3D print instruments

8 Coolest 3D Printed Instruments You Can Print and Play Today!

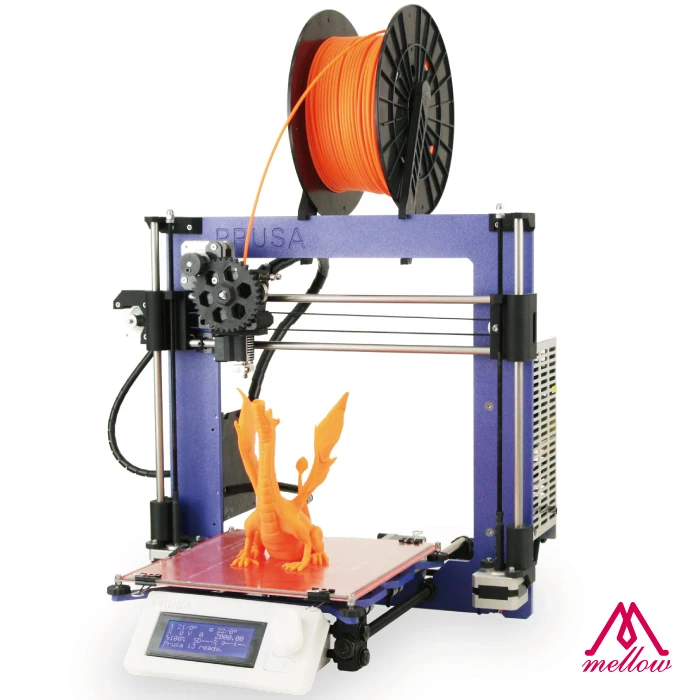

If you own a 3D printer you’ll undoubtedly be looking for new projects to work on, and neat things to use and show off. 3D printed musical instruments are one of the coolest things you can create, and with a plethora of options out there, it’s easy to see why.

- We also have a guide to all the coolest things to 3D print.

Many instruments require extra parts like tuners or strings, but it’s amazing what can be accomplished with 3D printing instruments. These range from wind instruments like flutes and ocarinas, to stringed instruments like guitars and basses.

Most of us have at least considered picking up and learning an instrument at some point in our lives. It’s easy to get bogged down in the options available, not to mention how hard it is to think of your instrument as unique when it simply came off a shelf.

This is where 3D printed instruments stand out. Not only will you have made your instrument yourself, but you’ll make it unique to you. These make for good looking pieces that are worth bragging about, even before you pick up and play.

Therefore, here’s some of the coolest 3D printed musical instrument projects you can make at home today.

The Black Widow 3D Printed Guitar – A New Take on an Old Favorite

Guitars are often the first thing that comes to mind when we think of musical instruments, and the same goes for 3D printed instruments.

Whether you play or not, you’ll know that guitars come in many different forms. While there are plenty of acoustic and mini guitar models out there to try out, one of the coolest designs for a 3D printed guitar is easily the Black Widow.

Not only does it look cool, the Black Widow has found a good following from many different 3D printing enthusiasts willing to share their advice with others.

This following is thanks to its sound as well as its design. Whether it’s your first guitar or a new addition to your collection, the Black Widow is a great 3D printed guitar for anyone interested in picking up a new axe.

With a printing time of 100+ hours, and plenty of opportunities to change the design to your liking, the Black Widow is customizable and fully open to tweaks and touches. This makes it a great choice for anyone looking for a 3D printed musical instrument project with a little extra challenge.

Because it’s an electric guitar, it will need strings, tuners, and various other parts to function. Fortunately, the creator has also linked these along with the free files here.

3D Printed Croaking Frog – A Cute Touch of Zen

Essentially a cross between a washboard and a singing bowl, guiros are a neat instrument that anyone can play. Commonly depicted as a frog, this 3D printed musical instrument doubles as a cute decorative piece.

The frog shape comes from both the ideal shape, and the fact that the noise produced sounds like croaking. Because it’s an easy-to-play percussion instrument with no extra parts, this is a great go-to for a 3D printed instrument for beginners to both music and 3D printing.

The croaking frog is satisfying, even soothing, to play, and the design includes a stick that can be held in the frog’s mouth for both convenience and cuteness. The designer has even included links to separate model hats to decorate your new instrument.

You can find the free files for this simple 3D printed percussion instrument here.

3D Printed Ocarina – Yes, That One

Because of the varieties in density, PLA filaments lend themselves well to fully playable 3D printed wind instruments. In general, wind instruments are great, simple projects to enjoy and show off. The ocarina is particularly cool because it’s both exotic and recognizable.

Despite being around for centuries and coming in a variety of shapes and sizes, the ocarina is best known these days for its prominence in Nintendo’s famous Ocarina of Time for the Nintendo 64.

Unsurprisingly, 3D designers have been preparing and tweaking designs for their very own playable 3D printed ocarina at home.

Even if you’re not a gamer, the simple yet elegant design should appeal to anyone who wants to 3D print their own wind instrument. Made in only a handful of parts and requiring little to no engineering, this fully playable ocarina models come in two forms.

The other is the updated 12-hole ocarina, which is aesthetically closer to the ocarina we all know and love today.

Simplicity and style aside, these are still fully playable 3D printed musical instruments.

