Blue sky bio 3d printer

Blue Sky Plan by BlueSkyBio ♥♥

Micron

- dentures

- orthodontics

- surgical guides

- aligners

- freemium

Ortho - https://www.barongrutterdds.com/blueskyplan-ortho/

Open Dental Design Software

- orthodontics 15

- aligners 12

- surgical guides 11

- basing models 9

- crown and bridge 9

- indirect bonding trays 8

- freemium 7

- general cad 7

- support generation 6

- dentures 4

- splints 4

- custom trays 4

- implant dentures 3

- identification 2

- model and die 2

- temporaries 2

- flippers 1

- essix retainers 1

- stl file repair 1

- 510k 1

Most Viewed Software

- Dentiq Guide from 3DII (Korea)

- Exceed Ortho Planning

- ULAB Systems

- Archform by Martz Inc (San Jose CA) ♥♥

- AutoDesk Meshmixer ♥♥♥

- Ortho Insight 3D by MotionView 3D

- iROK Digital Dentistry Studio

- GuideMia

- Ortho System by 3Shape $$$

- CloudCompare STL Comparison Tool (Free)

- Implant Planner & Tray by ZirkonZahn

- ArCAD 3D Align

- ImplaStation by ProDigiDent (Ukraine)

- MeshLab

- 3shape Design System $$$

Upcoming Tradeshows

- Feb 21-22, 2020 - LMT - Chicago IL

- Mar 26-27, 2020 - UDA - Salt Lake City UT

- Apr 2-4, 2020 - WRD - Phoenix AZ Read more ...

Is 3-D printing ready for prime time?

When Dr. Chris Salierno approached me about writing an article on 3-D printing and digital dentistry, I became quite nervous. Digital dentistry is layered with many tiers of difficulty and requires in-depth study to fully grasp—and certainly more knowledge than I would have to share in a single article. It then occurred to me that the current movement in digital dentistry is toward everyday dentists, just like me.

It then occurred to me that the current movement in digital dentistry is toward everyday dentists, just like me.

Digital dentistry is an atmosphere of fast-paced development and discovery happening more rapidly than ever before. It is a groundswell that is involving new players in an old game and turning the dental world on its ear. The old guard is still plugging along, but the disruption is real. It is time to get on this bus. Five years ago, a 3-D printer would have been a novelty at a dental conference or show. The chairside milling workflow had long been in place in many dental offices around the country. Things have definitely changed. This year, you will probably see more 3-D printers on display at dental trade shows than ever before. The current zeitgeist of digital dentistry may require you to step out of your comfort zone, but the possibilities are endless.

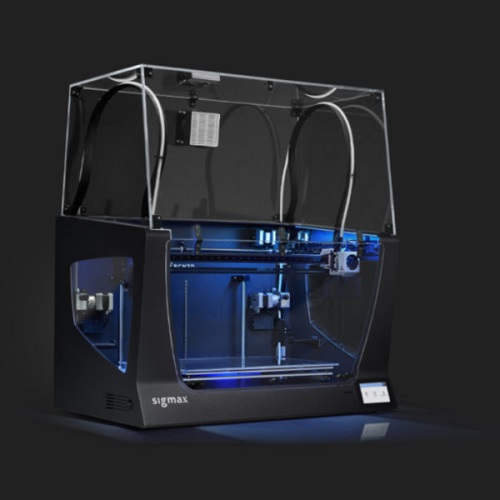

Open versus closed systems

One of the first things that you will notice about today’s digital dentistry is the push for an “open system. ” Many of us who owned a chairside milling system in the past are accustomed to a closed system—that is, a system contained within the confines of one company, one software, and a limited array of peripherals such as mills and blocks. In an open system, one can utilize a stand-alone design software, such as exocad, then pair it with a mill from any company, or use a 3-D printer from a nondental company. Some of these pairings come at a much-reduced cost over those offered by dental companies and allow access to technological advances that are showing up at an amazing clip. These advances are possible when the world at large works together to find new solutions to old problems. This is happening right now in 3-D printing. Engineers and tinkerers are creating innovations at an astonishing rate, and it is trickling down to the dental community. Actually, that trickle will soon feel more like Niagara Falls!

