3D printing and additive manufacturing pdf

3D Printing and Additive Manufacturing

Editor-in-Chief: Skylar Tibbits, MS, MS, BArch

ISSN: 2329-7662 | Online ISSN: 2329-7670 | Published Bimonthly | Current Volume: 9

Impact Factor: 5.355* *2021 Journal Citation Reports™ (Clarivate, 2022)

CiteScore™: 8.3

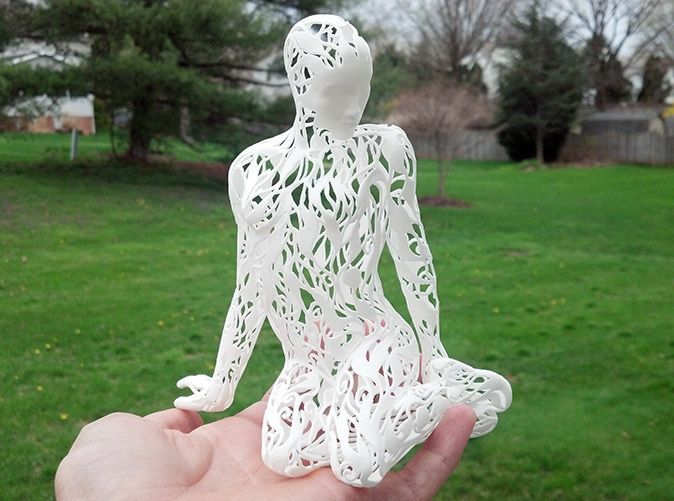

The only peer-reviewed journal focused on the rapidly moving field of 3D printing and related technologies, providing comprehensive coverage of academic research and industrial and commercial developments that have applications in medicine, education, food, and architecture.

- View Aims & Scope

- Indexing/Abstracting

- Editorial Board

Search Subscribe/Renew Recommend This Title Sign Up for TOC Alerts View Submission Instructions Share with a Colleague

Announcements

The views, opinions, findings, conclusions and recommendations set forth in any Journal article are solely those of the authors of those articles and do not necessarily reflect the views, policy or position of the Journal, its Publisher, its editorial staff or any affiliated Societies and should not be attributed to any of them.

Recommended Publications

Tissue Engineering, Parts A, B, & C

Stem Cells and Development

Soft Robotics

Big Data

Genetic Engineering & Biotechnology News

3D Printing and Additive Manufacturing

Editor-in-Chief: Skylar Tibbits, MS, MS, BArch

ISSN: 2329-7662 | Online ISSN: 2329-7670 | Published Bimonthly | Current Volume: 9

Impact Factor: 5.

355*

*2021 Journal Citation Reports™ (Clarivate, 2022)

355*

*2021 Journal Citation Reports™ (Clarivate, 2022)

CiteScore™: 8.3

The only peer-reviewed journal focused on the rapidly moving field of 3D printing and related technologies, providing comprehensive coverage of academic research and industrial and commercial developments that have applications in medicine, education, food, and architecture.

- View Aims & Scope

- Indexing/Abstracting

- Editorial Board

Search Subscribe/Renew Recommend This Title Sign Up for TOC Alerts View Submission Instructions Share with a Colleague

The views, opinions, findings, conclusions and recommendations set forth in any Journal article are solely those of the authors of those articles and do not necessarily reflect the views, policy or position of the Journal, its Publisher, its editorial staff or any affiliated Societies and should not be attributed to any of them.