Both designs are easy to make and customize. Find the free files for the small 3D printed ocarina here and the slightly more complicated 12-hole updated version here.

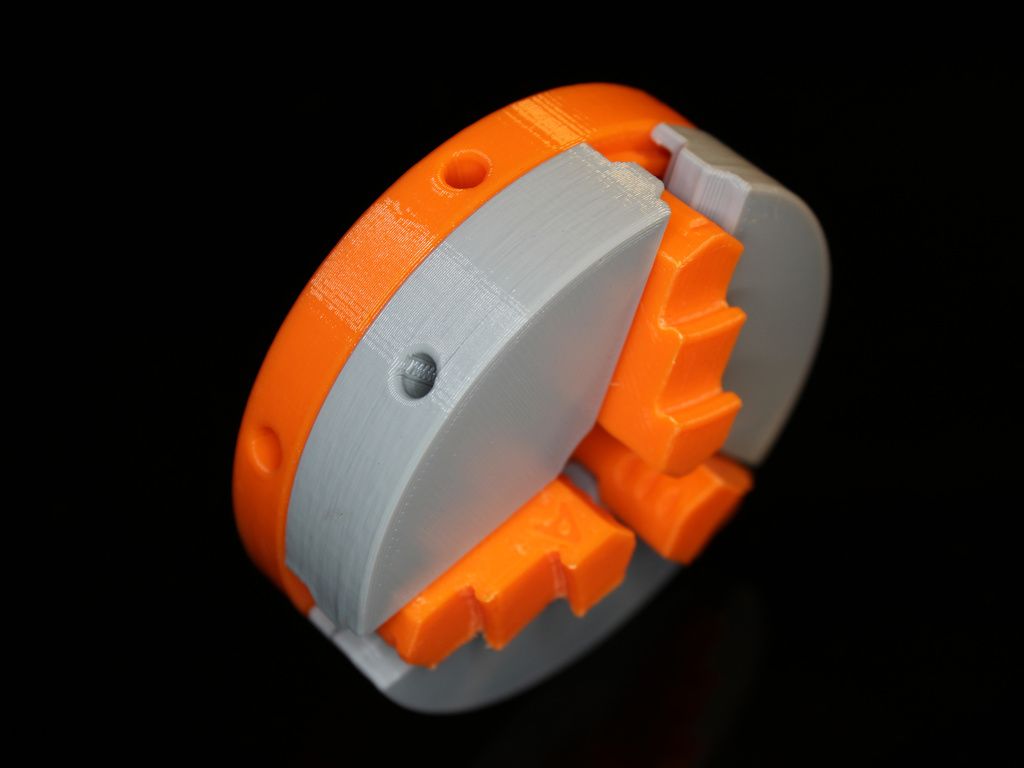

Twist-Off Maracas – Twist and Shake this 3D Printed Musical Instrument!

Maracas may seem like one of the most basic instruments available, but the variety of sounds they can make depends on what’s in them.

This design for 3D printed maracas includes a twist-off top that you can fill with anything from buttons to paper clips to produce different noises as you shake.

Testing out which materials and fillings make the best sounds can be a fun and educational activity for kids and adults alike.

The model can be made with any material and only takes around 2 hours to print, so it won’t be too long before you’re free to test out different fillings to get into the rhythm!

The free files for this fun and easy 3D printed instrument are available here.

Soprano 3D Printed Ukulele – Find the Right Chord

While ukuleles may seem like more of a CNC router project, they’re also available as a 3D printed instrument project.

This design model for a full-sized and playable for a 3D printed ukulele has seen great popularity across the internet, with many people making and sharing their own tweaks to make the design more affordable or easier to print.

Ukuleles require extra parts, like soundboards and tuners, which can also be 3D printed for your convenience.

While the initial design was made with an industrial grade 3D printer in mind, the design has been tweaked so more affordable 3D printers can print it.

The files for this instrument are available for free here.

Recorder Flute – an Ancient Classic reimagined as a 3D printed instrument

The recorder was many people’s first instrument, largely due to its age and relative simplicity to learn. So it’s not surprising that it’s a very popular 3D printed instrument project for many people today.

Recorder flutes look sleek, are fun to play, and also look great as a bookshelf or mantlepiece ornament.

Much like the ocarina, there are many varieties and shapes of flute available that can be made of almost any material. Make sure the edges are smooth and sanded down before you play for both comfort and safety, especially if you’re using wood.

Flautists may not be the rock stars of the music world, but after printing your own from the files found here, you’ll soon see why this centuries-old instrument is still a popular choice for modern musicians.

