Wireless 3d printers

The Best Cheap 3D Printers for 2023

While we'd hesitate to call 3D printing a mature technology, you might say it has reached its teenage years. Through their first decade-and-change, 3D printers have come down in price, grown easier to set up and operate, and become more reliable. And you may pay less than you expect: Many once-high-end features have migrated down to inexpensive models.

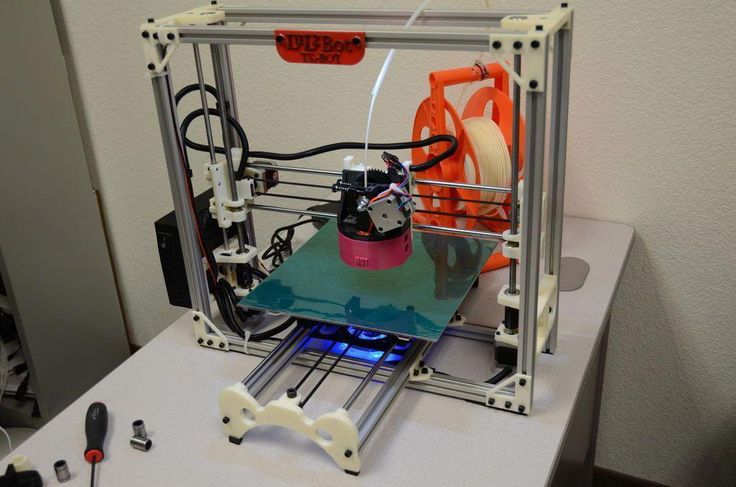

PC Labs has been reviewing 3D printers since 2013. Today, the state of 3D printing is strong, but that wasn’t always the case. For the first several years, it was often an adventure getting one of these printers up and running, let alone successfully through our testing regimen. Issues with filament-based—aka fused filament fabrication (FFF) or fused deposition modeling (FDM)—printers were abundant.

Filament feeders had to be coaxed into delivering filament from the spool to the extruder. Print beds had to be manually aligned. The extruder or hot end had to be positioned just right to minimize the gap between the nozzle and the build plate (the flat surface on which the object is printed). Objects frequently stuck to the build plate, and required careful, sometimes unsuccessful, efforts to pry them off. These and other issues required painstaking effort to resolve, often combined with calls to tech support.

Not so much anymore. While they can still be rebellious at times, 3D printers have grown up a lot, and achieving the 3D printer basics has gotten a lot less likely to end in a shouting match over small things. And they've gotten a lot more affordable, too, for curious DIY-ers and hobbyists to try.

If you're in the market for a beginner or low-cost 3D printer, it's important to know how lower-end models differ. Read on for mini-reviews of the top budget 3D printers we've tested. After that, we go into more detail on understanding the 3D printer specs and tech relevant to beginning buyers. Ready to take the plunge? Read on.

Deeper Dive: Our Top Tested Picks

Original Prusa Mini

Best Overall Budget 3D Printer

4.5 Outstanding

Bottom Line:

It requires assembly and calibration care (plus shipping from the Czech Republic), but the Original Prusa Mini is a compact, open-frame 3D printer that consistently produces superb-quality output for a great price.

PROS

- Top-notch object quality

- Supports a variety of filament types

- Useful, professionally printed user guide

- Great support resources

- Versatile, user-friendly software

CONS

- First-layer calibration can be tricky

- Only includes starter packets of filament

- Requires monitoring if young children or pets are around

| Sold By | List Price | Price | |

|---|---|---|---|

| Prusa Research | $399.00 | $399.00 | See It (Opens in a new window) |

Read Our Original Prusa Mini Review

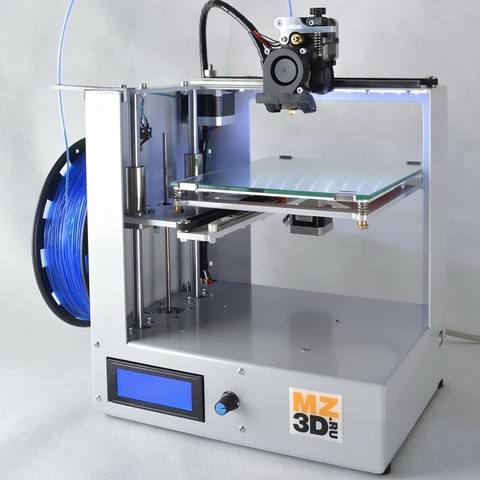

XYZprinting da Vinci Mini

Best Budget 3D Printer for Schools, Community Centers

4.0 Excellent

Bottom Line:

The XYZprinting da Vinci Mini is a consumer-oriented 3D printer that provides a winning combination of low price, ease of setup and use, solid print quality, and smooth, misprint-free operation.

PROS

- Very low price.

- Reasonably priced filament.

- Good print quality.

- No misprints in testing.

- Easy setup and operation.

- Quiet.

- Prints over a USB or Wi-Fi connection.

CONS

- Occasional problems in trying to launch prints.

- Removing printed objects from the print bed is sometimes tricky.

| Sold By | List Price | Price | |

|---|---|---|---|

| Walmart | $199.95 | $199.95 | See It (Opens in a new window) |

| Amazon | $199.95 | $199.95 | See It (Opens in a new window) |

Read Our XYZprinting da Vinci Mini Review

Toybox 3D Printer

Best Budget 3D Printer for Children

4.0 Excellent

Bottom Line:

The Toybox 3D Printer works well as a model designed for children, offering reliable printing from a browser or mobile device and a few thousand toys to print, plus creative options to output drawings or photos. Just bear in mind the tiny build area.

Just bear in mind the tiny build area.

PROS

- Reliable, misprint-free printing

- Easy setup

- One-touch operation

- Well-composed help resources

- Access to more than 2,000 printable toys and projects

- Lets you create your own printable designs

CONS

- Tiny build area

- Not ideal for importing 3D files created elsewhere

| Sold By | List Price | Price | |

|---|---|---|---|

| Amazon | $299.00 | $299.00 | See It (Opens in a new window) |

| Toybox Labs | $379.00 | $299.00 | See It (Opens in a new window) |

Read Our Toybox 3D Printer Review

Monoprice Mini Delta V2 3D Printer

Best Budget 3D Printer for Beginners, Non-Techies

4.0 Excellent

Bottom Line:

3D printing gurus will be intrigued by the Monoprice Mini Delta V2's use of the delta rather than Cartesian coordinate system, but beginners will just enjoy its low price, ease of use, and speedy printing.

PROS

- Sub-$200 price

- Quick, nearly misprint-free printing

- Easy setup and operation

- Sturdy steel-and-aluminum frame

- Supports multiple filament types

CONS

- Tiny build area

- So-so print quality

- Mere one-year warranty

| Sold By | List Price | Price | |

|---|---|---|---|

| Amazon | $323.98 | $323.98 | See It (Opens in a new window) |

Read Our Monoprice Mini Delta V2 3D Printer Review

Anycubic i3 Mega S

Best Budget 3D Printer With an Open Design, Big Build Area

3.5 Good

Bottom Line:

The Anycubic i3 Mega S, an inexpensive open-frame 3D printer, produced decent-quality prints in our testing. To get the most out of it, though, may require precise calibration.

PROS

- Modestly priced

- Large build area for an inexpensive printer

- Supports a variety of filament types

- Generally solid print quality

- Uses well-known Cura software

CONS

- Finicky print-platform alignment

- Supported coils of filament are small

- Poorly placed spool holder

| Sold By | List Price | Price | |

|---|---|---|---|

| Amazon | $229. 98 98 | $229.98 | Check Stock (Opens in a new window) |

| AnyCubic | $279.00 | $279.00 | Check Stock (Opens in a new window) |

Read Our Anycubic i3 Mega S Review

Anycubic Vyper

Best Budget 3D Printer for the Biggest Build Area Possible

3.5 Good

Bottom Line:

Anycubic's modestly priced Vyper whips up large 3D prints on its open-frame design, and provides automatic print-bed leveling. Just know that some minor assembly is required—and printed objects may require a bit of cleanup.

