3D printer stops extruding mid print

6 Ways How to Fix Your 3D Printer That Stops Mid-Print – 3D Printerly

I’ve experienced my 3D printer stop extruding halfway in a 3D print, and just start printing in mid-air which can get frustrating. It took a while, but I finally found the solution to fixing a 3D printer that stops extruding mid-print.

Keep on reading to finally get the detailed solution to fix a 3D printer that stops extruding mid-print.

Why Does My 3D Printer Stop Extruding Halfway?

There are many reasons why your 3D printer might stop extruding halfway through a print. It could be due to the filament, incorrect temperature, a clog in the extrusion system and much more.

Below is a more extensive list of

- Filament has run out

- Extruder gear tension stripping filament

- Bad retraction settings

- Low extruder temperature

- Blocked nozzle or extruder pathway

- Extruder motor driver overheated

How to Fix 3D Printer That Stops Extruding Mid Print

1.

Yes, I’m going to state the obvious one to get the solutions kicked off! This kind of thing happens to the best of us, so double check that your filament is still finding its way through to the nozzle.

You also want to make sure there aren’t any obstacles or twists and turns which make it hard for filament to extrude. It would mean your motor has to work harder, and it might not have enough power to supply the filament through.

- If the spool is out of filament then simply insert new filament to continue

- Make the filament pathway smooth and unobstructed

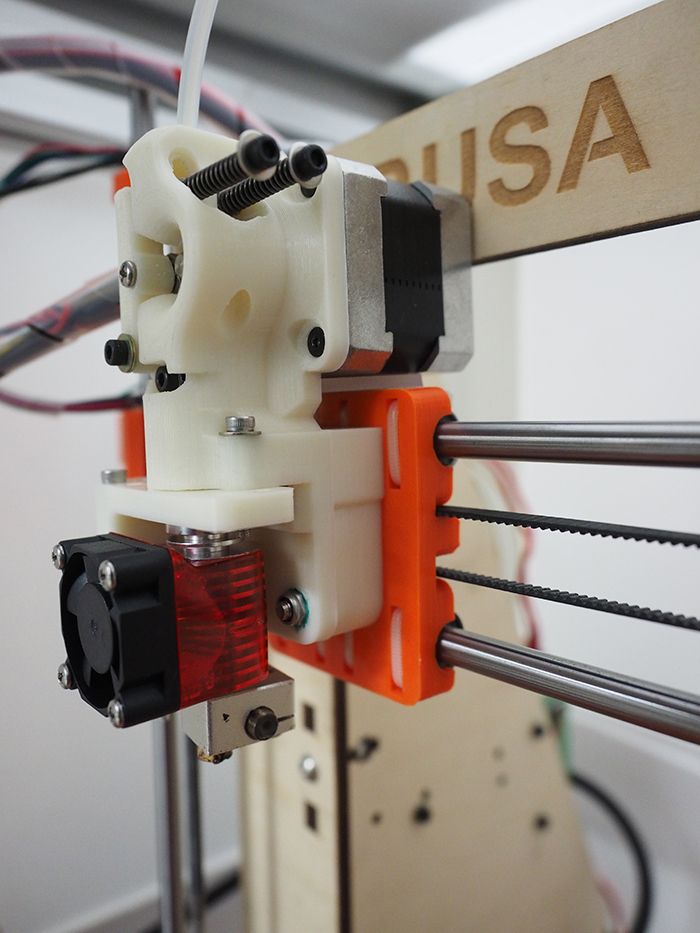

2. Fix Extruder Gear Spring Tension

During a print, the extruder motor continuously spins. The motor tries to push the filament to the nozzle to extrude the filament from the nozzle.

However, when you attempt to print excessively fast, or you attempt to extrude much more filament than the nozzle capacity, the filament may get stripped off.

What can happen here is the extruder motor may crush the filament until there is nothing left for the gear to take hold of. The gear may end up filled or stuck with the plastic and lose the capability to grab more filament to extrude.

To resolve this problem, you may have to check a few things:

- Check if your motor is spinning and not extruding filament

- Undo the tension spring on your extruder, so it isn’t so tight and firm

- Look at the filament to see whether it has been chewed away at, meaning the spring tension is too tight

3. Retraction Settings

Retraction settings are really important to keep extruder working properly throughout your prints. You should look into the retraction settings as they are crucial.

If your retraction speed is too high the stress on the extruder will increase.

Even having a retraction distance too long can cause problems, as the filament gets pulled back a little too far which can cause clogs in your 3D printer.

- The first thing I would do is find an ideal retraction speed and length for your 3D printer

- Now, dial in your retraction settings using a retraction test so you can truly figure out the optimal settings

- Use trial and error with multiple prints until you pick the settings which return the best quality 3D prints.

4. Increase Your Printing Temperature

Temperature settings are also very important in fixing a 3D printer that stops extruding mid-print. There is generally a temperature range that is set for your filament which should be followed.

Within that range you should dial in your settings the same way as the retraction settings.

- I usually start with the middle of the range for printing temperature (205-225°C would be 215°C)

- If you really want to dial it in, run a test print using each temperature from 205°C then increase by 5°C increments

- Compare and contrast each 3D print and determine which print gives you the best quality.

- It should be high enough that it melts and extrudes smoothly

5. Clear Up the Clogged Nozzle

After following the previous steps If the problem persists, and it is slowing down the print speed, your printer nozzles are probably clogged.

A clogged nozzle makes it harder for the filament to come out properly which may result in your stopping extruder halfway.

Usually, the nozzle clog is identified at the beginning of the print job, however, it can get blocked midway through printing too. There can be several reasons for a nozzle clog.

Most common is a build up of dust and residue which gets heated up to high temperatures and gets burnt. This ends up leaving carbon in the extruder and can cause hardened plastic to get stuck in your nozzle.

Other reasons may include an idle nozzle or moisture affecting your extrusion process.

To resolve this issue try the following:

- Clear out the nozzle with a nozzle cleaning needle or wire brush

- You can sometimes clear the nozzle by manually pushing the filament in the nozzle by hand from behind the extruder.

- There are cleaning filaments out there which are commonly used to clean out a nozzle (cold a cold & hot pull)

- Heat up your nozzle to a high temperature and put the cleaning filament through, and it should clear out the clogs.

- If the clog is stubborn, some people have used a heat gun to loosen the material

- At last, if nothing works than just disassemble the hotend and clean the debris by soaking the nozzle in the recommended solvent.

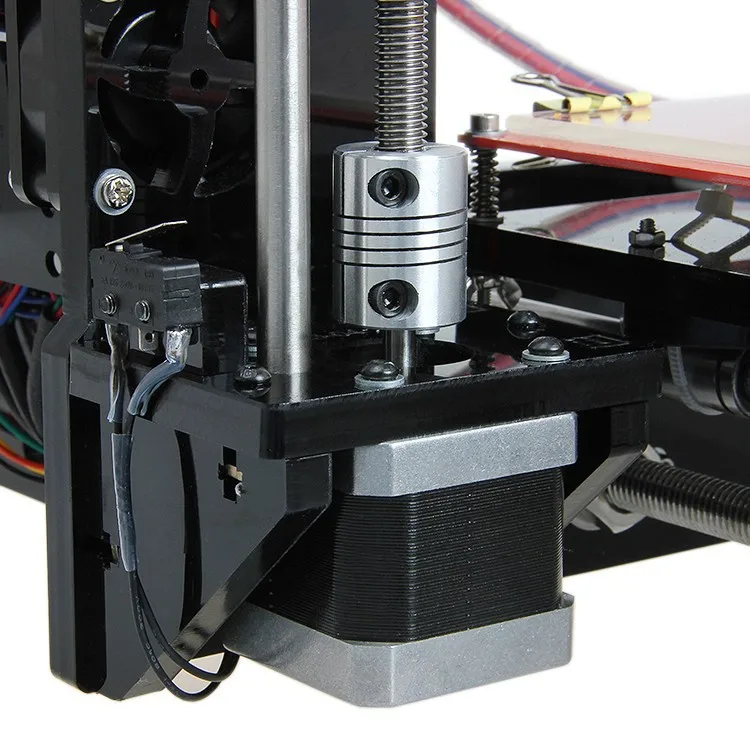

6. Cool Down the Overheated Extruder Motor Driver

If the printer stops extruding in the middle of the print then another reason can be an overheated extrusion motor.