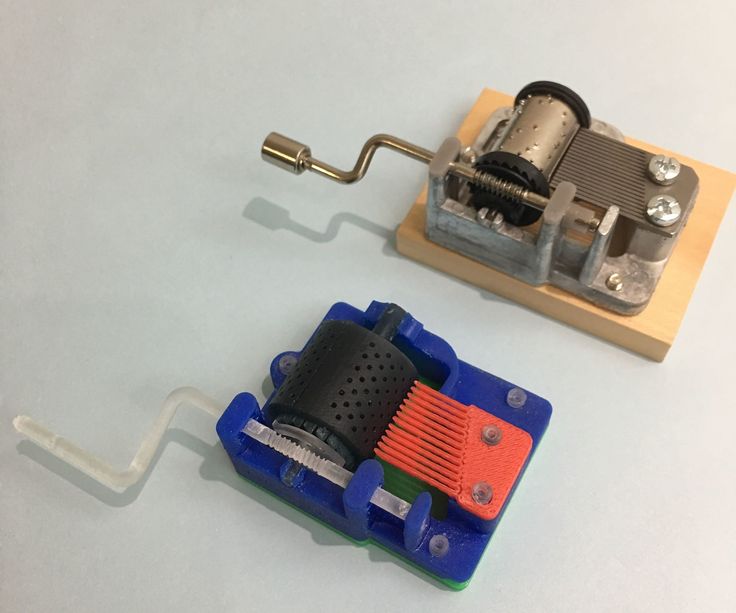

Customizable Music Box – 3D printed musical instrument with a twist

Calling a music box an instrument may not sound quite right, but your mind may be quickly changed when you try out this fully customizable design using built-in combs and music cylinders to play any kind of tune.

Entirely 3D printed, this instrument earns a spot on this list because its design incorporates a click-in slot for changeable cylinders. This means that, with enough knowhow and practice, you’ll be able to design and create your own music to play whenever you want.

From Happy Birthday and Mary Had a Little Lamb, to your favorite TV show themes, and even custom tracks, there are plenty opportunities to let your creativity fly.

This 3D printed instrument also makes for a great educational tool to teach youngsters how toothed instruments work, as well as inspire them to see if they can design their own tunes using a melody generator like the one found here.

The original design found here and can be altered for different materials, or to play longer pieces as you learn and grow.

Pushing the boundaries of technology

Overview: what is it possible to 3D print in the music industry?

A lot of experimentations are made on different levels inside of the music industry in order to use additive manufacturing. Here are the most promising ones:

Here are the most promising ones:

- 3D printed records

Here is an initiative that could please some records enthusiasts. For the moment the quality of the sound is not good enough. However, tests are quite promising and at least, we now know that it is possible to 3D print music!

- 3D printed speakers

Aleph 1 is the proof that 3D printing can also impact the sound system business. It is now possible to get speakers with amazing designs thanks to 3D printing.

- 3D printed headphones

For example, it is possible to get headphones adapted to any morphology or earbuds custom-made, thanks to the additive manufacturing technologies. Check out our customer story with AudioQuest’s for more details about 3D printed headphones.

- 3D printed musical instruments

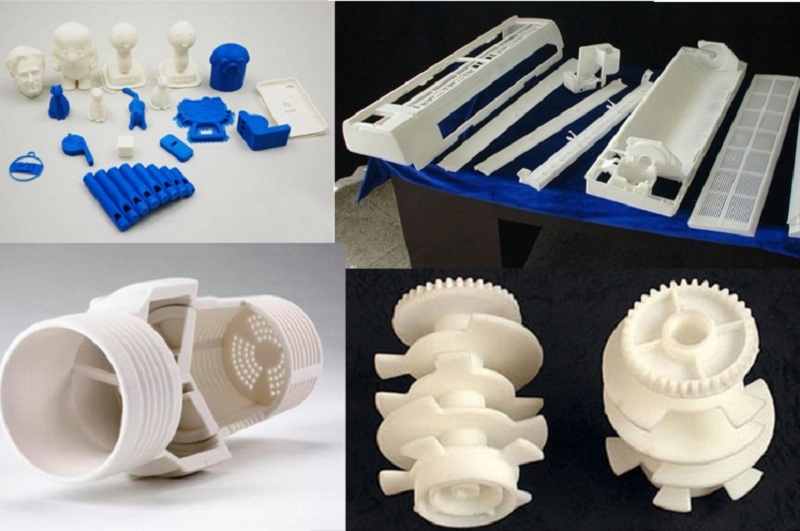

Obviously, to make music you need musical instruments, and we will see that it is possible to make amazing 3D printed instruments. It is actually possible to print various instruments, from wind instruments to string instruments or even percussions.

Why can it be a good choice to 3D print musical instruments?

3D printing as an alternative to traditional manufacturing

3D printing can be used to create replications of existing instruments or instrument parts, at a lower cost. For example, with this technique you could recreate the missing part of an instrument at a lower price. But it can also be used to produce and in this case, this technology appears to be a manufacturing technique like another. Using additive manufacturing allows to work with other materials, with a cheaper process.

A great method to work on designs

Additive manufacturing is an amazing technology, that allows to work on crazy instrument designs. For some musicians, the look of their instrument is a priority, because it has to match with the imagery of their music. As 3D printing gives a lot of freedom on this aspect, it appears to be an interesting solution. Astonishing guitar designs like the one in the video below, are easier to produce with this manufacturing technique.

It is an effective way to transform quite faster customer requirements into real printed products We will see later in this blogpost that 3D printed instruments can have really complex shapes. Some designers are making the most of this technique to create instruments with an atypical and futuristic look, impossible to create with traditional manufacturing methods.

One of the biggest advantages of this technology is that it will improve your product development process. It is possible to work and rework on a 3D design before 3D printing it.

Additive manufacturing is allowing mass customization

Additive manufacturing also allows mass customization. Using it to create instruments is a good way to create musical instruments adapted to the needs of the musician. For example, thanks to 3D printing, it’s possible to make lighter instruments. Some instruments such as saxophones or even some Les Paul guitars are quite heavy, and it can become a real problem over time. By choosing the right 3D printing material, you could make instruments that will improve the comfort of the musician while playing.

