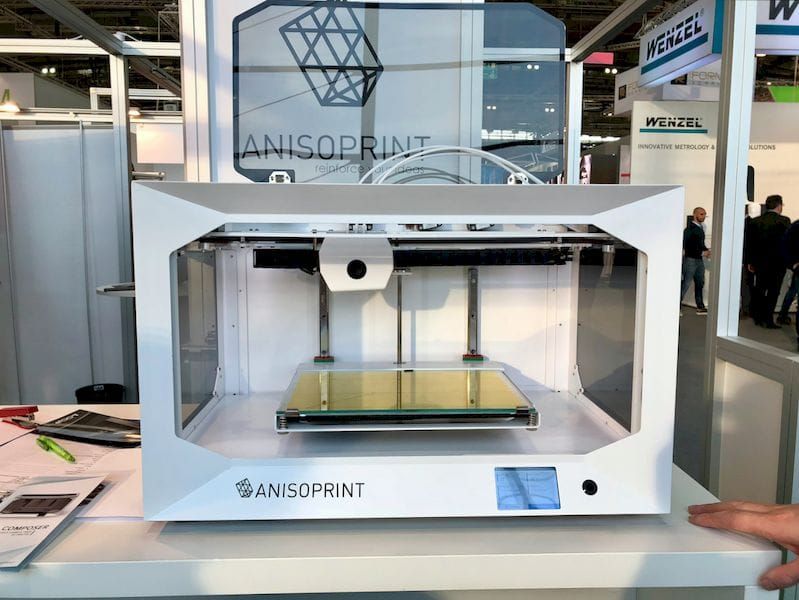

Pei 3d printer

PEI Sheet (1mm) 3D Printing Build Surface

Gizmo Dorks

$10.95

Current stock: 0

3D Printing Platform (Made in the USA)

