Print 3d building

Largest 3D printed building in Africa

- Power2Build finished their second and largest 3D printed building yet in Angola with the BOD2 construction printer.

- 140 m2 house printed 4,5 times faster than the first 3D printed building Power2Build made.

- D.fab concrete solution from COBOD International and CEMEX enabling cost-saving up to 90% – first shown in Angola, now spread all over the world.

- COBOD completely dominates the 3D construction printing market in Africa with the six 3D printed buildings, all done with COBOD technology.

Power2build have recently finished their largest 3D printed building with a COBOD BOD2 construction printer in Angola. The company has set out to transform the housing market and are pioneers aiming to solve affordable housing in Angola with 3D printed buildings.

The house is the second 3D printed residential building in Angola. It is a 140 m2 house that holds a suite, two bedrooms, three bathrooms, a dining room, and a living room. As the three bathrooms indicate, this is not a social housing project, but rather a house showcasing the design and architectural possibilities of 3D printed buildings.

Power2build is working with COBOD’s 3D printing technology to significantly reduce the housing shortage in Angola. The 3D printing technology is an innovative method that allows construction of affordable and high-quality housing in the region in a faster and more competitive way.

Power2Build printed Angola’s first 3D printed building – a 53 m2 house. This was an incredible milestone, marking the beginning of a revolution, as the house was the world’s first 3D printed house in real concrete (defined by particle size above 8 mm).

While the first house was printed in 48 hours, the second house with 140 m2 was printed in 30 hours. This equates to a 4,5 times improvement in productivity. In addition to this, the team was able to both do the printing, and the water and electrical installations at the same time.

Ricardo Almeida, CEO from Power2Build said: “We are very proud of our progress; people were questioning if we couldn’t print bigger. We have now printed a 2,6 times bigger house and in about 2/3 of the time compared to the first house. We improved the speed of execution remarkably, but still believe there is room for improvement. In the future we will only become better at mastering this technology. We are getting more efficient by the day and closer to achieving our vision to deliver better housing at affordable prices to Angolan families.”

Angola was the first country in the world that printed with the D.fab solution from COBOD International and CEMEX, making printing of real concrete possible. The solution has since been used in projects in a.o. Japan, Malaysia, Saudi Arabia, Ireland and Canada.The 3D printed house was done with the D.fab material solution, a ground-breaking additive mix developed by COBOD and CEMEX, that enables printing with real concrete, leading to cost-savings of up to 90% compared to printing with mortars. D.fab enables the usage of 99% locally available materials and only 1% Magic Mix supplied by COBOD. 3D printing with real concrete is a genuine step change in the industry of 3D construction printing and serves as a prominent gateway to properly commercializing the technology.

D.fab enables the usage of 99% locally available materials and only 1% Magic Mix supplied by COBOD. 3D printing with real concrete is a genuine step change in the industry of 3D construction printing and serves as a prominent gateway to properly commercializing the technology.

Commenting on the successful build of the house, Henrik Lund-Nielsen, Founder & General Manager of COBOD International said: “We are proud to have made the technology for this project. Power2Build have increased their speed of execution tremendously compared to their first and now second project. This is a great example of how we and our customers are continuously improving the technology and can build faster, better, and cheaper as our customers and partners become experts at mastering the 3D printing technology.”

COBOD International’s 3D construction printing technology is dominating the market in Africa, which so far has six 3D printed buildings all done with COBOD technology. The company was the first (and only) to print in Malawi, Madagascar, Kenya, and Angola, two of which are schools and four residentials. Later this year COBOD’s customer 14trees will begin printing a double-digit number of houses in Kilifi in Kenya.

Later this year COBOD’s customer 14trees will begin printing a double-digit number of houses in Kilifi in Kenya.

World leader in 3D construction printing solutions with +50 printers sold world-wide.

COBOD’s mission is to build smarter through multifunctional construction robots based on 3D printing technology and COBOD’s vision is to automate minimum 50% of construction processes on building sites. All leading to better, faster, cheaper and more sustainable construction than conventional concrete. We constantly strive to reduce the co2 footprint of 3D printed concrete.

