’s futuristic and beautiful, selling itself as a chocolate making experience, not just a 3D printer. It’s fast too, able to print between 30 and 60 mm/s of delicious 3D printed chocolate.

There’s a reason for the high price. The Mmuse chocolate 3D printer is designed to be as convenient as possible to operate, so you can 3D print food via WiFi, USB or SD card. The beautiful touchscreen on the Mmuse makes printing a breeze, and features a strong aluminium shell. Mmuse also claim it utilizes an ‘intelligent temperature control technology’, allowing it to 3D print chocolate at the perfect temperature so the chocolate prints as smoothly and evenly as possible. Additionally, Mmuse have designed the printer nozzle to be as easy to clean and replace as possible to maintain hygiene over years of printing.

It comes fully assembled, so all you need to do is get hold of the chocolate bean filament, choose the print settings you prefer, and let it print away. The easy-to-use touchscreen makes delicious chocolate printing a pleasant experience. If you’ve got the money and you love chocolate enough, this may be the one for you. Also, if you’re a chocolatier and want to automate some aspects of production, this could be perfect.

If you’ve got the money and you love chocolate enough, this may be the one for you. Also, if you’re a chocolatier and want to automate some aspects of production, this could be perfect.

8. Natural Machines Foodini

- Country based: Spain

- Food 3D printer price: $4,000

- Print volume: 250 x 165 x 120 mm

One of the most well-known food 3D printers out there, the Foodini is a food 3D printer breaking barriers left, right and center in the foodtech sector. Foodini, made by Spanish firm Natural Machines, recognize that though cooking is an enjoyable process for many, there are many tasks that could be automated. The Foodini food 3D printer was therefore created to streamline the repetitive tasks which are time consuming and difficult to do by hand.

Foodini is a versatile food 3D printer, able to print pizza, spaghetti, and even burgers. Its glowing reviews led to fairly wide use in restaurants, like the byFlow Focus has similarly achieved. Restaurants which use the Foodini include London’s Food Ink restaurant, the entirely 3D printed restaurant, as well as La Endeca at Hotel Arts, in Barcelona.

Overall, the price is steep, but this is because of how advanced the Foodini is. It’s less of a cooking tool for use within homes and more of an industrial tool for professional kitchens, but this doesn’t make it any less of an incredible foodtech achievement.The Foodini food 3D printer has wide use across restaurants.

9. byFlow Focus

- Country based: Netherlands

- Food 3D printer price: €3,300

- Print volume: 208 x 228 x 150 mm

The byFlow Focus is a sleekly designed food 3D printer with a surprisingly wide reach in businesses around the world. Unlike most fanciful and futuristic machines that seem like they won’t see wide adoption for twenty plus years, the byFlow Focus is a 3D food printer which is already used in a number of restaurants and businesses.

Part of the reason is due to its reliability and ease of use. It can take a multitude of different 3D food printer materials, and switching them round is quick and easy. What’s more, you can even add your own recipes to the machine to 3D print with the ingredients you enjoy most. This allows you all the freedom you need to print any chocolate, pastry, or other 3D printed food dish you like, and byFlow even have over 50 downloadable 3D designs for free on their website.

This allows you all the freedom you need to print any chocolate, pastry, or other 3D printed food dish you like, and byFlow even have over 50 downloadable 3D designs for free on their website.

As a result, businesses such as B2B chocolatier Barry Callebaut giant use byFlow Focus food 3D printers, as well as well-reputed chef Jan Smink in his ‘Restaurant Smink’ restaurant.The byFlow Focus food 3D printer is another food printer used across restaurants, especially in Europe.

10. Choc Edge Choc Creator 2.0 Plus

- Country based: UK / China

- Food 3D printer price: €2,330

- Print volume: 180 x 180 x 40 mm

Originally based out of a uni campus, Choc Edge is now thriving as a leading food 3D printer manufacturer. The Anglo-Chinese chocolate 3D printer company’s third food 3D printer, the Choc Creator 2.0 Plus, is a picturesque and innovative machine. Though it prints edible objects, the Choc Creator still utilizes the same layer-by-layer method as with Fused Deposition Modeling. Retailing at just under $3,000, it’s a great option for niche bakers and chocolatiers out there.

