Pasta 3d printer

Barilla’s 3D Printed Pasta Is Now Available for Sale

Published on June 13, 2022 by Clemens M.

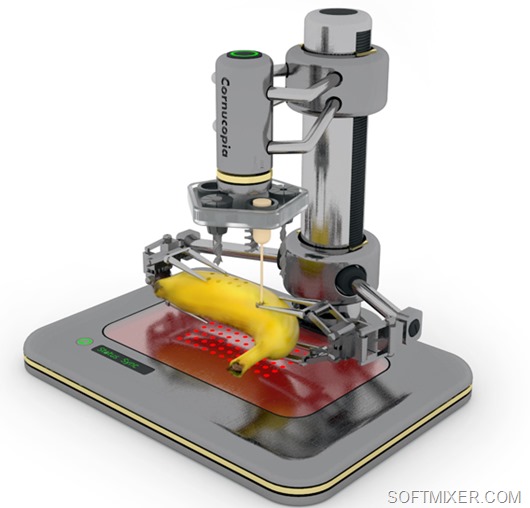

Over the years, 3D printing has already affected multiple sectors and is now even finding its way onto our plates. These days, the food industry is relying on all the advantages 3D technologies have to offer. This time, we took a closer look at one of the veterans in the pasta market, the Italian company Barilla. In 2016, it introduced its food 3D printer, which is capable of creating fresh pasta on demand. Since then, the company has remained fairly quiet on the idea and consumers had almost forgotten about the idea of 3D printed pasta. Now, a few years later, Barilla is back in the spotlight with 15 different pasta models available on its BluRhapsody 3D website. In fact, some famous chefs are already using some of these kinds of pasta in their kitchens.

BluRhapsody, a spin-off project born out of Barilla’s R&D research, began by creating a service that provides the 3D pasta printer developed by Barilla to produce designs. Today, the company has evolved to offer chefs the ability to purchase customized 3D printed pasta. Based in Parma, Italy, BluRhapsody is the first startup of Blu1877, a company created to interact with and support those creating the future of food.

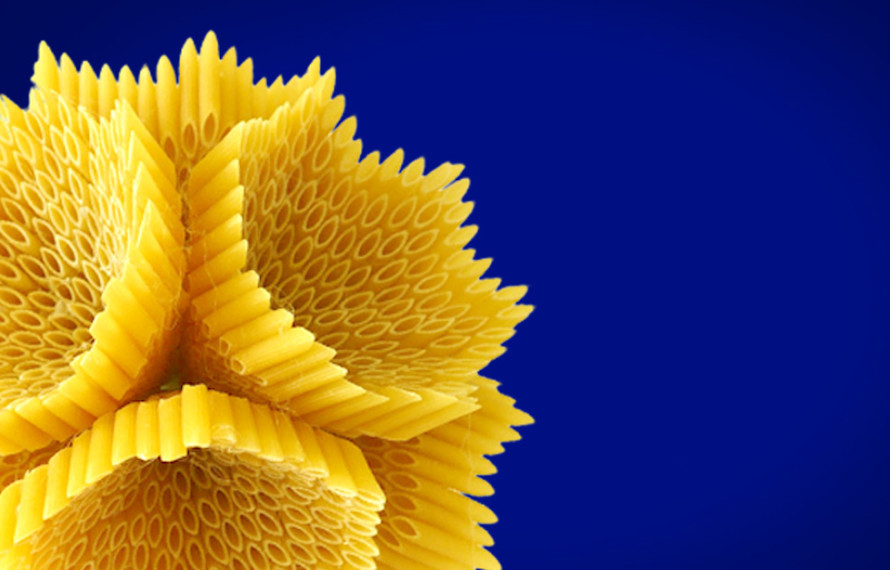

3D printed pasta in the shape of a star (photo credits: BluRhapsody 3D)

The basic product of BluRhapsody is a selection of first-quality durum wheat semolina, carefully processed and kneaded in small quantities to guarantee a perfect texture. It is mixed with water and a natural extract with coloring properties. BluRhapsody’s use of technological innovation allows chefs, as well as artists, to create pasta shapes inspired by nature or any flavor of the season, and turn their dishes into personalized edible works of art. The site offers a great variety of shapes including butterflies, hearts, spheres, shells, and even sea urchins!

