Best diy corexy 3d printer

7 Best CoreXY 3D Printers (2022 Updated)

- Last Updated: November 8, 2022

- Pat Nathaniel

CoreXY printers are some of the most reliable and versatile on the market, making them ideal for both hobbyists and artisans.

Unlike other 3D printer design styles, such as the delta 3D printer, CoreXY printer heads only move on the X and Y axis (hence the name).

Why is that a benefit?

Because they are more agile and faster than the competition. Since the head doesn’t have to move on the Z-axis, it can provide much more detail within your builds.

In this article, we’ve compiled a list of the best 7 CoreXY 3D printers.

Let’s get started!

Tronxy X5SA Pro

Build volume: 330 x 330 x 400 mm

Check Latest Price

Creality Ender 6

Build volume: 250 x 250 x 400 mm

Get Discount (Official)

Check Latest Price

Vivedino Troodon CoreXY

Build volume: 300 x 300 x 400 mm

Check Latest Price

Table of Contents

- 7 Best CoreXY 3D Printers At A Glance

- 1.

Tronxy X5SA Pro (Best Value)

- 2. Creality Ender 6 (Best Choice)

- 3. Vivedino Troodon CoreXY (Premium Choice)

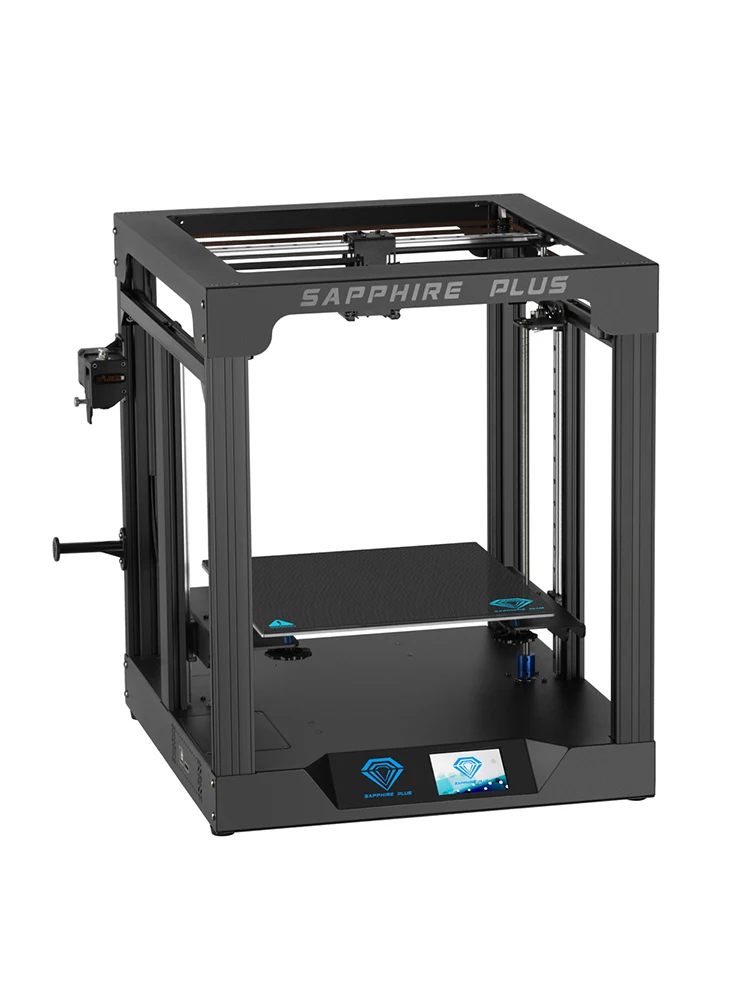

- 4. Two Trees Sapphire Pro (Best Budget)

- 5. Voron 2.4 R2 CoreXY (Best DIY)

- 6. Rat Rig V-Core 3.1

- 7. SecKit SK-Go³ (Best for Experienced Users)

- 1.

- CoreXY 3D Printer Buyer’s Guide

- What are CoreXY 3D Printers?

- Advantages of CoreXY 3D Printers

- Disadvantages of CoreXY 3D Printers

- FAQs

- Do These Printers Provide High-Quality Prints?

- Are These Printers More Expensive Than Other Models or Brands?

- Is Assembling a CoreXY Printer Difficult?

- Are These Printers Easy to Use?

- Final Verdict

7 Best CoreXY 3D Printers At A Glance

1. Tronxy X5SA Pro (Best Value)

2. Creality Ender 6 (Best Choice)

3. Vivedino Troodon CoreXY (Premium Choice)

4. Two Trees Sapphire Pro (Best Budget)

5. Voron 2.4 R2 CoreXY (Best DIY)

Voron 2.4 R2 CoreXY (Best DIY)

6. Rat Rig V-Core 3.1

7. SecKit SK-Go³ (Best for Experienced Users)

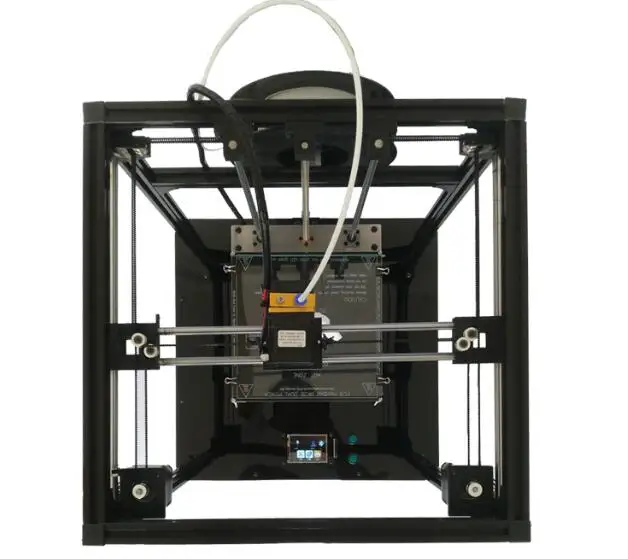

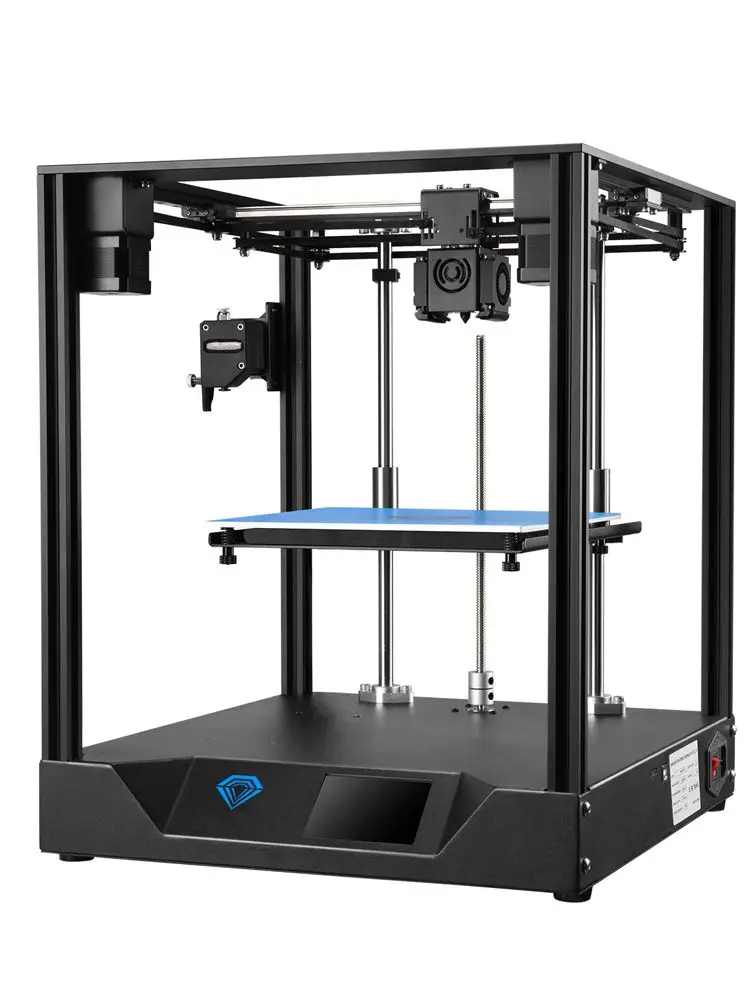

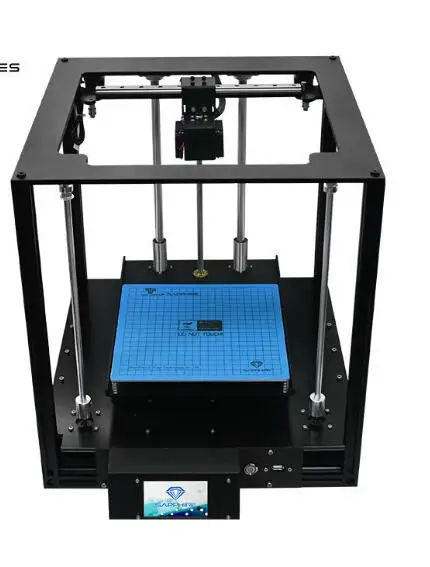

1. Tronxy X5SA Pro (Best Value)

3D Printer Type: FDM | Layer Resolution: 0.1-0.4 mm | Materials: PLA, PLA+, TPU, ABS & PETG | Build Volume: 330 x 330 x 400 mm | Print Speed: 20-150 mm/s | Printer Size / Weight: 580 x 645 x 660 mm / 14 kg

The X5SA Pro is for you if you frequently print large projects and prefer a quiet machine.

Be warned however that the instructions it comes with aren’t the clearest so I recommend watching videos online to help assemble it. Because of this, I don’t recommend the X5SA Pro for beginners (unless you like to tinker and DIY).

