3D printer for polycarbonate

6 Best 3D Printers For Polycarbonate In 2023

- Last Updated: January 19, 2023

- Jackson O'Connell

When you think of 3D printing, the word “strong” probably doesn’t come to mind.

I mean, most 3D printed models are pretty weak and brittle. But what if I told you there’s a filament material so strong that a simple hook printed in the filament can hold over 650 pounds without breaking?

That filament’s name is polycarbonate, or PC for short, and it’s the strongest filament material for consumer-grade 3D printers known to man. It’s literally used in bulletproof glass. So if the President of the United States trusts the strength of polycarbonate, then so can you!

Polycarbonate is an excellent filament choice if you want to 3D print real-use parts that will face a lot of physical stress, like a door hinge or an RC car frame.

However, with great strength comes many struggles, and PC filament is notoriously difficult to print with very intensive hardware requirements.

If you want a printer to use for PC filament, I’d suggest getting the Prusa i3 MK3S+ and building (or buying) your own enclosure. However, if you’ve got a smaller budget, the Creality CR-10S is a great bang for your buck, though you still will have to get your own enclosure for the machine.

Want to learn more about PC and find other great machines for printing this type of filament?

Read on!

Creality CR-10S

Build volume: 300 x 300 x 400 mm

Get Discount Now

Check Latest Price

Qidi Tech X-Plus

Build volume: 270 x 200 x 200 mm

Check Latest Price

Prusa i3 MK3S+

Build volume: 250 x 210 x 210 mm

Get Discount Now

Check Latest Price

Check Kit Price

Table of Contents

- Best 3D Printers for Polycarbonate At A Glance

- Product Reviews:

- 1.

Prusa i3 MK3S+ (Premium Choice)

Prusa i3 MK3S+ (Premium Choice) - 2. Qidi Tech X-Plus (Best Choice)

- 3. Creality CR-10S (Best Value)

- 4. Qidi Tech X-Max (Best for Large Prints)

- 5. Bibo 2 Touch (Best for Beginners)

- 6. MatterHackers Pulse XE (Easy to Use)

- 1.

- What is a Polycarbonate?

- When To Use Polycarbonate?

- Advantages and Disadvantages of Polycarbonate 3D Printing

- Advantages

- Disadvantages

- How to 3D Print Polycarbonate?

- Factors to Consider When Choosing a 3D Printer for Polycarbonate:

- Material Compatibility

- Bed Temperature

- Enclosure

- Build Plate

- Build Volume

- Conclusion

Best 3D Printers for Polycarbonate At A Glance

1. Prusa i3 MK3S+ (Premium Choice)

2. Qidi Tech X-Plus (Best Choice)

3. Creality CR-10S (Best Value)

4. Qidi Tech X-Max (Best for Large Prints)

5. Bibo 2 Touch (Best for Beginners)

6. MatterHackers Pulse XE (Easy to Use)

MatterHackers Pulse XE (Easy to Use)

Product Reviews:

Now let’s dive into what printers can handle this beast of a plastic!

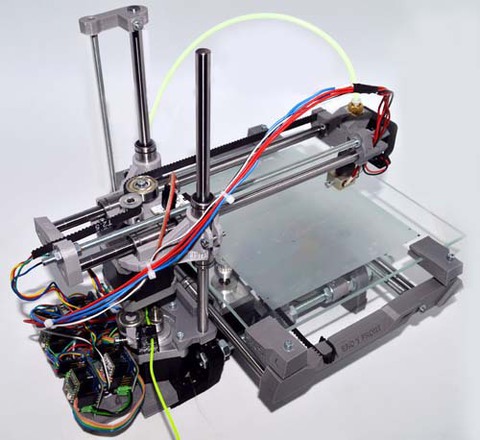

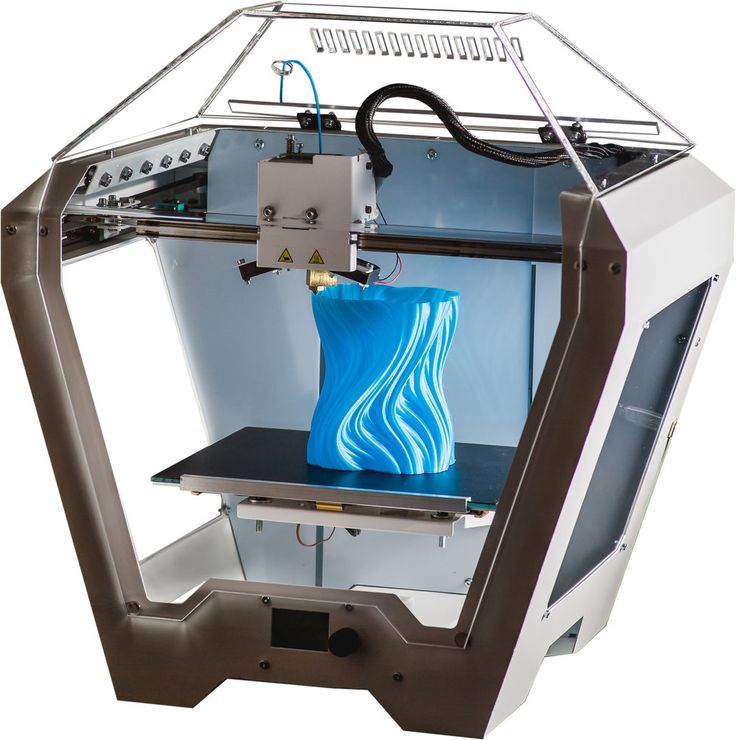

1. Prusa i3 MK3S+ (Premium Choice)3D Printer Type: FDM | Materials: PLA, PETG, ASA, ABS, PC, HIPS, Flex, Nylon, Carbon filled & Woodfill | Build Volume: 250 x 210 x 210 mm

First up, we’re taking a look at the Prusa i3 MK3S+. This printer is known to be one of the best 3D printers on the market. It is a step up from the original Prusa i3 MK3S with an upgraded extruder, among a handful of other improvements.

