Carbon m1 3d printing

The Carbon M1 3D Printer - Start 3D Printing at Full Scale

The Carbon DLS™ process at an entry-level price

Nicht in Europa erhältlich!

Contact an Expert

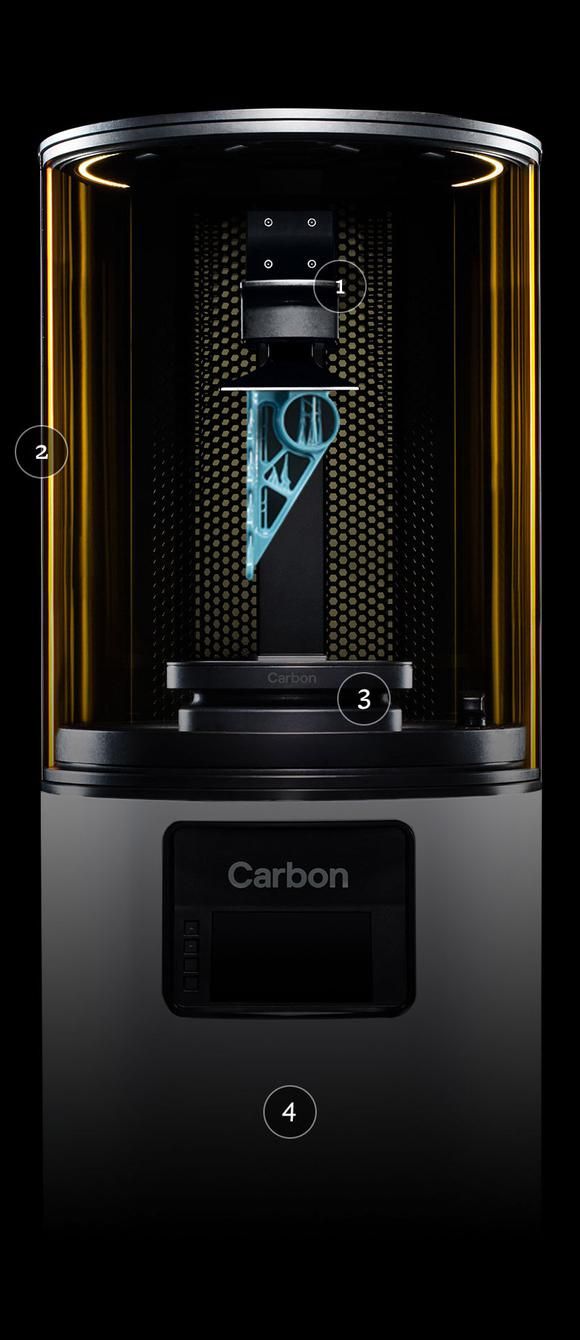

The M1 Printer

Prototyping and production at small volumes

Offering the same speed, accuracy, and reliability as the larger M2 printer, the M1 enables any company to unlock the benefits of producing parts using the groundbreaking Carbon Digital Light Synthesis™ (Carbon DLS™) process at an affordable price. The M1 printer is compatible with all one-part resins, third-party resins, and dual-cure resins that do not require heating during the print.

Get Started with the DLS Process

Get the great accuracy, consistency, reliability, and material performance of Carbon DLS technology at a low price point.

Accelerate Prototyping and Production

Small batch sizes and fast print times are perfect for printing a high mix of low-volume applications throughout the day, such as functional prototypes in multiple dual-cure resins, or multiple dental applications.

Contact an Expert

DLS Process

Carbon Digital Light Synthesis technology uses light projection in combination with oxygen-permeable optics to produce isotropic parts with exceptional surface finish.

Learn More

Materials

Carbon offers the widest range of real, functional materials and industry-proven third-party dental resins.

Learn More

The DLS Advantage

We offer unique capabilities and industry-leading service and support. See why Carbon is more than a printer.

