Steel 3d printing filament

Metallic 3D Printing Filament | MatterHackers

- Home

- Store

- 3D Printer Filament

- Metallic 3D Printing Filament

Which metallic filament is right for me?

Real Metal Filament - real stainless steel filament printed on your desktop 3D printer. This metal 3D printing filament can be debinded and sintered, leaving your 3D printed part solid 316L or 17-4 PH stainless steel metal. If you are looking for an affordable way to create one-off, custom metal parts, small-batch manufactured parts, or just want to finally print with real metal on your desktop printer, this is your best option.

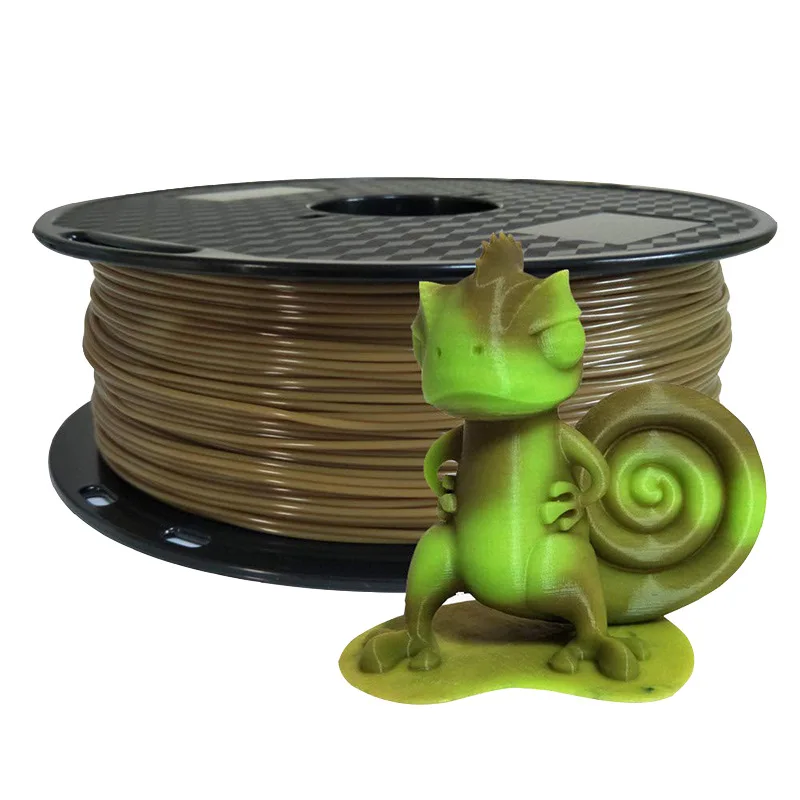

Metal Composite Filament - plastic filament infused with metal powders. These materials are still mostly PLA plastic and will have typical PLA filament characteristics. The metal powder (bronze, copper, or magnetic iron) provides aesthetic characteristics as opposed to their real metal properties. For example, printed parts in metal composite filament can rust/patina and even be sanded and polished to shine. So, if you are just searching for a metallic look, using a metal composite material is your best option.

Metallic 3D Printing Filament Collections

All Metallic 3D Printing Filament 3D Printer Filament

Metallic 3D Printing Filament

Metal 3D Printing Filament

Print with real metal on your desktop 3D printer.

The Virtual Foundry

If you can print plastic, you can print pure metal parts.

Metal Composite Filament

Plastic materials like PLA that are infused with metal powders

Guides & Articles

How to Succeed with 3D Printing Metal on a Desktop 3D Printer

The time is here to explore easy and affordable metal 3D printing. 3D printing with real metal on a desktop 3D printer is now possible using Ultrafuse Metal 3D printing filament from BASF Forward AM.

BASF Forward AM: A Look at One of Additive Manufacturing's Top Chemical Producers

BASF Forward AM is the production branch of BASF that creates a wide range of additive manufacturing materials for businesses and personal 3D printing.

3D Printer Filament Comparison Guide

There are many different kinds of 3D printer filament, and each one has it's own strengths for different projects. Knowing these differences is key to a successful 3D printing experience and so we have created a Filament Comparison Guide with everything you need to know about every type of filament available.

Stainless Steel Metal 3D Printing on Benchtop 3D Printers

A MatterHackers presentation on advanced materials and their rising presence in 3D printing and BASF Ultrafuse 316L, a composite filament that yields pure metal components

Casting Metal Parts From 3D Prints

Follow Sylatech as they transform legacy casting processes with 3D printing.

How to Succeed When 3D Printing With Metal PLA

Learn the best tips and tricks for 3D printing with metal-infused PLA 3D printing filament.

