Original prusa i3 mk2s 3d printer

Original Prusa 3D printers directly from Josef Prusa

Our 3D Printers

Price quote request

Are you considering Original Prusa 3D printers for your classroom, school, library, university or maker space?

Our specialists are here to assist you throughout the whole buying and information-gathering process. To get in touch with us, please fill out the form below and we will take it from there.

Contact us

Bestsellers

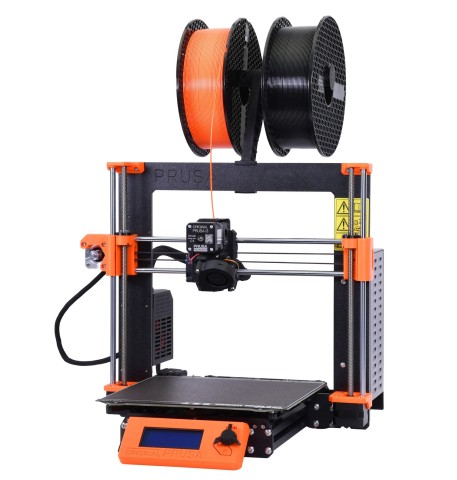

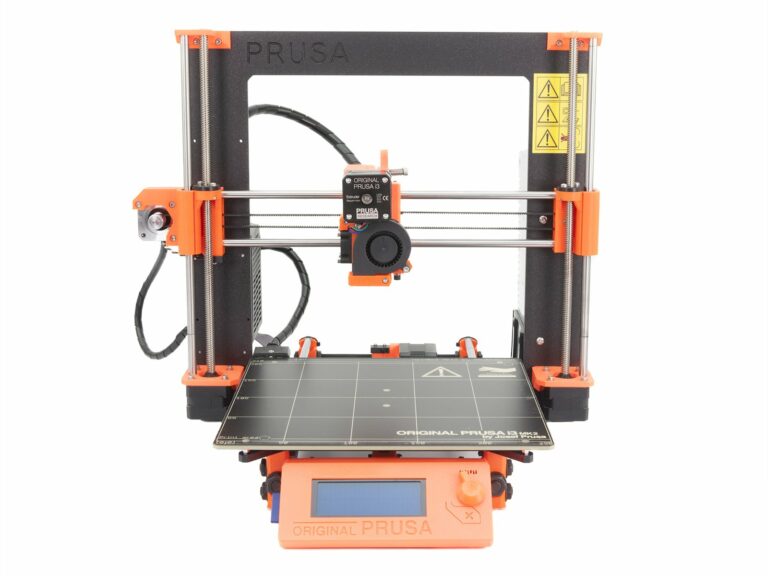

Original Prusa i3 MK3S+ kit

In stock

€849 with VAT

Choose variant

Original Prusa i3 MK3S+ 3D printer

In stock

€1,159 with VAT

Choose variant

Prusament PETG Prusa Galaxy Black 1kg

In stock

€29.99 with VAT

Double-sided Textured PEI Powder-coated Spring Steel Sheet

In stock

€39.

99 with VAT

Original Prusa MINI+ Semi-assembled 3D Printer

In stock

€489 with VAT

Choose variant

Prusament PETG Prusa Orange 1kg

In stock

€29.99 with VAT

Prusament PETG Jet Black 1kg

In stock

€29.99 with VAT

SuperPINDA

In stock

€25.99 with VAT

Spring Steel Sheet With Smooth Double-sided PEI

In stock

€34.99 with VAT

Prusament ASA Sapphire Blue 850g

In stock

€29.99 with VAT

Prusament ASA Lipstick Red 850g

In stock

€29.99 with VAT

Prusament PLA Blend Pearl White 970g

In stock

€29.99 with VAT

Hello, we are Prusa Research!

And we make more than just amazing 3D printers!

Read our story

Prusa Services

Printables.

com

comDiscover thousands of great printable 3D models

Downloads

Get the latest firmware and apps

Forum

Discuss 3D printing topics with the community

Prusament

Affordable filament for everyday printing in premium quality

Help

Assembly and troubleshooting guides, technical documentation

Blog

3D printing highlights, tips and interviews all in one place

E-Book: Basics of 3D Printing

This book will help you understand what kinds of 3D printing technologies are currently available and how they work. We will take you through the whole process of 3D printing.

I don’t agree with subscribing to newsletterand I want to buy the e-book for 5 USD / 5 EUR.

News from the blog

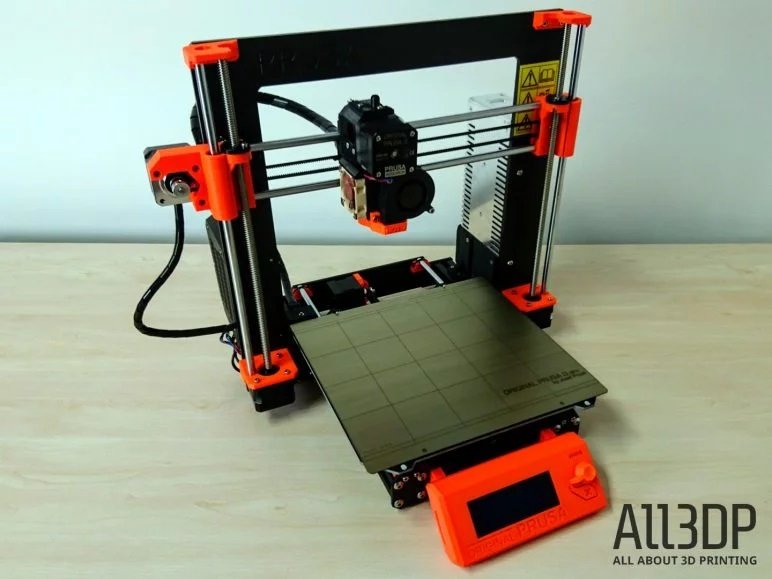

Our printers continue to collect great reviews and awards all around the world. Original Prusa i3 MK3/S is the best 3D Printer in the Ultimate Guide to Digital Fabrication by MAKE: Magazine and our printers also received several editor's choices and awards from respected media outlets like All3DP, PC Mag, Tom's Hardware, TechRadar, Forbes, WireCutter, Windows Central and many more!

When we weigh up the price, performance, reliability and overall product, it is highly recommended for most people to purchase because it does things so well.