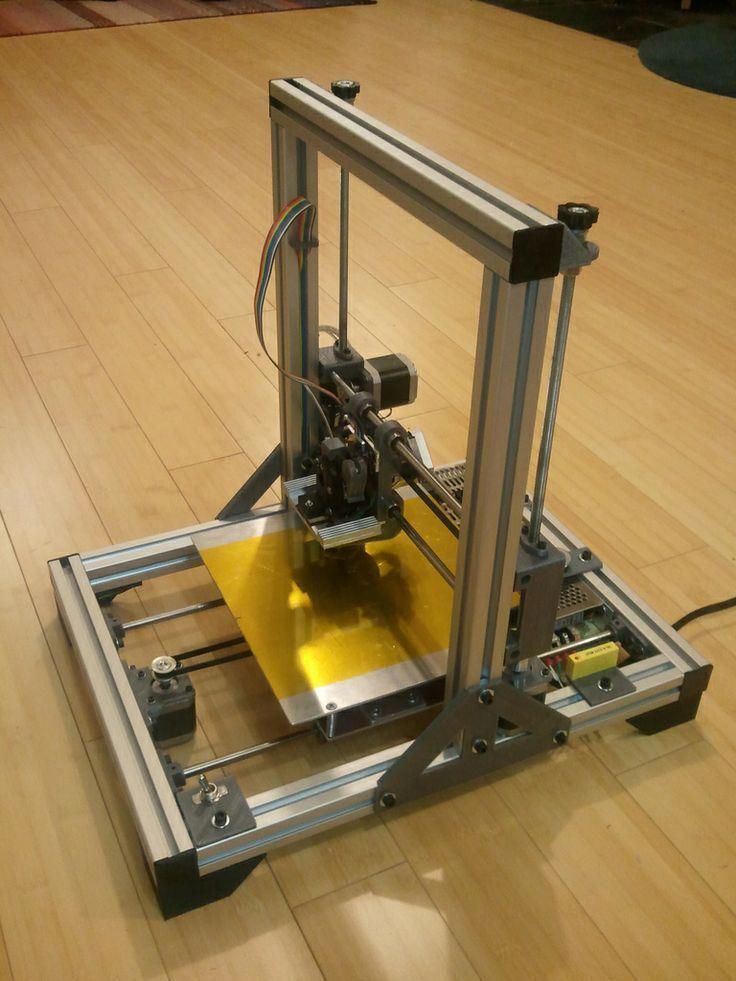

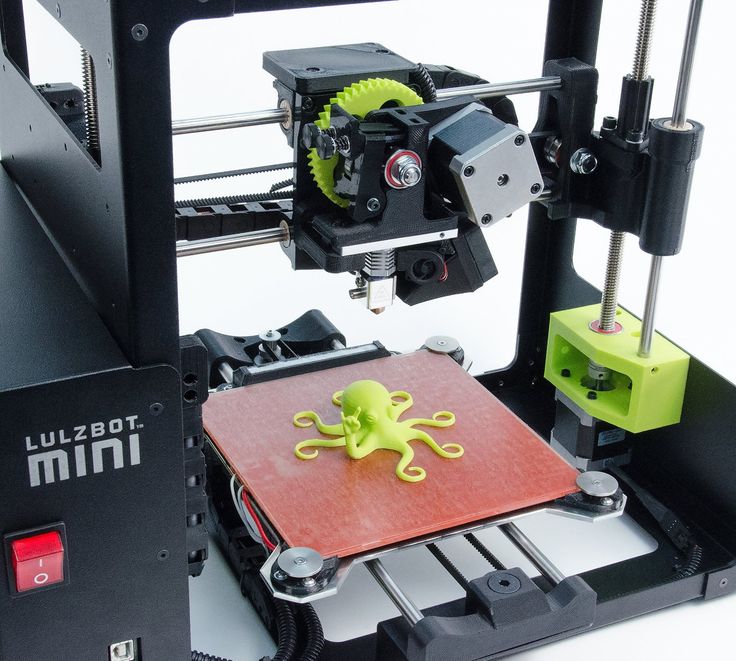

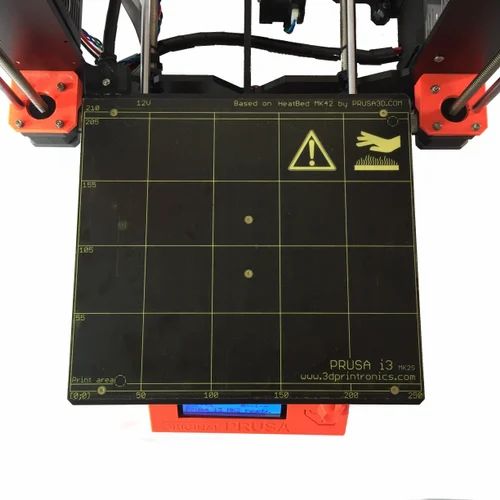

PEI (Polyetherimide) is a great building surface for any 3D printer. The amber / yellow colored surface is commonly used to print a whole range of different filament types such as the two most commonly used ones, ABS and PLA. Depending on the filament type a heated build surface might still be required. PEI sheet as a build plate requires little to no surface preparation. Printed parts adhere extremely well to the build surface making the use of kapton tape, blue tape, hairspray, or glue sticks unnecessary. Typically, even printing brims or rafts is unnecessary. PEI is widely becoming the gold standard build surface because it is so convenient to use. Our PEI is Ultem 1000 grade.

Size Options

- 4.7x4.7 inches

- 5x5.5 inches (fits Monoprice Mini)

- 8x8 inches

- 10x10 inches

- 12x12 inches

- 16x16 inches

- 20x20 inches

- 4.

3 inch diameter (round circle - fits Monoprice Mini Delta)

- 8 inch diameter (round circle)

- 12 inch diameter (round circle)

All sizes have a thickness of 1 mm.

If the size you are looking for does not perfectly match your build plate, you may purchase a bigger size and score / cut the PEI sheet down to the needed dimensions. PEI can be easily snapped off if you first score the surface. If there is a size that you need which isn't available, drop us a line, and we'll try our best to assist you.

