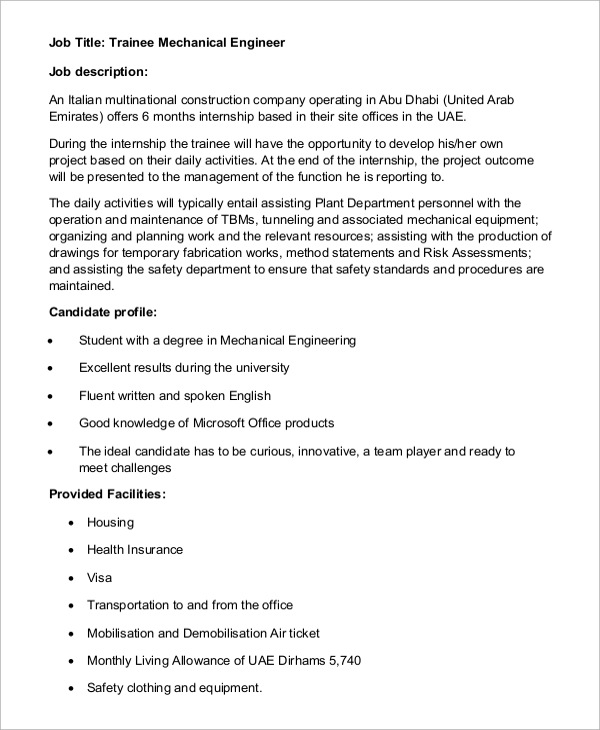

3D printing engineer job description

3D Engineer Job Description | Velvet Jobs

Job Descriptions

3D Engineer Job Description

4.5

173 votes for 3D Engineer

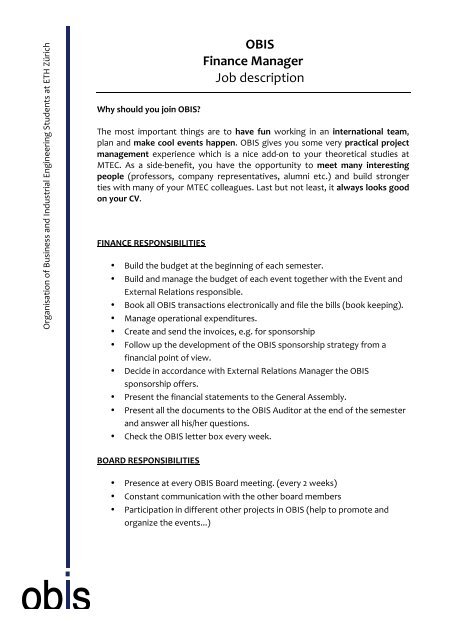

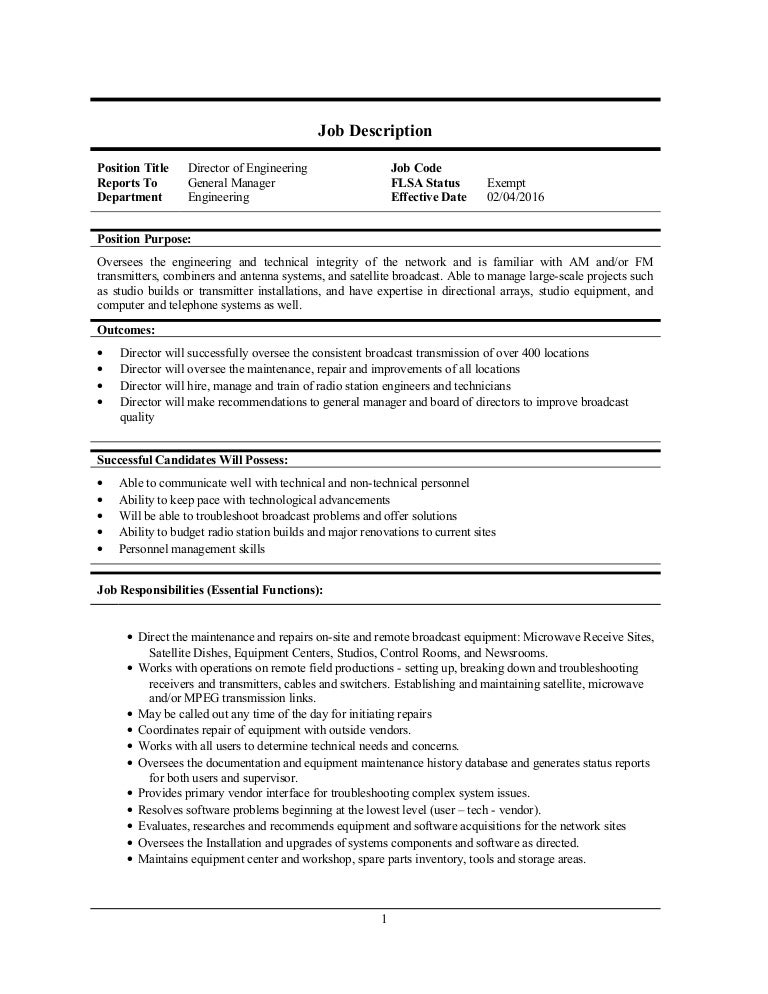

3D engineer provides technical expertise in areas such as Information Systems Architecture, Weapon Systems Architecture, Information Systems Integration, Software Development Methodologies, Security Engineering, Communications, Network Systems Management, etc.