A Bite of Art With 3D Printed Pasta

Each pasta unit weighs 7 grams and is 2.8 cm x 3 cm (~1. 1 x 1.18 inches) in size. Prices range from 25 to 57 euros (~$26 to $60) for 12 large pieces of personalized pasta, which is enough to prepare a few dishes. This price is affordable for restaurants and chefs who create unique dishes, offering more of a sensory experience than just a meal, as these unique products are currently not intended for the average consumer. Chefs from around the world will be able to enjoy these new 3D-printed kinds of pasta. It remains to be seen whether this will cost consumers more in a restaurant setting, and more importantly, whether the taste will be preserved. As we know, pasta remains a widely consumed food in the world and is easy and quick to prepare. Will we soon be ready to eat 3D printed pasta? In the meantime, find the different models available HERE.

1 x 1.18 inches) in size. Prices range from 25 to 57 euros (~$26 to $60) for 12 large pieces of personalized pasta, which is enough to prepare a few dishes. This price is affordable for restaurants and chefs who create unique dishes, offering more of a sensory experience than just a meal, as these unique products are currently not intended for the average consumer. Chefs from around the world will be able to enjoy these new 3D-printed kinds of pasta. It remains to be seen whether this will cost consumers more in a restaurant setting, and more importantly, whether the taste will be preserved. As we know, pasta remains a widely consumed food in the world and is easy and quick to prepare. Will we soon be ready to eat 3D printed pasta? In the meantime, find the different models available HERE.

The shapes of the pasta are inspired by the sea (photo credits: BluRhapsody 3D)

What do you think of this 3D printed pasta? Let us know in a comment below or on our LinkedIn, Facebook, and Twitter pages! Don’t forget to sign up for our free weekly Newsletter here, the latest 3D printing news straight to your inbox! You can also find all our videos on our YouTube channel.

*Cover Photo Credits: BluRhapsody 3D

3D Printers Make Incredible Pastas Your Nonna Could Only Dream About

3D printed pastaIf you could make anything out of pasta, what would it be? A miniature of your cat? Edible post-it notes? A chess set?

Well start sketching, because you can. 3D printing is here to make your pasta dreams a reality.

Every year, Barilla, the world's biggest pasta company, hosts a competition to create innovative new pastas for their 3D pasta printer. This year they received 1,300 design proposals, and are still in the midst of testing them out. But consider this past winner, Lune, a hollow moon-like sphere with crater-shaped holes for sauce to peek through. Or a pineapple-shaped pasta in development at the Barilla lab, with small holes to soak in sauce.

“It’s something you can’t really imagine,” says Jacqueline Delgado, the business manager of Blu 1887, Barilla’s food innovation company. “There are so many flavors and shapes that you don't realize you are eating pasta. It's hard to explain in words.” Blu started to experiment with 3D printing seven years ago, and were able to build their own printer in 2015.

It's hard to explain in words.” Blu started to experiment with 3D printing seven years ago, and were able to build their own printer in 2015.

ADVERTISEMENTAD

AD

Pretty shapes are part of the fun, but the 3D-printed pasta is ultimately about innovation: using software to sculpt forms that could never be made by hand or mechanical extruder. The technology gives you the freedom to think about how geometry affects flavor and texture, and how a pasta shape interacts with a sauce.

Here’s how it works: First you download your 3D model into the printer (it's the size of a small fridge), then load printer cartridges with semolina dough. And then you press print. The printer builds the pasta layer by layer, with a nozzle that moves along the X, Y and Z axes, spitting out the dough in a steady stream. It takes two to three minutes for the printer to make nine pieces of pasta.

Pasta galaxy, made by a 3D pasta printer.

ADVERTISEMENTAD

AD

“We want to astonish people,” Delgado continues. “To give them pasta that can’t be done with hands. For example, for one customer we made a pasta in shape of the Eiffel Tower. We want to create totally new experiences with pasta: it can be finger food, even sweet.” She sees opportunity for custom pastas at special events like weddings, and in fine-dining restaurants.

The most interesting design proposal Delgado has seen? “Octopus!” she bursts in laughter. “Think about it, how it would look, if you would put it in a soup, and its arms would be all around! When you start dreaming—there are so many things you could do with pasta.”

