3D printed house california

Mighty Buildings - Beautiful, Sustainable Homes for All

Welcome to

Stop choosing between speed, design, & protecting the planet.

Build with us

Faster construction time

Less waste generated by 3D printing

More tensile and flexural strength vs. concrete

Combining 3D printing, robotics, & material science

View technology

Mighty Kit System

Pre-built, factory-made 3D printed panels can be customized to any plan. They are assembled onsite, cutting construction times in half.

Learn more

Material Science

Our patented Light Stone Material quickly cures into a stone-like composite and has 4x the tensile and flexural strength of concrete while weighing 30% less.

Learn more

Of production operations automated

Mighty Factory

We build panels in our factory and deliver them onsite ready to assemble, saving time and emissions.

Learn more

Recycled materials

Less waste produced per home

Homes built to reduce and withstand the effects of climate change

3D printing and our composite stone material, made from 60% recycled resins, allow us to build walls with less material and eliminate 99% of waste.

Sustainability

Developing for diverse communities and environments

We bring beautiful homes to market 2x faster. Customizable panels can be arranged in nearly any plan.

Mighty developments

Faster construction

Cut construction times in half

Beautiful homes, healthy planet

We are transforming residential construction through fast and versatile modern design that reduces time, labor, and waste.

About us

Design capabilities

Our kit system design quickly delivers almost any floor plan and our 3D printing capabilities offer unique exterior design possibilities.

Time and labor savings

Speed through design and assembly with less skilled labor and get faster returns on investment.

Environmental benefits

Our walls made from material composed of 60% recycled, sustainably sourced components, and produced with 99% less waste.

Why Mighty Buildings

"It is always challenging to introduce a new technology and a new product to the market. But with Mighty Buildings, it's a company filled with very smart people who are forward thinking and are working to solve problems everyday. And that's what I appreciate about working with Mighty Buildings… this is the Tesla of Housing!"

Basil Starr

CEO & Founder of Palari

"Out of all the modular, offsite fabrication solutions we are currently collaborating with, Mighty House is the most innovative. The Mighty House concept and product is incredibly exciting and is well placed to disrupt the construction industry across the residential sector."

David Herd

Managing Partner at BuroHappold

"UL has worked with Mighty Buildings since 2017 to develop a program for the evaluation of their 3D printed building unit and has successfully obtained the first UL certification for a 3D printed building unit and the first UL Evaluation Report of a 3D printed wall construction. "

"

Howard Hopper

FPE, Regulatory Services Manager at UL

Featured news

View all

November 4, 2022

Mighty Buildings completes 3D-printed net-zero home in southern California

Read more

June 22, 2022

3D printing can help the construction industry become carbon-neutral. Here's how

Read more

April 13, 2022

Airbnb Alums Join House 3D Printing Startup Mighty Buildings

Read more

Build a mighty career

Help us tackle housing and climate crises by building sustainable, beautiful, and mighty homes.

Join our team

Better for people and planet

You don't need to choose between speed, quality, design and protecting the planet, together we can build a better future for the construction industry and the environment.

Build with us

Mighty Buildings - Technology

Automated production

Less construction waste

Recycled printing material

Mighty Kit System

Precision engineered to deliver the future of construction, our patented Mighty Kit System™ is built in our automated factory with fewer parts and materials than other prefabricated solutions. Panels arrive onsite ready to install and can be assembled with fewer labor hours and crew.

Panels arrive onsite ready to install and can be assembled with fewer labor hours and crew.

3D printed panel

Printed using our patented composite stone material, and coated with epoxy based primer and acrylic paint. No air/water barriers.

PU foam insulation

Near zero waste insulation process and customizable R-value.

Steel frame

Provides an added layer of strength to our walls and load bearing capacity.

Material Science

Our patented Light Stone Material is stronger and lighter than concrete, fast curing and flexible to support modern design, and reduces environmental impact.