3D Engineer Duties & Responsibilities

To write an effective 3D engineer job description, begin by listing detailed duties, responsibilities and expectations. We have included 3D engineer job description templates that you can modify and use.

Sample responsibilities for this position include:

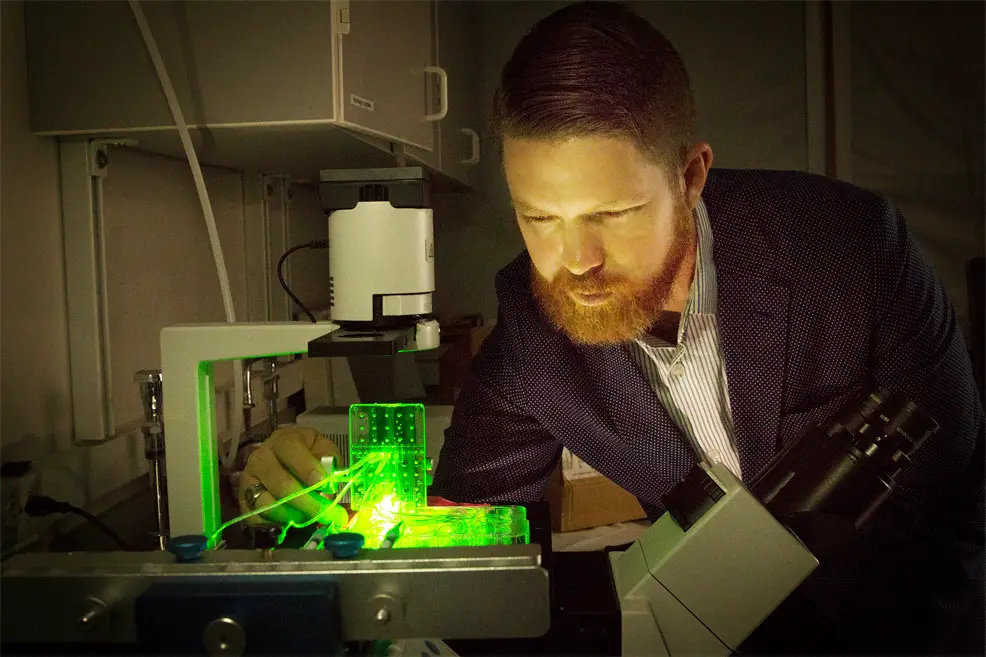

Collaborate with molecular biologists, bio-informatics engineers and pathologists in partner academic hospitals to explore, create and validate new innovative concepts in the area of data fusion and big data analytics

Own your work, for better or worse

Developing real-time rendering algorithms in 2D and 3D, optimized for deployment on millions of mobile devices and connected cars worldwide, and have a voice in the development of an exciting industry

Working on the cutting edge of GIS technology with satellite imagery, 3D terrain and landmarks, and geographic vector data

You will also have opportunity to work with big-name companies to provide mapping services for them

Proficient in Rhino 3D and Solidworks, Surface modeling and Solid modeling techniques

Experience in PCBA In-Circuit Testing and functional tester development

Have knowledge in testing technology such as Boundary scan and flying probe test system

Familiar with EDA tools such as Cadence and Mentor Graphics

Must be able to read gerbers and schematics very well

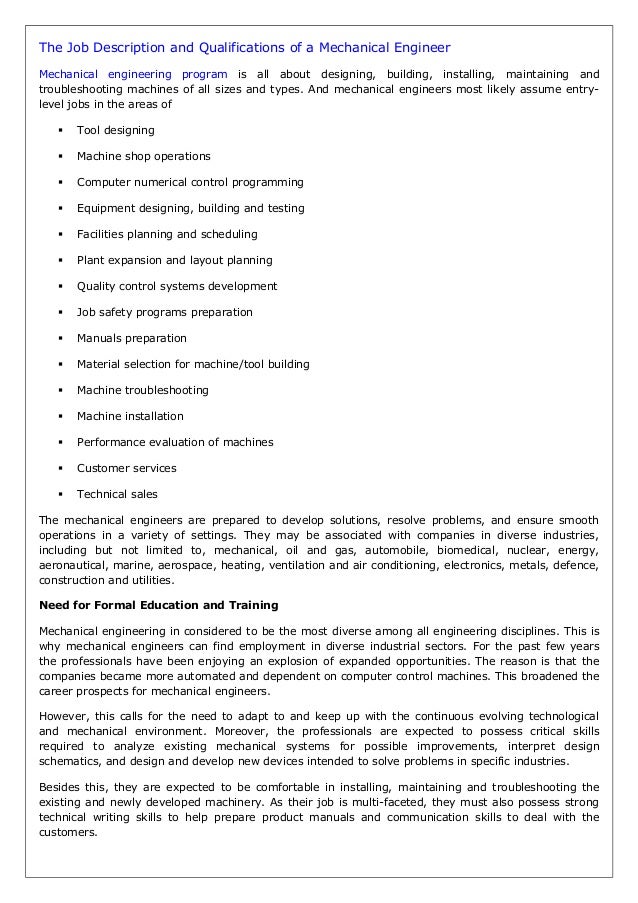

3D Engineer Qualifications

Qualifications for a job description may include education, certification, and experience.