I like that the printer is quite sturdy once built.

A few other features I like:

Large Enclosure

This CoreXY 3D printer has one of the biggest platforms on the market, with a 330 by 330 by 400 mm printing surface. You can let your creativity shine with larger pieces such as printing cosplay armor.

You can let your creativity shine with larger pieces such as printing cosplay armor.

Automatic Leveling

If you have to use multiple color filaments to build your piece, leveling can be a challenge. With the automatic leveling function, you can keep going without any noticeable errors in your design. This printer also supports manual leveling when applicable.

Titan Extruder

The ‘Pro’ version of the X5SA comes with a Titan extruder which means you can print flexible filament like TPU. And switch to PETG or ABS with ease. The versatility of printing different materials is a huge pro.

Overall, this is a decent CoreXY 3D printer with a few drawbacks. Keep in mind that to get the best out of it modifications may be needed. While these aren’t usually too expensive, it will raise the cost.

If you want a 3D printer that doesn’t need to be upgraded then check out the next two reviews below.

- Large printing area

- Automatic leveling

- Power sensor

- Filament sensor

- Lifetime tech support

- Silent operation

- Some build instructions can be confusing

- Can take a while to master the leveling feature

Check 3DPrintersOnlineStore

Check Latest Price

2.

Creality Ender 6 (Best Choice)

Creality Ender 6 (Best Choice) 3D Printer Type: FDM | Layer Resolution: 0.1 mm | Materials: PLA | Build Volume: 250 x 250 x 400 mm | Printer Size / Weight: 495 x 495 x 650 mm / 30 kg

If you want a 3D printer that’s more beginner-friendly, than I recommend the Ender 6. This is Creality’s first foray into the world of CoreXY and they did a great job with this entry-level unit.

Assembling the Ender 6 was a breeze – it took us only one hour. And what we enjoyed the most was that the test prints came out beautifully.

A few other things we liked:

Large Housing Unit

Although the Ender 6 isn’t as big as the X5SA Pro, it is larger than most other printers. It has a 250 by 250 by 400 mm enclosure, which is almost as big as their CR-10 models. However, with such a relatively massive chamber, you need to make sure that you have enough counter space to house it.

Fast Printing Speeds

Since the Ender 6 uses a CoreXY structure, it can achieve printing speeds of up to 150 mm per second. With an excellent cooling function and smooth FDM head, you can get more precision and better results in less time.

If you want a well-designed, easy to operate machine from one of the most well-known and respected companies the Ender 6 is for you.

- Rugged construction

- Large printing area

- Fast printing speeds

- Touchscreen interface

- Rapid cooling

- Hassle-free assembly

- Suffers from fan noise common to Creality printers

- Colored panels can make it harder to see your products during printing

Get Discount Now (Official Store)

Check Latest Price

3.

Vivedino Troodon CoreXY (Premium Choice)

Vivedino Troodon CoreXY (Premium Choice) 3D Printer Type: FDM | Layer Resolution: 0.05-0.3 mm | Materials: ABS, PLA | Build Volume: 300 x 300 x 400 mm | Printer Size / Weight: 516 x 643 x 764 mm / 38 kg

If you’re ready to upgrade your 3D printing to the next level, the Troodon is for you. This is one of the largest (and priciest) models on the market, but it is better for advanced printing options.

Why do I like the Troodon?

Extra Large Printing Area

With a 300 by 300 by 400 mm enclosure (like the X5SA Pro), you have the option to print much larger. Even better, the Troodon works faster than them, too, all without sacrificing precision or build quality.

HEPA Air Filter

One of the primary advantages of buying an enclosed 3D printer is that it can trap potentially harmful fumes. This model goes a step further by scrubbing the air clean so you can work more efficiently, particularly when building multiple models in sequence.

Pre-Built Machine

Rather than having to build this 3D printer yourself, it comes fully assembled. This is part of the reason why the price tag is higher, but it allows everyone to get involved, not just those with engineering skills.

The Vivedino Troodon is one of the more beginner friendly CoreXY printers and is perfect if you want to get high-quality prints from the get-go.

- Pre-assembled housing

- Large design for bigger models

- Rapid printing and cooling

- A HEPA filter traps harmful emissions

- Automatic pause and power sensor

- Quiet operation

- More expensive than other 3D printers

Check 3DPrintersOnlineStore

Check Latest Price

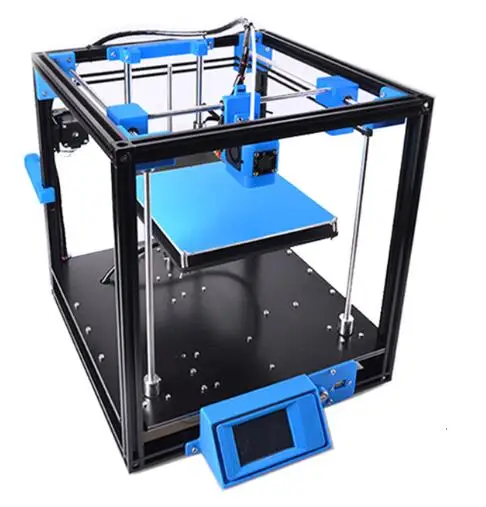

4.

Two Trees Sapphire Pro (Best Budget)

Two Trees Sapphire Pro (Best Budget) 3D Printer Type: FDM | Layer Resolution: 0.1 mm | Materials: PLA, ABS, TPU, Flexible, Wood, PVA, HIPS | Build Volume: 225 x 235 x 235 mm | Printer Size / Weight: 405 x 360 x 480 mm / 14 kg

When comparing different 3D printers, you’ll notice that many of them can be quite costly. If you’re hoping to save some money while getting the most value, the Two Trees Sapphire Pro is an excellent choice.

Why is this the best budget pick?

Print Different Materials

The Sapphire Pro can do things machines priced higher can’t. Chief among them is print in TPU and flexible filament.

Rapid Cooling

Because these printers use the FDM method of printing, distortion can be possible if the filament doesn’t cool down in time. Thankfully, the Sapphire Pro alleviates that problem so that your finished products will look smoother, uniform and be more durable.

Automatic Pause

Just as you wouldn’t want to dry-fire a gun, running your 3D printer without filament can damage the internal components. The Sapphire Pro has built-in sensors that shut the machine down as soon as the material runs out. This feature is also helpful if there are any blockages or errors while printing.

Another advantage of pausing is that you don’t lose your place while printing. Once you get more filament into the machine, it will resume where it left off, so there won’t be any issues with the results.

If you want to experiment with CoreXY design and not shell out a ton of cash then the Sapphire Pro is for you.

- Quieter with TMC2208 stepper motor

- Lighter and more agile printing method

- Large 3.5-inch touchscreen

- Easier to build than other models

- Rapid cooling for smoother, more uniform products

- Automatic pause when filament runs out

- Not designed for commercial purposes

- Some components can overheat, causing damage to the machine

Check Banggood Price

Check Latest Price

5.

