Ownage 3d printing china

JLC3D - Online 3D Printing Service | Custom Electronics Enclosures

How it works

-

Upload your 3D files

Upload your CAD file online and select materials to get an instant quote, price starts from $1.00.

-

3D Printing it

Our industrial 3D printers and professional operators will produce your prototypes and end-use parts with the highest quality.

-

Delivery straight to you

JLCPCB 3D printing service covers a worldwide delivery, we will ship parts to your doors directly from our 3D printing factory.

3D Technologies

Stereolithography (SLA) is an additive manufacturing process that can 3D print parts with small features, tight tolerance requirements, and smooth surface finishes.

LEDO 6060 - Photosensitive Resin

From $1.00

Technology :

SLA

Build time :

24 - 48 hours

Tolerance :

±0.2mm or within 0.3%

Wall thickness :

0.8mm

Maximum size :

580*580*390mm

Heat deflection temp :

56℃

Characteristics :

High dimensional stability, good temperature resistance, samll-batch parts.

Application :

Waterproof models, functional prototypes in automotive, medical, consumer electronics fields.

9000R - Photosensitive Resin

From $1.00

Technology :

SLA

Build time :

24 - 48 hours

Tolerance :

±0.2mm or within 0.3%

Wall thickness :

0.8mm

Maximum size :

780*780*540mm

Heat deflection temp :

46℃

Characteristics :

High dimensional stability, low shrinkage, excellent yellowing resistance.

Application :

Master molds, accessories&functional parts in automotive/medical/consumer electronics fields.

8000 - Photosensitive Resin

From $1.00

Technology :

SLA

Build time :

24 - 48 hours

Tolerance :

±0.2mm or within 0.3%

Wall thickness :

0.8mm

Maximum size :

780*780*540mm

Heat deflection temp :

46℃

Characteristics :

Natural white, Good Surface Finish, High Toughness/Strength

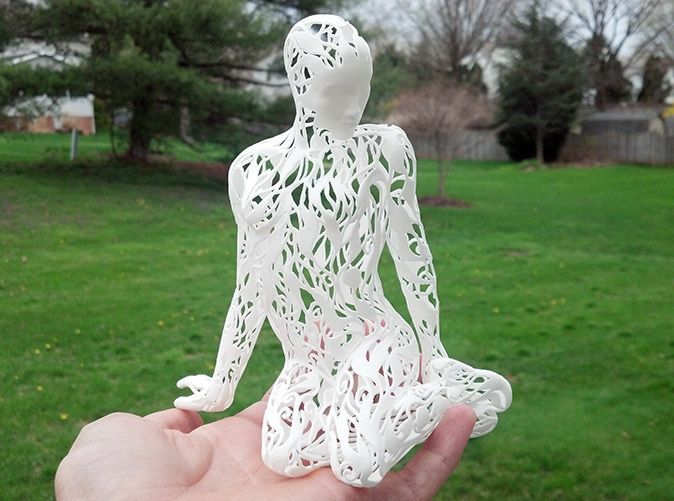

Application :

Accessories, prototypes, enclosures and art sculptures.

8228 - Photosensitive Resin

From $1.00

Technology :

SLA

Build time :

48h (batch orders: 1-3 more days )

Tolerance :

±0.2mm or within 0.3%

Wall thickness :

0.8mm

Maximum size :

580mm*580mm*390mm

Heat deflection temp :

56.4 ℃

Strengths :

Good surface finish, good toughness, high dimensional stability, low shrinkage, excellent yellowing resistance.

Good temperature resistance. Suitable for batch production.

Good temperature resistance. Suitable for batch production.Weaknesses :

Not suitable for high temperature & strong sunlight environment.

Application :

Master molds, conceptual models, general or functional parts in automotive, medical, consumer electronics fields.

Black - Photosensitive Resin

From $1.00

Technology :

SLA

Build time :

72h (batch orders: 1-3 more days)

Tolerance :

±0.2mm or within 0.3%

Wall thickness :

0.