PROS

- Relatively large build area

- Automatic bed leveling

- Simple assembly

CONS

- Short (one-year) warranty

- Includes only a small starter filament coil

- Using Cura software with the Vyper requires tweaking a couple of settings

- Test prints showed some "hairy" filament residue

| Sold By | List Price | Price | |

|---|---|---|---|

| Amazon | $499. 00 00 | $339.99 | See It (Opens in a new window) |

| AnyCubic | $369.00 | $319.00 | See It (Opens in a new window) |

Read Our Anycubic Vyper Review

Creality Ender-3 V2

Best Budget 3D Printer for Tinkerers and DIY Types

3.5 Good

Bottom Line:

Hands-on tweaking defines Creality's budget-price Ender-3 V2, an open-frame 3D printer that you build from a kit. It produces generally above-par prints, but its print bed can be tricky to keep leveled.

PROS

- Inexpensive

- Slightly above-average print quality

- Good-size build area for its price

- Supports several filament types

CONS

- Manual print-bed leveling can be tricky

- Setup instructions could be deeper, more legible

- Questionable quality control on some parts

| Sold By | List Price | Price | |

|---|---|---|---|

| Amazon | $299. 00 00 | $246.00 | See It (Opens in a new window) |

Read Our Creality Ender-3 V2 Review

Flashforge Finder 3D Printer

Best 3D Printer for the Very Tightest Budgets

3.5 Good

Bottom Line:

The Flashforge Finder 3D Printer is moderately priced and offers good print quality, but it proved tricky to get up and running in our tests.

PROS

- Quiet.

- Good print quality.

- Connects via USB 2.0 cable, USB thumb drive, or Wi-Fi.

- Reasonably priced.

CONS

- Some objects pulled off the platform during testing.

- Poor documentation.

- Modest build volume.

- Limited to printing with polylactic acid filament (PLA).

| Sold By | List Price | Price | |

|---|---|---|---|

| Amazon | $259.90 | $259.90 | Check Stock (Opens in a new window) |

Read Our Flashforge Finder 3D Printer Review

Polaroid PlaySmart 3D Printer

Best Budget 3D Printer for Dabbling in Small Objects

3. 5 Good

5 Good

Bottom Line:

The Polaroid PlaySmart 3D Printer is a compact, stylish 3D printer with above-par overall print quality, but, alas, a tiny build area for the money.

PROS

- Small, lightweight for a desktop 3D printer.

- Easy to set up and use.

- Supports PLA, PETG, and wood composite filaments.

- Multiple-color support.

- Wi-Fi camera monitors print jobs.

- Prints from USB drives, SD cards, or mobile devices.

CONS

- High price for its capabilities.

- Small build area.

- Too-brief warranty.

| Sold By | List Price | Price | |

|---|---|---|---|

| Amazon | $699.00 | $699.00 | See It (Opens in a new window) |

Read Our Polaroid PlaySmart 3D Printer Review

XYZprinting da Vinci Jr. 1.0 A Pro

Best Budget 3D Printer With Closed Design, Roomy Build Area

3. 5 Good

5 Good

Bottom Line:

The XYZprinting da Vinci Jr. 1.0 A Pro is a moderately priced closed-frame 3D printer with a large build volume and overall good performance, but a potentially balky filament-feeding system.

PROS

- Spacious build area

- Works with third-party filaments

- Self-leveling print bed

CONS

- Build plate is not heated

- Limited to PLA- and PETG-based filaments

- Guide tube is prone to detaching

| Sold By | List Price | Price | |

|---|---|---|---|

| Amazon | $299.95 | $199.95 | See It (Opens in a new window) |

| Best Buy | $449.95 | $449.95 | Check Stock (Opens in a new window) |

Read Our XYZprinting da Vinci Jr. 1.0 A Pro Review

Monoprice Voxel 3D Printer

Best Budget 3D Printer for Cheap Filament

3. 0 Average

0 Average

Bottom Line:

The Monoprice Voxel is an under-$400 3D printer that's easy to set up and use. It exhibits generally good print quality, but it was unable to print two of our test objects.

PROS

- Easy to set up and use.

- Budget price for printer and filament spools.

- Supports PLA, ABS, and several composite filament types.

- Versatile software.

- Prints over Ethernet or Wi-Fi, or from a USB thumb drive.

CONS

- Frequent misprints on certain test objects.

- Slightly balky touch screen.

| Sold By | List Price | Price | |

|---|---|---|---|

| Amazon | $449.99 | $369.26 | See It (Opens in a new window) |

| Walmart | $429.99 | $369.26 | See It (Opens in a new window) |

Read Our Monoprice Voxel 3D Printer Review

Buying Guide: The Best Cheap 3D Printers for 2023

How to Buy a Cheap 3D Printer

The biggest changes to 3D printers over the last few years have come to the cheaper models. Nowadays, many of those classic, ornery 3D-printing issues have been resolved (most of the time, anyway), even for consumer and bargain-priced 3D printers. Automatic print-bed leveling is the norm, and you can usually remove 3D-printed objects from heated and/or flexible build plates with a minimum of coaxing. And most 3D printer manufacturers have either developed and refined their own software, or have adapted an open-source printing platform such as Cura(Opens in a new window).

Nowadays, many of those classic, ornery 3D-printing issues have been resolved (most of the time, anyway), even for consumer and bargain-priced 3D printers. Automatic print-bed leveling is the norm, and you can usually remove 3D-printed objects from heated and/or flexible build plates with a minimum of coaxing. And most 3D printer manufacturers have either developed and refined their own software, or have adapted an open-source printing platform such as Cura(Opens in a new window).

(Credit: Zlata Ivleva)

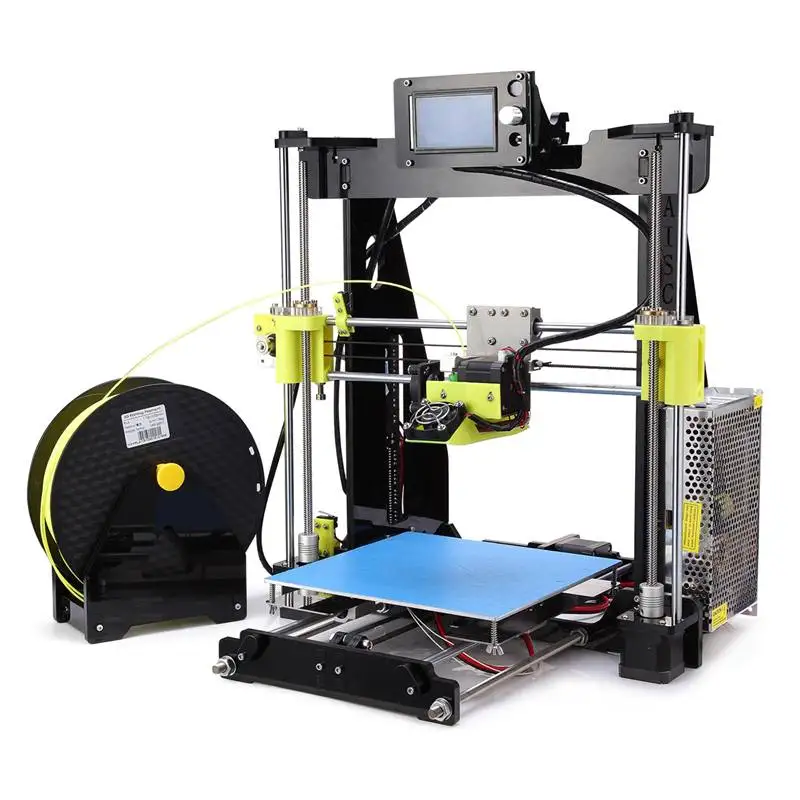

What separates more expensive 3D printers from cheap ones ("cheap" defined as $500 or less, for the purposes of this article) is often a select group of features. These include the build volume, the type of frame, the varieties of supported filament, the software, and the connectivity mix. Let's run through those in turn.