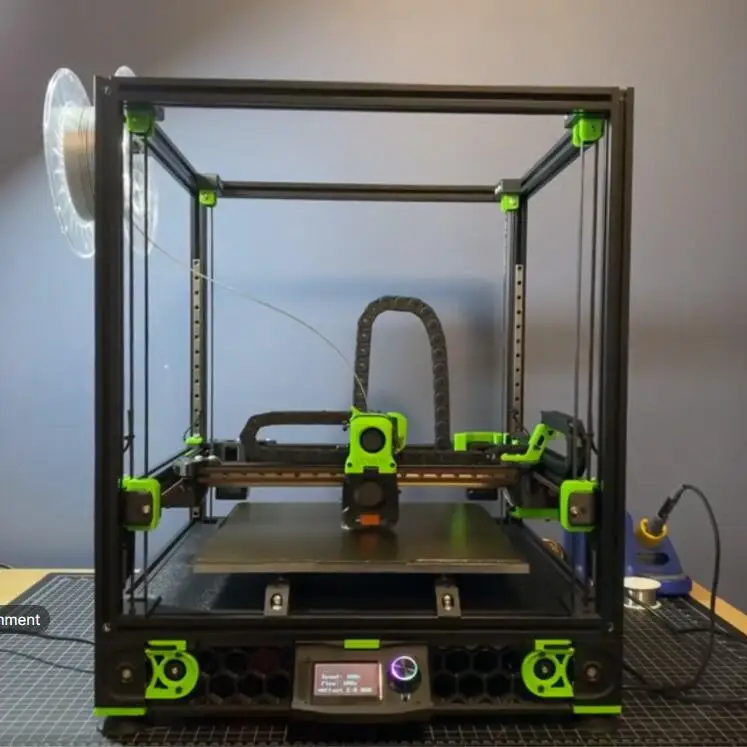

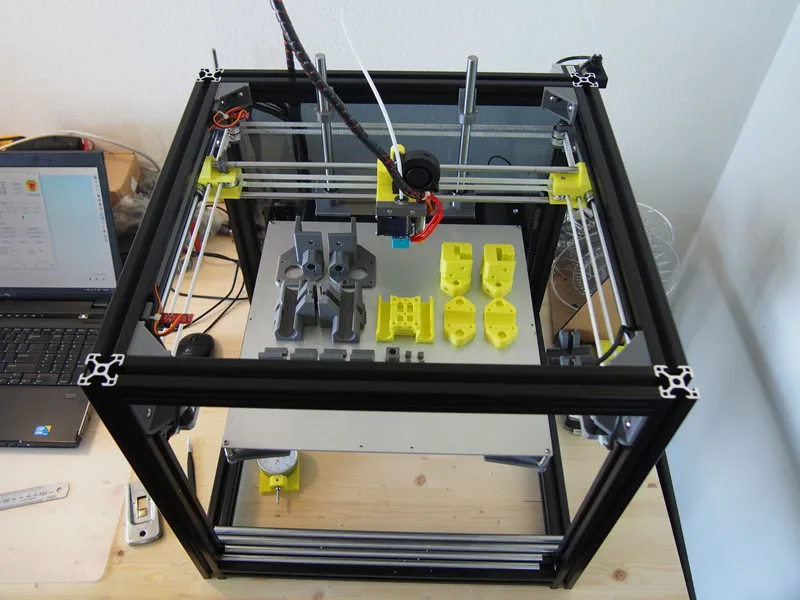

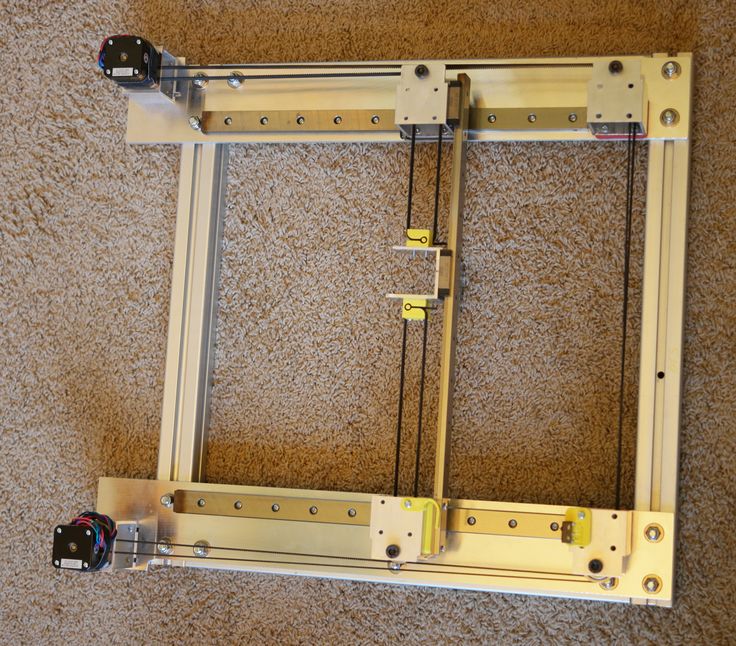

Voron 2.4 R2 CoreXY (Best DIY)

Voron 2.4 R2 CoreXY (Best DIY) 3D Printer Type: FDM | Layer Resolution: 0.025 mm | Materials: PLA, ABS, PETG, etc. | Build Volume: 250 x 250 x 250 mm, 300 x 300 x 300 & 350 x 350 x 350 mm

Like the X5SA, the Voron 2.4 R2 CoreXY is for those who have a DIY-can-do attitude and want the ultimate 3D printing machine.

Be warned, however, that you will have to build your model from scratch. Because of this process, you will spend more on this machine than you would with most others on this list.

Why do I like the Voron?

No Vibrations

One of the issues with CoreXY printers is that the arm moves on the Z-axis. As a result, it can shake and rattle the machine, leading to errors during printing. Because the Voron moves the head on all three axes, that is not an issue.

Durable Components

Voron’s mission statement is to create a 3D printer that doesn’t need constant tweaking or upgrading. Buying and assembling these parts means that you will have a printer built to last.

Buying and assembling these parts means that you will have a printer built to last.

HEPA Filter

As we’ve mentioned, 3D printers can emit semi-toxic fumes. To alleviate this potential hazard, the Voron comes with a HEPA filtration system.

- High-quality parts

- Low noise and vibration

- Customizable build

- Vibrant online support community

- Large print area

- On the expensive-side ~$1200 to build

- Requires expertise to build

Check Latest Price

6.

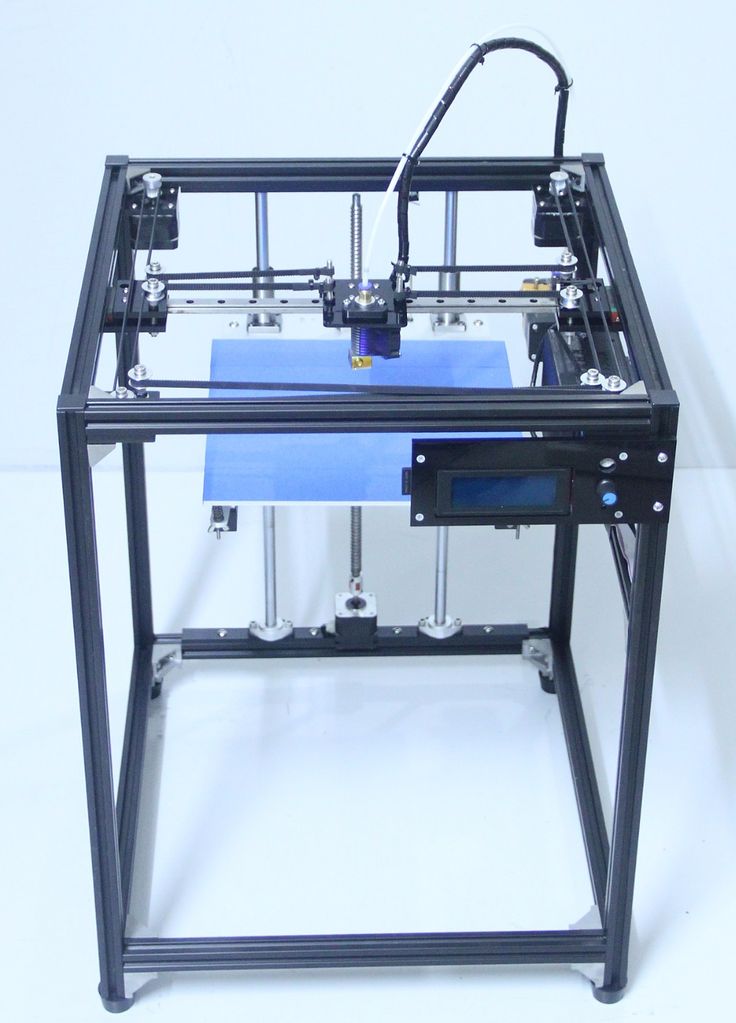

Rat Rig V-Core 3.1

Rat Rig V-Core 3.1 3D Printer Type: FDM | Materials: PLA, ABS & PETG | Build Volume: 200 x 200 x 200, 300 x 300 x 300, 400 x 400 x 400 & 500 x 500 x 500 mm

Those who want to pick and choose what goes into their 3D printer must meet Rat Rig V-Core 3.1. This open-source printer offers the user a fantastic variety of customization, from frame size and print volume to various EVA 3-compatible print heads, controller boards, enclosures, and more.

The print volume ranges from 300 x 300 x 300 mm to 500 x 500 x 500 mm — making V-Core 3.1 the largest printer on this list. The aluminum frame is sturdy and V-Core 3.1 is built like a tank.

Some users experienced reliability issues with certain components on the previous V-Core 3 version, particularly the idlers, but Rat Rig has replaced most of them with new ones. The upgraded machine should let you simply print without worrying about maintenance.

But what if you don’t want to build your own machine? That’s fine — Rat Rig offers packaged options of the V-Core 3.1. Simply pick the build volume you want and you’ll get the same package Rat Rig itself uses at its print farm.

To wrap it all up, Rat Rig V-Core 3.1 is a premium printer and a dream machine for those who want to customize their machine precisely to their needs.

- Amazing variety of customization options

- Large build volume (depending on the frame)

- Active online community

- Good print quality

- Needs a Raspberry Pi, not included in the set

- Customizations can rack up the price

- Not very beginner-friendly

Check Latest Price

7.

SecKit SK-Go³ (Best for Experienced Users)

SecKit SK-Go³ (Best for Experienced Users) 3D Printer Type: FDM | Materials: PLA, ABS, PETG & TPU | Build Volume: 310 x 310 x 350 mm

SecKit SK-Go³ probably shouldn’t be your first printer — even the brand’s name stands for “second kit.” But it’s a fantastic machine to move on to once you’ve learned the ropes of 3D printing.

SK-Go³ has a decent print volume of 310 x 310 x 350mm. It won’t print the largest parts, but the size is adequate. The print bed is also supported by a rigid, sturdy all-metal frame, which gives the machine welcome longevity.

Where SK-Go³ truly shines is in print quality. It prints excellently detailed parts with little to no warping, stringing, or other quality issues. You can get the same high quality with almost any material — if you run into issues, it’ll likely be because of the material’s limitations.

Despite what you might expect, SK-Go³ is surprisingly affordable, particularly when you consider the printing quality. The final price varies somewhat based on the parts you choose, as the manufacturer offers some customization options (mostly a choice between a basic and premium component).

The final price varies somewhat based on the parts you choose, as the manufacturer offers some customization options (mostly a choice between a basic and premium component).

SecKit SK-Go³ brings to the table fantastic print quality and versatility, making it a perfect choice for your second 3D printer.

- Excellent print quality with practically any material

- Good value for the quality

- Small but happy community that the manufacturer actively talks to

- Decent customizability

- Very noisy

- Not for beginners

Check Latest Price

CoreXY 3D Printer Buyer’s Guide

Now that we’ve seen some of the best 3D printer models available, let’s dive into the primary features of a CoreXY machine. Before making a final decision, here is what you need to know.

Before making a final decision, here is what you need to know.

What are CoreXY 3D Printers?

Source: Youtube Thomas SanladererThe name for these printers stems from the fact that the head only moves on the X and Y axes. To create a 3D structure, the base moves along the Z-axis. This design offers some significant benefits, namely speed, and precision.

These machines typically have a square enclosure to allow freedom of movement, and the base has to be able to move freely up and down. Higher-end models will have glass sides to trap fumes and act as a safety barrier.