Pasta is just one application for 3D printers and food. The first 3D restaurant in the world, Food Ink, is serving printed fine dining dishes like lobster-shaped pastries filled with lobster. And as printing technology becomes more affordable, anyone can indulge their fantasies of sculpting a hummus castle, then laying siege with with pita chips.

There's also a wealth of practical applications for the technology. In Germany and in Utah, scientists are printing food for elderly people who have difficulty swallowing solid foods. The machine can create elaborate-looking dishes with easy-to-chew textures, in a far more appealing and dignified presentation than a mashed-up paste. For the elderly and disabled, 3D printers offer new ways to gain access to nutritious meals without traditional cooking. The technology may not be there yet, but some day soon, it will be.

ADVERTISEMENTAD

AD

A printed-out meal also offers new ways to personalize dishes to the nutritional needs of individual eaters. American company BeeHex is developing a food printer for the U.S. Army to customize meals for individual soldiers' nutritional deficits: if the soldier hasn't eaten enough protein or needs some caffeine, the printer can make a protein bar that contains everything they need, based on their ready-made profile. And in Iceland, a food and biotech research center is using printer to reduce seafood waste by using leftover fish to create new dishes.

And in Iceland, a food and biotech research center is using printer to reduce seafood waste by using leftover fish to create new dishes.

Could 3D printers become the microwaves of the future? “Eventually, I see it happening,” says Benjamin Feltner, the COO of BeeHex. “But it's not going to compete with throwing a Hot Pocket in a microwave. Printers are to upscale your kitchen. It's like having a chef robot sitting there.”

Barilla dreams of feeding the world with 3D printed pasta

News

Italian pasta manufacturer Barilla, with the support of the Dutch organization TNO, continues to develop a 3D food printer for printing its main products. The first prototype of a "pasta" 3D printer was demonstrated last year, but so far the developers have not been able to achieve the desired performance. The current version prints four pieces of paste in about five minutes, and a full plate takes about half an hour. nine0003

“When we first started the project, it took much longer to print the paste – twenty minutes per piece. Now we can print four pieces in a few minutes. We continue to work on reducing print times: our goal is a full plate in two minutes,” says Fabrizio Cassotta, R&D Manager at Barilla.

Now we can print four pieces in a few minutes. We continue to work on reducing print times: our goal is a full plate in two minutes,” says Fabrizio Cassotta, R&D Manager at Barilla.

Thanks to 3D printing technologies, pasta can take on the most unusual shapes. In 2014, the company held a gourmet 3D modeling competition called "PrintEat". There were three winners at once: "Moon" in the shape of the Moon with craters, "Rosa" in the shape of a flower bud and "Vortipa" - an elegant conical design that somewhat resembles a Christmas tree. “All of these molds are unique in their own way in terms of texture and functionality, and they are impossible to manufacture with traditional methods. For example, the spherical Moon can be filled with stuffing, while the Herringbone evokes unique sensations due to the geometric complexity of the texture,” explains Cassotta. nine0003

According to the developers, not only the form is important, but also the possibility of customization: "This technology will allow consumers not only to create their own designs on computers, but also to decide which ingredients the paste will be made from. " 3D-printed pasta still practically does not differ in composition from traditional pasta - the consumable consists of durum wheat flour and water.

" 3D-printed pasta still practically does not differ in composition from traditional pasta - the consumable consists of durum wheat flour and water.

However, Cassotta says that after the success with the base formula, the developers are experimenting with other formulations, including gluten-free diet options and vegetable supplements. “These experiments will allow us to determine the possibilities of personalization, because there must be some restrictions. Keep in mind that 3D printing technology is still very young, and we are the first company to 3D print pasta prototypes, so adapting standard 3D printing technologies for pasta production is a very difficult task, ”says Cassotta. nine0003

The project has been under development for about five years, but, according to the creators, is still in the early stages of development. In the long term, restaurants are being equipped with “pasta” 3D printers and even the possibility of domestic use. One option for field testing could be the installation of prototype machines in four of the company's signature restaurants in the United States. In addition, consumer and professional versions of a 3D printer will differ from each other due to different technical requirements. nine0003

One option for field testing could be the installation of prototype machines in four of the company's signature restaurants in the United States. In addition, consumer and professional versions of a 3D printer will differ from each other due to different technical requirements. nine0003

But the main problems still remain performance and cost. “To give you an idea, a 3D printer can produce about four kilograms of product per day, while a conventional conveyor produces four to eight or even nine tons of paste in the same time,” Cassotta explains. In other words, we should not expect a full-fledged "pasta" revolution yet, but even if 3D-printed paste does not replace the usual one, it may well find acceptance among gourmets.