Recommended Publications

Tissue Engineering, Parts A, B, & C

Stem Cells and Development

Soft Robotics

Big Data

Genetic Engineering & Biotechnology News

Other pages - Page not found

Ratings and awards Management Expert Council Licenses and accreditations Reviews and thanks Sustainability Management and ESG Cooperation Corporate venture fund

About company >

Accompanying the conclusion of the SPIC Anti-crisis consulting Tax consulting Audit of RAS / IFRS Financial consulting due diligence Investment consulting and valuation HR consulting Management consulting Legal consulting Accounting consulting Transition to FSB Intellectual Property Management Attracting investments

Services and practices ›

Oil and gas Construction and development Mining and exploration Medicine and pharmaceuticals Food industry and agriculture infrastructure construction Energy Transport and logistic mechanical engineering Metallurgy IT industry Retail Light industry Financial sector Science and innovation Management companies Telecommunications and communications Chemical industry Timber industry and woodworking Production

All industries ›

company's news Legislative news Expert Publications Analytical studies

Press Center ›

Jobs Command Internship Alumni

Career >

Send a message and our managers will contact you as soon as possible

We use cookies to improve the site and its user experience. By continuing to use the site, you consent to the use of cookies.

By continuing to use the site, you consent to the use of cookies.

Accept

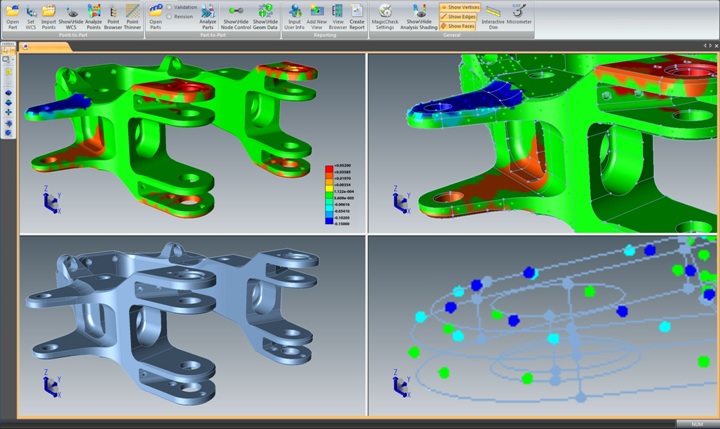

nine0000 Six Big Trends" from CADmaster #1(95) 2021Time is today's most valuable commodity. High competition and new business models require faster development cycles to bring innovation to life quickly and flexibly. With new, more efficient equipment,