If the printer does not have a good cooling system, the extruder motor gets overheated. The drivers of the extruder motors typically have a thermal cut-off or a decided threshold at which the drivers make the extruder motor stop automatically.

Following will keep the temperature moderate and the extruder motor keeps on working effortlessly without any resistance.

- Stop printing for some time to let the motor rest and cool down

- Make sure that the printer gets resting time in between multiple printing jobs

- Check that your extruder motor isn’t working harder than it needs to with bad filament pathways

How to Fix 3D Print That Fails at Same Height/Point

To fix 3D prints that fail at the same height or point, you want to physically check your printer to see if there are any obstructions or tangles in the wiring or cables which are getting caught on something. A good lubrication of your printer is a good idea, as well as checking that your gantry isn’t screwed too tight.

These are just a few things you can try to fix this issue, as well as more listed below.

I would recommend trying to print a cube with no infill or top layers that has a height above where the failure is. You can do this with a 0.3mm layer height.

If the cube prints fine, you can then try a low-poly print like a Low-Poly Pikachu and see if the problem occurs.

This will allow your printer to quickly reach the observed point of failure so you can view what exactly is happening.

It could be a problem with the tightness of your gantry wheels on the side of the Z-axis.

For specific prints, it could be a problem with not having enough infill material to support the layers above, leading to a print failure.

Another thing you can do is to use an infill that is naturally more dense like the Cubic infill pattern.

I’d also look into increasing your printing temperature to account for any under extrusion because it can definitely cause prints to fail. If you are getting layer delamination or bad layer adhesion, a higher printing temperature can fix that.

One thing that many people do is to 3D print a pre-sliced file like one that comes with the SD card alongside the printer. If these files work fine but your sliced files have those same issues, then you know it’s most likely a slicer problem.

Either updating your slicer to the latest version or using a whole different slicer can fix the issue of 3D prints that fail at the same height. Cura has really good default settings nowadays so it should work fairly good without changes.

Cura has really good default settings nowadays so it should work fairly good without changes.

It’s a good idea to check the physical features of the printer such as the cables, wires, belts, rods and screws. Even a good lubrication around the moving parts can provide a solution to 3D prints from a machine like the Ender 3 or Prusa printers failing at the same height.

Ensure that you tighten screws around the printer because they can loosen up over time.

ConclusionAs you can see, there are a few different ways that you can solve the issue of your 3D printer stopping extrusion halfway through the printing process. Once you identify the cause, the fix is usually pretty easy.

I’m sure after you try out the methods detailed above, you should be well on your way to fixing this issue.

how to solve it – 3D Solved

During the regular and normal use of a 3D printer, there is a wide variety of problems that can appear. Some of them will just delay our job for a few minutes, while others can render our machine completely useless until we are able to solve the issue.

A common and annoying issue is when our printer suddenly stops extruding mid-print. After yelling and crying for a reasonable amount of time, we may proceed to ask ourselves: what’s is causing this problem and how can we solve it?

The most common issues that cause a printer to stop extruding filament in mid-print are a clogged extruder or an overheated extruder motor drive. The extruder could be clogged due to poor calibration, incorrect printing temperature, poor quality of the filament, or the presence of dust and dirt in the vicinity of the printer.

You can unclog the extruder with an acupuncture needle or a guitar string, or by performing a cold pull. In the case of an overheated extrusion motor driver, the solution relies on cooling the component with an always-on fan or by replacing the part with a new one.

We will go into further detail, discuss each cause, how to troubleshoot appropriately, how to solve it, and finally, how to reduce prevent this from happening again.

Table Of Contents

- What causes the extruder to stop in mid-print?

- Out of filament

- Clogged extruder

- Overheated extruder motor driver

- Fixing a clogged extruder

- Manually push the filament into the extruder

- Unclog with a guitar string or an acupuncture wire

- Atomic Method / Cold Pull

- Deep Cleaning

- How to prevent this from happening again

- Reduce printing speed

- Always use good quality filament

- Hotend fan

- PTFE Tube

- Conclusion

- Check out our recommended products section

What causes the extruder to stop in mid-print?

Out of filament

It may seem obvious, but always check that this is not the case before starting to troubleshoot. If the spool has run out, you will need to start up with a new spool before resuming the print.

If you are new to 3D printing, I would recommend you to check the slicer’s estimate of the amount of filament that your model will consume before you start printing any object.

Another way to avoid this problem is to install a filament runout sensor that will pause the printing job and allow you to load a new filament spool without needing to stop the printing completely. The good news is that more and more 3D printer manufacturers are including this feature by default.

It may also be the case that the filament spool got tangled. This can be due to a manufacturing issue but is more probably caused by us. To prevent this from happening you must maintain the filament tension and not let the end of the filament lose when you store it.

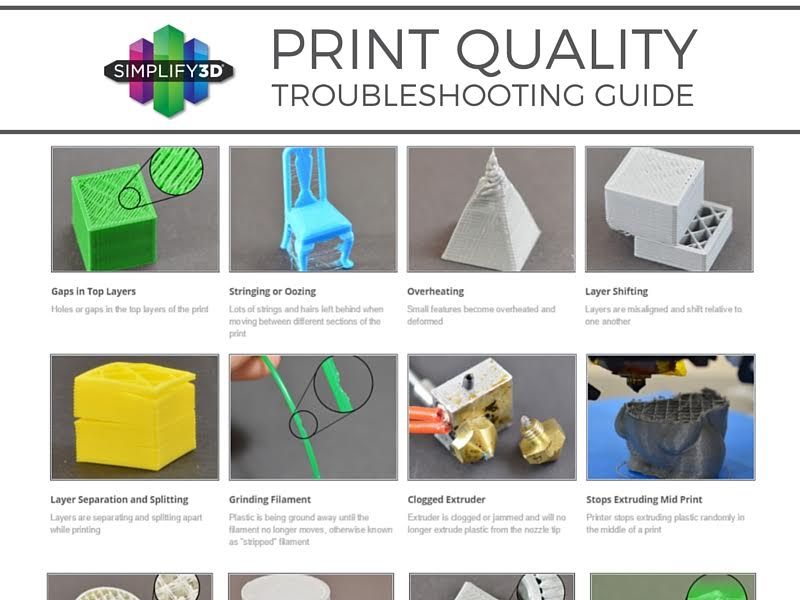

Clogged extruder

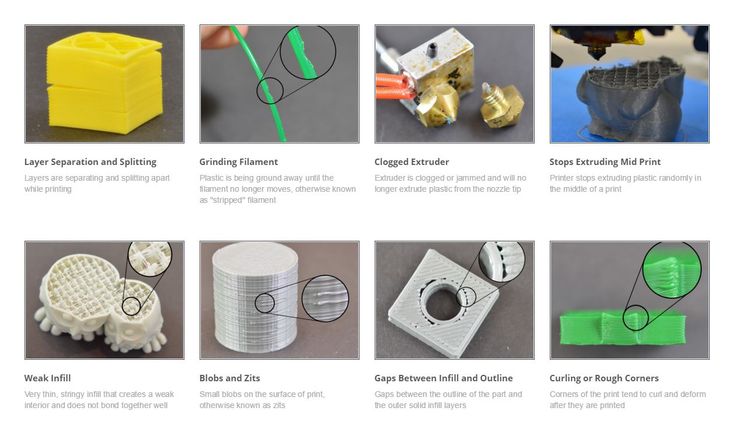

Source: Simplify3d.Now that you know that your machine has not run out of filament, let’s start with the real troubleshooting! Let’s start by checking the things that may lead to a clogged nozzle.

Incorrect nozzle height or poor calibration

This problem is very common, and lucky for us, it is also very easy to fix. If your extruder doesn’t start extruding plastic when the print starts it may be due to an incorrect nozzle height (bed not leveled properly and the nozzle is digging into it).

If the nozzle is too low, there is not enough space between the nozzle tip and the build plate surface. This leads to the nozzle being blocked by the build plate, and thus the filament won’t be able to flow smoothly.

You will notice this problem when the filament does not extrude onto the first or even the second layer, but from the third or fourth layer, the extrusion should be normal. If your extruder stops depositing filament on the successive layers, it is almost definitely not caused by this.

The solution for this problem is to calibrate your 3D printer (Bed Levelling) so that the space between the nozzle and the printing surface is enough (between 0.1mm and 0.2mm for 0.4 mm nozzle) to guarantee a normal filament extrusion. As a rule of thumb, you should be able to place a piece of paper between the nozzle and the build plate.