How To: Post Process Metal Filled Filaments

While 3D printing in true metal is still cost prohibitive to most people, 3D printing composite materials to achieve the look and feel of metal is easy, and all it takes is time.

Tech Breakdown: A Detailed Account of ColorFabb SteelFill Filament

An in-depth review of SteelFill 3D filament, the next great metallic PLA from ColorFabb that delights users with its metal characteristics and relatively easy printing.

FFF Metal 3D Printing for the Lab, Classroom or Studio

Your Choice of EquipmentFlexibility and ControlFully In-House Metal 3D PrintingUse your favorite FDM / FFF 3D printer

Use your favorite kiln or furnace

Or

Get the same equipment we use

Influence every step of the process

No cloud-based software

Military Form 889 Compliant

Make full metal parts in-house

No need to send your parts away

PRINT > DEBIND > SINTER Common FDM 3D PrinterCommon Kiln/FurnaceThe only fully hands-on metal 3D printing system

Go Deeper with the Basics

The basics of getting started and working with Metal FilamentWatch as Integza uses Stainless Steel filament to 3D print an aerospike Rocket Nozzle.

See how Filamet™ Compares to other FFF Metal Technologies

What materials are on your wish list?

If you could 3D print any metal (or glass or ceramic), what material would it be?

You can do it, and you can do it now.

Learn about Custom Filamet™ Projects

The Advantages of Printing with Filamet™ 3D Printing Filaments

✔ Low barrier to entry

✔ Familiar processes

✔ Minimal energy consumption

✔ Mature technology (FFF)

✔ Low hardware costs

✔ Hardware flexibility – capability to customize printer

✔ Safer solution – no chemicals in printing, no chemicals in debinding

Reach out!Give us a call at +1 (608) 509-7146

Email [email protected]

Complete the Contact Form

Or, Schedule some time with us using this button

Meet with a TVF Rep

Head Straight to the Shop

We make every material 3D printable. Contact our sales team to learn more. Some limitations may apply.

Contact our sales team to learn more. Some limitations may apply.

Just so you know that you’re in good company…

Here are just a few of the organizations using our technology.We have dozens of relationships within many of the members of the National Lab system. We work on military applications with friendly nations all over the world, but these are our favorite.Just a few of the schools we work with. A through D alphabetically, many more to add.

Steel 3D printing - a quick guide

112 views

Metal 3D printing using pure steel and alloys produces durable functional parts for mechanical and industrial products.

Any metal 3D printing technology can print with steel. This is the most popular material. But which steel grades and which technology is best for your application? Will printed steel parts really be as strong and durable as traditionally made parts? nine0003

Let's see how a 3D printed steel part is revolutionizing manufacturing and opening doors to new applications in aerospace, medical equipment, automotive, tool making, heavy industry, architecture and more. In addition, more affordable desktop printers are expanding the scope and scope of real steel 3D printed parts.

In addition, more affordable desktop printers are expanding the scope and scope of real steel 3D printed parts.

Strength of steel printed parts. nine0003

Cast steel part (left), 3D printed version (center). On the right, a 3D-printed whole hinge requires no assembly (Source: Desktop Metal)

The most common question when it comes to a 3D printed metal model is "Will it be as strong as a forged or cast part?". The short answer is yes... and no.

3D printed steel parts can be just as strong, and sometimes even stronger, than those made in the traditional way. It depends on many factors such as: end use, type of steel, choice of 3D printing method, post-processing and shape of the part. Also, the comparison depends on which of the strength characteristics you focus on: tensile strength, static load strength, fatigue strength, etc. nine0003

Parts printed from steel are used in the aerospace industry, for the military, and also, for example, for the manufacture of a footbridge, shown below. Therefore, the strength of printed products is beyond doubt, but let's take a closer look.

Therefore, the strength of printed products is beyond doubt, but let's take a closer look.

Queen Maxima of the Netherlands officially opens a 3D printed metal bridge. Photo by Adriaande Groot (Source: MX3D)

3D printed or laser powder sintered (LPBF) steel part has a finer grain structure than cast metal products. This provides better tensile strength characteristics, but in other respects the cast parts are currently still stronger. Most often, LPBF 3D printing is used to replace cast components, but in some cases, 3D printed components can replace forged parts. nine0003

One study showed that, under certain conditions, stainless steel parts made using LPBF 3D printers were three times stronger than parts made from the same steel using the traditional method.