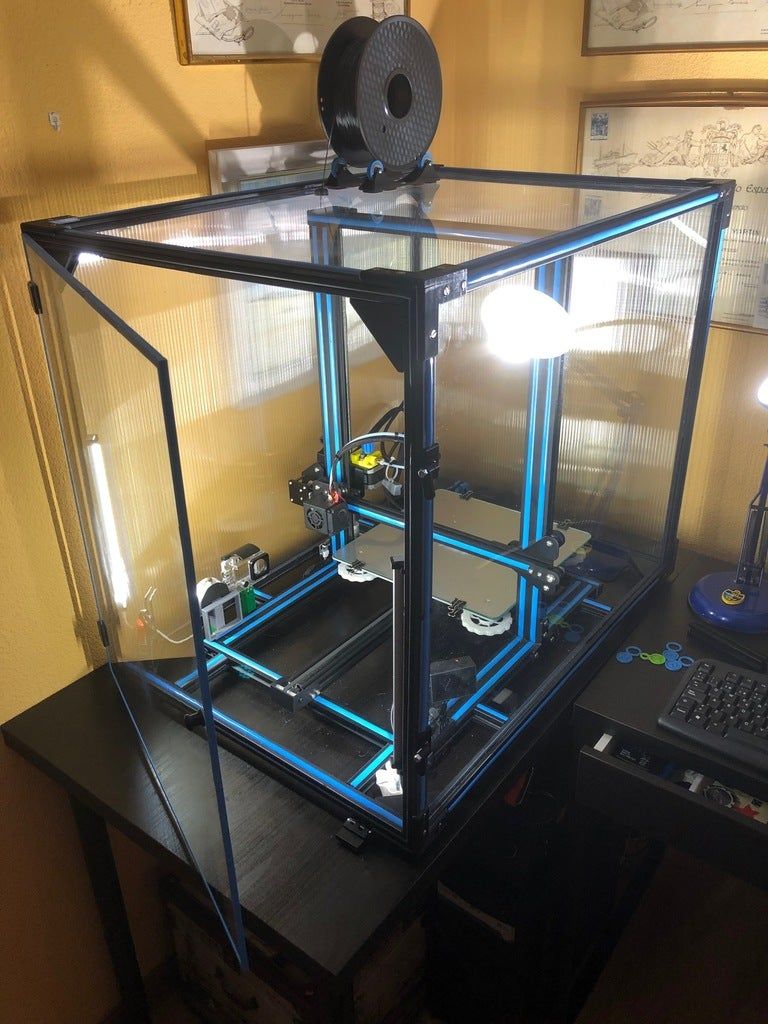

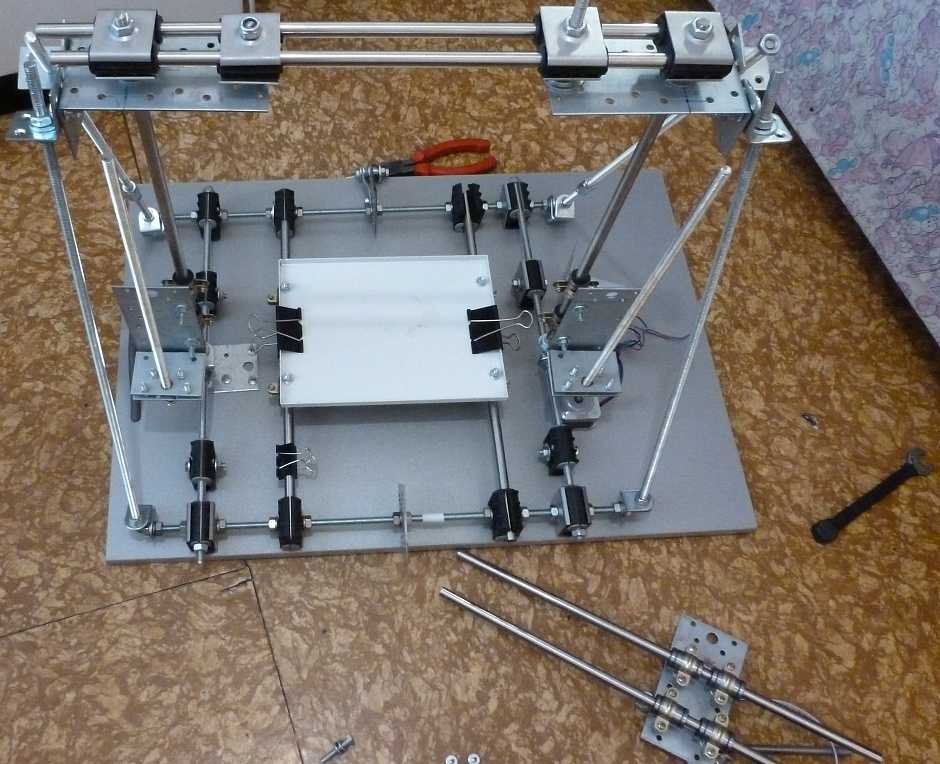

One thing to mention before we dive into the printer’s features is that the printer is an open-frame printer and does not have an enclosure. You’ll need to get an enclosure for the printer before you can print with PC filament.

Although pricier compared to other open-end printers with the same build volume, this printer is well worth the cost.

The printer comes with the SuperPINDA, a brand new temperature-independent sensor. This probe makes the first layer calibration and bed leveling easier and more consistent. This feature really comes in handy when using materials like Polycarbonate for your 3D prints.

The complexity of a print is definitely not a concern with this printer. Printing any of your most intricate ideas is a breeze as the Prusa i3 Mk3S+ can tackle just about anything! Its various features, from heated bedding to automatic mesh bed leveling, make it more than capable.

The Prusa i3 Mk3S+ has more features than just its heated bed. It boasts new print profiles on its Slic3r Software, a power loss recovery feature, and a filament sensor, among others. The impressive frame stability allows for a fast but quiet printing process.

Another plus, the printer is extremely easy to set up and use. Its professional and neat appearance is perfect for any setting, whether it be in your house or the office.

The printer offers an impressive range of printing temperatures, with a maximum extruder temperature of 300°C and a maximum bed temperature of 120°C. You will never have to worry if the printer can handle PC filament. Consistently producing prints of above-average quality, there is a slim chance of the Prusa i3 Mk3S+ ever letting you down.

- Removable printing sheets

- Impressive range of printing temperature

- Compatible to printing many filaments

- Easy setting manipulation

- Can pause printing if needed

- Not enclosed (you will need to buy an enclosure)

- Build volume is not the biggest

Check Official Website

Check Latest Price

Check For Kit Price

2. Qidi Tech X-Plus (Best Choice)

Qidi Tech X-Plus (Best Choice) 3D Printer Type: FDM | Materials: PLA, ABS, PETG, TPU, Nylon, Carbon Fiber & Polycarbonate | Build Volume: 270 x 200 x 200 mm

The Qidi Tech X-Plus holds an outstanding reputation among its customers. The company strives to make high-quality printers available to everyone. Its ratings make it clear that the printer boasts many impressive capabilities on top of an amazing performance.

Qidi Tech X-Plus has a bunch of useful features that allow users to print high-quality prints with little effort. Unlike other 3D printers, the bed leveling system is extremely easy to operate. With a flexible magnetic build place, the two create a system that provides great performance without requiring a lot of work.

Not only is the printer consistent with its great print quality, but the Qidi Tech X-Plus also meets all the requirements needed to print Polycarbonate. One of the two extruders on the printer can reach a high temperature of 300°C, more than enough for printing PC filament. In fact, this extruder was included specifically to print high-performance filaments like Nylon, Carbon Fiber, and polycarbonate.

In fact, this extruder was included specifically to print high-performance filaments like Nylon, Carbon Fiber, and polycarbonate.

In addition to the printer being really simple to set up, the slicer software is also easy to get the hang of. It is possible to operate the software without knowing much about it!!

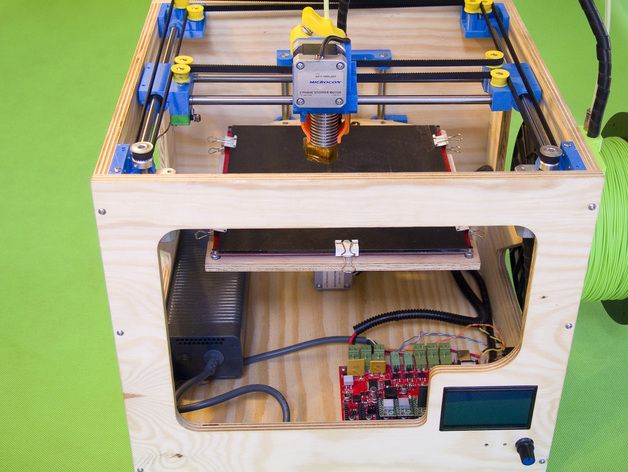

Unlike the previous printer, the Qidi Tech X-Plus is enclosed so you won’t have to purchase or create an enclosure! The printer holds a large build volume and print size, so don’t worry about having to compromise to smaller prints.

We won’t go into all of the printer’s features (there are a lot), but it’s worth mentioning some. Along with the printer’s large enclosure installation space, the Tech X-Plus offers a Wi-Fi connection and a computer monitoring interface, a quiet printing feature, air filtration, and automatic shutdown after printing. The printer is perfect for those who want to print with a variety of filaments without compromising on high-quality prints.

There are some things to watch out for with the printer. Reviews have mentioned damaged printer parts every now and then, but not to worry, as Qidi Tech holds an amazing track record for helpful customer service.

Overall, the printer is simple yet extremely robust– perfect for any PC prints you want to make. It’s a suitable 3D printer for anyone at any level. Along with the exceptional engineering, great touch screen UI, and amazing compatible slicer options, it even has really cool LED lights. While these don’t affect print quality, they make your machine extra sexy by giving off an ethereal glow.

- Extremely reliable and great quality

- Amazing customer service

- Very clear instructions when it comes to printer and software

- Sturdy and durable in the long run

- Easy to use but still a good machine for intermediate and expert users

- Affordable

- Confusing operation and display at first (but doesn’t take too long to figure out!)