Sustainability

Tensile and flexural strength vs. concrete

Elevated quality

Our 3D printed exterior finishes are of the highest quality, and feature head-turning parametric designs.

Developments

Mighty in strength

Fast-curing, stone-like material has 4x tensile and flexural strength and 30% less weight than concrete.

Build with us

Kind to the environment

Our material produces less Co2 than concrete, and is composed of 60% recycled components.

Sustainability

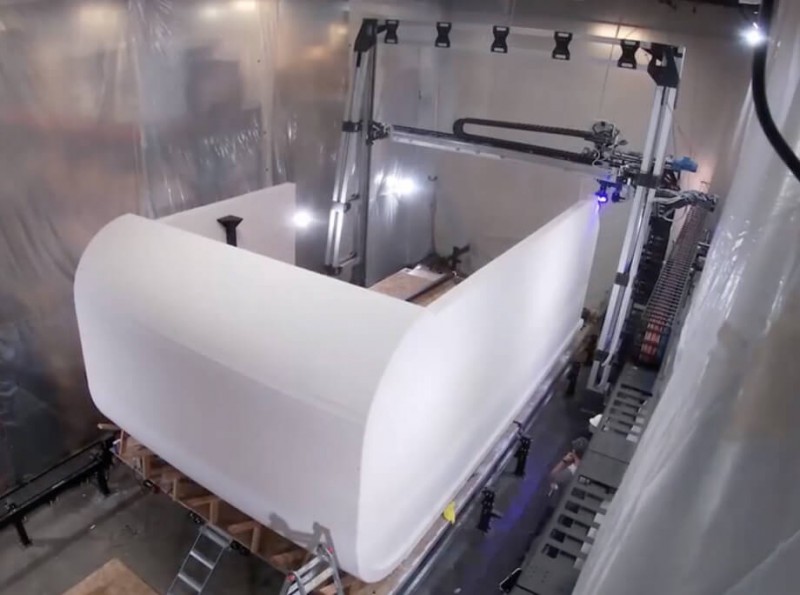

Mighty Factory

We remove conventional production limits with automated off-site factory 3D printing, quick delivery and use of Light Stone Material instead of concrete.

Advanced 3D printing and material

Proprietary composite stone and 3D printing method support efficient, sustainable and uniquely creative design.

01 / 04

Automated precision milling

Our automated milling reduces manual effort, smoothing edges or entire surfaces and creating textures or even engravings.

02 / 04

Efficient insulation

Insulating panel interiors with PU-foam, produced with a near zero waste process, leads to superior energy efficiency.

03 / 04

Extreme weather protective coating

Robotic coating application increases weather resistance. Customers can swap colors without impacting manufacturing.

Customers can swap colors without impacting manufacturing.

04 / 04

Featured news

View all

November 4, 2022

Mighty Buildings completes 3D-printed net-zero home in southern California

Read more

June 22, 2022

3D printing can help the construction industry become carbon-neutral. Here's how

Read more

April 13, 2022

Airbnb Alums Join House 3D Printing Startup Mighty Buildings

Read more

Build a mighty career

Help us tackle housing and climate crises by building sustainable, beautiful, and mighty homes.

Join our team

Better for people and planet

You don't need to choose between speed, quality, design and protecting the planet, together we can build a better future for the construction industry and the environment.

Build with us

built 10 houses in one day in Shanghai

Archive

on which in one day it will be possible to print a multi-storey building.

