How can i make money with 3d printing

How To Make Money With 3D Printing In 2022

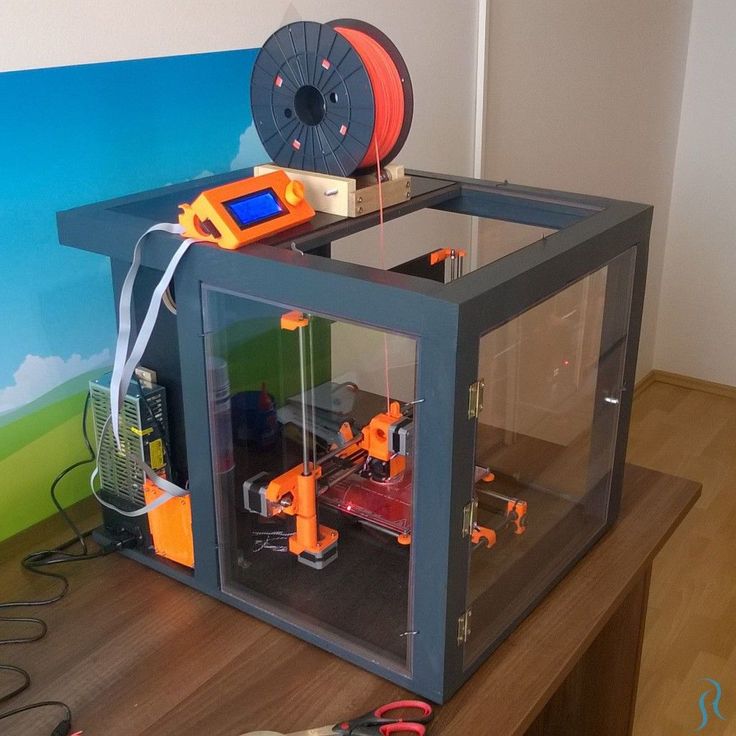

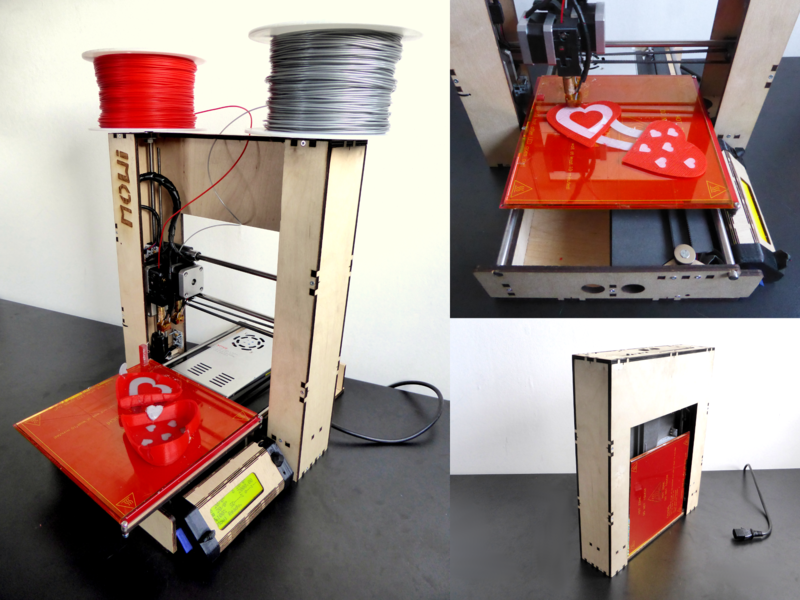

Above: The build size of the 3D printer will determine the size of the print/Source: Manufactur3DDid you know that to make money with 3D printing in 2022 you don’t need to pursue it full-time, instead it can also be a side hustle while you pursue other earning opportunities.

In one of our previous articles, we discussed the various 3D printing business opportunities you can pursue. However, these were full-time businesses, and the level of expertise, investment, time, and effort required for those ideas was prohibitively high.

We understand that not everyone wants to run a full-time 3D printing business, and you may be looking for side hustle opportunities. Side hustles are ideal for students, stay-at-home moms, working professionals, and even small businesses looking to add a new revenue stream.

So, in this article, we focus solely on side hustle ideas that help you make money with 3D printing.

Contents

- 1 Can you really make money with a 3D Printer?

