Peopoly 3d printer

Phenom Forge by Peopoly

Roll over image to zoom in Click on image to zoom

Save $550.00

Peopoly

Country: US

US

CA

EU

UK

Other

Product: Forge

Kit: None

None

Panel and 2x FEP

Curing Box Pro

2x Deft White

2x Deft Grey

2x Nylon-Like

Variant

US / Forge / None - $1,349. 00US / Forge / Panel and 2x FEP - $1,523.00US / Forge / Curing Box Pro - $1,557.00US / Forge / 2x Deft White - $1,394.00US / Forge / 2x Deft Grey - $1,394.00US / Forge / 2x Nylon-Like - $1,412.00CA / Forge / None - $1,349.00EU / Forge / None - $1,529.00EU / Forge / Curing Box Pro - $1,737.00UK / Forge / None - $1,709.00UK / Forge / Curing Box Pro - $1,889.00Other / Forge / None - $1,529.00Other / Forge / Panel and 2x FEP - $1,703.00Other / Forge / Curing Box Pro - $1,737.00Other / Forge / 2x Deft White - $1,574.00Other / Forge / 2x Deft Grey - $1,574.00Other / Forge / 2x Nylon-Like - $1,592.00

Share this product

An Introduction Video for Forge

Order now for immediate shipping.

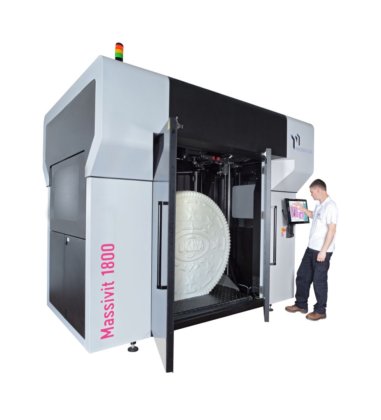

Introducing Forge, a production-grade large-format MSLA printer built for workshops and factories. It is the only large MSLA printer with heated Vat, the highest contrast monochrome screen, and the most accurate parallel light source. It is powered by the all-new Vlare Core controller with features that will make printing easier, faster, and more accurate.

It is powered by the all-new Vlare Core controller with features that will make printing easier, faster, and more accurate.

Key Features

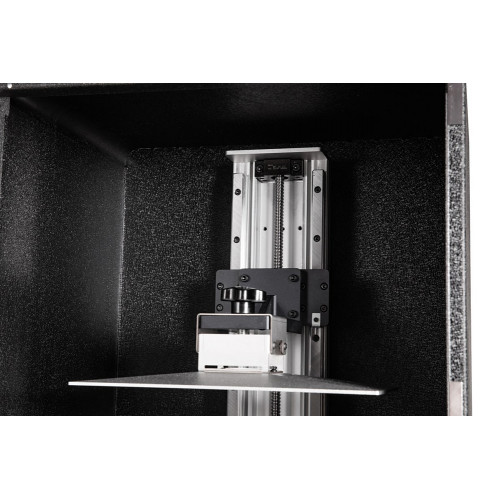

- Build Volume 288 x 163 x 350mm

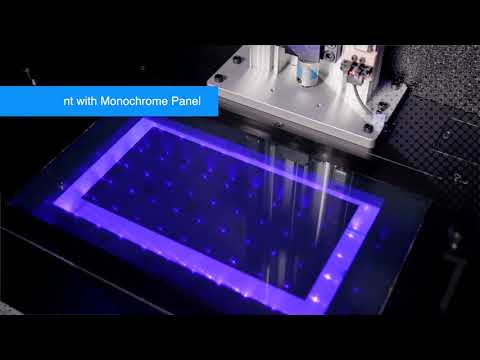

- High Contrast (500nit) 6K Monochrome Panel for even better resolution and excellent life span.