8mm

8mmMaximum size :

580mm*580mm*390mm

Heat deflection temp :

58 ℃

Strengths :

Good surface finish, good toughness, high dimensional stability and low shrinkage. Good temperature resistance, durable, suitable for batch

Weaknesses :

Not suitable for high temperature and strong sunlight environment.

Application :

Master molds, conceptual models, general or functional parts in automotive, medical, consumer electronics fields.

8111X - Photosensitive Resin

From $1.00

Technology :

SLA

Build time :

48h (batch orders: 1-3 more days)

Tolerance :

±0.

2mm or within 0.3%

2mm or within 0.3%Wall thickness :

0.8mm

Maximum size :

780*780*530mm

Heat deflection temp :

59.1 ℃

Strengths :

Good surface finish, fast manufacturing time, high dimensional stability, low shrinkage, excellent yellowing resistance, good temperature resistance.

Weaknesses :

Not suitable for high temperature & strong sunlight environment.

Application :

Prototype of enclosure verification, general assembly parts, functional parts.

Discover our best 3D Learning Hub

SLA 3D Printing Process

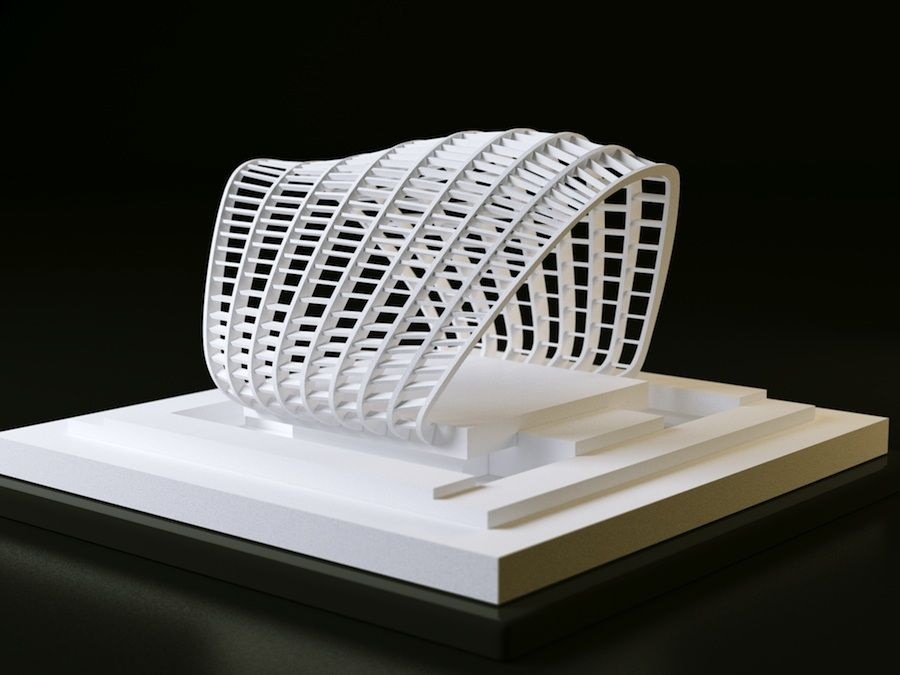

3D Printing Products Show

Put your parts into production today

making a fake id reddit

AlleVideosBilderShoppingMapsNewsBücher

Suchoptionen

Does anyone on reddit know anything about creating Fake ID's?

www. reddit.com › AskReddit › comments › does_a...

reddit.com › AskReddit › comments › does_a...

I know many people that could make use of fake drivers licenses. ... I have downloaded a few ID templates, and know where to get necessary supplies.

How do people create fake ID's : r/myfriendwantstoknow - Reddit

www.reddit.com › myfriendwantstoknow › comments

16.08.2022 · But in reality, if you wanted to properly make a laminated fake ID. You can get a card printer from online, get some laminate. Then just add ...