Incorrect printing temperature

When using PLA plastic, the optimum extrusion temperature can range from as low as 180°C up to 220°C. Attempting to print at too low of a temperature will most likely result in no extrusion at all, and printing at unnecessarily high temperatures can, counterintuitively, be even worse.

Attempting to print at too low of a temperature will most likely result in no extrusion at all, and printing at unnecessarily high temperatures can, counterintuitively, be even worse.

In fact, if you are trying to print at a temperature that is too high for a given material, your filament may simply vitrify in the extruder and therefore clog it.

In a nutshell, I advise to always check the optimal temperature recommended by the filament manufacturer. They can usually be found somewhere on the packaging or even on the spool itself.

On the off chance that you do not find it there, you can always google the brand and pray that someone found the ideal temperature. Not finding this simple parameter easily is also an indication that your filament is, to state it politely, sub-optimal.

Poor quality filament

As we mentioned above, bad factory practices can result in a high probability of issues arising during a print. It means that filaments with a larger diameter or with an inconsistent and imperfect width along the spool can cause problems during the printing process.

A poor quality filament and involuntary contaminants lurking inside the material can accumulate and clog directly inside the nozzle at random intervals.

The main determinants of a filament’s quality are the raw materials used to make the filament, the production line technology, and the control processes that the manufacturer puts in place. It’s rather important to use a quality tested material from a reliable brand. Always check for reviews and opinions before buying a new brand.

However, if you want an affordable and high-quality spool of PLA, get this one from Amazon since it works great.

Dust or dirt in the room

If your printer is placed in a room that is not properly cleaned, dust and dirt can interfere with the operation of the machine. If dust somehow gets into the extruder, it will get carbonized. As time goes by, more dirt will accumulate inside the nozzle. It will impede the correct flow of the material and lead to poor quality prints. Eventually, it may even clog the extruder.

Overheated extruder motor driver

When the extruder motor driver is overheated, it may skip some random steps which may also lead to a clogged nozzle. The first sign of overheating is erratic stepping motor behavior. Typically, this can be recognized by the sounds of the stepper motor suddenly losing power.

It can even result in a thermal shutdown. If this is the case, the extruder motor will not move at all.

If this happens to your printer, you should most definitely turn off the machine and allow the electronics to cool down before trying to print again. To prevent this from happening again, I recommend cooling the printer board with the fan always on.

This could also be caused by a faulty component, in which case I would not recommend you to tinker with solutions unless you really know what you are doing.

Fixing a clogged extruder

The fact that heated filament can smoothly go through a 0.4mm hole and only fail on rare events still amazes me. Regardless of my propensity to be astounded, let’s see how we can fix a clogged nozzle when our machine requires it!

Regardless of my propensity to be astounded, let’s see how we can fix a clogged nozzle when our machine requires it!

There are multiple ways to fix a clogged nozzle. Some will fix the issue temporarily while others should serve as a more definitive solution. Let’s go through each one of them!

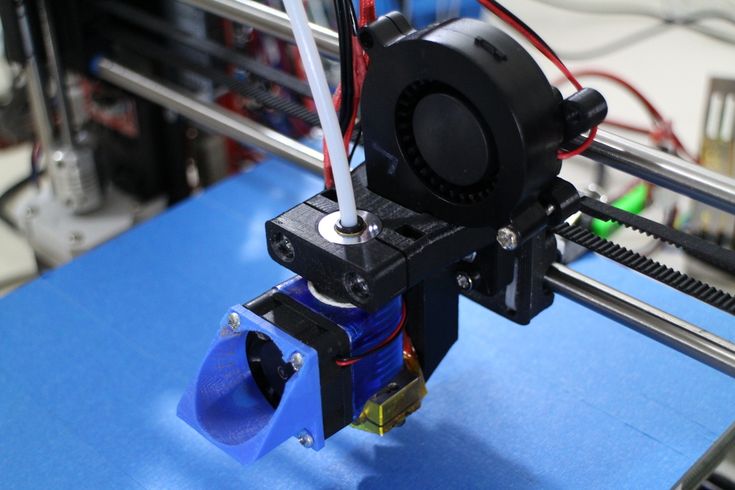

Manually push the filament into the extruder

Rest assured: this nozzle is clogged. Amazingly, almost everything is wrong with this print.Source: Whadda

The easiest way to fix a clogged nozzle is by manually pushing the filament into the extruder. Before doing so, make sure that the hot end is fully heated. Squeeze the extruder arm to compress the spring, push the filament through (not too hard) and verify that it comes out through the nozzle.

This solution may fix your issue, but it won’t guarantee that all residue got extruded out of the nozzle. You could still have some residues inside the nozzle that can lead to an uneven flow of filament, so keep an eye on the quality of the first layers after doing this.

Unclog with a guitar string or an acupuncture wire

To solve de clogged extruder without disassembling the hot-end you can try to clean the nozzle with a stainless steel needle, a fine wire, or even with a guitar string.

The procedure to follow is rather simple:

- Step 1: Heat the hotend to the extrusion temperature of the material that caused the clogging.

- Step 2: Insert the needle/wire/string through the nozzle between 10mm and 30mm deep (a few times).

- Step 3: If a continuous flow is not obtained, repeat the whole process again.

Atomic Method / Cold Pull

If the needle method didn’t work, try the cold pull. For this method, you will need a filament with good thermal resistance such as ABS or Nylon filament.

- Step 1: Heat the nozzle to 220°C (If you just printed with PLA).

- Step 2: Insert a piece of white or light-colored Abs, Nylon, or any strong filament with good thermal resistance.

- Step 3: Push it manually as hard as possible.

- Step 4: Observe if the filament flowing through the nozzle (if the obstruction is total, it may not extrude anything).

- Step 5: Let the printer cool down to around 90°C for PLA and 160°C for ABS. Keep the pressure during cooling.

- Step 6: When the printer reaches the lowest temperature mentioned in step 5, remove the filament quickly and forcefully from the hotend and inspect the semi-fused part of the filament. This must have a little bit of dirt (black spots). Those black spots were causing the blockage.

- Step 7: Cut the dirty part of the filament and repeat from step 2 until the filament comes out clean.

Source: rigid.ink

Deep Cleaning

This method involves disassembling the nozzle at the higher temperature our extruder can reach. Heat the nozzle using a torch, a heat gun, or even the house stove. Eliminate all of the plastic inside and outside of the nozzle.

To check if cleaning really worked, aim the nozzle towards a light source and try to look through the hole. If you see a nice and round circle of light, it means you have cleaned your nozzle. To further clean the nozzle, you can dip your nozzle in acetone (for ABS) or caustic soda (PLA) and let it sit for a night.

How to prevent this from happening again

By now you should be the proud owner of a printer that extrudes filament evenly during the entire job. Now that the event is recent and you still remember how much you hated fixing this issue, you may be willing to read about the things you can do to reduce the probability of doing this again in the near future.

Here are some tips to prevent printer from suddenly not extruding during a print:

Reduce printing speed

When working with flexible materials and or that require higher temperatures (such as Nylon), it is important to respect the speed limit imposed on the 3D printer datasheet.

What will determine the speed of printing in FFF/FDM 3D printers are the properties of the material being used as well as the quality of the components of your 3D printer.

For flexible filaments on Bowden machines, it’s not recommended to go faster than 20mm/sec. For machines with a direct drive, the recommended speed is 40mm/sec for medium and high hardness flexible filaments and 25mm/sec for low hardness flexible filaments.

Always use good quality filament

As mentioned lines above, the filament you use can be the greatest enemy when it comes to the overall health of your hotend. Non-regular material can trap the filament within the tract until the end of the hotend’s stroke. Additionally, a dirty filament can cause small dust remains to form a wall of sediment inside the nozzle cavity or in the hotend throat.

To prevent this problem, we can create a small filter for impurities. Just wrap a clean piece of sponge attached to a plastic clamp around the filament so that the dirt ends up gets cleaned there before getting into the hotend path.

