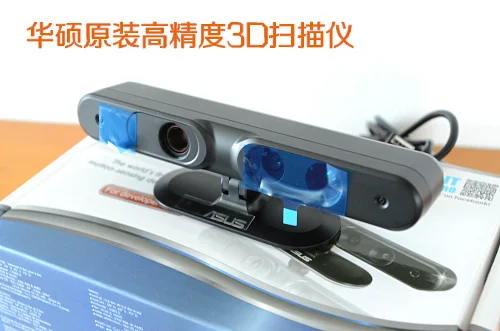

Xtion pro live 3d scanner

3ders.org - How to upgrade your Asus Xtion into a handheld 3D scanner

Jan.3, 2014

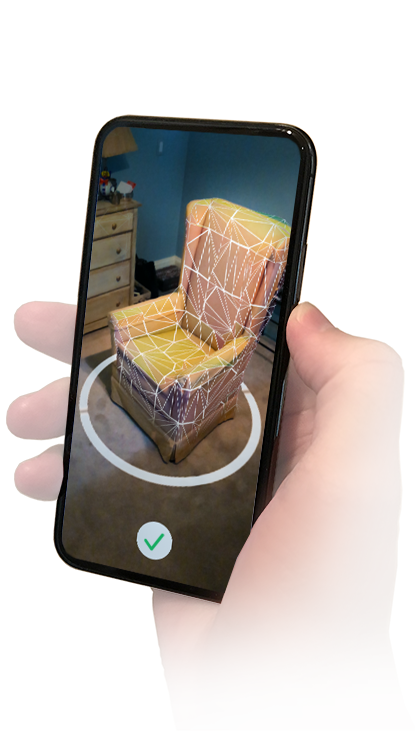

3D scanners give you the power to "scan your world" and rapidly creates 3D maps of objects, complete with colors and textures. At le FabShop in Paris, makers have been using the Asus Xtion or Kinect and software package Skanect for capturing full colour 3D scans. However none of these objects is ergonomic. Instead of just creating another handle for the Xtion, le FabShop decided to transform it into a professional looking tool.

le FabShop's handle is designed to be comfortable, while solving a few other problems. It has following features:

- It keeps a 45 degrees axis for the scan to be oriented easy

- The USB cable is hidden inside the handle, so it isn't in the way

- The base is large enough, so the scanner can balance on itself

- The base is copying the shape of manfrotto's classic plate for entry level tripods.

- If you own a different type of tripod, you can still screw your plate in the handle by using the hole at the bottom

- It also includes a lense protector that clips around the sensor, for safe transportation.

"We found the Kinect a little bit annoying to carry with us on events and presentations. We were also quite disappointed by the performance of the Sense from 3D System, which isn't bad, but just not better than what we already had." says Samuel Bernier, industrial designer and Creative Director at le FabShop.

"Combined with Skanect, the ASUS Xtion is a great scanning tool. Be careful of one detail. If you want color on your 3D file, you got to purchase the Xtion pro LIVE, not just the Xtion pro. Only the LIVE version has the camera that captures the colors. In total, expect to pay 300 dollars for tour DIY 3D scanner. "

"

You can see some results of their scans here. The 3D design files for le FabShop's handle are available for download on Thingiverse. If you are in Europe, you can also order the Xtion on the FabStore here.

3D printable grip and lens cover from CreativeTools

le FabShop is not the only one who wanted to make 3D scanning much easier and the device more comfortable to use. CreativeTools from Sweden has made another 3D printable grip for ASUS XTION handheld 3D scanner with different design.

It has the following features/advantages:

- The lens cap protects the optics when the XTION is stowed away

- The lens cap can be snapped to the back of the XTION while 3D scanning. This keeps it always together with the device so it is not lost.

- The XTION can stand upright on the flat base surface of the grip.

- The holes on the base make it easy to attach the device to a table top, wall, camera stand, etc.

- The grip has a dedicated pocket for the ferrite core of the USB cable, thus making the design slim.

- The USB cable resides inside the grip and comes out on the back part of the base. This keeps it out of the way while 3D scanning and lets the XTION stand on flat surfaces.

- The cable is held in place by inserting short pieces of 1.75 mm 3D print filament. No glue or screws required.

- The four legs of the lens cover and flat base makes it easy to wrap the USB cable and keep it tidy when the XTION is stowed away.

CreativeTools has uploaded the original Rhino surface CAD file and a STEP version, as well as STL file of the handle and the lens cover on Thingiverse. Watch the video below, or check out the the basic steps on how to 3D scan a human body and finalise the mesh in Autodesk MeshMixer on Instructables.