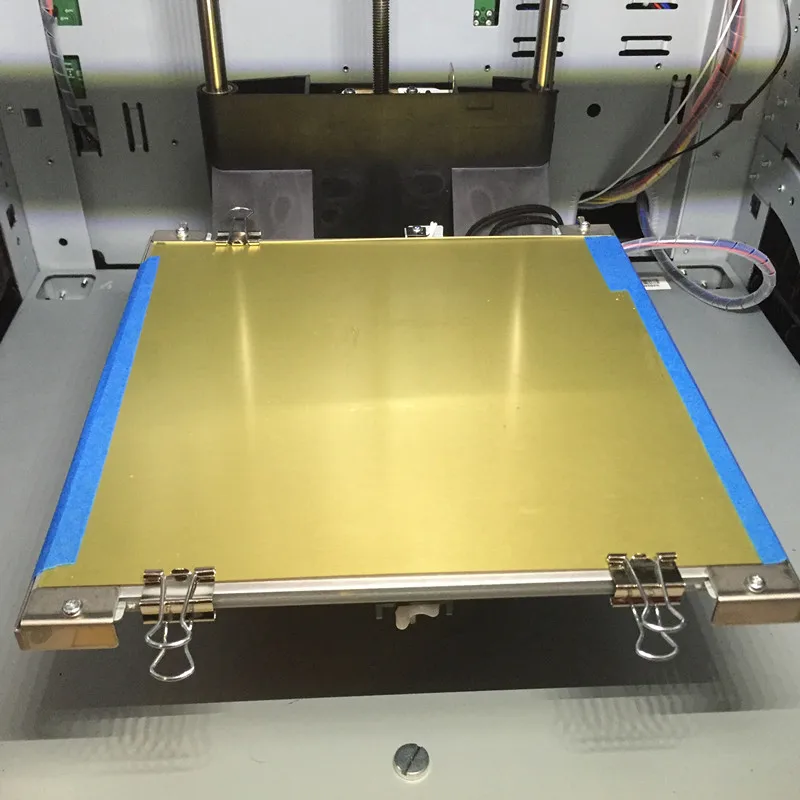

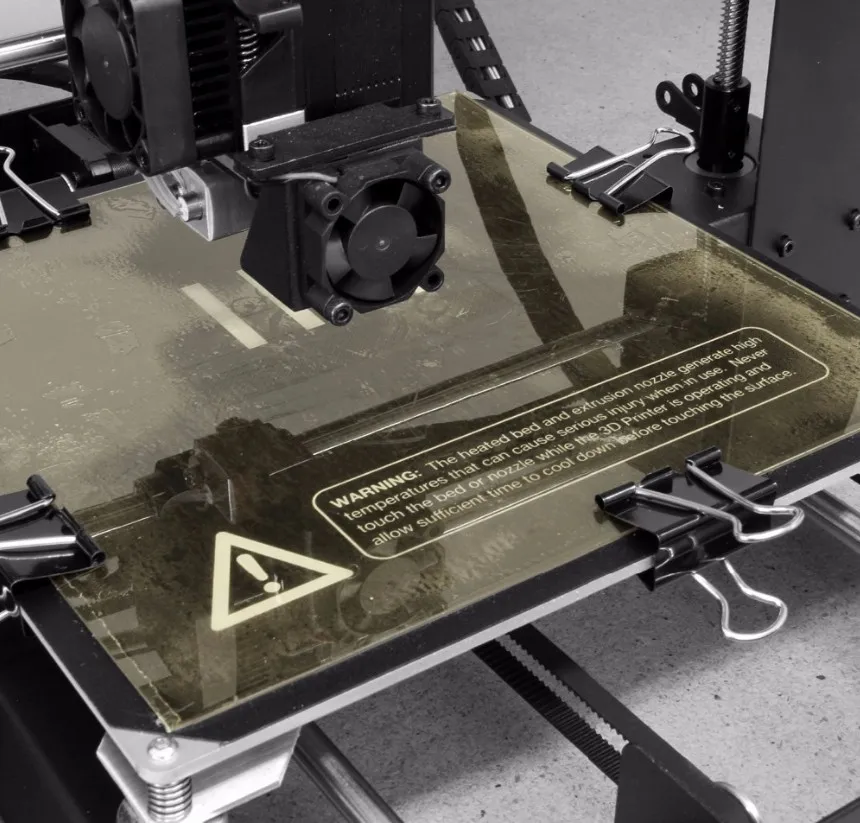

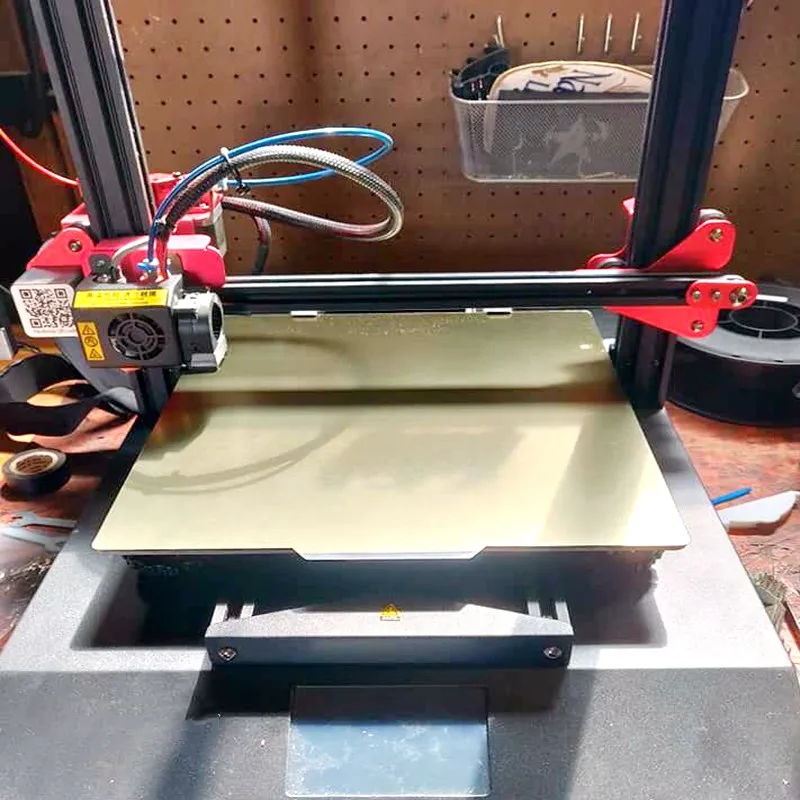

Application

PEI can be applied a number of ways, but generally there are two easy methods. The first method is to simply put the PEI sheet on top of your existing bed platform and clamp it down with binder clips (alligator clips) or similar. The second method is applying the 3M 468MP adhesive in conjunction with the PEI sheet. First apply the 3M 468MP adhesive directly to the PEI sheet, and then affix the other side of the 3M 468MP adhesive to your build surface. Please note that depending on how many layers your build surface is the bed temperature that is set may not match the surface temperature of the PEI sheet. Additionally, it should be noted that 3M 468MP is a very sticky adhesive. The 3M adhesive will clump up after you touch it, so re-positioning the adhesive is not feasible. If you do not have the 3M 468MP adhesive, you may purchase it here or purchase one of the combo packs that come with a PEI sheet and 3M 468MP adhesive.

Please note that depending on how many layers your build surface is the bed temperature that is set may not match the surface temperature of the PEI sheet. Additionally, it should be noted that 3M 468MP is a very sticky adhesive. The 3M adhesive will clump up after you touch it, so re-positioning the adhesive is not feasible. If you do not have the 3M 468MP adhesive, you may purchase it here or purchase one of the combo packs that come with a PEI sheet and 3M 468MP adhesive.

The application of adhesive to the 16 x 16 inch PEI sheet can be done by applying four separate 8 x 8 adhesive squares. Please do not overlap the adhesives to maintain a flat surface.

Additionally, the PEI sheet comes with blue protective film on each side that must be removed prior to use. It is very important to remove the blue protective film.

Care and Use

Before each print it helps to clean the surface of the PEI sheet with isopropyl alcohol (70-91%). Fingerprints or residue will build up on the surface and inhibit surface adhesion which the isopropyl alcohol will clean. After a good number of prints, PEI may lose it's surface adhesion. Please simply sand the PEI sheet down with 2000 grit sandpaper.

After a good number of prints, PEI may lose it's surface adhesion. Please simply sand the PEI sheet down with 2000 grit sandpaper.

Your shopping cart

Account

Log in

Email Address *

Password *

Forgot password?