Some instruments such as saxophones or even some Les Paul guitars are quite heavy, and it can become a real problem over time. By choosing the right 3D printing material, you could make instruments that will improve the comfort of the musician while playing.

What 3D printing material to create an instrument?

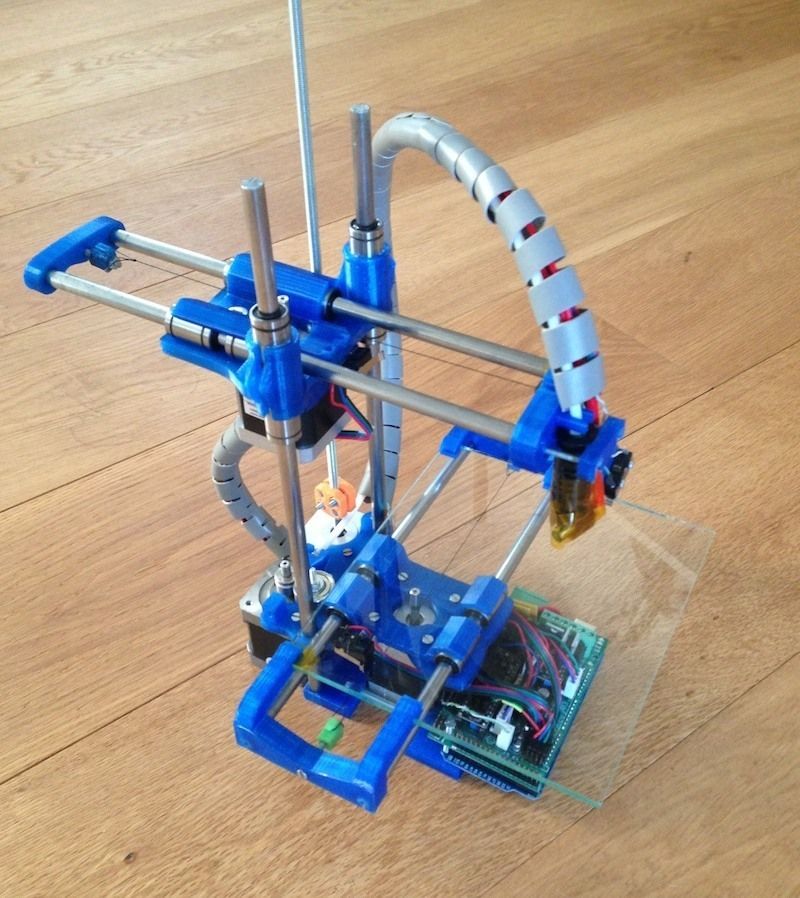

A wide range of 3D printing materials is available on the market, it totally depends on your needs and your project. Olaf Diegel, that you will meet numerous times in this blogpost, uses nylon to 3D print his instruments. He is working with the Selective Laser Sintering technology. If you want more information about SLS and all the 3D printing materials available with this technology, check out our SLS page.

But it is possible to 3D print instruments with other techniques and materials. For example PLA plastic and FDM 3D printing have been used to create some instruments from the MONAD Studio that you will see in this article.

Other example: the violin manufacturing 3Dvarius is 3D printing with resin material, using stereolithography. Each project has special requirements and needs a different 3D printing material.

Each project has special requirements and needs a different 3D printing material.

3D printed instruments: the most impressive creations

3D printed guitars and bass guitars

- Olaf Diegel and his amazing 3D printed guitars

Olaf Diegel is a professor in product development, he is also passionate about new technologies and guitar making. Its 3D printed guitars are amazing by the way they look, but also by the way they sound. They are high-quality guitars, totally customisable. Like a traditional guitar, you can play using chords or just with finger picking, it’s actually possible to reach an impressive sound. In this video, Olaf Diegel shows how he is crafting instruments:

If you are interested in these 3D printed electric guitars, take a look at the ODD guitars website!

You can also see in this video that it is possible to play a wide range of musical genres with these guitars, like with a traditional instrument. Indeed, it is possible to get the right sound to play funk, progressive rock, heavy rock or blues.

Indeed, it is possible to get the right sound to play funk, progressive rock, heavy rock or blues.

- The 3D printed Hybrid Slide Guitar

This 3D printed guitar is a creation of the MONAD Studio, designed by Eric Goldemberg and Veronica Zalcberg with the musician and luthier Scott F. Hall. It is part of an installation called “MULTI”, that includes different 3D printed instruments, playing on complex and disturbing aspects, but also on sound explorations. This guitar totally reinvents the traditional design of a guitar. It has a fretless neck, as this printed instrument is made to play with a slide technique.

If you’re interested in the sound of this atypical instrument, you can listen to it here:

- Olaf Diegel is creating guitars, but also 3D printed bass guitars

The sound and morphology of the instrument are obviously different, but Olaf Diegel offers the same possibilities. It is possible to adapt the design of the 3D printed instrument according to the tastes of the musician. Here is an example with the Atom 3D printed bass guitar.

It is possible to adapt the design of the 3D printed instrument according to the tastes of the musician. Here is an example with the Atom 3D printed bass guitar.