- It’s known that parts of the hot end and extruder can degrade somewhat quickly

Check Latest Price

3. Creality CR-10S (Best Value)

Creality CR-10S (Best Value) 3D Printer Type: FDM | Materials: PLA, TPU, ABS, Wood, Carbon Fiber, Copper | Build Volume: 300 x 300 x 400 mm

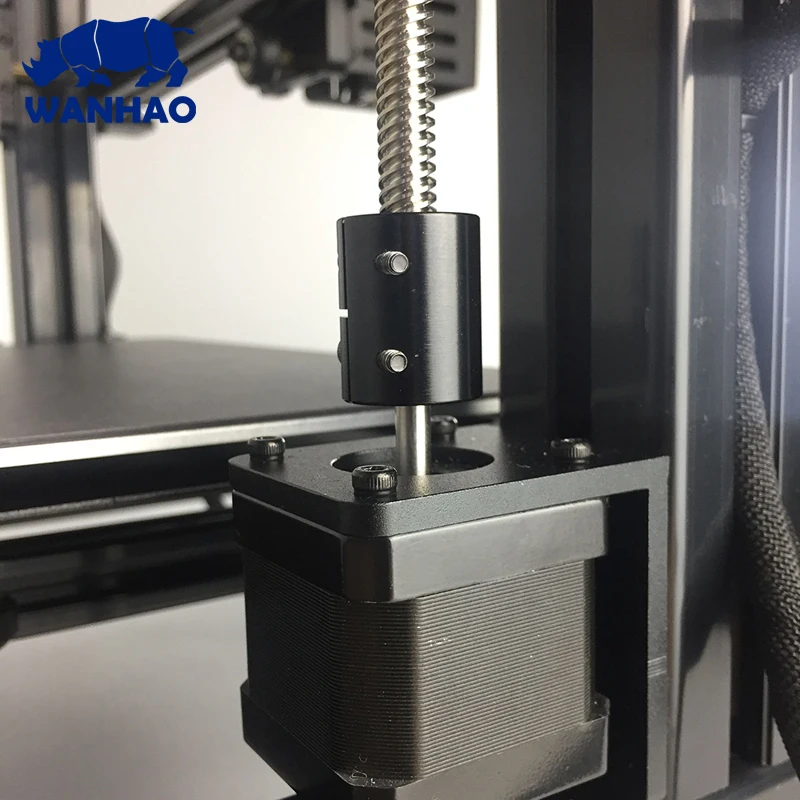

A step up from the CR-10, Creality’s CR-10S has notable upgrades and improvements from the previous version. The printer holds some of the best 3D printing features, including a filament run-out sensor and dual z-axis drive screws, and more.

The CR-10S also boasts a large build volume, so you will be able to print without a strict limit. However, the printer has an open build area. So, to print PC you will need to invest in an enclosure. It is definitely worth the investment as Creality CR-10S is able to handle PC filament while producing strong and heat-resistant prints.

While the build volume is one of the main highlights, the printer is also extremely fast to assemble. It’s easy to appreciate the CR-10S’ simplistic but effective design. On top of the previously mentioned features, the printer also provides automatic bed leveling and has a heated removable glass print bed.

The printer is extremely affordable, and you will definitely get the most out of it as it is a great value for the price. Easy operations, simple customization, and highly advanced features are all availed at a relatively low price.

However, given the low price, there are things to watch out for. The most obvious is the noise. The CR-10S is not a quiet printer– some customers even say it’s obnoxiously loud. But don’t worry! Using a stepper motor damper can easily fix this issue.

Another problem that is mentioned is that the printer has no thermal runaway protection enabled. Meaning if the heated bed or hot end has a failure to maintain heat, it could be a serious fire hazard.

Overall, the Creality CR-10s is a great option if you are looking for something less pricey. It can get detailed 3D prints immediately and allows you to print models with a wide range of printing materials. Regardless of some issues, the machine offers constant reliability, high quality, and an area big enough for large models.

- Huge build surface

- Reliable

- Fast printing speeds

- Cheap printer option without loss of quality

- Automatic bed stabilizer

- Sturdy frame

- Doesn’t come with an enclosure; you have to build or buy one if you want to print polycarbonate

- Noisy

- Setup instructions are not the clearest

- Filament detector is super loose; no bolts holding it in place, so it comes off really easily

Get Discount (Official Store)

Check Latest Price

4. Qidi Tech X-Max (Best for Large Prints)

Qidi Tech X-Max (Best for Large Prints) 3D Printer Type: FDM | Materials: PLA, ABS, PETG, TPU, Nylon, Carbon Fiber & Polycarbonate | Build Volume: 300 x 250 x 300 mm

We’ve got another Qidi 3D printer on our list– the Qidi Tech X-Max. This printer holds just as great of a reputation as the X-Plus and will not let you down.

The X-Max supports a wide variety and range of filaments, including PLA, ABS, and TPU to filaments like PC, Nylon, and Carbon Fiber. The printer comes with two different extruders depending on the type of filament being printed and its demands. For example, one extruder supports printing more advanced materials.

Additionally, the printing area is more than enough for any of your projects. It allows users to print large models while providing a more stable and high-performance 3D printing experience. In fact, the printer comes with dual Z-axis support which is suitable for large-size 3D printers to keep it stable and allow for professional quality printing.

The enclosed environment helps to maintain temperature for long periods of time. This makes it able to handle filaments that are normally considered difficult to print. But, it is recommended to invest in a filament dryer for hygroscopic 3D filaments like PC to make sure there is no moisture in the filament.

In addition to the dual z-axis, the printer holds several other features. From an air filter to a touch screen with an amazing UI all the way to the printer’s magnetic removable build platform, there’s a lot the X-Max has to offer.

Another plus is that the printer is not too noisy. You won’t have to worry about getting noise dampers and can place the printer wherever you like. As mentioned earlier, Qidi Tech also offers great customer service for any problems you may encounter.

However, the X-Max isn’t all sunshine and rainbows. There are some things to watch out for…

The Qidi Tech X-Max is a heavier machine in comparison to other printers. It also does not come with a filament runout detector sensor which could be a problem for some people. Additionally, don’t confuse the two extruders with dual extrusion on the printer– the printer can only hold one extruder.

Additionally, don’t confuse the two extruders with dual extrusion on the printer– the printer can only hold one extruder.

Overall, the Qidi Tech X-Max is an incredible machine and will not let you down. Not only is it easy to set up, but it is also easy to use and has an amazing user interface. It is great for polycarbonate and is capable of printing accurate and detailed 3D prints regardless of the material.

- Excellent User Interface

- Versatile with different printing materials

- Durable, stable, and reliable

- Two extruder options (swappable)

- Enclosed chamber

- Capable of maintaining high temperatures

- Low noise level

- Low noise level

- No filament detection sensor

- Not actually dual extrusion (just a swappable extruder)

- Pricier

Check Latest Price

5. Bibo 2 Touch (Best for Beginners)

Bibo 2 Touch (Best for Beginners) 3D Printer Type: FDM | Materials: PLA, ABS, HIPS, TPU, PETG, Nylon, Carbon Fiber & Polycarbonate | Build Volume: 214 x 186 x 160 mm

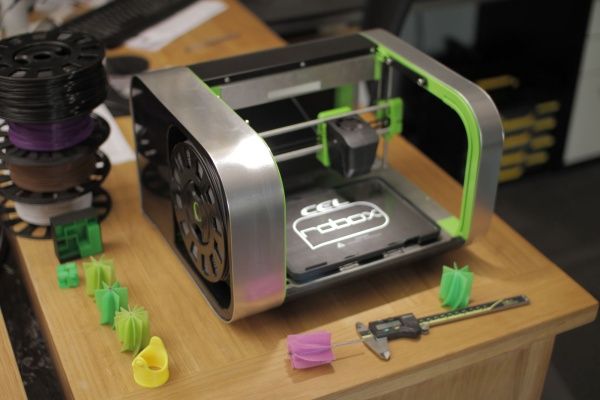

The Bibo 2 Touch has rightfully earned its place on this list and is a serious contender when choosing your 3D printer. The printer offers a lot and has been growing in popularity among 3D printing enthusiasts. Let’s look into the printer’s features!