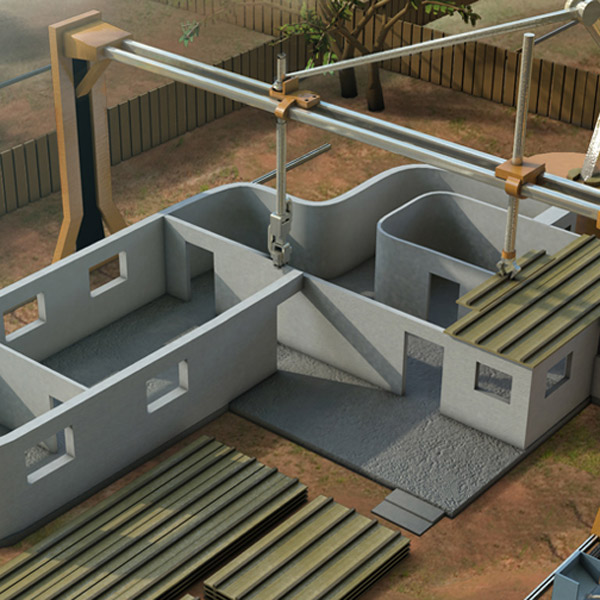

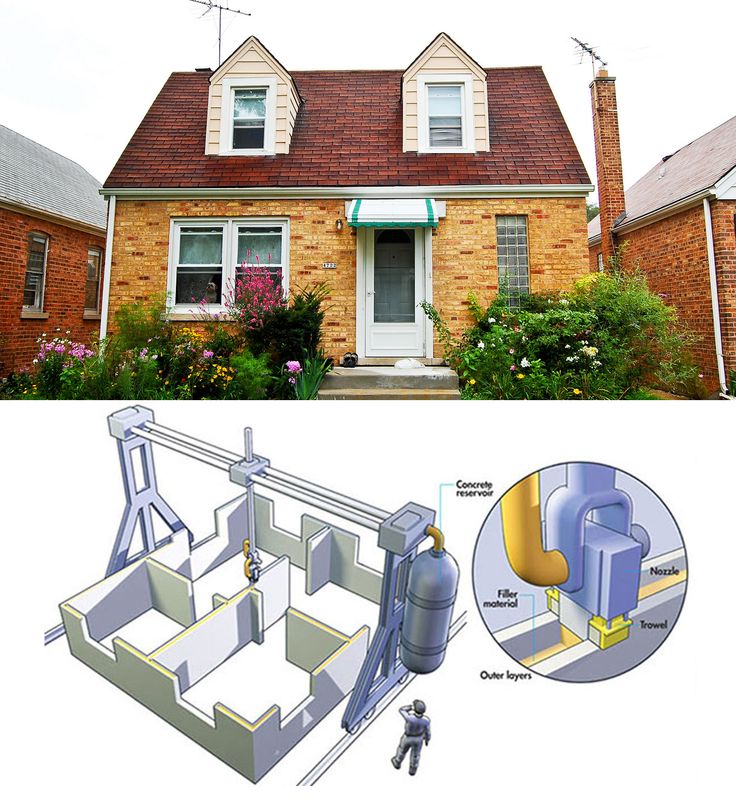

Recently, several 3D printed houses of 200 m² each appeared in Shanghai, China. They were made of concrete using a giant 3D printer. The cost of building each of them is only 4800 dollars.

They were made of concrete using a giant 3D printer. The cost of building each of them is only 4800 dollars.

Shanghai WinSun Decoration Design Engineering Co, who built the houses, said it had been developing technology and materials for several years. It owns 77 national patents for building materials such as fiberglass-reinforced cement and gypsum.