- A student 3D printed the body of a bass guitar

A student decided to create a custom bass guitar body for a school project and he made a complete video about it. He created and assembled it by himself. This 3D printed instrument is fully functional.

You can watch this video to understand the creation process and see a little demonstration.

3D printed pianos and melodicas

- 3D printing a piano: the example of the Lucid – EXO piano

This impressive instrument comes from the same installation as the 3D printed Hybrid Slide Guitar that we saw previously. This futuristic piano is designed by Eric Goldemberg and Veronica Zalcberg from the MONAD Studio. Because of its size, 3D printing a piano is quite a challenge.

Because of its size, 3D printing a piano is quite a challenge.

To listen to the sound of this 3D printed piano:

- A Steinway piano with 3D printed parts

This example is showing that even a big piano manufacturer such as Steinway is taking seriously the growing use of 3D printing technology. These 3D printed parts don’t have any impact on the sound of the instrument, it is only decoration. Indeed, the 3D printed porcelain parts are here to innovate on the final aspect of the piano. It shows that new technologies and tradition can be used together, to work on the design of an instrument.

- The first 3D printed melodica

Daren Banarsë is a pianist, but sometimes, he likes to play melodica. He started to do some experimentations to create a 3D printed melodica because he wanted his instrument to look less juvenile and sound more professional.

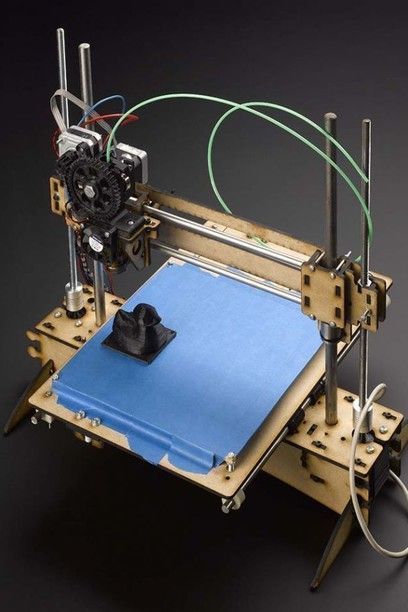

You can find all the details about his experimentations and the creation of this melodica, here. Daren Banarsë shares all the steps of his experiments on this website, the 3D modeling process, his desktop 3D printer choice, the printing process, the assembly, and the finishing!

3D printed saxophones

- Olaf Diegel and his printed saxophone

This music passionate, that we already know for his 3D printed guitars, also tried to 3D print a saxophone. Once again, his new 3D printed instrument is a success. Olaf Diegel is really gifted when it comes to instruments crafting. This 3D printed saxophone is the result of a meticulous and impressive work. Indeed, this saxophone has 41 components 3D printed in nylon.

Even if it is impossible to sound like a real saxophone made with brass, the sound that Olaf Diegel obtained with this 3D creation is more than correct. You can listen to his demonstration right here:

3D printed violins

- Hovalin: the traditional and 3D printed acoustic violin

Hovalin is a little brand created by The Hovas, a couple offering more than 3D printed instruments: they are actually offering a whole 3D printing experiment. Indeed, there are three different ways to get your printed violin with Hovalin. You can 3D print it by yourself. 3D models are free and available on their website, anyone can download these 3D files and then print them thanks to an online 3D printing service. They are also offering to send the whole kit to their customers, or directly, the finished product.

Their creations stay very close to the traditional look of an acoustic violin, and their sound is really close to the sound of a wood violin.

- The only 3D printed violin that could compete with a real Stradivarius

3D varius is a french violin manufacturer. These electronic violins are based on the same models as the famous Stradivarius violins. They are customisable, and can totally be adapted to the morphology of the musician. But the design can also be modified for aesthetic reasons, in order to match the customer’s tastes.

They are customisable, and can totally be adapted to the morphology of the musician. But the design can also be modified for aesthetic reasons, in order to match the customer’s tastes.

Behind this modern look, there is a surprising violin sound. You should absolutely listen to this amazing performance of the founder of 3Dvarius:

- The futuristic violin of the MONAD Studio

You can now recognize the style of the instruments printed by the MONAD Studio. This 3D printed violin and his astonishing look is also part of the installation “MULTI”.

If you are curious about hearing the sound of this atypical instrument, here is a video for you:

3D printed drums

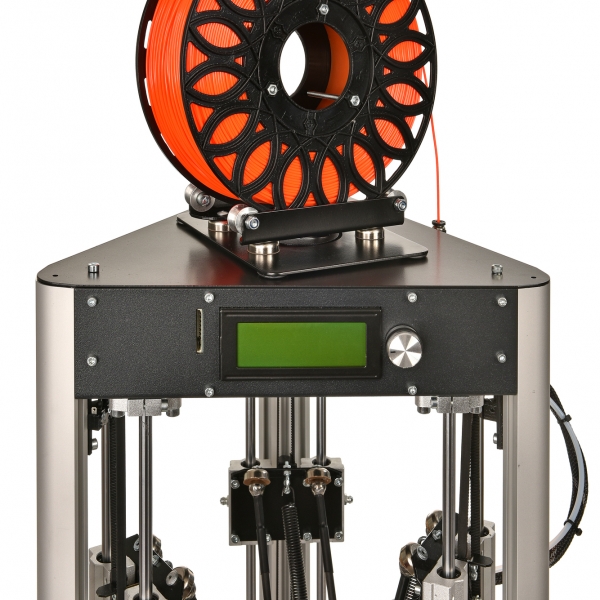

- ZMorph 2.