Learn More

Discover the right Carbon 3D printer for your production needs and budget

M1 | M2 | M3 | ||

| Build Volume (X x Y x Z) | 141 x 79 x 326 mm 5.  6 x 3.1 x 12.8 in 6 x 3.1 x 12.8 in | 189 x 118 x 326 mm 7.4 x 4.6 x 12.8 in | 189 x 118 x 326 mm 7.4 x 4.6 x 12.8 in | |

|---|---|---|---|---|

| XY; Z Resolution* | 75 µm; 25, 50 or 100 µm | 75 µm; 25, 50 or 100 µm | 75 µm; 25, 50 or 100 µm | |

| General Accuracy** | Up to ±70 μm + 1 μm per mm dimension size Up to ±0.003 in + 0.001 in per in dimension size | Up to ±70 μm + 1 μm per mm dimension size Up to ±0.003 in + 0.001 in per in dimension size | Up to ±65 µm+ 1 µm per mm dimension size Up to ±0.0026 in + 0.001 in per in dimension size | |

| Production Repeatability Accuracy** | Up to ±40 μm Up to ±0.002 in | Up to ±40 μm Up to ±0.002 in | Up to ±37 μm Up to ±0.  002 in 002 in | |

| Printer Software | Included in your subscription with regular OTA software updates about every eight weeks. | |||

| Service & Support | Integrated service package with real-time customer support and preventative maintenance for optimized machine uptime. | |||

| Pricing | Carbon 3D printers start at $25k per year and come with a variety of packages suited to your needs. Contact us for printer-specific pricing details. | |||

* Z resolution is adjustable from single digit microns to multiple hundred microns, and can be optimized through working with Carbon on your target application.

** For more information about accuracy, please refer to Carbon DLS accuracy guidelines for engineering materials and dental materials.

See the full lineup of Carbon printers

Get a Quote

Contact an Expert

Smart Part Washer

Reduce labor costs and increase throughput

Simple, Mess-Free Washing

A game-changer in cleaning parts. Simply place the build platform from an M2 printer into the Smart Part Washer and let it run.

Simply place the build platform from an M2 printer into the Smart Part Washer and let it run.

Maximize Part Quality

Get a consistent, predictable, and thorough clean of your prints by moving from a manual process to a smart, automated process.

70% Labor Savings Per Wash

With optimized wash protocols, labor time per print is minimal. Spend that time more productively—making new parts.

| Size | 35 in. x 24 in. x 49 in |

| Weight | 350 lb |

| Washer Volume | 1x build platform |

Cutting-Edge Design Powered by Advanced Software

Use Familiar Tools

Carbon 3D printers support STL files. Use standard CAD tools to generate your design, then upload your STL into Carbon’s print planning tool.

Lattice DesignCarbon’s Design Engine software helps customers generate the perfect lattice to fit desired form, mechanical response, and durability requirements.

Learn More

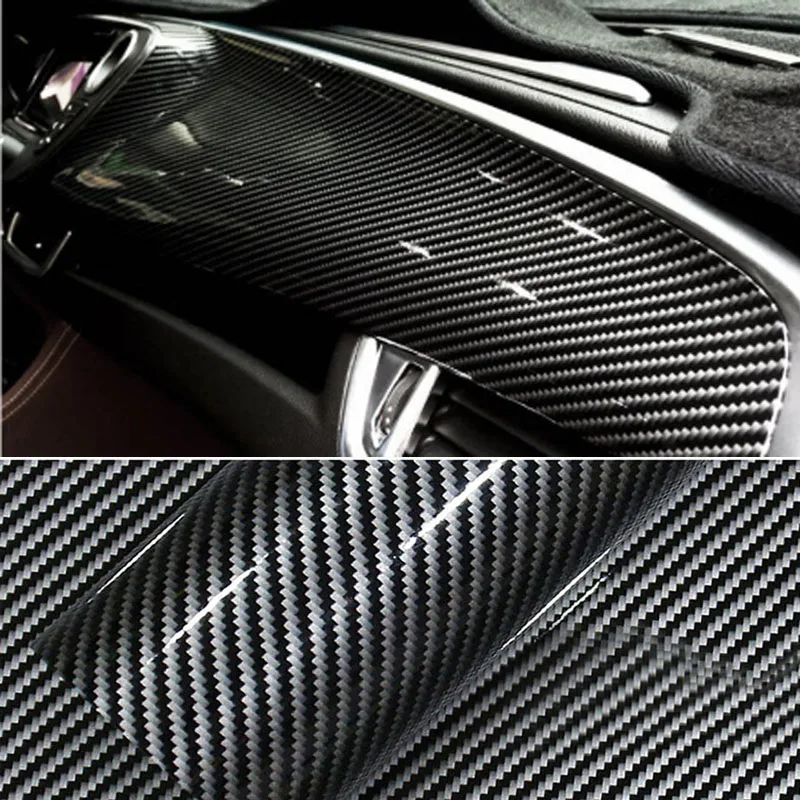

Surface TexturesThere’s no need for a complicated pipeline of third-party tools. Add branded, aesthetic, or functional textures to your parts, all from within Carbon software.