COBOD’s 3D printers made Europe’s first building in 2017. Subsequently our printers made the first 2- and 3-story buildings in Europe (Belgium & Germany), North America (US & Canada) and India. Also, the first 3D printed villa in Dubai and buildings in Africa have been done by COBOD 3D construction printers, just like the first wind turbine bases.

Also, the first 3D printed villa in Dubai and buildings in Africa have been done by COBOD 3D construction printers, just like the first wind turbine bases.

COBOD has an open-source material strategy, partnering with customers, academic institutions, and suppliers around the world.

COBOD is privately owned by General Electric, CEMEX, Holcim and PERI as key shareholders, and our partners further include Dar Al Arkan (Saudi Arabia), L&T Construction (India), JGC (Japan), Siam Cement (Thailand) and Orascom (Egypt).

COBOD is headquartered in Denmark with regional offices and competence centers in Florida and Malaysia. Our team consists of +100 passionate pioneers from 25 nationalities and through our installed base of printers, we have a truly global presence in North- and Latin America, Europe, the Middle East, Africa, and Asia-Pacific.

Video of Power2Build house: https://youtu.be/zRKVQ6SNLlI

COBOD announces distribution agreement with nidus3D

- COBOD announces distribution agreement with nidus3D (Ontario, Canada) to bring multifunctional construction robots based on 3D printing to Canada

- nidus3D recently built Canada’s first 3D printed multi-unit residential building, fully permitted for occupancy, and North America’s first 3D construction project to use real concrete

3D printing technology has transformed processes in medical, aerospace, and tool-making fields. Now, that same disruption is being brought to the construction sector, and nidus3D is at the forefront, paving the way for new builds to be achieved faster, more affordably, and with less waste, using COBOD technology.

Now, that same disruption is being brought to the construction sector, and nidus3D is at the forefront, paving the way for new builds to be achieved faster, more affordably, and with less waste, using COBOD technology.

As a testament to their ambitions, nidus3D has recently succeeded 3D printing Canada’s first multi-unit structure in real concrete using COBOD’s BOD2, the world’s best-selling 3D construction printer. The project is a first-of-its-kind consisting of four units each measuring 560 ft2 and is the first 3D printed home to obtain permission for occupancy in Canada. The 3D printed homes are expected to be available by Summer 2022 for individuals and couples seeking attainable housing.

“The opportunity to work with COBOD, world leader in 3DCP is incredible,” said Ian Arthur, President in nidus3D. “The BOD2 printer is an industry-leading construction printer that outstrips competitors in its versatility, scope, and durability. nidus3D is actively deploying 3D construction printing technology to lower building costs and expand access to resilient, efficient, and sustainable housing while complying with Canadian building standards. ”

”

Commenting on signing nidus3D as a distributor, Philip Lund-Nielsen, Co-Founder & Head of Americas at COBOD International said, “We are proud to be partnering with nidus3D to bring our state-of-the-art 3D construction printing technology to Canada, further solidifying our position as the #1 supplier in North America. With their recent project, nidus3D successfully demonstrates how our technology can be applied to build faster, better, and cheaper as our partners learn to master the 3D printing technology.”

Nidus3D reports to have multiple residential and non-residential buildings lined up for 2022 and 2023, these are subject to announcement at a later stage.

nidus3D used COBOD technology for their first 3D printed multi-unit residential building fully permitted for occupancy in Canada. Finished units will be provided to the market as long-term affordable rentals. The 3D printed homes are expected to be available by Summer 2022 for individuals and couples seeking attainable housing. About nidus3D

About nidus3Dnidus3D is a strategic partner and distributor of COBOD BOD2 printers based out of Kingston, Ontario. With experience in construction, lean manufacturing, and public affairs, the team at nidus3D is actively deploying 3DCP (3D Construction Printing) technology to lower building costs and increase access to housing that is resilient, efficient, and sustainable, all while complying with Canadian building standards. Visit nidus3D.com for more information.