Posted in 3D Scanning

Maybe you also like:

- 3D scanning turns a metro journey into an abstracted virtual trip

- Rembrandt prints in 3D: for research on painting process

- MakerBot shows off Digitizer 3D Scanner, optimized for 3D Printing

- Aussie scientists create first detailed 3D scan of the Tower of Pisa

- Structure Sensor turns your iPad into a 3D Scanner

- Artec 3D scans the original battle field of Borodino

- With $2.8M Series A-1 funding, 3-D Scanner Co. Matterport prepares for rollout

- $199 Rubicon 3D scanner on indiegogo

- MakerBot launches the MakerBot Digitizer 3D Scanner

Toto wrote at 9/1/2015 6:36:09 PM:

I say use the software of http://www. 3duniversum.com/

3duniversum.com/

▷ asus xtion pro live 3d models 【 STLFinder 】

Asus Xtion Pro Live

grabcad

RGBD Camera Asus Xtion Pro Live 3D modeled for robot Bender simulations in Gazebo.more information about Bender in http://robotica-uchile.amtc.cl/bender-index.html

Ergonomic handgripp for Asus Xtion Pro Live

thingiverse

Ergonomic handgripp for Asus Xtion Pro Live for who, who want to use their Xtion as handheld 3D-Scaner. Made of 2 Half-Parts and 2 Pins to stick them together. Instructions I made the Gripp of Black. ..

..

Asus Xtion Pro Live Lens Cover

thingiverse

Just a simple cover to protect the lenses on the front of an Asus Xtion Pro Live RGB-D sensor. It has a slot for the stand and also has ears so that you can wind the USB cable around the whole thing to keep the cover on the sensor. Instructions...

ASUS Xtion Pro Live

grabcad

Roughly measured with a caliper

Camera Mounts for Asus Xtion (Pro Live) on Servo-Brackets

thingiverse

With this mounts the cameras Asus Xtion or Asus Xtion Pro Live can be mounted on a servo bracket to be able to pan and tilt the camera for example on a robot. The part "camera_mount_fix.stl" fixes the camera in a strict vertical position regarding to...

The part "camera_mount_fix.stl" fixes the camera in a strict vertical position regarding to...

Camera Mounts for Asus Xtion (Pro Live) on Servo-Brackets

prusaprinters

With this mounts the cameras Asus Xtion or Asus Xtion Pro Live can be mounted on a servo bracket to be able to pan and tilt the camera for example on a robot.The part "camera_mount_fix.stl" fixes the camera in a strict vertical position regarding to...

Asus Xtion Pro Mount

thingiverse

This is a mount to attach an Asus Xtion Pro or Asus Xtion Pro Live by 1 or 4 M6 bolts. The hole for the single is in the center of the base and has room for a M6 nut. The holes for the 4 M6's are located at the corners of the base spaced 25mm apart...

The holes for the 4 M6's are located at the corners of the base spaced 25mm apart...

TurtleBot2 Asus Xtion Pro Clamp

thingiverse

It supports to hold the asus xtion pro in position.

Asus Xtion Pro Grip Stand

thingiverse

Fast made simple handle for Asus Xtion Pro. There are two versions, one with four feet and one with six for anxious persons. Constructed in about 20 minutes it's surely not a beauty but it works for me. Printing time about 100 minutes at .25...

Mobile 3D Scanner ( Asus Xtion Pro Mount Holder)

thingiverse

This is the result a 7 inch "Low Budget Tablet PC" and Xition Pro mounted on a grip (thx at the developer from creative Tools for this beautiful grip ) http://www. thingiverse.com/thing:126936 and its was realy cheap for a all parts of the 3D Scanner...

thingiverse.com/thing:126936 and its was realy cheap for a all parts of the 3D Scanner...

Motor mount for Asus Xtion Pro

thingiverse

This is a mount to attach a dc motor (diameter 24mm) to an Asus Xtion Pro or Asus Xtion Pro Live. The motor will have an off-axis weight attached, so it will cause a vibration. ...This was designed for a project of robotics research group of the...

Asus Xtion PRO mount for MacBook Pro Retina.

thingiverse

This is a Asus Xtion PRO mount for Macbook Retina.

mirrorboy's scan data from Xtion PRO Live

thingiverse

I'm using ・Processing ・Modelbuilder ・Meshlab ・Xtion PRO Live Check "Making Things See" . http://makingthingssee.com

http://makingthingssee.com

support ASUS Xtion

thingiverse

For support ASUS Xtion

ASUS XTION stand

thingiverse

Mounting for the ASUS XTION 3D sensor to be used with a Samsung ultrabook. Instructions Printed in PLA this time. The width of the mounting is slightly larger than the lid of the Samsung ultrabook so...