Save Time and Improve Quality with Automated Print Preparation

Auto Layout

Save time when preparing builds with multiple parts by using Carbon’s auto layout feature.

Advanced Auto Supports

Advanced auto supports save time and ensure high-quality results by offering a reliable, FEA-backed strategy for supporting parts during printing.

Boost Efficiency with Print Analytics

Manufacture at Scale

Because every machine is connected, Carbon’s entire workflow can be logged, monitored, and reviewed through tools and dashboards to offer deep insights into fleet performance and utilization.

Fleet Management Dashboard

Review production data and manage a fleet of devices in real-time from one dashboard. Queue new projects seamlessly.

Queue new projects seamlessly.

Part Traceability

Preserve a part’s entire history—from CAD file, to design, to print—in one digital record. Streamline quality assurance with embedded unique part identifiers to quickly review a part’s history.

Better Operations with Connected Hardware

Over-the-Air Software Updates

Carbon’s 3D printers constantly get better, even after they’re installed. Regular software updates improve every aspect of the Carbon DLS™ process, offering improved user experience, faster and more accurate prints, and more sophisticated process management.

View Software Release History

Real-time Status and Control

Monitor and manage printer and parts at every stage of the printing process wherever you are, regardless of whether you have one or hundreds of Carbon 3D printers.

Accelerated Customer Support

Carbon’s customer support team can identify and troubleshoot printer issues remotely without interrupting business operations. Data-backed predictive maintenance through real-time alerts inform customers about issues that might impact production.

Data-backed predictive maintenance through real-time alerts inform customers about issues that might impact production.

Carbon 3D Printer Pricing - Carbon

Carbon 3D printer pricing starts at $25k per year. Contact a Carbon expert to help you select the right printer and tailor pricing based on your needs.

Get a Quote Now

Carbon product offerings and pricing vary by country and region. Please contact a Carbon expert for a quote.

Discover the right Carbon 3D printer for your production needs and budget

Carbon printers come in a variety of models with build volumes and price points to suit your specific needs.

M1 | M2 | M3 | M3 Max | L1 | ||

| Build Volume (X x Y x Z) | 141 x 79 x 326 mm 5.  6 x 3.1 x 12.8 in 6 x 3.1 x 12.8 in | 189 x 118 x 326 mm 7.4 x 4.6 x 12.8 in | 189 x 118 x 326 mm 7.4 x 4.6 x 12.8 in | 307 x 163 x 326 mm 12.1 x 6.4 x 12.8 in | 400 x 250 x 460 mm 15.7 x 9.8 x 18.1 in | |

|---|---|---|---|---|---|---|

| XY; Z Resolution* | 75 µm; 25, 50 or 100 µm | 75 µm; 25, 50 or 100 µm | 75 µm; 25, 50 or 100 µm | 75 µm; 25, 50 or 100 µm | 160 µm; 25, 50, or 100 µm | |

| General Accuracy** | Up to ±70 μm + 1 μm per mm dimension size Up to ±0.003 in + 0.001 in per in dimension size | Up to ±70 μm + 1 μm per mm dimension size Up to ±0.003 in + 0.001 in per in dimension size | Up to ±65 µm+ 1 µm per mm dimension size Up to ±0.  0026 in + 0.001 in per in dimension size 0026 in + 0.001 in per in dimension size | Coming Soon | Up to ±70 μm + 1 μm per mm dimension size Up to ±0.003 in + 0.001 in per in dimension size | |

| Production Repeatability Accuracy** | Up to ±40 μm Up to ±0.002 in | Up to ±40 μm Up to ±0.002 in | Up to ±37 μm Up to ±0.002 in | Coming Soon | Up to ±40 μm Up to ±0.002 in | |

| Explore M1 | Explore M2 | Explore M3 | Explore M3 Max | Explore L1 | ||

* Z resolution is adjustable from single digit microns to multiple hundred microns, and can be optimized through working with Carbon on your target application.

