What 3d printer does shapeways use

Shapeways 3D Printing Materials: Checking Out the Top Five

From durability to high ductility—and from requirements in flexibility to great strength—the study of materials science is vast. Knowledge and expertise in this area is critical to quality manufacturing though, and 3D printing is no exception. There is a lot to learn, but for industrial 3D printing, the most popular materials are easily narrowed down into the following five, all of which are commonly used in even the most advanced applications.

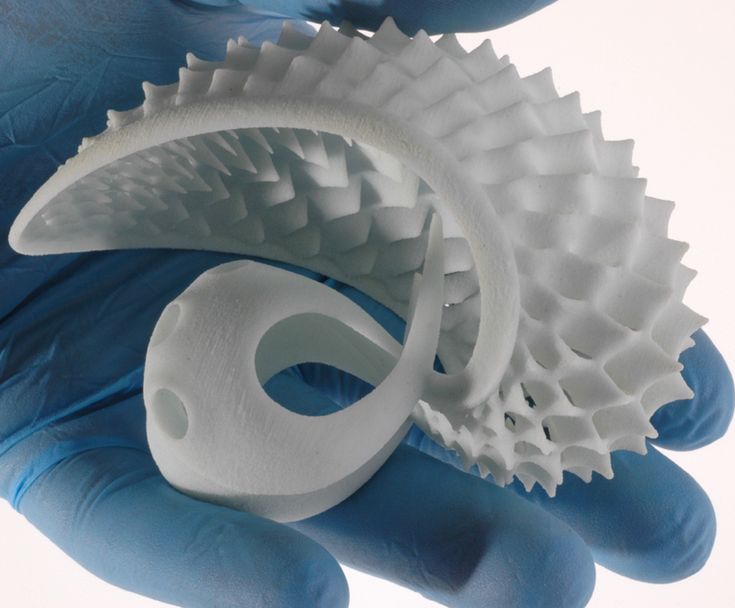

Nylon 12 [Versatile Plastic]Nylon 12 [Versatile Plastic] currently tops the list in terms of popularity, and epic versatility. Reinforcing one of the greatest benefits in 3D printing with the ability to create complex geometries not possible in traditional manufacturing, Nylon 12 [Versatile Plastic] is used with Selective Laser Sintering (SLS) for 3D printing everything from detailed medical models and surgical planning tools to fine jewelry. Because no supports are required in powder-based SLS 3D printing, designers are afforded greater freedom in creating, and production departments are able to nest hundreds or even thousands of parts together in each build.

Used for rapid prototyping as well as high-performance, functional parts, Nylon 12 [Versatile Plastic] is unique because in its thinner form it is flexible, making it suitable for springs and interlocking parts—and in its thicker state, strong enough for end-use parts in critical applications like medicine. Shapeways offers Nylon 12 [Versatile Plastic] in standard white, but it can be dyed in eight different colors, and is available in Natural, Processed, and Premium finishes. Find out more in the design guidelines here.

PA11PA11 is also used with SLS 3D printing technology, but many are surprised to learn that it is derived from castor beans, making it environmentally friendly and easy to recycle. Not only is PA11 a flexible material, but it is also known for durability, good tensile strength, and impact resistance with high elongation at break too, meaning that it will be less likely to break under stress. This nylon material is also biocompatible, making it suitable for 3D printed exterior medical devices like knee braces or prosthetics.

High ductility also makes PA11 an excellent choice for end-use parts that must hold up during rigorous conditions, to include offering protection in sports with customized equipment, as well as during harsh weather conditions—and especially heat. Because of its high impact resistance, PA11 is also excellent for use in industrial applications like automotive and aerospace. Shapeways offers PA11 in white, with a slightly rough surface as a standard finish, as well as matte. Find out more in the design guidelines here.

MJF Plastic PA12MJF Plastic PA12 is another popular 3D printing material that is similar to Nylon 12 [Versatile Plastic]. Used with HP’s revolutionary Multi Jet Fusion technology—a powder-based method relying on inkjet technology—MJF PA12 is unique because it is printed at a lower layer thickness and provides higher resolution for intricate features, as well as overall uniformity. MJF PA12 also offers flexibility in its thinner material form and is known for greater elasticity and less breakage, while offering strength and durability for thicker designs.

Used in many industrial applications due to its ability to support sophisticated geometries, MJF PA12 is known for low porosity as well as possessing excellent mechanical properties, and is recommended for applications like drone technology, medical devices like prosthetics, and mechanical parts. Offered in gray or black with a slightly grainy finish, MJF PA12 is available in natural, smooth, and a slightly glossy finish. Find out more in the design guidelines here.