Asus Xtion Mounts

thingiverse

A pair of mounts for the Asus Xtion depth sensor. The first is a single piece (xtion-ax-mount.stl) which can be used to mount an Xtion to a Bioloid frame component. The second mount comprises two pieces (top and bottom) for mounting the Xtion to a...

The first is a single piece (xtion-ax-mount.stl) which can be used to mount an Xtion to a Bioloid frame component. The second mount comprises two pieces (top and bottom) for mounting the Xtion to a...

ASUS XTION 3D scanner - Handle and Lens Cover

grabcad

VIDEO https://www.youtube.com/watch?v=Brn2EJ-3JEU THE HARDWARE - ASUS XION - http://www.asus.com/Multimedia/Xtion_PRO/ MORE INFORMATION Please contact [email protected] - www.creativetools.se KOMPATIBLE 3D SCANNER SOFTWARE - Artec Studio -...

Asus Xtion support

thingiverse

Xtion support for Lynxmotion Base Rotate.

ASUS XTION 3D scanner - Handle and Lens Cover

cults3d

A 3D printable grip and lens cover for the ASUS XTION motion sensing hardware which is very affordable and popularly used as a hand-held 3D scanner.

ASUS XTION 3D scanner - Handle and Lens Cover

youmagine

No glue or screws required.- The four legs of the lens cover and flat base makes it easy to wrap the USB cable and keep it tidy when the XTION is stowed away.THE HARDWARE - ASUS XION - http://www.asus.com/Multimedia/Xtion_PRO/MORE INFORMATIONPlease...

ASUS XTION 3D scanner - Handle and Lens Cover

thingiverse

(Se video https://www. youtube.com/watch?v=Brn2EJ-3JEU) THE HARDWARE ASUS XION - http://www.asus.com/Multimedia/Xtion_PRO/ KOMPATIBLE 3D SCANNER SOFTWARE Artec Studio - http://www.artec3d.com/software/ ReconstructMe - http://reconstructme.net/ Skanect...

youtube.com/watch?v=Brn2EJ-3JEU) THE HARDWARE ASUS XION - http://www.asus.com/Multimedia/Xtion_PRO/ KOMPATIBLE 3D SCANNER SOFTWARE Artec Studio - http://www.artec3d.com/software/ ReconstructMe - http://reconstructme.net/ Skanect...

ASUS XTION 3D scanner grip and lens cover

sketchfab

A 3D printable grip and lens cover for the ASUS XTION motion sensing hardware which is very affordable and popularly used as a hand-held 3D scanner. ...Instructions: http://bit.ly/KoxNPG

ASUS XTION 3D scanner - Handle and Lens Cover

myminifactory

A 3D printable grip and lens cover for the ASUS XTION motion sensing hardware which is very affordable and popularly used as a hand-held 3D scanner. ...Here is the link for Youtube video showing the making process.

...Here is the link for Youtube video showing the making process.

Xtion Pro Live mount for RX-64 servo / FR05-h2 frame

thingiverse

Mount for attaching a Asus Xtion Pro Live RGB-D sensor to a Robotis FR05-h2 servo frame

Xtion Pro Live mount for RX-28 servo / FR07_h2 frame

thingiverse

Mount for attaching a Asus Xtion Pro Live RGB-D sensor to a Robotis FR07_h2 servo frame

Asus Live G500TG 3D model

cgtrader

High Detailed Asus Live G500TG black 3d model with MeshSmooth applied. This 3d model main file format is 3ds Max 2009 and other formats are available can be used for all 3d applications. Product Features:: With Studio Clean Geometry Product is...

This 3d model main file format is 3ds Max 2009 and other formats are available can be used for all 3d applications. Product Features:: With Studio Clean Geometry Product is...

Asus Xtion mount for TurtleBot

cults3d

This is a mount for an ASUS Xtion 3D sensor (similar to the Primesense and Kinect sensors) for the TurtleBot http://www.turtlebot.com http://store.iheartengineering.com/TurtleBot-Complete-Kit-Assembled/dp/B005SX6MCO mobile robot. These parts are...

Asus Xtion mount for TurtleBot

thingiverse

This is a mount for an ASUS Xtion 3D sensor (similar to the Primesense and Kinect sensors) for the TurtleBot http://www. turtlebot.com http://store.iheartengineering.com/TurtleBot-Complete-Kit-Assembled/dp/B005SX6MCO mobile robot. These parts are...

turtlebot.com http://store.iheartengineering.com/TurtleBot-Complete-Kit-Assembled/dp/B005SX6MCO mobile robot. These parts are...