Licensing or Certifications for 3D Engineer

List any licenses or certifications required by the position: PMI, PMP, SSL, CV, ITIL, ASQ, STD, IPC

Education for 3D Engineer

Typically a job would require a certain level of education.

Employers hiring for the 3D engineer job most commonly would prefer for their future employee to have a relevant degree such as Bachelor's and Master's Degree in Engineering, Computer Science, Science, Electrical Engineering, Mechanical Engineering, Technical, Computer Engineering, Education, Industrial, Physics

Skills for 3D Engineer

Desired skills for 3D engineer include:

Data manipulation and analysis techniques in Microsoft Excel

Excel and Powerpoint

Harness manufacturing processes and best practice in ‘design for manufacture’

Road design/alignment design/drainage design

Methodologies and practices

Similar

AutoLISP

British Standards

Programming

C++ language

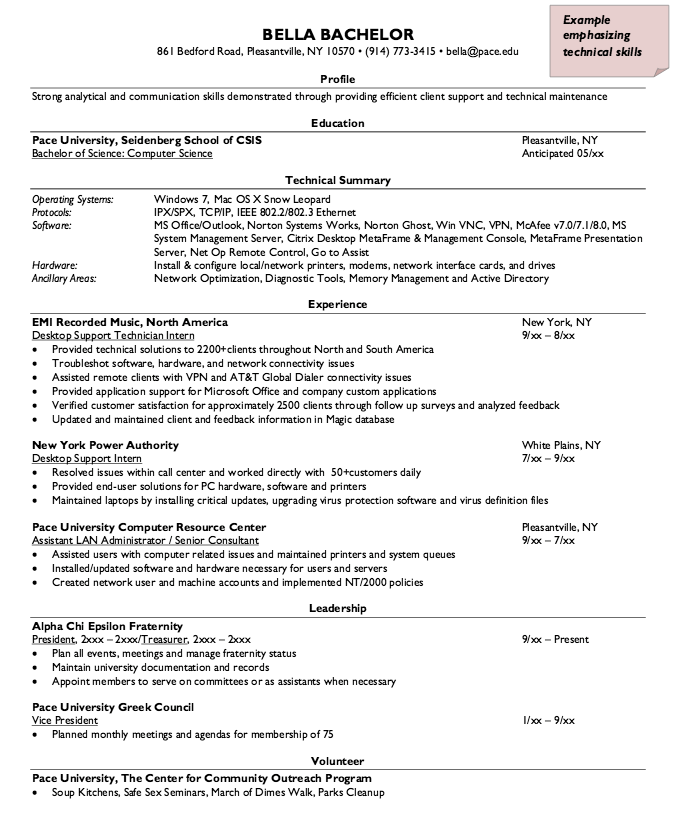

Desired experience for 3D engineer includes:

We expect that you have an outstanding academic background, a focus on quality, and a proven ability to get things done

You can write high-quality C++ code in your sleep, and have experience developing performance-critical systems

Ideally, you have a good knowledge of computer graphics/computer vision and are familiar with graphics APIs like OpenGL/OpenGLES/Direct3D

Proficient with IaaS providers (AWS, Google, Azure, Heroku, OpenStack, IBM, HP)

Interact and engage with other departments production, quality as part of the design process and specifically on larger or more complex projects

BSc/M. Sc degree in Software Engineering, Computer Science

Sc degree in Software Engineering, Computer Science

3D Engineer Examples

Our innovative and growing company is searching for experienced candidates for the position of 3D engineer. If you are looking for an exciting place to work, please take a look at the list of qualifications below.

Responsibilities for 3D engineer

- Support and responsive to factory build readiness issues and product performance escalations on EE sub-systems owned

- Manage and collaborate with outsourced Manufacturing Partner to deliver to program support needs in the factory throughout industrialization phase and post MR requirements environment

- Establish digital printing and processing conditions (time, temperature and environmental)

- Design, integrate, validate, and support the digital printing prototype

- Assist with the design and deployment of digital software to production, and designing and upgrading software architecture

- Work with researchers, systems and hardware engineers in system integration and commercialization efforts

- Work with vendors and suppliers to communicate design specs and drive on-time delivery of final components and devices

- Develop concepts, design, build and place into manufacturing the equipment necessary to meet facility requirements

- Document work via appropriate drawings, solid models and other written information

- Develop equipment cost justifications based upon part cost and volume

Qualifications for 3D engineer

- 4 years plus experience in software development

- If you have a good knowledge of computer graphics/computer vision and are familiar with graphics APIs like OpenGL/OpenGLES/Direct3D, that would be a great advantage

- Willingness to work in a team based culture

- Master/PhD degree in the related discipline(computer science & engineering, mathematics)

- Passions in the video game development and/or related work

- Experience with 3D applications and their APIs is a plus

Our company is growing rapidly and is looking to fill the role of 3D engineer. We appreciate you taking the time to review the list of qualifications and to apply for the position. If you don’t fill all of the qualifications, you may still be considered depending on your level of experience.