What's the Right Build Volume for a 3D Printer?

A 3D printer’s build volume is the maximum dimensions (HWD) of a part that it can print. (We say “a part” because a 3D-printed object can consist of multiple parts that are printed, then glued or otherwise pieced together.) While the smallest build volume of any 3D printer we have tested is 3.9 by 3.9 by 4.9 inches, we consider any build volume smaller than 6 by 6 by 6 inches to be small, any between that and 10 by 10 by 10 inches as medium, and any printer with at least one build dimension of more than 10 inches as having a large build volume.

(We say “a part” because a 3D-printed object can consist of multiple parts that are printed, then glued or otherwise pieced together.) While the smallest build volume of any 3D printer we have tested is 3.9 by 3.9 by 4.9 inches, we consider any build volume smaller than 6 by 6 by 6 inches to be small, any between that and 10 by 10 by 10 inches as medium, and any printer with at least one build dimension of more than 10 inches as having a large build volume.

(Credit: Molly Flores)

As a general rule, inexpensive 3D printers have small build volumes, while more expensive ones have larger build volumes. This depends in part on the type of printer. Closed-frame 3D printers—and most semi-open models, which have a rigid top, base, and sides but are open in front and, often, back—tend to have small build volumes, while open-frame printers, lacking as rigid a physical structure, often have relatively large build volumes for the price. You'll want to weigh the build volume against the kinds of objects you will print.

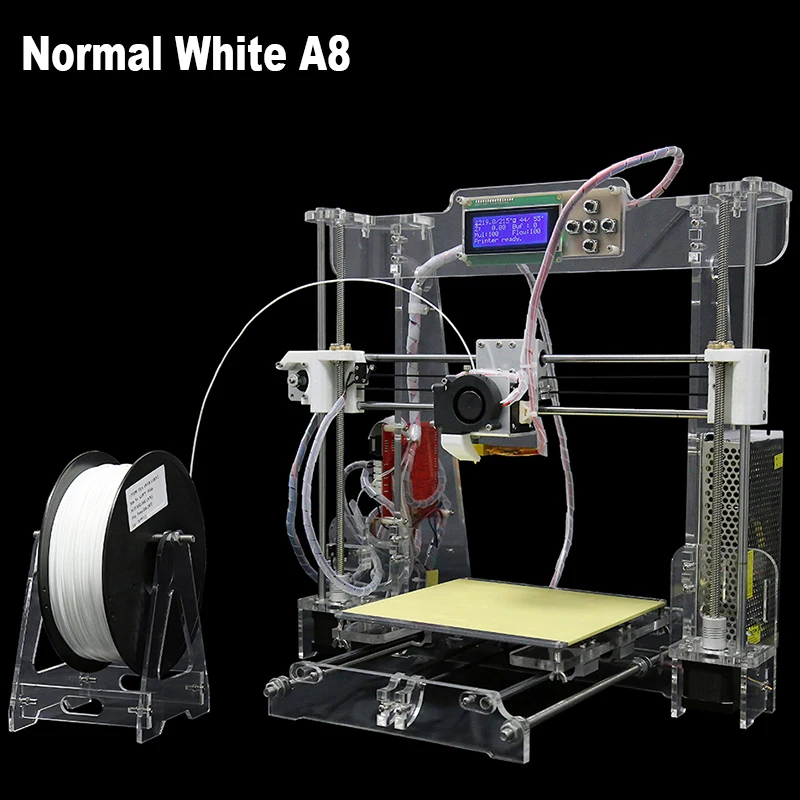

Should I Get an Open-Frame or Closed-Frame 3D Printer?

Which brings us to the frame "form factor" question: open-frame versus closed-frame. Closed-frame 3D printers are boxlike devices, with a rigid base, walls (with a see-through door in front), and top. Among their advantages? They muffle the operating noise, as well as reduce the odor from melted filament (which is potentially an issue with ABS plastic), and they provide some protection for people or pets who might inadvertently touch the hot extruder. A downside: They tend to have smaller build volumes than open-frame 3D printers, which have fewer (often, no) walls to constrict them.

(Credit: Zlata Ivleva)

Low-cost 3D printers include both open-frame and closed-frame models, as well as a few stereolithography printers. If a relatively large build volume is a priority, you’re likely to get more bang for the buck with an open-frame model. Open-frames do have some clear downsides by definition: They tend to be noisy, emit odors when certain plastics are melted, and provide little protection for someone who might touch the hot extruder.

(Credit: Molly Flores)

Also, recognize some potential negatives of open frames, depending on the model. Some require assembly, being essentially kits, and most require more setup care than a closed-frame printer, plus more maintenance to keep them running smoothly. Still, these very traits should not deter—and may even appeal to—hobbyists and DIY folks.

What Should I Look for in 3D Printer Software and Connectivity?

Gone are the days when tinkerers had to cobble together several different programs to get a 3D printer to run. Manufacturers either include their own 3D printing program or modify an existing platform such as the open-source Cura.

3D printing software performs three main functions: processing an object file (resizing, moving, rotating, and in some cases duplicating it), slicing it (into virtual layers, based on your chosen resolution), and printing it. These are almost universally combined into a seamless process. Some high-end printers have software that supports a wider range of settings you can tweak, but even the basic suites work at least reasonably well.

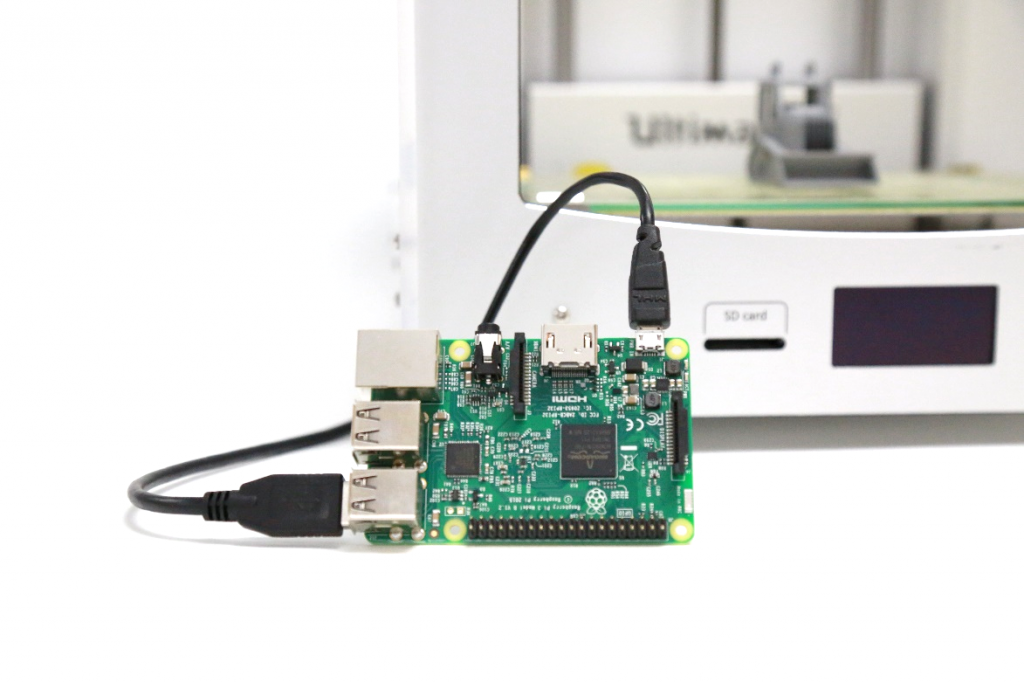

More likely to vary among the cheaper set is the array of connection options from model to model. Nearly all have a USB Type-A port to fit a thumb drive for printing from document files. Most also have a USB Type-B port for connecting directly to a computer, and some offer Wi-Fi, too (or as an alternative), while a handful let you connect via Ethernet to share the printer across a local network.