Asus Live

grabcad

-ASUS Live -G500TG - Azul

ASUS XTION 3D scanner - Handle and Lens Cover Free 3D model

cgtrader

A 3D printable grip and lens cover for the ASUS XTION motion sensing hardware which is very affordable and popularly used as a hand-held 3D scanner.VIDEOhttp://youtu.be/fOZo-fL2NCATHE HARDWARE - ASUS XION -...

Videos: Artec Studio for Kinect

217 +1

Exchange PROSTENS

Added: 08/26/2013 at 17:30

Duration: 01:26

ARTEC Studio is a professional dedication software, which is, which turns your Kinect, Asus Xtion Pro or PrimeSense sensor into a real 3D scanner.

With this application you can:

• make real-time scanning, automatic alignment. Post-processing is done at scan

• Scan in full color

• Automatically optimize models to get the best results

• Scan live objects and small movements are compensated to ensure good quality of the final model

• Use a full, interactive GUI in 10 languages

• Measuring tools

• Complete documentation and customer support

0029

Wood lathe - do it yourself!

Wear resistance in industry: case studies of advanced ceramics

Delivery of CNC hydraulic press brake SX 40220 to Kashira nine0005

Different ways of laser welding and their advantages

Launch of CNC milling machine TS 2030 PRO in Yoshkar-Ola

Press for creating plastic bricks - do it yourself nine0005

Metal sculptures by Spanish artist Giorgi Pulariani

Commissioning of a fiber laser for cutting pipes XTC-T220/1500 Raycus in Neftekamsk

Alexandra Ivleva aka Weld Queen is a contemporary Russian artist, sculptor and performer. nine0005

nine0005

Related video

how to quickly create prostheses and other unique products

Reverse engineering

Implementation stories

Medicine

Author: Alexey Chekhovich

Author: Alexey Chekhovich

Video: Real-time 3D Face Scan | Order a free test scan | 3D scanner helps victims | 3D scanning of the human body in great detail

Creating prostheses using 3D technologies: the era of new possibilities

As technology improves and becomes more accessible, there are new opportunities to solve the most complex medical problems. A team of researchers from the company Chabloz Orthopedie (France) managed to create a unique and truly revolutionary prosthesis.

Chabloz Orthopédie worked with Denis Gauthier, who had his forearm amputated. First, the experts performed a 3D scan of the patient's healthy arm using a peel 3d scanner to obtain its mirror image. This was done so that the designed product ideally repeated the proportions of a healthy limb. The rest of the amputated arm was also scanned to achieve a comfortable and ergonomic fit for the prosthesis. nine0005

The rest of the amputated arm was also scanned to achieve a comfortable and ergonomic fit for the prosthesis. nine0005

Denis Gaultier with finished prosthesis

The team then proceeded to design a CAD model and develop a myoelectric prosthesis. Batteries, sensor cables and an artificial hand were integrated with the fabricated forearm. The prosthesis itself was designed in CAD and printed on a 3D printer. HP Jet Fusion technology was used to print various components of the forearm. After manufacturing, all parts were finished and painted. nine0005

The use of 3D scanning and 3D printing guarantees not only the correct fit of the fixture, but also gives complete freedom of movement. A new approach to prosthesis design allows professionals to develop solutions that are lightweight and highly customizable. Did you know that 3D printed parts are 20% lighter than their carbon or fiberglass counterparts? Such products also have the necessary rigidity, hardness and durability. nine0005

nine0005

Later, this innovative prosthesis was combined with the BeBionic hand, one of the most advanced bionic limbs, and a state-of-the-art myoelectric forearm and hand was custom-made. Gauthier's case is a great example of the innovative use of 3D measurement and 3D printing technologies.

The video shows the complete process of digitizing the face and ears using the Creaform Go!SCAN 20 portable 3D scanner (its analogue in white peel 2 is now being produced). This solution provides a detailed digital model for use in areas such as plastic and reconstructive surgery, in particular, facial prosthetics. nine0005

Order a test 3D scan for free!