New Customer

Create an account with us and you'll be able to:

- Check out faster

- Save multiple shipping addresses

- Access your order history

- Track new orders

- Save items to your wish list

Create Account

Forgot Password

Fill in your email below to request a new password. An email will be sent to the address below containing a link to verify your email address.

Email Address *

All you need to know about PEI/ ULTEM ® for 3D printing

Published on August 3, 2020 by Aysha M.

In recent years, the use of high-performance thermoplastics has become increasingly important in the 3D printing industry, as the technology moves away from rapid prototyping to the production of finished parts. As a result, the requirements for 3D printing materials have increased and high performance thermoplastics are becoming more and more common. Their properties make them an economical alternative to certain metals and are valued by many sectors such as aerospace and medical. Within this family are Polyaryletherketone (PAEK) which can withstand high temperatures and which you may be familiar with from PEEK and PEKK. There is a much cheaper alternative, Polyetherimide (PEI), an amorphous material better known by its trade name ULTEM®. Available as a filament for FDM 3D printers, it is compatible with certain machines, including those of Stratasys. Let’s go back over the main characteristics of ULTEM.

Let’s go back over the main characteristics of ULTEM.

The PEI was developed in the 1980s by Joseph G. Wirth and was marketed by General Electric’s Plastics Division under the name ULTEM. In 2007, the company sold its plastics business to Saudi Basic Industries Corporation (SABIC), which thus recovered the associated patent. Although ULTEM® was embraced by many industrialists thanks to its mechanical properties, it only became suitable for mass production with the development of high-performance FDM/FFF printers; the extruder of the machine must be heated up to 350°C in order to melt the thermoplastic.

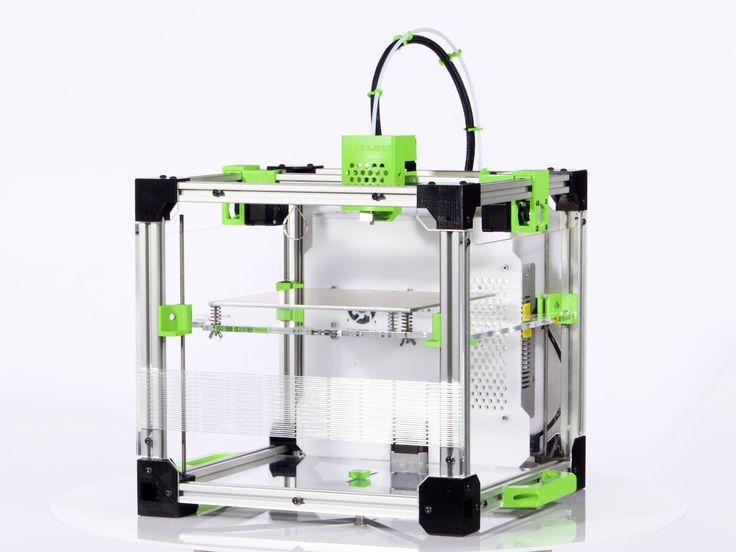

Image credits : GEWO3D

The main characteristics of ULTEM

Temperature management is therefore essential when it comes to printing ULTEM®. The temperature in the chamber must be maintained at all times, otherwise irregularities may occur and the adhesion of the different layers may suffer. As the temperature of the PEI is between 345 and 400°C, you will need an extruder capable of rising to these levels.

PEI is known for its dimensional stability and creep resistance. SABIC now offers two different resins, ULTEM® 9085 and ULTEM® 1010. As for the first one, it is intrinsically flame retardant and has very good results in FST (Flame, Smoke, Toxicity) tests: it has a high flame resistance, low smoke emission and low toxicity. The material also has a high strength-to-weight ratio and can even replace certain metals thanks to its mechanical properties. Finally, it has good resistance to automotive fluids, hydrocarbons, alcohols and aqueous solutions. ULTEM® 1010 resin has a high tensile strength, showing great solidity and durability. It is biocompatible and NSF 51 certified for food contact. It can also withstand steam sterilization.

Image credits: Stratasys

Compared to PEEK, PEI is cheaper – it costs €150 per kilo compared to at least €300 for the same amount of PEEK. It is a material that has the advantage of being certified for a number of aerospace applications, meeting highly standardized requirements. However, PEI will have lower impact and temperature resistance.

However, PEI will have lower impact and temperature resistance.

IAP Applications

PEI is widely used in the aerospace industry, particularly ULTEM® 9085 because of the characteristics mentioned above. It is also a material of choice in the automotive, medical and food industries, especially in the design of kitchen utensils. This thermoplastic is also widely used in tooling, whether to design moulds, jigs or various fasteners. Bombardier, for example, uses this material to manufacture its custom tools, customize components on its production lines and also to produce finished parts for its trains.

Finally, on the manufacturers’ side, SABIC is today the only one to supply the raw material, in the form of resin or foam. The company manufactures its own filaments for additive manufacturing: historically, they were only compatible with the Stratasys range of machines but in recent years, SABIC has formed other partnerships such as with Roboze which can print the filament ULTEM™ AM9085F. Some manufacturers offer their own filaments such as KIMYA, 3DXTech or 3D4Makers.

Some manufacturers offer their own filaments such as KIMYA, 3DXTech or 3D4Makers.

SABIC has developed a 3D printing support for the ULTEM

Finally, you should know that if you are considering printing with ULTEM®, the manufacturer SABIC has launched a detachable support filament, the AMS31F, which is easier to remove than other support materials that often need to be warmed up. Thus, the part can keep all its mechanical properties and the user saves precious time.