- Vlare Core controller board with Open File Format support and onboard EMMC storage

- Build-In masking function for more even light distribution

- Slicer options: Lychee Slicer, Tango Voxeldance, and Vlare Slicer

- WiFi and Infrared Camera for remote monitoring and management

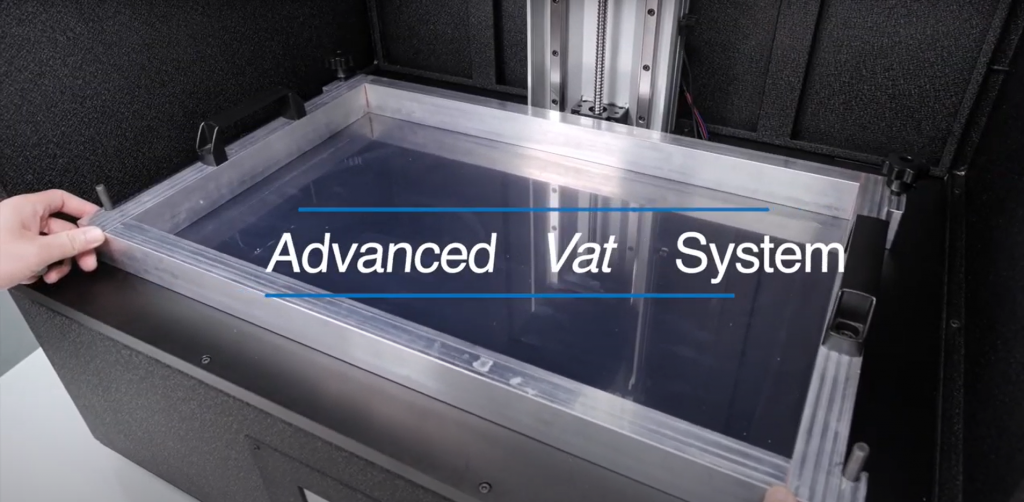

- Temperature-Controlled Vat for more consistent printing

- Fleet management functions for print farm

- Advanced Parallel LED for higher resolution

- More power-efficient, less fan noise design with UL Certified power source.

- Highly customizable with add-ons like air duct vent, chamber heater, LED strip, and more.

- All new Nylon-Like Tough resin to work with Forge printer

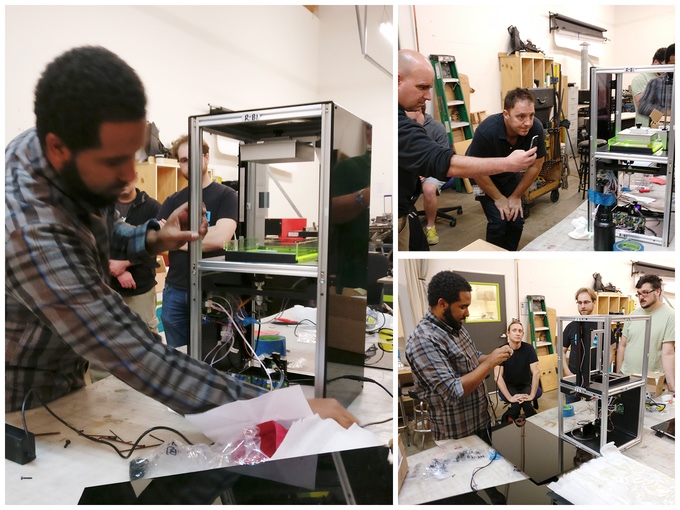

Forge is shipped in two boxes and requires 30-60 minutes of assembling to connect the top and the bottom part of the printer. The assembling does not require any special tools or soldering.

For users who print for productions, speed and ease of use are often as important as resolution if not more so. The flat build plate allows for quick removal and cleaning, unlike a perforated plate. The heated vat ensures printing consistency and avoids reprint that costs time and money. Users can swap a new film or a new panel in under 20 minutes instead of an hour. And most components can be accessed by removing one panel for quick maintenance.

Details

- Printer Size: 470x 360x 640mm

- Print volume: 288 x 162 x 350mm

- Resolution: 50 um

- Technology: MSLA 3D Printing

- Vat Volume: 2. 5 kg

5 kg

- Physical Weight: 30KG

- Shipping Weight: 43KG

- Additional FEP film x1

- Panel Lifespan: 1200 on average using recommended resin and settings

Additional Consumables

Peopoly | MatterHackers

- Home

- Store

- 3D Printers

- Peopoly

The Moai and Phenom lines of 3D printers from Peopoly are some of the most popular on the market, due to their affordability, high resolution, and variety of machines to choose from. The Moai 200 is the large version of the Moai, utilizing the same laser technology on a grander scale. The Phenom Series is making waves as being some of the largest MSLA 3D printers on the market, all of which boast efficient UV LED systems, making them much faster and more accurate than standard SLA 3D printing.