MJF Plastic PA12 Glass BeadsMJF Plastic PA12 Glass Beads is definitely a unique material, employing glass beads to add strength and stiffness to parts. Although 40% of this material is infused with glass beads, MFJ PA12GB still offers good flexibility like its MJF PA12 counterpart. PA12 Glass Beads are also relied on to ensure structural integrity and dimensional accuracy for industrial parts, along with offering continued accuracy and repeatability whether using Multi Jet Fusion to 3D print customized parts in volume or on demand.

MJF PA12GB are recommended for large pieces, especially when issues like warping must be avoided in high-performance parts. This material is recommended for applications like robotics, drones, medical devices, mechanical devices, and tooling. Shapeways offers MJF PA12GB in gray and dark gray. Find out more in the design guidelines here.

Thermoplastic Polyurethane (TPU)Thermoplastic Polyurethane (TPU) is a well-known material used in numerous types of manufacturing, to include injection molding. Created in a German lab in 1937, TPU is made up of both thermoplastic materials and rubber. Shapeways offers TPU in standard white for use with SLS technology using EOS 3D printers, as well as Ultrasint TPU01 material from BASF, available in gray, using Multi Jet Fusion 3D printers.

Offering great opportunity for versatility and customization, TPU is known for resistance in terms of chemicals, heat, and abrasion, along with excellent load-bearing capacity, good elongation at break, and high tensile strength—defining the amount of strain a part can handle before fracturing. TPU is suitable for applications like automotive, robotics, medical devices, sports gear, and even footwear. Find out more in the design guidelines here.

TPU is suitable for applications like automotive, robotics, medical devices, sports gear, and even footwear. Find out more in the design guidelines here.

Materials like Nylon 12 [Versatile Plastic] rate at the top for durability, exemplified by work with Shapeways customers like 67 Designs. With an ongoing dedication to 3D printing—even for high-volume printing—SLS technology was the perfect fit for their luxury off-roading accessories like the MagMount, a device meant to hold tablets in place during outdoor adventures.

MJF PA12 and MJF PA12GB offer greater durability too due to the deep absorption of thermal energy during 3D printing with Multi Jet Fusion. The addition of glass beads to MJF PA12GB allows for further strength and stiffness. Materials like PA11 are suitable for products requiring durability also due to a wide range of material characteristics making it suitable for sturdy end-use parts, as well as prototypes that won’t break down over time.

Several popular 3D printing materials are strong and durable, yet in some cases also offer great flexibility. This is true of Nylon 12 [Versatile Plastic], as well as PA11; however, TPU is the clear stand-out in terms of elasticity due to its composition of thermoplastic material and rubber, making it highly suited for medical devices like braces, prosthetics, and implants. Soft robotics are another popular application for TPU, as flexible parts are required for actuators, simulated digits and limbs, and flex grippers.

Heat ResistanceResistance is often a key factor in making a choice between materials. Heat resistance is particularly important in applications like aerospace and automotive where parts are consistently exposed to high temperatures.

Materials like PA11 are suitable for these types of environments, as well as harsh weather conditions, making it highly attractive for industrial applications. PA11 is also resistant to a wide range of chemicals. MJF PA12GB offers stiffness and strength for larger, flat parts, with thermal resistance helping to avoid warpage.

MJF PA12GB offers stiffness and strength for larger, flat parts, with thermal resistance helping to avoid warpage.

Many functional parts require sealants for waterproofing. Again, materials like Nylon 12 [Versatile Plastic] top the list. Although this material is moisture-resistant, a variety of different sealants or coatings can be used to make it completely waterproof. Shapeways customer Verner Architects designed a six-foot-long vanity for a children’s bathroom in a luxury re-modeling project. After Shapeways 3D printed the vanity and shipped it to Verner Architects, they coated it with polyurethane to ensure continued water resistance over the years.

About ShapewaysShapeways offers over 90 materials and finishes, and is always interested in sourcing other materials customers may be interested in using too. Contact Shapeways now to enjoy the benefits of advanced technology and materials for manufacturing creations with accuracy, complex detail, and no minimum or limits in terms of mass customization or single part orders.

Shapeways has worked with over 1 million customers in 160 countries to make over 21 million parts! Read about case studies, find out more about Shapeways solutions, and get instant quotes here.