Another hallmark of a CoreXY printer is that it uses the FDM printing method, which utilizes thermoplastic filament to create structures. Other techniques include stereolithography (SLA), digital light processing (DLP), and selective laser sintering (SLS). Overall, FDM is relatively easy to master and can deliver durable products quickly and reliably.

Source: Youtube David AldrichAdvantages of CoreXY 3D Printers

Here are some primary reasons to purchase a CoreXY 3D printer:

- Speed – Because the printing head doesn’t move in all three axes, it can print faster and smoother than other models.

- Longevity – Another benefit of moving on two axes is that the machine requires fewer parts. These printers are relatively low-maintenance.

- Cost – While you have to pay for more filament, these machines’ upfront costs are far lower than other high-end models.

- Small, Precision Printing – If you aren’t trying to build large objects, CoreXY printers are ideal for smaller pieces. You can also scale down your designs to get more precise details.

Disadvantages of CoreXY 3D Printers

Here are some potential reasons to avoid CoreXY printers.

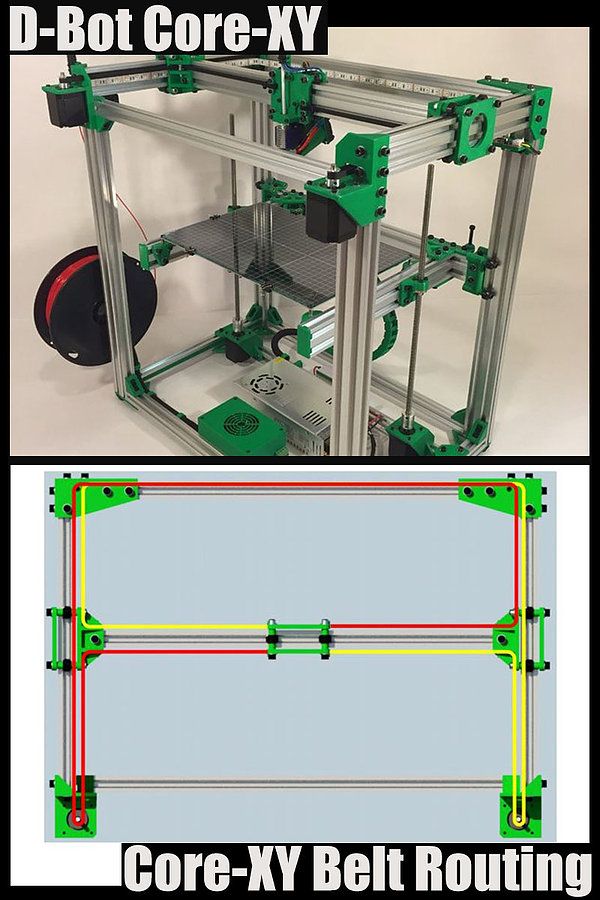

- Belt Maintenance – Although these machines have fewer parts, the ones they do require care and upkeep. If the belts aren’t aligned correctly, they can yield disastrous results.

- Vibrations – Since the pad moves, it can cause the machine to wobble and vibrate slightly. When this happens, you can spot small imperfections in your finished pieces.

- Complex Setup – You can buy pre-assembled CoreXY printers, but they tend to be more expensive.

Building one of these machines requires some know-how, so beginners may not like the process.

Building one of these machines requires some know-how, so beginners may not like the process.

Do These Printers Provide High-Quality Prints?

Although these machines don’t provide as much precision as other models, they can deliver excellent results.

Are These Printers More Expensive Than Other Models or Brands?

On average, CoreXY printers will be in the middle of the pack, but some units are much more affordable.

Is Assembling a CoreXY Printer Difficult?

These printers are harder to assemble than others, such as Cartesian printers. Part of the challenge is getting the belts in the right position.

Are These Printers Easy to Use?

Yes, once they are assembled, you can utilize the touchscreen to create vibrant finished pieces. However, some specific models can be tricky to master, particularly when it comes to leveling.

Final Verdict

We’ve shown many high-quality CoreXY 3D printers on this list, but our top two are the X5SA Pro and the Voron 2. 4 R2. If you want something easy to use and reliable, the X5SA is an excellent choice. It has a substantial build surface, so you can create larger masterpieces than you would be able to on other models. We also like that it has durable parts that will last for a long time.

4 R2. If you want something easy to use and reliable, the X5SA is an excellent choice. It has a substantial build surface, so you can create larger masterpieces than you would be able to on other models. We also like that it has durable parts that will last for a long time.

If this isn’t your first rodeo and you’re more serious about 3D printing, the Voron is unmatched. While it is far pricier than the X5SA, you get what you pay for. We like the customization options of the Voron, as well as the ruggedness of the build.

Related Articles:

- Best 3D Printer for Multiple Colors

- Best 3D Printer for Resin

- Best 3D Printer for Wax

The Top 6 Best CoreXY 3D Printers of 2022

Known for speed and precision, CoreXY 3D printers are some of the most powerful (and affordable) FDM printers.

With FDM 3D printers largely accounting for the multi-billion dollar growth in the 3D printer market, it’s safe to assume that the CoreXY 3D printing system is reaping the benefits of this attention.

But how do they differ from standard FDM builds?

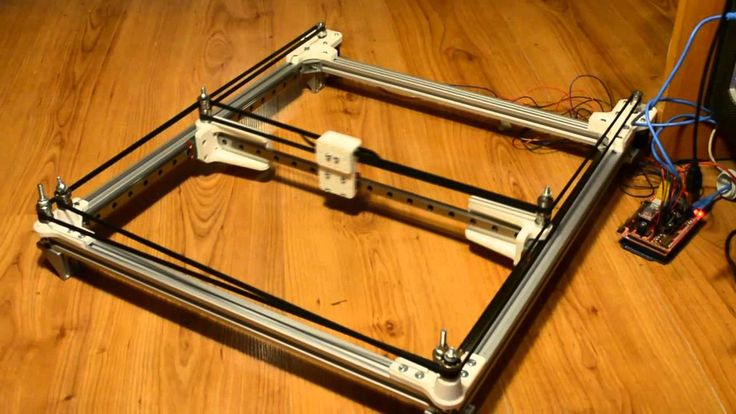

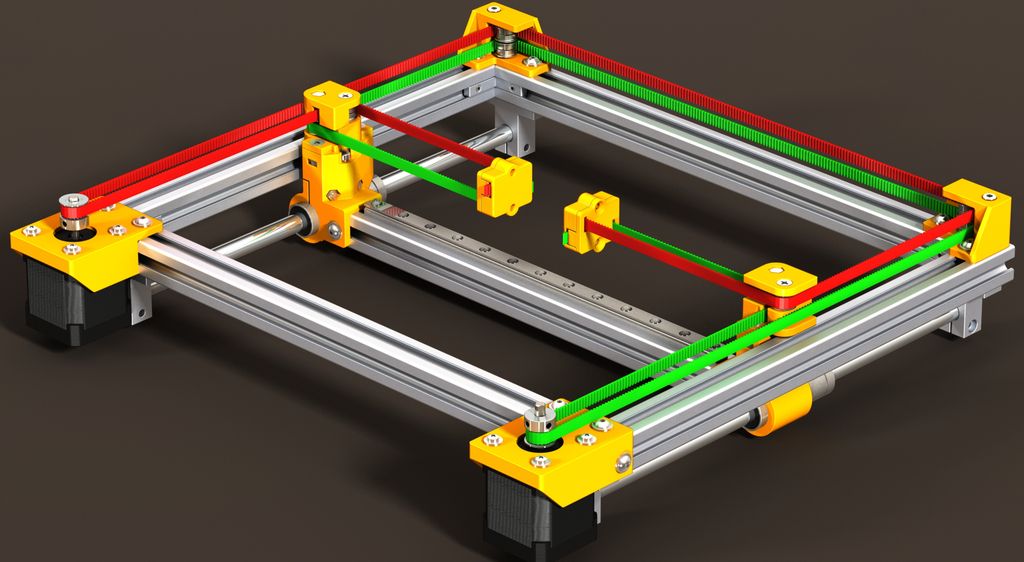

Aside from their speed and precision, CoreXY printers employ an innovative design consisting of belts that control the printer head (and in some cases even printer beds!), giving them productivity-boosting features like a stationary gantry system and motorized X and Y axes.

If you’re ready to take a deep dive into the best CoreXY 3D printer kits, then keep reading as we explore the technology behind CoreXY printers, their advantages, disadvantages, and take a look at the top CoreXY 3D printers on the market and who they work for best!

What is a CoreXY 3D Printer?

If you’re looking to invest in an FDM 3D printer, the most popular style is a Cartesian printer, and it’s within that subset we find the CoreXY system. Now, CoreXY is technically a form of Cartesian 3D printer, but you’ll often find comparisons of the two and that’s because of CoreXY’s unique design.

For more info: read our guide to the 4 main types of FDM printers.

CoreXY is a 3D printing system that was developed by an MIT engineer in 2013. These printers are typically cube-shaped and consist of belts that operate using stepper motors to move the printer head along the X and Y axes. In this case, the printer head is the only object actually moving with any significant speed.

While the printer head moves along the X and Y-axis, the printer bed moves along the Z, and all of these combine to 3D print the model.

This is compared to standard Cartesian printing systems, which are similar as the printer bed moves along the Z-axis, whilst the printer head moves along the X and Y. However, the difference is the printer head is connected to the gantry system, not belts. This means the entire gantry is moving with the printer head, as opposed to just the printer head moving.

With CoreXY 3D printing systems, there’s less opportunity for the gantry system to move. This decreases the chance of excess vibration, which if you’ve ever used a 3D printer before you know too much vibration can lead to side effects like ringing and ghosting. This isn’t to say it never happens, but it’s less likely to.

This isn’t to say it never happens, but it’s less likely to.