I used to make fake IDs. AMA. : r/IAmA - Reddit

www.reddit.com › IAmA › comments › i_used_to_make_fake_ids_ama

12.12.2012 · 63 votes, 223 comments. I used to make novelty IDs. Legit ones, too, like the kind you find getting imported from China these days.

ILPT Request: How To Make Fake IDs? : r/IllegalLifeProTips - Reddit

www.reddit.com › comments › mucrc7 › ilpt_reque...

19.04.2021 · I got the idea to make 365, one every day. Then make a list of the free stuff in my city. Edit: there's a card printer for a few hundred ...

Edit: there's a card printer for a few hundred ...

I ran the largest fake ID distribution ring in my state. AMAA.... - Reddit

www.reddit.com › IAmA › comments › i_ran_the_largest_fake_id_distribu...

I manufactured fake IDs before being convicted for my crimes. I'm currently free and will answer most questions but won't identify myself.

How do you get a fake ID? : r/AskReddit

www.reddit.com › AskReddit › comments › bdazb

I find it is better if you make an out of state ID as most bars don't know out of state IDs ... Making fake ID's in most(all?) states is a felony though.

ELI5: Why is even possible at all to create a fake ID? Where ... - Reddit

www.reddit.com › explainlikeimfive › comments

ID is checked into a lot more deeper than that when it comes to things like getting credit, or if you're stopped by an officer of the law. Fake ID's work in the ...

ILPT: Some fake ID tips. : r/IllegalLifeProTips - Reddit

www. reddit.com › IllegalLifeProTips › comments › ilpt_some_fake_id_tips

reddit.com › IllegalLifeProTips › comments › ilpt_some_fake_id_tips

06.09.2019 · Actually call someone to make it more realistic. As you are shopping around get more and more agitated with the phone call. Pretend it's a ...

ILPT: Advice if you're getting a fake ID : r/IllegalLifeProTips - Reddit

www.reddit.com › IllegalLifeProTips › comments › ilpt_advice_if_youre_...

22.02.2020 · doesn't always work but it can help prevent your ID from getting confiscated at ... Source: I used to make and sell fake IDs in college.

I am a 23 year old American college student that made fake ID's for 3 ...

www.reddit.com › IAmA › comments › sex56 › i_a...

One of the guys in my dorm bought a fake ID (not a driver's license) from a company based in China. They sent it to him with the wrong gender or something ...

Industrial Custom 3D Printing Services in China

We use cookies to personalize content and ads, to provide social media features, and to analyze our traffic. We also share information about your use of our site with our social media, advertising and analytics partners. Privacy Policy

We also share information about your use of our site with our social media, advertising and analytics partners. Privacy Policy

With two decades of on-demand manufacturing and prototyping services, ProtoFab is the ideal partner to bring ideas to life. We have a wide range of processes and materials to choose from, each with their own benefits and applications. nine0003

What is CNC?

CNC (Computer Numerical Control) Machining is a subtractive process that uses precise tools to cut material to obtain the desired part or product. The software-controlled instrument head is much more accurate than any human and allows for accurate reproduction.

Who needs CNC machining?

CNC machining is better for working with metals than 3D printing, although metal 3D printing is also possible. Other materials often used in CNC machining include wood, foam, and wax, and it should be noted that each type of material requires different tools. CNC machining is slower than 3D printing, but once prepared, the subtraction method is significantly faster than the additive method used in 3D printing CNC machining is also generally more accurate than 3D printing, with tolerances up to 0. 001 mm. A disadvantage of CNC machining is that very complex designs may not be possible due to tool access issues. Therefore, CNC machining is best suited for relatively simple designs using traditional materials such as metal or wood and where a high level of precision is required. nine0003

001 mm. A disadvantage of CNC machining is that very complex designs may not be possible due to tool access issues. Therefore, CNC machining is best suited for relatively simple designs using traditional materials such as metal or wood and where a high level of precision is required. nine0003