** For more information about accuracy, please refer to Carbon DLS accuracy guidelines for engineering materials and dental materials.

Need Pricing for Your Part?

Not in the market for a printer but want to understand pricing for your part? Get a quote from a certified Carbon production partner. These manufacturers are certified experts in the Carbon DLS 3D printing process––from design to production.

Get Part Pricing

Carbon 3D Printer Pricing FAQs

How much does a Carbon 3D printer cost?

Carbon 3D printer pricing starts at $25k per year. Contact a Carbon expert now to help you select the right printer and tailor pricing based on your needs.

Contact a Carbon Expert

“The subscription model is beneficial as we are able to make payments over time versus one large capital investment. This enables us to keep costs down and allows for the flexibility to add more printers as the division grows.” Nick Windlow Smile Shapers, Director of Business Development

Why are Carbon 3D printers offered as a subscription?

We focus on helping you succeed in delivering better products in less time–not on selling you equipment. We build an ongoing relationship with you starting the day your printer is installed, and consistently and reliably deliver technology updates, expertise, and support to help you every step of the way. We have proven this approach with a broad range of customers, from major global brands to family-owned businesses, helping them deliver exceptional products efficiently.

We build an ongoing relationship with you starting the day your printer is installed, and consistently and reliably deliver technology updates, expertise, and support to help you every step of the way. We have proven this approach with a broad range of customers, from major global brands to family-owned businesses, helping them deliver exceptional products efficiently.

Advantages of the Carbon subscription

-

A partner committed to your long-term success instead of a one-time printer sale.

Paying upfront for a printer puts all the performance risk on you as the customer for your success. We believe in our technology and approach enough to share the risk to ensure you are successful. Instead of paying us upfront for equipment, you pay us as you use it. If we don’t deliver exceptional value, you won’t renew your subscription.

-

Flexibility in your capital equipment investments.

Carbon subscriptions can vary in length depending on your needs.

Shorter subscriptions allow our customers to try out different printers without having to buy them outright. You have the option to renew your subscription, return your 3D printer, or upgrade your 3D printer.

Shorter subscriptions allow our customers to try out different printers without having to buy them outright. You have the option to renew your subscription, return your 3D printer, or upgrade your 3D printer. -

Updates, maintenance, and support are included.

Owning a printer means you own maintenance and upkeep. With Carbon, we handle maintenance and we routinely upgrade printers with new software to improve your printers’ performance. Carbon printers have a track record of consistent, reliable and accurate production over time. We maintain them and ensure excellent uptime so that you can focus on developing and producing great products.

The value of a subscription model for connected 3D printers

| Traditional Ownership of Non-Connected 3D Printer | Subscription Model for Connected 3D Printer | |||||||

|---|---|---|---|---|---|---|---|---|

| Continual platform improvement | Gradually becomes obsolete after date of purchase | Improves over time with over the air updates every few weeks | ||||||

| Immediate support for new materials | Purchase separately or available on new version | Included* | ||||||

| Integrated technical support | Purchase service package separately | Included | ||||||

| Minimal unplanned downtime | Not connected, resulting in slower response time | Real-time customer support | ||||||

| Predictive maintenance to optimize machine uptime | Lagged service response time halts production efforts | Preemptive troubleshooting by Carbon keeps machines running | ||||||

* Exceptions include additional hardware costs for specific materials, e. g., RPU 130 and EPU 41 Black. g., RPU 130 and EPU 41 Black.Learn more about our subscription pricing model. | ||||||||

What happens after my subscription term is finished?

Once your subscription has finished, you have the option to renew your subscription, return your 3D printer, or upgrade your 3D printer.

Can I upgrade my printer during my subscription term?

Yes, you can upgrade your 3D printer during your Carbon subscription term.

What types of platform improvements can be expected?

Gain access to the latest software tools and support for new materials

Improvements to the Carbon platform add new features and capabilities in design and automation, fleet and factory management, and printing and post-processing. These updates can instantaneously deliver improved print outcomes, better workflow management, new design capabilities, and seamless support for new resins. See our recent platform improvements here.

What makes Carbon technical support so great?

Real-time customer support with predictive maintenance

Our connected 3D printers offer streamlined, remote troubleshooting and accelerated customer support. By monitoring customer operational metadata, we can precisely predict and prevent issues before they impact production. With a customer’s permission, our services team is able to view important contextual data and replicate issues quickly, cutting downtime.