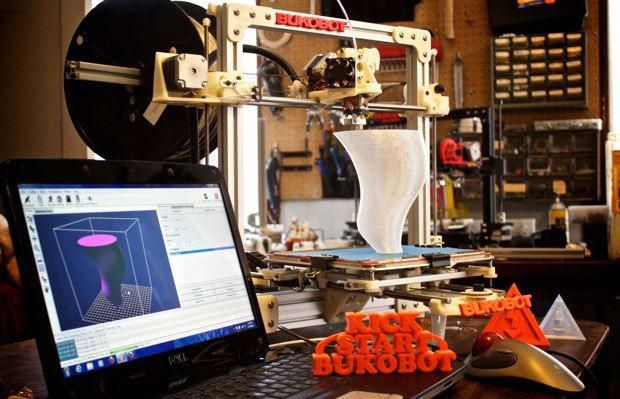

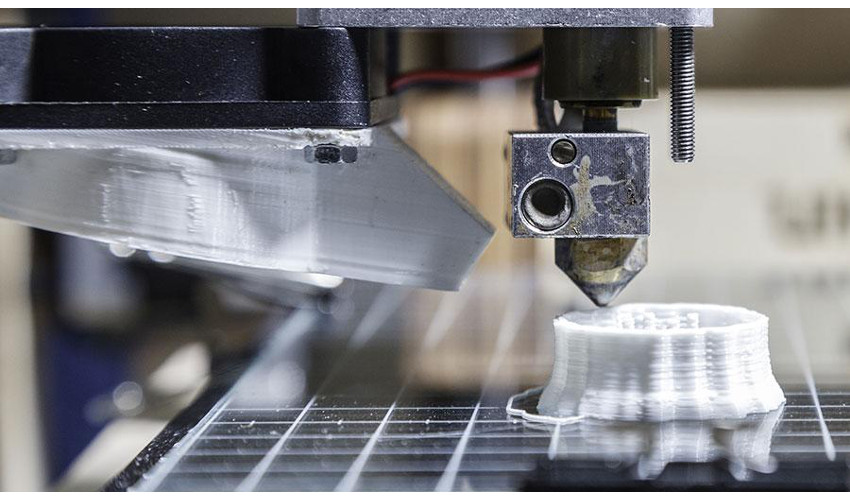

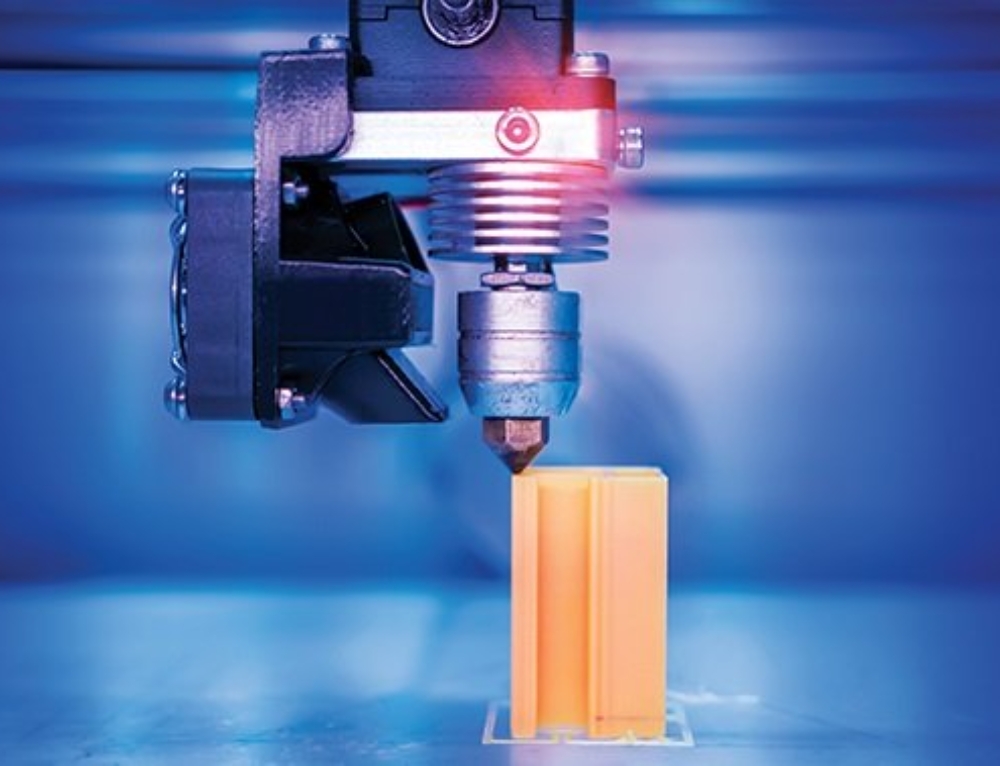

3D printing was originally designed to revolutionize manufacturing, with a number of strategic advantages such as design flexibility, reduced lead times, market, mass customization, distributed manufacturing, etc. Despite some difficulties, 3D printing continues to show undeniable advantages.0003

Over the past few years, Jabil, an international manufacturing services company, has sponsored three 3D printing trend studies to determine the direction of additive manufacturing and assess current realities. The 2021 survey included more than 300 people responsible for making 3D printing decisions in manufacturing companies. The report allows you to get acquainted with the experience and opinion of professionals working "at the forefront". Respondents work in a wide range of industries, including electronics, plastics and packaging, industrial engineering, automotive, healthcare and many others, giving us a complete picture of the 3D printing market and how additive technologies are being used. nine0003

The report allows you to get acquainted with the experience and opinion of professionals working "at the forefront". Respondents work in a wide range of industries, including electronics, plastics and packaging, industrial engineering, automotive, healthcare and many others, giving us a complete picture of the 3D printing market and how additive technologies are being used. nine0003

3D printing is rapidly expanding

Thirty years is a very short time when it comes to traditional production methods. Additive technologies are making revolutionary changes in various industries.