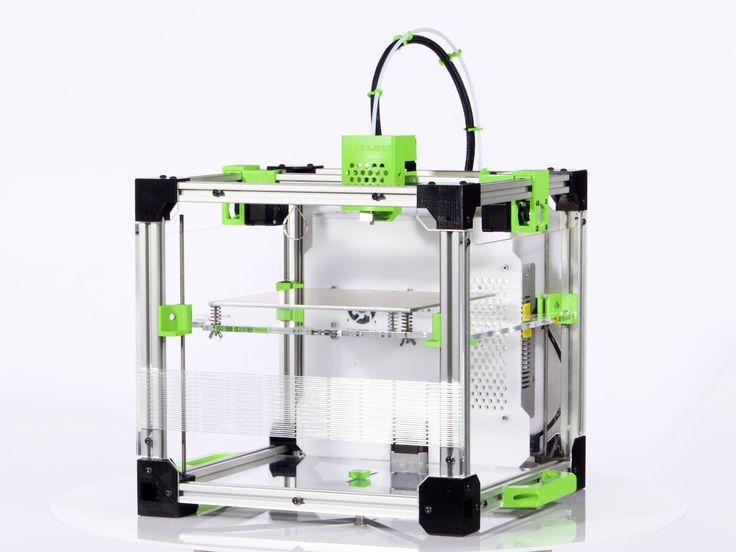

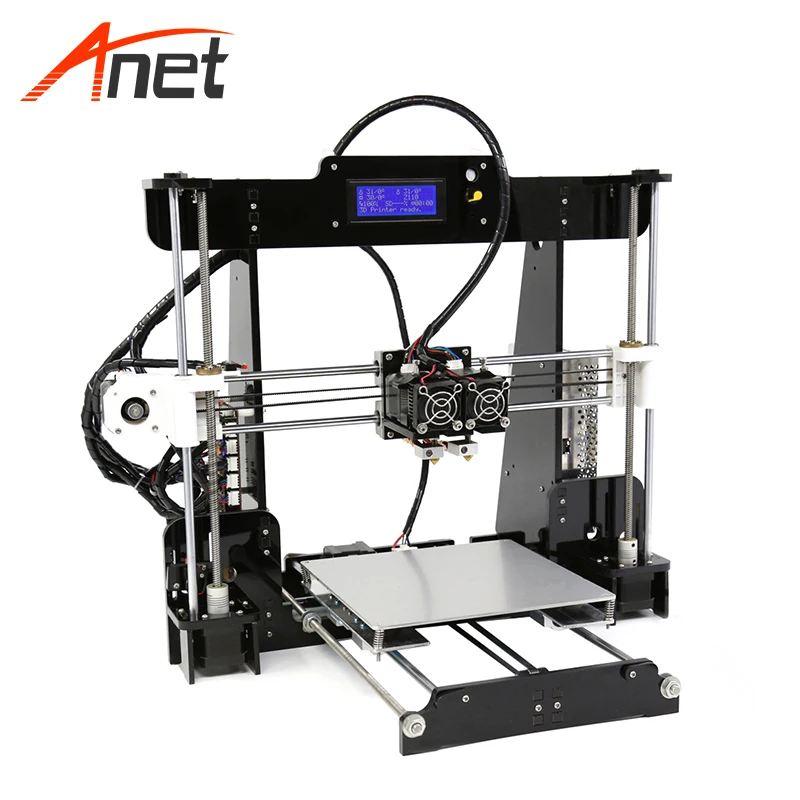

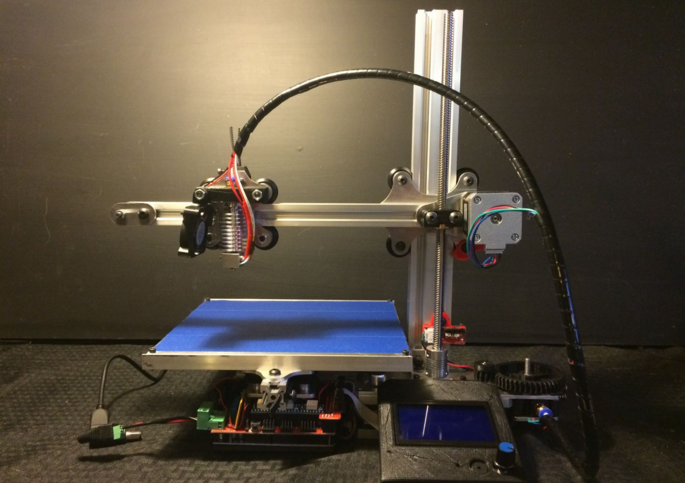

Of course, homemade printable models can be purchased for as little as a hundred dollars and then printed out of plastic and resin, but the company has taken this technology to a whole new level. By using concrete instead of plastic, WinSun intends to revolutionize how homes and other buildings are built.