– 3D Printerly ReviewThe preassembled version of the Original Prusa i3 MK3S is a cinch to get up and running, is easy to operate, and has a good slicing program. It produced consistently beautiful prints in our testing, with no misprints.

– PC Mag ReviewOf the 11 printers we have tested over the past five years, the Prusa i3 MK3S printer has produced the largest and best-looking prints.

– THE NEW YORK TIMES REVIEW

We tested it using its default settings and found it extremely capable. Its print quality is truly exceptional and it’s an easy-to-use, straightforward machine.

– All3DP MK3S ReviewThe team at Prusa Research have made something special with the MK3. If you only ever own one printer, make it this one. Of course, once you buy it you will want more of them, and that's ok too.

– Windows Central ReviewIt is the most well-made resin printer that I have and it objectively produces the best prints.

– The Prusa SL1S redefines SPEED!

Original Prusa i3 MK3S+ | Original Prusa 3D printers directly from Josef Prusa

See the Original Prusa i3 MK3S+ in action!

Assembled Printer & Kit Comparison

Assembled 3D Printer |

3D Printer Kit |

|

| Warranty | 2 Years in EU, 1 Year ROW - Built, calibrated, tested, and with a full warranty | 2 Years in EU, 1 Year ROW - Warranty on parts only |

| Owner Discount | 10% discount on subsequent orders of assembled i3 printer and selected filaments | 5% discount on subsequent orders of selected filament |

| Support | Premium 24/7 support via chat and e-mail + forum | Premium 24/7 support via chat and e-mail + forum |

| Consulting and Documentation | Printed version of 3D Printing Handbook and Free Access to the Prusa Academy - Online Course of 3D Printing and Modeling. |

The best assembly instructions proved by thousands of builders, printed version of 3D Printing Handbook |

| Assembly | Ready to print | Full Assembly Experience (6-8 hours), which teaches you how the printer works |

Main Features

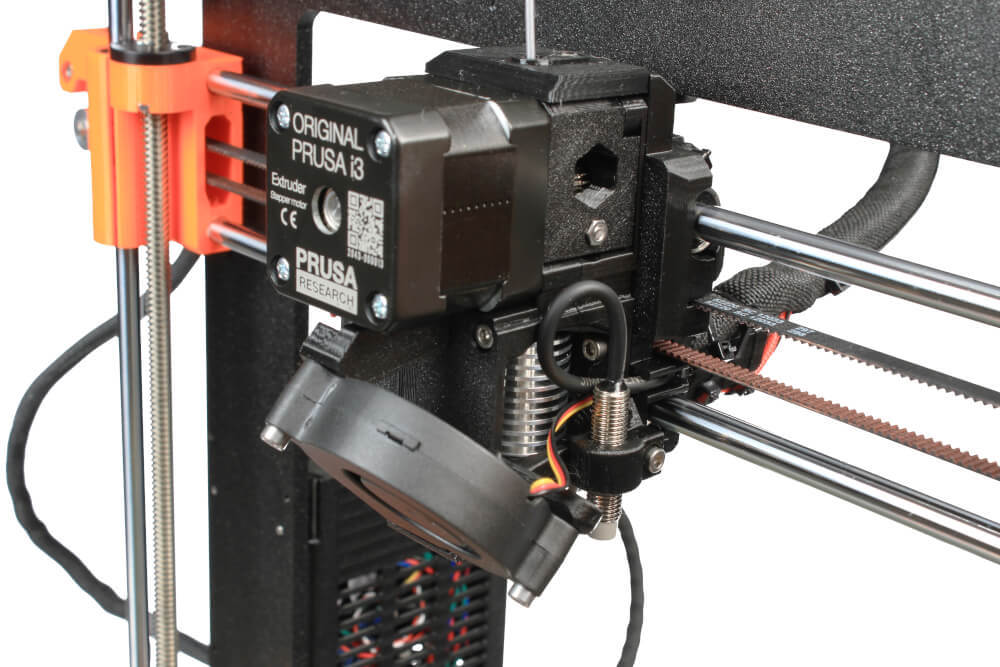

SuperPinda Probe

SuperPINDA probe features a hiqh-quality sensor for a fully-automatic Mesh Bed Leveling process. Before every print, the MK3S+ probes the bed in several places and creates a virtual heightmap of the print area. This process ensures that the first layer will always be spot on!

Misumi Bearings & more

The MK3S+ features a new set of metal clips for the genuine MISUMI bearings on the Y-axis. The belt tensioning mechanism on the X-axis was reworked and the X-end plastic parts reinforced. The filament path in the extruder was altered for better support of flexible filaments.

Removable Print Sheets

Spring steel sheets are easy to maintain and make removing the printed object from the print surface a breeze. We offer three types of print surface: smooth, textured and satin to cover all your needs when printing from a wide range of different materials - most of which do not require any special separation layers or surface preparation.

High-Quality Parts

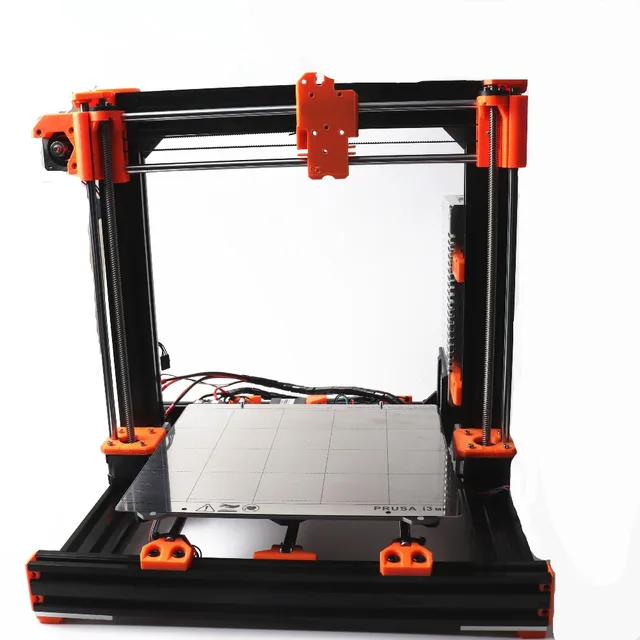

The MK3S+ features an aluminum extrusion Y-axis assembly. Thanks to the milled dural frame, the MK3S+ is stable, rigid, and easy to assemble. Combined with our internally developed extruder featuring Bondtech gears and the E3D V6 hotend, the MK3S+ can print high-quality objects up to 210 mm in height.