About COBOD InternationalCOBOD is the World’s leading supplier of 3D printers for the construction industry, with strategic investors GE Renewable Energy (USA) and PERI (Germany). COBOD’s mission is to disrupt the global construction industry through world-class multifunctional construction robots based on 3D printing systems. Faster. Better. Cheaper. The company 3D printed Europe’s first building in 2017. Subsequently the first 2- and 3-story buildings in Belgium and Germany were made with COBOD technology. The first villa in Dubai and the first buildings in Africa have also been done by COBOD 3D construction printers, like the first wind turbine bases.

The first villa in Dubai and the first buildings in Africa have also been done by COBOD 3D construction printers, like the first wind turbine bases.

COBOD has an open-source strategy, partnering with customers, academic institutions, and suppliers around the world. Its partners include GE (USA), CEMEX (Mexico), PERI (Germany), Holcim (Switzerland), Dar Al Arkan (Saudi Arabia), L&T Construction (India), and JGC (Japan). COBOD’s vision is to see buildings and concrete structures in every city around the world made by multifunctional construction robots. COBOD is headquartered in Denmark, employs of 90+ highly competent colleagues from 25 nationalities, and has a truly global presence in North- and Latin America, Europe, the Middle East, Africa, and Asia-Pacific.

17 real buildings printed on a 3D printer - The Future on vc.ru

3D printing technologies are developing extremely fast and are used in various areas of human life.

42501 views

Recently, much attention has been paid to the printing of buildings, and printed houses are increasingly appearing in recent years in different countries of the world - in the USA, Saudi Arabia, Mexico, France, Russia, the United Arab Emirates and others. I have prepared a list of existing 3D printed buildings for 2020.

I have prepared a list of existing 3D printed buildings for 2020.

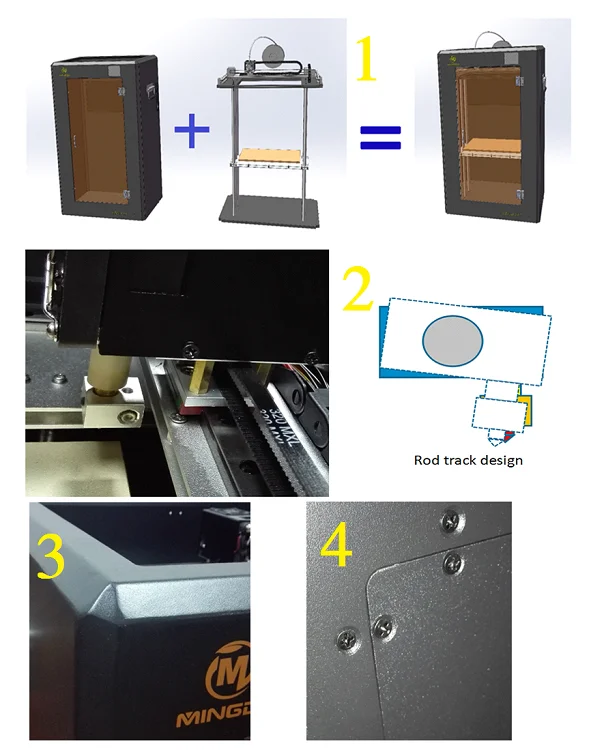

What is a 3D printer for construction.