” Many of us who owned a chairside milling system in the past are accustomed to a closed system—that is, a system contained within the confines of one company, one software, and a limited array of peripherals such as mills and blocks. In an open system, one can utilize a stand-alone design software, such as exocad, then pair it with a mill from any company, or use a 3-D printer from a nondental company. Some of these pairings come at a much-reduced cost over those offered by dental companies and allow access to technological advances that are showing up at an amazing clip. These advances are possible when the world at large works together to find new solutions to old problems. This is happening right now in 3-D printing. Engineers and tinkerers are creating innovations at an astonishing rate, and it is trickling down to the dental community. Actually, that trickle will soon feel more like Niagara Falls!

These open systems offer such a variety of combinations that it has begun a veritable war of who will come out as the “expert” in the field. Many educators in the field are trying to top one another with innovations in the field of 3-D printing, design, materials, and even milling. Some of these experts include Cory Glenn, DDS, and Baron Grutter, DDS, with Blue Sky Bio; Jonathan Abenaim, DMD, with Smile Syllabus; August de Oliveira, DDS, with Digital Enamel; Michael Scherer, DMD; and others. All of them are making great advances with digital design, digital implant planning, digital orthodontics, digital dentures, and improved digital workflows. Many of them disagree with one another on what the best products may be, but it makes for great entertainment and learning. In my opinion, Facebook is the best way to catch up with all of these enlightened gentlemen, and their thought processes may just blow your mind.

Many educators in the field are trying to top one another with innovations in the field of 3-D printing, design, materials, and even milling. Some of these experts include Cory Glenn, DDS, and Baron Grutter, DDS, with Blue Sky Bio; Jonathan Abenaim, DMD, with Smile Syllabus; August de Oliveira, DDS, with Digital Enamel; Michael Scherer, DMD; and others. All of them are making great advances with digital design, digital implant planning, digital orthodontics, digital dentures, and improved digital workflows. Many of them disagree with one another on what the best products may be, but it makes for great entertainment and learning. In my opinion, Facebook is the best way to catch up with all of these enlightened gentlemen, and their thought processes may just blow your mind.

Within these circles there is a strong sentiment against closed-system technology. Many docs are becoming frustrated with high recurring fees and large entry costs to enter the digital realm. In alignment with this trend, large Facebook groups designed to help doctors enter the digital realm for a greatly reduced price are popping up. One example is the Blue Sky Bio Facebook group. It has many threads teaching doctors to virtually place implants and create their own surgical implant guides via the use of an affordable desktop 3-D printer.

One example is the Blue Sky Bio Facebook group. It has many threads teaching doctors to virtually place implants and create their own surgical implant guides via the use of an affordable desktop 3-D printer.

Another option is a software such as Meshmixer, which has hours of free training on YouTube. Meshmixer is a powerful 3-D design software that you can use to take a scan from your 3M scanner, Trios, or CEREC, and create 3-D models, wax-ups, occlusal splints, or even dentures in the 3-D space. For those who don’t want to print their own, Barry Voltz from 3-D Digiworks offers a great, inexpensive service.

In addition to the free software, some paid software programs are coming into the spotlight. Exocad, formally a lab tech software, is becoming a darling of the daring dental tinkerers. This extensive dental design software will give you the capability to design almost anything digitally—crowns, bridges, custom abutments, you name it. During the writing of this article, I learned that exocad will be coming out with a chairside software that may accompany the iTero intraoral scanner. I would speculate that this will be used to design chairside crowns for milling in any open source mill out there.

I would speculate that this will be used to design chairside crowns for milling in any open source mill out there.