We appreciate you taking the time to review the list of qualifications and to apply for the position. If you don’t fill all of the qualifications, you may still be considered depending on your level of experience.

Responsibilities for 3D engineer

- Evaluating serviceability for new automobile models in development

- Creating 3D simulations to demonstrate component removal and installation

- Identifying design L/O issues and negotiating countermeasures with R&D

- Provide application support to the 3D Printer Value Added Resellers (“VAR”)

- Support complex sales of products or solutions to customers on a partnership basis

- As Application Engineer, she/he will participate / lead activities to execute the 3D Printing Deployment Plan to the EMEA & Italy team

- To help sales identify new business opportunities for Multi Jet Fusion

- Create meaningful solutions for healthcare based on data fusion of 3D pathology and molecular imaging

- Cable routing and cable trays

- Substation/Electrical rooms general arrangements (GA)s

Qualifications for 3D engineer

- Deep understanding and experience in developing end to end security solutions

- This job will require partnership and collaboration with different asset teams and product teams

- The technical lead will be leading technical meetings with asset and product partners to align on architecture, design and delivery of 3D Printing Solutions

- Minimum of 2 years of professional experience in R&D with strong management background

- Experience in the medical device industry with focus on process engineering

- Have experience in 3D StudioMax or PhotoShop

Our innovative and growing company is looking to fill the role of 3D engineer. Thank you in advance for taking a look at the list of responsibilities and qualifications. We look forward to reviewing your resume.

Thank you in advance for taking a look at the list of responsibilities and qualifications. We look forward to reviewing your resume.

Responsibilities for 3D engineer

- Setup and management of new and existing engineering projects within SmartPlant 3D

- Managing and creating reporting options through the project lifecycle

- Providing support to project resources

- Managing and maintaining backup systems

- 3D printer product sub-systems (Powder Delivery/Supply) owner, responsible for the sub-systems product/process engineering performance to specifications/functions

- Participate in product prototyping builds at GBU (Vancouver USA) to provide DFM and for product/process knowledge transfer successfully

- Supervise the different testing activities

- Designs engineering solutions for 3D printer mechanical systems, including structural, dynamic systems, thermal, servo systems, fluidics and bulk powder management, based on established engineering principles and in accordance with development technology practices and guidelines

- Participate in the entire 3D Manufacturing Software life cycle from concept to release

- Build software solutions for Stereolithography, 3D Printing, CNC Milling, Laser Marking, Laser Trimming, and X-Ray Tomography

Qualifications for 3D engineer

- 3 to 5 years of experience in an equivalent technical support role or as a mechanical engineer

- Experienced with various 3D modelling applications

- Prior customer facing experience resolving critical technical and account issues

- Excellent working knowledge of Windows based computer systems, networks, installation deployment technologies, and virtual environments

- Functional use of Microsoft Office Excel, Word, and PowerPoint

- Ability to coordinate projects and work with various departments within an organization

Our growing company is searching for experienced candidates for the position of 3D engineer. Please review the list of responsibilities and qualifications. While this is our ideal list, we will consider candidates that do not necessarily have all of the qualifications, but have sufficient experience and talent.

Please review the list of responsibilities and qualifications. While this is our ideal list, we will consider candidates that do not necessarily have all of the qualifications, but have sufficient experience and talent.

Responsibilities for 3D engineer

- Interact with customers and our internal testing department to improve the product

- Help define technical requirements for products

- Help define user acceptance testing scenarios

- Research current trends, emerging technologies and effectively implement them

- Leap beyond the limits of previous technologies and enter a world where 3D printing allows you to move rapidly from thoughts to things, from radical prototyping to final parts manufacturing

- We're launching a unique technology that will disrupt the market and open a new world in the 3D printing industry and we want you to be part of this exciting opportunity that we've in front of us

- Support our customers, channel partners and HP Service workforce and sales team to accelerate the adoption of the HP Multi Jet Fusion by building a competitive advantage through a lean support experience in the 3D printing market for 3D service bureaus and enterprise customers

- Work together with our sales force team to assure the HP 3D Printing solution (HW, SW and Services) portfolio is understood by our customers and channel and is perceive a perfect fit for their business need

- Project leader for advanced node TSV integration to support 3D products

- Follow-up and checking interface data with client, partners, equipment suppliers, piping, civil

Qualifications for 3D engineer

- Positive, self-motivated individual with a high level of enthusiasm and willingness to learn and incorporate coaching and instructions into daily tasks and assignments

- Bachelor’s degree in Engineering, Automotive Technology, or equivalent work experience

- 9-12 years of work experience plus 6-8 OEM automotive industry experience dealership technician experience preferred

- Experience with Dassault System Software applications (CATIA, Delmia) or experience working in virtual 3D environment preferred

- Expertise in Automobile diagnostics and repair

- Ability to evaluate vehicles/vehicles components in a virtual or physical state (static and dynamic evaluations)

Our company is looking for a 3D engineer. We appreciate you taking the time to review the list of qualifications and to apply for the position. If you don’t fill all of the qualifications, you may still be considered depending on your level of experience.

We appreciate you taking the time to review the list of qualifications and to apply for the position. If you don’t fill all of the qualifications, you may still be considered depending on your level of experience.