The results of the last two studies contrast sharply with the information that was obtained in the first survey in 2017. Even in the last two years, the adoption of 3D printing has increased significantly. The study clearly shows the rise in popularity and expansion of the scope of additive manufacturing. nine0003

In 2017, the most popular answer to the question “what is 3D printing used for in your company?” was the answer "for rapid prototyping". Seven out of ten respondents confirmed the use of 3D printing for this purpose. The remaining answer options lag far behind the first: only three out of ten respondents chose the second option (tooling production). Since then, the scope of 3D printing has expanded significantly.

Seven out of ten respondents confirmed the use of 3D printing for this purpose. The remaining answer options lag far behind the first: only three out of ten respondents chose the second option (tooling production). Since then, the scope of 3D printing has expanded significantly.

© jabil.com

R&D has become the most popular area for 3D printing, ahead of prototyping. At the same time, there is a sharp increase in application scenarios in other areas. Since 2017, the share of companies using additive manufacturing to make parts and tooling has doubled, and the use of these methods for mass production of parts has tripled. nine0003

Nearly 100% of study participants reported that they use 3D printing to produce functional or final parts. Undoubtedly, the scale of their production varies. Nearly 80% of respondents report using additive manufacturing to produce at least 25-50% of functional parts.

© jabil. com

com

Improvements in 3D printers allow companies to experiment with additive technologies in areas where they were previously unavailable. As the performance of 3D printers increases and their prices decrease, the technology will become more accessible and will change the manufacturing industry as a whole. nine0003

The growth of additive manufacturing: forecasts are more optimistic than ever

Prospects for the development of 3D printing are extremely positive. Market participants are confident in the future significant growth in the popularity of technology. 97% of respondents believe that the adoption of 3D printing in their companies will increase in the next five years.

The majority of study participants believe that the use of 3D printers in their organizations will at least double over this period of time. Nearly half of respondents expect usage to double, and 4 out of 10 expect the increase to be much larger (five times or more). In addition to the growing popularity of additive technologies, a significant role in expanding their use, as already mentioned, will be played by their availability. nine0003

nine0003

© jabil.com

Companies in general plan to increase their additive capacity, but the highest expectations are related to mass production of parts and goods. Slightly more than 80% of respondents expect their organizations to use additive manufacturing for mass-produced products to at least double over the next five years.

3D printing offers many benefits to companies

During the first study, many of the benefits were perceived as "intangible" concepts. However, over the past few years, the use cases have increased, the concepts have become a reality, and two years later, respondents are even more inspired by the benefits of additive technologies. Researchers have highlighted the main benefits of additive manufacturing based on reviews. nine0003

© jabil.com

Perhaps the rise in popularity of 3D printing is not a coincidence, but is due to increased demand for additive manufacturing during the COVID-19 crisis. As the pandemic spread, companies with 3D printers began to produce personal protective equipment such as respirators and masks that suddenly became scarce. When developing new diagnostic equipment and analysis kits, the use of 3D printing has accelerated the process of prototyping and design. nine0003

As the pandemic spread, companies with 3D printers began to produce personal protective equipment such as respirators and masks that suddenly became scarce. When developing new diagnostic equipment and analysis kits, the use of 3D printing has accelerated the process of prototyping and design. nine0003

Respondents chose faster production of parts as the main benefit of additive manufacturing. Jabil has seen this firsthand: indeed, the desire to forego the labor-intensive iterative process has been the driving force behind the introduction of additive manufacturing into the Auburn Hills facility. Not only did this help speed up workflows, but it also helped reduce costs by being able to immediately recreate the exact geometry (no need to cut off excess material). In fact, the savings amounted to 30-40% on tooling and 80% on lead times. nine0003

“ 3D printing has improved every aspect of the ,” says John Wahl VI, Tooling Engineer at Jabil's Auburn Hills facility.

- The first aspect is time, the second is a more creative approach, the third is costs, the fourth is materials .