- 2 Guide on how to make money with 3D printing in 2022

- 2.1 Sell Educational Models to Schools

- 2.2 3D Printer Reviewer

- 2.3 3D Printing YouTube Channel

- 2.4 Invest in 3D Printing Stocks

- 2.5 Consultancy

- 2.6 3D Scanning

- 2.7 Rent out your 3D printer or 3D Pen

- 2.8 Sell digital 3D models

- 2.9 Sell Personalised Products

- 3 How to Get Started?

- 4 Full-time Business Ideas

Can you really make money with a 3D Printer?

The straightforward answer is Yes! You can undoubtedly make money with a 3D printer or operating in the 3D printing industry in 2022.

How much money you ask? Well, that will depend on your level of knowledge and expertise in technology, as well as how much time you devote to this side hustle.

You can check out our list of some popular and some yet-to-be-popular ideas to make money and decide which one suits your routine.

Guide on how to make money with 3D printing in 2022

Sell Educational Models to Schools

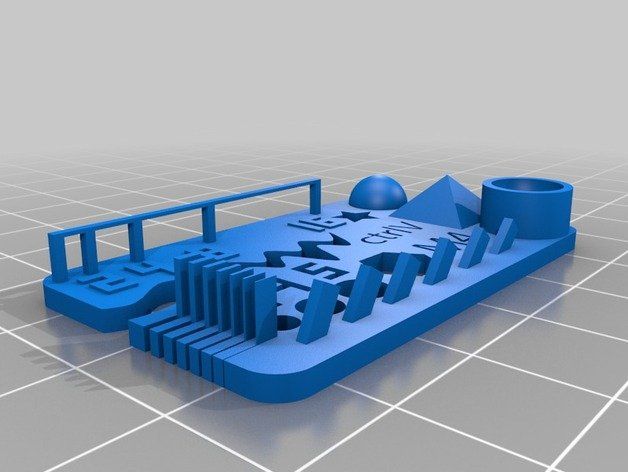

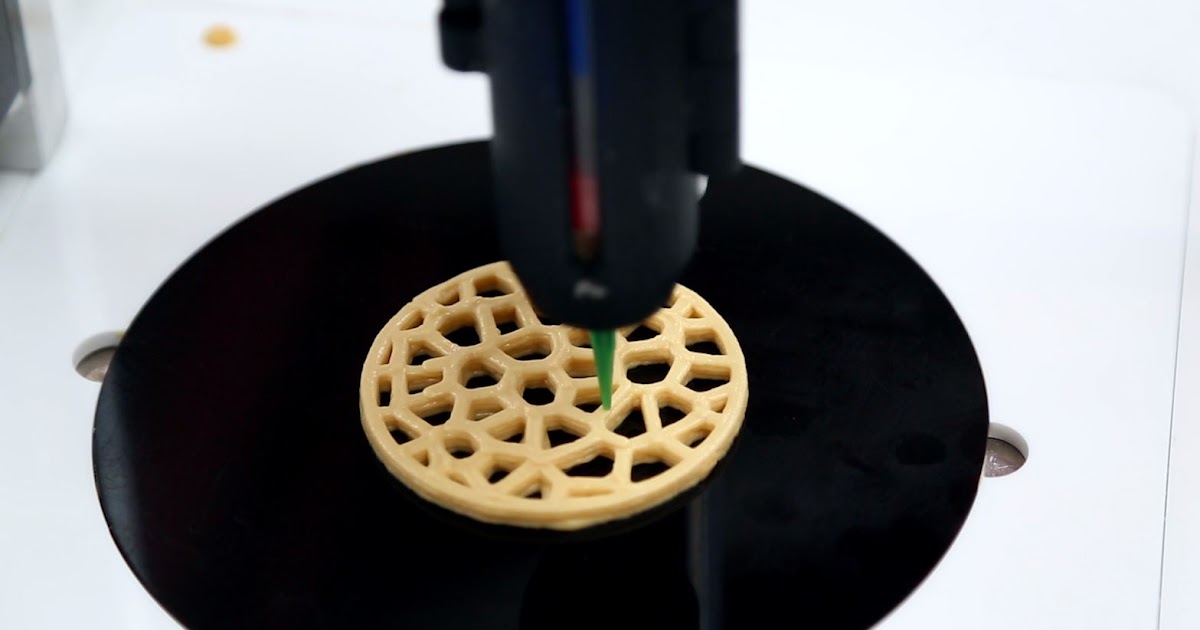

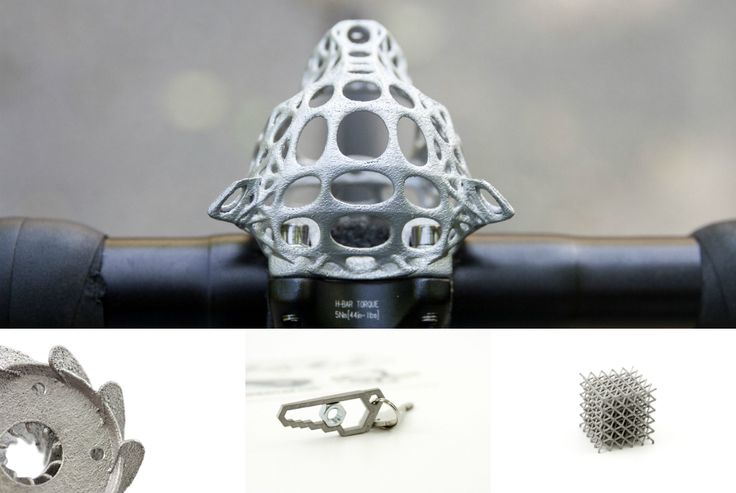

Above: 3D printed educational models/Source: ZMorphOne of the best ways to make money with 3D printing in 2022 is to sell educational models to schools. It is now widely accepted that 3D printing is an excellent learning tool that is widely used in STEM education. But not all schools have the funds to purchase 3D printers, or have trained educators who can teach 3D printing to students. Instead of selling them 3D printers – which already most businesses are pursuing – you can persuade schools to purchase educational models.