In an experiment comparing 3D printed steel parts to traditionally made steel parts, researchers create identical parts using two methods and compare their performance. However, head-to-head comparison of details is only part of the big picture. nine0003

nine0003

The main advantage of printing with steel is not only its strength, but also the unique ability to create internal channels and lattice fillings in parts, which is impossible using traditional manufacturing methods. Metal 3D printing makes it possible to produce parts faster than traditional production, since this method does not require the use of special equipment and tools, it allows you to create assemblies as a whole, eliminating the need for subsequent assembly and welding. Designing a printed part usually means that less metal is needed to make it, and therefore less weight, for the same strength. nine0003

Architectural support printed in steel using Wire Arc Additive Manufacturing (WAAM) by MX3D (Source: MX3D)

Steel 3D printing is also more stable and cost effective as it reduces waste. When using subtractive manufacturing methods, such as CNC machining, you make a part by cutting it out of a large one, with a lot of waste. With additive manufacturing, you only use the material you need to make the finished product. nine0003

nine0003

Steel 3D printing is not intended to replace traditional methods in all areas, but it may be a better choice for a wide range of applications. Particularly when the required parts are unique and designed for specific applications, such as rocket engines, racing cars or the oil and gas industry. 3D printing is the fastest and most flexible technology for mass production and prototype production. For military and industrial applications, steel 3D printing is a faster and more efficient way to create individual parts for vehicles and machines. Stainless steel 3D printing is rapidly finding applications in medicine to create unique surgical instruments and implants. nine0003

If you know what characteristics your final product should have (tensile strength, compressive strength, hardness, density, etc.), then all these parameters can be incorporated into the product at the production stage.

Steel grades for 3D printing

Metal powder is the most used metal material for 3D printing (Source: GKN Additive)

There are thousands of different grades of steels and alloys with different mechanical properties used in traditional production, but in 3D printing there are only a few dozen, and some of them are unique, created specifically for this technology. Among the steel options, the following can be distinguished:

Among the steel options, the following can be distinguished:

- Stainless steel (316L, 304L , 17-4PH, 15-5PH, 420, 254, Ph2, GP1, 630, 410)

- Tool steel (D2, M2, h23, h21, MS1, 1.2709)

- Low alloy steel (4140)

- Structural alloyed (20MnCr5)

Recently, unique alloys specially developed for 3D printing have been introduced to solve the problems that occur with classical production methods. nine0003

For example, 3D printer manufacturer Desktop Metal released a patented stainless steel in 2022 that the company says combines the tensile strength, ductility, and corrosion resistance of 13-8 PH stainless steel, combined with the hardness low alloy steel like 4140. The company says customers can go to market with this material and skip the galvanizing step to protect products from corrosion.

ExOne offers two special blends of steel and bronze that the company says allows 3D printed steel parts to achieve increased corrosion resistance while being easy to machine and polish. nine0003

nine0003

While most of the metal powders used in 3D printing are similar to those used for other manufacturing methods, their numbers are on the rise as more companies adopt the technology. Some metal powder manufacturers, such as GKN, also make custom powders for specific 3D printing applications.

HOW TO PRINT STEEL

The strength, properties, and applications of 3D printed steel products largely depend on which 3D printing technology you use. Some methods produce stronger parts, other methods provide better hardness or abrasion resistance, and some technologies are simply very fast. nine0003

Below are the main metal 3D printing methods, their properties and some of the most common application examples.

Fused Deposition Printing (FDM)