What do you think about ULTEM? Let us know in a comment below or on our Facebook and Twitter pages! Sign up for our free weekly Newsletter, all the latest news in 3D printing straight to your inbox!

3D printers and 3D printing

3D printers have appeared in our lives not so long ago, but are already very popular in the field of high technology. In the future, instead of buying various items in the store, will we simply download a file from the Internet and print them on a home 3D printer? Will there be a 3D printer on the International Space Station that will print the parts and spare parts necessary for space exploration? You can find answers to these and other questions in this section.

3D production

5 The science

F2 Innovations, founded by graduates of the Perm National Research Polytechnic University, announced a granular 3D printer called F2 Gigantry, which can print large parts with overall dimensions up to 4, 2 and 1 meters in length, width and height, respectively.

one Technologies

Three-dimensional printing in construction is developing rapidly. Today it is a viable and promising technology that has every chance of becoming dominant in the industry. Right now in Texas, the grandiose project of the Genesis Collection at Wolf Ranch is unfolding to build an entire residential ...

1 Technologies

Specialists of the Perm Research and Development Institute have developed and proposed for application a technology for 3D printing of graphene parts of complex shapes for use in aviation, which will significantly reduce the cost of their production while improving the quality of products.

0 Weapons

A radio station in Utica (USA) released an interview with a man under the pseudonym "Kem", who told how he managed to take advantage of a hole in the state program for buying weapons from the population. Due to the extremely criminal situation in the state of New York, the authorities began to give out $ 500 gift certificates to those who ...

four Science

Engineers from the University of Washington conducted a series of experiments that proved the fundamental possibility of creating strong and reliable cermets from regolith. In this case, "regolith" is a conditional substance, an imitation of lunar soil and Martian dust. During the exploration of the Moon and Mars, this ...

four Space

According to TASS special correspondent and cosmonaut Oleg Artemiev, the latest Russian-designed 3D printer, created by RRC Energia specialists from the Roscosmos structure, has already arrived at the ISS and is fully prepared for printing.

0 Technology

For the first time, the possibilities of 3D printing technology in space were tested in December 2018 by Russian cosmonauts Alexei Ovchinin and Oleg Kononenko - then they launched the Organ. Avt”, developed by the staff of the laboratory 3D Bioprinting Solutions (Russia).

one Technologies

The use of 3D printing technology in construction has already shown its effectiveness in many countries of the world, so it is not surprising that the US Army plans to build three 530 sq. meters each. For comparison, the area of one of the administrative buildings in Dubai, erected on…

0 Technology

One of the world leaders in 3D printing, the American company ICON, together with the homebuilder Lennar, are embarking on an ambitious project to build a residential area of 100 family homes in Austin, Texas, designed by the design firm Bjarke Ingels Group (BIG). The settlement will become…

The settlement will become…

one Technologies

Scientists from the Massachusetts Institute have created a new tool that replaces tactile sensors, pressure meters and displacement sensors at the same time. It is a flexible structure built from metamaterials that responds to the user's touch and transmits commands depending on their strength and direction. One more…

0 Technologies

Developers from the American startup Lore have found a way to increase the efficiency of the legs of cyclists during races. They decided to eliminate such a factor as the displacement of the foot inside the shoe - this consumes a certain amount of energy that could be used to pedal. As a solution, they offer…

3 Technology

The world's first 3D-printed stainless steel bridge connecting the banks of one of the city's canals was opened in Amsterdam with the participation of the Queen of the Netherlands Maxima.

one Technique

The rocket industry is actively developing advanced 3D printing technologies. In the production of their spacecraft, it has already been adopted by Rocket Lab, NASA and Space X. The next may be the startup Relativity Space, whose participants are going to print the world's first launch vehicle Terran R on a 3D printer ...

3 Technologies

The construction of houses using 3D printing is no longer the lot of individual experiments and is gradually reaching the industrial level. One such project is nearing completion in Austin, Texas, where construction firm Icon has begun building the first $450,000 "printed" homes.

1 Technology

Over the past few years, 3D printing home building technology has gone from the first amateur experiments to the construction of full-fledged offices and affordable housing. The next step seems to be the creation of the world's first printed school in Madagascar.

ten DIY

For quite a long time, 3D printed weapons were unreliable and often disposable crafts that were only enough for one shot. But technology does not stand still, and today the weapons printed on the printer are becoming more and more formidable.

0 Technology

The construction industry is rapidly embracing 3D printing. There are already enough examples of this: this is the creation of an entire village in Mexico, consisting of printed houses, and the construction of two-story houses in Germany using the 3D printing method. Next in line is a three-story house.

0 Technology

MIT Media Lab graduate student Jack Foreman has figured out how to take advantage of a defect in FDM printers that creates specific gaps in an object during printing. Formally, they are considered a lack of technology, a consequence of insufficient extrusion, and the product turns out to be defective. However, Foreman noticed that…

However, Foreman noticed that…

0 Gadgets

3Doodler has updated its lineup with the new Pro Plus pen. The main goal of the developers is to get rid of associations with toys, entertainment, change the image of a 3D printing pen and present it as a professional tool. At the same time, the essence and purpose have not changed - with the help of a pen ...

0 Technologies

For many years, coral reefs have been under the threat of extinction. The solution to this problem was proposed by scientists from the University of Hong Kong. Using 3D printing technology, they created special mosaic tiles that are supposed to be placed on the bottom of shallow water areas.

3 Technologies

KFC announced that it intends to produce chicken nuggets using 3D printing technology of fake meat.