Retrieved Do you have any interesting news? Share your developments with us, and we will tell the whole world about them! We are waiting for your ideas at news@3Dtoday. ru.

ru.

Follow author

Follow

Don't want

5

Pancakes on a 3D printer

Next article

At the NAUKA 0+ festival, they talked about new prospects for the development of 3D printing in the food industry

Author:

Maria Vorobieva

Eduard Shibanov, Chief Designer of the Laboratory of Additive Technologies at MSUPP, spoke at the NAUKA 0+ festival about new trends in the development of 3D printing and traditional food technologies.

©https://pixabay.com/

Eduard Shibanov gave a lecture in an online format, in which he highlighted the success of 3D printing technologies in various areas of production: mechanical engineering, robotics, medicine, construction and clothing. He also spoke about interesting facts related to 3D printing. The most curious of them is associated with the film "007: Skyfall Coordinates" by Sam Mendes. It used a car that, according to the plot, was supposed to explode in the finale. The filmmakers developed a three-dimensional model of this car, reduced by three times and printed it on a 3D printer. So the movie used a real car to move around, and the shot where the car explodes was a 3D model. Made of plastic, it looked like a real one and was also blown up, really. But Eduard Shibanov devoted the main part of the lecture to the role of 3D printing in the food industry. nine0003

It used a car that, according to the plot, was supposed to explode in the finale. The filmmakers developed a three-dimensional model of this car, reduced by three times and printed it on a 3D printer. So the movie used a real car to move around, and the shot where the car explodes was a 3D model. Made of plastic, it looked like a real one and was also blown up, really. But Eduard Shibanov devoted the main part of the lecture to the role of 3D printing in the food industry. nine0003

A bit of history

Back in 2013, NASA discussed building 3D printers to feed astronauts during space flights. In space, it is quite problematic to cook any kind of food, and 3D printers could solve this problem.

In 2017, scientists from Denmark expected that 3D printed food would supplement the standard diet of people based on the needs of the individual. 3D food printing will open up possibilities for the nutrition of every person. If a certain person does not like a certain product, the 3D food printer can exclude that ingredient. nine0065

nine0065

In the same year, scientists from Australia came to the conclusion that 3D printers can be used in hospitals. For example, there is such a disease as a disorder of swallowing food. For people with such an ailment, food should be in a consistency convenient for them, namely in the form of a liquid mass. 3D printing can help such people in the form of creating food that is comfortable for them, while it will be varied and palatable. Printers can be placed in each hospital.