WinSun's giant 3D printer, measuring 150m (length) x 10m (width) x 6.6m (height), can print an entire building in just a few hours. High-strength cement and fiberglass are used as "ink". Like conventional 3D printers, the printer carefully applies these materials layer by layer, gradually building up the building.

With the help of a computer and 3D modeling programs, elements such as insulation, plumbing, electricity and windows can be included in the building design, which are easy to install after the concrete structure has hardened and become strong.

It is also impressive that all construction and industrial waste can be disposed of and reused. WinSun plans to build 100 recycling plants in the country, each covering an area of 300 km, to collect and process construction debris into 3D printing material through special processing and separation technology. “No debris will be left behind during the construction of new homes,” said WinSun CEO Ma YiHe.

WinSun believes that 3D printing technology will help construction companies save up to 50% in the course of work, and hope that the use of this 3D printer and technology will allow the construction of "affordable and representative housing" for the poor.

Article prepared for 3DToday.ru

Follow author

Follow

Don't want

1

5

Follow author

Subscribe

Don't want

Alexander Gessler wrote a small handy program to convert 40+ 3D file formats (OBJ, S. ..

..

Read more

four

Subscribe to the author

Subscribe

Don't want

If yesterday 3D printing was the lot of boys of different age groups trying to adapt new...

Read more

four

Subscribe to the author

Subscribe to the author

Subscribe

Don't want to

The progress of 3D printing in recent years has gained such a rapid pace that we will soon stop...

Read more

Read the article about the first 3D printed houses?

3D printing has been used in construction for several years. In this article, you will learn about the first real houses printed on 3D printers.

3D printing of houses is still quite new to the layman. While construction 3D printing technologies have been developed for many years, only a few "real" projects have already seen the light of day. We are still far from technology taking over conventional construction methods. But with each new project, she is getting closer to becoming mainstream.

While construction 3D printing technologies have been developed for many years, only a few "real" projects have already seen the light of day. We are still far from technology taking over conventional construction methods. But with each new project, she is getting closer to becoming mainstream.

There are many benefits to 3D printing. For example, the cost of a 3D printed house can be much lower. And it will take much less time to build.

In order to draw a line under what has already been achieved in this area and show some interesting projects, we have devoted an article to the "first" and the best. These projects will always remain milestones in the 3D construction printing industry as they set the stage for future advances in the field.

First 3D printed house in Germany

Germany is a country often associated with cutting-edge engineering, so let's start our list with Germany's first ever 3D printed house.

The house itself is located in Beckum, a city that is partly located in North Rhine-Westphalia, next to Holland and Belgium. This is the first 3D printed house to be fully certified to official building codes. This project will give way to many other 3D printed construction projects in Germany as well as the rest of Europe.

This is the first 3D printed house to be fully certified to official building codes. This project will give way to many other 3D printed construction projects in Germany as well as the rest of Europe.

The project is the result of a collaboration between German construction company Peri and Danish construction 3D printing firm COBOD. Peri is a large corporation that operates not only in Germany, but throughout the EU. Its portfolio includes many products, including scaffolding and formwork solutions that every construction site needs.

Peri followed the construction 3D printing segment for many years before acquiring a stake in COBOD in 2018. Now they are pushing the technology together and further. The construction of the house in Beckum began two years after the acquisition of the share.

For 3D printing at home, a BOD2 modular 3D printer from COBOD was used. The printing itself took just over 100 hours.