3D Printing Materials MJF PA12 glass beads MJF PA12 Plastic Nylon 11 Nylon 12 nylon plastics TPU

How Shapeways 3D Printing Works

Creating a product has never been easier

1. Design a Product

Use a 3D Printing App

Tweak and tinker your product to perfection using an easy 3D printing app.

Use Your Favorite Software

We support a wide range of programmatic, parametric, sculpting and modeling software.

Hire a Designer

Work with the best 3D modellers in the world to bring your idea to life.

2. Upload to Shapeways

INSTANT PRICING

45+ HIGH QUALITY MATERIALS

AUTOMATED & MANUAL CHECKS

FIXING TOOLS

24/7 GLOBAL SUPPORT

NO MIN ORDER SIZE

Upload Your Model

Experience the journey of a 3D printed product.

Arrow Ring by Courtney, etc.

Run Your Business on Shapeways. You design amazing products, we'll help you reach a global market.

Learn MoreShop the Marketplace

Get feedback and support from a global community, wherever you are in your design process.

First to Try

You're not alone in the creative process. Get support on your early stage product, from your first print through product iteration.

Community Forums

Join hundreds of thousands of Shapeways community members all over the world. Explore our forums and blog.

Get Support Wherever You Are

Whether you're creating a product for the first time or you're an expert, Shapeways has over 150 tutorials to help you along your way.

What our Community is Saying

Many of the things I design are so complex that they would not be possible using traditional techniques, and I love how 3D printing takes jewelry design to the next level.

Maaike van der Horn - MCODE

[Shapeways] is our lemonade stand. Mostly to gain entrepreneurial muscles and work together. And we're having a blast trying it out.

SANTIAGO P. - SUNNY DAY SUPPLIES & CO.

Shapeways is easy to work with, and has the quality level and price that gives me the freedom to realize my creations in the way I want to.

Summer Powell - Summerized

I was able to prototype at such low cost, yet end up with a product that was great. Shapeways enabled me to take a finished product to investors &distributors.

MATT V. - FOUNDER OF BUMPRZ

Getting Started

JEWELERS

PRODUCT DESIGNERS

ARTISTS

ENGINEERS

ANIMATORS

TINKERERS

ENTREPRENEURS

CROWDFUNDING

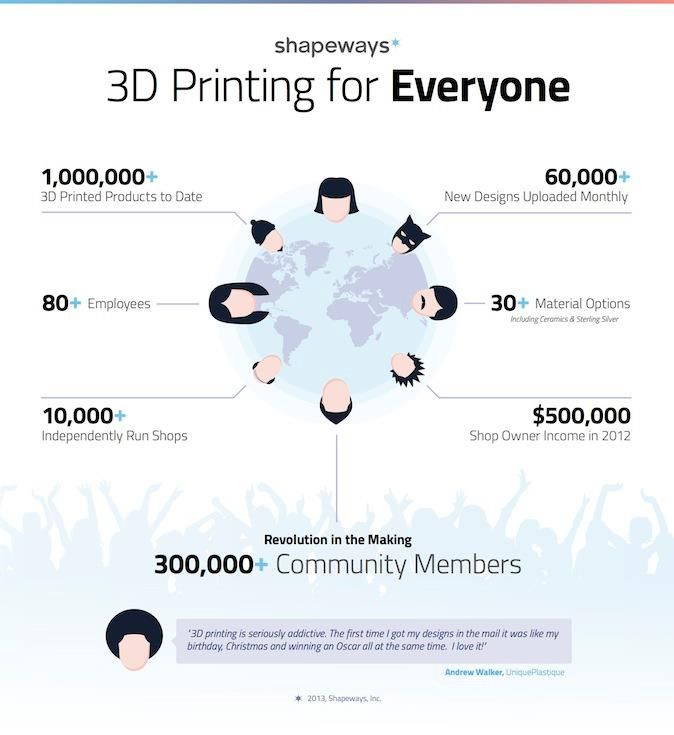

Classification of 3D printers / Sudo Null IT News

3D printing is steadily gaining momentum and we are increasingly seeing posts that a 3D printer has been taught to print parts for the ISS, organs, houses and much more. Foreign technology publications are beginning to say that 3D printing is able to resurrect the industry in the states, and the shapeways service, before our eyes, is showing interesting growth rates, albeit far from industrial ones. With such an abundance of laudatory texts about the impending revolution in production, the thought comes to mind that the Russian segment is practically free, but is it so easy to achieve industrial scale with the assurance of the printers themselves and the emergence of open source projects? It's up to you to decide, but food for thought on the topic under the cut. nine0003