- Fast and accurate

- Compact and affordable

- Large build volume

Peopoly Collections

All Peopoly 3D Printers

Peopoly

Moai Printers and Kits

Affordable, High-Resolution Laser SLA Printing

Phenom 3D Printers

Fast, large-format MSLA 3D printers from Peopoly.

Peopoly SLA Resins

SLA 3D printer resins formulated for 405µm curing lasers and LCD arrays

Peopoly Accessories

Vats, UV curing lights and more for Moai SLA resin 3D printing.

Guides & Articles

How To: Perfectly Level Your Resin 3D Printer's Build Plate

With any 3D print, a perfect first layer is essentially, especially so with resin 3D printing. Let's take a look at how you might be able to increase the adhesion of your resin 3D prints.

How To Succeed with LayerLock SLA Build Surfaces

Successfully achieve strong bed adhesion for Laser, DLP, and SLA resin prints using LayerLock SLA Resin 3D Printing Build Surfaces.

How to Succeed When 3D Printing with MH Build Resin

Make SLA resin 3D printing easier with this helpful detailed article on how to successfully fine-tune photopolymer resin to your 3D printer.

MH Build Resin Profile Settings for SLA 3D Printing

Succeed with MH Build Resin using these helpful printer and support ChiTuBox profile settings for your specific SLA machine.

Tech Breakdown: Peopoly Phenom Noir Resin 3D Printer

For high definition resin 3D printers, Peopoly is hard to beat, and with the Phenom Noir you can print faster than ever.

Getting Started with the Peopoly Moai SLA 3D Printer

MatterHackers' Pros detail the unboxes and set-up steps of the awesome Peopoly Moai SLA 3D printer.

How To: Print, Clean, and Post-Process SLA 3D Prints

Laser and resin 3D Printers have a very different workflow from the more common extruder and plastic 3D printers. Learn what it takes to use these high-resolution machines.

How To: Safely Handle, Use, and Dispose Resins for SLA 3D Printers

3D prints from SLA 3D printers solidify liquid resin to create high-resolution parts. These resins need to be handled with care from opening to disposal.

These resins need to be handled with care from opening to disposal.

Tech Breakdown: Peopoly's Moai SLA 3D Printer

MatterHackers' pros take an in-depth look at why this incredibly precise resin 3D printer is quickly becoming a crowd favorite.

Peopoly was born from one of the most successful 3D printer Kickstarter campaigns in history, with their initial campaign reaching over 800% of goal. The Moai was born from the need for more affordable, at-home SLA 3D printing. For the last four years, Peopoly has continued to refine and expand their SLA 3D printing materials and accessories. Headquartered in Hong Kong, Peopoly has a huge, vibrant user community of thousands of users. Moai owners enjoy the ability to 3D print with a wide range of Peopoly and third-party resins for castable, sandable, and model projects on the Moai and Moai 200. The Moai line of 3D SLA laser printers are the best, low-cost option for high-resolution resin 3D printing on the market today.

Photopolymer 3D printer, technologies, materials, working principle – 3dprofy

Turch October 21st, 2014

Resin-based printing is carried out using SLA stereolithography method . I printing process applied liquid polymer. The printer itself consists of a powerful laser, as well as a bath in which the base platform is located.

Features of the printer for SLA

The essence of the 3D printer is as follows. The platform is lowered into the bath to a depth that depends on the thickness of the print layer. Then a layer of the future model is projected onto it with a laser. Under its influence, the photopolymer hardens, that is, the formation of the part begins. The platform is then lowered to begin forming the second layer. And so on until a three-dimensional model is obtained. After the printing is completed, the product is treated with special compounds to remove excess material. In the final stage of work, the part is placed in an ultraviolet chamber, in which it hardens.