Some printers support storing 3D files on an SD or microSD card (which may also contain the printer’s system files). Most 3D printer manufacturers (even the discount ones) have a mobile app to launch and monitor print jobs, and a few provide access to cloud services from which you can print.

While high-end 3D printers tend to have an abundance of connection choices, discount models vary widely in their choices. Some are generous and some are basic, so it pays to assess what a given model offers.

What Should I Look for in Filament Support?

Filament support tends to be a key area that separates the cheaper models from the higher-end ones. (See our guide to understanding 3D printing filaments for more particulars.) Inexpensive 3D printers tend to support a limited number of plastic filament types, some of them only PLA and/or ABS.

(See our guide to understanding 3D printing filaments for more particulars.) Inexpensive 3D printers tend to support a limited number of plastic filament types, some of them only PLA and/or ABS.

Recommended by Our Editors

3D Printing: What You Need to Know

3D Printer Filaments Explained

(Credit: Molly Flores)

PLA (polylactic acid) is a biodegradable, plant-based polymer, while ABS (acrylonitrile butadiene styrene) is the same tough plastic that Legos are made from. Objects printed from ABS are durable and nontoxic, though the material can be tricky to work with. ABS can emit an acrid, unpleasant odor during printing, and the bottom corners of objects being printed with it have a tendency to curl upward a bit, especially if you are using a non-heated print bed. This can lead to unsightly prints, and/or prints prematurely pulling off the build plate, ruining them.

Many entry-level and low-price 3D printers stick exclusively to PLA. If you want to experiment with a larger variety of filaments—which include water-soluble filament, wood- and metal-laced composites, and both tough and flexible varieties—you may have to pay more, although a few discount models support a wide range of materials.

If you want to experiment with a larger variety of filaments—which include water-soluble filament, wood- and metal-laced composites, and both tough and flexible varieties—you may have to pay more, although a few discount models support a wide range of materials.

Should I Consider a 3D Printing Pen Instead?

Although they aren’t printers per se, inexpensive 3D pens are close kin to 3D printers—using the same filament types and a similar extrusion system—and we include them in the 3D printing category. Rather than tracing out a programmed pattern, you use the 3D pen much like a normal pen, except that you draw with molten plastic. You can trace a pattern or draw freehand, and even draw in three dimensions as the plastic quickly solidifies and hardens once extruded.

(Credit: 3Doodler)

Most 3D pens cost less than $100, and some cost $50 or less. At a glance, 3D pens may appear to be toys, but some artists and craftspeople have taken to them, as it is possible to make quite complicated and beautiful objects with them. If your aim in 3D printing is something closer to freehand design and free expression than computer-centric, structured, and repeatable output, you might give one a try.

If your aim in 3D printing is something closer to freehand design and free expression than computer-centric, structured, and repeatable output, you might give one a try.

So, What Is the Best Cheap 3D Printer to Buy?

Buying a budget 3D printer needn’t mean a world of sacrifice. Plenty of capable and reliable models sell at less than $500, and while they may not be as feature-rich as their more expensive cousins, there's no sense in paying for things you don’t need.

Many casual 3D-printing experimenters will be fine with printing over a USB cable or from a thumb drive, and sticking to PLA may be the best choice for a starter 3D printer. If you focus just on the features you want, you may be pleasantly surprised at what you find. Below, check out a spec breakdown of the best under-$500 3D printers we have reviewed, paralleling our picks above. Also, for a look at the broader market, see our guide to our favorite 3D printers overall.

Staples® Official Online Store

End of the year deals are here

End the year with a bang and prep for the new year with awesome deals from Staples. Start with Staples Black Friday deals on everything from computers and tech to gaming chairs, printers, and more! The savings continue with a week of Cyber Monday deals you don't want to miss! Use this time to stock up on essentials, update your office, and find gifts they'll love receiving.

Start with Staples Black Friday deals on everything from computers and tech to gaming chairs, printers, and more! The savings continue with a week of Cyber Monday deals you don't want to miss! Use this time to stock up on essentials, update your office, and find gifts they'll love receiving.

With the new year right around the corner, it's the perfect time to refresh your office and replenish your supplies. Get back to work and take advantage of savings on ink and toner, office furniture, packing and shipping supplies, and more. Stock up and save on all kinds of supplies for the office. Get deeper discounts on supplies like copy paper, file folders, and writing supplies when you set up a business account with Staples Business Advantage or order using the Staples AutoRestock feature.

Make sure you're prepared for the upcoming tax season

As the year comes to an end, it's time to get your financial documents in order and prepare for the upcoming tax season. Keep your financial records up to date throughout the year with the right financial software for your personal or company needs. As well as making sure that your office is well stocked with the necessary tax forms and envelopes to get your employees or contract workers their paperwork as soon as possible. See how Staples can help you prepare for your taxes:

Keep your financial records up to date throughout the year with the right financial software for your personal or company needs. As well as making sure that your office is well stocked with the necessary tax forms and envelopes to get your employees or contract workers their paperwork as soon as possible. See how Staples can help you prepare for your taxes:

- Starting with the right financial software can help keep you ahead of the game before the next tax season. With recognized financial brands such as Quicken Finance Software. Take the hassle out of staying financially organized.

- Getting your employees and contract workers' tax forms out to them on time is as simple as just pressing print when you have the appropriate tax forms on hand. From W2, 1099, 1095, and even the envelopes to mail it out, we have your tax form need in mind.

- When it comes time to file your taxes, we can even help you find the right tax software that fits your filing requirements. From software for personal taxes, business taxes, or both, we offer top brands such as Turbo Tax and H&R Block.

With the ability to e-file or print and mail both your federal and state taxes.

With the ability to e-file or print and mail both your federal and state taxes.

From employees' tax forms to software to keep your finance in order, or software to get your taxes done, Staples has you covered this upcoming tax season!

Rest assured it arrives safely & securelyWhether you are sending business documents or customer products, shipping and mailroom supplies from Staples make the process seamless.

Keep packing supplies ready for easy shipping. Padded envelopes and bubble mailers are perfect for shipping small, non-fragile items. Pack larger items in shipping boxes that are slightly larger than the item and use packing peanuts, bubble roll, or other packing materials to keep objects from moving in the box during transport. Choose the right packing tape to seal shipping boxes and keep them sealed. Staples carries clear acrylic packing tape for everyday shipping and reinforced packing tape, or water activated tape for packages that require a heavier duty seal.

Manage the day-to-day office correspondence smoothly with a wide selection of business envelopes, inter-office envelopes, and catalog envelopes in the mailroom. Have finger pads and envelope moisteners on hand for speedy document collation and a quick seal. Choose security envelopes for confidential office correspondence and inter-office communications. If your office or organization sends out large mailings, consider a paper folding machine and self-sealing envelopes to increase efficiency.