Process

The CNC machining process is somewhat similar to 3D printing. As with 3D printing, a detailed CAD drawing is needed, which is analyzed by a technician and imported into specialized software. In the case of CNC processing, in ProtoFab we convert the files to a format and import them into Mastercam. During the programming phase, the technician must decide what type of cutting tool to use based on the materials used and any specific problems caused by the shape. Once the tools are ready and programming is complete, the cutting process can begin. Both CNC milling and turning are available at ProtoFab. Milling is the method used for normal parts, while turning is used for parts with cylindrical parts. Once the cutting is completed, each piece is sent to post-processing where the finishing process begins. nine0003

Once the cutting is completed, each piece is sent to post-processing where the finishing process begins. nine0003

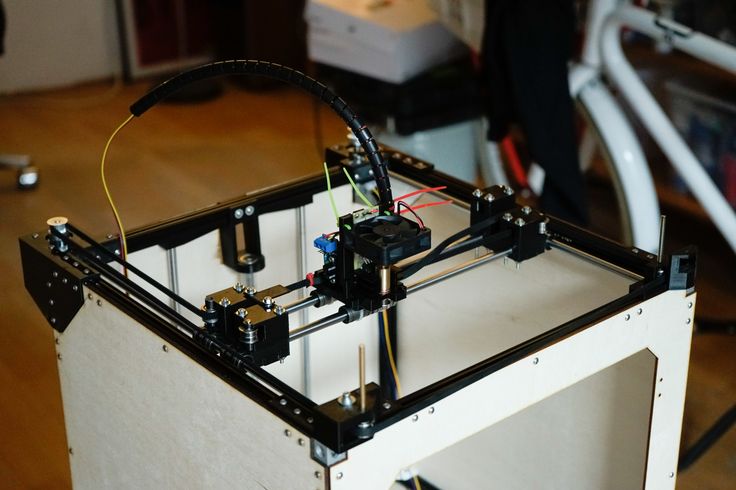

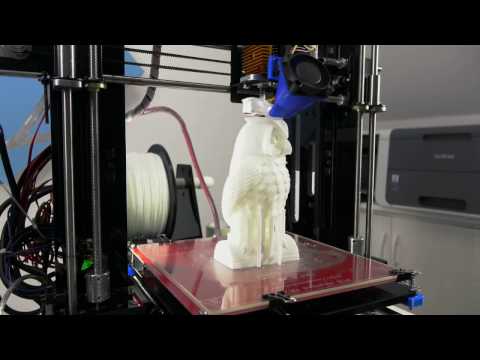

What is 3D printing?

3D printing is an additive manufacturing process in which a three-dimensional object can be created by precisely adding layers of material. It revolutionizes multiple industries and offers previously unimaginable levels of customizability and convenience. 3D printing is capable of producing complex parts that are literally impossible with traditional methods, all it takes is a CAD drawing. Because it is an additive process, parts can be produced with an absolute minimum of waste, and the rapid nature of the technology makes it ideal for modern industries that cannot afford to wait. nine0003

Who is 3D printing for?

3D printing is one of the most versatile manufacturing technologies and can be used in almost any industry. It is best used in cases where the part or product has a very complex shape, such as lattice structures, or when internal detailing is required. It is also particularly suitable for rapid production, and often a 3D printer can produce a finished product without the need for further assembly. It is also useful for extremely short runs, such as just one or two prototypes, as there are no tooling costs and no need to make a mold. nine0003

It is also particularly suitable for rapid production, and often a 3D printer can produce a finished product without the need for further assembly. It is also useful for extremely short runs, such as just one or two prototypes, as there are no tooling costs and no need to make a mold. nine0003

Process

First, detailed CAD file imported into 3D printing software (Magics). This software analyzes a CAD drawing and breaks it down into ultra-thin cross-sectional layers. The engineer will analyze the object to be printed and decide if additional supports need to be printed so that the structure can remain stable. This extra material is later removed in post-production. The printer head is controlled by a laser and gradually builds up the object, working along thin cross sections identified by the software. A wide range of materials is available, and this range is constantly increasing as technology becomes more advanced. nine0003

What is small batch production?