By monitoring customer operational metadata, we can precisely predict and prevent issues before they impact production. With a customer’s permission, our services team is able to view important contextual data and replicate issues quickly, cutting downtime.

Ready to Get Started?

Speak with an expert to learn more about how Carbon can support your product development process at every step, from concept to mass production.

Contact a Carbon Expert

Get a Free Sample Part

There’s no substitute for holding a 3D printed part in your hand. Experience the quality of Carbon DLS-printed parts by requesting a free sample part below.

Request a Free Sample Part

Get Your Parts Made

Not in the market for a printer but still want Carbon DLS-printed parts? Find a certified Carbon production partner to get your parts made. These manufacturers are certified experts in the Carbon DLS 3D printing process—from design to production.

Find a Carbon Production Partner

Find a Carbon Dental Outsource Partner

Carbon 3D Printers

The L and M Series printers and Smart Part Washer offer versatility and enable scalable manufacturing.

Learn More

Materials

Find the right material for your project, from consumer product elastomers to high-temperature automotive materials.

Learn More

Carbon Design Engine

Design high-performance conformal lattices to improve product performance and speed up print time.

Learn More

Carbon advances high-speed 3D printing with a focus on mass additive manufacturing

News

Carbon has announced a new model of a high-speed industrial-grade stereolithographic 3D printer using proprietary CLIP technology, which enables continuous high-performance photopolymer 3D printing. Carbon L2 systems are being considered by Adidas, Ford and Riddell in the context of mass additive manufacturing. nine0003

The range of potential users of the novelty has been deliberately limited so far: Carbon is offering a new system to individual enterprises in need of mass additive manufacturing tools and possessing the necessary financial resources, such as Adidas and Ford. The German shoe brand is ramping up 3D printing of soles for its Futurecraft 4D line of sneakers to half a million pairs a year, while Ford is ramping up mass production of 3D printed automotive parts at its newly opened Detroit Digital Manufacturing Center. The other day, Riddell Sports Group, a sports equipment manufacturer, also received access to a new additive platform - this company intends to print customized linings for protective helmets used, among other things, by players in the US National Football League (NFL). nine0003

The German shoe brand is ramping up 3D printing of soles for its Futurecraft 4D line of sneakers to half a million pairs a year, while Ford is ramping up mass production of 3D printed automotive parts at its newly opened Detroit Digital Manufacturing Center. The other day, Riddell Sports Group, a sports equipment manufacturer, also received access to a new additive platform - this company intends to print customized linings for protective helmets used, among other things, by players in the US National Football League (NFL). nine0003

The original 3D printer in the Carbon line was designated M1, and the first-born was replaced by a modified and scaled version of the M2. L1 can be considered a further development of the model range, which differs from its predecessors in the first place by an increased usable volume - five times compared to M2 and ten times compared to M1. The company has not yet disclosed the exact measurements of the working area, as well as the cost of the proposal. We only recall that the M1 and M2 are not available for purchase, but for rent: for example, for forty thousand dollars a year, the user gets access to the M1 3D printer, washing and annealing equipment, software updates and full technical support. It can be assumed that L2 will be similarly offered for a subscription fee. nine0003

We only recall that the M1 and M2 are not available for purchase, but for rent: for example, for forty thousand dollars a year, the user gets access to the M1 3D printer, washing and annealing equipment, software updates and full technical support. It can be assumed that L2 will be similarly offered for a subscription fee. nine0003