The 3-D printing frontier

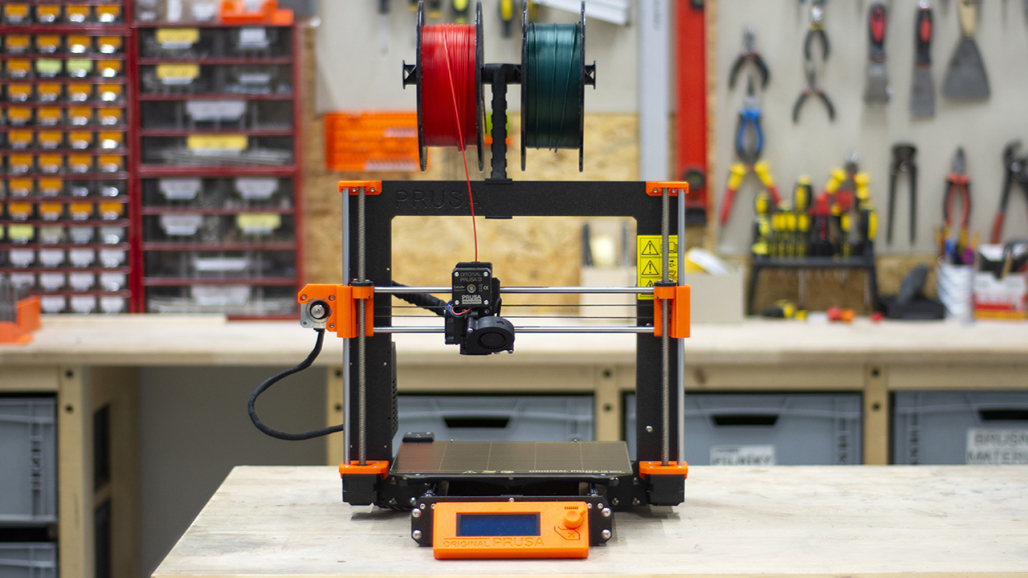

For many engaged dentists, 3-D printing is the new shiny object. I have become entranced with the thought of 3-D printing and own a Form 2 3-D printer. My orthodontist friend actually called me the other day and said, “I was told that I need a 3-D printer.” He asked questions about the cost, speed, and materials. At the end of the conversation, he realized that a 3-D printer is not magic and wouldn’t fit his needs and time constraints.

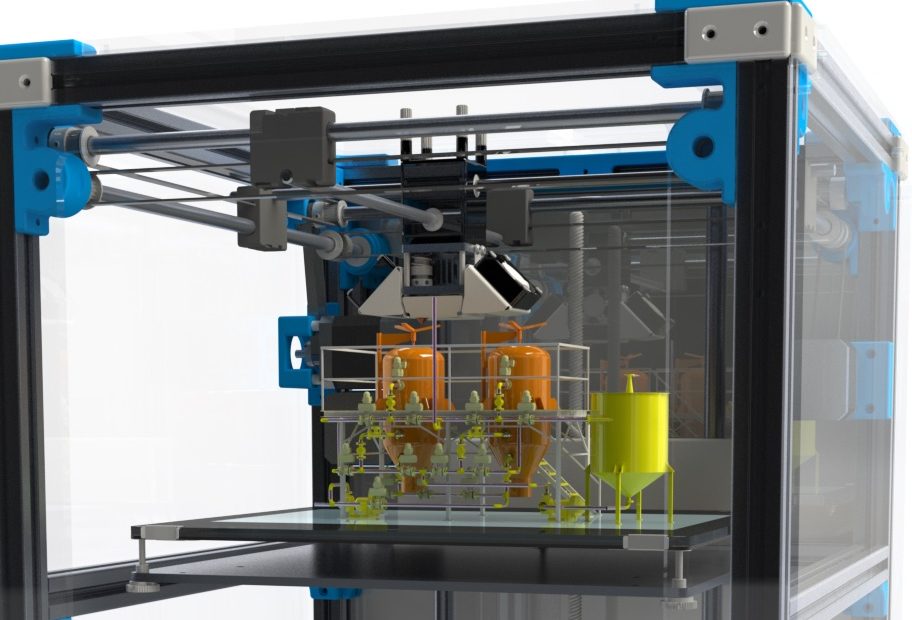

I would be cautious of the “gotta have” feeling and evaluate whether the technology is the right fit for your office. For now—and this will definitely change—there are limited applications for 3-D printing in the dental office. Approved options for the under $5k printers are: model production, surgical implant guides, occlusal splints, temporary restorative production, and coming soon—digital dentures. More expensive printers can provide these options more predictably. These printers will usually cost more than $50k. Bear in mind that the capabilities of affordable 3-D printers will most definitely improve over time. 3-D printer manufacturers, such as Formlabs, have embraced the dental community and offer new developments on a quarterly basis.