Foreign technology publications are beginning to say that 3D printing is able to resurrect the industry in the states, and the shapeways service, before our eyes, is showing interesting growth rates, albeit far from industrial ones. With such an abundance of laudatory texts about the impending revolution in production, the thought comes to mind that the Russian segment is practically free, but is it so easy to achieve industrial scale with the assurance of the printers themselves and the emergence of open source projects? It's up to you to decide, but food for thought on the topic under the cut. nine0003

I’ll make a reservation right away that the standards in the industry are very conditional, so far. But a brief overview with the order of prices can be generated now. And so, let's get started.

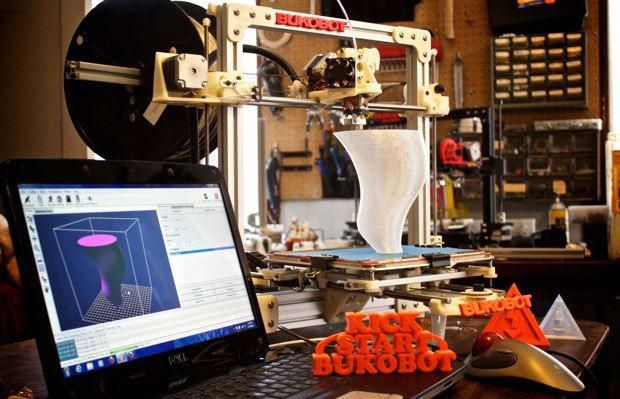

Consumer

A type of printer intended primarily for personal use. Supplied in the form of a designer, or assembled. The vast majority of printer models of this type are derived from the open source RepRap project. Since they have basically the same platform, their characteristics are also very similar. nine0003 Designed with an eye on the average user and equipped with a fairly simple and intuitive interface. Printed, as a rule, ABS and PLA plastic. Complex and high-precision objects will be quite problematic to print, but they print ordinary crafts with ease, albeit for a long time.

Since they have basically the same platform, their characteristics are also very similar. nine0003 Designed with an eye on the average user and equipped with a fairly simple and intuitive interface. Printed, as a rule, ABS and PLA plastic. Complex and high-precision objects will be quite problematic to print, but they print ordinary crafts with ease, albeit for a long time.

Price range: $500 - $3500

Target audience:

Designers / artists / inventors who work from home.

Personal

An edge class of printers that is home but also the lower rung of industrial business printers. These devices have much in common with their consumer-grade brothers, but have the higher quality and precision of printing that is inherent in professional 3D printing systems. The appearance of such printers is rather a reaction of large manufacturers to the growing market for home systems. Given the low accuracy of the consumer class, vendors have offered reduced models of professional systems with performance close to them. nine0003 Operating printers of this class is just as simple and boils down to loading an image and pressing the start button. At the same time, this limits the possibilities in terms of various advanced printing options.

nine0003 Operating printers of this class is just as simple and boils down to loading an image and pressing the start button. At the same time, this limits the possibilities in terms of various advanced printing options.

Suitable for use in offices, however, the noise and high temperature conditions of some models require their placement at some distance from the working area. The ease of cleaning output objects was not carried over to this class from industrial models, so it would be logical to place them in a separate workspace. nine0005

Price range: $7,000 - $40,000

Target audience:

Small business with a small budget but need to use 3D printing occasionally. It can be engineering companies, design studios, marketing agencies.

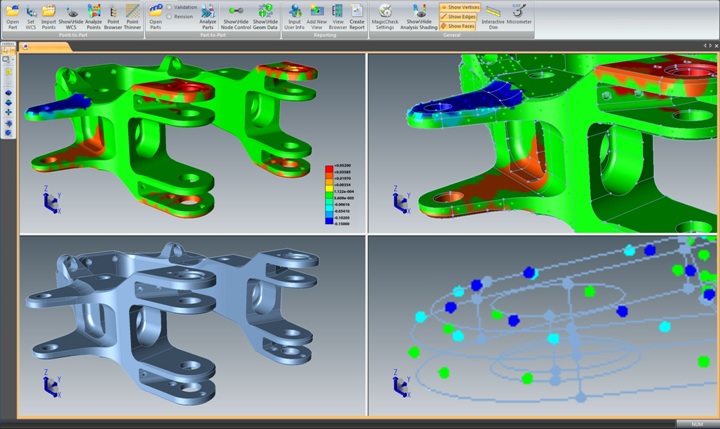

Professional

Systems in this class no longer look compact, but rather look like large refrigerators. This is the basis of 3D printing technology, which includes all the achievements and possibilities available to the industry. The purpose of professional systems can be very different, from prototyping to full-scale production, which in turn makes them an excellent option for both large businesses and high-tech companies with a small staff. ShapeWays, by the way, uses printers of this class. nine0003 Unlike their small brothers, these printers, due to the large number of modes and additional options, already require certain skills to work with them, so you cannot do without an operator.