Retailing at just under $3,000, it’s a great option for niche bakers and chocolatiers out there.

A few reasons why the Choc Edge Choc Creator 2.0 Plus is an industry leader are firstly how easy it is to use. The chocolate 3D printer features a large and responsive touchscreen for easy access and printing. The 0.8mm nozzle is easily removed and changed based on the 3D food material used, with the 30ml metal syringe just as easy to replace. Overall, it’s a one of the best chocolate 3D printer machines on the market, and prints in the same way as your average FDM 3D printer.The Choc Creator by Choc Edge is known as one of the best chocolate food 3D printers around.

Bonus: The Food 3D Printer That Never Happened — 3D Systems ChefJet & ChefJet Pro

- Country based: USA.

- Food 3D printer price: $5,000 & $10,000.

- Print volume: 203 x 203 x 203 mm.

The ChefJet food 3D printer created by industrial 3D printer giant 3D Systems is an unfortunate case.

3D Systems bought Sugar Labs in 2013, suggesting there may be movements from the American company in the foodtech sector in the future. Then, when they announced and demonstrated the ChefJet Food 3D Printer throughout 2014 and 2015, people couldn’t wait to get their hands on this incredible piece of tech. It could make 3D food structures out of sugar with flavours including chocolate, vanilla, mint, sour apple, cherry, watermelon, and even more!

3D Systems’ ChefJet Food 3D Printer now looks like it will get a worldwide release, thanks to a new distribution deal.But it wasn’t to be. Some internal friction within the company meant that the project was put on hold for several years. Then in late 2017, 3D Systems announced a partnership with CSM Bakery Solutions to create and distribute the food 3D printers along with custom-made food 3D printer material.

Therefore, though the ChefJet 3D printer isn’t out yet, we still felt it was worthy of its place on this list as it will get a release soon, and has demonstrated its ability to 3D print food. We look forward to seeing how far the ChefJet and ChefJet Pro can push 3D printed food in the future. The ChefJet is to retail at $5,000, whilst the ChefJet Pro will retail at $10,000.

We look forward to seeing how far the ChefJet and ChefJet Pro can push 3D printed food in the future. The ChefJet is to retail at $5,000, whilst the ChefJet Pro will retail at $10,000.

3D food printer F2. Order all over Ukraine!

Promotion!

UAH 39,000

Print volume: 100 x 100 x 100 mm

With the new F2 food 3D printer, you can create culinary masterpieces right in your kitchen!

When buying a 3D printer, we provide mandatory training to work with the device! We guarantee technical support during operation and highly qualified service.

Available

Product quantity 3D food printer F2

Categories: 3D printers, Buy 3D printer

- Description

- Details

- Reviews (0)

Description

Buy 3D Food Printer F2

This is a unique device that allows you to reproduce patterns and shapes from edible mass. Basically, it's 3D printed food. The 3D food printer F2 uses a creamy paste as a material for printing. For example, it can be pancake batter, creamy sugar, chocolate spread, or thick ketchup. Such a device will help diversify culinary activities, bring a little positive to everyday meals and give a new way of creative expression. Think for yourself, the fruits of your imagination will actually be edible and very appetizing 🙂

With a 3D food printer, your dishes will be not only tasty and healthy, but also beautiful and original!

Specifications:

| Print technology | FDM |

| Print area size | 100 x 100 x 100 mm |

| Layer thickness (Z) | 0.5 mm |

| AC Power | 50 / 60Hz 11 OV-220 |

| Weight | 4.5 kg |

| Media | liquid material (Ketchup, chocolate sauce and others) |

| Build Speed | 150~300mm/s |

3D food printer F2

0001

In this section, we wanted to trace the history of 3D printing from its inception to the present day, as well as give a forecast regarding the future development of technology.