All schools use standard medical or science models to teach students, and these are mostly outdated and even loosely mended together to keep from breaking apart. So, replacing their existing models and more interestingly, offering them new and unique 3D printed models to enhance the students’ understanding of concepts, ideas and topics, is significantly interesting to schools.

You will have to develop conceptual models and either design them yourself or get them designed and 3D printed. Once you have the sample models, you just need to go on a selling spree. If you secure an order, get them manufactured on-demand and deliver it to the school.

You can create 3D printed models of all human body bones, conceptual models to explain science, math, geography, history, and literally any subject that can be explained substantially well with models. Focus on developing products that not only help students but can also reduce the effort of educators to teach those concepts.

3D Printer Reviewer

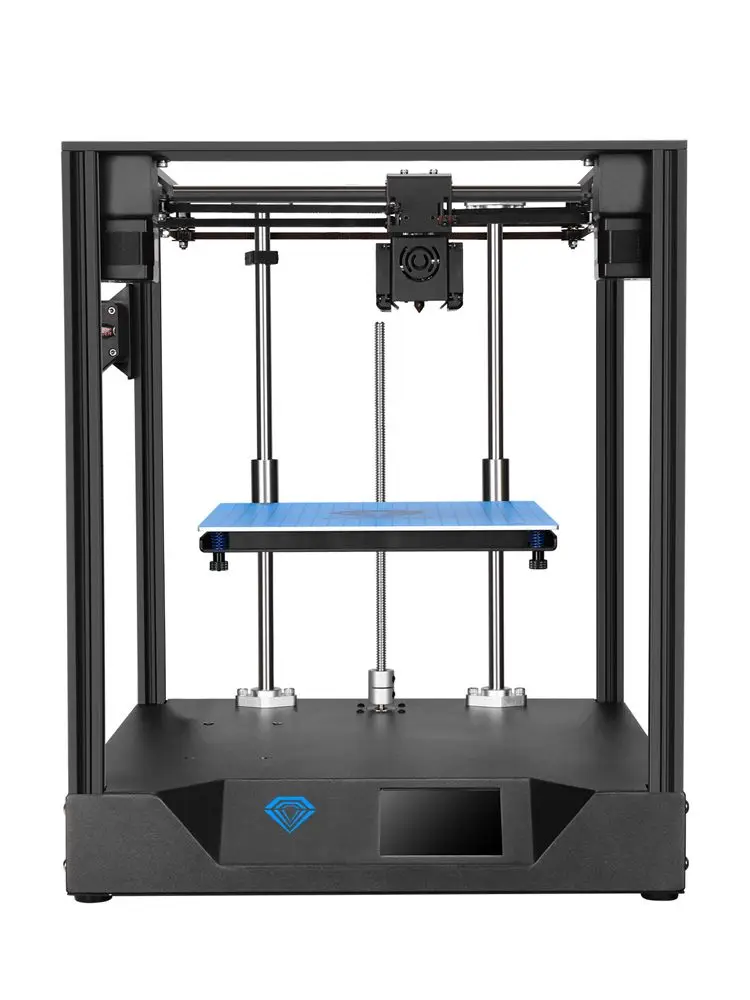

You can become a 3D printer reviewer if you are an expert in handling and using a 3D printer. You can contact manufacturers to obtain a 3D printer and write an exciting review of the 3D printer. This review can be posted on third-party blogs or even on your own YouTube channel. You can earn money from the manufacturer who wants his product reviewed by a third party or from the blog that will publish your content. This is one of the most straightforward ways to make money with 3D printing in 2022.

