Sculpto pro2 3d printer

Sculpto PRO2 - Sculpto

THE ALL NEW SCULPTO PRO2

Available now

Let your creativity loose

Introducing Sculpto PRO2

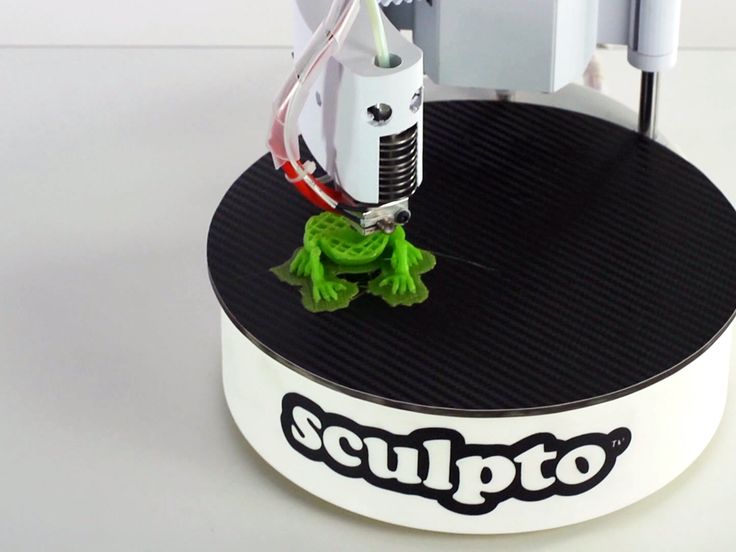

Meet your new favorite way to do projects. The Sculpto 3D Printer will change how you do DIY projects forever. Designing and printing models makes Sculpto the ultimate creative tool.

100.000 projects are waiting right in our app

Innovative technology

No hassle. It's all wireless.

Forget about wires, USB and SD cards. Sculpto is connected through wifi as a standard, unlike most other 3D printers. Setup is easy - Type in your printer's serial number in the app, and Sculpto will automatically ask to connect to your wifi. It's that simple.

100% carbon neutral

25 colorful options

Print your projects in stunning colors. Matt, glitter, gloss - Pick your favorites. Sculpto PLA filament is biodegradable and 100% carbon neutral. It is made from corn, but it's strong and durable. It's a truely innovative material to work with.

It starts with

The Sculpto app

When your Sculpto 3D printer is connected to your local Wi-Fi, the Sculpto App takes over. The app is your remote control to the printer and from there you can browse between 100.000 different 3D models, follow the status of the printer and start your prints.

Advantages of the app:

- Print projects directly from the app

- Wireless control of the printer

- One-click-printing

Venture into 3D modelling

Move beyond our app

There's a world of creative making waiting for you. Getting started with 3D modelling is easier than you think. For beginners we recommend using Tinkercad. 3D modelling is the ultimate way to create unique and custom projects with your Sculpto PRO2 3D printer.

Video guide

Get started

Simple. Professionel.

Full features

- Print directly from your phone, tablet or pc. Finding and printing 3D models has never been this easy. Just download our app, and you're ready to go.

- 100.000 free projects and counting. You will never run out of projects. More are added every day. Best of all, there is a project for everyone, and any occasion. Get inspired by visiting our projects page.

- Upload your own designs. You can create your very own 3D model projects or upload projects you find elsewhere on the internet or get from friends.

- Easy to use and setup. And when we say easy, we really mean it.

- Built in model editor. Edit projects right within our app. Change the size, duplicate and rotate models directly in our app.

Simple, yet powerful.

Simple, yet powerful. - Wirelessly connected. Sculpto is connected to your wifi, like any other smart device you own. Forget about needing to transfer projects through USB or wires. It all works magically through the cloud.