With the continued development of modern manufacturing technologies and businesses increasingly looking for flexibility in production, low volume manufacturing has become much more popular in recent years. As a term, this is difficult to define specifically, but we can say that low-volume production implies a significantly lower quantity than full-scale production and uses more flexible methods. At ProtoFab we specialize in this type of production and can make the process as simple and efficient as possible. nine0003

As a term, this is difficult to define specifically, but we can say that low-volume production implies a significantly lower quantity than full-scale production and uses more flexible methods. At ProtoFab we specialize in this type of production and can make the process as simple and efficient as possible. nine0003

Benefits of low volume production

There are at least 3 reasons why companies choose low volume production. First of all, the use of small-scale production can reduce many of the costs associated with full-scale production. Even up to about 100,000 units, it may be more economical to use low volume production, depending on the materials used. For small volumes, such as a few thousand, the economic benefit can be enormous. nine0038

Second, low volume production is inherently more flexible. Tweaks can be made easily, and adjustments can often be made reactively based on consumer feedback. In mass production, this sort of tweaking is usually out of the question, and minor flaws are baked all over. Low volume production is also much faster and allows for very fast time to market, which is very important in some industries.

Low volume production is also much faster and allows for very fast time to market, which is very important in some industries.

Finally, small-scale production can be used as a bridge to full-scale production. The initial run can be done on a low volume to keep costs down and maintain flexibility, and once the product is successful and any problems have been ironed out, production can be switched to full scale. In general, low-volume manufacturing offers many benefits and is worth considering for a wide range of industries and product types. Feel free to contact us to find out more. nine0003

What is plastic injection molding?

Plastic injection molding is one of the fastest production technologies. The liquid plastic is injected into a mold where it cools, solidifies and is ejected. The same mold can be used countless times, and the process of making a part can take only a few seconds. There are thousands of different types of plastics available, and a variety of polishes and textures can be applied, allowing for a huge degree of customization and flexibility. nine0003

nine0003

Who is plastic injection molding intended for?

Plastic injection molding is great for those who want to produce a relatively large number of parts or products quickly and economically. After the initial cost of the tool, further costs are very low, so it makes sense to use plastic injection molding for long runs. If you only require a small number of prototypes, 3D printing is likely to be more cost effective. Unlike vacuum casting, the same mold can be used over and over again over 100,000 times, so usually only one mold is needed. The ability to mix different types of plastics (through co-injection molding) is another reason why people choose plastic injection molding. For other manufacturing technologies, it may be difficult to fabricate structures from mixed materials. Common uses for plastic injection molding include pilot work, low volume production, and parts on demand. nine0003

Process

First of all, a mold is made, usually CNC machined from aluminium. The material is produced in the form of granules, which are melted in a barrel. This liquid is then compressed and injected into the mold through a guide system where it rapidly solidifies. The ejector pins then push the solid into the feed hopper and the process can be repeated again. The time it takes to make each part depends on its size and the material used. This ranges from a few seconds for small projects to one or two minutes for larger and more complex projects. It should be noted that the production phase is fully automated, so labor costs are kept to a minimum. nine0003

The material is produced in the form of granules, which are melted in a barrel. This liquid is then compressed and injected into the mold through a guide system where it rapidly solidifies. The ejector pins then push the solid into the feed hopper and the process can be repeated again. The time it takes to make each part depends on its size and the material used. This ranges from a few seconds for small projects to one or two minutes for larger and more complex projects. It should be noted that the production phase is fully automated, so labor costs are kept to a minimum. nine0003

What is vacuum casting?

Vacuum casting uses a vacuum chamber to force liquid plastic into a finished mold where it then solidifies. Molds are usually made from silicone rubber and are in turn based on a master model.

Who is vacuum casting used for?