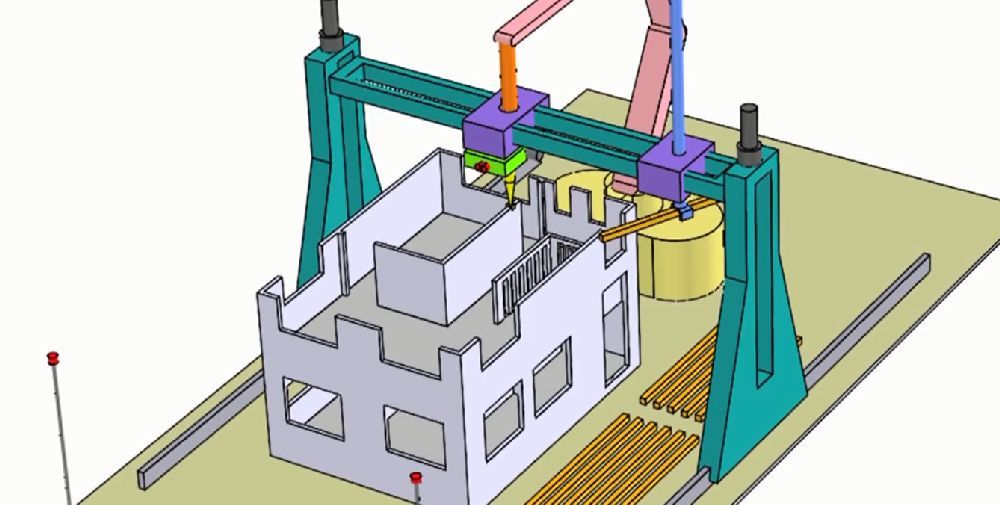

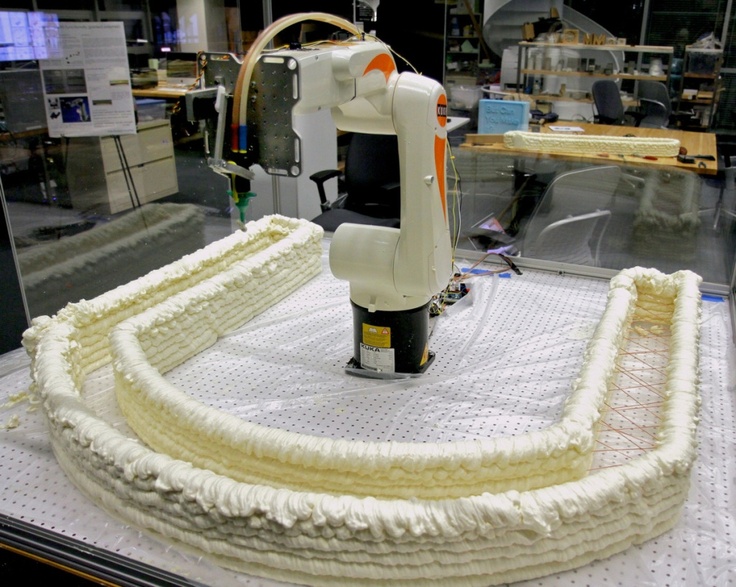

Today's 3D construction printers differ in designs and wall construction methods. The most common printers are portal construction, two- and four-support construction, on the basis of a manipulator arm or a circular design. The equipment allows you to create small architectural forms and elements of structures for their subsequent assembly on site, or allow you to print the entire building on the construction site. The height and dimensions of the printed building depend on the specifications of the printer being used.

How the printing process works.

The extruder extrudes a fast-hardening concrete mixture with various additives. Each subsequent layer is applied on top of the previous one, due to which a vertical structure is formed. The concrete layers below are thus compacted, thereby increasing their ability to withstand the next layers, and hence the entire weight of the structure. To strengthen the structure, it is reinforced, which can be both vertical and horizontal. The laying of the horizontal armored belt is carried out between the layers, the vertical reinforcement is installed after the composition has hardened, and then it is poured with concrete.

To strengthen the structure, it is reinforced, which can be both vertical and horizontal. The laying of the horizontal armored belt is carried out between the layers, the vertical reinforcement is installed after the composition has hardened, and then it is poured with concrete.

Advantages of 3D printing over other construction methods.

3D printer fabrication opens up great opportunities for construction and related industries. Practical application has revealed the following advantages of additive manufacturing:

- It removes the limits from the imagination of designers and architects who design buildings, as it provides opportunities that are not available with the construction methods we are used to.

- High speed of construction of buildings and structures.

- Complete process automation.

- Low power equipment.

- Significant savings compared to conventional construction methods by reducing labor and energy costs and accelerating construction time.

- The formation of waste building materials is completely eliminated.

- Minimization of human intervention in the construction process not only allows building in places inaccessible to people, but also eliminates the human factor in ordinary territories and reduces the likelihood of error.