Pros and cons of the SLA printer

Resin cures only 20% during printing, which is caused by difficulties in choosing the laser power. The advantages of this printer include the high accuracy of every detail and the ability to create prototypes for various fields. On the other hand, the equipment is quite expensive, and the printing itself takes too much time. In addition, the created parts require additional work, which is expressed in washing and hardening of the product. In addition, the liquid polymer is expensive.

How is printing done?

The prototype is grown on a special mesh platform. The first photopolymer layer is thin, but during the process, under the influence of a laser, it gradually hardens. The hardening of the model occurs in those areas that are specified on the computer model. At the final stage of work, an almost finished model is lowered into a container with a chemical solution - in it, unnecessary artifacts are removed from the product, and it is also cleaned. The printing process will require the preparation and alignment of auxiliary structures that will achieve optimal physical and chemical properties and will be removed upon completion of the prototype.

The printing process will require the preparation and alignment of auxiliary structures that will achieve optimal physical and chemical properties and will be removed upon completion of the prototype.

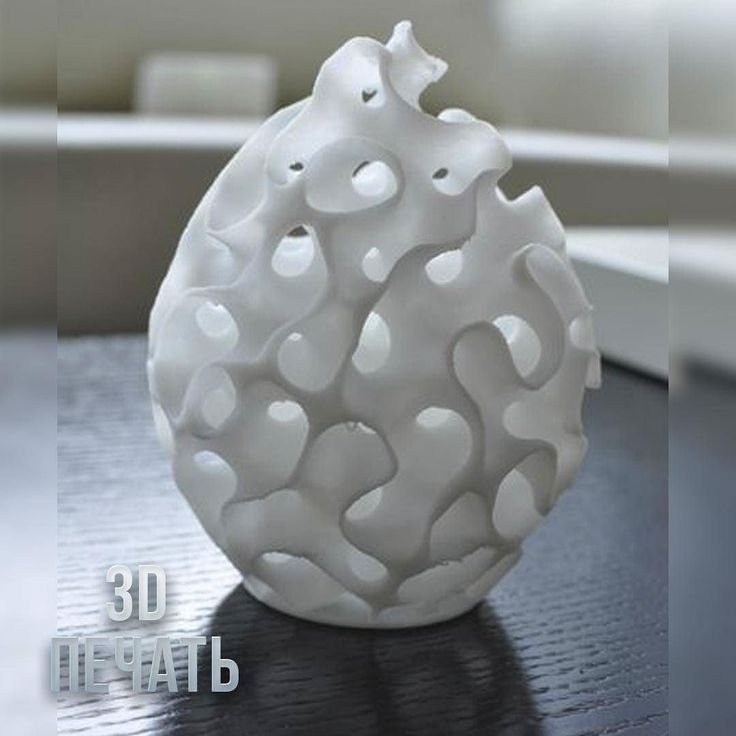

What is good about 3D printing using the SLA method? Firstly, the speed of the process - you can grow an object in just one day. Secondly, on the basis of this method, it is possible to create structures with complex relief. Thirdly, you can pick up a large number of materials that will allow you to conduct a high-quality and fast printing process.

Objet Printer

One of the popular devices that can be used for printing with photopolymer materials is the Objet brand. The peculiarity of the technology is that the layer thickness is slightly higher, while the finished product is durable and reliable. Objet brand printers can work with two materials at once, while they can be used to create one or two prototyping models. Each printing process can be given specific characteristics so that the final models meet the necessary requirements.

The Objet24 allows you to create highly detailed prototypes that can be equipped with moving parts. The final part will be durable, despite the thin walls, and the smooth surface will be an opportunity for further painting in the desired color scheme. This printer model is suitable for designers or engineers who need to create high precision models. This device works with VeroWhitePlus hard photopolymer, which is easy to use: it can be painted, drilled, machined.

More advanced SLA printer model - Objet30 Pro . Based on it, you can create prototypes from eight different materials, each of which is characterized by heat resistance, different structure and texture. Most importantly, the print quality will be excellent. The printer has a capacious tray, which allows you to print large quantities of goods, for example, for medicine.