The first 3d printer was invented by the American Charles Hull, he worked on the technology of stereolithography (SLA), a patent for the technology was issued in 1986. The printer was a fairly large industrial installation. The installation "grew" a three-dimensional model by applying a photopolymerizable material to a moving platform. The basis was a digital model pre-modeled on a computer (3D model). This 3d printer created three-dimensional objects, rising by 0.1-0.2 mm - the height of the layer. Despite the fact that the first device had many disadvantages, the technology has received its application. Charles Hull is also the co-founder of 3dsystems, one of the world's leading manufacturers of industrial 3D printers.

Charles Hull was not the only one to experiment with 3D printing technology, as in 1986 Carl Deckard invented Selective Laser Sintering (SLS). You can learn more about the method in another article, briefly: a laser beam sinters a powder (plastic, metal, etc.), while the mass of the powder is heated in the working chamber to a temperature close to the melting point. The basis is also a digital model pre-modeled on a computer (3D model). After the laser passes through the horizontal layer, the chamber is lowered to the layer height (usually 0. 1-0.2 mm), the powder mass is leveled with a special device and a new layer is applied.

However, the most famous and widespread 3D printing method today is layer-by-layer direction (FDM). The idea of technology belongs to Scott Crump (Scott Crump), the patent dates back to 1988. You can learn more about the method in another article, in short: material (usually plastic) is fed from the heated nozzle of the print head using a stepper motor, the print head moves on linear guides along 1 or two axes, and the platform moves along 1 or 2 axes . The basis of the movement is also a 3D model. The molten plastic is laid on the platform along the established contour, after which the head or platform is moved and a new layer is applied on top of the old one. Scott Crump is one of the founders of Stratasys, which is also one of the leaders in the production of industrial 3D printers.

All the devices described above belonged to the class of industrial devices and were quite expensive, so one of the first 3d Dimension printers from Stratasys in 1991 cost from 50 to 220 thousand US dollars (depending on the model and configuration). Printers based on the technologies described above cost even more and until very recently, only a narrow circle of interested specialists knew about these devices.

Everything began to change since 2006, when the RepRap project (from the English Replicating Rapid Prototyper - a self-replicating mechanism for rapid prototyping) was founded, with the goal of creating a self-copying device, which was a 3D printer working on technology FDM (layer by layer deposition). Only, unlike expensive industrial devices, it looked like a clumsy invention made from improvised means. Metal shafts serve as a frame, they also serve as guides for the print head. driven by simple stepper motors. The software is open source. Almost all connecting parts are printed from plastic on the 3D printer itself. This idea originated among English scientists and aimed at spreading available additive technologies so that users can download 3D models on the Internet and create the necessary products, thus minimizing the production chain.

Leaving aside the ideological component, the community (which exists and develops to this day) managed to create a 3d printer accessible to the "ordinary person". So a set of unprinted parts can cost around a couple of hundred US dollars and a finished device from $500. And even though these devices looked unsightly and were significantly inferior in quality to their industrial counterparts, all this was an incredible impetus for the development of 3D printing technology.

As the RepRap project developed, 3D printers began to appear, taking as a basis the base laid down by the movement in technical and, sometimes, ideological terms (for example, commitment to the concept of open source - OpenSource). The companies that made printers tried to make them better both in terms of performance, design and user experience. The first RepRap printers cannot be called a commercial product, since it is not so easy to manage (and even more so to assemble) and it is not always possible to achieve stable work results. Nevertheless, companies tried to close the more than significant gap in quality, leaving a significant gap in cost whenever possible.

First of all, it is worth mentioning the company MakerBot, which started as a startup, took the ideas of RepRap as a basis and gradually turned them into a product of a new quality.

Their flagship product (and in our opinion the best to this day) remains the MakerBot Replicator 2 3D printer. The model was released in 2012 and later discontinued, but remains one of the most popular 3D printer models to this day " personal" segment (according to 3dhubs). The word "personal" is in brackets because this printer, which cost $2,200 at the time of release, was (and is) primarily used for business purposes, but falls into the personal segment due to its cost. This model differs from its progenitors (RepRap), being, in fact, a finished commercial product. Manufacturers abandoned the concept of OpenSource, closing all sources and software codes.