1. June 2014. China. China's Shanghai WinSun Decoration Design Engineering Co has unveiled 3D printed houses at an industrial park in China's Jiangsu province. A total of ten houses were created, each of which cost a little more than three thousand pounds sterling. Over the next ten months, the technology improved and the company produced several different types of buildings for the exhibition, the tallest of which has five floors.

2. August 2014. USA. Andrey Rudenko's company Totalkustom printed the lock. The printing took a total of 2 months. The machine's printing speed was 50 cm in 8 hours. The main part of the castle, measuring 3m x 5m and 3.5m high, was printed as a single unit, and the towers were then printed separately.

The main part of the castle, measuring 3m x 5m and 3.5m high, was printed as a single unit, and the towers were then printed separately.

3. July 2015. China. Chinese company Zhuoda assembled a two-story house in record time. The modular home, made up of six 3D printed modules, was assembled on site in less than 3 hours. Of course actually about 90% of the work was carried out in the company's workshops, and on the site they were only assembled into a single building.

4. September 2015. Philippines. Andrey Rudenko's Totalkustom company built apartments on the territory of a hotel in the Philippines, 10.5 mx 12.5 m in size and 3 meters high. The building was built using local materials - sand and volcanic ash.

5. May 2016. UAE. Chinese company Shanghai WinSun Decoration Design Engineering Co printed prefabricated structures for the subsequent assembly of an office building in Dubai. The area of a one-story building is about 250 square meters. m.

m.

6. March 2017. Russia. Apis Cor introduced the first 37 sq. m.. The printed house has an interesting shape, but as the participants themselves say: this is just to show the flexibility of printing technology, the shape of the buildings can also be the usual square. Compared to other construction 3D printers, this printer is very compact (4×1.6×1.5 m), weighs 2 tons, and can be easily transported to the construction site.

7. October 2017. Russia. In Yaroslavl, the company Spetsavia presented the first residential building in Europe and the CIS, built using construction 3D printing technology. Construction of the house began in 2015. The box of the building was printed by a portal printer piece by piece and then assembled on the foundation in one month in December 2015. In the summer of 2017, the roof was completed and the bulk of the interior finishing work was carried out.

8. March 2018. France. Yhnova presented a five-room one-story house with an area of 95 square meters. For its construction, the engineers used a large manipulator, at the end of which an extruder for polyurethane foam is fixed. While working, he applied the foam in accordance with the 3D model of the building loaded into it. After applying the foam, the builders periodically filled the erected part with concrete, and also inserted the frames of doors and windows.

For its construction, the engineers used a large manipulator, at the end of which an extruder for polyurethane foam is fixed. While working, he applied the foam in accordance with the 3D model of the building loaded into it. After applying the foam, the builders periodically filled the erected part with concrete, and also inserted the frames of doors and windows.

9. March 2018. USA. American Company Icon built a prototype home in Texas to prove the technology's performance. The area of the building was 32 sq.m., printing was performed by a portal type 3D printer moving along rails installed on the site.

10. July 2018. Spain. Be More 3D printed a 24 m2 concrete building. For the construction, a two-support 3D printer was used, the width of which is 7 meters and the height is 5 meters.

11. September 2018. Denmark. 3D Printhuset printed a 50 square meter office in Nordhavn. The 3D printer used for printing is of the portal type and has a size of 8 x 8 x 6 meters. Print speed 2.5 meters / min. Each layer is 50-70 mm. The print material is concrete made largely from recycled tiles and sand.

Print speed 2.5 meters / min. Each layer is 50-70 mm. The print material is concrete made largely from recycled tiles and sand.

12. October 2018. Italy. Company Crane Wasp using a three-bearing construction 3D printer erected a building in ten days. The house uses passive solar heating technology and natural ventilation. The composition for printing was created on the basis of waste from rice cultivation (it was 25% local soil (clay and sand), 40% straw, another 25% - from rice husks and 10% - from hydraulic lime).

November 13, 2018. Italy. Arup in collaboration with the architectural bureau CLS Architetti erected a building in 1 week with an area of 100 sq.m. The building was printed in segments with subsequent assembly at the construction site.