More expensive printers can provide these options more predictably. These printers will usually cost more than $50k. Bear in mind that the capabilities of affordable 3-D printers will most definitely improve over time. 3-D printer manufacturers, such as Formlabs, have embraced the dental community and offer new developments on a quarterly basis.

The Form 2 and Moonray printers seem to be the most popular options among the doctors whom I observe. They are under $4k, which is manageable for most offices. These printers currently have limitations in materials, but that is sure to change in the near future. The Form 2 is known to have great accuracy, but is limited to the Formlabs resin. Their resin library is limited at the time, but it will continue to expand. The Moonray can use NextDent resin, which is approved for many applications in dentistry, but some question its accuracy compared to the Form 2. Both are great for printing models, short-term orthodontics, implant guides, some temporaries, and bite splints. Look for denture functionality very soon. 3-D printers used by dental labs have much-improved speed and functionality, but they will run more than $20k to $50k and sometimes north of $200k.

Look for denture functionality very soon. 3-D printers used by dental labs have much-improved speed and functionality, but they will run more than $20k to $50k and sometimes north of $200k.

Milling isn’t dead

These great advancements in 3-D printing may lead you to believe that milling is passé. Why would we mill when we can create something from almost nothing, right? We are actually in the midst of a milling renaissance. More companies are bringing their mills to market that could fit within the confines of a general dental office. Today’s mills have more robust capabilities than those in the past. The concurrent growth of 3-D design software also allows the general dentist to create a wider array of “millworthy” items within the office. Utilizing design CAD software and third-party milling CAM software frees up the dentist to mill a wide variety of products, including acrylic, wax, zirconia, lithium disilicate, and titanium, among others.

These are things that a dental printer just can’t do right now. With a mill like this, a general dentist can reliably and efficiently mill out 15 zirconia crowns from a block just like a lab. I know that I am making this sound remarkably easy, but it won’t be long before this is relatively common. But before you decide it’s time to invest in all of this technology, it’s worth remembering that sending an impression to your lab—that likely has invested in these technologies on your behalf—still works as well.

With a mill like this, a general dentist can reliably and efficiently mill out 15 zirconia crowns from a block just like a lab. I know that I am making this sound remarkably easy, but it won’t be long before this is relatively common. But before you decide it’s time to invest in all of this technology, it’s worth remembering that sending an impression to your lab—that likely has invested in these technologies on your behalf—still works as well.

Your first steps into the digital world

With all the options that I have thrown out there, let’s think about how to fit this into your practice. If you’re going to use a digital workflow, you will need a way to make a digital impression. You will need a 3-D scanner—either intraoral or desktop. We are all pretty familiar with the intraoral scanners by now. 3M and iTero offer some great lower-cost options, and other open-source options include 3Shape, Carestream, and Planmeca. A desktop scanner might even offer a better solution for some docs or may add another option for those who are already using an intraoral scanner. 3Shape has several options, but also check out some models from Evolution Dental or Blue Sky Bio. These desktop scanners are an easy way to go digital by scanning impressions and digitizing them. They often come in handy by scanning dentures and prostheses.

3Shape has several options, but also check out some models from Evolution Dental or Blue Sky Bio. These desktop scanners are an easy way to go digital by scanning impressions and digitizing them. They often come in handy by scanning dentures and prostheses.

Once you have a digital impression, you could use one or more of the many aforementioned software to design. Meshmixer is a great place to get started, and there are many educational videos out there from the likes of Drs. Baron Grutter, Cory Glenn, and Michael Scherer. The Blue Sky Bio software is a great way to plan surgical implant guides, create your own short-term ortho, and design digital dentures (coming soon). Some doctors also use the service iRock DDS to design digital ortho solutions in-office. Of course, exocad should also be on your radar. The software ranges from $4k to $10k depending on your add-ons, but it has many useful modules. Of course, the big chairside guys are options too.

This is just a mere summary of what is happening in the world of digital dentistry right now. Technology moves very quickly, and I expect some of this to be outdated very soon. Get started by using some of the free software that’s available, and maybe try an inexpensive 3-D printer. The muscle memory that you will build will make it easier to move forward in the future. Remember to have fun and innovate!