Responsibilities for 3D engineer

- A relevant Bachelors/Masters Degree &/or equivalent experience in Computer Science, Software Engineering, Computer Systems Engineering, Mathematics, or other Degree with strong emphasis on software development or mathematical engineering

- Demonstrated computer vision and/or image/video processing experience

- The ability to work effectively as part of a multi-disciplinary, regionally dispersed research team, and carry out tasks autonomously in support of scientific research

- Demonstrated ability & willingness to contribute novel ideas and approaches

- Designs portions of engineering solutions for mechanical parts, subsystems, integrated circuitry, and algorithms based on established engineering principles and in accordance with provided specifications and requirements

- Implements established test plans for existing designs, including validation of tolerances, form/fit/function, shock and vibration, safety, reliability, thermal generation, and fatigue

- Develops understanding of and relationship with internal and outsourced development partners on mechanical design and development

- Participates as a member of project team of other mechanical engineers and internal and outsourced development partners to develop reliable, cost effective and high quality solutions for low to moderately- complex products

- You are a full stack software engineer with a primary focus on large scale web services

- You provide technical leadership to the team with a focus on delivering large scale production services

Qualifications for 3D engineer

- Excellent written and oral communication, problem solving and presentation skills

- Enthusiastic about seed-stage startups

- Proficiency in using 2D design applications

- Experience with scripting languages, Python, Perl, and Bash

- Solid foundation in computer vision

- Deep understanding of machine learning technology and experience on turning machine learning technologies into practical, state-of-the-art systems

Related Job Descriptions

Browse More

Hawk Ridge Systems 3D Printing Technician

- Full-time

Company Description

Hawk Ridge Systems is a global leader in engineering design and manufacturing solutions. Our vision is to bring engineering design and product realizations solutions to our customers that radically change the way they do business. We do that by employing the most talented and dedicated people in our industry that in turn build trusted relationships with our customers by solving their most critical problems.

Founded in 1996 we have 17 offices and employ over 155 people in the United States and Canada. We currently have customers across all manufacturing industries. Over the last 3 years we have achieved an annualized revenue growth rate of over 22% and our plan is to do the same over the next 3 years.

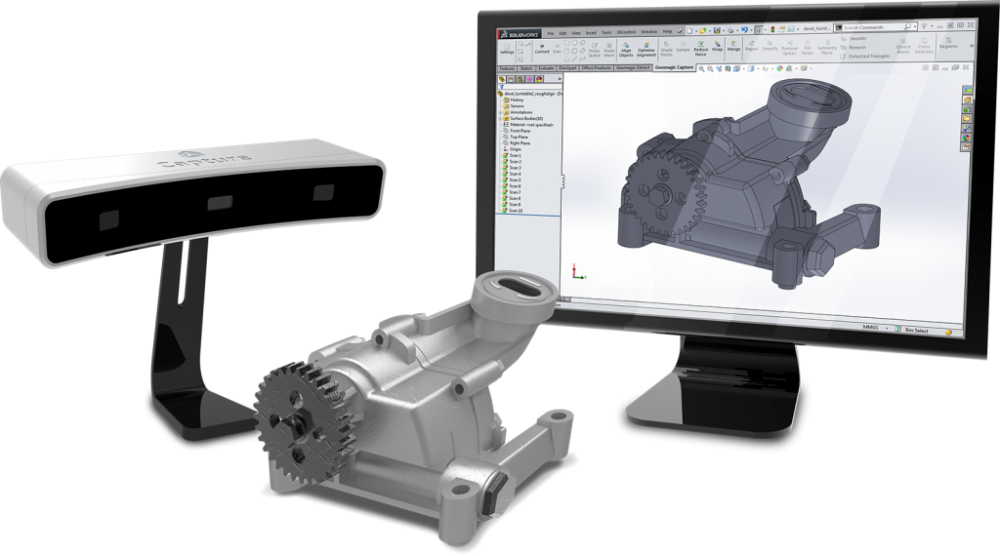

Our portfolio of Solutions is vast but includes SolidWorks 3D CAD from Dassault Systems, the most recognized 3D mechanical CAD product on the market, CAMWorks from Geometric technologies, 3D Printers (additive manufacturing) from 3D Systems and our own brand HawkWare.

Job Description

HRS is hiring a 3D Printing Technician in Santa Clara to support the production, processing, and maintenance associated with our 3D Printing business and Digital Manufacturing Lab facility.

Essential duties and responsibilities may include any of the following.

- Assist in the preparation and maintenance of shop components and tools inventory.

- Shipping and receiving activities.

- Ensure proper inventory levels and process orders and audits as needed.

- Maintain prototyping shop facility organization and cleanliness on daily and regular basis.

- Comply with policies, rules and regulations and reporting requirements relating to safety/heath, performance standards, operating procedures, processes, and training.

- Other duties as assigned.

Advanced duties and responsibilities may include any of the following.

- Process 3D model print request activities:

- Receive and prioritize all requests

- CAD model pre-processing and validation, and benchmark costing

- Manage queues and executes 3D prints

- Post process 3D prints

- Inspect 3D Printed models for quality

- Package and process shipping

- Confirm completion, update logs and notify recipients

- Assist with repair, upgrade and installation of various software and hardware related to Digital Manufacturing Laboratory facility.