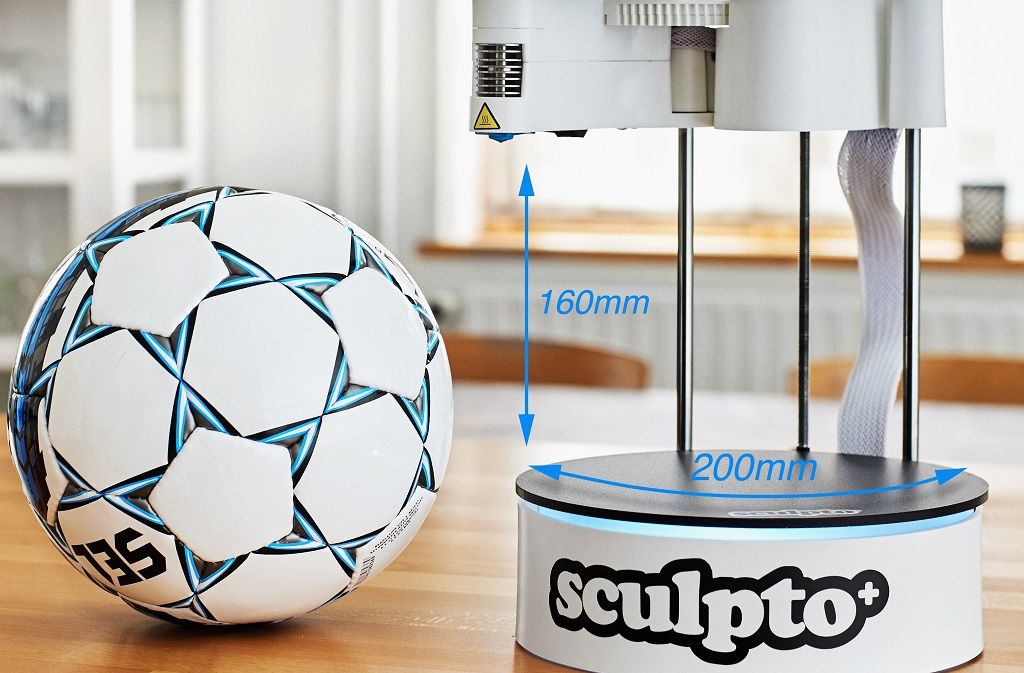

- Large printing volume. An impressive printing volume, especially considering how compact the Sculpto PRO2 is. Print items the size of a football.

- Very quiet and close to soundless. Believe it or not, most 3D printers make a lot of noice. Innovative technology makes Sculpto an almost soundless machine at only 45 dB.

- Environmentally friendly. The Sculpto PRO2 uses a biodegradable material to print with known as PLA, which is created from corn. It's 100% carbon neautral, so you can create projects with good conscience.

The specifications

Everything you need

Included in the box

Sculpto PRO2 3D Printer • Buildplate PRO • Filament sample • User guides • Power supply

Here to help

Need support?

Sculpto US - The world's most user-friendly 3D Printer

THE ALL NEW SCULPTO2 3D PRINTER

A revolutionary product that makes 3D Printing easier than ever.

simple machine, powerfull features

Meet the Sculpto 3D Printer

Sculpto is designed to make 3D printing as easy as 1-2-3. It'a a whole new way to create craft projects. With a Sculpto 3D printer, you can print directly from your smartphone or tablet. The only limitation is your imagination.

Create with conscience. Sculpto prints using a biodegradeable material, called PLA. It is derrived from corn and sugar beets. Sculpto PLA filament is 100 percent carbon neutral.

Sculpto PRO2 is intuitive and easy to use

Good value purchase, and affordable in use

Print projects directly from your phone, tablet or pc

It's simply mesmerizing

This is how Sculpto works

Step 1

Browse the app

Explore the Sculpto app, and select a project to print. Find projects by categories, view the most popular projects or use the search function.

Step 2

Your project comes alive

It's exciting to watch, as the Sculpto PRO2 prints your selected project from biodegradable PLA material. Now that's environmentally friendly.

Step 3

It's done. Or keep crafting.

Once your project has printed, just pick it off the printing plate. Now the choice is yours. Leave the print as it is, or paint it and add your own touches.

All of the ideas in your mind and

100.000 projects right at your fingertip

Cookie cutters

Cookie cutters for any occasion. Browse hundreds of pre-made cookie cutters or design your own.

game of connect four

Print an entire game of Connect Four, and add your own unique personal touches.

Self-watering planter

Add a smart touch to your decor. Browse hundreds of self-watering planters and pick your favorite.

creative Plant pots

Pots in any shape, size and color. It can be hard to find the perfect fitting pot in store. Not anymore.

It can be hard to find the perfect fitting pot in store. Not anymore.

a bathroom like no else

It's time to impress your guests with bathroom decor, they have never seen before.

Organize your life

There are many ways to make life easier. Find and print organizers for almost anything in your house.

Discover 3D modelling

Or get super creative

The Sculpto app with its 100.000 projects, is not the limit. The Sculpto PRO2 3D printer supports almost all 3D modelling software out there. 3D modelling: Sounds hard doesn't it?

Getting started designing and printing your own 3D Prints is easier than you would think. Get started with making your own unique DIY projects today.

Design your own prints

It starts with

The Sculpto app

When your Sculpto 3D printer is connected to your local Wi-Fi, the Sculpto App takes over. The app is your remote control to the printer and from there you can browse between 100. 000 different 3D models, follow the status of the printer and start your prints.

000 different 3D models, follow the status of the printer and start your prints.