0 Technologies

Engineers from the Max Planck Society in Düsseldorf and the Fraunhofer Institute for Laser Technology in Aachen (Germany) have developed a new technology for creating heterogeneous microstructures using 3D printing. To visualize their work, they printed an analogue of the famous Damascus steel. This is not a blank for weapons, oh ...

To visualize their work, they printed an analogue of the famous Damascus steel. This is not a blank for weapons, oh ...

0 Technologies

Today, the size of objects that can be printed on a 3D printer is limited by the size of the 3D printer itself (unless you design complex prefabricated structures). Therefore, when it becomes necessary to print a large object - for example, for the needs of the aerospace industry - the manufacturer has to ...

one Technology

Professor Jonathan P. Singer of Rutgers University in New Jersey (USA) has developed a technology for coating complex three-dimensional structures throughout their area. It can be used both for simple coloring of products (including those printed on a 3D printer), and for treating them with special substances. Working…

0 Technology

The new application of 3D printers has nothing to do with stamping complex engineering parts. Food printed with such a printer changes the structure of products in such a way that a person feels more full, while consuming less food.

Food printed with such a printer changes the structure of products in such a way that a person feels more full, while consuming less food.

0 Technologies

The Laboratory for Applied Photonic Devices at the Federal Polytechnic School of Lausanne (Switzerland) has developed a technology for high-speed three-dimensional printing of objects. Its main advantage and difference from the usual additive printing in the absence of layers is that the entire object is created at once. True, there are fundamental ...

0 Gadgets

At CES-2020, Taiwanese company XYZ Printing introduced the da Vinci Color 5D desktop FDM 3D printer. Developers define 5D in its name as "3D + 2D".

0 Technologies

The possibilities of aluminum 3D printing are a dream come true for car manufacturers and re-enactors when it comes to small-scale or custom production. Brands such as Koenigsegg and Bugatti officially use printed parts when assembling cars to order. Wheel manufacturer HRE with…

Wheel manufacturer HRE with…

one Technologies

The main goal of the non-profit organization New Story is to help the most socially vulnerable groups of the population find affordable housing. According to experts, by 2050, 3 billion people will be deprived of the opportunity to live in normal conditions. One of the directions in solving this problem is the construction of economical houses with…

2 Technology

Researchers from the ETH Zurich (Switzerland) conducted an experiment in which they tried to create DNA for inanimate objects. The goal is to learn how to convey information about the structure of synthetic structures in each of their particles, so that with the help of any fragment it is possible to reproduce the entire object ...

0 Gadgets

On the eve of the New Year holidays, the Chinese company Tronxy has launched what is probably the most affordable 3D printer in the world. The Tronxy X1 model with a regular price tag of 13600r with a holiday coupon is on sale for only 6500 (if you want to try your hand at 3D printing and start with Tronxy, use when buying ...

The Tronxy X1 model with a regular price tag of 13600r with a holiday coupon is on sale for only 6500 (if you want to try your hand at 3D printing and start with Tronxy, use when buying ...

0 Technologies

In the Chinese city of Suzhou, work has been completed on the creation of a unique retaining wall to strengthen the coastline of one of the water channels. What makes it special is that the wall was built using construction 3D printing technology. With a length of 500 m and a height of several meters, this is by far the largest structure ...

HIGHLIGHTS

Swarms of insects generate as much electricity as an entire thundercloud

TCL unveiled a new version of the NXTWEAR virtual display

Random article

An interesting fact

Dolphins can recognize themselves in a mirror.

Refresh

Latest Comments

Valya → Bioelectronics from mushrooms will safely decompose in compost

Well, about the manufacture of frames for implants in medicine - there can be unpredictable consequences, for example: the frame will dissolve before the implant "takes root". And where is the guarantee of complete safety ...

And where is the guarantee of complete safety ...

Valya → NASA has successfully launched the most powerful rocket in the world into space

Let's wait until December 12, when the rocket will return. Yes, the Americans are preparing for space wars, for the location of their bases on the Moon and on Mars. They don't have enough land!

Valya → Ordinary smartphones will help to monitor the condition of bridges

Are high-rise buildings also afraid to determine their location?

Panika → Rostec specialists prepare engines for PAK DA

9 for production0006 40 billion for an area of 2.4 m3!?!?!?!?! Why the hell! if there is such money, then give people good salaries, fucking Kashchei probably never lived in debt from salary to advance! And he will do all the work…Luck → In Russia, developed the technology of "diamond" flash drives

Where is at least one flash drive, where!?

Valya → Super-GPS is able to change navigation in the city due to the abandonment of satellites

Excessive exposure: "the towers are interconnected by fiber optic cables and connected to a single atomic clock. .."

.."

Valya → Midnight air taxi goes into series production

I thought it was a drone. And 600 meters is, it seems to me, a bit low for skyscraper America!

PEEK 3D Printer Overview

Contents:

- Introduction

- Material Features PEEK

- Professional and industrial 3D printers

- Apium P220

- TOTAL Z Anyform 500-PRO HOT+

- Creatbot PEEK-300

- AON3D M2 2020

- IEMAI Magic HT Pro

- TSAR 3D TS547-PEEK

- Tractus T850P

- Stratasys F900 Pro

- Conclusion

Introduction

PEEK is widely used in traditional manufacturing, but is also used in some 3D printers. The thermoplastic polymer offers impressive mechanical properties including high temperature performance, mechanical strength and excellent chemical resistance. These properties make it popular in additive manufacturing, especially for metal replacement.