0 S: the amazing 3D printed electronic drums

0 S: the amazing 3D printed electronic drums

3D printed percussions are maybe the most complex instruments to 3D print. A student called Michal Szydlowski created low cost electronic drums thanks to the 3D printing technology. These 3D printed drums are called ZMorph 2.0 S. Michal worked with Autodesk to work on the 3D modeling of his drums. Then he printed the parts of his instrument with different infill, in order to get the right sound for each part.

Watch how Michal created his drums in the video below:

3D printed flute

- The 3D printed acoustic flute by Amit Zoran

This flute has been created by Amit Zoran for a research project. Amit Zoran made this flute in order to show the opportunities offered by additive manufacturing when it comes to acoustic instruments. This researcher built the 3D model of a flute that will be printed in only one part, without any assembly. He had to reinvent the whole instrument in order to get to this result.

He had to reinvent the whole instrument in order to get to this result.

- The 3D printed flute, a real revolution for the music industry?

Researchers are interested in 3D printed flutes. The University of Wollongong Australia is working on the possibilities offered by 3D printing in the musical sector. They are studying how changing technologies can impact culture and society. During these researches, they created custom 3D printed flutes able to play microtonal tunings, normally unavailable on traditional instruments.

If you are interested in this project, you can check this video for more information:

3D printed ukulele

- Hovalele offers the opportunity to print a ukulele

It is the same process as for Hovalin. The Hovas created Hovalele, a simple platform allowing you to get a great 3D printed ukulele. As for their 3D printed violin, they are offering their customer three different ways to get a 3D printable ukulele.

As for their 3D printed violin, they are offering their customer three different ways to get a 3D printable ukulele.

With all of the 3D printed instruments that we saw in this blogpost, you could totally make a band with 3D printed instruments only! Find out a good example in the video below:

Is the 3D printing technology mature enough to 3D print instruments?

We can totally say that 3D printing is now mature enough to create real musical instruments, and not only fake ones for wall decoration. There are now functional instruments, with great sounds and qualities. Once again, 3D printing appears to be the best solution to work on designs. It shows the degree of accuracy and performance of this manufacturing technology.

We can see that some instruments seem to be more perfectible than other ones. 3D printed violins and guitars seem to be the most successful experiments for the moment. Even if it can be complicated to reach the warm sound of a wood instrument, the first result obtained for these electronic instruments are good. For the moment, it is still very complicated to create acoustic guitars with these manufacturing techniques.

Even if it can be complicated to reach the warm sound of a wood instrument, the first result obtained for these electronic instruments are good. For the moment, it is still very complicated to create acoustic guitars with these manufacturing techniques.

Needless to say, most of these projects are made to push the boundaries of 3D printing technologies. Indeed, a lot of these projects are made by designers, students or researchers. Musical instruments getting out of 3D printers is quite a big change for the musical industry, but it could become more common in the future.

At Sculpteo, we are curious about your opinion regarding 3D printed instruments. Leave a comment to share with us your impressions about these creations. Are you ready to make a 3D printed record with your future 3D printed instruments?