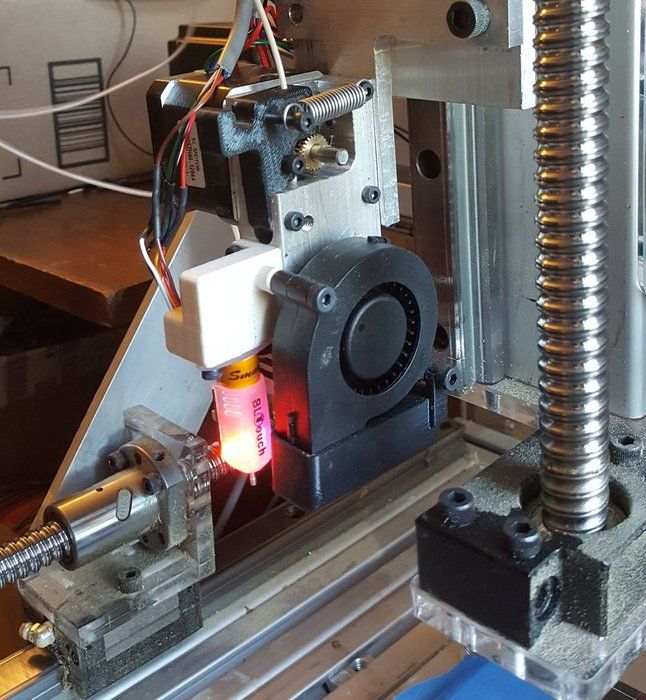

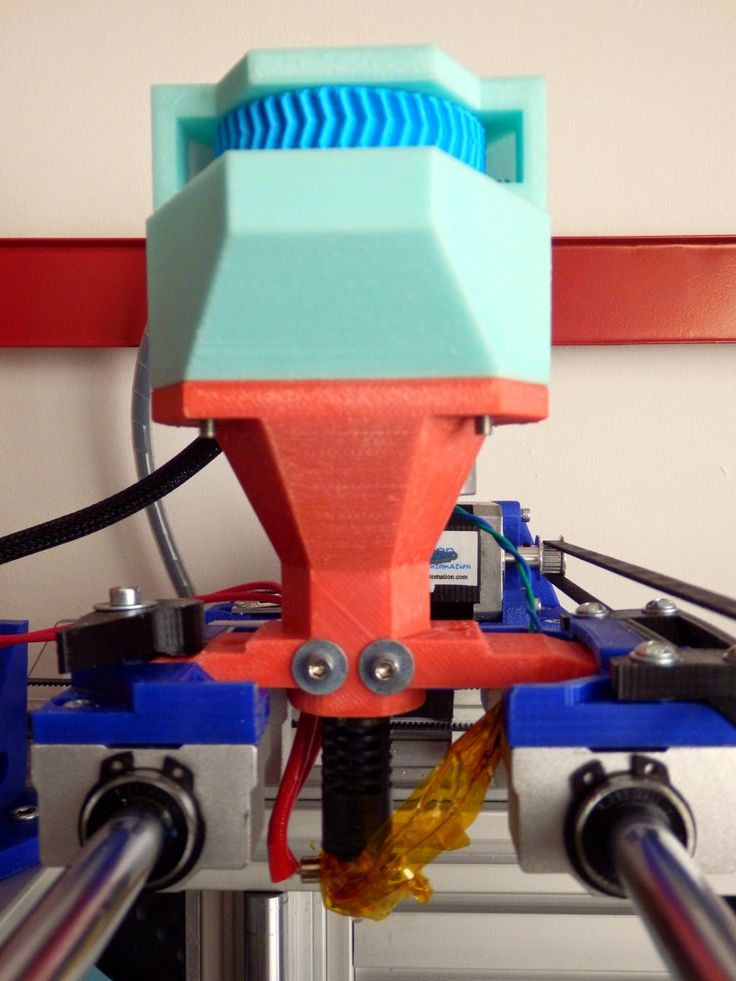

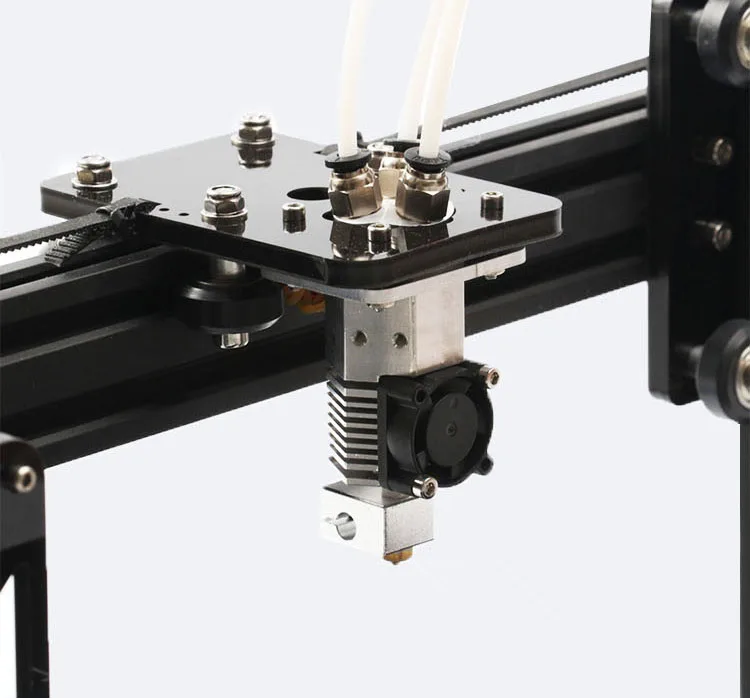

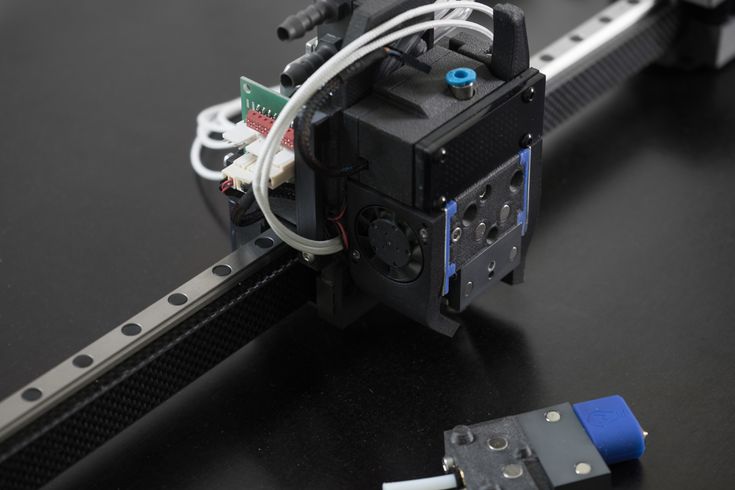

Hotend fan

The hotend fan is crucial for the filament to remain at a stable temperature before being heated by the heating block. If it loses efficiency, the filament will heat up ahead of time, expanding inside the hotend’s body and causing an obstruction. Therefore, you must always keep the fan clean and in excelent condition.

If it loses efficiency, the filament will heat up ahead of time, expanding inside the hotend’s body and causing an obstruction. Therefore, you must always keep the fan clean and in excelent condition.

PTFE Tube

The Teflon tube has a lifetime that is limited by the temperature and its use. The standard 3D printer tube can´t handle temperatures above 240°C. One of the first signs of a faulty PTFE tube are under-extrusion or filament noises inside the extruder. When this happens, replace the PTFE tube in order to avoid clogging the nozzle.

An even better fix would be to purchase the blue Capricorn tube since it can withstand higher temperatures.

Conclusion

A clogged extruder is often a huge headache for many users and even more so when we need to print something as soon as possible. It’s important to guarantee a smooth and continuous flow of the filament into the extruder. This, in addition to lengthening the life of the extruder, will also lead to overall better print quality.

All of the solutions and fixes detailed neither difficult nor expensive. You just need a little patience and resilience to enjoy these incredible machines!

We created a recommended products section that will allow you to remove the guesswork and reduce the time spent researching what printer, filament, or upgrades to get, since we know that this can be a very daunting task and which generally leads to a lot of confusion.

We have selected just a handful of 3D printers that we consider to be good for beginners as well as intermediates, and even experts, making the decision easier, and the filaments, as well as the upgrades listed, were all tested by us and carefully selected, so you know that whichever one you choose will work as intended.

3D printer stops printing randomly during printing

Fockus

Administrator

#1

#1

If your printer extruded normally at the start and then suddenly stops extruding, then this problem is usually due to just a few reasons. We will explain each of them and suggest a way to fix the problem.

We will explain each of them and suggest a way to fix the problem.

Filament 9 out0020

This is obvious: before looking for the reason why the printer does not print, it is extremely useful to make sure that it has something to print. If the coil is over, you need to fill a new one, and then continue.