Power Loss Recovery

Are you afraid of a blackout ruining your 48-hour print? Worry no more - the MK3S+ can deal with that! The printer can fully recover from the loss of power and continue printing exactly where it left off. It detects power interruptions and shuts down the heatbed and extruder heating, and saves the last known location.

It detects power interruptions and shuts down the heatbed and extruder heating, and saves the last known location.

Filament Sensor

The MK3S+ further enhances the reworked extruder from the MK3S. The built-in filament sensor uses a reliable trigger system, which detects whether a strand of filament is inserted into the extruder. It can detect any type and color of filament and is not susceptible to mechanical wear.

Mesh Bed Leveling

Thanks to the SuperPINDA probe, the MK3S+ can use the Mesh Bed Leveling process to compensate for microscopic imperfections of the print sheet, and inconsistencies caused by the assembly and stacking of the manufacturing tolerances of various parts. Achieving a great-looking first layer is quick and easy.

Slice with PrusaSlicer

Our internally developed multiplatform slicer comes with in-house made and fully tested profiles for all of our 3D printers and a wide range of filaments. With built-in tools, such as advanced support generation, cutting, automated object distribution, ironing and many others, you will turn your 3D models into print files in no time!

With built-in tools, such as advanced support generation, cutting, automated object distribution, ironing and many others, you will turn your 3D models into print files in no time!

Support for a wide range of Materials

The MK3S+ is fully compatible with a wide range of various types of materials. No matter whether you want to print something for fun from PLA and flexible materials, or you need to produce durable prototypes from PETG, ASA, Polycarbonate and Polypropylene - the MK3S+ can handle them with ease.

Open-source Hardware & Firmware

We develop firmware for all of our 3D printers and test every new version thoroughly before release. Ongoing development and regular updates ensure that our machines are packed with useful features, such as print sheet profiles, automated calibration, Mesh bed leveling, advanced diagnostics, remaining print time estimation, Octoprint support and more!

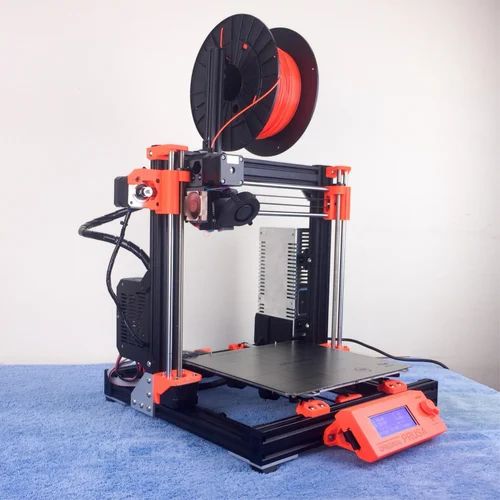

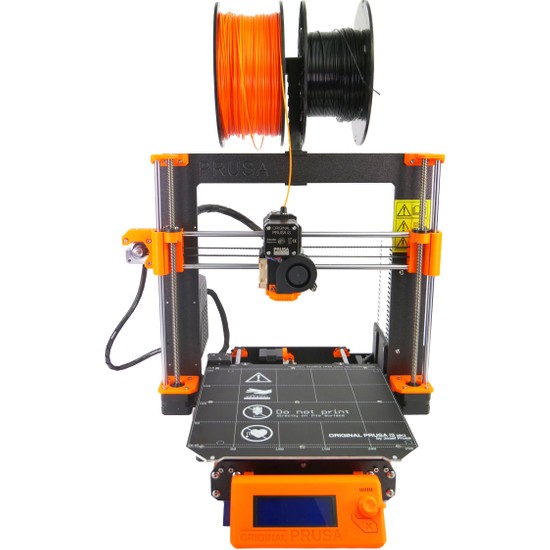

Original Prusa MMU2S Upgrade

Multi Material Upgrade 2S (MMU2S) is the second generation of our unique multi-material addon, which enables your 3d printer to print with up to 5 colors at the same time.

More details

Awards

Our printers continue to collect great reviews and awards all around the world. Original Prusa i3 MK3/S is the best 3D Printer in the Ultimate Guide to Digital Fabrication by MAKE: Magazine and our printers also received several editor's choices and awards from respected media outlets like All3DP, PC Mag, Tom's Hardware, TechRadar, Forbes, WireCutter, Windows Central and many more!

Reviews

6 reasons to buy the MK3S+

1

Great User Support

We offer 24/7 tech support via live chat and email in seven languages. Our printers come with detailed instructions and guides for easy assembly and maintenance. You can also visit our knowledge base, community forum, Facebook groups and official Blog, where we publish useful 3D printing tips and tricks, contests and more!

2

FUN TO ASSEMBLE

The MK3S+ assembly kit is an excellent first step into the world of 3D printing. You will get to know your 3D printer inside out and find out how it works! The assembly is quite easy, requires no soldering, all cables are cut to length and ready to be plugged in. The assembly instructions are easy to follow and all texts are translated into 8 languages. All of this makes the kit very friendly to younger builders, too!

You will get to know your 3D printer inside out and find out how it works! The assembly is quite easy, requires no soldering, all cables are cut to length and ready to be plugged in. The assembly instructions are easy to follow and all texts are translated into 8 languages. All of this makes the kit very friendly to younger builders, too!

3

Built-in Safety Features

Original Prusa 3D printers are well-known for their reliability and safe operation. Every part of our printers is thoroughly tested in-house. The MK3S+ is equipped with three thermistors and comes with a custom-built high-quality Delta power supply. The printer can recognize issues with heating and stop operation to prevent damage.

4

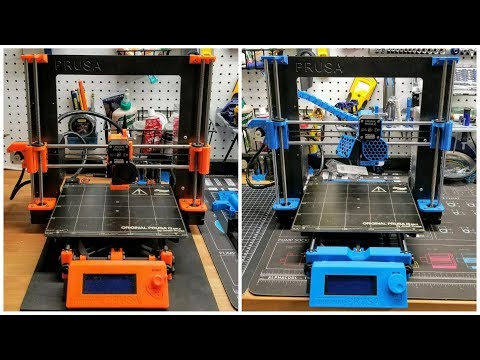

Open-source and Community Friendly

All parts of our printer are open-source, which means we publish all source codes and blueprints online. The community around our products is huge and the feedback is overwhelmingly positive - don't believe us? Check out Facebook groups and YouTube videos! There's so much to do with your 3D printer - buying it is just the beginning!