Most obvious is the Bibo 2 Touch’s amazing design alongside its many features. It is clear how much effort was put into the printer just by looking at it.

You won’t have to worry about getting an enclosure as the printer has an enclosed print chamber. The enclosed print chamber provides stable print conditions for any material, including PC. It also helps by containing printing fumes and reducing overall print noise.

Additionally, the Bibo 2 touch has a dual extruder system meaning you can make a 3D print with multiple colors and materials without having to change the filament. The printer also has filament detection, so don’t worry about running out of filament. If that happens, the printer will pause and save all of your work and resume again once you reload the filament.

The printer also has filament detection, so don’t worry about running out of filament. If that happens, the printer will pause and save all of your work and resume again once you reload the filament.

Other features of the Bibo 2 Touch include its Wi-Fi Control. This allows you to 3D print remotely by letting you connect to a smartphone or laptop. You can also enjoy the printer’s open-source flexibility as the Bibo 2 Touch can be used with any software.

The metal frame offers extra stability for the printer and also will make it quieter than most machines.

Sadly, though, the maximum print volume on the Bibo 2 Touch is only 214 x 186 x 160 mm. While this is more than enough for regular-sized prints, you likely won’t be able to print some of the larger models in your Thingiverse collections.

Assembly also may be a little bit difficult given the extruder and filament holder, but overall very straightforward with the instructions. And, once you’ve set it up, it’s lightwork from there! Many customer reviews mention how easy the printer is to use, highlighting the beginner-friendly interface.

Overall, the abundance of features and benefits that come with the printer makes it an amazing option for anyone, especially beginners. It provides amazing print quality, and you also get to play around with the printer’s laser engraving system. There are not a lot of downsides to the printer, and definitely worth it!

- Great print quality

- Removable heated glass bed

- Dual extrusion

- Enclosed printing space

- Easy software to navigate

- Easy setup

- Nozzle max temp of 270 degrees celsius

- Lower bed temp

- Not as large of a build space

Check Latest Price

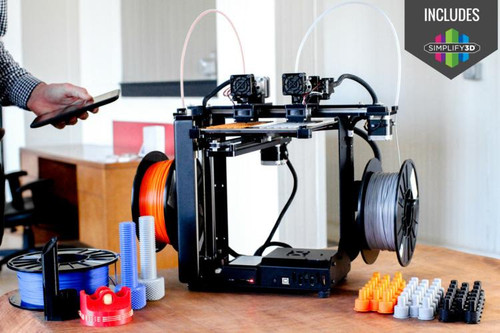

6. MatterHackers Pulse XE (Easy to Use)

MatterHackers Pulse XE (Easy to Use) 3D Printer Type: FDM | Materials: PLA, ABS, TPU, TPE, Flex, Ryno, PET, PETT, PETG, CPE, PVA/BVOH, HIPS, nGen, Polyamide / Nylon, PC (Polycarbonate), Polypropylene, Metal, Carbon-filled, Woodfill, Metalfill, and more | Build Volume: 250 x 220 x 210 mm

The MatterHackers Pulse XE is a top-of-the-line 3D printer. But, it’s not just for anyone. The printer is perfect for those who are making tough manufacturing parts or are working with exotic materials (like polycarbonate).

The Pulse XE is built with a thick, solid aluminum frame making it extremely sturdy. The frame makes sure that the printer doesn’t move around, keeping the printer stable and resulting in great quality prints. While heavier in comparison to other printers, the weight ensures Pulse XE can last for days without any error.

Even better, you won’t need to worry about upgrading almost anything as MatterHackers loaded the Pulse XE with top-of-the-line hardware. Moreover, the XE has a powerful extruder motor, high-temperature hot end, automatic bed leveling, power loss recovery, and even a filament runout sensor. All of these features come stock on the machine and will make the printing experience a breeze and your prints look spectacular, even when printing with PC.

Moreover, the XE has a powerful extruder motor, high-temperature hot end, automatic bed leveling, power loss recovery, and even a filament runout sensor. All of these features come stock on the machine and will make the printing experience a breeze and your prints look spectacular, even when printing with PC.

The Pulse XE also comes with its own slicing and print monitoring software, MatterControl. It may take some time to get used to the software, but once you spend time with the software, it’s clear how good it is. You can control a lot simply by connecting your laptop to your 3D printer, but it comes at the cost of potentially failing prints if anything happens (e.g. laptop crashes).

As great as a printer the Pulse XE is, there are things to consider before purchasing it. First, be careful where you put the printer as a lot of filaments are susceptible to water in the air. The printer is also not enclosed, so you will need to buy an enclosure.

Matterhackers does offer the Pulse XE bundle, and it comes with the PrintDry machine, which helps control the filament’s moisture content. This will further improve the quality of your prints because no moisture on the filament means no bubbling and better layer adhesion.

This will further improve the quality of your prints because no moisture on the filament means no bubbling and better layer adhesion.

Overall, the Pulse XE is an incredible printer, able to print just about anything. It’s a good printer for general use but is amazing for printing filaments beyond the norm. The Pulse XE makes sure those sorts of filaments are printed successfully.

This printer is recommended for anyone wanting to print beyond the limits of PLA and ABS filaments (perfect for PC printing!!).

- High-quality prints

- Can print a variety of filaments

- Matterhackers also sell a filament drying system perfect for PC storage

- Everything is preinstalled

- Not enclosed; you will need to purchase an enclosure

- Heated bed, but not up to the high temperatures necessary for PC

- Max nozzle temp at 295 degrees celsius

Check Latest Price

What is a Polycarbonate?

Source: Youtube Thomas SanladererPolycarbonate is a thermoplastic material originally derived from processed propane and other materials. Plastic is commonly used for medical devices, eyewear, and so much more. It’s also pretty popular for 3D printing!

Plastic is commonly used for medical devices, eyewear, and so much more. It’s also pretty popular for 3D printing!

In fact, polycarbonate filament is considered the single strongest filament material, achieving tensile strengths greater than ABS, PETG, and even Nylon. When tested, a clip 3D printed in polycarbonate was able to hold an incredible 685 pounds without breaking, while PLA and ABS both failed before 300 pounds. So next time you’re printing a gear or another model that will face physical stresses, definitely give PC filament a consideration.

But strength isn’t the only unique property of polycarbonate!

For instance, PC is a hygroscopic material. This means the plastic absorbs moisture from the air pretty rapidly. So, if you leave a spool of PC filament in a humid environment, it will soak it all in, leading to bubbling in the hot end and brittle prints. As such, it’s recommended to always store PC filament in a drybox or sealed container of some kind.

Similar to PLA, PC is also decently sensitive to UV light so it should only be used for indoor projects.

Polycarbonate filament comes in a multitude of colors but is usually transparent as this is the natural color of the plastic. This makes PC a unique choice as it is one of a few filaments that you can use for printing transparent items like lamp shades.

Sadly, though, printing polycarbonate is no easy feat.

We’ll talk more about how you can print PC in a later section, but it requires much more intensive hardware requirements than almost any other traditional filament material. And, even with the necessary hardware, you’ll have to fine-tune a slicer profile in order to achieve high-quality prints.

When To Use Polycarbonate?

Source: Youtube Thomas SanladererPolycarbonate is perfect when you are in need of a strong or transparent material. That’s why PC is so popular for industrial applications that require a lot of strength, such as machinery guards, eyeglasses, and even bulletproof glass.

Similarly, in a 3D printing setting, you should use PC filament whenever you want a model to be super strong and durable. For example, if you’re printing a computer monitor stand, door hinge, or a gear for a robot, you’ll want all the strength you can get, and PC provides just that!

For example, if you’re printing a computer monitor stand, door hinge, or a gear for a robot, you’ll want all the strength you can get, and PC provides just that!

Sadly, though, you shouldn’t use PC for outdoor prints as the plastic won’t respond well to the UV light from the sun. So if you need a strong outdoor print, consider using PETG filament.

Also, you shouldn’t use polycarbonate filament when you want to print a display model, like a miniature or cosplay set. While you may want these models to be strong, PC isn’t the best at providing detail in 3D prints, so you should consider materials like PLA or ABS instead.