Professional printers

Professional printer model 9 can be used0005 Objet Eden260V . This is a truly profitable investment because you can quickly create prototypes from 18 materials. The ultra-thin layers of the 3D model allow for exceptional detail, complex shapes and very thin walls. The device works silently, so it will be an excellent solution for office space. This printer model works with several types of materials:

This is a truly profitable investment because you can quickly create prototypes from 18 materials. The ultra-thin layers of the 3D model allow for exceptional detail, complex shapes and very thin walls. The device works silently, so it will be an excellent solution for office space. This printer model works with several types of materials:

- transparent, on the basis of which you can create parts of strong shapes and with a smooth surface,

- opaque rigid materials in various colors,

- with polypropylene based raw material, which is flexible yet strong so you can prototype with moving parts,

- elastic materials that allow you to print parts with a non-slip or soft surface,

- with heat-resistant materials to create functional parts.

The main distinguishing feature of the finished product is a radiant color, which is ensured by the use of materials of various colors.

Objet500 Connex3 3D Printer is a prototyping device that can combine up to 46 colors. Several durable photopolymers can be combined in this printer.

Several durable photopolymers can be combined in this printer.

Photopolymers: types and applications

This type of plastic is characterized by high temperature resistance and high strength. Based on the material, high impact resistance and toughness models can be printed. Based on Digital ABS , you can create:

- functional prototypes,

- molds,

- housing parts that operate at low or high temperatures,

- housings for electronic parts, e.g. for mobile phones,

- engine parts, covers.

High Temperature Material - White RGD525 Material . It is dimensionally stable. On the basis of a photopolymer, it is possible to create simulations of the thermal characteristics of industrial plastics. Ideal for functional testing, for example in hot air or hot water. This material is useful for shaping, fitting and functional testing of static parts, which require high quality in terms of surface and definition. Photopolymer RGD525 is used to create models for the exhibition, moving parts, pipe taps and household appliances.

Photopolymer RGD525 is used to create models for the exhibition, moving parts, pipe taps and household appliances.

In the dental field, photopolymers are used, which have rigidity and an opaque structure. When creating prototypes, excellent detail and high accuracy play an important role. Based on VeroDent, VeroDentPlus and MED610 photopolymers, you can create plaster models, removable mouthguards, surgical guides and other devices for dentistry and orthodontics.

Tango elastic photopolymer 3D prints prototypes that are extremely hard and tear resistant. Based on them, you can print products for exhibitions, various pens, hoses and shoes. Thus, photopolymer 3D printing based on SLA technology is an opportunity to obtain high-quality models that can be used in various fields.

Choosing a liquid photopolymer for a 3D printer. Classification of materials for SLA/DLP 3D printing.

Contents:

- Introduction

- Overview of SLA materials

- SLA Standard Resins

- Standard photopolymer resin - Standard

- Clear photopolymer resin - Clear

- Engineering photopolymer resins

- Rigid photopolymer resin - Tough (like ABS)

- Durable photopolymer resin - Durable (PP-like)

- Heat resistant photopolymer resin - Heat resistant

- Rubber-like photopolymer resin - Rubber-like (Elastic)

- Ceramic photopolymer resin - Ceramic filled (Hard)

- How to choose the right resin for your application

- Dental and medical SLA resins

- Medical Device Photopolymer Resin - Custom Medical Appliances (Class I Biocompatibility)

- Dental Long Term Biocompatible Resin (Class IIa Biocompatible)

- Class I biocompatibility vs Class IIa biocompatibility

- Castable SLA resins

- Cast resin for jewelry making

- Generalized rules

Hello everyone, Friends! With you 3DTool!

This article compares photopolymer resins using Formlabs SLA 3D printing products –

Catalog of photopolymer 3D printers

Photopolymers from FormLabs

Detailed review of the Formlabs Form 3 3D printer

Introduction

The stereolithography prints plastic parts with high resolution, good fine detail, and a smooth surface. Due to the variety of photopolymer resins available for SLA, this technology is used in many different industries:

-

"Standard" photopolymers are used for prototyping

-

Engineering photopolymers have certain mechanical and thermal properties

-

Dental and medical photopolymers have biocompatibility certificates.

-

Cast photopolymers have a zero ash content after burning.

SLA 3D printing resin overview

SLA uses a laser to cure a liquid photopolymer resin. This process is called photopolymerization. Various combinations of polymers and other additives that are part of the resin allow you to get different material properties.