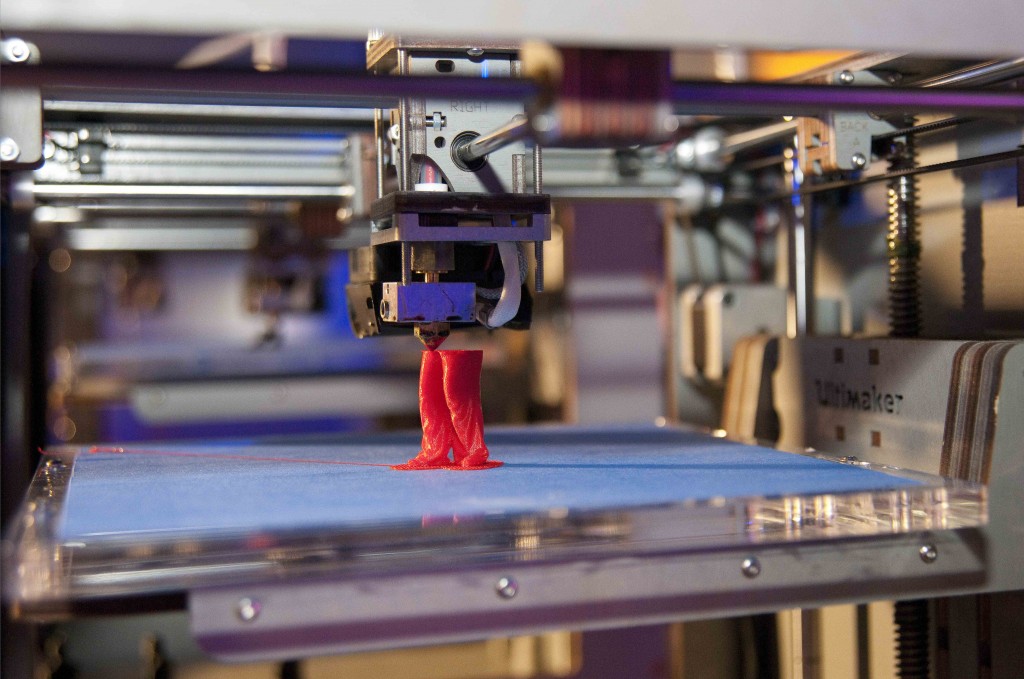

BCN3D's Epsilon printer extrudes stainless steel metal filament (Source: BCN3D)

Fused Deposition Forming (FDM) is a new technology for metal 3D printing, but it is developing rapidly as more printer manufacturers certify metal filaments for use on their printers, such as Ultimaker, BCN3D, Makerbot, Raise3D. Raise3D has recently released a complete metal printing suite - Metalfuse (3D printer, debinding oven and sintering oven). This method is still much more popular for printing plastics, but with new plastic filaments filled with stainless steel powder, strong metal parts can be produced. nine0003

Raise3D has recently released a complete metal printing suite - Metalfuse (3D printer, debinding oven and sintering oven). This method is still much more popular for printing plastics, but with new plastic filaments filled with stainless steel powder, strong metal parts can be produced. nine0003

FDM media was once limited to thermoplastics. Companies like BASF Forward AM and The Virtual Foundry now offer metal filaments that can be used on almost any FDM printer as long as it has a hardened steel nozzle for abrasive media.

These materials are approximately 80% metal and 20% plastic. After printing, the post-processing process removes the plastic, resulting in 100% metal parts. nine0003

Due to the removal of the bonding plastic, FDM metal parts shrink during post-processing. The amount of shrinkage is constant and can be taken into account in CAD systems, which allows to obtain relatively accurate finished parts.

Forward AM's 316L Stainless Steel Ultrafuse filament produces finished parts with material properties that the company claims are comparable to injection molded metal parts. nine0003

nine0003

(Source: BCN3D)

While 3D printing with metallic materials may not be suitable for applications with tough strength requirements (such as aerospace), the economics of producing simple metal components without critical loads on an affordable FDM printer may outweigh the impossibility of using them in some spheres.

Metal prototype parts and finished parts that will not be subjected to extreme stress are ideal uses for this technology. nine0003

Bound Metal Deposition (BMD)

Desktop Metal's Studio System 3D printer used wired metal rods that were extruded layer by layer to form a metal part (Source: Desktop Metal)

Similar to FDM, Metal Mesh Method (BMD) or Bonded Powder Extrusion (BPE) is an extrusion-based 3D printing process. This method uses bonded metal rods or bonded powdered metal filaments, which consist of a much higher percentage of metal powder than the filaments used in FDM. As with FDM, post-treatment to remove the binder and heat treatment in a final sintering oven are required. nine0003

As with FDM, post-treatment to remove the binder and heat treatment in a final sintering oven are required. nine0003

There are only a few 3D printers using this method such as Desktop Metal, Markforged and more recently 3DGence, but more companies are entering this market, so stay tuned. These printers are valued as a convenient solution for office 3D metal printing, they are more expensive than most FDM printers, but cheaper than the powder-based metal 3D printing technologies described below.

These printers use their own proprietary filament. Desktop Metal and Markforged offer four types of steel. nine0003

Ideal niches for this technology are metal prototype parts, where it is necessary to test the functionality of a part before mass production using traditional methods. Popular applications are molds, punching dies, nozzles, impellers, fasteners and heat exchangers.

For example, Shukla Medical uses Markforged's Metal X printer to print steel prototypes of its orthopedic implant removal instruments. nine0003

nine0003

Laser powder sintering.

Powder laser sintering technology uses one or more lasers to melt powdered metal layer by layer into a desired shape (Source: GE Additive)

Laser powder sintering (LPBF), also known as selective laser sintering (SLM), is the most common form of metal 3D printing. This technology is used by 80% of all metal 3D printers on the market. nine0003

This method uses powerful lasers to selectively sinter metal powder layer by layer.

LPBF 3D printers come in a wide range of sizes, prices and laser powers. These and other characteristics affect the properties of the finished part, print speed and other parameters of the finished products.