The purpose of professional systems can be very different, from prototyping to full-scale production, which in turn makes them an excellent option for both large businesses and high-tech companies with a small staff. ShapeWays, by the way, uses printers of this class. nine0003 Unlike their small brothers, these printers, due to the large number of modes and additional options, already require certain skills to work with them, so you cannot do without an operator.

In terms of the workspace, everything is not so simple here either. They are very large and noisy, so they require a separate room with good ventilation. Space requirements vary, but the space should be something like a laboratory and have a high-voltage line connected. nine0003 As a result, we get a universal 3D printing machine that provides the highest print quality and increased product sizes compared to the lower grades. ShapeWays, for example, collects several objects per print cycle, placing them at some distance from each other, which ultimately has a positive effect on the speed of order processing.

Price range: $30,000 - $750,000

Target audience:

Companies that have a constant need for prototyping, modeling, manufacturing of various kinds of objects with high quality and accuracy. nine0005

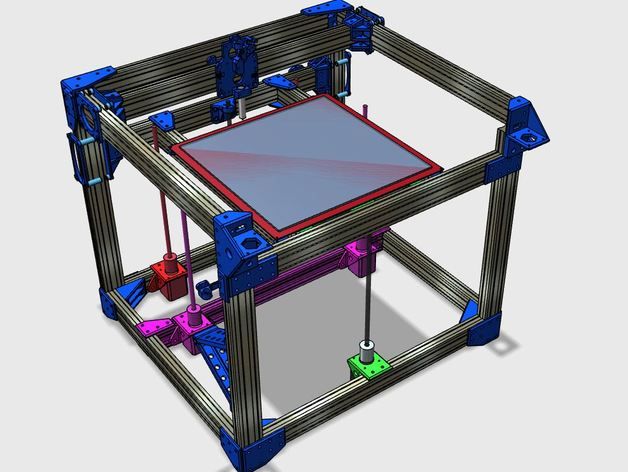

Production

The name of the class speaks for itself. These machines combine the precision and quality of professional printers, large print area, high level of automation and process control. On them, as well as on professional installations, it is possible to print not only prototypes, but also the final consumer product.

Systems of this kind are not intended for ordinary users, and the amounts that will have to be invested in such production will make you logically want to hire an experienced operator who will make the whole mechanism work 24 hours a day without downtime. nine0003 Small spaces are no longer enough. Here you need to clearly plan the future line and take care of the supply of the high-voltage line and gas pipe.

The result is a high-tech production that can quickly change the profile and use materials from ABS plastic to titanium.

Price range: $300,000 - $1,000,000

Target audience:

Companies with a need to produce high-precision large-sized products, or companies with a need to produce a large number of smaller volume items with high accuracy and high level quality. nine0005

Summing up, I would like to add that despite the fact that the threshold for entering this industry is still very high, the future belongs to such systems. Within the event horizon, we will be able to see a real revolution, at least in high-tech manufacturing. General Electric was one of the first to realize this and has already begun to produce complex titanium parts for aircraft engines using 3D printers.

As Albert Einstein said:

It's very simple. All people think that this is impossible. But there is one daredevil who does not agree with this ...

Shapeways Introduces New Multicolour 3D Printing Plastic

Archive

Subscribe Author

Subscribe

Don't Want

Shapeways is the undisputed leader in 3D printing services. In addition, it produces a huge variety of products and materials for 3D printing. It is constantly developing and improving its technologies to be among the first.

In addition, it produces a huge variety of products and materials for 3D printing. It is constantly developing and improving its technologies to be among the first.