The community around our products is huge and the feedback is overwhelmingly positive - don't believe us? Check out Facebook groups and YouTube videos! There's so much to do with your 3D printer - buying it is just the beginning!

5

Ready for the Multi-Material Upgrade 2S

Multi Material Upgrade 2S is our unique add-on option for printing with up to 5 different filaments simultaneously. Multi-material could be your next step in the 3D printing world and the MK3S and MK3S+ are completely ready for the upgrade! MMU2S also allows you to print a soluble support interface - check out the video!

6

Upgradability

One of the most popular features of the Original Prusa i3 concept is upgradability. When you buy our 3D printer, you can upgrade it later to a newer version, so you don't need to buy a whole new model every two years like, for example, your phone or laptop. We also keep supporting our 3D printers with regular firmware updates that bring new features!

Get the Original Prusa i3 MK3S+ now

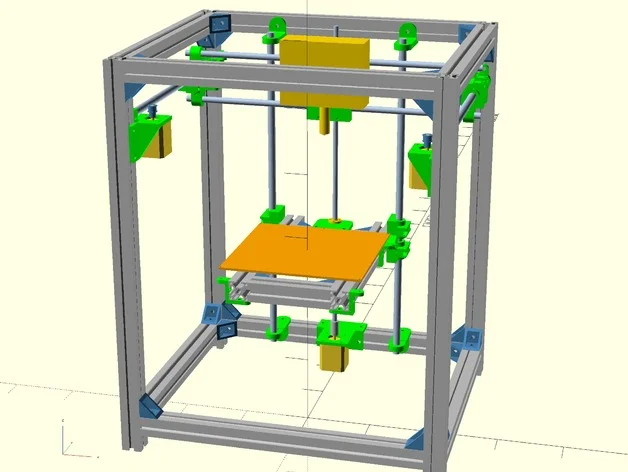

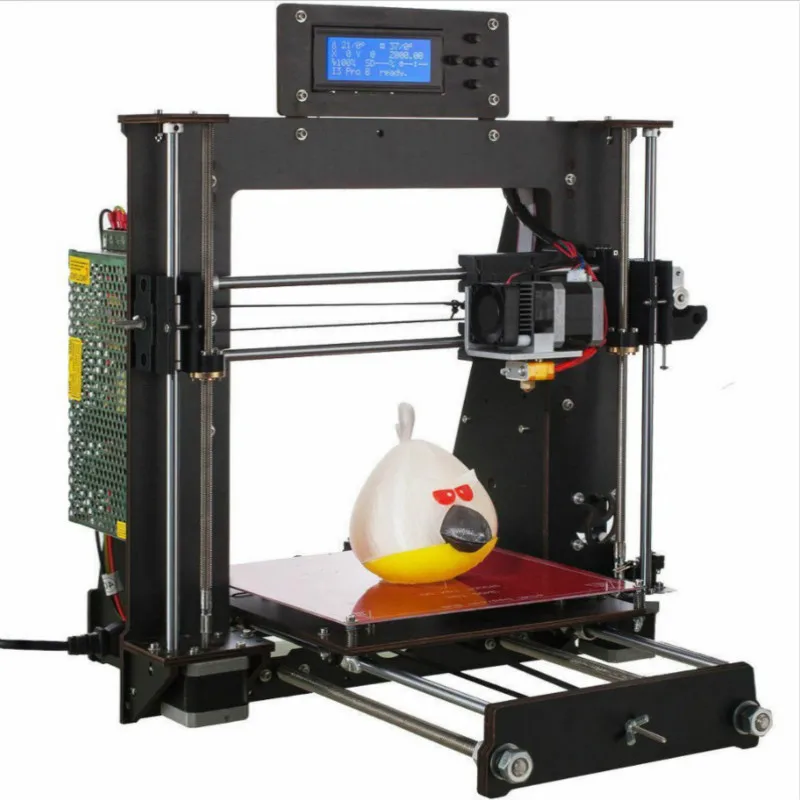

Original Prusa i3 MK2

3D printer reviewSpecifications and features

Prusa i3 is an open source software and mechanical project. And the MK2 model gives us new interesting features.

And the MK2 model gives us new interesting features.

The MK2 design is a tried and tested solution with a vertical center plate that is the base for the Z and X axes and M12 guide screws. This design allows for a working space of 250 mm wide, 210 mm deep and 200 mm high.

The model is printed on the heated table MK42. This solves most adhesion problems. This table has good rigidity, so you don’t have to invent a bicycle and install some kind of heat-resistant glass surface on top. In addition, the top of the printing table is covered with a thin PEI film. Thanks to this, fingerprints will not remain on it. The table heats up and cools down very quickly. If you're printing with PLA, the platen heats up at about the same speed as the extruder.

In addition, the MK42 table has zones with different heating characteristics. Due to this, such an unpleasant moment as more intense cooling at the corners of the table is compensated (the fact that the table has different temperatures from the edges to the center has a bad effect on printing 3D models from high-temperature plastics with a large contact surface).

The Original Prusa i3 MK2 has an E3D v6.1 all-metal extruder. This means that you can use almost any material for 3D printing: PLA, ABS, PET, nylon, wood-based materials or brass particles. If you want to experiment with carbon, you can put a hardened nozzle. If you need precision, you can install a nozzle with a diameter of 0.25 mm. In fact, the print quality with the original nozzle is excellent, but you can't help but notice how much flexibility the E3D v6.1 gives you.

An inductive sensor is located next to the extruder. In my opinion, such a solution should be implemented in all modern 3D printers. This inductive sensor is easy to set up, operates directly from 5V, takes up very little space.

The sensor performs several tasks. First, the virtual mesh of the 3D printing table is corrected. Due to this, even if there are small deformations, they are included in the extruder movement program. Secondly, if you have built the original Prusa i3 MK2, it has special calibration spots on the print table. Thanks to these calibration sections, the X and Y axes are automatically calibrated and small deviations, which are bound to occur during assembly, will also be compensated.

Thanks to these calibration sections, the X and Y axes are automatically calibrated and small deviations, which are bound to occur during assembly, will also be compensated.