Hybrid work just got easier Whether you work in a traditional office, from home, or anywhere in between, the right supplies and technology will keep you working efficiently no matter where you are. Update your tech with a new laptop computer or 2-in-1 tablet for work on the go. Keep important files accessible wherever you are with portable hardrives and USB flash drives that fit easily into a laptop bag. Choose a headset for virtual meetings or noise-cancelling headphones to block out unwanted sounds when working in public.

In your home office, make sure to have a comfortable set up that's built with you in mind. Select an ergonomic office chair or gaming chair, and browse our selection of sit and stand desks for a convertible work area. Add an extra computer monitor to your set up, and choose from our wide selection of mice and keyboards. And don't forget to stock up on office supplies. From notebooks and copy paper, to pens and highlighters, Staples offers flexible AutoRestock options on all the basics, so you can get supplies shipped to your door without having to remember to order.

Take the guess work out of shopping for ink & toner When it comes to selecting the right ink or toner cartridges for your printer, the choices can be confusing. Let Staples Ink and Toner Finder take the guess work out of choosing the right refills for your printer. You can search by model or browse by brand, including top brands like HP, Brother, Canon, and Xerox ink and toner. With cartridges available for over 30 brands, you'll be sure to find what you need to keep printing. When your cartridge is empty, take it to any Staples store for free tech & ink and toner recycling every day!

With cartridges available for over 30 brands, you'll be sure to find what you need to keep printing. When your cartridge is empty, take it to any Staples store for free tech & ink and toner recycling every day!

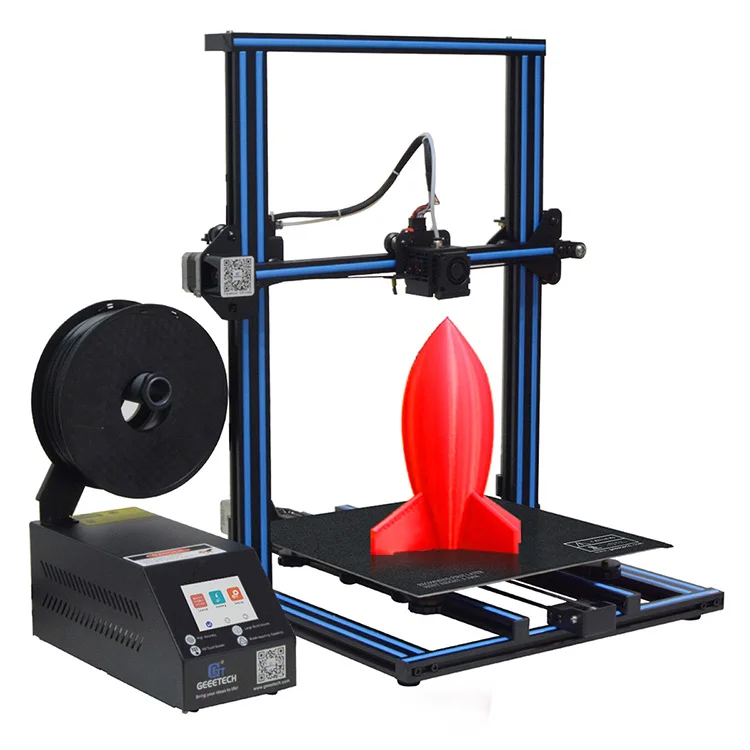

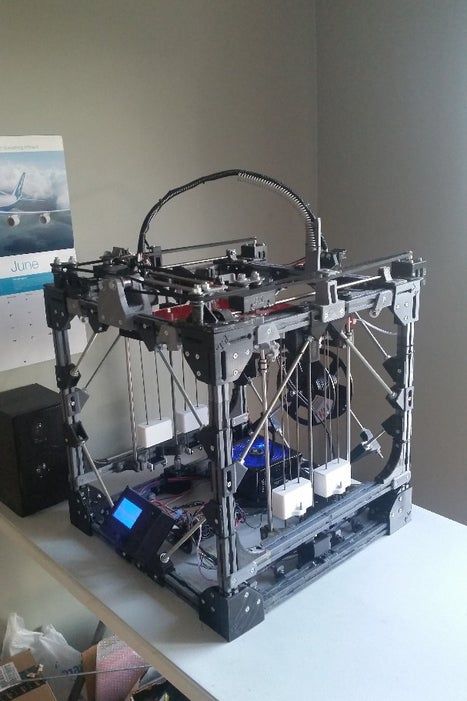

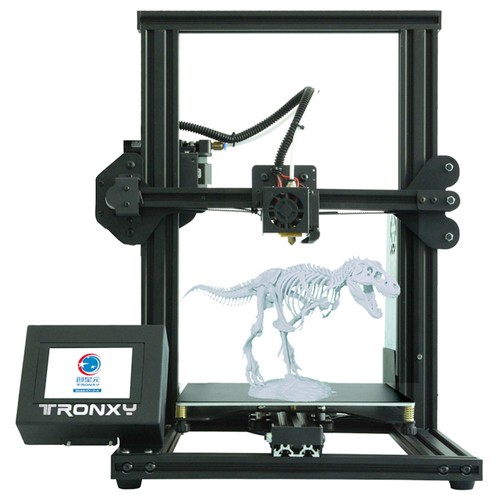

Overview of a large, solid Flyingbear Reborn 3D printer, as well as a course for a young fighter for beginners / 3D printers, machines and accessories / iXBT Live

In today's review, we will talk about the latest Flying Bears 3D printer model, the FlyingBear printer reborn. This device is equipped with a rigid, aluminum body, has increased accuracy and print area size (350x310x350 mm), which allows owners to create large objects without the need to glue them. nine0003

Specifications Flyingbear Reborn

- Print support from: microSD, USB, WiFi

- Power supply: 500W;

- Power supply output voltage: 24V;

- Kinematics: CoreXY;

- X-axis movement: 2 round shafts 8 mm diameter;

- Y-axis travel: profile rail 12 mm;

- Z-axis movement: 4 round shafts Ø 10 mm, 2 screws Ø 8 mm with 8 mm pitch;

- Belts: ring, 6 mm

- Extruder: direct, BMG-like

- Printable area (XYZ): 350x310x350 mm;

- Dimensions: 570x530x580 mm;

- Weight: approx.

22 kg.

22 kg.

Packaging and delivery

The Flyingbear Reborn 3D printer comes in a massive, heavy (about 30 kg) recycled cardboard box, the Flyingbear logo can be found on the box, the box is quite soft. There is no information about the content on it.

The organization of the internal space inside the box is well thought out and built in such a way that none of the elements was damaged during transportation. To ensure reliable fixation of the elements inside the box, polyethylene foam trays are used, inside the box they are neatly laid out one above the other, all elements are fixed rigidly. nine0003

Traditionally for this type of device, a 3D printer is delivered unassembled, and the package includes all the necessary elements for its assembly, and we are talking not only about screws, but also about tools. The kit includes hex keys, a screwdriver, wire cutters, a multi-key (similar to an old bicycle key), a spatula, tweezers, cable ties, a stylus, a card reader, a 4 GB micro SD memory card, a brief instruction in English, etc. etc., etc. To facilitate the task of the user, all fasteners are arranged in packages, and the packages are numbered. nine0003

etc., etc. To facilitate the task of the user, all fasteners are arranged in packages, and the packages are numbered. nine0003

Assembly of the device

At the beginning it was planned to describe the assembly process in detail, but after two hours a different decision was made. There is no need to talk in detail about the assembly of the device. The instruction manual contains QR codes with a link to a very detailed video instruction for assembling the device. The instructions are so detailed that there is nothing to add.

If someone has a desire, you can watch the videos by clicking on the link to the official YouTube channel of FlyingBear 3D Printer. nine0003

Be prepared that you will have to tinker with the installation of corner profiles (most of the time when assembling the device was spent on this).