Technology moves very quickly, and I expect some of this to be outdated very soon. Get started by using some of the free software that’s available, and maybe try an inexpensive 3-D printer. The muscle memory that you will build will make it easier to move forward in the future. Remember to have fun and innovate!

Techno Print 3D Company

This is our first review of the most popular and inexpensive 3D printers for 2020. The list will include the best-selling devices in two price ranges (up to 30 tr and up to 60 tr). Printers working with both plastic filament (FDM) and photopolymers (LCD/DLP) will be presented. This list will always be up to date, as it is periodically updated and supplemented. Read more→

The Chinese company Dazz3D announces the launch of the project on KickStarter and accepts pre-orders for Dazz3D Basic and Dazz3D Pro 3D printers. These revolutionary new devices are aimed at both the professional and amateur markets. Read more→

We all know that precise calibration of the 3D printer desktop is the foundation and the key to successful printing on any FDM printer. In this article we will talk about the main and most popular ways to level the "bed". So, as mentioned above, 3D printing without desktop calibration is impossible. We face this process Read more→

It's hard to go through a day today without hearing about 3D printing technology, which is bursting into our lives at an incredible speed. More and more people around the world are becoming addicted to 3D printing technology as it becomes more accessible and cheaper every day. Now almost anyone can afford to buy a 3D printer, and with the help of Read more→

The FormLabs Form 2 and Ultimaker 3 are perhaps the most popular 3D printers today, capable of high quality printing with incredible surface detail. Moreover, these two devices use completely different technologies, and therefore, there are a lot of differences between them. Many will say that it is wrong to compare them or Read more→

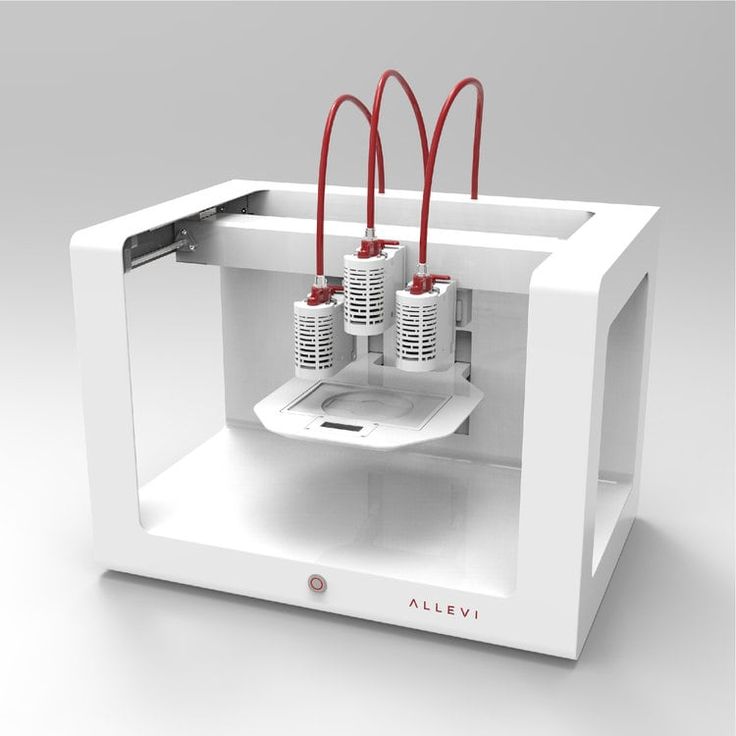

XYZprinting, best known for its daVinci line of desktop 3D printers, is bringing five new devices to the professional and industrial environment. One will use laser sintering technology, the second full color inkjet printing and three DLP machines. First of all, the novelties will be of interest to dentists and jewelers. Read more→

One will use laser sintering technology, the second full color inkjet printing and three DLP machines. First of all, the novelties will be of interest to dentists and jewelers. Read more→

Cleaning the nozzle of a 3D printer is a fairly common process that any user of such a device has to deal with. This is not at all a complicated procedure that anyone can handle. You can complete this task in 15 minutes, using only handy tools and accessories. Read more→

Acetone steam polishing of ABS plastic is a process for smoothing the surface of 3D printed models. The result of this processing makes your printed products look as if they were made by professional injection molding. If you want to understand how this is done correctly, then read this article. Aceto Read more→

3D printers are able to "print" copies of objects and people

Computer technology is increasingly intertwined with real life. A real industrial revolution was made by 3D printers, capable of "printing" copies of any object and even a person. New technologies, in the development of which they began to actively invest in China, make it easier to realize their creative potential and allow dreams to materialize literally.