Steel and steel alloys are the most popular material for LPBF equipment and, unlike FDM and BMD, metal powders are commercially available as they are most commonly used in traditional production methods. nine0003

LPBF is a technology that maximizes the quality of a 3D printed part. Applications include aerospace components such as monolithic thrust chambers, rocket engine components and heat exchangers, molds, tools and other applications, as well as high wear parts and surgical instruments.

Applications include aerospace components such as monolithic thrust chambers, rocket engine components and heat exchangers, molds, tools and other applications, as well as high wear parts and surgical instruments.

Binder Jetting

Binder 3D printing technology uses metal powder and a binder to form metal parts (Source: ExOne)

Inkjet bonding is another powder printing method in which layers of metal powders are bonded using a liquid binder rather than a laser. During post-processing, the binder is removed.

Binder application stands out for its high printing speed compared to other 3D printing methods or traditional manufacturing, and metal parts made with this technology have material properties equivalent to those made by metal injection molding. nine0003

The number of manufacturers producing metal-bonded inkjet 3D printers is much smaller than that of LPBF machines. Leading manufacturers include ExOne, Desktop Metal, Digital Metal, GE Additive and HP.

Binder blasting is ideal for medium to high volume production of metal tools and spare parts.

In fact, HP claims that its Metal Jet 3D printer was designed specifically for mass production of 316L stainless steel products. HP has partnered with Parmatech to produce metal parts for the medical industry. Pennsylvania-based ExOne uses this technology to manufacture hard metal cutting tools and tool steels. nine0003

Electron Beam Melting (EBM)

(Source: GE Additive)

Electron beam melting (EBM) is another technology for powder cladding material. It works in a similar way to selective laser melting (SLM), but instead of using a laser as the energy source, it uses a much more powerful beam of charged particles.

The recoater moves the powder onto the printing plate and an electron beam selectively melts each layer of powder. After each layer is printed, the plate is lowered and another one is applied on top of the previous layer. nine0003

nine0003

EBM can be much faster than SLM, but SLM produces smoother and more accurate pieces. The electron beam is wider than the laser beam, so EBM cannot produce the same precise parts as SLM. Another difference is that the manufacturing process takes place in a vacuum chamber, which reduces the amount of impurities in the material that can lead to defects. That is why EBM is often chosen for printing components for the aerospace, automotive, defense, petrochemical and medical implant industries. nine0003

Titanium is the most popular metal for most EBM applications, however steel can be used.

Cold Spray

(Source: Impact Innovations)

Cold spray 3D printing technology is carried out by injecting metal powders through a jet nozzle into a supersonic stream of pressurized gases such as air, nitrogen or helium. The process is called "cold" because the metal particles do not melt, but hit the metal substrate and adhere to its surface during the so-called plastic deformation. nine0003

nine0003

Cold spray printed products are not prone to porosity, thermal cracking and other defects associated with melt-based technologies. This method has several advantages over other production methods. The technology is used in the military and aerospace industries around the world. For example, the US Army uses cold spray to repair the mounts of a worn Bradley 25mm steel turret gun.

In the automotive industry, cold spray steel is used for crash repairs because the high strength steel substrates in cars can be susceptible to thermal repair methods such as welding. nine0003

Direct Energy Deposition (DED) and Wire Arc Additive Manufacturing (WAAM)

WAAM steel parts from MX3D (Source: MX3D)

Direct energy deposition (DED) uses welding powder or wire that enters through a nozzle and is fed into a power source to melt the metal. A melt region is created and applied to the substrate. DED is a new process, reminiscent of an old building technology known as "cladding", in which a coating is applied to a substrate, often for thermal insulation or weather resistance. DED is useful for fabricating large objects as a whole, as well as complex geometries that require extensive machining. DED can get such parts much closer to finished than traditional CNC machining. nine0003

DED is useful for fabricating large objects as a whole, as well as complex geometries that require extensive machining. DED can get such parts much closer to finished than traditional CNC machining. nine0003

Because DED uses a coating process, it can be used to add complex geometries to existing steel parts, thus combining complexity with cost reduction. For example, the French company AddUp advertises a rocket nozzle that uses a preformed large 304 stainless steel hopper cone printed with an isogrid structure, usually made from a larger piece by traditional methods.

A technology related to DED is wire-arc additive manufacturing (WAAM). Instead of powder, WAAM uses a metal wire that is melted by an electric arc. The process is controlled by robotic arms. WAAM is also capable of producing large-sized metal parts, as demonstrated by the Dutch company MX3D and its nine thousand-pound 41-foot stainless steel bridge in Amsterdam, as well as an oil and gas equipment repair part, proving that parts can be made in the field. nine0003

nine0003

Micro 3D printing

Micro parts printed from steel (Source: 3D MicroPrint)

Micro-scale additive manufacturing, or micro 3D printing, can produce products with a resolution of a few microns (or less). There are three micro 3D printing methods to produce metal parts.