On my own behalf, I would like to add that during assembly I did not have any difficulties (with the exception of installing profiles), however, when calibrating the table, a flaw was discovered, which manifested itself in the fact that when adjusting the position of the table along the Z axis, the screw rod periodically scrolled, and to carry out calibration failed. I had to remove the side walls, remove the screw rods and reinstall them (it was possible not to remove the side walls, but it was much more convenient for me). nine0003

I had to remove the side walls, remove the screw rods and reinstall them (it was possible not to remove the side walls, but it was much more convenient for me). nine0003

In this regard, I want to recommend to all users (especially beginners like me) who will assemble the printer: after the screw rods are connected, do not be lazy, connect the printer to the mains and check how well everything works moving elements, whether they are wedged. If all is well, you can continue the assembly, following the guidelines. Flyingbear Reborn mm. Such placement of the holder is extremely unfortunate. This is due to the fact that it is fixed on the rear support, and as a result, the printer cannot be moved close to the wall, because the reel with plastic will not allow this. nine0003

So, the sides of the Flyingbear Reborn are covered with plastic panels, they have ventilation holes, and the Flyingbear logo. As mentioned earlier, on the left side there is a holder for a filament spool. Just above the holder is a filament gauge.

The rear cover of the printer has no design elements.

The front has two transparent acrylic doors (blue). I would like to remind you that the printer is delivered unassembled, and in order for the doors to close well, I had to sweat a little. nine0003

We installed four massive rubber feet on the bottom surface.

When assembled, the printer looks very good, one might even say elegant. Here I would like to mention that the manufacturer took care of the aesthetic appearance, in connection with which all the wires to the motors and limit switches are laid in special grooves on the profile, which are then closed with special plugs made in the color of the profiles. The wires from the head are hidden in the corrugation. In this regard, nothing sticks out anywhere and does not bristle. nine0003

Opening the doors, we get access to a 3.5-inch touchscreen display, just below it is a slot for microSD memory cards, as well as a USB-B port.

The base of the table is a stamped metal plate 2 mm thick. On the table is glass, 6 mm thick, which has a special coating.

On the table is glass, 6 mm thick, which has a special coating.

On the lower surface of the table, a heat-insulating plate covering almost its entire area can be placed. Here, in the corners, there are four screw connections with large and very comfortable winglets, designed to level the table. nine0003

The Y axis is built on a linear rail, while the X and Z axes move along the shafts on linear bearings. The movement of the table occurs on four shafts with a diameter of 10 mm, which are located in the corners, 8 mm screws with a thread pitch of 8 mm are responsible for moving the table up / down. To ensure a higher quality of work, anti-play nuts are installed on the table.

Two motors with belts drive the extruder. If necessary, the belts can be tightened. For this, a special hole for screws is provided near each motor, by screwing which the motor moves back, thereby tensioning the belt. nine0003

Even in the lowest position, there is a large enough space under the table, which makes it easy to store various small items there.

The transparent plastic body of the extruder makes it easy to check the position of the rod during its installation.

After removing the basement cover, you can see the control board (MKS Robin Nano v1.3) and four removable TMC2225 drivers. Some surprise was delivered by the fact that the yellow sticker with the inscription WiFi is here for a reason. When looking at the inside of the cover, you can see that under the sticker the metal case has a window, and the antenna of the WiFi module is glued to the sticker itself. nine0003

I would like to note that in order to achieve a better result when printing, the air duct was replaced during operation.

Testing

When printing, the device uses advanced CoreXY kinematics, which provides the printer with excellent stability and print speed with a positioning accuracy of about 0.002 mm along the Z axis, and 0.01 mm along the X and Y axes. In fact, at the current time, CoreXY is one of the most advanced systems, due to the use of which the mass of moving parts is minimized, and as a result, vibrations are reduced. Flyingbear Reborn's printing layer thickness ranges from 0.05mm to 0.3mm, and the print speed can reach 150mm/s. The use of new, low-noise, high-precision TMC2225 drivers also has a positive effect on print accuracy. During operation, most of the noise is made by the fan, and not by the drivers, which are actually very quiet. nine0003

Flyingbear Reborn's printing layer thickness ranges from 0.05mm to 0.3mm, and the print speed can reach 150mm/s. The use of new, low-noise, high-precision TMC2225 drivers also has a positive effect on print accuracy. During operation, most of the noise is made by the fan, and not by the drivers, which are actually very quiet. nine0003

Flyingbear Reborn's extruder uses the proven and easy-to-maintain BMG transparent extruder with a maximum temperature of 260°C, making it easy to process PVC, ABS, PLA, TPU, and other filaments .

A powerful 40x20 radial fan is responsible for cooling, while the 370x325 mm print bed is capable of almost uniform heating in the range from 60 to 110 °C. The table is made of glass and equipped with a special coating to improve adhesion. nine0003

I would also like to note that FlyingBear Reborn has the ability to print objects from various sources. the device is equipped with a port for microSD memory cards, has USB-B (for connecting and printing from a personal computer), and is also equipped with a WiFi module, which allows you to send objects for printing by wireless transmission of information. The FlyingBear Reborn 3D printer supports the most popular formats such as STL, OBJ, DAE, AMF. The printer is controlled using a 3.5 inch touch screen with an intuitive interface. nine0003

The FlyingBear Reborn 3D printer supports the most popular formats such as STL, OBJ, DAE, AMF. The printer is controlled using a 3.5 inch touch screen with an intuitive interface. nine0003

To thread the printer with filament, the filament must be cut at an angle, after which it must be manually pushed up to the motor.

Special thanks for the low filament sensor and auto-resume feature after a power outage.

The table needs to be calibrated before printing. It is desirable to do this when the table reaches the operating temperature. In most cases it is 60 degrees. Calibration does not take much time and is a real pleasure, because. the lambs, mounted on the bottom surface of the table, spin easily and conveniently. The calibration procedure boils down to the fact that after selecting the appropriate menu section, the nozzle alternately moves to four points on the table, after the nozzle is set at a given point, it is necessary to insert a sheet of paper between the nozzle and the table surface and raise the table until the sheet is move with difficulty, and do not clamp the sheet too quickly. This procedure is repeated for four points. nine0003

This procedure is repeated for four points. nine0003

Speaking about the operation of the device, I would like to note that the table warms up somewhat unevenly. The edges warm up much better than the cent.

This situation can be easily corrected by pressing the bottom thermoplate against the center of the glass (bottom).

The device was tested on stock settings. The objects have been written to the memory card.

This method is the simplest and most convenient in most cases, especially when it comes to printing large files. However, this is not the only way to print with this printer. The device can be connected to a personal computer via USB or WiFi. In this case, the Cura application is used, which is pre-configured to work with a specific device. Moreover, to print via WiFi, you need to install an additional plug-in, after which it becomes possible to control the printer from the application. nine0003

Once again returning to the print quality, you should pay attention to the fact that in the process of blowing the workpiece with a standard blowing system, the air is not directed to the workpiece, but in front of it, and this is wrong. For more correct operation, you need to download another air duct and glue it to the extruder fan, which, in fact, was done after a week of using the device with a standard cooling system.

For more correct operation, you need to download another air duct and glue it to the extruder fan, which, in fact, was done after a week of using the device with a standard cooling system.