It would be a crime to ignore such a versatile polymer, and 3D printer manufacturers have not ignored it. With the development of additive technologies, 3D printers that print, among other things, with PEEK material, are becoming more accessible not only for large-scale industries with large budgets, but also for medium and small businesses and even for private clients. From PEEK it is convenient to print prototypes of future metal products and even final products that will immediately go to work. The market for printing with engineering materials is constantly expanding, which invariably causes two consequences: a decrease in the cost of the installation itself and an increase in its build chamber.

PEEK material features

To print PEEK, the printer must have 3 important features:

- High temperature extruder

The melting point of PEEK is 343° C. This means that the extruder must be heated to at least this temperature, and in fact to a higher temperature. The hot end of the extruder must also be all-metal and resistant to abrasives.

The hot end of the extruder must also be all-metal and resistant to abrasives. - Heated print platform

For printing high performance resins, a heated bed is required, which must be heated to at least 120° C. This ensures the correct adhesion of the first layers and the overall quality of the 3D print. - Closed heated chamber

PEEK is very prone to shrinkage and warping. Ideally (and this is especially important for large parts), the printer should have a closed chamber and maintain the temperature in it at 143 ° C, i.e. glass transition temperature of PEEK. Otherwise, the product will delaminate after printing.

It is extremely important to control these temperatures and keep them constant, as fluctuations can ruin the print.

Using their experience, our company's engineers have compiled a list of modern 3D printers capable of printing with PEEK and other refractory plastics. If you are planning to get acquainted with printing with engineering plastics or start production using 3D printing, we offer our TOP printers in 2020.

Professional and industrial 3D printers

Apium P220

I would like to start with the Apium P220 printer. Apium is one of the first printers to print with PEEK, the benchmark in print quality in the industry. The manufacturer deliberately does not increase the print chamber, as is fashionable with other manufacturers, in favor of the quality of the resulting products. The

P220 is classified as a professional printer only because of its small size and low noise level, in fact, in terms of print quality and technologies used in the installation, this printer can be safely called industrial. The printer produces all the required temperatures: the extruder is heated up to 540° C, the table - up to 160° C, and the temperature in the chamber can be stably maintained at 180° C. Build area 205x155x150mm

In addition, the printer has a unique technology for maintaining the temperature in the print area, thus allowing the lower layers already printed to cool down a little. This approach as a result increases the accuracy of printing, adhesion between layers and improves the controllability and predictability of the entire process. Even the smallest details are printed perfectly.

This approach as a result increases the accuracy of printing, adhesion between layers and improves the controllability and predictability of the entire process. Even the smallest details are printed perfectly.

TOTAL Z Anyform 500-PRO HOT+

Undoubtedly the best domestic industrial printer that prints with engineering plastics. There is a large insulated build chamber measuring 500x500x500mm and the ability to maintain a temperature of 300°C, which is even redundant for PEEK printing. The basic printer is equipped with one extruder with a working temperature of 500 ° C, optionally you can install another one of the same.

The printer fits through a 900mm doorway, which in turn means it will fit in almost any lab or office.

Creatbot PEEK-300

PEEK 300 is a 3D printer from Chinese manufacturer Creatbot. It offers a lot of features that are usually found only in more advanced industrial-grade 3D printers. Thanks to the high temperature extruder and closed chamber, this machine can print consistently good results on both PEEK and PEI. The extruder is heated up to 500°C, and the platform - up to 200°C, constantly maintained temperature in the chamber - up to 120°C.

The extruder is heated up to 500°C, and the platform - up to 200°C, constantly maintained temperature in the chamber - up to 120°C.

It also has a low filament sensor to alert the user when the filament is about to run out. In addition, it is equipped with the function of baking the product directly in the build chamber. The printer has an impressive build area of 300x300x400 mm.

AON3D M2 2020

Aon-M2 2020 is one of the largest printers, the build area has dimensions of 454x454x640 mm and allows you to print complex tooling, cases and many other large format products.

Aon-M2 2020 is designed for printing on high performance thermoplastics such as PEEK, PEKK, ULTEM. It is compatible with many material brands including Solvay, Sabic, DSM, Infinite Material Solutions and more and comes with proven print profiles for them. This printer has two independent extruders, one for printing polyetheretherketone (PEEK) parts directly, the other for printing supports.

Despite its size, the printer is up and running in less than 15 minutes.