LMM (lithography-based metal fabrication) is a light-based technology that creates tiny parts from raw materials, including stainless steel, for applications such as surgical instruments and micro-mechanical parts. nine0003

Electrochemical deposition is the latest micrometal 3D printing process developed by the Swiss company Exaddon. In this process, the printing nozzle applies liquid with metal ions, creating details at the atomic level.

A third micrometal 3D printing method is microselective laser sintering, in which a layer of metal nanoparticle ink is applied to a substrate, then dried to produce a uniform layer of nanoparticles.

German researchers have successfully tested micro SLS printing of hollow microneedles using 316L stainless steel. nine0003

nine0003

Metal parts from 3D Systems, Desktop Metal, MX3D and Materalise.

Source: translated from all3dp.com by Ryan Bazinet

3D Printer Filament Buyer's Guide

- home

- 3D printing technologies

- Weld FDM, FFF and FGF material nine0054

- 3D Printer Plastic Filament Buyer's Guide - Part 4

19 — Wood (Wooden)

WHAT IS A WOODEN FILAMENT?

Thinking of printing an object that looks and feels like wood? And you can make it happen! But of course it won't be wood - it's PLA filled with wood fiber.

USER NOTE

There are many Wood-PLA 3D printer filaments on the market today. These include standard woods such as pine, birch, cedar, ebony and willow, but the range also extends to less common bamboo, cherry, coconut, cork and olive. nine0003

nine0003

As with other types of 3D printer filament, wood filaments also have a reverse side. In this case, aesthetic and tactile appeal is achieved by reducing flexibility and strength.

Be careful with the temperature at which you print the wood, as too much heat can result in a charred or caramelized appearance. On the other hand, the look of your wooden creations can be greatly improved with a little post-printing treatment. Wood filament can also wear out your 3D printer's nozzle, so use steel or reinforced nozzles. nine0003

WHEN SHOULD WOOD FILAMENT BE USED?

Wood is popular for printing items that are valued not for their functionality, but more for their natural appearance. When printing interior and decor items, wood filament for a 3D printer is often used, for example, for printing bowls, figurines and awards. One really creative use of wood as a 3D printer filament is to create scale models used in architectural models. nine0003

Resume

-

Plus: aesthetically, ideal for visual models

-

Minutes: Failure Mechanical properties, requires an enhanced nozzle with increased diameter 9002 9,0002 — Metal (Metal)

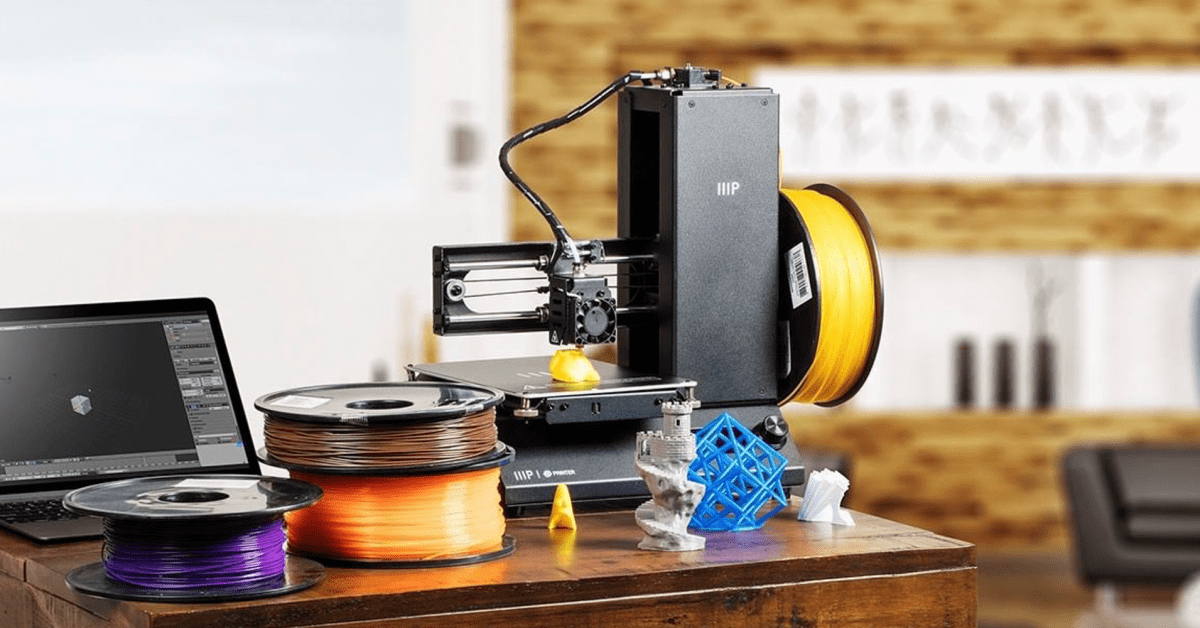

WHAT IS A METAL FILATION?