By the way, in many reviews of this 3D printer model, for some reason the last moment is missed. Well, it calibrates itself, and it's great ... But! Automatic calibration technology using calibration squares was not just developed by the Prusa Research team. Since it's open-source, this technique has become part of the Marlin firmware and now anyone can use it!

In most cases, you will interact with the Original Prusa i3 MK2 via an inconspicuous LCD control panel. In our opinion, the handle with the wheel looks amazing! In addition, the handle is very comfortable to use. Yes, this seems to be a trifle, but in fact, it is precisely such trifles in total that make a 3D printer as a whole better and more convenient. And it is the little things that distinguish a quality product from a quality fake.

Using the LCD screen, you can start calibration, feed media. And it won't be running simple scripts. If something goes wrong, such as the heating elements don't respond with the correct signal or the sensor doesn't send a signal at the expected distance, the Original Prusa i3 MK2 will not continue in "self-destruct mode"

And it won't be running simple scripts. If something goes wrong, such as the heating elements don't respond with the correct signal or the sensor doesn't send a signal at the expected distance, the Original Prusa i3 MK2 will not continue in "self-destruct mode"

During operation, the heating systems are protected by the Ultimachine Mini Rambo . On the opposite side of the frame is a power supply without a cooler. During operation, it is hot to the touch.

It is very convenient that the power supply has a special cover on the side of the connectors. You do not have to worry about connecting individual wires, just connect the power cord to the IEC fuse connector, and the other side of the cable to the Mini Rambo motherboard. This is amazing! The frame is also grounded using the power supply.

Another interesting innovation concerns wires. Among the wires that go to the extruder and the heated table, 3 mm nylon thread is mixed in, which prevents them from tangling and bending. In our opinion, a very interesting and elegant solution to the problem with wires.

In our opinion, a very interesting and elegant solution to the problem with wires.

Assembly and print quality

If you decide to assemble the Original Prusa i3 MK2 yourself, you need to set aside five hours. There is a high-quality video of the complete assembly and launch of this model, which was recorded by Thomas Sanladerer (the author of the original English review, by the way). On the video, the assembly took more than 5 hours, but you also had to spend time on entertaining the audience ;).

The manual covers each assembly step, the automatic calibration process. Although the quality of the photographs in the printed version is not the best, you can find the same instructions online. There, the images are stored in excellent quality.

Two 3D printers were ordered for the review. One fully assembled and the second as separate parts for self-assembly. Unfortunately, the assembled printer arrived with minor damage. Apparently, the table latch broke and as a result the LCD case was damaged. I printed the new case myself, but in fact, if such a situation arises, Prusa Reseach will send you a new part under warranty without any problems.

I printed the new case myself, but in fact, if such a situation arises, Prusa Reseach will send you a new part under warranty without any problems.

After assembling the Prusa Kit, it turned out that they work exactly the same. In fact, if it weren't for damage in transit and slight differences in frame color, they could only be distinguished by the serial number.

Each printer comes with a test program. And the quality is really amazing!

The dragon pictured below is the first piece printed on the assembled Original Prusa i3 MK2. Printed through a cloud service, without installing software on a PC. There is simply nothing to complain about!

But what's the point of a quality test print? After all, we are counting on excellent printing of our own, not test 3D models. Well, Prusa Research provides all the necessary programs for installation on different operating systems: Windows, Mac OS. If you are using GNU/Linux, there are separate instructions for installing the required packages. The software contains all the necessary drivers, pre-configured slicer, printer host, Netfabb installer, tools for color printing.

The software contains all the necessary drivers, pre-configured slicer, printer host, Netfabb installer, tools for color printing.

I would like to consider drivers separately. When you connect Original Prusa i3 MK2 via USB, it connects via serial port. So you can use it from PC, Raspberry PI, Octoprint or other cloud based 3D printing solution. There is full support for Windows 10 (most likely Windows 8.1 as well), so you can use the integrated Builder app to print directly from professional CAD programs like Solidworks.

This is really cool, and apart from 3D Systems and Stratasys, no other 3D printer provides such a wide range of possibilities. In general, if you become the proud owner of an Original Prusa i3 MK2, you can use any Windows application that supports direct 3D printing. Very, very comfortable.

Naturally, you can use the traditional methods of exporting your model to an STL file and processing it in a slicing software. Slicing software Slic3r with ready-made settings is included. This version has some features and modifications compared to those available for official download.

This version has some features and modifications compared to those available for official download.

It has a full profile with settings for a 3D printer, for different layer heights, nozzle sizes and a whole range of 3D printing materials - from standard ones like PLA, ABS, PET to Taulman T-Glase or Bridge Nylon. All the materials we tried to work with gave excellent 3D printing results (if, of course, you choose the right settings).

If you prefer to work with other slicing programs such as Cura or Simplify3D, you can download ready-made profiles with printer settings from the official Prusa website.

In our opinion, the availability of ready-made settings for different slicing programs is a huge plus. After spending half a day or more building a 3D printer, having fun with settings and messing up the first 5-10 models is not the most inspiring thing to do. And thanks to ready-made configurations, you can set up your usual software in one click and get excellent quality 3D printing on the Original Prusa i3 MK2.

You will only have to play with the settings if you are using a really unusual material for 3D printing.

Let's now move on to the software part. The software for the Original Prusa i3 MK2 is constantly being improved and if you use Slic3r you will see notifications about the possibility of updating the firmware. After tuning, we were offered some updates that should improve performance, but to be honest, the difference is not noticeable.

One of the coolest features is color printing. Even though the Original Prusa i3 MK2 prints in one color, the development team has included some features to implement color 3D printing (by changing the material in the extruder). You can set up color printing using the LCD controller or by adding G-code coordinates, after reaching which the 3D printer will prompt you to change the material in the extruder.

Original Prusa i3 MK2 - the perfect 3D printer?

Yes, we can say that the testing of the Original Prusa i3 MK2 showed that it is indeed a very good 3D printer. But do not forget that although this is a very successful, but still an ordinary FDM printer, which has certain limitations inherent in the technology of layer-by-layer deposition modeling.

But do not forget that although this is a very successful, but still an ordinary FDM printer, which has certain limitations inherent in the technology of layer-by-layer deposition modeling.