Advantages and Disadvantages of Polycarbonate 3D Printing

Source: Youtube Thomas SanladererAdvantagesAs mentioned above, there are numerous advantages when it comes to printing with PC. In addition to the material’s strength, heat resistance, and natural transparency, PC is also more durable, flexible, and less dense than other filaments.

Transparency comes with its own advantages! The transparent nature of PC is helpful in printing and also serves as an aesthetic option.

DisadvantagesHowever, there are some things to look out for and consider such as printing machinery, print settings, and the surrounding environment before using PC.

When printing with PC, there are several extensive hardware requirements. PC requires the use of a hot nozzle, heated bed, and an enclosed printing space. These requirements are necessary as PC is very sensitive to its surroundings and will not print properly unless all parts are correctly set.

Printing issues such as warping of the finished product and over-extrusion can arise if printing and storage requirements are not met. As mentioned earlier, PC is hygroscopic and will react negatively (usually swelling) when introduced to water directly or if there’s any water in the air. It is critical to keep your PC filaments and projects in dry areas.

PC’s last disadvantage is its price. While it is a little steeper than other filaments, it is worth it in the long run for certain projects due to the strength and heat resistance PC has. Prices vary between brands and based on quality but they usually sit between $30 and $60 for a spool around 750 grams.

While it is a little steeper than other filaments, it is worth it in the long run for certain projects due to the strength and heat resistance PC has. Prices vary between brands and based on quality but they usually sit between $30 and $60 for a spool around 750 grams.

How to 3D Print Polycarbonate?

Source: Youtube Datulab TechPrinting with PC can be difficult if you don’t have the proper setup or settings met. However, once you have perfected the necessary requirements, the payoff is worth it.

Your first step when printing with PC is to make sure the material is dry. The hygroscopic PC will warp if it was exposed to too much water before printing, so before you even touch your printer settings, make sure your filament was stored properly in a dry environment.

Next, you need to look at the temperature of your nozzle. PC is extremely heat resistant, which is great for the final project but makes the printing process a little difficult. You want your nozzle temperature to sit between 300-310 °C to make sure the PC will flow properly, but of course, play around with your own setup to see what works best for you.

After setting your nozzle temperature, it is time to adjust the bed temperature. Considering that the PC is already coming out extremely hot, it’s important that you make sure that the filament does not stick to the bed!! To do so, the ideal bed temperature ranges from 145-150 °C, but a consistent heat of 135°C is also acceptable if it is the most your printer can do.

It is also important to have an enclosed printer to ensure that the ambient temperature around your printed model is high enough to ensure good layer-to-layer adhesion during the printing process.

There are some extra things to take care of before you start printing. Make sure to disable any cooling fans during the printing process as it can cause the filament to warp and have other negative responses. Also, just like other filaments, the first layer is the most important!! If your print settings are not met perfectly, the rest of your print can suffer. But PC is easily recyclable so don’t worry if your first layer isn’t ideal.

Factors to Consider When Choosing a 3D Printer for Polycarbonate:

If you’re still here, you’re probably interested in purchasing your own 3D printer. But don’t just buy any 3D printer because most aren’t equipped with the hardware necessary to print polycarbonate filament. In the mini-sections below, we’ve gone over the main features to look for on a 3D printer for printing PC, such as bed temperature, enclosure presence, and more!

Material Compatibility

The first and most important factor to look at in a 3D printer is its material compatibility. Usually, the manufacturer will list which filaments do and don’t work on the machine but don’t always trust this information. Instead, look in the reviews and on Reddit (or other forums) to see which filaments actual users were able to print on the machine.

Also, make sure to check the maximum nozzle temperature, as this is a big regulator for material compatibility. If the nozzle can’t reach and stay at the necessary temperatures for printing PC, then the printer can not actually print polycarbonate. Remember: you want a maximum nozzle temperature of between 260-310 °C if you want to print PC.

Remember: you want a maximum nozzle temperature of between 260-310 °C if you want to print PC.

Bed Temperature

It’s crucial to check the printer’s maximum bed temperature and to have a properly heated bed. PC will stick to a bed that’s not properly heated, which can cause damage to your print and can even make it impossible to remove the print from the bed. The max bed temperature in most printers sits at 135°C. However, the optimal temperature for printing PC sits between 145°C and 150°C. Looking for or modifying a printer that can reach those bed temperatures can make or break a project.

Enclosure

As we mentioned, an enclosure is also necessary for printing PC filament, as it keeps heat around your model and prevents air draft. Without one, your PC prints will be super brittle, contain low-quality detail, and have other issues.

As such, you should look for a 3D printer that has a built-in enclosure. However, you can also get a printer without one and then build or buy an enclosure for the printer afterward. This is what I like to do as it usually ends up being cheaper (especially if you DIY it), and gives you some customization abilities. Check out our article on the best enclosures here.

This is what I like to do as it usually ends up being cheaper (especially if you DIY it), and gives you some customization abilities. Check out our article on the best enclosures here.

Build Plate

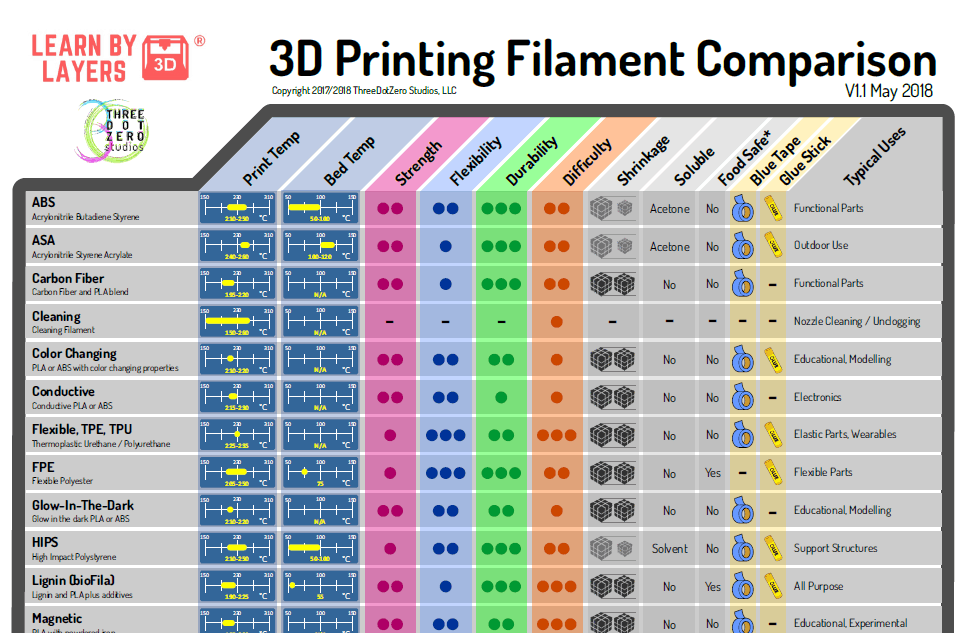

The bed’s material is just as important as its temperature. A Polyetherimide (PEI) sheet is the best printing bed option for PC. Painters tape or glue sticks will adhere permanently to the prints due to its high printing temperatures, so they are not viable options, but PEI is extremely heat resistant and has high-temperature stability– great for PC printing!!

Build Volume

Lastly, don’t forget about the build volume. You wouldn’t want to get a printer that’s perfect at everything but can only print super tiny models.

While there’s no single volume that’s good for everyone, it’s smart to think about the sizes of the models you’ll be printing and establish a minimum volume that you’re looking for. For example, when I look for a 3D printer, I don’t choose one unless it’s got at least 200 x 200 x 200 mm of print space.

Conclusion

Are you ready to start printing with PC now? While printing with polycarbonate may be intimidating due to the filament’s requirement for a perfect climate, don’t worry! This is an opportunity to use this incredible material.

PC is extremely strong, durable, heat resistant, and unique to use. The main takeaway about printing with polycarbonate is the printing environment. Make sure to store your PC in a dry environment, or it will swell and can ruin your print. Also, make sure your printer has the proper nozzle and bed temperature and is a properly enclosed space to create the best environment for the PC.