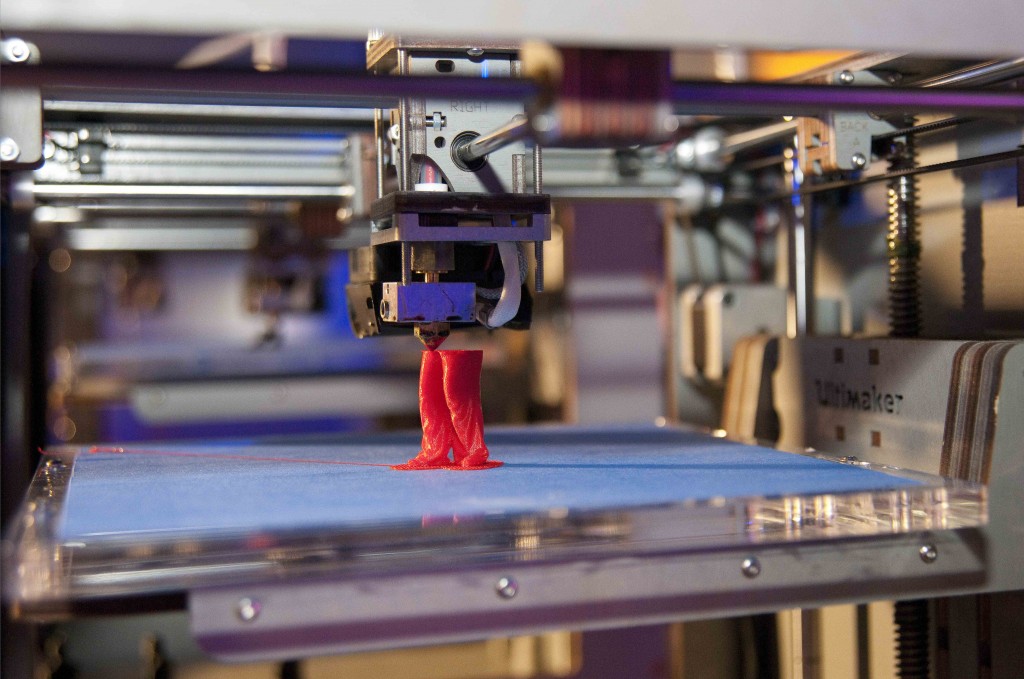

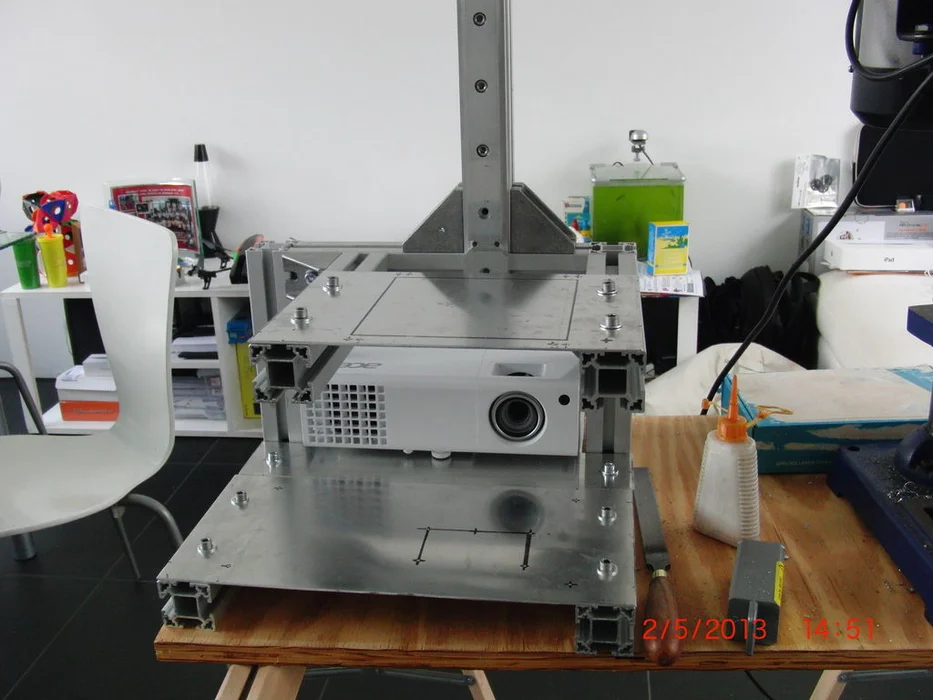

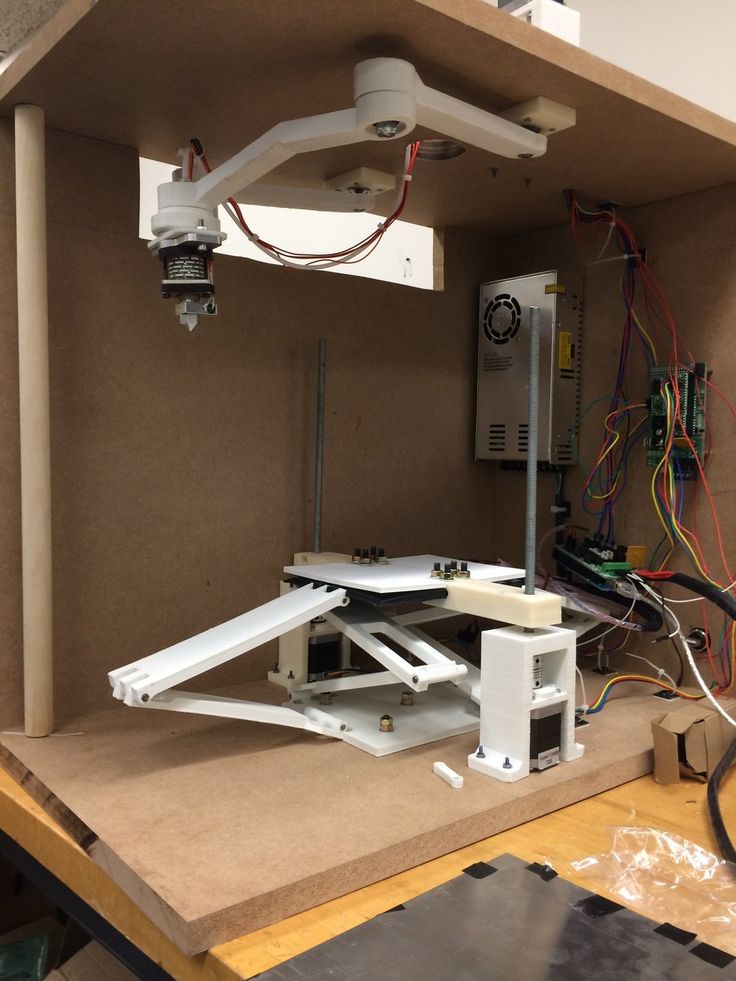

The main feature of all these systems is the proprietary technologies CLIP (Continuous Liquid Interface Production) and DLS (Digital Light Synthesis). Based on the technique of stereolithographic 3D printing with illumination of photopolymer resins by digital projectors (SLA-DLP), the designers equipped the cuvettes with a gas-permeable bottom, due to which a thin inert photopolymer layer is formed, which reduces vacuum attraction and allows printing at higher speeds.

The developers claim that performance is 25 to 100 times higher than conventional stereolithography systems. The continuity of the process provides increased isotropy and, as a result, improved strength characteristics of products. More information about Carbon's offerings is available on the official website. nine0003

More information about Carbon's offerings is available on the official website. nine0003

Do you have interesting news? Share your developments with us, and we will tell the whole world about them! We are waiting for your ideas at [email protected].