There was an example of bad 3D printing. But in defense, we can say that the model is already complicated and at the same time was reduced relative to the base dimensions. As a result, the transitions were too sharp and you can see the result in the photo below.

While the Original Prusa i3 MK2 is running, you can choose between "power" or "silent" mode. The failed model was printed in quiet mode (this mode is really quiet. The loudest part is the working cooler to cool the model). Perhaps printing in powerful mode would be better. But if you use the powerful mode, being in the same room with a 3D printer is not comfortable. 9The 0005

Original Joseph Prusa i3 MK2 is $845.79 (self-assembled) or $1,087.79 (assembled). Although not the most "advanced" mainstream model, it is in many ways superior to its counterparts and even the most innovative models. At the same time, some fundamentally new and really useful features have been implemented.

At the same time, some fundamentally new and really useful features have been implemented.

Original Prusa i3 MK2 prints great right from the start, without the need for tedious manual adjustments. Probably, this is really one of the highest quality open-source 3D printers today.

Prusa i3 MK3S original review

Today, if you are talking about 3D printers, there is one company that stands out from the rest and that is Prusa Research.

Its founder, Joseph Prusa, who gave the company its name, is not only the brains behind the operation, but also the figurehead and overall vision for the 3D printing circuitry.

He and his company bridged the gap between the open source software community and the commercial enterprise.

Prusa, man and machine, do things differently through customization and innovation at the core of technology. This means that if you invest in a model today, there is a high chance that it can be updated in the future, as all Prusa machines have done before.

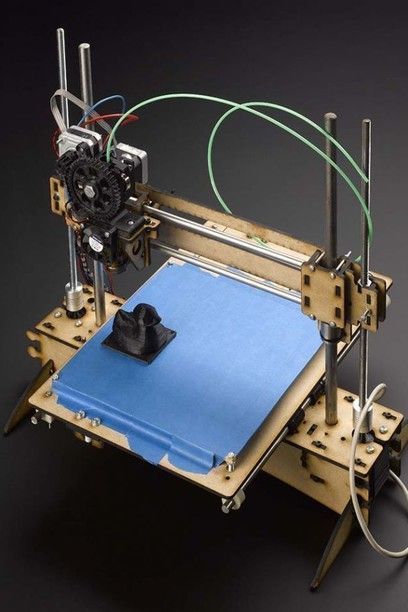

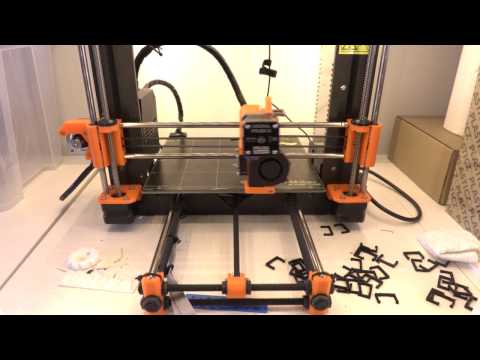

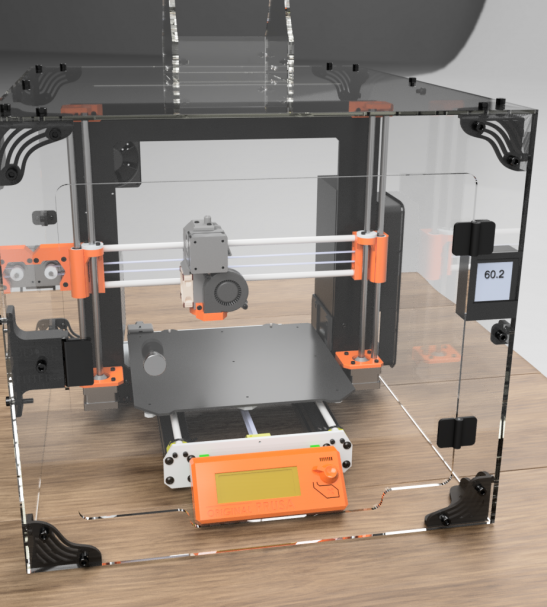

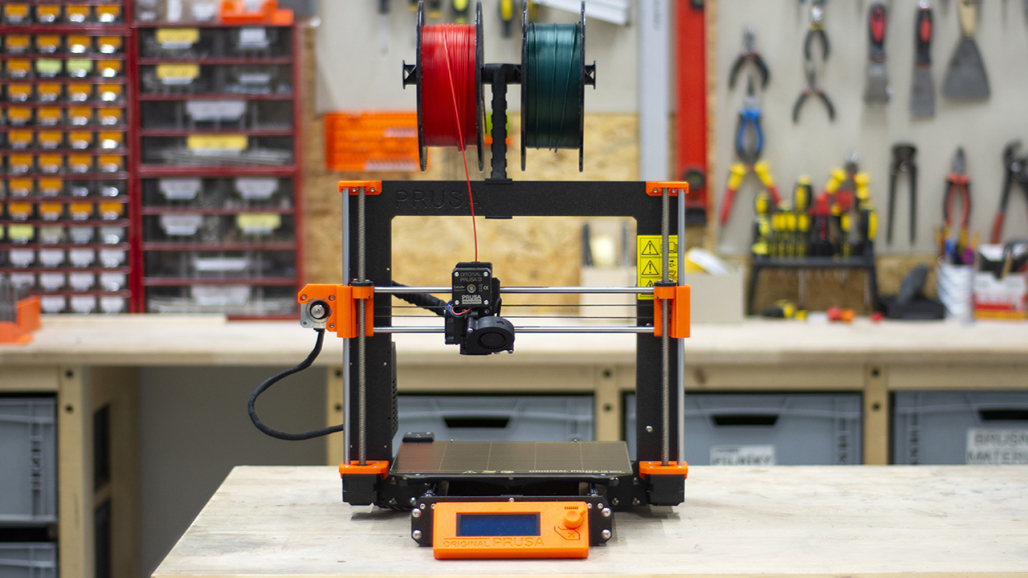

The new Original Prusa i3 MK3S printer, like previous generations, is available in a variety of formats, free as printable parts and shopping list, as a kit you build yourself, or as an expert system that can be unboxed and ready to use .

I've built several in the past and this time Prusa sent a factory version. I have to say that the quality of the finishes, especially with the wiring, is a world apart from my usual wiring mess.