Our recommendations from this selection of printers would vary based on what you want. If you’re looking for an enclosure for quality, the Prusa i3 MK3S+ is the best option for you. The CR-10S is perfect if you want an enclosure for build space and the Pulse XE is the go-to for any other feature you want, like automatic bed leveling.

The feats of 3D printing are never-ending and, while a more difficult process, printing with polycarbonate only further proves that anything can be possible.

Ultimate Materials Guide - 3D Printing with Polycarbonate

Overview

Polycarbonate (PC) is a high strength material intended for tough environments and engineering applications. It has extremely high heat deflection, and impact resistance. Polycarbonate also has a high glass transition temperature of 150° Celsius. This means it will maintain its structural integrity up to that temperature, making it suitable for use in high-temperature applications. It can also be bent without breaking and is often used in applications where some minor flexibility is required. Most available Polycarbonate filaments contain additives that allow the filament to be printed at lower temperatures, so make sure to consult the guidelines for your specific brand of plastic.

Polycarbonate is extremely hygroscopic, meaning it will absorb moisture from the air, which will affect its printing performance and strength. It should be stored in air-tight, moisture-free containers after opening. It also requires very high temperatures for printing and will exhibit layer separation if printed at too low of a temperature or with excessive cooling enabled. Polycarbonate is frequently best printed on a machine that has an enclosed build volume and is capable of handling high bed and extruder temperatures.

It also requires very high temperatures for printing and will exhibit layer separation if printed at too low of a temperature or with excessive cooling enabled. Polycarbonate is frequently best printed on a machine that has an enclosed build volume and is capable of handling high bed and extruder temperatures.

- Impact resistant

- High heat resistance

- Naturally transparent

- Bendable without breaking

- Requires very high print temperatures

- Prone to warping

- High tendency to ooze while printing

- Absorbs moisture from the air which can cause print defects

Hardware Requirements

Before 3D printing with Polycarbonate make sure your 3D printer meets the hardware requirements listed below to ensure the best print quality.

Bed

Temperature: 80-120 °C

Heated Bed Required

Enclosure Required

Build Surface

PEI

Commercial Adhesive

Glue Stick

Extruder

Temperature: 260-310 °C

All-metal hotend required

Cooling

Part Cooling Fan Not Required

Best Practices

These tips will help you reduce the chances of common 3D printing issues associated with Polycarbonate such as warping, stringing, and oozing.

Use a Proper Build Surface

PEI is the best build surface for Polycarbonate. Standard build surfaces like blue tape and glue stick have adhesives that break down at the high temperatures required to print Polycarbonate. Build-tak can also be used but tends to permanently adhere to Polycarbonate at temperatures higher than 80°C, and can sometimes warp aggressively enough at this temperature to pull the Build-tak off the plate. PEI sheets consistently hold on to Polycarbonate at 110°C, without permanently adhering to the part. Once the bed cools down, the part usually self-releases, or can be easily removed with a spatula.

Adjust Settings to Prevent Stringing and Oozing

Due to the extreme printing temperatures and low cooling fan speeds required to print Polycarbonate, there is a high possibility of stringing and oozing with this material. To prevent this, try increasing the retraction distance and retraction speed. Simplify3D also includes a useful option called Coasting, which will automatically reduce the pressure in the nozzle right before the end of a segment to avoid oozing when moving to the next segment. This option can be enabled on the Extruders tab of your process settings. If your 3D printer can handle it, you can also try increasing the XY travel speed on the Speeds tab of your Simplify3D process settings. This allows the printer to make faster movements, which means less time for oozing. For other tips on how to prevent stringing and oozing, please refer to our Print Quality Guide which has an entire section dedicated to this issue.

This option can be enabled on the Extruders tab of your process settings. If your 3D printer can handle it, you can also try increasing the XY travel speed on the Speeds tab of your Simplify3D process settings. This allows the printer to make faster movements, which means less time for oozing. For other tips on how to prevent stringing and oozing, please refer to our Print Quality Guide which has an entire section dedicated to this issue.

Customize First Layer Settings

Due to the high warping tendency of Polycarbonate, the first layer is extremely important when printing with this material. From our research, the material seems to stick the best with slow thick extrusions on the first layer. We recommend using a first layer height of 100-150%, a first layer width of 12-150%, and a first layer speed of 15-30%. All of these settings can be entered on the Layer tab of your Simplify3D process settings. Additionally, setting the first layer to print about 30° hotter than the rest of the part can greatly improve first layer adhesion.

Smooth Top Layers

High print temperatures mean that extruded filament will tend to droop if it is unsupported. Solid Infill Layers should be printed slowly, at around 50% speed, so that they have the best chance of successfully bridging the spaces between infill lines. At least 4 top layers should be used, which will ensure that top layers are as smooth as possible. Infill percentage should generally be kept higher than 25% density to ensure support for these top layers. If a part needs less infill, in order to be lighter or use less material, extra top layers can be added to increase the likelihood of a solid top-most layer.

Calibrate your Bridging Settings

Similar to the point above, bridging segments can also be affected by the high printing temperatures of Polycarbonate. As the plastic is extruded in thin air between either side of the bridge, it will have a tendency to droop while it cools. Simplify3D added many new bridging features in Version 4. 0, so these can be used to customize exactly how the bridges are printed for the best results. We found that using a bridging speed multiplier of 40%, a bridging extrusion multiplier of 120%, and setting the bridging fan speed to come on at 25% offered a good starting point for most materials. You want to make sure the bridging fan speed stays at a low value, otherwise it has a tendency to cause warping and separation due to the rapid temperature change.

0, so these can be used to customize exactly how the bridges are printed for the best results. We found that using a bridging speed multiplier of 40%, a bridging extrusion multiplier of 120%, and setting the bridging fan speed to come on at 25% offered a good starting point for most materials. You want to make sure the bridging fan speed stays at a low value, otherwise it has a tendency to cause warping and separation due to the rapid temperature change.

Pro-Tips

- If parts are overheating, curling, or showing signs of drooping when printing sharp overhangs, consider setting the fan to 0% for the first layer (to ensure good bed adhesion), but then increase the fan speed to 40% or below after about 4 or 5 layers.

- If some moisture has been absorbed by the material, try lowering the printing temperature to 280°C or below, which can help prevent artifacts or bubbles in the print from the moisture content.

Get Started with Polycarbonate

Now that you know the basics, you are ready to tackle your first print with Polycarbonate. Below are a few suggestions to help you get started.

Below are a few suggestions to help you get started.

Common Applications

- High-strength parts

- Heat resistant prints

- Electronics cases

Sample Projects

- Carabiner

- Platform Jack

- Coffee Sleeve

Popular Brands

- Polymaker PC Plus, PC Max

- Matterhackers Flameproof PC

- eSun ePC

Polycarbonate for 3D printing

Description

Polycarbonate is a thermoplastic in honeycomb form widely used as a durable substitute for conventional glass. In addition, polycarbonate has found use as a material for the manufacture of CDs, contact lenses, protective equipment (for example, bicycle helmets or glasses). The combination of transparency of polycarbonate and high strength (about 250 times higher than ordinary glass) makes it possible to produce even bulletproof glass.

Another advantage of polycarbonate is its high resistance to high and low temperatures - from -40 to 120°C. In addition, polycarbonate is prone to attenuation when exposed to open flame, contributing to fire safety, and resistant to acids.

In addition, polycarbonate is prone to attenuation when exposed to open flame, contributing to fire safety, and resistant to acids.

Among the disadvantages of polycarbonate, one can single out a rather high hygroscopicity. Thread spools are recommended to be stored in dry places, and preferably vacuum-packed. In addition, polycarbonate is somewhat vulnerable to ultraviolet light, which leads to loss of strength over time, and is vulnerable to attack by petroleum products and organic solvents.

3D printing application

Polycarbonate printing example

Polycarbonate is rare in FDM printing due to certain technological difficulties, but is rapidly gaining popularity as technology improves.

Polycarbonate requires a fairly high extrusion temperature in excess of 300°C when printing at high speed.