Filament ground off drive gear

During printing, the extruder motor rotates continuously trying to push the filament into the nozzle so the printer can extrude the plastic. If you're trying to print too fast or extrude too much plastic, the motor can bite into the filament to the point where it grinds everything away and the gear has nothing to grab onto. If the extruder motor is spinning but the filament is not moving, this is probably the cause.

Extruder clogged

If none of the above apply, it is very likely that the extruder is clogged. If this happens during the printing process, you can check the filament itself for dirt, and also make sure that the spool is not dusty. If dusty filament is fed into the nozzle, everything ends up clogged.

If dusty filament is fed into the nozzle, everything ends up clogged.

Extruder motor overheated

The extruder motor is having a hard time when printing. It constantly rotates back and forth, pulling and pushing the plastic back and forth. Fast movements are associated with a high consumption (and release) of energy, so if the printer electronics do not have enough cooling, they can easily overheat. Typically, motors have a thermal protection that turns them off if the temperature gets too high. In this case, it may turn out that the motors along the X and Y axes continue to work and move the extruder head, but the motor of the extruder itself is stopped. The only way to solve this problem is to turn off the printer and let the electronics cool down. It may also be helpful to install an additional cooling fan if the problem recurs.

I also ask you to answer the questions below, so that I can help you solve the problem

1) It can't be that you set printing in the slicer to a certain layer or is there a pause command on this layer?

After cutting, check the model.

2) Does the display show an error like "Termal runaway"?

3) It happens that on a certain layer the wires go off on the engines, of course the reaction would not be the same, but still check the wires and not only on the stepper motor.

4) Try writing gcode to another sd card.

Last edit:

For all questions, contact PM

SeregaWild_Dragon

Newbie

#2

#2

hello. none of the methods work. I started printing, then suddenly on the 1st or 2nd layer the extruder motor simply stopped spinning. I restart printing - deja vu.

none of the methods work. I started printing, then suddenly on the 1st or 2nd layer the extruder motor simply stopped spinning. I restart printing - deja vu.

Fockus

Administrator

#3

#3

SeregaWild_Dragon wrote:

hello. none of the methods work. I started printing, then suddenly on the 1st or 2nd layer the extruder motor simply stopped spinning. I restart printing - deja vu.

Click to expand...

Which printer?

For all questions, contact PM

Share: Vkontakte Odnoklassniki Mail. ru Facebook whatsapp Telegram Viber Skype Email Link

ru Facebook whatsapp Telegram Viber Skype Email Link

Problem with extrusion? You are here / Habr

Do you know what a real universal fakap is? Recently, I fully felt it in my skin. I hope the text will be useful for novice 3D printers, since the problem is not an isolated one, but it was not easy to find a solution, and even I, an old atheist, almost believed in miracles. Forgive me for the presentation, since I am not a writer or a blogger, but a simple engineer - a firm engineer.

In addition, the text is intended for people with minimal experience with 3D printing.

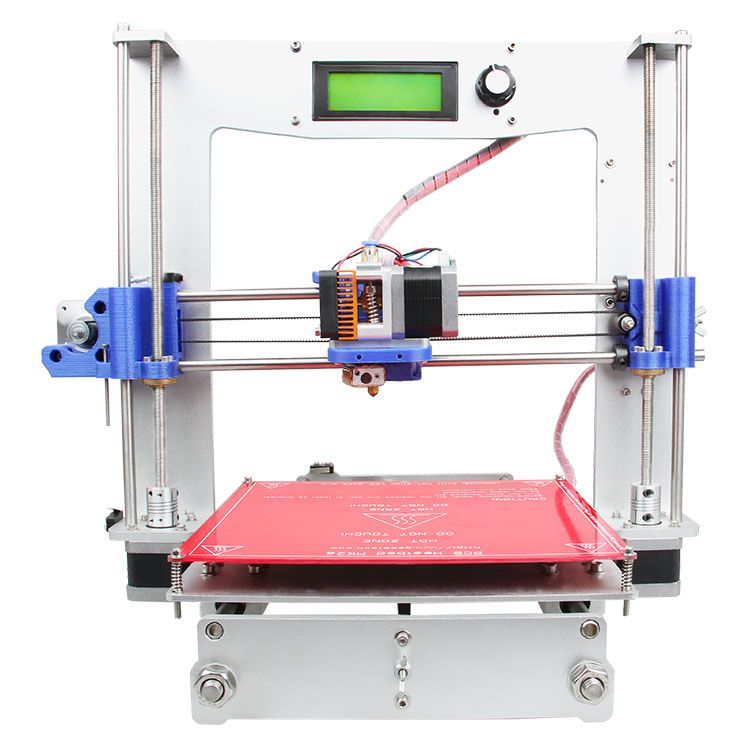

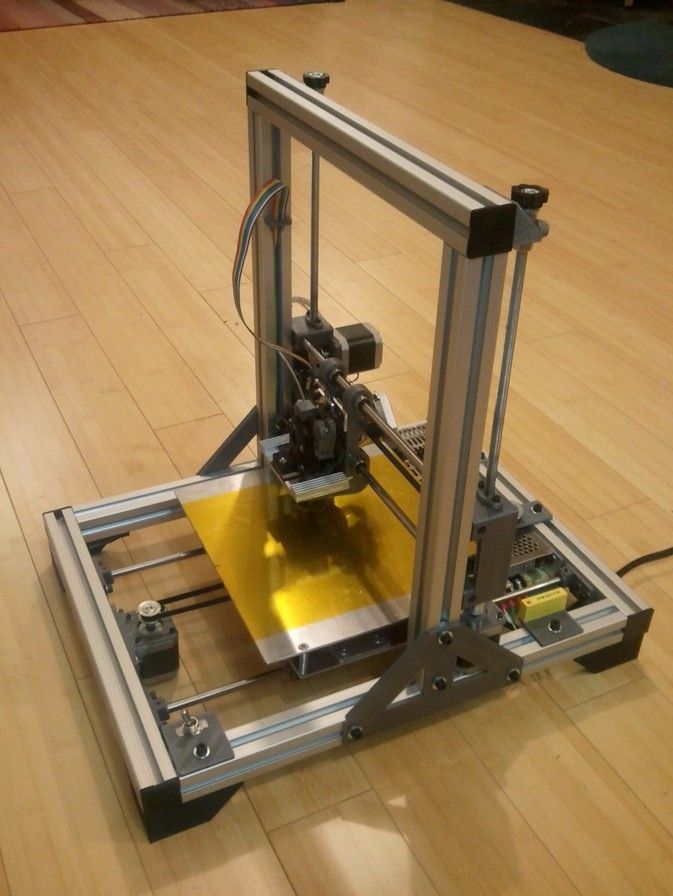

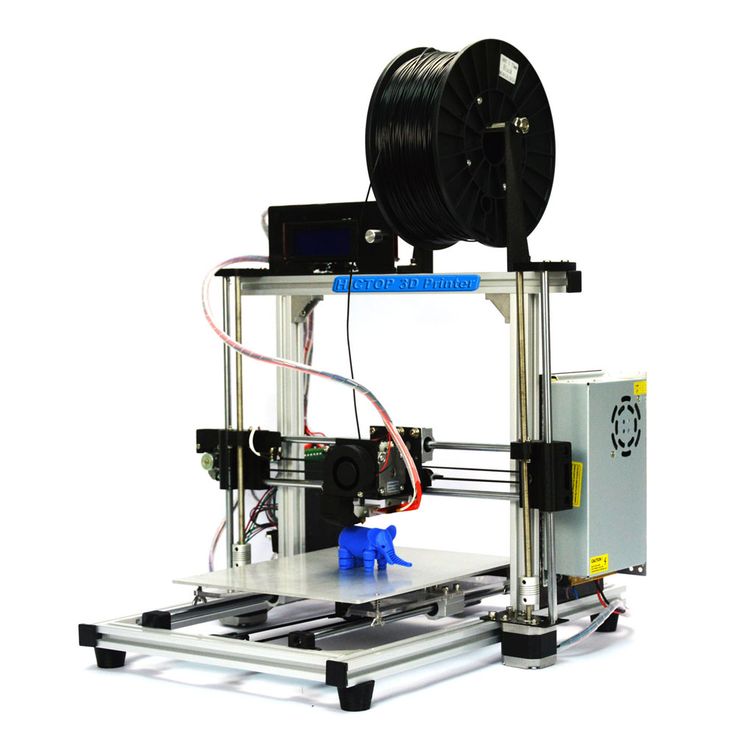

Solely for the reason not to inflate the article and not explain the purpose of various details and slang words. I'll start with the backstory. A little less than a year ago I bought myself an inexpensive 3D printer. One of the most popular (not as advertising, but to make it clear what it is about) is Ender 3. The assembly was simple, there are many recommendations on the Web. Of course, assembling it according to the instructions, I would have received a non-working unit, but after “smoking the manuals”, I managed to complete the first test print for 5 plus for such a simple machine! Everything was fine up to a certain point. But then it began ...