- Maintain and operate various types of 3D printers and related technologies.

Qualifications

- High school diploma or equivalent

- Related experience with computer/peripheral maintenance and repair, printer servicing or similar background

- Familiarity with Microsoft Office Suite

- CRM software knowledge

- Strong analytical and machine shop mathematical skills

- Ability to read CAD Drawings

- Detail oriented

- Self-starter with the ability to take initiative and accomplish tasks

- Excellent problem definition and resolution skills

- Ability to multi-task, prioritize, organize and manage tasks

- Adaptable and flexible

- Solid verbal and written English language communication skills are required.

- Ability to carry out instructions furnished in written, oral, or diagram form.

- This is a technical as well as physical position. Candidates must be able to lift and carry up to 70 lbs.

Reasonable accommodations may be made to enable individuals with legally protected disabilities to perform the essential functions.

Reasonable accommodations may be made to enable individuals with legally protected disabilities to perform the essential functions. - Must have valid driver’s license and vehicle.

Additional Information

Pay range is $16 to $18/hour DOE.

Please no recruiters or calls about this career opportunity.

HRS is an equal opportunity employer.

Powered by

(Data Processor)

Privacy Policy and Terms of Use

3D printing engineer - description of the profession, obtaining a specialty, job duties and salary in Moscow

3D printing engineer - description of the profession, obtaining a specialty, job responsibilities and salary in Moscowhome

Professions

Engineering

3D printing engineer

- Geodesy, cartography

- Mining, mine surveying, geology, resource extraction, excavations

- office work

- Design

- Journalism, writing, criticism

- Engineering

- Art, cinema, theater, sound work

- IT, programming

- Personnel, work with personnel

- Logistics, merchandising

- Marketing, advertising, PR

- Medicine, healthcare, medical material manufacturing

- International relations, linguistics

- fashion, beauty

- Scientific specialties

- Pedagogy

- Nutrition, gastronomy

- Working with animals, agriculture and nature management

- Working specialties

- Craft, printing, industry

- Sport

- Construction, design, property management

- Transport, auto industry

- Tourism and entertainment

- Management of organizations and personnel, administration

- Economics, business, consulting, insurance

- Jurisprudence

- Other

3D printing engineer is engaged in technical support, work with equipment, software, creation of 3D models. Specialists must have in-depth knowledge of engineering, programming and mathematics. The profession is connected with future specialties.

Specialists must have in-depth knowledge of engineering, programming and mathematics. The profession is connected with future specialties.

The profession is suitable for people interested in physics and mathematics (see

choice of profession, which is important for school subjects).

Brief description

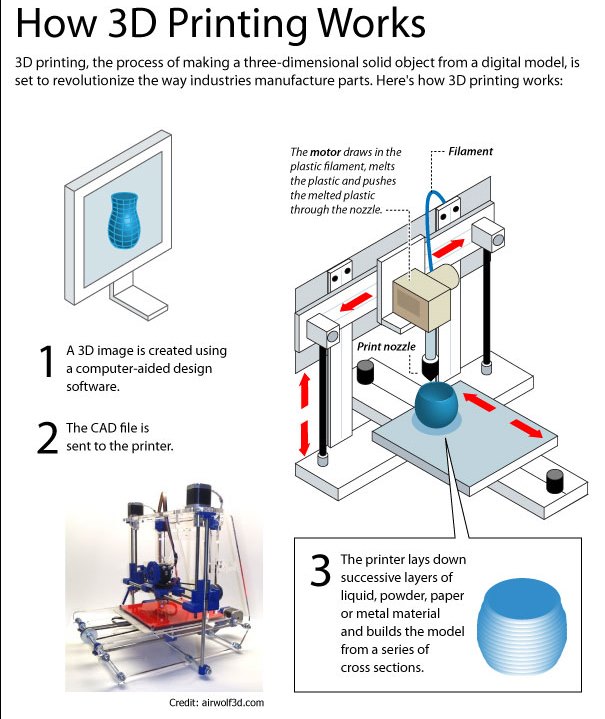

The profession of a 3D printing engineer has appeared quite recently, but its value and social significance cannot be underestimated. Thanks to 3D printing, unique products are used today that are used in the field of medicine and industry. Mathematicians and engineers are constantly developing more advanced technologies that allow them to create spaces, anatomical models, memories, homes, and prostheses using this type of printing. And the printers used to print biomaterials make it possible to create human skin, a step forward in the treatment of injuries, injuries, accelerating the rehabilitation period. The engineer, who is an excellent programmer, technician, biologist and even a chemist, is in full control of the introduction of 3D printing, as the profession makes him feel the composition and characteristics of various materials. To work in this area, you need to have a technical education, attending IT courses, model conferences will be an advantage. The specialist must be able to independently design a 3D model, select the necessary materials, calculate all the risks, and then print, create products for the medical, aviation, industrial, etc. industries.

To work in this area, you need to have a technical education, attending IT courses, model conferences will be an advantage. The specialist must be able to independently design a 3D model, select the necessary materials, calculate all the risks, and then print, create products for the medical, aviation, industrial, etc. industries.