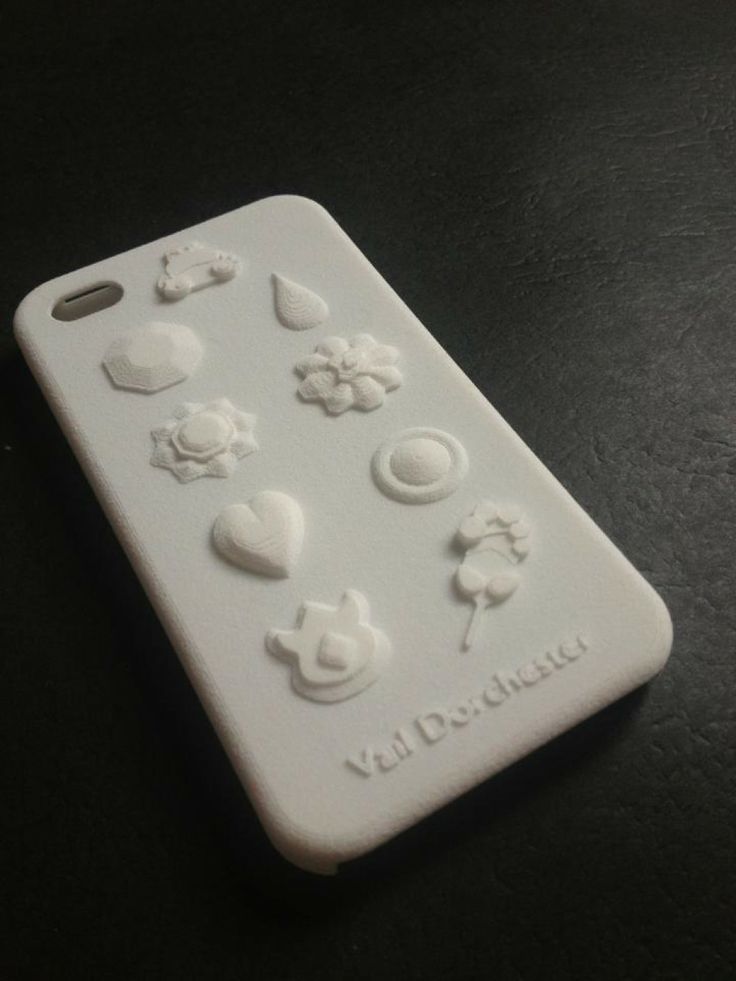

One of the most popular materials offered by Shapeways is colored sandstone. Many Shapeways designers use this material due to its high resolution and accurate color reproduction. However, sandstone lacks flexibility, and if even a drop of water gets on it, it will most likely fall apart. Most of the popular items featured on the Shapeways website have flexible and/or moving parts (toys, action figures and smartphone cases). Such items cannot be printed from sandstone, so they have to be made using boring, one-color plastic. nine0005

But today everything has changed! Today, Shapeways has officially unveiled a new multicolored plastic material. Items made from it are not only smooth and neat, but can also be made in a variety of colors. Shapeways claims that in terms of its color scheme, the novelty is in no way inferior to the popular sandstone.

The following are the general characteristics of the new material:

- Minimum allowable wall thickness: 0.7 mm. nine0096 Minimum permissible wall thickness: 0.7 mm.

- Minimum allowable wire thickness: 0.8 mm.

- Minimum impermissible wire thickness: 1.6 mm.

- Maximum dimensions: 150 mm x 150 mm x 150 mm.

- Minimum dimensions: X + Y + Z ≥ 10 mm.

- Minimum dimensions of convex parts: height and width 0.2 mm.

- Minimum engraved dimensions: height and width 0.2 mm. nine0097

- Minimum outlet diameter 4 mm (provided there is only one outlet).

- If there are more than two holes, the diameter can be 2 mm.

- Tolerance: 0.5 mm.

- Intertwined and connected parts? Yes.

- Multiple parts in one file? No.

First, a small group of designers will receive the new material and put it to the test. After that, anyone can buy it. If you want to be among the first lucky ones, leave a request here. In terms of cost, during the testing period, the price of the new material will be as follows: $3 (start-up costs) + $2/cc. nine0005

After that, anyone can buy it. If you want to be among the first lucky ones, leave a request here. In terms of cost, during the testing period, the price of the new material will be as follows: $3 (start-up costs) + $2/cc. nine0005

Article prepared for 3DToday.ru

Subscribe to the author

Subscribe

Don't want

Article comments

More interesting articles

7

Subscribe to the author

Subscribe

Don't want

Volgograd schoolboy Mikhail Kozenko joined the ranks of 3D-makers by designing his own 3D-...

Read more

five

Subscribe to the author

Subscribe

Don't want

Alexander Gessler wrote a small handy program to convert 40+ 3D file formats (OBJ, S.