The main advantages and limitations that are common to all resins in SLA 3D printing are:

Benefits:

Weaknesses:

Base Resins for SLA

Post-Processing SLA/DLP 3D Printing Article

Standard photopolymer resin - Standard

Standard resins produce parts with high stiffness, detail and a smooth surface. The low cost of resins, from $250 per liter, makes them ideal for prototypes.

The color of the resin also affects its properties. For example, in FormLabs products, gray resin is suitable for models with fine details, and white resin for parts that require the smoothest possible surface.

Benefits of using Standard grade resins:

Cons Standard:

Also included in the class of "Standard" photopolymer resins from FormLabs is the Color KIT - a set of special dyes and "Color Base" photopolymer resin for mixing and obtaining a variety of color solutions. This eliminates the need for painting parts after 3D printing.

This eliminates the need for painting parts after 3D printing.

FormLabs Engineering Photopolymer Resins

Engineering resins have a range of properties for injection molded plastics.

All engineering resins require additional UV curing, such as using the Form Cure, to achieve their maximum properties.

Tough photopolymer resin - Tough (similar to ABS)

Tough resin was developed for models that need to withstand high loads and be durable.

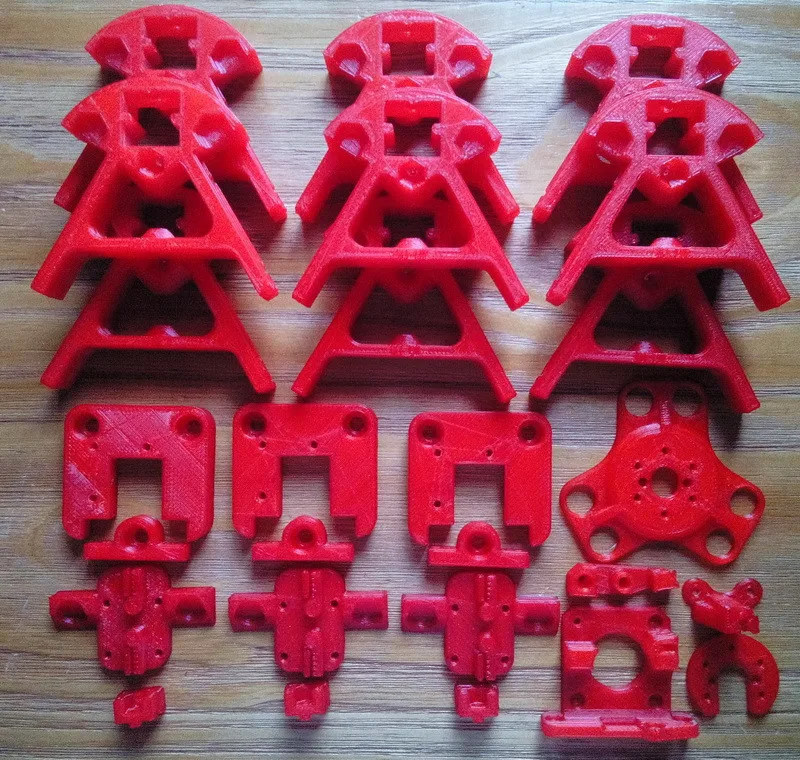

This material produces strong, shatter-resistant parts and functional prototypes such as snap-on housings.

Pros:

Cons:

Ideal for: functional prototypes, mechanical parts

Durable photopolymer resin - Durable

Durable resin is a wear-resistant and flexible material with mechanical properties similar to polypropylene.

Durable photopolymer produces models with a smooth glossy surface and high resistance to deformation.

Durable Resin is ideal for:

- Bushings and bearings;

- Various functional compounds

Pros:

Cons:

-

Not suitable for thin wall parts (recommended minimum wall thickness 1mm)

-

Low heat distortion temperature

-

Low flexural strength (lower than hard resin)

Ideal for: functional prototypes.

Refractory Photopolymer Resin - Formlabs High Temp Resin

The heat resistant resin is ideal for parts that require high temperature resistance and operate at high temperatures.