Performance characteristics

3D printing engineers use a variety of materials, computer programs, and industrial 3D printers for their work. Today, these specialists need medical centers, industry, aerospace, engineering and other industries. There are few specialists, their work cannot be named simply because the duties of a 3D printing engineer include: choosing new materials, conducting tests, using modern software to improve and adjust the parameters of a 3D printer; development of layouts, development of raster images for subsequent printing; full control over the letter; Studying new technologies; Knowledge of certification rules, requirements for 3D models and finished products. documentation development, software debugging; selection of new equipment, training of other employees; equipment maintenance. Responsibilities vary by location, but a 3D Printing Engineer must be a broad-based specialist who is willing to quickly learn new technologies and then successfully apply them in practice. Employers have strict engineering requirements because the salary of such specialists is significant. They must have at least 3 years of practical experience, it is important to have technical knowledge of a foreign language. A 3D printing engineer must know the basics of economics and marketing, because his duties include optimizing workflows aimed at reducing the cost and speed of printing.

documentation development, software debugging; selection of new equipment, training of other employees; equipment maintenance. Responsibilities vary by location, but a 3D Printing Engineer must be a broad-based specialist who is willing to quickly learn new technologies and then successfully apply them in practice. Employers have strict engineering requirements because the salary of such specialists is significant. They must have at least 3 years of practical experience, it is important to have technical knowledge of a foreign language. A 3D printing engineer must know the basics of economics and marketing, because his duties include optimizing workflows aimed at reducing the cost and speed of printing.

Pros and cons Pros An important profession that will help save millions of lives in the future, improve the environment, it is advisable to let you waste natural resources. 3D printing engineers today are unique specialists. demand in different areas. The specialist will not have problems finding work in megacities. The salary is stable and high. An experienced engineer can open his own production for the production of souvenirs or other products. You can study in Russia and register at a technical university. Lack of physical activity Disadvantages: Seated work, but not monotonous. Irregular working day, because the production of a large product may take more than 5 hours. The cost of industrial 3D printers is high, so in order to organize your own production, think about the initial capital or look for an investor. Any mistake made by a 3D printing engineer is full of huge financial losses. Difficulties in finding work in small towns. Working on a computer leads to visual impairment. Important Personal Qualities A 3D printing engineer is the bearer of a large amount of professional knowledge, so he must be an erudite person with an excellent memory. In nature, this rare specialist should be responsible, curiosity, creativity. The engineer is obliged to study, welcome and constantly study science and linguistics, since further instructions, books and technical documentation are also created mainly in foreign languages.

The salary is stable and high. An experienced engineer can open his own production for the production of souvenirs or other products. You can study in Russia and register at a technical university. Lack of physical activity Disadvantages: Seated work, but not monotonous. Irregular working day, because the production of a large product may take more than 5 hours. The cost of industrial 3D printers is high, so in order to organize your own production, think about the initial capital or look for an investor. Any mistake made by a 3D printing engineer is full of huge financial losses. Difficulties in finding work in small towns. Working on a computer leads to visual impairment. Important Personal Qualities A 3D printing engineer is the bearer of a large amount of professional knowledge, so he must be an erudite person with an excellent memory. In nature, this rare specialist should be responsible, curiosity, creativity. The engineer is obliged to study, welcome and constantly study science and linguistics, since further instructions, books and technical documentation are also created mainly in foreign languages.

Additional education courses

| The Interregional Academy of the Construction and Industrial Complex (MASPK) invites specialists to professional retraining and advanced training courses developed under the guidance of leading specialists in the most demanded industries. Distance learning at professional retraining courses in the direction of "Product Engineering Engineer" will allow you to receive a document confirming your qualifications without interrupting your work. |