November 14, 2018. Saudi Arabia. The Dutch company CyBe Construction has completed the construction of a building with an area of 80 sq.m. It took about a week to 3D print the necessary elements, and a little more than a day to assemble. The walls are made up of 27 printed blocks, and the parapets needed another 21 blocks to make.

The walls are made up of 27 printed blocks, and the parapets needed another 21 blocks to make.

15. August 2019. USA. S-Squared 3D Printers (SQ3D) showed a prototype residential building that can be built from floor to roof in just twelve hours. The house has an area of 46 m2. During the printing process, a 3D printer of a two-support design was used.

16. October 2019. UAE. Apis Cor has announced the completion of the world's largest 3D printed building. Located in Dubai, the 650 sq. meters has a building height of 95 meters and entered the Guinness Book of Records as the largest building printed directly on the construction site.

17. December 2019. Mexico. American company Icon erected two residential buildings for the non-profit organization New Story, in southeastern Mexico. The imprinted buildings have a flat roof, curved walls and an area of 46.5 square meters

As can be seen from the impressive list of completed projects, progress in the field of construction 3D printing clearly does not stand still, new techniques are constantly being introduced, various materials are being created, including from recycled raw materials, and high-tech equipment is being developed. In a short period of time, the technology has attracted the interest of a large number of enterprises that are engaged in the development of equipment, special building mixtures, libraries of structural solutions for designing buildings for 3D printing, as well as the preparation of a legislative, regulatory and regulatory framework.

In a short period of time, the technology has attracted the interest of a large number of enterprises that are engaged in the development of equipment, special building mixtures, libraries of structural solutions for designing buildings for 3D printing, as well as the preparation of a legislative, regulatory and regulatory framework.

I am sure that in the future the entire construction process will be able to become fully automated, without human intervention, not only when printing foundations and walls, but also when printing ceilings and roofs, automatically install utilities, doors and windows. Also, perhaps in the future we will not be limited to printing houses of 2-3 floors, but will be able to move on to multi-storey construction. All this is no longer something impossible and has ceased to sound like fantastic dreams of a high-tech future. It is only necessary to give time for the natural evolution of 3D construction technology.