Higher-end CoreXY models also often come with enclosures made from a variety of materials like plastics, acrylics, and fiberglass. This helps regulate the temperature when printing your models.

The overall result of this technology is increased space efficiency, speed, stability, and accuracy.

CoreXY 3D Printer Advantages vs Disadvantages

Advantages

- Faster print speeds.

- More affordable than other 3D printers.

- Despite higher speeds, it can still deliver accurate and precise models.

- A vertical moving printer bed means it can deliver the same build volume but in a more compact size.

Disadvantages

- The belt system can be finicky, if the tension is too high or too low it can lead to increased wear and malfunctions.

- If the printer’s frame isn’t assembled and lined up correctly it will lack accuracy, and the frame can shift over time.

The Best CoreXY 3D Printers

Understanding what CoreXY printers are is only half the battle, now it’s time to compare. Ranking from lowest to the highest price, here are our top CoreXY 3D printers.

Ranking from lowest to the highest price, here are our top CoreXY 3D printers.

1. Tronxy X5SA

- Price: $329 –– Available on 3DPrintersBay / Available on Amazon here

- Build volume: 330 x 330 x 400 mm

From the trusted global developers at Tronxy comes the X5SA, which proves to be one of the fairest priced CoreXY printers on the market.

With a build volume almost twice as much as the Sapphire Pro, the X5SA comes with assisted-manual bed leveling, where it helps support manual bed leveling by showing off-level areas. The bed is also 24V powered and produces a nice even heating across the surface.

The printer supports laser engraving, an integrated Y-axis guide rail, a double screw motor on the Z-axis, open-source Malin Firmware, and uses the same Bowden extruder as above.

What gives the X5SA its popularity is its customization. You may not get much use out of it on its own, but it’s become a favorite amongst printers who enjoy being able to customize their printer with out-of-the-box modifications, like the coated glass bed. On Tronxy’s site, you can even find an X5SA upgrade kit.

On Tronxy’s site, you can even find an X5SA upgrade kit.

Beginners may find setting up and upgrading this printer daunting, as it’s not the easiest, but experienced hobbyists and professionals will love the price and modification support this printer holds.

2. Two Trees Sapphire Pro: Best Affordable CoreXY 3D Printer Kit

- Price: $299.99 –– Available on Two Trees Store here / Available on 3DPrintersBay

- Build volume: 235 x 235 x 235 mm

Founded in 2017, Two Trees set out to fill the gap in the market to deliver performance, affordability, and user-friendly assembly all in one printer, and that message still rings true today with the Sapphire Pro.

The Sapphire Pro boasts a number of high-end features for minimal costs, like automatic bed leveling and precision linear rails for the X and Y axes, which help reduce wear over time and create smooth applications.

That’s not all that keeps this printer in the limelight.

It also has a smart power failure detector, so it stops and picks up right where you left off in case of outages, twin turbofans for fast setting of the printed model, a dual-drive Bowden extruder, and a Makerbase MKS 32-bit Robin Nano control board. The printer comes easy to set up and ready to print. You may have to finagle a few settings to achieve the desired effect, but overall, it’s a solid printer for a solid cost.

While this printer is an excellent choice for every user (and every wallet), we really believe this to be the industry standard entry-level CoreXY printer, and perfect for anyone looking to break into the community.

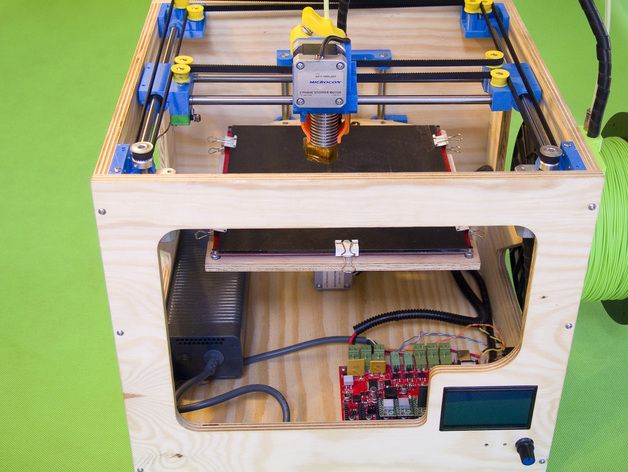

3. Creality Ender 6: Best CoreXY 3D Printer for the Price

- Price: $550 –– Available at Creality’s Official store here / Available on 3DPrintersBay / Available on Amazon here

- Build volume: 250 x 250 x 400 mm

Dubbed the “3D printing industry evangelist”, Creality aims to bring the convenience of technology to everyone, and their midrange Ender 6 3D printer does the job nicely.

Nestled between the Ender-5 Pro and the CR-10 series, this semi-enclosed printer promises to be the fastest and most intelligent one of the series yet. With removable enclosures, as well as an optional top plate for full enclosure, this printer lets you stabilize temperature-sensitive filaments more efficiently.

It has a print speed of up to 150mm/s, and uses the Carborundum glass platform, with similar properties to Anycubic’s Ultrabase platform, giving you ultra-smooth layers.

The Ender- 6 comes with a custom-built, imported, ultra-silent TMC motion controller from Germany, and the TMC-2208 motherboard ensures tranquil silent movement. It also comes with a large 4.3-inch color touchscreen. Although it is manual bed leveling, you can accessorize it with an automatic bed leveling probe for assistance.

The large community surrounding Creality also comes in handy, creating powerful mods as well as offering amazing support. Partnered with the online tutorials and detailed guide, you’ll have this printer assembled in no time.

All in all, the Ender 6 is one of the best technological upgrades for mid-range printers and is best for those looking for optimized speeds at a bargain.

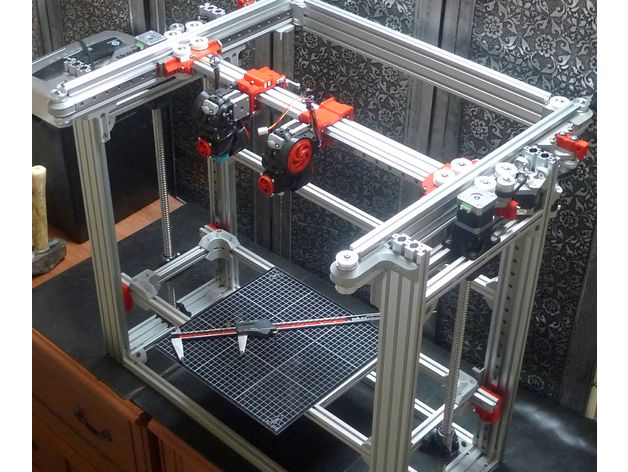

4. Voron 2.4: Best CoreXY 3D Printer for DIY

- Price: $879.00 –– Available on 3DPrintersBay

- Build volume: 250 x 250 x 250, 300 x 300 x 300, and 350 x 350 x 350 mm

Made by engineers for true home micro-manufacturing, Voron started back in 2015 under the belief that a 3D printer should be uncompromised, fun to assemble, and a joy to use.

And that brings us to today with the Voron 2.4.

This is a nice entry-level printer into the high-end spectrum that boasts a plethora of possibilities. Not only is it pleasing to look at, but it offers unique features like opting for a stationary bed and linear rails on all three axes to help cut down on vibrations.

The engineers were serious when they said a printer should be fun to assemble, taking DIY CoreXY 3D printers to the next level. In this almost meta process, you’ll need a 3D printer to build this fully open-sourced DIY printer.

In this almost meta process, you’ll need a 3D printer to build this fully open-sourced DIY printer.

The company website has fantastic schematics, so you know exactly what you need, but to get this printer you’ll have to embark on a search for all the parts. However, it does have a zealous community eager to welcome newcomers and help them get started sourcing and building the parts for this printer. The website also has materials itself, like the Bowden drive and printer bed, or you can order bundle kits from third-party sellers at your own risk.

If you go for the kit, each size comes including a 32-bit BTT Octopus mainboard, a Raspberry Pi controller to run Octoprint, a heated chamber, as well as most necessities for the printer.

This printer is definitely an experience, and not for the light-hearted, but if you’re up to the task, you’ll find immense joy in this community and the process of building the Voron 2.4 that’s as unique as your own fingerprints.

5. Creality CR-30 (3DPrintMill)

- Price: ~$1,050.

00 — Available on Amazon here

00 — Available on Amazon here - Build volume: 200 x 170 x ∞ mm

Another Creality special on this list and it’s the slightly more exuberant model, the CR-30.

What first catches your attention about this printer is not only its sleekness but its obvious revolutionary design. While most CoreXY printers are cubic, the CR-30 is triangular with an infinite Z-axis.

The printer bed runs like a treadmill, or a rolling conveyor belt, which promises to increase productivity, cost-efficiency, and save time. There’s even an extension bracket you can add on for printing extra-long models. It has a Nylon-based heated bed that’s easy to replace and has excellent adhesion.

To combat logistical setbacks, its printer head sits at a 45-degree angle. While they keep certain specs under wraps, from what we can tell, the printer comes with an ultra-silent motherboard and silent chip, which seems reminiscent of the Ender 6 specs. Its infinite Z-axis has the capability to make this printer a manufacturing powerhouse, and don’t worry, the revolving belt comes already leveled.

Overall, we recommend this printer for users looking to boost productivity and take advantage of the extra-long printing capability for models.

6. Vivedino Troodon

- Price: $1,574.00 –– Available on 3DPrintersbay here

- Build volume: 300 x 300 x 400 and 400 x 400 x 500 mm

The last price on this list may be jarring, but it’s not without merit.