Place of work

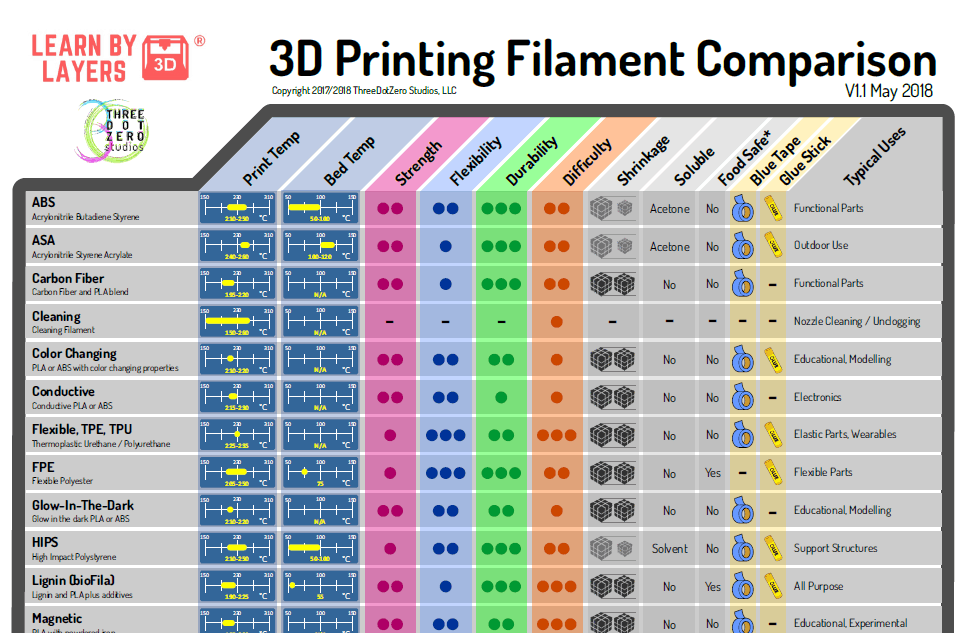

3D printing engineers will be able to work in agencies involved in the production of consumer goods. They are in demand by architectural firms, factories, medical centers and nanolaboratories, clothing design and production agencies. 3D printing is used in all areas of life, so a young college student can choose an interesting and useful direction. Salary Professional knowledge of 3D printing technology (SLA, FDM, etc.) 3D modeling 3D printing of materials (PLA, ABS, etc.). Slicers prepare for 3D printing, work with software (Autodesk 3ds Max, SolidWorks, Autodesk 123D Design and others). Knowledge of specifications of various models of equipment. Functionality of processing 3D printed models. English

Salary Professional knowledge of 3D printing technology (SLA, FDM, etc.) 3D modeling 3D printing of materials (PLA, ABS, etc.). Slicers prepare for 3D printing, work with software (Autodesk 3ds Max, SolidWorks, Autodesk 123D Design and others). Knowledge of specifications of various models of equipment. Functionality of processing 3D printed models. English

The purpose of this

resource is to help you

make a choice.

Instructions for labor protection when working with a 3D printer

Good evening everyone.

I decided to write something useful, so I adapted the instructions for t.b. for 3d printer.

The instruction can be rewritten for any specific printer, I expect that it will be used in educational institutions or in any organization where there is a 3D printer.

In the near future, perhaps, I will lay out a methodological manual, but not a fact.

Link to today and personally to me, quoting, etc. is welcome! Companies, if you complete your printers with this, I’m only for it, but have a conscience)

is welcome! Companies, if you complete your printers with this, I’m only for it, but have a conscience)

Instruction No. ____

on labor protection when working with a 3D printer

1. General requirements for safety instructions when working on 3 D printer

1.1. Persons who have reached the age of 18 and have studied these instructions at work on a 3D printer.

1.2. While working on a 3D printer, the following dangerous and harmful factors affect a person:

– plastic fumes;

- temperature;

- noise.

1.3. When working on a 3D printer, it is not allowed to locate the workplace in rooms without natural or artificial ventilation.

1.4. To protect the plastic on the reel from direct sunlight, sun protection devices (curtains, film with a metallized coating, adjustable blinds with vertical panels, etc.) should be provided.

1.5. In the office and in the workplace, it is necessary to maintain cleanliness and order, to carry out systematic ventilation.

1.6. All equipment malfunctions identified during operation must be reported to the manager; in the event of a breakdown, work must be stopped until the emergency circumstances are eliminated. If a possible danger is detected, warn others and immediately inform the manager; keep the workplace clean and not clutter it with foreign objects.

2. Safety requirements before starting work on the 3D printer

2.1. Inspect and verify that equipment and electrical wiring are in good condition. In case of malfunctions, do not start work. Report it and only after troubleshooting and permission to start work.

2.2. Check the availability and reliability of the protective earthing of the equipment.

2.3. Check the condition of the electrical cord and plug.

2.4. Check the operation of the switches and other controls of the 3D printer.

2.5. If any malfunctions are detected, do not turn on the printer and immediately notify the manager about it.

2.6. Thoroughly ventilate the room with the 3D printer, make sure that the microclimate in the room is within acceptable limits: the air temperature in the cold season is 22–24°C, in the warm season it is 23–25°C, relative air humidity is 40–60% .

3. Safety requirements while working on a 3D printer

3.1. Turn on and turn off the 3D printer only with switches, it is forbidden to turn it off by pulling the plug out of the socket.

3.2. It is forbidden to remove the protective devices from the equipment and work without them, as well as touch the heated extruder and stage.

3.3. Do not allow unauthorized persons who are not involved in the work to the 3D printer.

3.4. Do not move or carry the 3D printer during printing.

3.5. It is forbidden to drink any drinks or eat food nearby while the 3D printer is in operation.

3.6. Any physical intervention during their operation of the 3D printer is prohibited, with the exception of an emergency stop of printing or an emergency shutdown.

3.7. Do not leave the switched on equipment unattended.

3.8. Do not place objects on or into the 3D printer.

3.9. Strictly comply with the general requirements for electrical safety and fire safety, the requirements of this labor protection instruction when working on the 3D printer.

3.10. It is strictly forbidden to disassemble and repair the 3D printer on your own. These works may only be carried out by a specialist.

3.11. The total time of direct work with the 3D printer during the working day should not exceed 6 hours.

4. Safety requirements after finishing work with 3D printer

4.1. Disconnect the 3D printer from the mains, for which you need to turn off the toggle switch on the back, and then pull the plug from the outlet.

4.2. Remove and wipe the 3D printer table, which has cooled to room temperature, with a clean, damp cloth, or rinse with running water and wipe dry. Put the table back.

4.