According to the distribution by job level, senior managers are more optimistic about the benefits of 3D printing than department heads. Since it is the leaders who shape the vision (and plan the budget) for the future of the company, everything points to the further spread of 3D printing. nine0003

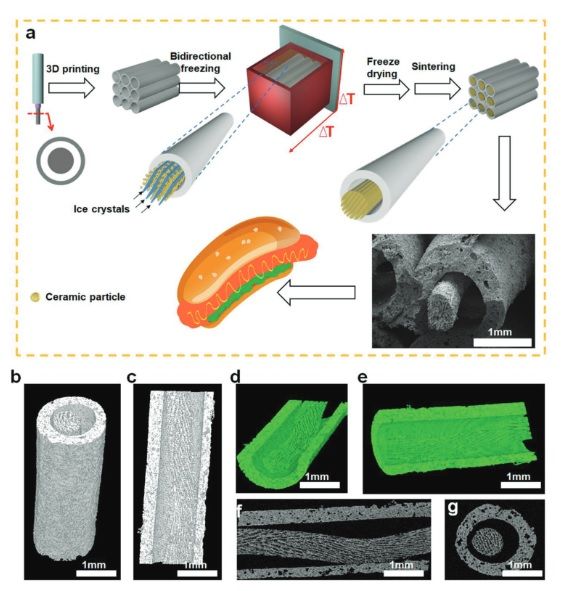

3D printing materials become more affordable

Compared to 2019, companies are using many more types of 3D printing materials. Despite the fact that plastics / polymers are still leading, other materials do not lose ground and catch up. This confirms our conclusion that the scope of 3D printing is expanding.

© jabil.com

When it comes to mainstream material, the difference between plastic and metal in 3D printing is not as big as you might think. More than a third of respondents answered that they use plastic and metal equally, and those who choose only plastics are only 10% more. nine0003

nine0003

Of course, certain problems must be overcome in order to use some materials. Respondents noted that the development of the necessary materials takes too much time. A number of materials are too expensive for large-scale use, are not available or are not certified.

© jabil.com

However, as these problems are overcome, interest in different materials increases. When looking at what materials companies actually use and what they would like to use, plastic still comes out on top. At the same time, the desire to use almost all materials exceeds the current use. It is noteworthy that interest in printing with glass exceeds the actual use by 20%, with ceramics by 14%, and with metal by 10%. It will be interesting to observe the changes in the use of materials in the next two years. nine0003

Additive manufacturing is still a source of problems

Despite the optimistic view of the development of additive manufacturing, companies still have to solve a number of problems associated with 3D printing. In 2019, half of the respondents considered the cost of materials as a problem, and this year only about two-fifths gave such an answer. All problems are located approximately on the same level: most of them fluctuate around 40%.

In 2019, half of the respondents considered the cost of materials as a problem, and this year only about two-fifths gave such an answer. All problems are located approximately on the same level: most of them fluctuate around 40%.

© jabil.com nine0003

However, many of the current challenges are related to costs, as 95% of respondents reported financial barriers to adopting additive manufacturing. Obtaining appropriate qualifications and certifications is the main challenge, followed by capital expenditures associated with equipment and the need for in-house specialists.

In 2021, pre- and post-processing costs have become a major concern. Companies are using more and more pre- and post-processing methods. In 2019Just over half of respondents reported using machining in 1999, and now it's almost three-quarters, with no polishing being the most common option. Given that the use of all processing methods has increased significantly, it is possible that companies are experiencing growth difficulties. If these problems continue to be given priority, then they can be overcome.

If these problems continue to be given priority, then they can be overcome.

Training of specialists is a priority

About three-quarters of respondents are now engaged in additive manufacturing themselves. Considering that half of the time they chose “lack of in-house talent” as a problem, it can be assumed that companies are prioritizing training their employees in additive manufacturing or attracting specialists with experience and knowledge in the field of 3D printing. nine0003

This does not mean that organizations are opposed to outsourcing additive manufacturing: almost 100% of respondents answered that they are considering this option. Companies take into account a variety of criteria when studying potential suppliers. Design capability is key, and scalability, pricing, and experience continue the list.

© jabil.com

In some areas, we are seeing a significant increase in the adoption of 3D printing. In others, this growth is still small.