Young fighter course. Or what problems an inexperienced user might face

Perhaps the very first problem that can be encountered in 3D printing is poor adhesion of the table surface. This is manifested in the fact that the filament is not fixed on the surface, but drags after the extruder, etc. There are several ways to solve this problem. One of them is to reduce the print speed (which is not entirely correct), and the second is to apply an additional layer on the surface of the table, which will provide a reliable adhesion to the filament. There are many different solutions, such as gluing masking tape, applying hairspray, but in our opinion, the most correct option is using BF-2 glue and isopropyl alcohol. In this case, it is necessary to mix these two ingredients in a ratio of 50 to 50, mix thoroughly, and then apply a thin layer on the surface of the table. Next, the table must be heated to operating temperature (about 100 degrees), and allowed to cool to room temperature. Now the hitch will be excellent and you can get to work. nine0003

Next, the table must be heated to operating temperature (about 100 degrees), and allowed to cool to room temperature. Now the hitch will be excellent and you can get to work. nine0003

The next step is to print a special calibration temperature scale (this must be done before each use of a new type of filament, or filament from another manufacturer). By printing this scale and looking at it, we can easily select the required temperature regime for each type of plastic.

Of course, there are many more difficulties with 3D printing, and at the stage of preparing the review they were, but we will talk about them in more detail in the following reviews. nine0003

Advantages

- Use of high precision, low noise TMC2225 drivers;

- Uniform table heating;

- Using a good fan on the printer bare;

- Powerful cooling fan;

- BMG transparent extruder;

- Print thickness from 0.05 to 0.3 mm;

- Print speed up to 150 mm/s;

- Ability to work with PLA, ABS, TPU materials, as well as with PVC and other types of filament; nine0008

- Filament end sensor;

- Function to automatically resume printing in the event of a sudden power outage.

Disadvantages

- Poor layout of controls;

- Need to update software immediately after purchase;

- The need to modernize the billet blower system.

Current price

Conclusion

What about the Flyingbear Reborn? Large, good printer that prints decently at stock settings, with some tweaking to improve print quality. The device uses silent TMC2225 drivers, advanced CoreXY kinematics and a number of other goodies, while the location of the control modules is not thought out. Of course, any device has flaws, but you always want the best. Overall, the Flyingbear Reborn is a great printer, capable of printing large models with decent print quality. The device requires a fairly large space, but we initially knew what we were going for, nevertheless, the size of the print area of 350x310x350 mm obliges something. nine0003

3D printer - the history of creation, how it works, and what can be printed

3D modeling is an incredibly complex process, which can be talked about for a very long time. But today we will analyze several types of 3D printers, see how each one works, and what is their difference.

But today we will analyze several types of 3D printers, see how each one works, and what is their difference.

The history of the 3D printer

A 3D printed motorcycle

Before things like computer-aided design (CAD) and lasers, models and prototypes were painstakingly carved out of wood or glued together from little pieces of map or plastic. They could take days or even weeks to create and usually cost a fortune. Making changes or tweaks was difficult and time consuming, especially if a third party model company was used, and this could discourage designers from making improvements or accepting last-minute “Too late!” comments. nine0003

With the advent of more advanced technologies in the 1980s, an idea called rapid prototyping (RP) emerged as a solution to this problem: it means developing models and prototypes in more automated ways, usually in a certain number of hours or days, rather than in weeks, as with traditional prototyping. 3D printing is a logical extension of this idea, in which product designers create their own rapid prototypes in literally hours using sophisticated inkjet-like devices. nine0003

nine0003

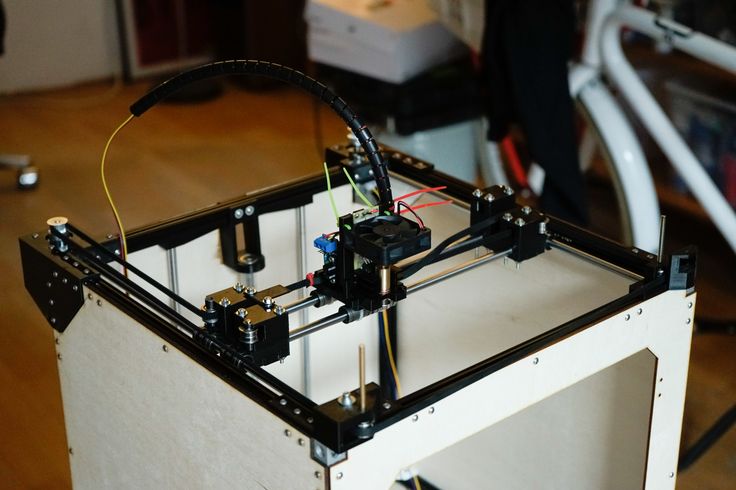

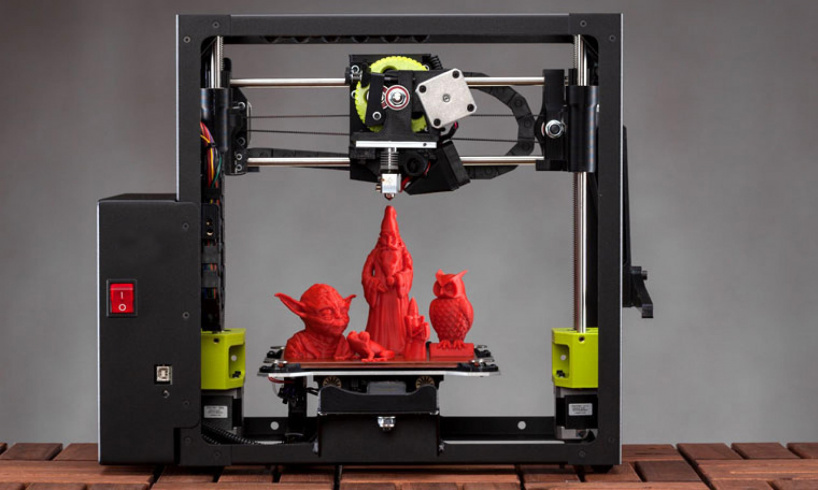

3D printer at work

Let's imagine that you are building a simple wooden car prototype. You would start with a block of solid wood and carve out the inside like a sculptor, gradually revealing the object "hidden" inside. Or, if you want to create an architectural model of a house, you would build it like a real prefab house by cutting out miniature wall replicas from cardboard and gluing them together. At least that's how I see it, based on the data given to me by a familiar architect. Over time, now the laser has learned how to easily carve a shape out of wood, and it is quite possible to teach a robot to glue cardboard, but 3D printers work in a completely different way. nine0003

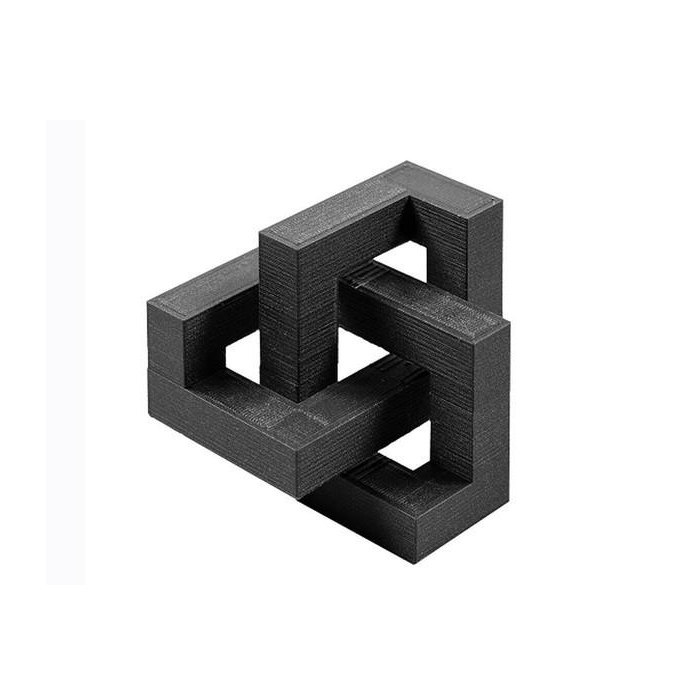

A standard 3D printer is like an inkjet printer controlled from a computer. It creates a 3D model one layer at a time, from bottom to top, by repeatedly printing on the same area in a manner known as Fused Deposition Modeling (FDM). Working fully automatically, the printer creates a model in hours, turning a 3D CAD drawing into many 2D cross-sectional layers, effectively separating 2D prints that are one on top of another, but with no paper in between. Instead of using ink that would never expand, the printer applies layers of melted plastic or powder and fuses them together with glue or UV light. nine0003

Instead of using ink that would never expand, the printer applies layers of melted plastic or powder and fuses them together with glue or UV light. nine0003

Why 3D printer plastic is used

It is actually a mixture of hard and durable plastic (acrylonitrile) with synthetic rubber (styrene butadiene). It is ideal for 3D printing because it is solid at room temperature and melts at just over 100°C, which is relatively low to melt inside the printer without getting too hot (that's the temperature at which water boils in a kettle or pot on stove). After setting, the plastic can be sanded or painted. nine0003

Another useful property of 3D printer plastic is that it is white/yellow in its raw state, but pigments (chemical dyes) can be added to give it almost any color. Depending on the type of printer you are using, you feed plastic into it in the form of small balls or threads (like plastic thread).