One observation from the start is that the Original Prusa i3 MK3S, being the latest version of the printer, looks pretty much the same as previous generations, but it's only upon closer inspection that you realize it's a completely different beast.

I'm looking at the S model which is a minor upgrade for the MK3 so this review is for the original Prusa i3 MK3 with the S upgrade.0005

One of the things that made Prusa machines so popular is the open design, you can download the parts and print them, buy them as a kit or buy an expert build (Image credit: TechRadar).

(Image credit: © Image credit: TechRadar)

design

3D printers in their current form are not classic designs. While 3D printing technology is limited, product design is not. Although there are a few manufacturers such as Cel-Robox and MakerBot that have attracted product designers to the aesthetic.

Part of the reason is that the 3D community loves to tinker and the industry grew out of the Open Source community. Prusa of all companies remained close to the original community and still supports much of the research and development.

Thus, the MK3S, as in previous generations, has an open design and appearance. It wouldn't look completely out of place in a garage or workshop, and would look less at home in a conscious design studio.

Looks can be deceiving and you shouldn't underestimate design - the Original Prusa i3 MK3S is one of the best printers on the market when it comes to print quality, but it's also the most versatile if you're prone to small tweaks.

The printer is for use, development, improvement and creation of your own; Prusa is the only widely available printer that allows you to do this.

Features

Let's see what makes the Original Prusa i3 MK3S different from most other printers.

First there are options, printer parts can be printed from files downloaded from the Prusa website and then with a little time and effort you can put together all the pieces you need to create your own.

It is doubtful if you will save yourself money, but if you are at a loss for a project, then this is a good challenge and more than possible.

The fact that there is a kit option is one of its most outstanding features; this is what drew me and many others to 3D printing in the first place. Build it and you will see how it works.

I have now built and designed my own 3D printer, so having one complete kit is a huge plus for me, but knowing that I may fiddle at some point, which is inevitable, I can upgrade the extruder if necessary. , mess with the firmware, well, that's all part of the fun.

, mess with the firmware, well, that's all part of the fun.

What's New

Although the MK3S is very similar to the MK2 and the original, there are some significant differences, and the MK3S has been designed and upgraded based on user feedback. The Model S is a slightly improved version of the MK3.

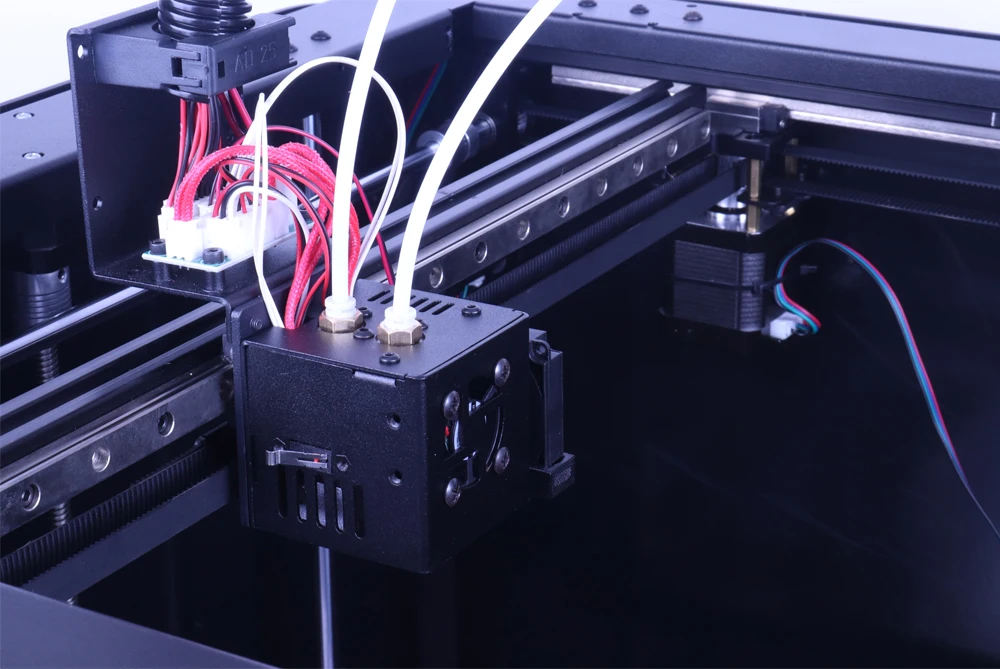

The Extruder has had several design changes from the previous version to make it easier to use and maintain, Prusa has also solved a small resonance issue. This issue has been overcome by moving the nozzle closer to the x-axis, which together with an updated fan helps improve print quality.

Redesigned extruder is now easier to use and maintain than previous versions and features the superior E3D V6 hot end (Image credit: TechRadar)

(Image credit: © Image credit: TechRadar)

Another improvement is the hybrid filament sensor; it combines a mechanical switch and an optical sensor. This circumvents the problems associated with printing with translucent and reflective filaments. An optical and mechanical sensor used in combination improves reliability when these filaments are loaded and ejected.

An optical and mechanical sensor used in combination improves reliability when these filaments are loaded and ejected.

Notable Features

These new features may seem small, but combine the improvements that have already been introduced with MK3 and they were much more significant.

The Original Prusa i3 MK3S is one of the cheapest 3D printers on the market when it comes to the balance of print quality and reliability. The design has a lot to do with it, but the quality of the details won't slip.

E3D Hotend: This use of quality parts is highlighted by the E3D attachments. Developed by a team in the UK, these metalheads are known to be the best in the industry and are widely used. MK3S uses E3 V6.

Bondtech drive: The hot end is nothing without constant filament flow and the extruder delivers consistent filament with upgraded Bondtech drives. They grip the thread from both sides to reduce slip and increase pushing force. This type of gearing is especially useful for flexible filaments, which are notoriously difficult to print.

This type of gearing is especially useful for flexible filaments, which are notoriously difficult to print.

Automatic filament loading: Traditionally, filament loading can be difficult, but in this case, the filament is pushed into the extruder, and the sensor detects it and sucks it into the machine. Once you're in, you just need to select the type of filament.

Steel Spring Bed: Removing prints from the print bed can be a real problem, the original version of the i3 is equipped with a glass plate and clip clips to hold it in place. This has improved with the MK2 and there is now a magnetic HeatBed with a PEI alloy coated spring steel sheet.