The assembly was simple, there are many recommendations on the Web. Of course, assembling it according to the instructions, I would have received a non-working unit, but after “smoking the manuals”, I managed to complete the first test print for 5 plus for such a simple machine! Everything was fine up to a certain point. But then it began ...

If you're interested, welcome.

For those who are too lazy to read:

The extruder pressure roller lever has broken.

The printer was needed for a specific task - printing non-standard cases for various small-scale electronic crafts. After I played enough with ready-made models and provided my daughter with various little animals and little men, I mastered FreeCAD “on top” and began to do useful things. Everything went well ... By and large, the print was launched "from the foot", set it and went to bed. Unless the first layer controlled. But the first "bells" appeared.

But the first "bells" appeared.

Somewhere part of the layer will fall out, somewhere the plastic will burn. I calibrated the table “according to a piece of paper”, sinned on the plastic and the nozzle, changed the settings in the slicer, plastics and nozzles - the problems disappeared. Bye…

At one "wonderful" moment, I ran into an "insoluble" problem. The end of March, a smooth transfer to a remote location (I successfully moved from the Moscow region to Minsk 2 years earlier), I decided to assemble a separate computer for work from what I had. In the stash was a good motherboard, processor, a couple of monitors and 2 cases. One is a huge full-fledged ATX, the other is a barebone. I decided to collect in a small one, so that it takes up less space. The case is non-standard. With cradle for 1 CD drive and 3.5 inch hard drive. I found 3x 2.5 SATA SSD of small volume, for the system and one is enough "more than" and 1x for 1Tb 2.5 HDD.

All this "living creatures" was placed in a large building on a makeshift adapter from old bank cards. But, since a printer has already appeared, it would be nice to use it. I created a holder model, put it on print and went about my business. When I looked at how it prints, I saw only noodles ... From that moment on, the path of repair went, 2 months long. I will try to paint on the shelves, what helped and what did not, and what was the root cause.

But, since a printer has already appeared, it would be nice to use it. I created a holder model, put it on print and went about my business. When I looked at how it prints, I saw only noodles ... From that moment on, the path of repair went, 2 months long. I will try to paint on the shelves, what helped and what did not, and what was the root cause.

Step 1 Adjusting the rollers {prevention is always good}

Once again, I set up the table “on a piece of paper”, launched it - the plastic does not stick. I changed the settings, plastics - without result. Instead of sticking to the table, it bends onto the nozzle. When I rechecked the nozzle gap settings, I found that the rollers were loose and the table had play by almost 5mm at the edges. It's strange how he used to print at all before ... It seemed that the reason was found. Adjusted. But it almost didn't get any better. I printed the part with grief in half, but the quality left much to be desired:

Obvious gaps in print are visible.

And here are the bundles…

Step 2. Song of Ze[l]de {not bad when everything goes like clockwork}

The first thing that came to my mind was the problem in the Z-axis drive. And all the advice on the forums on a problem similar to mine pointed to this. Took it apart and checked for smoothness. The nut bit the thread a little and found a “bug” in a couple of rollers. When moving without the drive screw, the "X" rail stuck a little for 1 turn of the roller. I ordered a drive nut, rollers (spare parts are always good, but that was not the point). Using the method of combinatorics and some kind of mother, I distributed the axle rollers according to the loads so that the defective ones had minimal effort. The "bite" is gone. Cleaned and lubricated the drive screw. Adjusted the position of his engine. As a result, a light touch of a finger is enough to lower the carriage down. The result is negative.

Step 3. Slicer {tuning, but not solving the problem}

Updated slicer. Moreover, the new release just had an improvement related specifically to the print quality for my printer. Played around with flow and speed, layer thicknesses, etc. Even successfully printed some simple small cases and parts. But the settings were frankly wild: flow - + 10%, speed - -5%. Considering that after assembly, excellent printing was obtained at the “default” settings. The problem of printing complex parts has not disappeared ...

Moreover, the new release just had an improvement related specifically to the print quality for my printer. Played around with flow and speed, layer thicknesses, etc. Even successfully printed some simple small cases and parts. But the settings were frankly wild: flow - + 10%, speed - -5%. Considering that after assembly, excellent printing was obtained at the “default” settings. The problem of printing complex parts has not disappeared ...

Based on this article: https://habr.com/ru/post/494058/ I made a brushing timer for my daughter. I am preparing a separate description for it. Spoiler: eight-legged controller, firmware - 119 assembler commands.

Step 3. Extruder {and happiness was so close...}

Logic dictates that since there are no problems with the geometry and drives of the axes, there must be something with the feed. Removed the filament feed gear and cleaned it. No visible wear is observed. I returned it to its place, slightly shifting along the flight, to even out wear. The result is 0. Eh, if I look a little to the right, I would save a month of nerves and $ 200.

The result is 0. Eh, if I look a little to the right, I would save a month of nerves and $ 200.

Step 4. Checking the SD drivers {no comment}

Excellent geometry, no problems with the mechanics. At the time of the first assembly, everything was much worse. A bunch of studied materials, improvements and settings, and the result is zero. I do not believe in miracles, electronics remained. Moreover, members of the forum often complain about burnt drivers. It is clear that a completely burnt out shoulder of the bridge can be detected “by eye” immediately, I thought about a “floating” malfunction. After all, the plastic lays down normally, then - passes, the thread becomes thinner, hair and other charms. I ordered an improved control board on ARM, but in order not to waste time, I decided to check the existing one. I removed the board, the Z-axis motor as an inductive load, assembled the stand on the table, set the temperature of the hot end with a resistor so that the extruder could be rotated. I looked at the waveforms on the SD coils. Everything is great. He warmed the driver with a hairdryer (a crystal defect or unwelding sometimes manifests itself), mechanically acted on the driver IC, cooled propane with butane (gas for lighters). Note. It cools quite well to -20, it is not necessary to buy an expensive freezer for this. Everything is great. Failures are not visible!

I looked at the waveforms on the SD coils. Everything is great. He warmed the driver with a hairdryer (a crystal defect or unwelding sometimes manifests itself), mechanically acted on the driver IC, cooled propane with butane (gas for lighters). Note. It cools quite well to -20, it is not necessary to buy an expensive freezer for this. Everything is great. Failures are not visible!

Step 5. Firmware update No, I am sure that miracles do not happen. There are bugs, glitches, tricks, lack of information, subjective perception of reality, after all. But not miracles! But how to explain that, with good mechanics and electronics, printing behaves extremely strangely? The Chinese made a bookmark in FW in order to additionally barry with boards? It is done elementarily, but, I think, they would have been discovered long ago and a white fluffy fox would have come to the trademark. Bug in the firmware? Everything is possible, only somehow it manifested itself strangely.

EEPROM settings wrong or FLASH* "bugging"? Most likely. Okay, since the board is on the table, nothing prevents it from being reflashed. Updated to "vanilla" Marlin 1.1.9, collected everything back. The result is that the miracle did not happen.

Okay, since the board is on the table, nothing prevents it from being reflashed. Updated to "vanilla" Marlin 1.1.9, collected everything back. The result is that the miracle did not happen.

*Purely theoretical substantiation of the possibility of connection of the problem with FLASH memory:

Let's say we have the following code fragment:

…

const uint8_t step = 0x18;

…

position += step;

…

At each iteration, the “step” setting is added to the current position. Since the program is executed on a microcontroller (MK), the code and constants are placed in ROM and can only be changed during an external programming procedure (we will omit the possibility of reprogramming the FLASH memory by internal means of the MK). This procedure is performed once by the manufacturer. Now 2 important points: the controller processor reads commands and constants from ROM every time, forget about caches, Atmega does not have them. That is, if the loop went through 1000000 iterations, then the constant was read the same million times. With each read, FLASH degrades a little. I don’t know what the critical reading threshold for NOR is, I think it’s tens of billions, but TLC NAND already degrades quite well after 10-20K readings ... The second point is not the fact that our narrow-eyed friends did not use rejected controllers. I actually got one like this. PICs. Not soldered, but there are strange marks on the case. FLASH was not erased, at 3.6V they did not want to be erased or flashed. I had to raise it to 5V, after which the recording / verification began to take place. Let's say our constant was written to a defective cell. While the device is new, 0x18 was read stably. But from time to time (and for Atmega, the guaranteed time for saving data is not the longest) and degradation, at some point it began to read not 0x18, but 0x08. Not every time, but still. I know, rather than degrading 1 to 0, but vice versa, this is just an example.