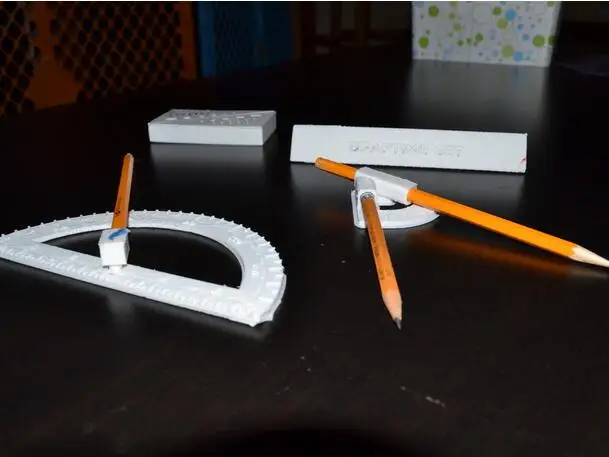

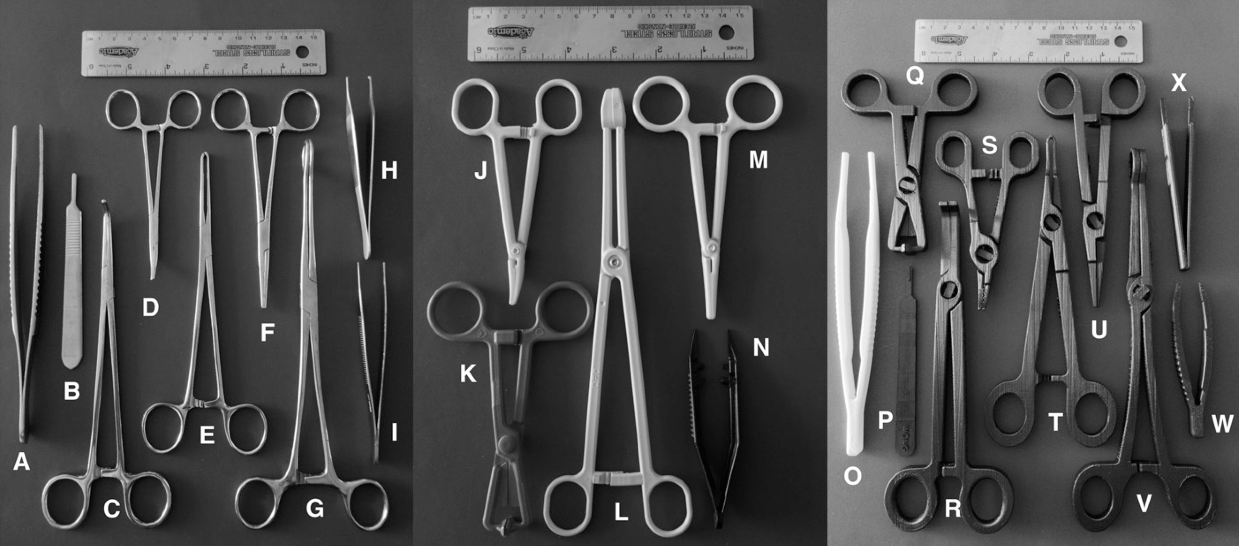

3D printing tools. What you need to have on hand.

If you have a 3D printer, then you will have to master the intricacies of 3D printing. And to facilitate this process, you need to acquire some tools (Tools for 3D printing).

Today we will talk about what kits and tools you may need.

Spatula, scraper…

You may need a spatula and scraper to get started. These can be painting or artistic devices that help to remove the finished model from the working platform. They are especially indispensable in cases where you print with difficult-to-separate plastic.

To remove the model with the blunt end of the spatula, try to pry the model from one side. Once you succeed, try to delete the model manually. If this does not work, then try to squeeze the spatula between the table and the model and slightly raise it.

It is important to be very careful not to scratch the surface of the table and injure yourself.

Deburring tool

This tool is the most indispensable tool of all. It really makes it easy to remove supports, clean up the model. At the same time, the tool is safe, and it is much more convenient to use it than to wield a knife. This tool will be especially useful when cleaning round holes.

Utility knife

This is a knife used for cutting appliqués, sometimes called a hobby knife. This tool is ideal for precise cutting of ABS, PLA and other popular plastics. It is important that this knife is very sharp. But it is also important to follow safety measures when working with the tool.

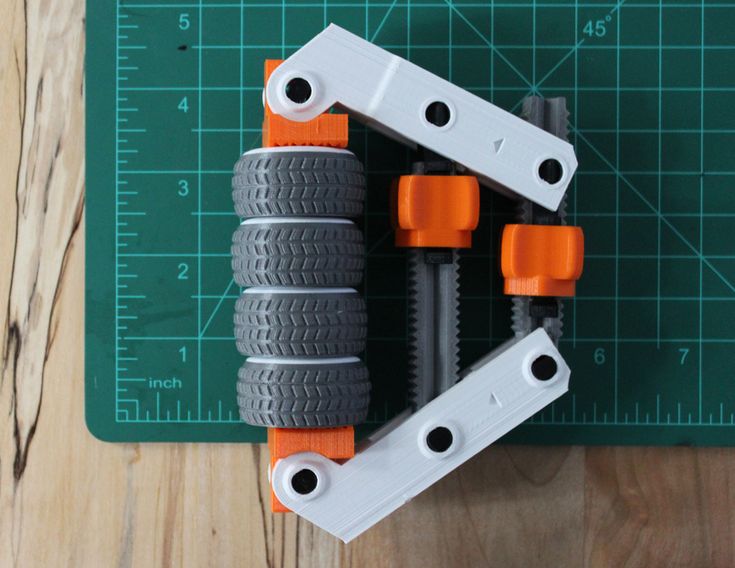

Pliers, round nose pliers

These tools are extremely useful when removing supports. At the same time, pliers are also useful for the 3D printer itself and for post-processing. Supports can be cut a little with a sharp knife and then with pliers it will be easy to remove them not one by one, but in blocks.

Wood carving set

This set is very useful for fine cleaning of models. The tips in this set have a variety of shapes, which allows for high-quality cleaning of models of any geometry and even in hard-to-reach places: corners, roundness, etc.

Super Glue

In fact, the choice of adhesives is now simply huge, and their possibilities are almost endless. Be sure to get superglue, as it is suitable not only for repairing or filling gaps, but also for gluing individual printed nodes. Be sure to focus on the viscosity of the composition, and also select the right tool. If you need to fill gaps, then we recommend choosing denser compositions than for assembling small parts. An important note - superglue works great with plastics such as ABS and PLA.

Be sure to get superglue, as it is suitable not only for repairing or filling gaps, but also for gluing individual printed nodes. Be sure to focus on the viscosity of the composition, and also select the right tool. If you need to fill gaps, then we recommend choosing denser compositions than for assembling small parts. An important note - superglue works great with plastics such as ABS and PLA.

Files

A set of mini files will come in handy. Various forms of tools will allow grinding and smoothing of various surfaces.

Sanding (sanding) paper

With the help of grinding, surfaces can be significantly smoothed, achieving the ideal condition of the models. Especially grinding will be relevant if in the future the model will be stained. Sandpaper with a grit size of 120-200 will be the ideal solution for all types of plastics. Models made of ABS are particularly suitable for sanding.