Maybe you're looking for a different type of aesthetic in your prints - something more voluminous and shiny.

To do this, you can use "live" metal. Like wood 3D printer filament, metal filament is not entirely made of metal. It is actually a mixture of metal powder and PLA or ABS. But this does not prevent the results from having the appearance of metal. nine0003

To do this, you can use "live" metal. Like wood 3D printer filament, metal filament is not entirely made of metal. It is actually a mixture of metal powder and PLA or ABS. But this does not prevent the results from having the appearance of metal. nine0003 Even the weight is metal-like as blends tend to be several times denser than pure PLA or ABS.

USER NOTES

Bronze, brass, copper, aluminum and even stainless steel filaments are just some of the "metallic" 3D printer filaments on the market. And if you need to get a special look for your product, don't be afraid to polish, tumble or matt products after printing with these filaments - even a little post-processing can have a huge visual impact. nine0003

However, please note that you will need to replace the nozzle sooner after printing with "metal", as the metal powder in such filaments is highly abrasive and will cause increased nozzle wear.

The most common metal-filled 3D printer filaments typically contain around 50% metal powder and 50% PLA or ABS, but there are also composites containing up to 85% metal.

WHEN SHOULD METAL FILAMENT BE USED?

Metal-filled filament is used to solve a wide range of tasks: both for aesthetics and to achieve certain functionality. Figurines, models, toys, and dog tags can all look great with metal 3D printing. And as long as the printed objects don't have to deal with undue stress, feel free to use metallic 3D printer filament to create functional prints such as tools, grills, or finishing components.

SUMMARY

-

Pros: mimics a metallic look, ideal for both aesthetic and functional models mm)

21 — BIOFILA (Biodegradable)

WHAT IS A BIODEGRADABLE FILAMENT?

Biodegradable 3D printer filaments constitute a unique category because their most valuable characteristics are independent of their technical parameters. As most 3D printing enthusiasts can attest, not every print comes out the way you intended, and that results in a lot of plastic being thrown away.

Biodegradable threads seek to negate the negative environmental impact that plastic waste has. nine0003

Biodegradable threads seek to negate the negative environmental impact that plastic waste has. nine0003 USER NOTE

As mentioned earlier in this article, PLA is actually a biodegradable filament, but also includes the BioFila lines from TwoBears and Biome3D from Biome Bioplastics.

WHEN SHOULD BIODEGRADABLE FILAMENT BE USED?

Regardless of their primary purpose of being environmentally friendly, biodegradable filaments can still be printed with good physical properties. Use them when you do not have high requirements for strength, flexibility or wear resistance of the printed product. And if you really want to take advantage of the waste-free printing of biodegradable filaments, try using them in your prototyping projects. nine0003

Resume

-

PLASS: Ecological security

-

Minuses: meager mechanical properties, limited choice on the market

22 - decorative types of PLA - Marmore sparkling, silk and colored glass

It would seem that all the advantages of the ease of use and variety of types of PLA filament have already been described earlier in this article in the first section.

Does it make sense to allocate decorative grades of PLA to a special additional section? Yes, it does, and more than that. All the variety of colors and additives that increase strength and elasticity will not convey the advantages of specialized decorative grades of PLA. These wonderful filaments allow you to create great visual effects in the professional field for creating special ways of decorating interiors and furniture or imitating handicrafts at no significant cost. They can also be useful for personal use, such as printing colorful children's toys. Many decorative varieties of various materials already exist and will still be created. As an example, we will consider marble, Marble, sparkling, Twinkling, and colored glass, Transparent Glass, which are already widely represented on the market thanks to enthusiastic manufacturers from the Celestial Empire. nine0003

Does it make sense to allocate decorative grades of PLA to a special additional section? Yes, it does, and more than that. All the variety of colors and additives that increase strength and elasticity will not convey the advantages of specialized decorative grades of PLA. These wonderful filaments allow you to create great visual effects in the professional field for creating special ways of decorating interiors and furniture or imitating handicrafts at no significant cost. They can also be useful for personal use, such as printing colorful children's toys. Many decorative varieties of various materials already exist and will still be created. As an example, we will consider marble, Marble, sparkling, Twinkling, and colored glass, Transparent Glass, which are already widely represented on the market thanks to enthusiastic manufacturers from the Celestial Empire. nine0003 USER NOTE

eMarble Marble FilamentBased on PLA with the addition of colored particles that visually imitate a stone surface.