• Built: (started) September 17, 2020

• Commissioned: summer 2021

• Where: Beckum, North Rhine-Westphalia, Germany

• By: Peri, COBOD

First occupied 3D printed home in the US

Several homes have been printed in the US, but this home is the first officially occupied home, according to CNN. Its creators: the construction company Alquist and the humanitarian organization Habitat for Humanity Peninsula.

Its creators: the construction company Alquist and the humanitarian organization Habitat for Humanity Peninsula.

From a distance, you might think that this is an ordinary house. However, when approaching it, the layered structure of the concrete walls becomes noticeable. After all, 3D printing creates an object in layers.

Surprisingly, the 111.5 square meter concrete structure of the house (was printed in about 12 hours, significantly faster than traditional construction methods would allow.

The house was reportedly bought by April Springfield, who lives there with her son and dog She bought the house through Habitat for Humanity's housing program, and given that the nonprofit's goal is to help solve the global housing crisis, it makes sense to use 3D printing to create affordable homes that will make many people's dreams of home ownership come true.0003

• Built: 2021

• Commissioned: December 22, 2021

• Where: Williamsburg, Virginia, USA

• By: Alquist 3D, Habitat for Humanity Peninsula, Greater Williamsburg

The first five-story 3D printed house

This project, made by the Chinese company WinSun, is a real record holder. It is a 3D printed five-story residential building with a height of 10 meters - the tallest 3D printed building so far.

It is a 3D printed five-story residential building with a height of 10 meters - the tallest 3D printed building so far.

The house is located in Suzhou Industrial Park in Jiangsu province in eastern China. It stands next to a mansion that was also built by WinSun using a concrete 3D printer.

Looking at WinSun designs, you can't help but notice that they don't look like they've been 3D printed. Usually 3D printed structures are gray in color, the layer lines are clearly visible. But WinSun adds color and makes walls smoother. Nowhere is it stated how the company achieves the smoothness of the walls, but we assume that the workers smooth them by hand. WinSun projects are not like the ones we're used to.

• Built: Winter 2014

• Commissioned: Not specified

• Where: Suzhou, Jiangsu, China

• By: WinSun

First 3D printed biodegradable house

Can you guess that there is rice in the walls of this house?

Most 3D printed buildings are made from concrete mix. But this project is different from the rest. With the aim of creating housing solutions with little to no environmental impact, Italian company WASP 3D printed Gay's house using soil and agricultural waste.

But this project is different from the rest. With the aim of creating housing solutions with little to no environmental impact, Italian company WASP 3D printed Gay's house using soil and agricultural waste.

WASP developed the sustainable blend in collaboration with Ricehouse, a company that specializes in using natural and agricultural materials such as clay and rice in construction.

The house is named Gaia in honor of the ancient Greek goddess of the earth. In fact, 25% of the mixture contains local soil, 10% hydraulic lime, 25% rice husks and 40% crushed rice straw (a by-product of rice production at harvest).

An innovative solution not only in terms of material, but also in the design of the walls themselves. The specific corrugated structure was used to provide ventilation on warm days as well as insulation on cold periods, virtually eliminating the need for air conditioning.

Gay's house is small - about 20 square meters. The wall printing took only 10 days, while the estimated materials cost is just under $1,000.

• Built: not specified

• Commissioned: October 7, 2018

• Where: Massa Lombarda, Ravenna, Italy

• By: WASP, Ricehouse

AirBnB's first 3D printed home

The perfect weekend getaway.

You can find many different types of accommodation on AirBnB, but what about a 3D printed home?

The so-called Fibonacci house is the first 3D printed house to be offered for booking through AirBnB. Considering that it is located in rural British Columbia, it will be a wonderful place to stay.

Although the Fibonacci house looks small, it has a lot to offer vacationers. About 35 square meters is enough to accommodate up to four people.

The concrete walls of the house were designed and printed by Dutch 3D printing firm Twente. 20 concrete parts were produced offsite in just 11 days. The material was produced by Laticrete. The parts were later transported and assembled at their current location.