Formlabs High Temp Resin provides the highest melting point (HDT): 238°C at 0.45 MPa.

The resin should be used to print detailed, accurate prototypes with high heat resistance.

Pros:

Cons:

Flexible Resin

Rubber-like resin allows flexible parts to be made. This material has a low tensile strength and high elongation at break and is well suited for parts that will be bent or compressed.

It can also be used to add ergonomic features to multi-material assemblies such as: dies, wearable prototypes, handles, pads and grips.

Pros:

-

High flexibility (high elongation at break)

-

Low hardness (simulates 80A durometer rubber)

-

High impact resistance

Cons:

-

Doesn't have all the properties of real rubber

-

Requires extensive support structures

-

Material properties deteriorate over time as the part is exposed to ultraviolet radiation (sunlight)

-

Not suitable for thin wall parts (recommended minimum wall thickness 1mm)

Ideal for flexible prototyping.

Ceramic photopolymer resin - Rigid Resin

This resin is reinforced with glass, which provides very high rigidity and a polished surface. The polymer is very resistant to deformation and is excellent for 3D printing thin elements.

Ideal for: molds and tooling, jigs, manifolds, retainers, electrical and automotive fixture housings

Thermal management components printed with SLA ceramic (hard) resin. Image credit: Formlabs

How to choose the right resin for your application

The table below shows the main mechanical properties of photopolymers for SLA:

Source: Formlabs

Standard resin ( standart ) has high tensile strength but is very brittle (very low elongation at break) so it is not suitable for functional parts. The ability to create a good part surface makes it ideal for visual prototypes and art models.

durable ( durable ) resin has the highest impact strength and elongation at break of any other SLA material. Best suited for prototyping parts with moving parts and latches. It lacks, however, the strength of thermoplastic 3D printing materials such as SLA nylon.

tough ( tough ) resin is a compromise between the material properties of tough and standard resin. It has a high tensile strength, so it is best suited for rigid parts that require high hardness.

heat resistant resin ( heat resistant ) can withstand temperatures above 200 o o C, but has poor toughness and is even more brittle than standard resin.

ceramic ceramic reinforce resin has the highest tensile strength and flexural modulus, but is brittle (poor elongation at break and toughness). This resin is preferred for thin wall parts that require increased rigidity.

The graphs below compare the mechanical properties of the most common SLA materials visually:

Comparison chart for elongation at break and toughness for common SLA printing specifications and standard media. Image courtesy of Formlabs.

Stress-strain curves for conventional SLA technologies and standard materials. Image credit: Formlabs

Comparative chart of material properties of various technical resins. Image credit: Formlabs.

Dental and medical resins

Photopolymer resin for medical devices - Custom Medical (Biosemus. Class 1 biocompatible resins can be used to make medical equipment such as surgical guides. Parts printed on this resin can be steam sterilized in an autoclave for direct use in the operating room.

Pros:

Cons:

- Moderate wear and tear resistance

Ideal for: Surgical aids and appliances

Dental Long Term Biocompatible Resin - Dental Long Term (Class 2A biocompatible)

These resins are specially formulated for long term dental fixtures. Class 2A biocompatible resins can come into contact with the human body for up to a year.

Class 2A biocompatible resins can come into contact with the human body for up to a year.

High resistance to breakage and wear make this resin ideal for making rigid cotter pins or retainers.

Pros:

Cons:

-

High price

Ideal for: durable dental instruments, fracture and wear resistant medical parts, rigid cotter pins, retainers

What is the difference between class 1 and class 2a biocompatibility?

Class 1 biocompatibility rules apply to materials that are allowed to be used for:

-

non-invasive devices that come into contact with intact skin

-

devices for temporary use or short-term use in the mouth or ear canal or in the nasal cavity

-

reusable surgical instruments

Class 2a biocompatibility rules apply to materials that are allowed to be used for:

-

devices that come into contact with bodily fluids or open wounds

-

devices used to introduce substances into or remove substances from the human body

-

invasive short-term devices such as invasive surgical items

-

long-term implantable devices placed in the teeth

Photopolymer resin in SLA 3D printing for jewelers

Jewelry resins

This material allows you to print models with fine details and a smooth surface without leaving ash or residue after burning.