Due to its high hygroscopicity, it may be necessary to dry the consumable immediately before printing.

To do this, it is recommended to keep the thread for 8-10 hours at a temperature of 70°C.

Otherwise, water vapor may be released during extrusion, clouding of the material and increased shrinkage, which increases the risk of deformation.

Even dry polycarbonate will require the use of a heated worktable up to 90°C-120°C.

It is recommended to use a polyimide film (Kapton) for better adhesion of the first layer to the worktable surface.

Printing examples with dry and slightly damp polycarbonate

Finding the right balance of extrusion temperature and print speed will be required to maintain transparency and avoid nozzle clogging and cracking.

Printing at 30mm/s will require heat up to approximately 265˚C, 285˚C at 60mm/s, 300˚C at 80mm/s and over 305˚C at 120mm/s. The glass transition temperature of polycarbonate is about 150˚C.

Polycarbonate threads are available in standard diameters of 1. 75mm and 3mm.

75mm and 3mm.

Polycarbonate Safety

Polycarbonate itself is safe, but the material typically uses BPA as the main raw material. Bisphenol A, in turn, is very toxic even in small volumes, up to the excitation of oncological diseases. Unfortunately, polycarbonates often contain residual Bisphenol A (albeit in extremely small amounts), which is released when heated. Accordingly, the use of polycarbonate products for storing hot food or drinks is not recommended. Limited bans on the use of polycarbonate in food packaging have already been introduced in Canada and the EU, and are being considered in the US. We recommend that you print in a well-ventilated area.

Go to the main page of the Encyclopedia of 3D Printing

The Ultimate Guide to Polycarbonate 3D Printing

Contents

- 1 What is polycarbonate?

- 2 How strong is polycarbonate as a 3D printing material

- 3 What is the use of polycarbonate?

- 4 How can I print with a polycarbonate 3D printer?

- 4.

1 1. Select a quality polycarbonate thread.

1 1. Select a quality polycarbonate thread. - 4.2 2. Select a suitable polycarbonate 3D printer.

- 4.3 3. Enclosed chamber for 3D printing.

- 4.4 4. Effective adhesion to the frame

- 4.

- 5 What are the limitations of polycarbonate 3D printing?

- 6 Can the Ender 3 print on polycarbonate?

- 7 Should I get polycarbonate 3D printing service in China?

- 8 Conclusion

What is polycarbonate?

polycarbonate is a thermoplastic compound known for its high strength and impact resistance. It is commonly used for demanding engineering applications as it can withstand any external force without breaking or corroding.

This thermoplastic material is also capable of withstanding high temperatures. At glass transition temperatures of up to 150°C, the material will still manage to maintain its physical and structural integrity.

In addition to heat-resistant polycarbonate, it is a fire-resistant material. Also, the fact that this material is an electrical insulator cannot be ignored.

Also, the fact that this material is an electrical insulator cannot be ignored.

Even with all these desirable characteristics, polycarbonate still bears minimal weight. It is lighter than most alternative materials that can be 3D printed.

How strong is polycarbonate as a material for 3D printing

As we mentioned, one of the key properties of polycarbonate is its strength. In fact, polycarbonate is commonly referred to as the "king" of 3D printing.

This is because it is the strongest material that can be 3D printed.

But how durable is this material compared to others? The strength of polycarbonate can be better understood by looking at the numbers.

In a test conducted by airwolf3d.com, various 3D materials were evaluated for their hardness. The main materials that have been tested include PLA, ABS, nylon and polycarbonate.

Each material was loaded with some weight that was attached to a hook.

Guess which material won? Polycarbonate won by a wide margin.

With a breaking strength of 7250 psi, the PLA material was able to lift the weight up to 285 pounds. ABS, which has a tensile strength of 4700, snaps into place when attached to the same weight.

Polycarbonate with a tensile strength of 9800 psi was able to lift the weight to 680 pounds without a click. No other material can lift such a weight.

I hope you now understand why polycarbonate is the "king" of 3D printing.

What is the use of polycarbonate?

Strength, heat resistance and durability make polycarbonate an ideal material for a wide range of applications. Some of the uses for polycarbonate include:

- Automotive industry for the manufacture of car parts.

- In the construction of buildings and transport infrastructure

- For the construction of electrical and telecommunications equipment / appliances

- For the creation of digital storage devices such as Blu-Ray discs, DVDs like bottles, food containers, crates, etc.

How can I 3D print polycarbonate?

How hard can polycarbonate be 3D printed? There is no doubt that polycarbonate can give you a headache when it comes to printing it on other related products.

However, with the right people and the best 3D printer, this process can be easily completed without any problems. Of course, the correct procedure must be followed when printing on polycarbonate media.

1. Choose Quality Polycarbonate Filament

Like other 3D printing media, it all starts with choosing the right material. This is because low quality filament can result in poor print quality.

Beware of cheap polycarbonate threads. While they may seem flawless, they can cause serious problems when printed with a 3D printer.

Some polycarbonate manufacturers tend to produce filaments with fillers and additives. Such additions will affect the 3D printing process and even degrade the quality of the final product.

Such additions will affect the 3D printing process and even degrade the quality of the final product.

Inferior polycarbonate has air pockets that can cause the 3D printer to jam or clog.

Don't be tempted by low prices. Instead, take your time to carefully examine the 3D printing material.

Variable diameter polycarbonate filaments can end up with drops, extrusions and other imperfections in the final print.

So how do I find good quality 3D polycarbonate filament?

The surest option is to buy polycarbonate from a trusted manufacturer. Thus, you can be sure of the quality of the resulting 3D materials.

You should also take the time to check with the manufacturer about the filament before buying it. Ask them if their polycarbonate contains any additives or other chemicals.

If the situation permits, take several thread samples to evaluate their quality.

After all, your ultimate goal of 3D printing on polycarbonate is to preserve the structural integrity and beauty of the material.