In parallel with the release of equipment, the company actively developed the Thingiverse resource, which contains many models for 3d printing, available for download for free. During the development of the first printer and beyond, the community has helped the company a lot, testing the product and offering various upgrades. After the release of the Replicator 2 (and the closure of development), the situation has changed. You can learn more about the history of MakerBot and other companies and people associated with 3d printing by watching the film Print the legend.

This film also highlights the history of Formlabs, one of the first companies to launch an affordable 3D printer based on SLA (Strereolithography) technology. The company raised funds for the first FORM 1 model through crowdfunding, encountered production difficulties, but eventually released an affordable and productive 3D printer, closing the quality gap described above.

Although the 3D printers described above were far from perfect, they set the stage for the development of affordable 3D printing technology that continues to this day. At the moment, the quality of FDM and SLA printers is increasing, but there is no significant price reduction, rather, on the contrary, it is growing slightly. Along with FDM and SLA, many companies are developing in the field of powder sintering (SLS), as well as metal printing. Despite the fact that such printers cannot be called affordable, their price is much lower in comparison with analogues from the professional segment. It is also worth noting the development of the line of materials, in addition to the standard ABS and PLA plastics, today many different materials are used, including nylon, carbon fiber and other durable and refractory materials.

Personal 3d printers of today are very close to professional devices, the development of which also continues unabated. In addition to the "founders" of the technology (Stratasys, 3dsystems), many small companies specializing in industrial 3D printing technologies (metal in particular) have emerged. 3D printing is also attracting the attention of large corporations, which, with varying degrees of success, are striving to take their place in a growing market. Here it is worth highlighting HP, which recently released the HP Jet Fusion 3D 4200 model, which has gained popularity among 3d printing professionals (as of 2018, it is at the top of the ranking of professional 3D printers in the quarterly reports of the 3dhubs portal).

However, 3D printing technologies are developing not only in breadth, but also in depth. One of the main disadvantages of 3D printing, compared to other production methods, is the low speed of creating models. A significant advance in terms of accelerating 3D printing was the invention of CLIP technology by CARBON, printers operating on this technology can produce models 100 times faster than classic SLA technology.

There is also a constant expansion of the range, properties and quality of materials and post-processing of products. All this accelerates the transition to the use of 3d printers in production, and not just as prototyping devices. Today, many large and not only companies and organizations are closely using a 3D printer in their production chain: from consumer goods manufacturers NIKE and PUMA to BOEING and SPACE X (the latter prints engine parts for its rockets that could not be made in any other way) .

In addition to the "classic" scope of 3D printing, today you can increasingly see news about how a house or some organ (or rather, a small part of it) was printed on a 3D printer from bio-material. And this is true, several companies around the world are testing or already partially using 3D printing in the construction of buildings and structures. This mainly concerns the contour pouring of walls (similar to the FDM method) with a special composite concrete mixture. And in Amsterdam there is a 3D printed bridge project and this list will only expand over time, since the use of 3D printing in construction can significantly reduce costs and increase the speed of work at certain stages.

With regards to medicine, here 3D printing also finds application, but at the moment it is not printing organs, but rather the use of technology in prosthetics (of various kinds) and bone replacement. Also, 3D printing technology is widely used in dentistry (SLA technology). Regarding the printing of organs, this is still far in the future, at the moment bio-3D printers are experimental facilities in the early stages, the success of which is limited to printing a few limited-viable cells.

Looking to the future, it is safe to say that 3D printing technology will expand both in breadth and depth, improving technology, speeding up processes, improving quality and improving material properties. 3D printers will increasingly replace old methods in production chains of various scales, and world production, due to this, will move towards the “on demand” scheme of work, increasing the degree of product customization. Perhaps someday, 3D printers will be widely used at the household level for the production of necessary things (the dream and goal of the RepRap movement), but this requires not only the development of technology, but also a paradigm shift in social thinking, as well as the development of a powerful design ecosystem ( 3d modeling) products (which is often forgotten).

3d printing of houses (and other structures) will no doubt also develop, reducing costs and production time, which, together with the development of new approaches in architecture and urban planning (such as modular construction and the prefabricated method), will give a tangible impetus to development the industry as a whole.