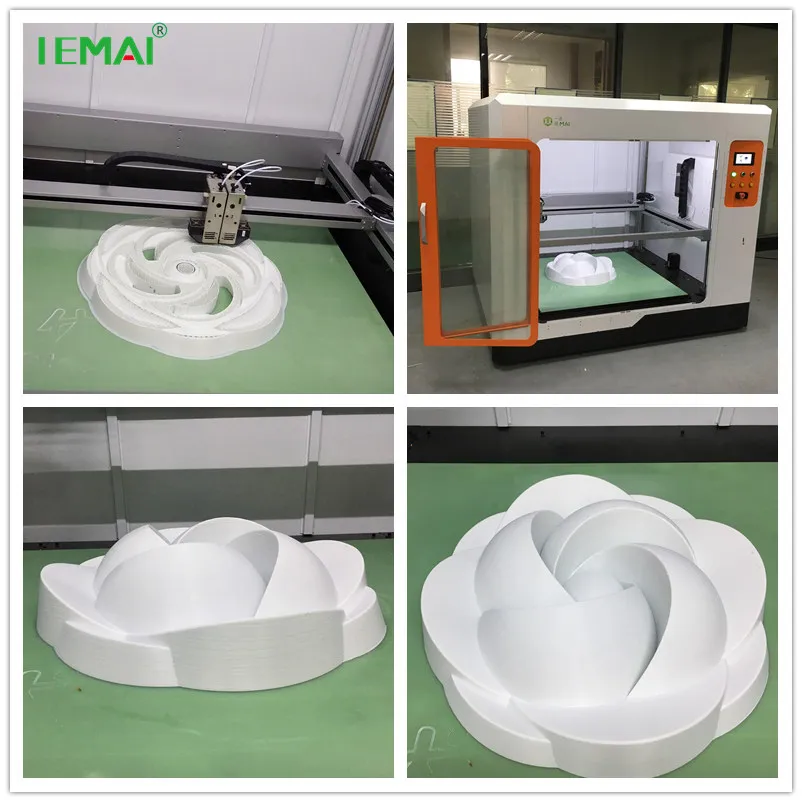

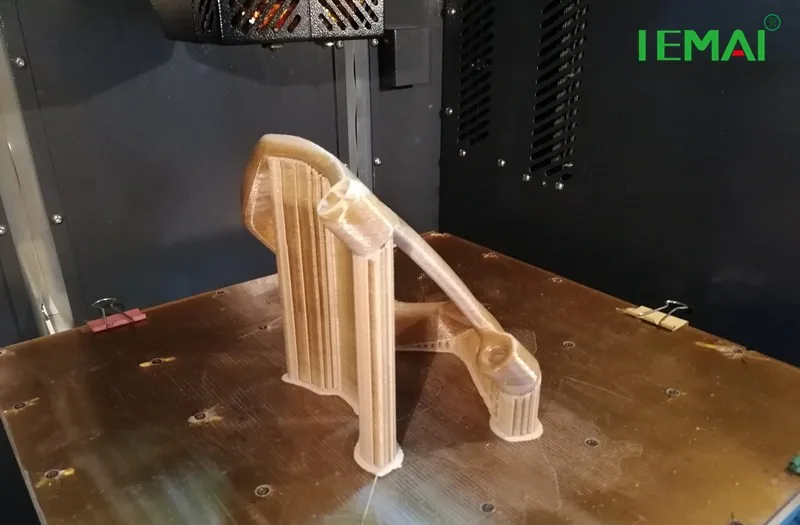

IEMAI Magic HT Pro

Another Chinese-made printer. The unit has all the necessary kit for printing PEEK plastic and fits easily on the desktop. The printer is also the most budget-friendly in the line of high-temperature printers. The size of the construction area is 310x310x480 mm, with a maximum temperature in the chamber up to 120° C.

The unit is perfect for the production of product prototypes.

TSAR 3D TS547-PEEK

Another domestic printer, which, according to the manufacturer, allows you to print PEEK plastic. The printer has an impressive build area and supports the ability to print with any plastic available on the market.

The printer stands out with a patented extruder change mechanism that allows you to change the extruder in less than a minute. You can even add a pellet extruder to the printer.

Tractus T850P

The Dutch company Tractus 3D specializes in the development of Delta printers. In fact, the T850P is the only delta printer on the market that prints with engineering plastics. This FDM printer has a build area of 550x476x1140mm and is great for the office. It can process materials such as PLA, PEEK and ULTEM. The T850 extruder heats up to 450°C and the platform heats up to 175°C. According to the manufacturer, the extruder requires less than 90 seconds to warm up to operating temperature. The T850P can print at speeds up to 450 mm per second with a resolution of 10 microns.

In fact, the T850P is the only delta printer on the market that prints with engineering plastics. This FDM printer has a build area of 550x476x1140mm and is great for the office. It can process materials such as PLA, PEEK and ULTEM. The T850 extruder heats up to 450°C and the platform heats up to 175°C. According to the manufacturer, the extruder requires less than 90 seconds to warm up to operating temperature. The T850P can print at speeds up to 450 mm per second with a resolution of 10 microns.

The printer is equipped with a filament dryer, which is also unique to delta printers.

Stratasys F900 Pro

The F900 is an industrial 3D printer manufactured by FDM patent holder Stratasys. Currently the largest PEEK printer. The printer works only with Stratsys materials, but it gives the user guaranteed print quality right out of the box, there is no need to test and configure the printer for each new spool.

The printer software provides a preview of the model. The printer has a built-in video camera with which you can monitor printing in real time. The build chamber size is 914x609x914 mm.

The printer has a built-in video camera with which you can monitor printing in real time. The build chamber size is 914x609x914 mm.

Conclusion

In conclusion, I would like to say that despite the apparent similarity, each printer has its own unique set of functions and purpose. This once again proves that the printer must be selected based primarily on the planned tasks.

If you have any questions about printing PEEK plastic, we will be happy to answer them.

Buying a PEEK printer in our company you get 20% discount on filament. You can choose a printer at the link: https://topstanok.ru/oborudovanie_dlya_3d_pechati/professionalnye_3d_printery/f/materialpechati-2098/

At TopStanok you can order not only equipment for printing with engineering plastics PEEK and ULTEM, but also printing products from engineering plastics. plastics to order. Turning to our company, you get an engineering study, assistance in the selection and operation, as well as an official manufacturer's warranty!

Read our other articles about engineering plastics and PEEK printing:

- Features of printing PEEK plastic

- Printing with PEEK and ULTEM (PEI) engineering plastics

For all questions, our specialists will be happy to advise you, you can contact them in any convenient way:

- By e-mail: Stanok@topstanok.

Learn more