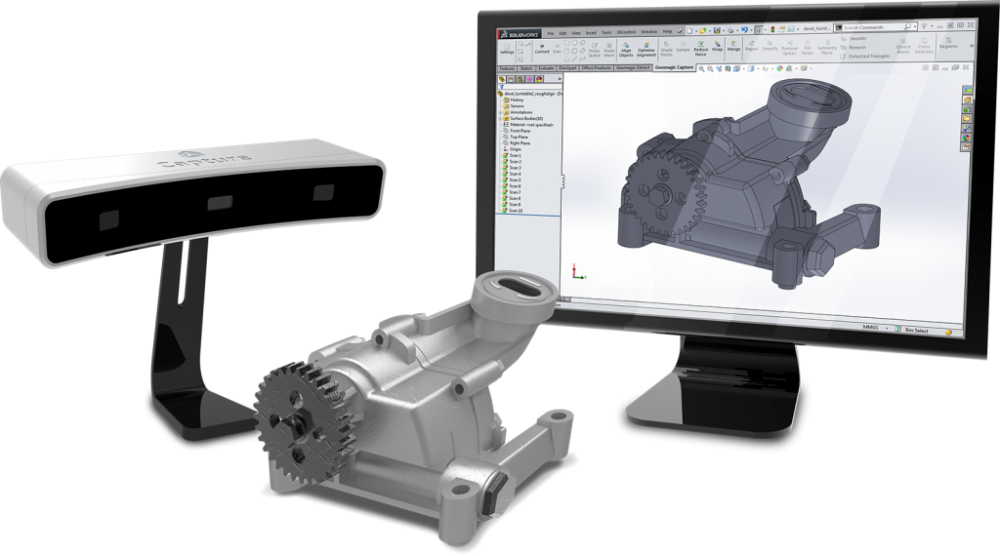

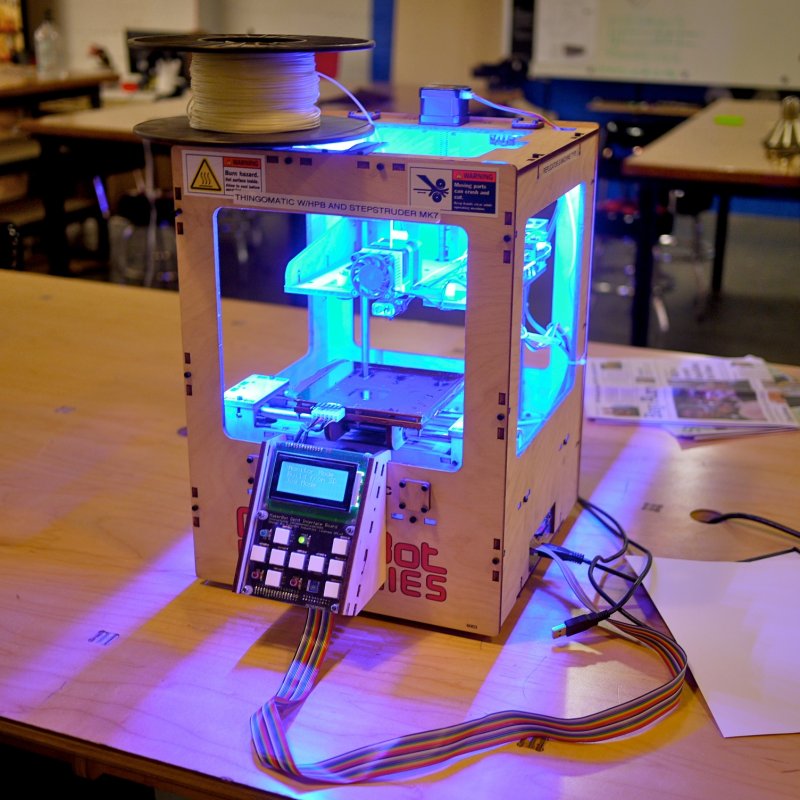

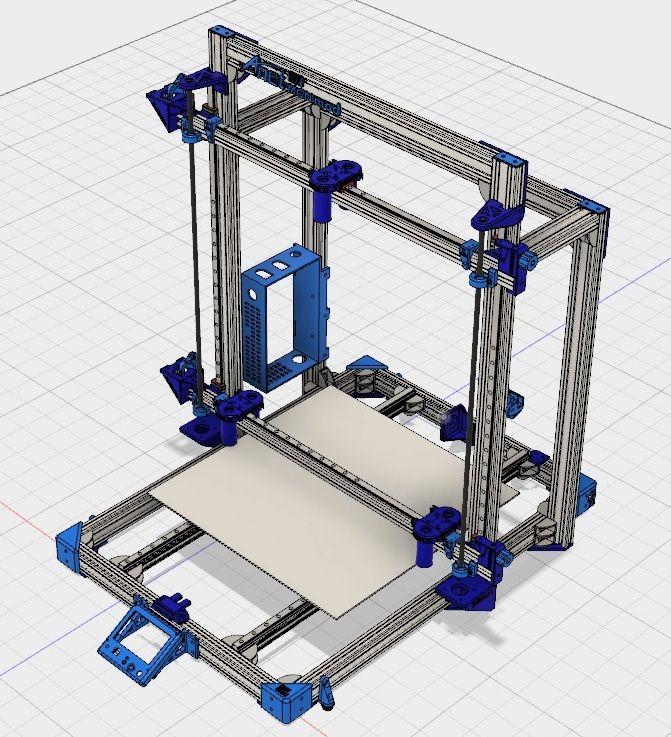

2. Choose the right polycarbonate 3D printer

Once you have selected a quality polycarbonate 3D printing filament, the next step is to find the right 3D printer.

Given the physical, chemical and structural properties of polycarbonate, you can't just use any 3D printer to do the job. The printer must have certain attributes that make it suitable for polycarbonate 3D printing.

For example, the printer must be able to withstand very high temperatures. It should also have a closed chamber in which the polycarbonate material will be heated.

For years, having the right printer has always been a major barrier to 3D printing. This is because most 3D printers cannot withstand the extremely high temperatures required to print polycarbonate filaments.

The highest temperature threshold for successful printing on polycarbonate is between 290°C and 320°C.

This automatically means that the few printers that can be used to print on this material are expensive. In fact, you will rarely find one that costs less than $50,000.

In fact, you will rarely find one that costs less than $50,000.

The good news is that you don't have to bear all these costs. You can easily outsource this service to a 3D polycarbonate production company and they will do all the work for you.

For example, Roche Industry has a suitable 3D printer. You must provide the thread and we will print for you.

3. Closed chamber for 3D printing

Again, having the right printer for the process is not enough. 3D printing on polycarbonate must be done in a closed chamber.

The purpose of the chamber is to ensure proper temperature control so that the final product is free from defects.

Temperature control prevents defects such as cracks and deformations of the product.

4. Effective adhesion to the bed

In addition to proper heat management, polycarbonate 3D printing also requires proper adhesion to the substrate. This is the hardest part when it comes to printing on high quality materials like polycarbonate.

This is the hardest part when it comes to printing on high quality materials like polycarbonate.

The fact that polycarbonate tends to warp when processed leaves you no choice but to pay attention to the adhesive properties of the bed.

At Roche Industry, we ensure that these four essential aspects of polycarbonate 3D printing are given the close attention they deserve.

What are the limitations of polycarbonate 3D printing?

While 3D printing is the best way to make polycarbonate items, it also has some limitations.

Here are some of the disadvantages of this method:

- Printing on polycarbonate material requires extremely high temperatures compared to other materials.

- Polycarbonate is prone to warping. This means that all conditions for printing must be ideal, otherwise deformation will be inevitable.

- High chance of leaking liquid polycarbonate during printing.

- Polycarbonate - hygroscopic material. It will probably absorb some moisture during the printing process. This can lead to 3D printing defects.

It will probably absorb some moisture during the printing process. This can lead to 3D printing defects.

How can I remove these restrictions?

The best solution is to seek the services of the best polycarbonate 3D printing company in China. They have the right tools and conditions to achieve the best results.

Reliable 3D polycarbonate companies also have specialists who can handle the entire process with the utmost precision.

Can the Ender 3 print on polycarbonate?

People who can't afford polycarbonate 3D printers usually prefer to use the Ender 3, which is a device commonly used for 3D printing.

While it can still be used for 3D printing, you need to take extra strict measures to get the best results from it.

For polycarbonate, this may be more difficult due to the nature of the material. For example, reaching very high temperatures with the Ender is no walk in the park.

Due to some deficiencies, the final product may have many defects. So it's safe to say that you shouldn't rely entirely on the Ender 3 for polycarbonate 3D printing.

Should I get polycarbonate 3D printing service in China?

If you want to make parts and products from polycarbonate material. This leaves you no choice but to print this material in 3D.

Should I pay for a polycarbonate 3D printing service or do the work myself?

As we have seen, printing on polycarbonate material is a complex technical process. This is also very expensive.

This is also a risky business, as you may end up doing the process incorrectly, resulting in wasted material.

It is best to outsource this service to reliable polycarbonate printing companies in China.

You will save a good amount of money, especially if you get an affordable polycarbonate 3D printing service.

Conclusion

As we have seen, anything can be obtained from polycarbonate. All you need is an elaborate polycarbonate 3D printing service.

All you need is an elaborate polycarbonate 3D printing service.

If you need this service, we are here to help. Roche Industry is specialized in providing polycarbonate precision 3D printing services in China. Contact for a free offer.

Links to related sources:

Handbook: Everything you need to know about PETG

PETG vs ABS: What's the difference?

PETG vs PLA: What's the difference?

Polycarbonate vs Acrylic: What's the difference?

Nylon vs Polyester: What's the difference?

Trivex vs Polycarbonate: What's the difference?

White Paper: The Complete Guide to Thermoforming

All You Need to Know About PVC Pipe Sizes

Roshindustri specializes in high quality Rapid prototyping, fast small batch production and high volume production. The rapid prototyping services we provide are professional engineering, CNC machining including CNC milling and turning, Sheet metal fabrication or sheet metal prototyping, Die casting, Metal stamping, Vacuum casting, 3D printing, SLA, Plastic extrusion prototyping and aluminum, rapid tooling, rapid injection molding, surface treatment finish services and other China rapid prototyping services, please contact us right now.