Instead of a conclusion

All the 3D printing tools that we reviewed above will not gather dust on the shelf, waiting in the wings. If you are into 3D printing, then all of them will be in your favor. This is, in fact, the base that any 3D printer should have. Many manufacturers equip their 3D printers with a set of tools that can help with their work. If your equipment comes with a tool kit, take a close look at it so you don't waste money on what you already have.

If you are into 3D printing, then all of them will be in your favor. This is, in fact, the base that any 3D printer should have. Many manufacturers equip their 3D printers with a set of tools that can help with their work. If your equipment comes with a tool kit, take a close look at it so you don't waste money on what you already have.

Tools needed to maintain the 3D printer

3DPrintStory Reviews Tools needed to maintain a 3D printer

Building a 3D printer from scratch is hard enough, not to mention trying to assemble it without the right tools. Below we highlight some of the most common 3D printer repair and assembly tools.

Caliper

Calipers are used to measure the distance between opposite sides of an object. Although used in many industries, including medicine and woodworking, modern calipers in mechanical engineering are often Vernier calipers that offer a high degree of accuracy compared to purely mechanical options. The included digital dials and scales can display measurements to the nearest thousandth of a millimeter/inch.

Although used in many industries, including medicine and woodworking, modern calipers in mechanical engineering are often Vernier calipers that offer a high degree of accuracy compared to purely mechanical options. The included digital dials and scales can display measurements to the nearest thousandth of a millimeter/inch.

Screwdrivers/Hex Keys

The 3D printer is made up of complex individual parts that are held together with a variety of materials and fasteners. In matters of assembly and repair of a 3D printer, screwdrivers and hex keys are crucial. Be sure to stock up on a flat head screwdriver as well as a set of hex wrenches of various sizes. Due to the huge number and variety of mounts, most 3D printers use metric mounts, but this statement is not an unshakable truth, anything can happen, there are a lot of manufacturers of desktop 3D printers.

Hex keys are simple and small hex head screwdrivers that are very cheap in cost. So it is convenient for both manufacturers and consumers, who can purchase a set of hexagons of various sizes for a small amount and use it not only for a 3D printer, but in general in everyday life.

Wrenches

Although there are dozens of wrenches, each with a specific purpose, for those who work with a 3D printer, the most useful will be hex keys, socket wrenches, wrenches and adjustable wrenches.

Due to the large number of fasteners used in 3D printers, manipulating in tight spaces and applying a lot of force without moving the entire wrench arm is key. To do this, hex wrenches have a relatively small footprint, and socket wrenches allow you to securely tighten fasteners without swinging the entire socket wrench arm (and likely avoid damaging the 3D printer frame). Adjustable wrenches have the same backlash as adjustable pliers, allowing precise control of fasteners in tight spaces. keys like these will be useful for working in and around the 3D printer's extruder.

Wire strippers/wire crimps, soldering iron

Often included in the same tool, wire strippers and wire crimps are used to strip wires and connect crimp connectors, respectively. While any pliers with sharp inside jaws can strip the wire, the process is more difficult than using a good wire stripper. Similarly, sharp-tipped pliers can be used to terminate crimp connectors at the ends of wires, although this requires more skill and patience than using crimp pliers.

While any pliers with sharp inside jaws can strip the wire, the process is more difficult than using a good wire stripper. Similarly, sharp-tipped pliers can be used to terminate crimp connectors at the ends of wires, although this requires more skill and patience than using crimp pliers.

3D printers often include dozens of wires, and having clean connections between various electronic devices ensures they last a long time. Along the same lines, a soldering iron may sometimes be required when assembling and maintaining the printer. However, solder joints can serve as replacements for crimp connector bodies, although the solder joint is not as flexible/modular if changes need to be made.

Please note that most solders cannot withstand the temperature of a 3D printer's hot end. Crimp connectors should only be used in areas of the printer that can become very hot. This applies to the greatest extent to the connections of the heating element and the hotend thermistor.

Pliers

When building your basic 3D printing tool kit, don't overlook a good pair of pliers. They will definitely come in handy for scraping off excess filament from the hotend and bed, or for fixing parts of a 3D printer and attaching wires. Due to the extreme temperatures around the hot end, you should never manually adjust components under the X carriage while the printer is heating up or cooling down. Pliers (and to some extent wrenches and screwdrivers) will allow you to manipulate the hot parts of a 3D printer without getting burned.

They will definitely come in handy for scraping off excess filament from the hotend and bed, or for fixing parts of a 3D printer and attaching wires. Due to the extreme temperatures around the hot end, you should never manually adjust components under the X carriage while the printer is heating up or cooling down. Pliers (and to some extent wrenches and screwdrivers) will allow you to manipulate the hot parts of a 3D printer without getting burned.

Lubrication

With many moving axles, bearings and carriages, a 3D printer is nothing more than a finely tuned dynamic machine. It is very important to properly lubricate the parts with a few drops of machine lubricant. Silicone-based compounds or those containing PTFE are best for protecting the rods, bearings, and bushings that allow the printer to print. Lubricant and timely maintenance of the mechanics of a 3D printer will definitely help protect your brainchild from unnecessary and unpleasant breakdowns.

Spirit level

A simple water level can help calibrate the 3D printer bed, X carriage and frame components.