That is, if the loop went through 1000000 iterations, then the constant was read the same million times. With each read, FLASH degrades a little. I don’t know what the critical reading threshold for NOR is, I think it’s tens of billions, but TLC NAND already degrades quite well after 10-20K readings ... The second point is not the fact that our narrow-eyed friends did not use rejected controllers. I actually got one like this. PICs. Not soldered, but there are strange marks on the case. FLASH was not erased, at 3.6V they did not want to be erased or flashed. I had to raise it to 5V, after which the recording / verification began to take place. Let's say our constant was written to a defective cell. While the device is new, 0x18 was read stably. But from time to time (and for Atmega, the guaranteed time for saving data is not the longest) and degradation, at some point it began to read not 0x18, but 0x08. Not every time, but still. I know, rather than degrading 1 to 0, but vice versa, this is just an example. So, as long as the correct number is read stably, the movement occurs correctly, but when failures occur, an incorrect setpoint is added to the result, which leads to feed failures. This is the simplest and most unlikely example. There may be other glitches, for example, in the addition command, the source of R6 will change to R7. The assembler instruction remains valid, the processor will execute it, but the result will be incorrect ...

So, as long as the correct number is read stably, the movement occurs correctly, but when failures occur, an incorrect setpoint is added to the result, which leads to feed failures. This is the simplest and most unlikely example. There may be other glitches, for example, in the addition command, the source of R6 will change to R7. The assembler instruction remains valid, the processor will execute it, but the result will be incorrect ...

Step 6. Flush the “throat” {keep your head cool and the hot end clean, I recommend doing this immediately after buying a printer}

A gift from "heaven" was a link on one of the forums to a video from the manufacturer. There they honestly admit that not all hotends are equally useful, that is, they are well assembled.

Teflon tube not fully pressed in, cut uneven. The consequence is the formation of a cork and the extruder cannot normally advance the plastic. Here it is - my case!

Abnormal flow and retract values, everything converges. Despite late Saturday evening and a visit to a brasserie, I decided to check it out. Exactly. Guana is unmeasured there, right down to the remnants of the plastic that I used to print a month ago (the same green holder). Very likely to win! I cleared the “throat”, cut the tube evenly, pressed it in as far as it would go, also fixed the second end of the tube more tightly, many people use electrical tape, but I wound a little 0.7 wire, which allows you to freely unscrew the holder:

Despite late Saturday evening and a visit to a brasserie, I decided to check it out. Exactly. Guana is unmeasured there, right down to the remnants of the plastic that I used to print a month ago (the same green holder). Very likely to win! I cleared the “throat”, cut the tube evenly, pressed it in as far as it would go, also fixed the second end of the tube more tightly, many people use electrical tape, but I wound a little 0.7 wire, which allows you to freely unscrew the holder:

And here is the “killed” end of the tube, you can see that it was cut crooked:

The model is cut into layers with default settings. The seal ... The border went, the contour went, there is no snot during the retract. Hooray!!! Victory!!! I was about to write an article so that others would not suffer, but ... A complete fiasco. Thinning and tearing of plastic, gaps in printing. Already ready to give up. The wife encourages, but you throw it away, buy a new one! I can't do that. There must be a reason. That's just where??? There were no more reasonable (and censored) thoughts ...

There must be a reason. That's just where??? There were no more reasonable (and censored) thoughts ...

Remark about cleaning the “throat”:

All operations with the hot end are done only “hot”, otherwise there is a chance to break everything. After warming up, the first step is to remove the nozzle and clean it from the remnants of the “cork”. I did this by heating the nozzle on a gas stove flame and carefully removing the plastic. Didn't clean the inside. Then, also on a heated hot end, the tube clamp is unscrewed. He can only move up. After retracting the latch, the tube should be carefully, but with force, removed from the “throat”. We remove all the clamps, since the damaged end still cannot be saved, carefully, back and forth, we clean out all the dirt, constantly removing it from the tube. As a result, the tube should easily pass through the throat through and through. The assembly was performed by the FIFO sequence. First, I installed the nozzle, then the tube retainer in the hot end, but did not tighten it completely, leaving about 1 turn. The worn part of the tube is cut off at a right angle and inserted into the throat as far as it will go. After that, the holder is tightened and the second one is installed, on the opposite side of the "teflon".

The worn part of the tube is cut off at a right angle and inserted into the throat as far as it will go. After that, the holder is tightened and the second one is installed, on the opposite side of the "teflon".

Step 7. Feed Calibration {with good mechanics, most likely not needed unless after replacement of drive parts or flashing}

In the instructions for upgrading to the "vanilla" Marlin, it was said that for the factory printer all settings are ideal, but the accuracy of the plastic feed may be slightly off. Okay, let's calibrate. He pulled out the plastic, warmed up the hot end (there is a lock in the firmware, it does not allow you to move “E” to a cold one). I unscrewed the tube from the feed mechanism, cut the plastic flush and executed the 300mm extrusion command. I have a ruler at 350. Extrusion lasts long enough, upon completion, I measured the length of the released filament and could not believe my eyes 226mm. I understand the difference of 3-5%, but not 25%! I'll try another plastic. ..

..

Note. I saw how the feed is regulated according to the marks on the bar marked with a marker, But with cutting, IHMO, more precisely.

Preparation for test extrusion:

After extrusion:

We measure with a ruler, in my case (after repair) it turned out 292mm. Next, go to the menu: control / motion / step mm, see how many steps per mm are set for the extruder. In my case it is 93. Let's do a simple calculation:

>>> (300*93)/292

95.54794520547945

Change the setting and save the setting. Re-extrusion - error at the measurement level.

Step 8. Victory!