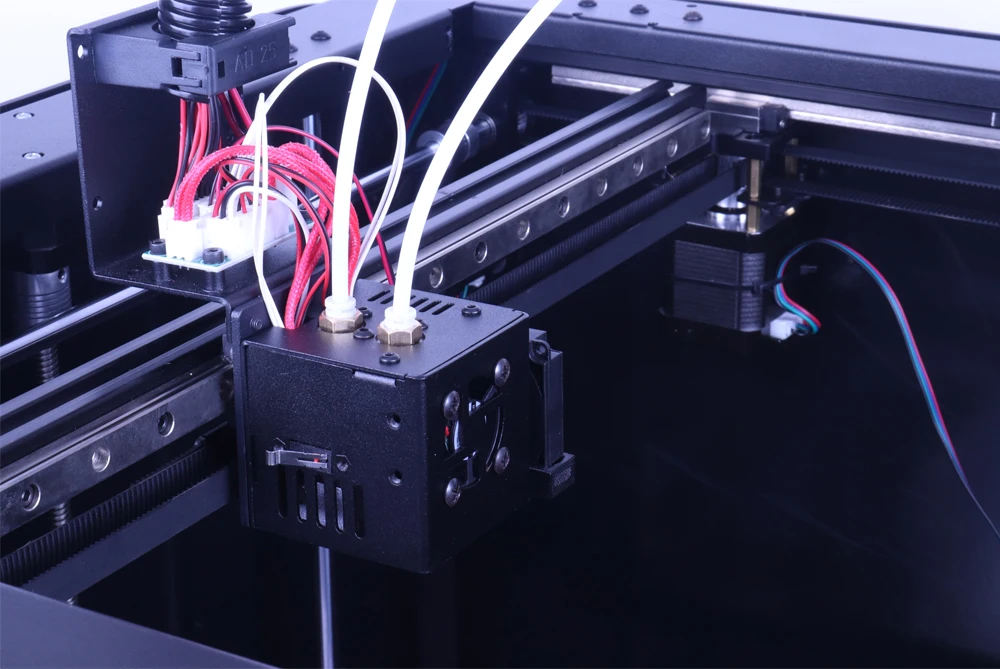

Coming in 2 sizes, this open-source printer comes with all the fixings of a seamless 3D printing experience. A wireless-capable 32-bit board, auto bed and gantry leveling, dual-gear extruder, linear guides, and silent stepper motors are just a few of the features that make the Troodon worth the price.

With a hot end and heated bed reaching 275 degrees and 150 degrees respectively along with its enclosed build area, you can manage temperature-sensitive filaments with ease. Striking inspiration from the Voron, it too uses a belt on the Z-axis to decrease wobbling.

Unlike the others on this list, it comes completely assembled, ready to print out-of-the-box. And while it supports modification, it creates amazing prints as is. Vivedino’s Troodon printer is for those willing to spend a little extra for massive convenience.

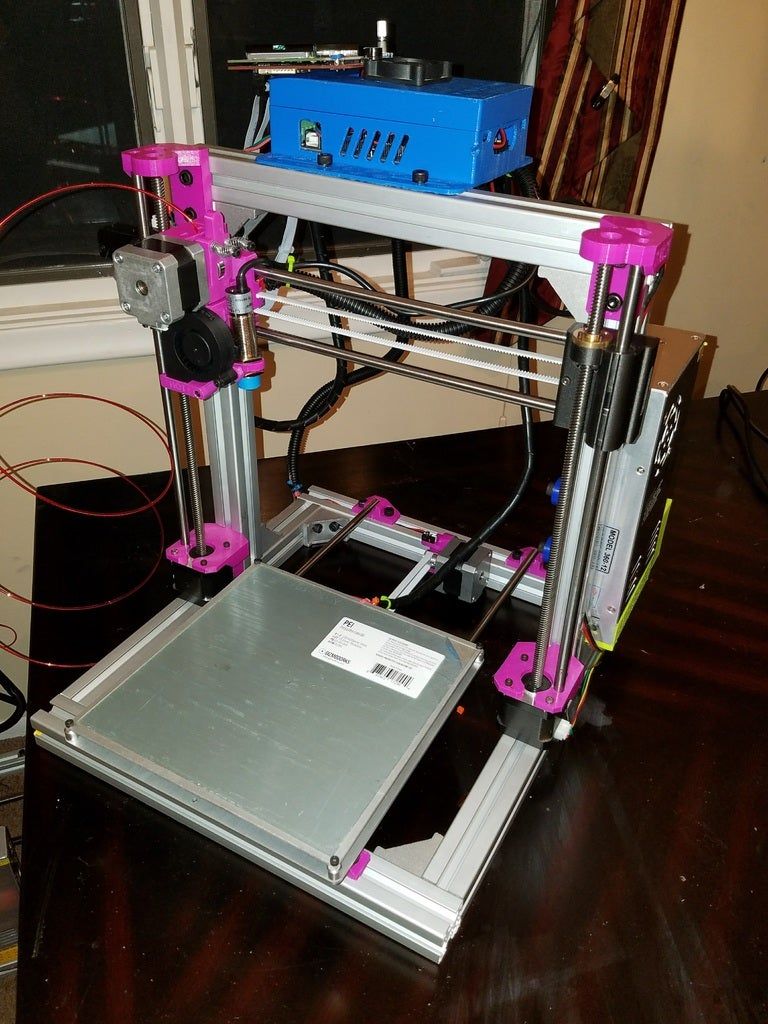

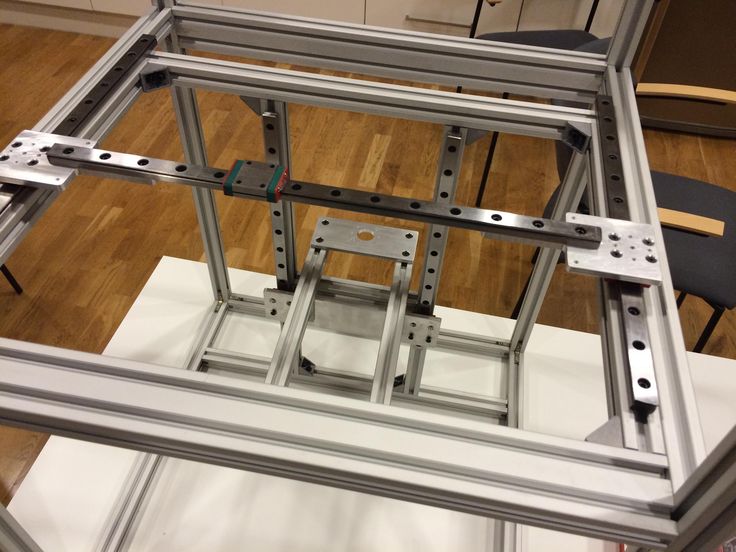

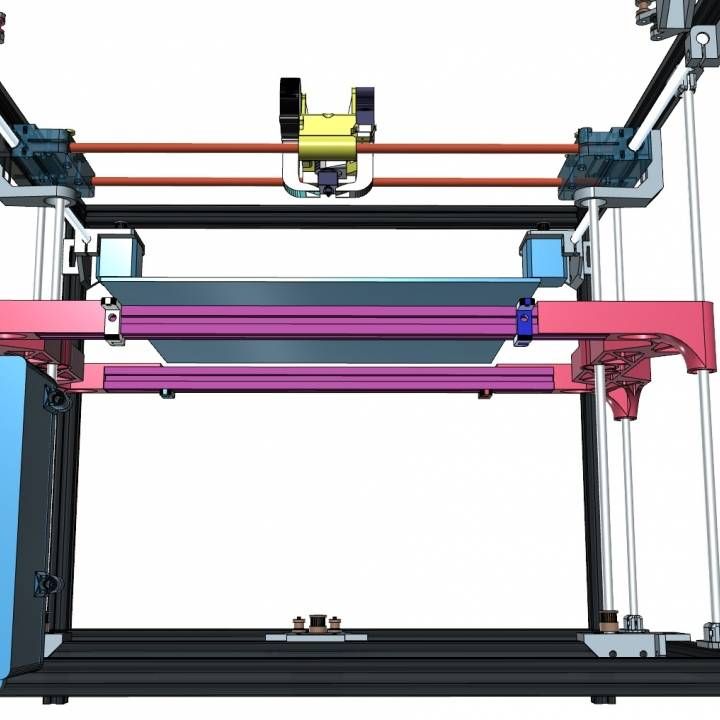

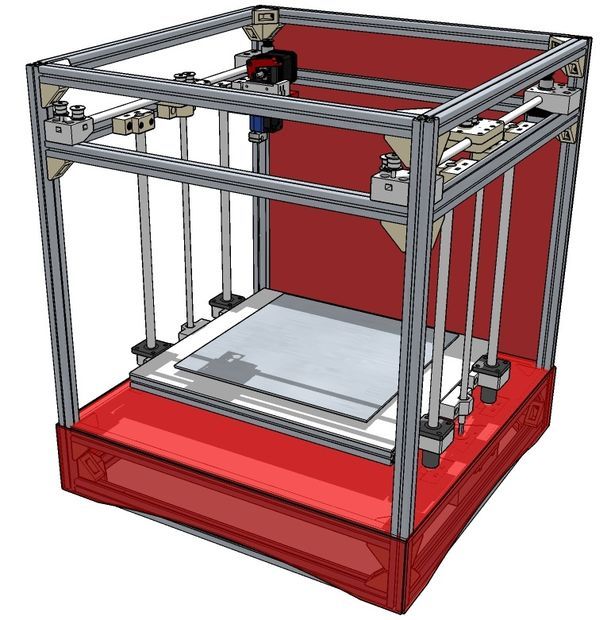

DIY 3D Printer Core XY 310*310 mm

Hi Everyone.

As you know, there are unfortunately no perfect printers in China.

Prush-like drygosts are cheap, but slow at the same time.

Core XY - more interesting, but low-quality components are also used.

Therefore, I decided to assemble my own printer and immediately say is not for sale.