This is one of the most straightforward ways to make money with 3D printing in 2022.

3D Printing YouTube Channel

This idea is closely related to the previous one about reviewing 3D printers. In addition to 3D printers, you can also review materials and software suites. No doubt a YouTube channel will require a considerable time to monetise, but as this is a side hustle, you won’t mind. All you have to do is post one video per 7 to 10 days. You may take a year to generate ad revenue but this idea certainly has a great long-term potential.

Invest in 3D Printing Stocks

Above: 3D printing stock trends/Source: Motley FoolIf you are a stock trader, you should look into 3D printing stocks. The market is undoubtedly young, but if you enjoy taking risks, you can certainly take a look at the stocks. Many companies have gone public in recent years, and if you want to take a chance, consider this option.

(Please keep in mind that this is not investment advice, and readers should make their own decisions about whether or not to invest. We are not responsible for any investment decisions made by reading this article.)

We are not responsible for any investment decisions made by reading this article.)

Consultancy

If you are a technology expert, why not put it to good use. You can start a consultancy business. This can easily be a side hustle, but with this idea, you can make a lot of money with 3D printing.

Globally, the rate of adoption of 3D printing technology remains slow. MSMEs believe that the capital investment is prohibitively expensive to even consider the technology. Though this is true to some extent, investing in 3D printers will provide benefits across the entire supply chain, as opposed to traditional machines, which only provide benefits in certain parts of the production.

This is where the consultant can assist businesses in making better decisions about adopting 3D printing. You, as a consultant, can assist in answering questions like the need of the 3D printing technology for the business, whether the business really needs the technology, and, if so, how to implement the technology and more. Having someone at their side, will certainly help the MSMEs deal with technology sellers.

Having someone at their side, will certainly help the MSMEs deal with technology sellers.