3D scanner helps victims

Unfortunately, tragedies inevitably occur around the world, and those affected need help. But, fortunately, there are organizations such as Médecins Sans Frontières (Doctors Without Borders) that do their best to provide them with the necessary treatment and care. Since 2016, the organization has been working tirelessly to solve the problem of providing prostheses to those in need around the world. The goal is to help amputees regain independence. The solutions that are used in this case are 3D technologies. nine0005

But, fortunately, there are organizations such as Médecins Sans Frontières (Doctors Without Borders) that do their best to provide them with the necessary treatment and care. Since 2016, the organization has been working tirelessly to solve the problem of providing prostheses to those in need around the world. The goal is to help amputees regain independence. The solutions that are used in this case are 3D technologies. nine0005

Upon completion of the medical examination of the patient, doctors determine his needs and expectations. Using the peel 3d scanner, with minimal discomfort for the victim, a high-precision digital model of the injured limb is created. Compared to traditional impression making, 3D scanning is significantly faster and does not require contact. The result of the 3D scan is then transferred to the virtual sleeve and prosthesis design software. The developed component is made on a 3D printer and installed on the patient's limb. If necessary, during the installation process, the prosthesis and sleeve are finalized. After three months of use, the patient is invited to evaluate the comfort of the prosthesis. nine0005

After three months of use, the patient is invited to evaluate the comfort of the prosthesis. nine0005

MSF has also developed a similar procedure to create compression masks for burn patients. Here, the use of non-contact technology also provides significant advantages over traditional plaster bandages, not only making the procedure less painful for the patient, but also speeding it up, allowing for a much larger number of people in needy countries to be treated.

Physiotherapist Pierre Moreau scans a patient with head burns. Then, based on the scan, a transparent pressure therapy mask is created / Photo: Elisa Oddone, Al Jazeera nine0005

Pierre Moreau, a physiotherapist from Médecins Sans Frontières, says: “The purpose of the 3D project is to help patients in need of special rehabilitation care. We launched this project in Amman in 2017, where we started providing upper limb amputees with 3D printed prostheses. But simply printing a prosthesis is not enough - we try to understand the needs of the victims, find individual solutions and keep them in their new position for as long as possible. We are assisted by an interdisciplinary team of rehabilitation workers and engineers. Then our specialists helped more than 30 patients in Jordan. nine0005

We are assisted by an interdisciplinary team of rehabilitation workers and engineers. Then our specialists helped more than 30 patients in Jordan. nine0005

In 2018, we began to use the technology in another direction - for patients with burns, especially on the face and neck. Skin complications are a very serious problem for burn victims. Hypertrophic scars may form, and pressotherapy is needed. This requires transparent masks, but they are quite difficult to produce on site. Therefore, we started to explore 3D scanning, 3D printing and computer modeling in an attempt to help our team in the production of these devices for patients who so desperately need them. Now we provide more than 50 transparent facial orthoses. nine0005

When I think about this project, I always remember one story that demonstrates its development. In 2017 in Jordan, we had a small patient with burns and an amputation - she had no arm, and the condition of her remaining part was too complex to develop a prosthesis. Then we couldn't help her. But she came back the following year and we were finally able to make a prosthesis for her. For the first time, she was able to use her hand. This is one of our best memories of the project and a measure of its success.” nine0005

Then we couldn't help her. But she came back the following year and we were finally able to make a prosthesis for her. For the first time, she was able to use her hand. This is one of our best memories of the project and a measure of its success.” nine0005

3D scanning of the human body in great detail

There are already more than 7.5 billion people on Earth, and although some are very similar to each other, there are no completely identical people. With such a variety of faces, it is not at all surprising that in the process of evolution the human brain became masterfully recognizing the smallest details that help to distinguish them. To get as close as possible to the original, the 3D scan of the statue must be extremely accurate and have a high geometric resolution. nine0005

3D copies: 2013 Kinect scan (left figure) and peel 3d (right figure)

To improve the quality of scanning, the Canadian company USIMM has begun using peel 3d. The company specializes in the machining of non-metallic materials and is constantly involved in artistic projects. The main goal was to show the evolution of CNC machining by comparing the results of a 3D version of one employee made a few years ago with current results. nine0005

The main goal was to show the evolution of CNC machining by comparing the results of a 3D version of one employee made a few years ago with current results. nine0005

According to USIMM's Leia Lepage, scanning a living person is not an easy task: “Scanners are usually quite sensitive to the smallest movements, even if it's just breathing. Scanning a person is very difficult.” In order to accomplish such an extraordinary task, the USIMM team needed a 3D scanner that was immune to certain movements - but at the same time had high resolution and accuracy. Peel 3d possesses such qualities: a resolution of up to 0.5 mm and a volumetric accuracy of 0.5 mm/m. nine0005

The team scanned the same employee in the same pose as they did a few years ago. The resulting 3D scan data was sent to a five-axis CNC machine, and then a full-size replica of a person was created from polystyrene. The results were incredible.

The scan results obtained earlier by the Skanect device did not stand next to the peel 3d results.