You don't have to 3D print with plastic: theoretically you can print objects using any melted material that hardens and sets fast enough. In July 2011, researchers at the University of Exeter in England unveiled a prototype food printer that can print 3D objects using melted chocolate. nine0003

In July 2011, researchers at the University of Exeter in England unveiled a prototype food printer that can print 3D objects using melted chocolate. nine0003

Let's now take a look at several 3D modeling technologies and find out what are the differences between them!

What are 3D printers?

FDM is a classic 3D modeling technology

We learned how a 3D printer works. And they remembered such a thing as FDM layer-by-layer deposition modeling. This is one of the most standard and common technologies used in 3D modeling. But there are other methods of creating plastic objects, namely:

- Stereolithography.

- SLS.

- Polyjet.

Let's briefly talk about each.

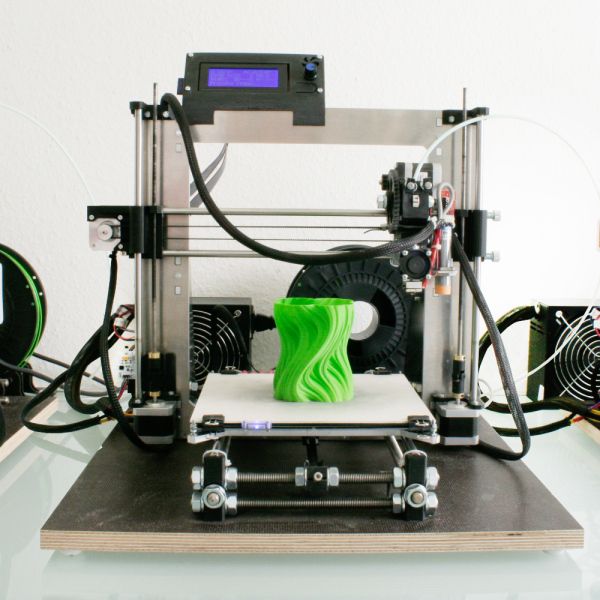

Classic 3D Modeling - FDM

FDM works like a glue gun and applies layers of plastic one after the other. This is the most popular modeling method, and during the development of the technology, various experiments were carried out with hot melt adhesive. ABS and PLA plastics are used. Molten plastic comes out through the hot nozzle, which solidifies when cooled a few degrees after it has been removed from the printer. This allows you to immediately make an exact drawing that was programmed by the program on the computer. nine0003

ABS and PLA plastics are used. Molten plastic comes out through the hot nozzle, which solidifies when cooled a few degrees after it has been removed from the printer. This allows you to immediately make an exact drawing that was programmed by the program on the computer. nine0003

Stereolithography

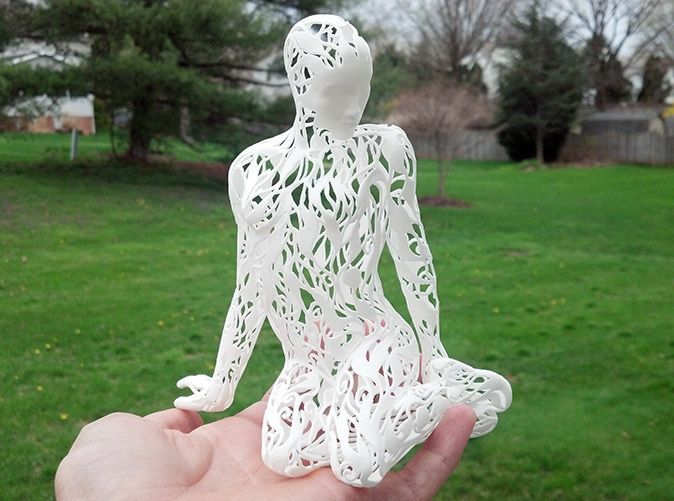

This technology is based on growing objects from photopolymer resin using special lighting. It differs from FDM in that the objects are smoother and of higher quality, since here the plastic is not squeezed out by the thread from the hot nozzle. It is divided into SLA and DLP.

Laser-assisted stereolithography - SLA. Digital modeling using a special projector is called DLP. What's better? I think SLA, because as we can see in the photo below, the DLP object is slightly pixelated, since it creates a model with a projector, and SLA thanks to a rapidly moving continuous laser. But in terms of speed, digital modeling overtakes laser modeling. nine0003

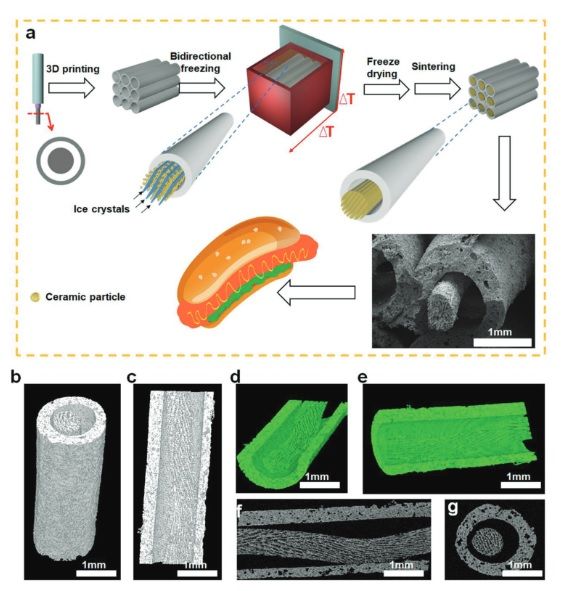

SLS - 3D modeling with laser and powder

A special powder is used here, on which the laser is directed. It fuses powder particles, forming a model of the object programmed initially. Next, the printer again scatters the powder, and again melts it with the help of a laser.

The accuracy of the figure is better than with FDM or stereolithography. SLS printers are very expensive. Their cost starts from 200 thousand dollars and above. nine0003

Polyjet

This technology uses photopolymer resin and UV light. The scale of the printer is huge, but the trick is that you can print with a lot of different materials at the same time, and not just from one plastic. Even sneakers were created in this way.

The scale of the printer is huge, but the trick is that you can print with a lot of different materials at the same time, and not just from one plastic. Even sneakers were created in this way.

The video below shows products made with Polyjet technology.

Conclusion

3D modeling used to be something unattainable, the future era of technology, but now it is the present. It is now used even in medicine to create artificial prostheses, as well as in the repair and creation of various equipment. I personally saw many times how a broken iPhone volume button was printed on an FDM printer, the edges were polished and installed in place of the broken one. You can buy the simplest printer for 500-1000 dollars and not worry if something plastic breaks at home.