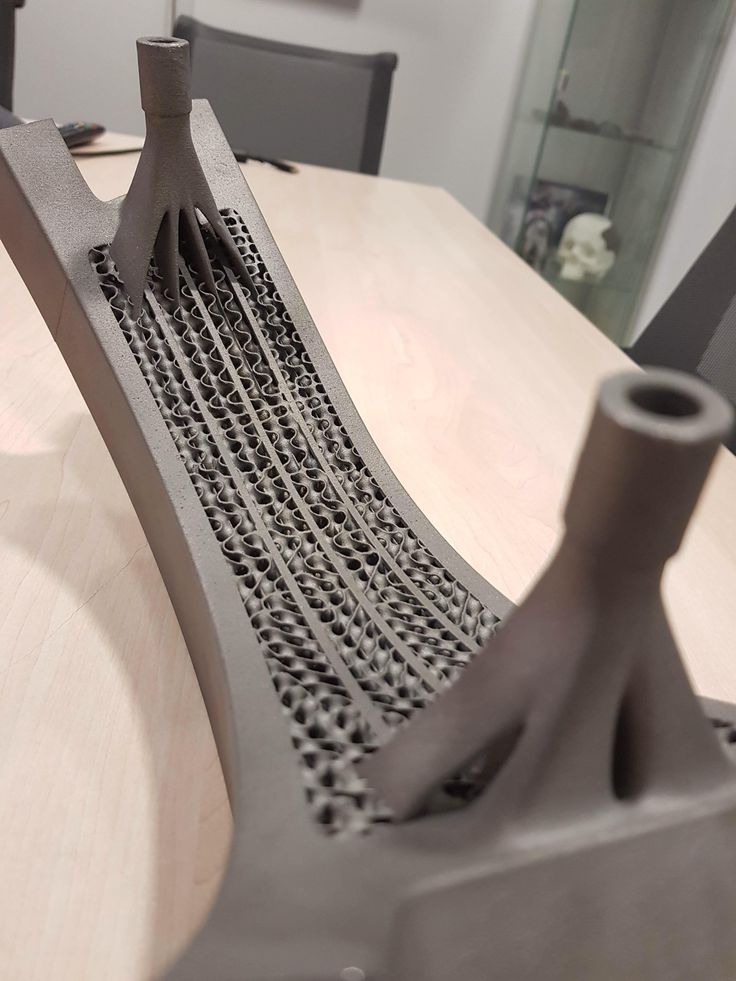

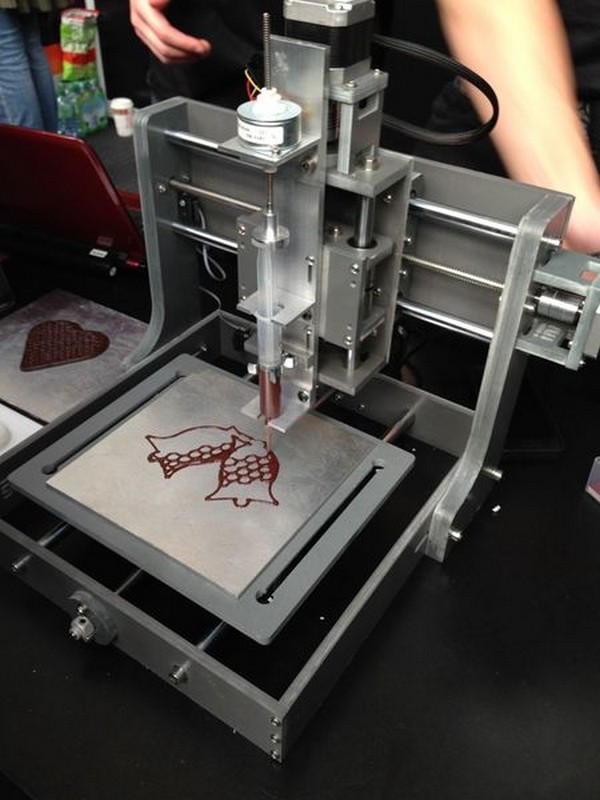

3D Scanning

Above: 3D scanning a high precision part for reverse engineering with a portable scanner/Source: Manufactur3DWith the introduction of 3D printing, reverse engineering has gained renewed interest and momentum. Because of the ease with which any type of object can be 3D printed, many industries are now scanning obsolete or old machine parts and having them 3D printed.

There are several ways to profit from 3D scanning. All you need is a scanner, which will undoubtedly be an investment, but you can also purchase smaller handheld scanners and provide scanning services.

Finding work through online freelancing jobs is the best approach. Several websites list available jobs, and you can also inquire directly with companies about contracting work. Once you’ve identified a few potential clients, you can start scanning and creating digital files.

Rent out your 3D printer or 3D Pen

In 2022, this is the best way to make money with 3D printing. If you have a 3D printer and/or a 3D Pen that you are not using, consider renting it out. Connecting with schools can earn you a quick buck by renting it to them during their science fairs, lab days, or any other special day. You can also rent it out to an engineering student for his academic project or to a local manufacturer. Additionally, you can even get resourceful and look for unique customers, such as families who want to have fun on weekends, parents that home-school their kids, and so on.

If you have a 3D printer and/or a 3D Pen that you are not using, consider renting it out. Connecting with schools can earn you a quick buck by renting it to them during their science fairs, lab days, or any other special day. You can also rent it out to an engineering student for his academic project or to a local manufacturer. Additionally, you can even get resourceful and look for unique customers, such as families who want to have fun on weekends, parents that home-school their kids, and so on.

Sell digital 3D models

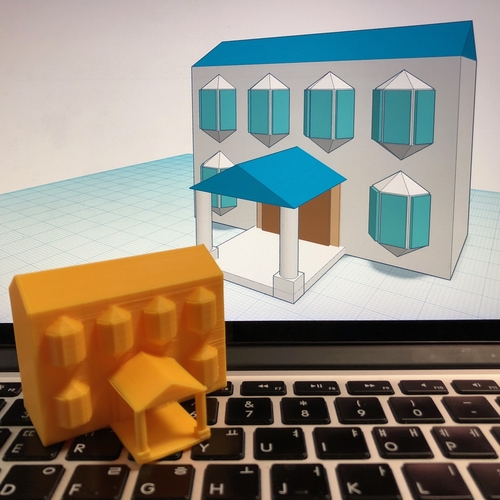

Above: You can buy and sell 3D models on sites like Gambody/Source: GambodyThis is a great online side hustle and easy way to make money with 3D printing. The only prerequisite is that you need to be proficient in designing for 3D printing. If you are, then you can try to search for trends and cash in on them by creating relevant 3D models.