I just wanted to prove to myself that even a humanist is able to develop and assemble a good enough apparatus.

And he started his journey with the purchase of quality components:

In the Autodesk Inventor program, he developed his version of the printer completely from scratch.

And then he used the services of a company for cutting machine profiles.

With the help of corners 2040, I fastened the profiles together and, by the way, very reliably and evenly

Next I decided to assemble the table on profiles and corners, but in the end I will abandon this idea in favor of the finished version.

I installed the sfu1204 ballscrew and the table itself on 12mm linear shafts with flange bearings, while the motor uses two 48x, which will eventually be synchronized with each other.

I abandoned the idea with profiles on the table in favor of the usual corners 2040, they turned out to be more convenient for installing the table and at the same time quite rigid due to the rib

This decision fully justified itself.

The motors along the z axis were mounted on aluminum plates 40mm wide and 8mm thick, and the shafts were fixed with shf clamps

The design turned out to be very successful and RELIABLE.

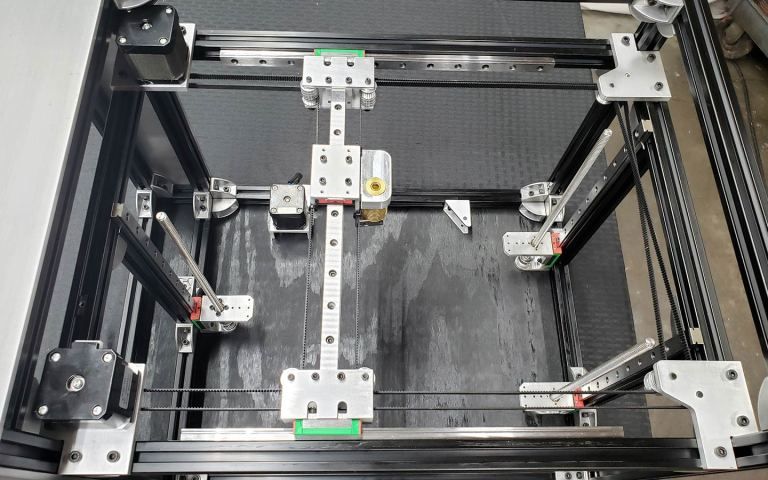

Moving on to the installation of Kinematics

From aluminum strips 40mm wide and 8mm thick, I cut out holders for motors of the XY axes, as well as holders for carriages and pulleys.

As a result, I had to drill, saw, cut, plan, grind and all this on the BALCONY of the apartment, which is not very good, so in the future I will leave this process in favor of the finished version

After all the manipulations and assembly, I measured the weight of the portal without the hot end, which was 650 grams, which is not much.

Then proceeded to installation on the frame

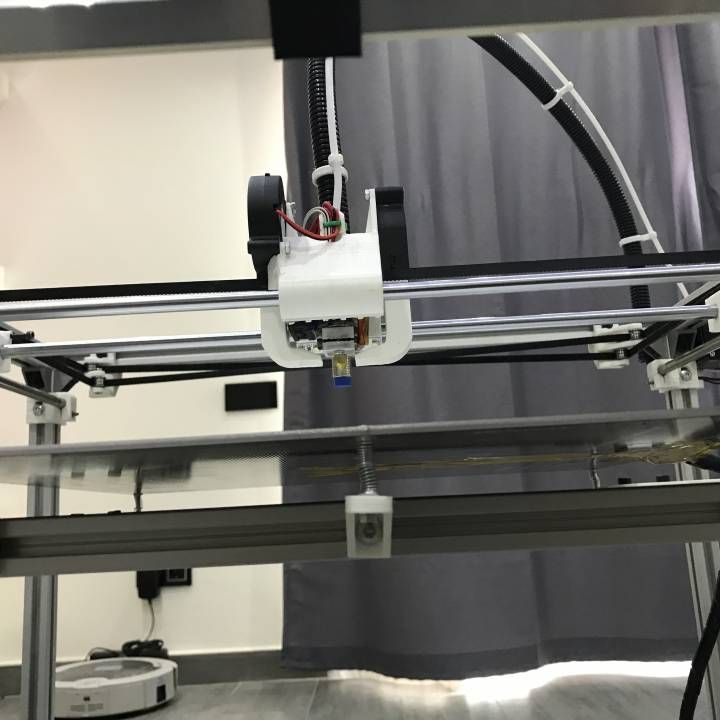

On the same corners of 2040, installed Mosquito hotend with airflow

Now it remains to connect the electronics, since I have two motors along the z axis, I decided to connect them Consistently:

I decided to test 8 liter bottle of water

Test passed without any problems

To control printers, I used an SKR1.3 motherboard with TMC2208 drivers and a TFT V2.0 screen, and this system will be powered by two Minvil 15 amp-24v power supplies.

One PSU is used for motherboard, hot end, fans and lighting.

And the second power supply through the mosfet supplies voltage to the heating table 310 * 310 for 24 volts0003

Initially I installed a Bowden system with a BMG feeder, but then I will replace it with a direct

I launched a test bench boat and I liked everything

I tested it with a Battle, with a speed of 120 mm / s, jerky 20, acceleration of 3000 mm / s2

3

I added a little more

I was satisfied with the print quality at different speeds, but at the maximum the airflow with the PLA could not cope anymore

EVEN COMPARED WITH THE ENDER))

On this it would be possible to complete the project, but as it turned out. Many viewers do not have the ability to saw and drill on their balcony, and this assembly option is completely unsuitable for the majority.

Many viewers do not have the ability to saw and drill on their balcony, and this assembly option is completely unsuitable for the majority.

I decided to meet my viewers and subscribers of my YouTube channel ChuchaTV and designed Samosbor ALL INCLUSIVE, which does not require the use of improvised materials and special tools.

In other words, a full-fledged Kit Kit, like from China, but with high-quality components.

I prepared a package with a file for laser cutting, bending, painting and engraving and found companies that did all these operations for me.

Mounting axle carriages and motors made of 4mm steel with subsequent painting

Table and x-axis carriage made of the same metal but 2mm thick Body sheathed with 1 mm sheet with subsequent flexible, painting and engraving

9002 All holes and the cutouts fit just perfect during assembly, I did not regret the money spent on laser cutting.

The table frame turned out to be ideal both in geometry and in strength and rigidity

Direct weight with MGN carriage 12 amounted to 350 grams

Having figured out the mechanics, I decided to install all the panels and corresponding elements

on the sides of two fans of 80mm, since more in size in size. won't get in. On the one hand there is blowing in, and on the other hand blowing out, for ventilation of the block with electronics

won't get in. On the one hand there is blowing in, and on the other hand blowing out, for ventilation of the block with electronics

I put two filament holders inside

From 5mm acrylic, I cut out the door and the lid exactly to size, and on the self-assembly I printed the curtains and the handle itself a small test of print quality and the result was satisfied

The printer turned out to be very nice)) and practical

Project cost $800, although I bought most of the parts on sale days in China.

I am very pleased with the build quality and operation of the printer, but most importantly, I was able to do it without outside help, despite criticism and negativity addressed to me.

A small guide for choosing a 3D printer for beginners / Sudo Null IT News0186 ”, at the end of which the author asks to answer a few questions. I will try to answer from the point of view of my seven years of experience as a 3D modeler and 3D printer.

First, a few caveats.

First, a few caveats. In this article there will be no advice: “Buy a printer from manufacturer X - it is good, but do not take manufacturer Y in any case”, only general recommendations.

Informal classification of printers, adopted in the domestic segment of printers.

Everything written is based on the personal experience of the author and is his personal opinion.

If these warnings do not scare you - welcome under cat.

First, let me introduce myself: my name is Maxim and I bought the first printer back in 2013. It was a Chinese clone of Makerbot 2 with the hilarious name "Migce Cuble".

Photo from the personal archive There was almost no information on 3D printing on RuNet, only one topic on the “Roboforum” and several scattered articles about what a cool thing it is - 3D printing, so to master it I had to google a lot in English, come up with their crutches and delve deeply into the physics and technology of the printer. We must pay tribute, in the English-speaking segment, then there was an active development of this technology and interesting articles such as “Selection of the type of notches of the extruder feed gear for a specific type of plastic” or “Determination of the optimal printing temperature using a strain gauge installed on the extruder” came across. Since then, 7 years have passed. I managed to master modeling, assemble a printer from scratch, be a moderator of “3D Today” for a while, work as a freelancer in the field of modeling and printing, organize a prototyping circle for children and bring it to the Russian level. Recent achievements: volunteered as a coordinator for the supply of plastic in the project “ Anti covid makers ”. A lot has changed during this time, including printers in my home zoo. One thing has remained unchanged - the question: "What should I buy as my first printer?".

Since then, 7 years have passed. I managed to master modeling, assemble a printer from scratch, be a moderator of “3D Today” for a while, work as a freelancer in the field of modeling and printing, organize a prototyping circle for children and bring it to the Russian level. Recent achievements: volunteered as a coordinator for the supply of plastic in the project “ Anti covid makers ”. A lot has changed during this time, including printers in my home zoo. One thing has remained unchanged - the question: "What should I buy as my first printer?".

Currently, two types of printers are mainly used at home: printing using FDM (FFF) technology - layer-by-layer plastic fusing, which is fed in the form of a rod and SLA (LCD) - printing with a photo-curing polymer. FDM technology is more common, due to the lower cost of equipment and consumables, but in recent years, the prices of LCD printers and printing resins have decreased significantly and photopolymer printing has almost caught up with FDM printing in terms of cost and entry level.