Advantages of the app:

- Print projects directly from the app

- Wireless control of the printer

- One-click-printing

the ultimate creative tool

A project for the whole family

It's the ultimate family machine. There is a project for every member of the family. Toys for kids, tech accessories for teens and so much more.

It's that simple

Works on all your devices

Print projects from your preferred internet connected device. Use your smartphone, tablet or computer to print. It just works.

On the news

Mentioned in

Astronauts on the ISS have prepared the Russian 3D printer for work and are waiting for print materials / Sudo Null IT News

On August 3, cosmonaut Oleg Artemiev announced the successful activation and testing of a Russian 3D printer on the ISS.

The astronauts also prepared the printer for printing. The Russian crew has not yet begun the main work with the printer. Cosmonauts are waiting for a special material for printing, which should be delivered to the ISS as part of the scientific cargo on the Soyuz MS-22 spacecraft in September.

Already at the end of September, the cosmonauts will try to print simple cubes on a 3D printer, and then they will experimentally print various forms, including details according to the drawings of Russian students. Then the resulting 3D printing samples will be returned to Earth. Roscosmos experts will study their characteristics under various laboratory conditions in order to comprehensively investigate the impact of microgravity on 3D printing.

In case of successful application of the device, the spacecraft may become part of the standard equipment of the ISS Russian Segment.

The Russian 3D printer was delivered for experiments to the ISS on the Progress MS-20 spacecraft in June. The device was specially created for the ISS by RSC Energia in cooperation with Tomsk Polytechnic University and Tomsk State University. Samples and parts that are used in large quantities on board the station will be printed on it from thermoplastic polymers by layer-by-layer imposition of a molten polymer thread (filament).

The device was specially created for the ISS by RSC Energia in cooperation with Tomsk Polytechnic University and Tomsk State University. Samples and parts that are used in large quantities on board the station will be printed on it from thermoplastic polymers by layer-by-layer imposition of a molten polymer thread (filament).

“This technology will allow astronauts to manufacture, for example, covers for electrical connectors of various nomenclature, research blades, wrenches and other tools, fasteners (nuts, bolts, etc.) necessary for work on the ISS,” said the representative Department of Radiophysics, Tomsk State University.

“The development of additive technologies at the station will open up new opportunities for the domestic astronautics to use 3D printing in the future. For example, in lunar expeditions, cosmonauts will no longer depend on the delivery of the necessary components and structures on transport ships from Earth, but will be able to print them directly in space, which will allow reaching a new level of performing various kinds of tasks, ”the Roscosmos added.

In November 2021, Russian cosmonauts complained that the sockets for hexagons were missing on the ISS and asked to send them, if possible, sockets for tools for 8, 10 and 12. With a printer, they will be able to print them on the station themselves.

Last August, NASA began testing a 3D lunar soil printer on the ISS. The project aims to test the strength and wear resistance of regolith, from which they plan to build colonies on the moon.

In September 2014, the Zero G 3D printer, also developed by Made In Space, was delivered to the ISS. In November, he became the first printer to print a three-dimensional product in space - a plate with the inscription "Made In Space NASA". Two years later, the researchers sent an improved printer model to the station.

3D printers provide astronauts with the necessary tools and parts for various designs. For example, in 2014, astronaut Berry Wilmore 3D printed a socket wrench.

3d printing of a person - 3d printing of figures of people on a 3d printer in Moscow

Masterpieces of fine art always amaze with filigree and liveliness of human images. It would seem that copying the human image will forever remain beyond the capabilities of ordinary people. But, nevertheless, time moves inexorably forward, sweeping away restrictions and providing opportunities.

It would seem that copying the human image will forever remain beyond the capabilities of ordinary people. But, nevertheless, time moves inexorably forward, sweeping away restrictions and providing opportunities.

Opportunities and benefits of the masterpiece technology

Every person on the planet is unique, therefore, any copy of a person, whether it be a statuette, a model or a portrait on paper, will also have a uniqueness. 3D printing of people is a technology that allows you to reduce the centuries-old most complex mystery of sculpture, painting, modeling of human images to a few simple manipulations with modern digital equipment.

And, let it sound a little cynical, but 3D printing of a person opens up incredible opportunities in various areas of our life. Just imagine, the creation of sculptural copies of a person takes months, and sometimes years. The cost of such a sculpture is often simply beyond the reach of an ordinary person. And the chances of becoming a model of a talented sculptor are negligible.

On the other hand, getting your own exact copy a few centimeters in size is now not at all difficult and not expensive. Moreover, a real boom in the popularity of 3D printing is brewing in the world, which will soon create a significant alternative to photo printing and video chronicles. And it's not just about private ambitions and fun!