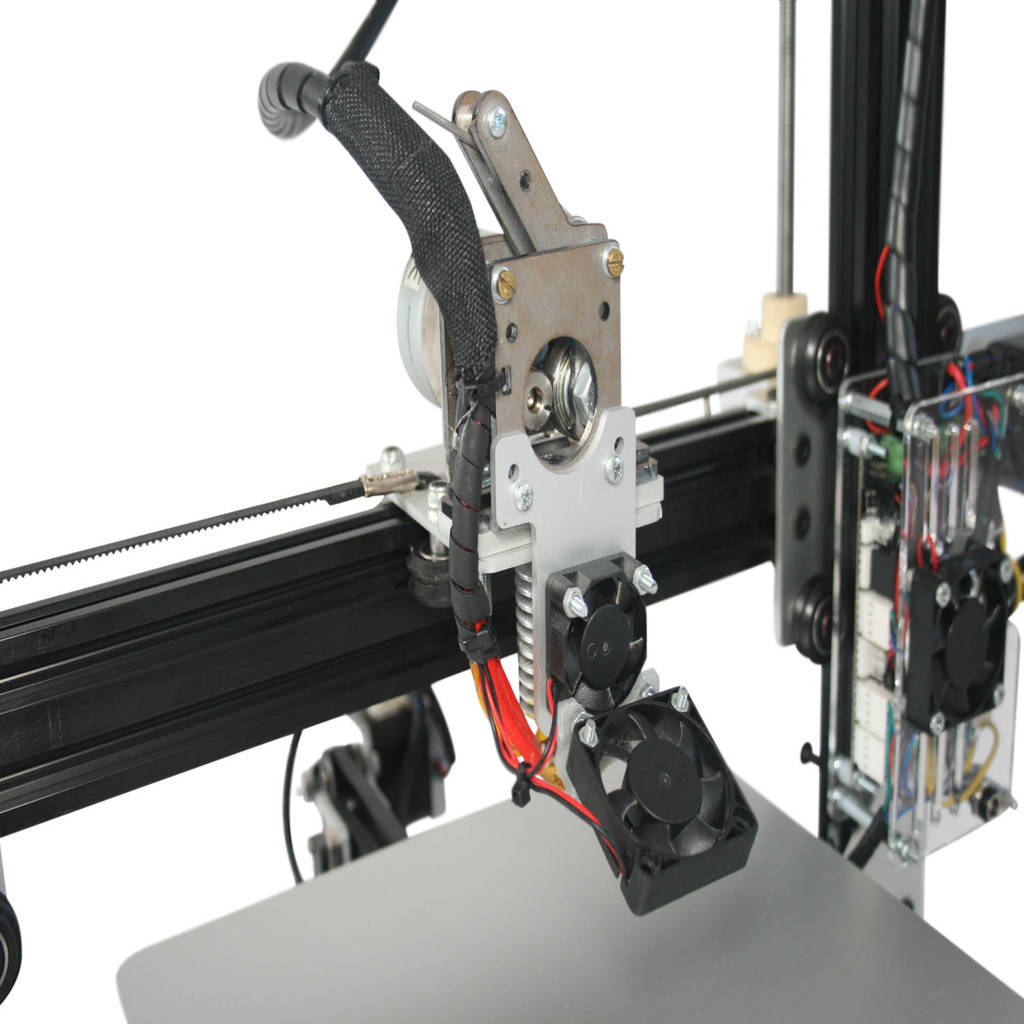

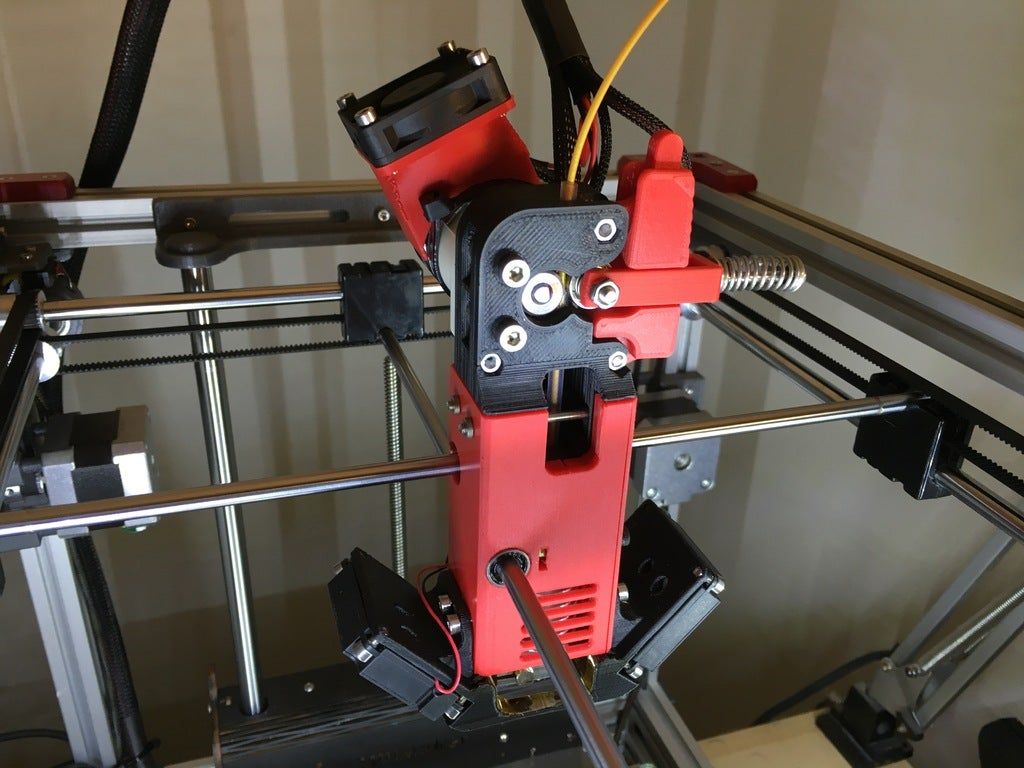

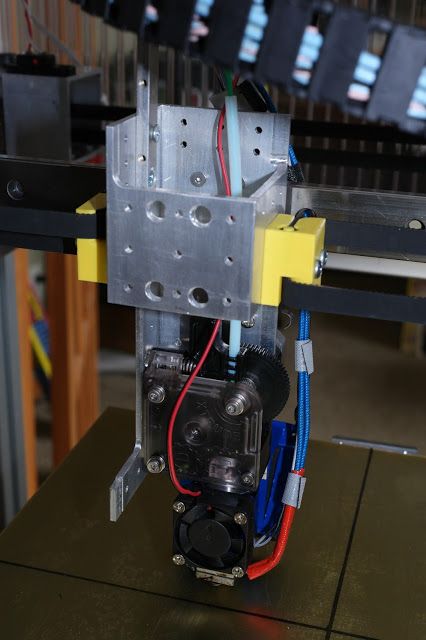

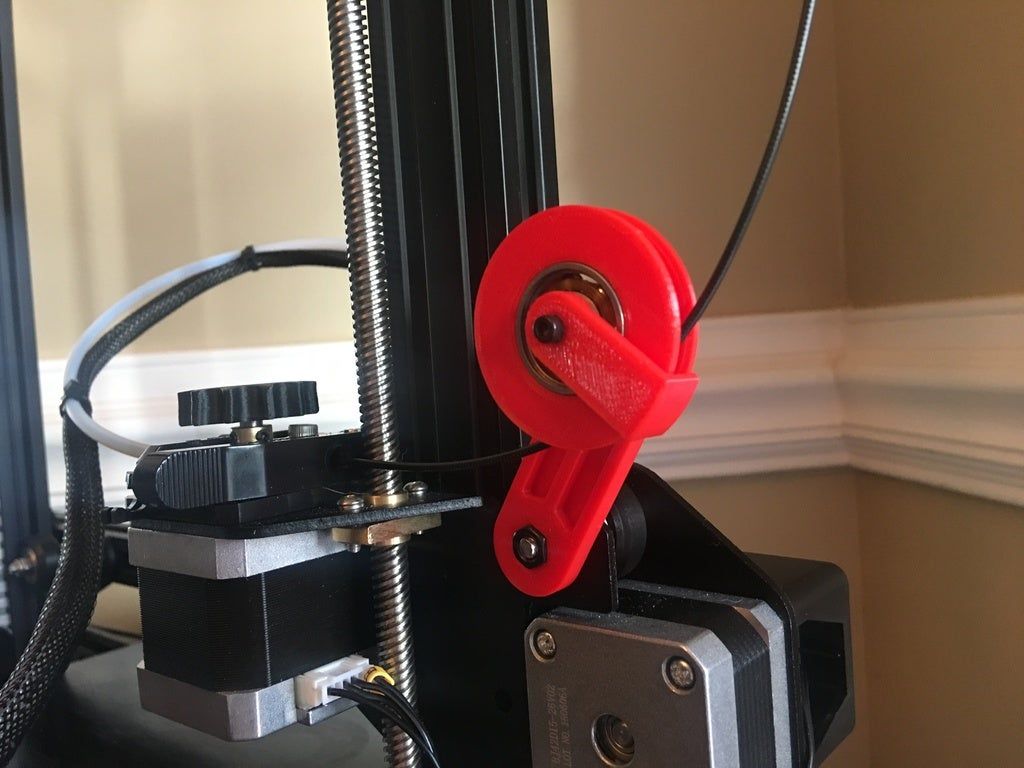

At first I checked for PETG, I decided to change to PLA. The first one I overheated a little during drying, I attributed the inadequate spread to possible sticking on the coil. Cutting, extrusion. And nothing. Plastic is not supplied at all. The axis of the drive rotates slowly, but the screws show that there is movement. I looked, the bar did not lie correctly between the gear and the pressure roller. Okay, I'm correct. That the roller dangles a little. Gotta pull it up. And fig! Here he is the culprit of all my troubles:

I looked, the bar did not lie correctly between the gear and the pressure roller. Okay, I'm correct. That the roller dangles a little. Gotta pull it up. And fig! Here he is the culprit of all my troubles:

The pressure roller arm is cracked. At the same time, the clamping force remained sufficient for partial advancement of the rod. Gear marks remained and the pressure roller rotated.

Accordingly, all games with the pressure spring setting were unsuccessful. The slips of the bar were invisible to the eye, and the crack could not be seen on the assembled mechanism. All! Engineer's ecstasy received! The lever was glued together, an aluminum mechanism was ordered, a spare was printed just in case (if it breaks while I wait for a new one). Here is a link to the model. Of course, it’s unpleasant to spend so much time and money over such a trifle, but it helped me dive much deeper into the processes of printing and catching glitches.

Actually, the first part after repair.