Vacuum casting is the ideal solution for fast and inexpensive prototyping. Molds can be produced cheaply and with a high degree of detail, so prototypes require little to no post-processing. Each form has a print run of about 50 copies and can be made quickly. For short runs, the technique is more economical than plastic injection molding due to the initial cost of the injection molding tool. However, for long batches, vacuum casting is less suitable. nine0003

Each form has a print run of about 50 copies and can be made quickly. For short runs, the technique is more economical than plastic injection molding due to the initial cost of the injection molding tool. However, for long batches, vacuum casting is less suitable. nine0003

Process

The first thing required is a master model. This can be provided by the customer, but is most commonly produced by ProtoFab using CNC machining. The master model is usually made of metal, but plastic is also acceptable, the main requirement is to withstand temperatures of 40 ° C for a long period. The master model is placed in a mold box, and the silicone rubber mold consists of two parts. The mold has a series of very small holes cut into it to allow air to escape and prevent pressure from building up. nine0003

The mold is the exact opposite of the master mold, so all it takes is filling the mold with material and getting a copy. However, simply pouring liquid material into a mold can sometimes produce inadequate results, so a vacuum chamber is required to push the material into even the tiniest of gaps, providing a perfect copy. Once the material has filled the mold, it is placed in a curing oven until the new object is completely cured. It is then removed from the mold and the process can start again. The molds can be used multiple times, up to a maximum of 50, without any reduction in copy quality. nine0003

Once the material has filled the mold, it is placed in a curing oven until the new object is completely cured. It is then removed from the mold and the process can start again. The molds can be used multiple times, up to a maximum of 50, without any reduction in copy quality. nine0003

What is a finish?

As the name implies, finishing is the final stage of production and comes after the actual production. At ProtoFab we offer a wide range of finishing services including painting, anodizing and steam polishing. Our finishing departments can adapt to the most specific requirements and have access to a wide range of cutting-edge technologies, allowing almost limitless customization during the finishing phase.

Services available

Painting is more than just slapping paint. The slightest defects that occur during the dyeing stage can spoil the product, and it is important to ensure complete uniformity throughout the cycle. Coloring takes place in laboratory conditions in a climatic chamber. A wide variety of paint finishes are available, including matte, glossy, semi-gloss and metallic.

A wide variety of paint finishes are available, including matte, glossy, semi-gloss and metallic.

Color matching. We are well aware of the importance of an exact match to the intended color. Staining always takes place in a controlled environment with constant light and climate conditions that can avoid some of the common problems when visually matching the sample. In addition to matching with a physical sample, we can also match Pantone colors exactly. nine0003

Sanding and polishing - we can provide custom finishes from mirror polished to rough sanded. Sanding can also be used to prepare the product for various varnishes such as matt.

Steam polishing is an advanced technique for removing small imperfections even in hard to reach areas. The surface of the plastic is exploded by the chemical vapor, which causes the surface to melt directly, but only to a tiny depth. As it hardens, any small defects disappear, and the surface becomes smooth and uniform. Note that this technique is only available for plastics. nine0003

Note that this technique is only available for plastics. nine0003

Blasting - Blasting is a simple yet effective finishing method that comes in a variety of shapes and sizes Fabricated parts and products can be sandblasted, water-blasted, or any number of materials to achieve specific results.

Pad Print - Used to print a 2D pattern on surfaces that would otherwise be difficult to print, such as convex or concave surfaces. It works by transferring a material (usually ink or dye) through an etched area on a silicone pad. When the pad is pressed against the surface, the material leaves the pad and moves across. Other printing methods offered by ProtoFab include screen printing. nine0003

ProtoFab 3D printers

ProtoFab SLA2000 - 翻译中...

ProtoFab SLA200

nine0003

ProtoFab SLA2400

ProtoFab SLM 100

ProtoFab SLA600B nine0094

ProtoFab SLA600E-DLC

3D printing services in China | SLS, FDM, SLA

China 3D Printing Services | SLS, FDM, SLA | Industrial 3D printingskip to content

0086-13392707499 info@rocheindustry. com RocheWorld

com RocheWorld

Best 3D printing service in China

Fast and accurate prototype shipping in 1-3 days

Zain

LOYAL CUSTOMER

Roche's industry team is very fast and efficient. Every member of their team I have worked with has been patient and understanding in explaining the next steps and process for my product. I look forward to future developments with the bunny design and my project. Highly recommend!