To be honest, I almost never did SLA printing and I still don’t have an LCD printer in my home zoo (but it may appear soon), so I will mainly talk about FDM printers. They can be divided into 3 main categories according to the type of mechanics:

Drygostables - printers with a table movable horizontally. Perhaps the most common printer model. It is distinguished by low cost of components, ease of assembly and adjustment, for which it is loved by the Chinese and printers. The disadvantages include the difficulty of creating a closed body and printing thin, tall parts that begin to wobble as the height increases, especially if the part is printed from flexible plastic such as TPU.

Typical drygosts Cubes - printers in which the table travels vertically. The cost of such printers is higher, as are the requirements for straightness of hands during assembly and setup. But a properly designed die delivers faster print speeds while maintaining print quality. At the same time, the design of the printer is very easy to make closed, which allows printing with engineering plastics such as ABS and Nylon. This type of design is often used in semi-industrial and industrial grade printers. Some manufacturers manage to shove the drygost into the body of the cube, but this does not bring any special advantages for printers.

At the same time, the design of the printer is very easy to make closed, which allows printing with engineering plastics such as ABS and Nylon. This type of design is often used in semi-industrial and industrial grade printers. Some manufacturers manage to shove the drygost into the body of the cube, but this does not bring any special advantages for printers.

Delta - printers with the so-called delta kinematics, when the print head is attached to carriages moving along vertical guides using a system of rods. The cost of the mechanics of such printers is comparable to the cost of dry-tables. Can print at very high speeds. But they are very demanding on the correctness of keeping the dimensions, the straightness of the hands during assembly and adjustment, and the speed of the “brains” due to the complex mathematical calculations of the trajectory of the head movement.

Strongly not recommended as a first printer, although the widespread use of the table level sensor somewhat reduces the requirements for straight hands during setup and operation.

By availability on the market, 3 main categories can also be distinguished:

Chinese (cheap Chinese printers) are almost always designers, even if they come assembled.

-

The advantages include low cost, wide distribution and uniformity, which allows you to buy failed parts in the nearest radio shop or on well-known Chinese sites. Popular models gather around a relatively large number of users who actively share their experience in the field of self-repair and improvement of this type of printer. The most popular models will most likely be printed right out of the box, but will require improvements during more or less long-term operation.

-

The negatives include the quality of the components / assembly and the need to refine these printers to obtain acceptable print quality / speed. It is recommended to take models that have already formed a large community around them. This means that most of the shortcomings have already been identified and there are standard inexpensive methods to solve them.

Kits (assembly kits, mainly domestic production) - google for the words “ ZAV ”, “ UlTi ”, “ UlTi ”, etc. Usually they are a set for assembling a plywood cube. Recently, options with metal cases have appeared. Supplied in different versions - from a kit for building a case with printed parts, ending with completely finished assembled products.

-

The pluses include a fairly good engineering study, the ability to choose the components for the mechanical and electronic parts and make the printer completely to your requirements. With good components, they provide fast, stable and high-quality printing. The price is somewhat more expensive than Chinese printers, but cheaper than semi-professional printers of domestic or European / American manufacturers.

-

The disadvantages include a decent amount of time spent on assembly and waiting for components if you decide to save money and order these components yourself from different sellers and assemble a printer from them.

When assembling, direct hands are required.

When assembling, direct hands are required.

factory printers (domestic or US/European semi-professional printers). There are a lot of models, the designs are very different.

-

The advantage of this class of printers is printing with acceptable quality out of the box. In addition, you get operational reliability and warranty support from the manufacturer.

-

The main disadvantage is the price. It is often not clear what factors it depends on. You can buy a high-quality printer relatively inexpensively, or you can take something incomprehensible for a high price. The second disadvantage is the presence of specific solutions that are incompatible with popular solutions on the market: these can be nozzles with their own thread pitch, special fans, electronics, belts, and even slicers. Some are demanding on the quality of plastic, there are models that work only on chipped coils.

Now that we have decided on the classification of printers, we can proceed to the procedure for choosing a printer for ourselves, our beloved. If you are on fire with the purchase of a 3D printer, first decide what you are going to take it for, the type and configuration of the printer depends on it. Let's analyze a few typical situations:

If you are on fire with the purchase of a 3D printer, first decide what you are going to take it for, the type and configuration of the printer depends on it. Let's analyze a few typical situations:

I want to do something for myself and my family - if you don't plan to print products from engineering plastics that can withstand decent loads and temperatures, a Chinese drygostol or a cube will suffice. If you have a budget and want to figure out how the printer works before starting, and not during printing, you can look in the direction of domestic assembly kits - with them you can get the best quality and painlessly switch to engineering plastics.

I can't do anything with my hands, but I have to. Therefore, I want a printer that will do everything for me - in this case it is better to look at semi-professional printers. If the budget is not enough, you can look at used ones or order an assembly of a domestic set - usually manufacturers offer this service through intermediaries. When ordering an assembly - look for experience and positive reviews, there are nuances.

When ordering an assembly - look for experience and positive reviews, there are nuances.

I want to print for sale - a farm of the same type of printers, depending on the budget. If there is no budget, but there are resources for regular tuning / repair - you can even from Chinese drygosts. Additionally - a printer with a large print area, a printer with a closed case and a heated table for printing engineering plastics, an SLA / LCD printer for printing products with a high degree of detail.

Whether at work or at home, the need arises to design and print enclosures and parts. If only small prototypes are planned - an LCD printer, if functional products - a closed cube with the ability to print with engineering plastics.

Kids are growing up and this is the technology of the future, I want you to master - see which printers are used in prototyping competitions in your area. Take the same one. May be used.

I want to make figurines for desktops, beautiful little things for home - LCD printer.

I want to figure out what kind of technology and how it works in general - a kit for assembling a domestic manufacturer. By the time you collect it, you will understand.

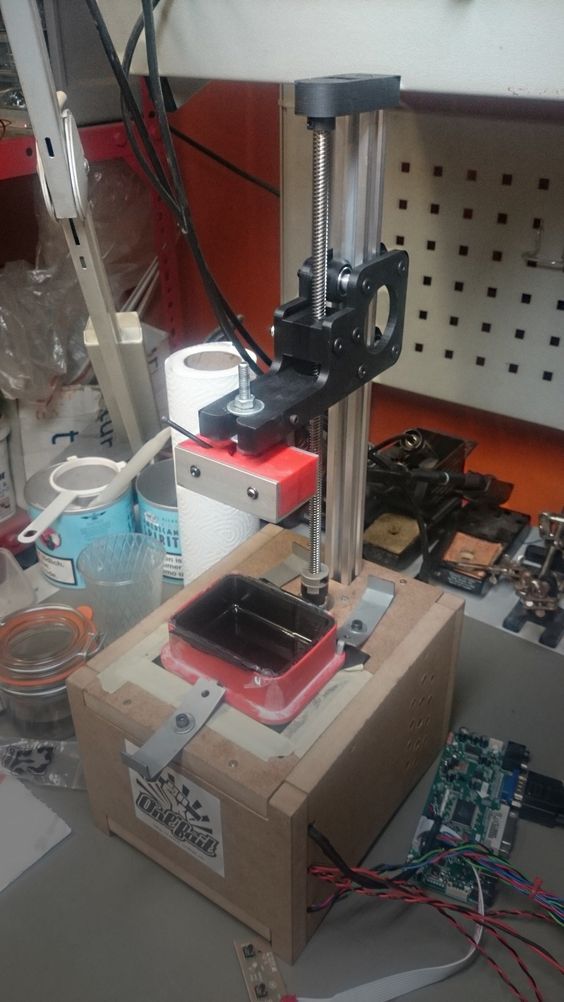

There is no money at all, but I want to print, I will collect from scratch myself - it will turn out better and cheaper than the Chinese. Strange as it may seem, no. The cost of components with Ali will be more expensive than a printer with Ali. Of course, if there is a machine park, the ability to use it, a set of iron, shafts and electronics lying around in the corner of the workshop, it can burn out. There are options for building printers from boards and furniture rails, but their print quality is, to put it mildly, lame. For example, the construction of the printer shown below cost its author 80-9, according to him.0 dollars.

If you want to completely build your printer from scratch, then it's better to treat this as a separate hobby and accept that it will not turn out very cheap. Well, or look in the direction of used printers.

Well, or look in the direction of used printers.

I don’t know why I need a printer, but I want to try - a Chinese or a domestic assembly kit. Can be used. If it doesn't work, you can always resell.

Decided on the type of printer - what to look for first of all when buying ?

-

First of all - on the rigidity of the structure - the accuracy and speed of printing depend on it. It is in the direction of strengthening the rigidity that your first modifications of the Chinese printer will be directed, since the material “steel plasticine 3 (c)” is considered an unaffordable luxury for the Chinese. In the case of the purchase of domestic kits, the situation is slightly better.

-

Secondly - if the printer will be in the apartment - "silent" drivers for stepper motors. 3D printing is not a fast process, and having a constant loud enough buzzer under your ear is annoying.

-

Third - the presence of a heated table and ease of modification to a closed case.

Over time, the desire (need) to print ABS will come, and it is problematic to do this on an open drygost.

Over time, the desire (need) to print ABS will come, and it is problematic to do this on an open drygost. -

Fourthly, the presence of a good plastic blowing system is also important.

-

Fifthly, when choosing printers with CoreXY, H-Bot or Delta mechanics, it is highly desirable to have a 32-bit control board, or you will encounter fading (freezes) at high print speeds.

-

In the sixth, seventh, etc. - there are many nuances in the design of printers. If something is unclear, feel free to ask the community.

In any case, if you are going to buy or have already bought a 3D printer, start learning some 3D editor. The easiest, in my opinion - https://www.tinkercad.com . You can simulate a washer in it or the well-known plate changer without much effort.

Over time, its capabilities will no longer be enough - then you can switch to more serious CAD systems. In my opinion, a printer should own two types of editors - a solid state for modeling technical products (CAD) and a polygonal tool (Blender, etc.