Spheres of demand for 3D printing technology of people

3D printing of figurines is already widespread today in:

● advertising;

● decoration of wedding celebrations;

● souvenir industry;

● prototyping of industrial and commercial facilities;

● design;

● medicine.

The noble mission of innovative technology

Moreover, the circle of people professionally interested in the service in order to develop their business is constantly growing. In addition to the persistent interest in technology, its profitability and spectacularity, 3D printing of people also serves noble purposes, for example:

● allows blind people to tactilely get acquainted with the external images of their relatives and friends, communication with which is limited to virtual space;

● allows future parents to admire their baby in the womb, not only with the help of ultrasound pictures. 3D printing of a baby figurine built thanks to innovations will allow you to get to know him visually even before he is born;

3D printing of a baby figurine built thanks to innovations will allow you to get to know him visually even before he is born;

● Printing figurines on a 3D printer helps people with mental trauma and disorders to adapt to a certain social environment;

● in psychology and educational disciplines, three-dimensional models of people are involved in methods of working with children.

Steps for creating 3D copies of a person

High-quality and high-quality 3D printing of people actually requires several preparatory steps.

● In the first, a full-length 3D scan of a person is performed

● In the second, a copy of the 3D model is carefully processed

● In the third, the figure is scaled down and printed.

The technology also includes a number of post-press processing steps. Figures may require surface grinding, painting or tinting, freeing them from auxiliary elements - clamps, additional details, coating with protective varnishes, finishing agents.

Consumables and features of technological processes

Various materials are used for 3D printing of human figures and

even different equipment, technically and technologically different from each other. So, the result can be presented in plastic, gypsum, polymer mixtures. It can be single color or multicolor. Realistic or only in general terms reminiscent of the original.

Human 3D printing technologies are also different. The most popular and frequently used are two:

● layer-by-layer reconstruction of the model on an inkjet 3D printer;

● Laser baking, stereolithography on a laser printer.

For the best and most accurate reproduction of the image of a person, it is advisable to use the method of layer-by-layer gluing of a cellulose-starch mixture.

The use of 3D printed human figures in the advertising industry

Of course, the advertising industry has traditionally been at the forefront of bringing innovation to its service. 3D printing of human figures has become the basis of several high-profile advertising campaigns in Spain, Germany, and the UK, during which passers-by on the streets and visitors to shopping centers were asked to quickly create their own miniature on a 3D printer.

3D printing of human figures has become the basis of several high-profile advertising campaigns in Spain, Germany, and the UK, during which passers-by on the streets and visitors to shopping centers were asked to quickly create their own miniature on a 3D printer.

But the scope of advertising use of this technology is much wider:

● Figures of real employees of the company in company uniform can be a static installation.

● May be part of a believable animated advertisement.

● Given as a souvenir, they will be a powerful motivation for a common cause and common success.

● 3D printing of figures of people in addition to the presentation of 3D models of industrial, construction, social facilities can bring liveliness and dynamics to the presentation of projects.

● Using a 3D printer, you can create not only mini copies of real people, but also transform familiar replicated images of famous sculptures. For example, dress the Venus de Milo in the costume of a stewardess of the advertised airline, and use a mini copy of Rodin's sculpture in an advertisement for ladies' accessories.

The position of 3D copies of a person in souvenir production

A treasure trove of invaluable prospects 3D printer and human printing will bring to souvenir production. With the help of technology, you can make:

● popular interior figurines;

● intricate paperweights;

● personalized gift figurines;

● wedding souvenirs of the bride and groom;

● commemorative figurines of anniversaries and heroes of the occasion.

Variants of representation of the image in a three-dimensional miniature

When creating souvenir miniatures of people, most often you can find three directions for recreating the image:

● realistic or ordinary, the one that can be found in an amateur photo or in life;

● staged, when models are presented in fantasy, stylized images, for example, superheroes or characters from famous fairy tales, movies, literary works, comics;

● wedding, couple real or fictional image.

Bride and Groom figurines - this is just the beginning!

The industry of wedding paraphernalia, in addition to commemorative figurines of the newlyweds, can use 3D printing of figurines to create original decorations for invitations, decorating a wedding cake, a festive table, use mini-copies as props for an original wedding photo shoot and video shooting of a romantic love-story.

Online services and their features

It is worth saying a few words about online 3D scanning services. This first step of 3D printing a figurine takes the least time and is the least labor intensive. The presence of many specialized applications on the network that help you scan the image yourself makes the task even easier.

Actually, the results of scanning and allow you to remotely provide services of three-dimensional modeling of a person. The more diligently the scan is made, the more similarity will be between the model and the figurine. By the way, the service of 3D printing of people can be provided not only on the basis of a scan of a real person, but also on the basis of photographs taken from different angles.