Of course, about any properties of stone strength or density, heat capacity, etc. there is no question - the imitation is only visual. However, with proper use, this material will reveal its full potential and allow you to imitate from sculptures to elements of marble decoration of furniture and / or interiors. Remarkable Feature Marble is low shrinkage due to the base used. This will help you immediately get into the dimensions laid down when modeling "stone" prototypes and easily mount the printed decorative element into the main product or interior.

Of course, about any properties of stone strength or density, heat capacity, etc. there is no question - the imitation is only visual. However, with proper use, this material will reveal its full potential and allow you to imitate from sculptures to elements of marble decoration of furniture and / or interiors. Remarkable Feature Marble is low shrinkage due to the base used. This will help you immediately get into the dimensions laid down when modeling "stone" prototypes and easily mount the printed decorative element into the main product or interior.

Twinkling eTwinklingAble to delight both the child and the professional graphic designer. Multi-colored bright colors and splashes of sparkles create the illusion of complex painting with tinsel on the printed product. The biggest misconception is to classify this material as "only for children's toys." This filament is indispensable for creating prototypes, bright indoor signs (but not for outdoor use!), advertising structures, Christmas decorations and anything that is designed to attract attention with a strong visual effect, especially in the case of backlighting (most materials are translucent).

nine0003

nine0003

Silk thread (eSilk)Features a high-gloss bright surface, visually reminiscent of silk fabric. Of course, this plastic does not have any properties of real silk, only a visual effect. However, its use in prototyping furniture finishing elements, decor items, Christmas toys and other decorative accessories can give a significant gain both in the cost and speed of manufacturing a prototype, and in the ability to reproduce a product of a very complex shape. Try silk upholstering a model of the Eiffel Tower or a wicker chair? A 3D printer using eSilk can do this in exactly the same time as printing these prototypes with regular PLA filament. Agree - this is a unique opportunity that, if used skillfully, can become a strong competitive advantage. nine0003

Colored glass (Transparent Glass)The filament, unlike the basic grades of PLA, is transparent in mass - as if made from tinted glass due to the high degree of purification of raw materials and additional chemical processing.

The product printed with it can be visually confused with the PETG product, but transparent PLA is easier to print and is much cheaper on the market. Orange, yellow, red, blue and green colors, which are often used in household appliances and radio engineering, are chosen as the main tints, which immediately outlines the scope of application - backlight indicators, translucent tinted buttons, prototypes of backlight elements, automotive parts, and, of course, lighting elements. advertising structures. nine0003

WHEN TO USE PLA DECORATIVE FILAMENT?

Decorative PLA is indispensable for quickly and accurately creating design elements for decorative elements, advertising structures and backlit product prototypes. Very much in demand for the development of children's creativity.

SUMMARY

-

Pros: ease of printing and post-processing, low cost, visual impact

-

Cons: increased abrasiveness of filaments with additives due to the effect of the filler on the nozzle.

PLA-based materials are not suitable for outdoor use due to the biodegradable base

PLA-based materials are not suitable for outdoor use due to the biodegradable base

23 - Fluorescent Glow in the Dark

Fluorescent Glow in the Dark 3D Printer Filament - very impressive! Leave your imprint in the light for a while, then flip the switch and there's that ominous green light. nine0003

Of course, it doesn't have to be green. There are also other colors of the luminescent thread: blue, red, pink, yellow or orange. But green is perhaps the most popular and echoes the classic night glow style.

USER NOTES

So how does it work? It all comes down to phosphorescent materials mixed with a PLA or ABS base. Thanks to these added materials, the 3D printer filament is able to absorb in the light and then emit photons in the dark, which resemble tiny particles of light. This is why your prints will only glow when exposed to light - they must store energy before they can release it. nine0003

For best results, we recommend printing with thick walls and little infill.

The thicker your walls, the stronger the glow!

The thicker your walls, the stronger the glow! WHEN SHOULD I USE LUMINESCENT FILAMENT?

Mostly PLA or ABS based luminescent materials are used in decorative applications such as Halloween installations, lanterns, window decorations. You can print wearable items (jewelry), toys, and figurines.

SUMMARY

-

Pros: visually bright (we mean it glows in the dark!) 5mm)

24 — Color-Changing

Remember those T-shirts from the 80s that changed color based on body temperature? Or what about chameleon rings? Well, it's the same idea here, because color-changing 3D printer filaments also change color based on changes in temperature or UV light. nine0003

USER NOTE

Threads in this category have a gradient between two colors, such as purple to pink, blue to green, or yellow to green.

As with other exotic 3D printer filaments, the color changing filament is based on PLA or ABS.

-