3D food printing in the world

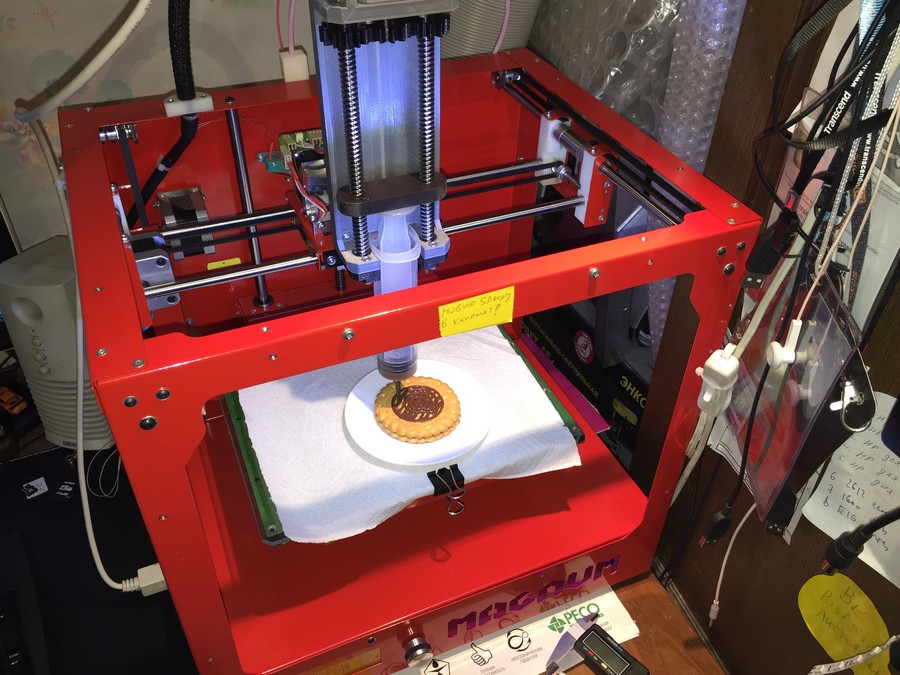

Barilla, an Italian pasta company, uses 3D printing to create pasta. The device allows you to print pasta of a given complex shape, then you just need to cook them.

Many cafes in the world focus on somehow standing out from the rest, creating their own unique dishes. For example, many of us have tried coffee with foam from someone's portrait.

There are also 3D printers for making chocolate figures. They are quite difficult to make by hand, so 3D printers work on their creation instead of people. They provide 100% product repeatability from a given pattern. nine0003

They provide 100% product repeatability from a given pattern. nine0003

There is also a pancake 3D printer that can print pancakes in various patterns. They can have a different color, shade. This is achieved due to the fact that the material that is applied earlier on the hot printer platform becomes darker. Accordingly, knowing the right time to apply the mass for each area, you can create different patterns. The printer does this automatically.

3D printers have been created that allow you to print dishes from several ingredients. Many chefs buy these printers for their restaurants and use them to serve food in a more beautiful and interesting way. If we talk about the technique itself, then the printer squeezes the liquid material onto the platform for printing, forming an integral structure over time. nine0003

There is also a 3D printer that can print pizza. He can use three ingredients to create a pizza. The mechanism uses a remote feed system that allows you to use the printer continuously. Thus, more ingredients can be loaded in order to print a large number of pizzas.

Thus, more ingredients can be loaded in order to print a large number of pizzas.

Thanks to 3D technologies, a number of new possibilities for catering for individual nutrition for each person open up. Today, this question is becoming more and more acute. Every year, the number of people suffering from allergies or intolerance to certain ingredients (for example, lactose or gluten) is increasing. There is a growing demand among the population for healthy food, which is expensive or time consuming. A 3D food printer will be able to prepare beautiful and healthy food with precisely defined ingredients. Also, another advantage is that the 3D printer prints unique dishes. Recently, it has become more and more difficult to surprise people, manufacturers are trying in a highly competitive environment to find new recipes, new production methods so that their product is interesting and different from competitors. 3D food printing can open up completely new horizons and directions in food production. For example, if we recall the well-known fast food chain McDonald's. Before its appearance, people could not even think that a dish can be prepared in advance and served as a sandwich wrapped in a package. nine0003

For example, if we recall the well-known fast food chain McDonald's. Before its appearance, people could not even think that a dish can be prepared in advance and served as a sandwich wrapped in a package. nine0003

Forecasts and outlook

“The 3D food printing market will reach $525.6 million by 2023. Every year the amount of funds in this area increases. Food will always be relevant."

“North America and Europe are currently the market leaders in 3D food printing, with high penetration in countries such as the US, the Netherlands, the UK, Spain, Italy and France. With rapid technological advances, food 3D printing is expected to open up great opportunities to revolutionize the global food industry.” nine0003

“In the future, this technology could change the way we prepare and eat food. Production of food directly at the place of consumption. This may be relevant for hospitals, for the military, space industry, for educational institutions and in the future it is possible for ordinary home users.

“Also, 3D technologies allow you to design your own food (shape, color, taste). This may lead to the emergence of a new profession of food architect, food designer. nine0003

“Successful mastering of 3D printing technology requires trained specialists who, in turn, understand all the possibilities and features of such production. This is at least the emergence of two new professions on the market - a 3D food designer and a 3D food printer operator.

“At the first stages of development and implementation of 3D food printing, it is necessary to create a database of digital recipes for a 3D printer. These will be both recipes and dishes already familiar to us, as well as unique options that have a completely different look. The number and variety of these recipes will determine the range of products offered to the consumer. How interesting and creative the designer approaches the solution of this problem, the buyer will be so interested when choosing a dish. The task of a 3D food designer is to create a beautiful dish that has an unusual, memorable shape, while taking into account the taste characteristics of the ingredients and their correct combination to ensure a pleasant taste.