John

LOYAL CUSTOMER

Without a doubt, Roche Industry is a great company. Thank you Robin, Clark, and the entire design engineering team for your support, creativity and guidance in taking my project to the next level, thank you so much for your great efforts. We look forward to great success together! nine0003

Andy

BUSINESS OWNER

Definitely hard work, responsibility and creativity are the terms I can define as a rosh company. Constant, clear and precise communication with the client by employees determines their professionalism. they deliver on their promises by providing timely and efficient delivery. Great job!

they deliver on their promises by providing timely and efficient delivery. Great job!

NDA sign

We sign NDAs with our clients and their projects. Each employee must undergo prior training in the company to follow our production process to ensure the company's information security. The NDA will be signed on the effective date. Like all of our suppliers, they must sign an NDA. For date security, we use ISO27001 as a reference. All data will be securely stored in our own network center, only authorized personnel can access the center and view the data. nine0003

Stream production

We use a work order system to control every step of the process, the schedule for each job is very clear for each team. All customer requirements will be reflected in the work order. When quoting, our process engineers will review the data and requirements and provide DFM if necessary. During production, we guarantee online and offline controls to ensure that the parts we produce are exactly to your specifications. nine0003

nine0003

Quality Control

We are ISO 9001 certified, first merchandise inspection, and support for FAI reporting. Before packing, we have a final check that will check all quality details by our QC. We care a lot about the safety of packaging. For the production of different sizes and materials, we use different packaging methods to ensure the safe delivery of products. Parts will be marked with item number labels. and no software. for customers to make it easier to recognize them. nine0003

Upload your designs to receive a free quote

3D printing, also known as rapid prototyping, is a technology based on digital model files in which solid materials such as powder or liquid are used to create solid bodies layer by layer. It has several good characteristics, such as high production speed, not limited by design complexity, customized production.

SLA applies to stereolithography is a resin based 3D printing technique. Printing occurs with the help of ultraviolet light, which affects the liquid resin and, if desired, turns it into a solid layer.

Printing occurs with the help of ultraviolet light, which affects the liquid resin and, if desired, turns it into a solid layer.

SLS refers to Selective Laser Sintering and is a 3D printing technique that uses powdered printing materials rather than resins to create 3D objects. Similar to SLA, this process also uses a laser to facilitate the 3D printing process.

3D printing is any of the various processes in which a material is combined or solidified under computer control to create a three-dimensional object, with the material added together (for example, liquid molecules or powder grains merging together). 3D printing is used in both rapid prototyping and additive manufacturing.

Currently, 3D printing is moving in a more efficient, smarter and faster direction in the prototyping industry. In addition, 3D printing technology is becoming a trend and is gradually becoming a new way to change the industry. nine0003

With the gradual advent of the era of large-scale industry, the manufacturing industry is rapidly developing in a more efficient, intelligent and fast direction. What are the benefits of 3D printing? See Impact:

What are the benefits of 3D printing? See Impact:

1. SLA/SLS/3D printed parts are fully solid, have complex geometries and precise internal features.

2. Structures can be produced quickly, with minimal material input and maximum strength.

3. Multiple identical parts can be produced on the same platform at the same time, greatly improving production efficiency. nine0003

4. Accurate detail drawing and high quality surface finish.

Looking for a 3D printing service?

That's right, you've come to the right place. We are a leading and professional 3D printing manufacturer and rapid prototyping company in China. Roche Industry has been engaged in SLA / SLS / 10D printing services for more than 3 years, our services can shorten production time, reduce production costs, produce more complex parts, meet customized production requirements, ensure clean and environmentally friendly. I am honored to be partner with you. We are happy to start working with you.