A major new feature on the MK3S is a removable magnetic print platform that makes it easy to remove prints (Image credit: TechRadar).

This is quick and easy to remove and the quick bending of the sheet makes it easy to remove the print. The MK3S comes with a smooth PEI sheet, but there is also a textured powder coated version for more adhesion to materials like nylon.

Extruded aluminum frame: The rigidity of the original i3 depended on build quality with a long threaded bolt design. Design and assembly have taken a huge step forward with the aluminum extrusion introduced in the MK3 and used for the Y axis and high quality lead screws.

Like the original Prusa, the original Prusa i3 MK3S features several printed parts as well as high quality stepper motors, lead screws and bearings (Image credit: TechRadar).

Quiet motors: 3D printers such as 2D printers have a reputation for being noisy due to multiple stepper motors running.

The standard was Nema 17 which was relatively cheap, now Prusa uses the highest quality and pairs them with Trinamic2130 drivers with Noctua fan cooling. The addition of stealth mode now makes this printer much quieter than most other printers on the market.

Energy Loss Recovery: Anyone who 3D prints knows how long multiple prints can take; hours and sometimes days. There is nothing worse than losing power during this process. Usually with some useful sole, it is accidentally turned off or tripped over the cable.

There is nothing worse than losing power during this process. Usually with some useful sole, it is accidentally turned off or tripped over the cable.

MK3S has a full loss recovery, so if you lose all power, don't worry, the printer will restart from where it left off.

Avoid skipped coats: This is not a common problem at first, but as your printer ages, you may experience issues with skipped layers. In addition to helping muffle the sound of motors, the Trinamic2130 drivers, along with the EINSY RAMBo motherboard, can detect misalignment or misalignment.

Finally, the P.I.N.D.A. 2 probes. The machine has two thermistors, one for checking the ambient temperature of the electronics, and a new P.I.N.D.A. 2 sensors that help adjust for temperature drift at the print level and ensure that the first following is always correct.

This pretty much covers the main new features and they combine more standard specifications.

Spec Sheet

Assembly volume: 25 x 21 x 21 cm

Memory capacity: Integrated LCD and SD card reader (8GB SD card included)

Nozzle size2: 9016 mm (can be changed)

Layer height: 0. 05 mm (50 microns)

05 mm (50 microns)

Bed: Automatic leveling bed

Printing surface: Heated bed with compensation for the cold angle

Spits: Automatic compensation for oblique axes

Software: PEO Printing platform kg filament includedWattage: PLA 80W / ABS 120W

Setup & Materials

Weighing 7 kg and measuring 50 x 40 x 55 cm (L x W x H) with no spool holder attached, the printer does not by no means small. Take it out of the box, though, and the open design, wires neatly packed and tangled, and the printer won't feel overwhelmed.

The footprint of 50 cm x 40 cm is relatively large, but with an average kitchen worktop or table having a depth of about 60 cm, the size is suitable for placing on a desktop.

After installing the spool holder, you can attach it to the base unit, remove all zippers and packaging, and insert the power cord.

Fitting the filament is extremely easy. With the power on and automatic feeding, dip the end of the filament into the hole in the extruder, and it will be sucked in, then select the filament type, and after a few minutes, the melted filament will come out through the nozzle.

With the power on and automatic feeding, dip the end of the filament into the hole in the extruder, and it will be sucked in, then select the filament type, and after a few minutes, the melted filament will come out through the nozzle.

FFF printers are by far the most popular form of 3D printer, and as such, the MK3S has a huge selection of materials to use (Image credit: TechRadar).

When it comes to replacing the filament, remove it using the small LCD with the control board and the filament pops up and another filament can be installed.

It's just that once you pass a few flight checks, the handy paper manual that comes with the kit details them and then you're ready for your first print.

Before uploading my own models, I tested the printer using the 3DBenchy test model, as well as a couple of others that came pre-installed on the SD card.

One of the most famous 3D printing tests. The Original Prusa i3 MK3S produces clean prints at all quality settings with small thin strings and the highest quality (Image credit: TechRadar).

After a couple of hours the printouts are finished and there are no problems, missing printouts or errors. The quality of the prints was also exceptional.

After making sure the printer arrived intact, everything worked and nothing was mechanically out of place, I checked for firmware updates. This test was conducted using firmware version 3.7.1.

I also downloaded three different slicers with i3 MK3S profiles: Simplify3D, Cura 4.0 and PrusaSlicer.

Setting up the original Prusa i3 MK3S was easy enough on Simplify3D and Cura, and of course on the PrusaSlicer specially designed for this machine.

The PrusaSlicer is relatively simple with the application launching printer selection and options at the start. Then it's just a case of loading a print-ready STL file and choosing the quality options you want.

For the internal software, this is impressive with a lot of options, both for settings and previews.

Navigating the app is straightforward, and one feature I like is flashing the firmware directly from the app after connecting via USB.

It also has some handy options like "Place to Face" which is very helpful when turning the model into position, and "Cut" which allows you to cut the models in half. Then the parts can be exported as plates, they are a little watery, but this is convenient.

PrusaSlicer was reliable with no crashes in the test, and with support for STL, OBJ, AMF and 3MF it has excellent overall compatibility.

Few 3D printers have their own cutting software, but here Prusa created the PrusaSlicer which proves to be a formidable partner for the machine (Image credit: TechRadar)

There is an STL fix option which is a great addition, for simple fixes it worked well , but for larger and more complex models, she had a little more trouble.

After setting the parameters in PrusaSlicer, you can export the G-code to an SD card or print directly.

If you choose the card route, the SD card can be inserted into the side of the control panel on the front of the printer, and then the LCD user interface and control buttons will allow you to select the desired print.

This control panel not only activates filament loading and unloading, you can change filament and go into ultra-quiet mode while printing (Image credit: TechRadar).

(Image credit: © Image credit: TechRadar)

This interface and control board can also be used to interrupt printing if something goes wrong, calibrate if necessary, and there are many other options and settings you can delve into.

One of the notable features that I started using, despite the slight slowdown in typing speed, was stealth mode. This can be turned on while printing, so if you need to work and the printer noise gets too much, you can quickly enable Stealth mode as needed.

Two features that stand out are the resumption of printing after a power outage and the ability to change filament while printing; demonstrated here to the extreme (Image credit: TechRadar)

Another feature that is used to help save on filament is the easy ability to change filaments while printing.