New technologies, in the development of which they began to actively invest in China, make it easier to realize their creative potential and allow dreams to materialize literally.

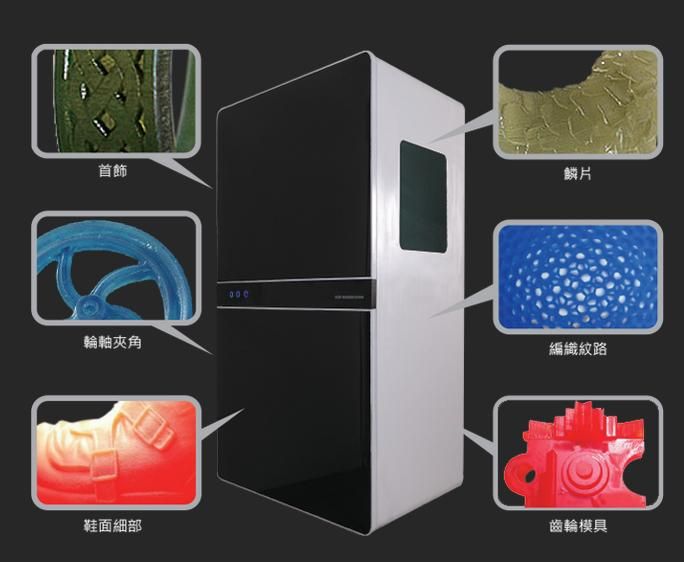

Unlike traditional printing methods, 3D printing is the process of creating three-dimensional solid objects with a dedicated digital printer. You can make a copy of not only any object, but also a person.

Shakhirezada Yeraliyeva, CCTV Correspondent-Russian:

"The digital model that the scanner creates is edited in a special computer program. Then this model is reproduced by the printer. Printing is based on the principle of layer-by-layer creation."

Shao Moyu, Director of 3D Printing Center:

"3D printing can be used in areas such as mechanical engineering, aviation, electrical engineering, medicine and construction, as well as innovative design. Printing materials are very different: gypsum, nylon, metal, plastic, resin and others.

After a few hours, the copy is ready. Its quality depends on how accurately the scan was made. Copy sizes can be set to a variety of sizes, printing is also done by different types of printers, depending on the complexity of the job.

This innovation is called the industrial revolution, the prerequisites for which have been outlined for a long time. But since that time, 3D printing has greatly pushed the boundaries of possibilities, the number of components suitable as raw materials is growing, as well as the quality of the objects created is improving. The new technology has been tried in the creation of clothing, medical items, weapons, and in the near future, 3D printing will be used in the construction of houses.

Shao Moyu, Director of the 3D Printing Center:

"This technology is not the latest, it appeared in the late 80s of the last century, and is more used in the industrial sector, so little is known about it in wide circles. By Compared with traditional manufacturing, 3D printing has the advantage of greater efficiency and lower costs.It cannot completely replace traditional manufacturing, but it has great development potential."

By Compared with traditional manufacturing, 3D printing has the advantage of greater efficiency and lower costs.It cannot completely replace traditional manufacturing, but it has great development potential."

You can print not only a scanned object, but also an object drawn or copied on the Internet. This is how design studios began to work with 3D printing. Everything that they create in their head, and then on paper or in a computer, then the printer puts it into a solid form. With the advent of home 3D printers, it will be possible to purchase any item without leaving home.

Experts predict great prospects for a new type of industry, whose performance is growing even in the stock markets. Shares of companies engaged in 3D printing are growing at the fastest pace (diagram). Some players have already realized the scale of the upcoming changes and have stopped investing in "traditional production".

Liu Jing, Designer:

"I work as a designer myself, I have a small studio.