• Built: 2020

• Commissioned: Not specified

• Where: Kootenays, British Columbia, Canada

• By: Twente Additive Manufacturing

The first 3D printed houseboat

Prvok is not only the first 3D printed house in the Czech Republic, but the world's first floating 3D printed house on a pontoon.

The project was implemented by the start-up company Scoolpt. The concrete structure of the houseboat took only 22 hours to print.

Approximately 43 square meters of living space divided into bathroom, bedroom and living room with kitchen. Weight isn't usually discussed in the context of houses, but given that this one is on water, it's interesting to note that Prvok weighs 43 tons.

The house is equipped with a built-in recirculating shower and tanks for drinking and municipal water and has a service life of at least 100 years.

• Built: June 2020

• Commissioned: August 18, 2020

• Where: Prague, Czech Republic

• By: Scoolpt

Europe's first 3D printed residential house

Not every 3D printed house has visible line layers.

More often than not, 3D printed houses are demos made to show what the technology can do. For most of them there is no information about the actual residents. But in 2017, the couple did move to live in a 3D printed house located in Nantes, France. Thus, the house of "Yanov" became the first of its kind, which was inhabited in Europe.

Thus, the house of "Yanov" became the first of its kind, which was inhabited in Europe.

The house is a project of the University and the Laboratory of Digital Sciences of Nantes. An interesting aspect of the project is the special technique used in its construction by BatiPrint3D. Instead of 3D printing a concrete structure, the robotic arm created wall shells using polyurethane, a material used for insulation. Later, these membranes were filled with concrete.

It took a total of 54 hours to print. It took a little over 4 months to complete the construction. Mainly due to the fact that the rest of the components were created using conventional means. House area - 95 square meters.

• Built: 2017

• Commissioned: March 2018

• Where: Nantes, France

• By: University of Nantes, Nantes Digital Science Lab

India's first 3D printed house

This building was built in a couple of days.

India's first ever 3D printed house was completed back in 2020. The project was carried out by construction startup Tvasta, founded by graduates from the Indian Institute of Technology Madras. In fact, the institute's Chennai campus was chosen as the location of the building.

The project was carried out by construction startup Tvasta, founded by graduates from the Indian Institute of Technology Madras. In fact, the institute's Chennai campus was chosen as the location of the building.

The significance of this project lies in its possible impact on the solution of the housing crisis worldwide and in India in particular. The ability to build such a house within a few days and at a low cost cannot be underestimated.

House 55.7 sq.m. with a spacious layout, one bedroom, combined kitchen and living room.

The concrete structure of the house was 3D printed off site and the parts were later transported and assembled on campus. The foundation, meanwhile, was built using the conventional method of pouring concrete into the ground.

• Built: 2020

• Commissioned: Not specified

• Where: Chennai, India

• By: Tvasta Construction

Africa's first 3D printed house

Back in 2019, in the Moroccan city of Ben Guerir, Spanish firm Be More 3D created Africa's first 3D printed house. The project originated during the team's participation in the Solar Decathlon in Africa. This is an international competition during which teams design and build solar-powered houses.

The project originated during the team's participation in the Solar Decathlon in Africa. This is an international competition during which teams design and build solar-powered houses.

Be More 3D printed house 32 sq.m. in about 12 hours, took first place and received the title of the most innovative startup.

Be More 3D didn't stop building in Africa and later created the first 3D printed house in Spain and developed its own concrete 3D printer in partnership with several corporations from the automation and materials industries.

• Built: 2019

• Commissioned: Not specified

• Where: Ben Guerir, Morocco

• By: Be More 3D

First 3D printed home for sale in the US

Last on our list is the first 3D printed home for sale in the US.

This house was printed in the same place by SQ4D, a company specializing in the development of robotic building systems. The building was printed with SQ4D's Arcs concrete extrusion system and has a 50-year warranty on the printed structure.