Subscribe to the author

Subscribe

Don't want

4

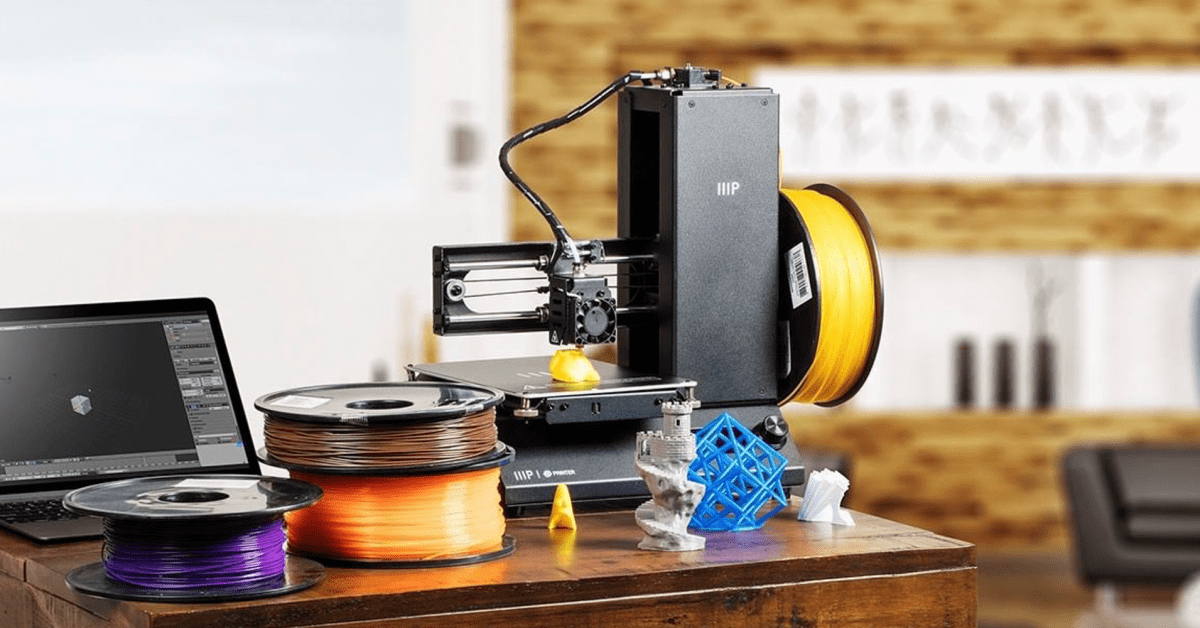

Printing with CARBON plastic in Moscow inexpensively on order with delivery

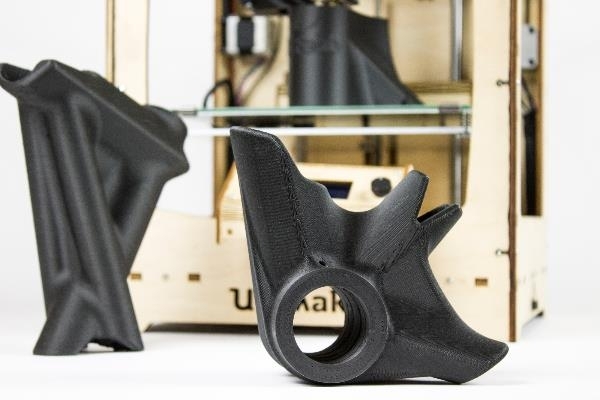

Currently, a large amount of plastic with the addition of carbon is used. Printing Carbon (ePA-CF) is in demand, as materials with sufficient strength and rigidity are used, which can be compared with metal. nine0003

high strength with low weight

UV resistant

Does not require high filling.

Can be used for printing prototypes and full-featured samples.

Very little shrinkage.

Mechanical resistance

Thermal resistance

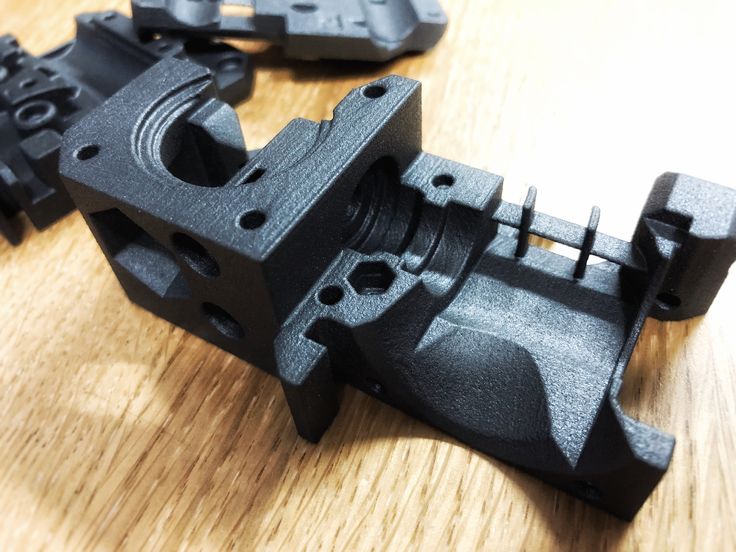

Suitable for automotive parts

Material features

Carbon is 3D printed using light and strong filaments with high elasticity.

The strength of the use of carbon fiber is 2-3 times less than duralumin. The structural material has tensile strength, unique parameters along the direction of the fibers. Its layers are stacked in different directions, the properties are evenly distributed in each direction.

The material can maintain its properties under high pressure, which makes it suitable for use in robotics. nine0003

The hulls of fireballs, rockets and airplanes are also made of carbon fiber.

The main raw material is Carbon based, the threads are highly stable.

For the home, 3D printing of parts, manufacturing, prototyping, prosthetics, 3D printing of housings and electronics, 3D printing of mechanisms, plastic for printing signs

Business ideas exhibitions - and much more branded product

Engineers and designers

a great option to make not only a layout of a future structure, but also print parts for it in the right colors and sizes

The uniqueness of the composite lies in the fact that it allows you to highlight the local internal direction, focus properties.