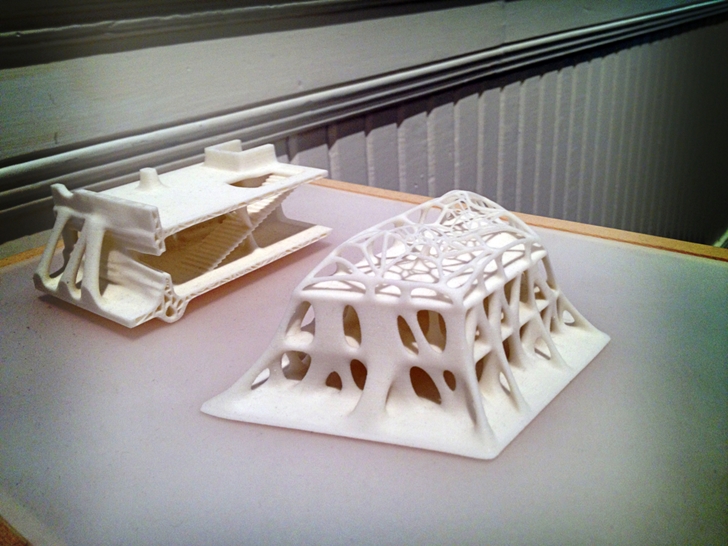

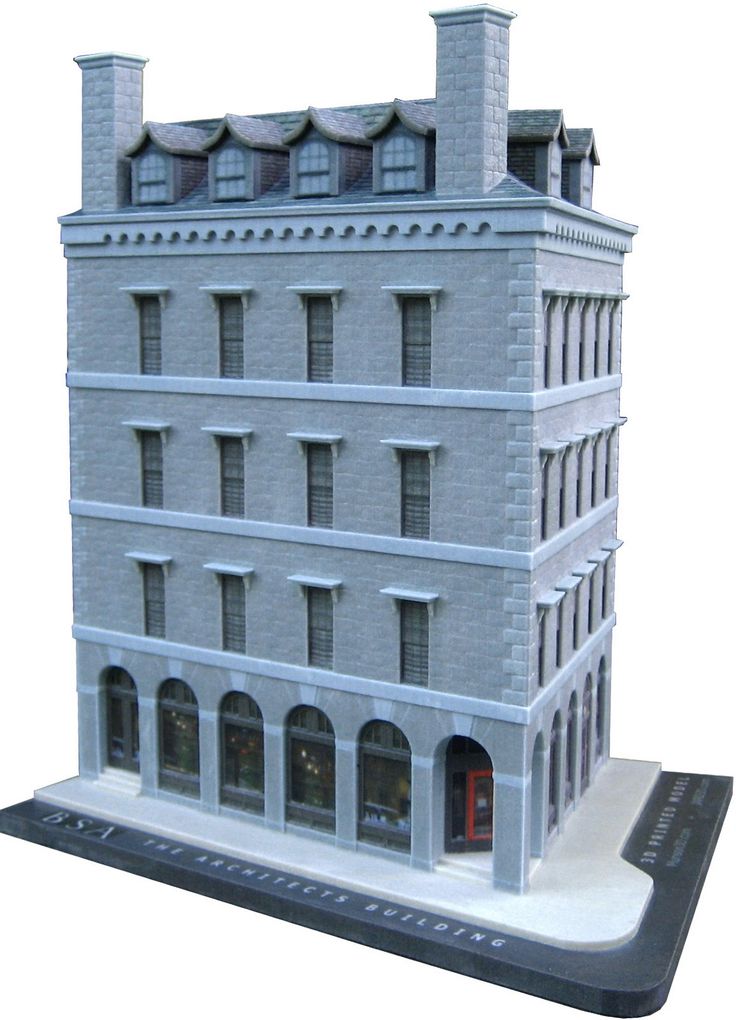

City buildings - 3D model

City buildings - 3D model

Errors present: no errors detected.

Quantity of item City buildings - 3D model

-

Description

General information

Model of city buildings. The model is designed to receive a physical layout on a 3D printer. The model is based on the scale of the original building.

File size - 17.9 MB.

Format - STL.

Overall dimensions of the model are 141 mm x 200 mm x 72 mm.

Payment and download

Payment for goods can be made by bank card or through an account for legal entities by placing an order on the site. Product images are actual and fully match the 3D model. After payment you will receive an e-mail with a link to download the model. You can always download a 3D model in your account on our website.

Please note that the purchase of the model for the purpose of resale is prohibited. Studia3D is a registered trademark that takes care of its own copyrights!

Where can I apply the 3D model?

First, this model was developed for a 3D printer.

If you buy this 3D model, you can print the downloaded file on a 3D printer. The printed model can be useful for use in mock-up business or as a souvenir. Secondly, this model can be used for any CNC machine, because the principles for developing 3D models for a 3D printer and other CNC machines do not differ significantly. Similarly, this model can be used for milling. Thirdly, this model can be used to implement 3D modeling projects. For example, you can use it in the 3Ds MAX program or similar software. In conclusion, I would like to note that using our models, you will not encounter polygon mesh problems or similar problems.

If you buy this 3D model, you can print the downloaded file on a 3D printer. The printed model can be useful for use in mock-up business or as a souvenir. Secondly, this model can be used for any CNC machine, because the principles for developing 3D models for a 3D printer and other CNC machines do not differ significantly. Similarly, this model can be used for milling. Thirdly, this model can be used to implement 3D modeling projects. For example, you can use it in the 3Ds MAX program or similar software. In conclusion, I would like to note that using our models, you will not encounter polygon mesh problems or similar problems. Model verification

All models are quality tested for compliance with the requirements and internal regulations. First of all, the polygonal mesh is fully stitched in the models. In addition, the model is single and does not allow multiple components. The number of polygons is optimally matched to the features of the model. The model does not contain inverted normals.

Learn more