You can also unique create models for household or office products like home décor. You can sell them on online 3D model repositories. Some designers also create designs for household parts that regularly break and can be replaced with 3D printed spare parts But this has to be done carefully to ensure you are not infringing on any copyrighted/trademarked designs.

Some designers also create designs for household parts that regularly break and can be replaced with 3D printed spare parts But this has to be done carefully to ensure you are not infringing on any copyrighted/trademarked designs.

Sell Personalised Products

The world is approaching a time when people are more inclined to purchase personalised products. Most customers are tired of mass-produced products that do not reflect their individuality. So, for such customers, you can design and 3D print personalised one-of-a-kind products that make them feel special. You can take user input on shape, size, texture, colour, geometry, and much more in account while creating such a unique product.

Selling such personalized products can help you make money with 3D printing, and it does not have to be a full-time job. It’s a great side hustle.

How to Get Started?

The answer on how to get started will depend on what you wish to accomplish. To get started you will need a CAD designing software (Read: Best CAD software for 3D printing), a 3D printer to print parts (Read: Factors to Consider When Buying a 3D Printer), 3D Scanner, registration on e-commerce sites or your very own website to sell online, and intrinsic knowledge of the technology. You may not necessarily need all the equipmentIn some cases, you may need all the equipment.

You may not necessarily need all the equipmentIn some cases, you may need all the equipment.

Once you choose which idea you want to pursue, you can buy the equipment and start your side hustle right away.

Full-time Business Ideas

If you are interested in getting into full-time 3D printing business then you can check out our dedicated article on the different 3D Printing Business Opportunities. To know the popular business ideas for providing 3D printing services, do read our article on the topic.

About Manufactur3D Magazine: Manufactur3D is an online magazine on 3D printing. which publishes the latest 3D printing news, insights and analysis from all around the world. Visit our 3D Printing Education page to read more such informative articles. To stay up-to-date about the latest happenings in the 3D printing world, like us on Facebook or follow us on LinkedIn and Twitter.

How to make money with a 3d printer?

How profitable is 3D printing?

But first, let's answer this question. Can you really make money with a 3D printer?

The answer is yes and no. It depends on the niche that you serve. If you're 3D printing for the general consumer, then your profit margin might not be high because it's for personal use. Consumers love cheap stuff. You'll barely cover your cost because of the amount of labor required to finish just one job. But if you're serving clients where 3D printing solves a costly problem that they have, then they are more willing to pay you a lot more to solve it for them.

Here's what we mean by that.

Scenario A: Joe is looking to 3D print a door handle because his door handle broke.

Scenario B: Amanda is looking to 3D print a prototype of a product she plans to sell on Kickstarter.

Believe it or not, we get a lot of Joe's looking to get a quote for their missing appliance part. And most of them are surprised by how expensive 3D printing is and why can't it be as a cheap as Amazon!

And most of them are surprised by how expensive 3D printing is and why can't it be as a cheap as Amazon!

We turn them away. Cheap clients are not worth your time.

Best entry level 3D Printer

Don't have a 3D printer already?

Phrozen Sonic Mini 4k 3D Printer

Check out this Phrozen Sonic Mini which is very popular among 3D printed miniatures enthusiasts.

$349.99 from Phrozen3D

Commisions earned

Different ways to make money with 3D printing

We've listed a couple of ways you can make money with a 3D printer. Some of these ideas are really good, some of them are bad. But we're listing them any way and it's up to you to make that decision if it's even worth considering.

Let's dive right in!

1. Sell pre-made 3D prints on Etsy

Etsy is one of the biggest marketplace for 3D printing. A lot of 3D printing hobbyists and even professional gravitate towards Etsy because of its large audience who are into handcrafted stuff. Some of them have even made a name for themselves on Etsy, whether that's selling pre-made items with a little bit of customization or selling full on 3D printed objects.

Some of them have even made a name for themselves on Etsy, whether that's selling pre-made items with a little bit of customization or selling full on 3D printed objects.

When we were starting out back in 2016, we were the first ones to start selling 3D printed planters. Made boatloads of money but ultimately had to stop because of copyright issues. But also partly, because it wasn't where we imagined company .

Remember how we said cheap clients aren't worth your time. On Etsy, you will encounter a lot of cheap clients.

Pros

- Quick way to validate your 3D printing idea

- Benefit from Etsy's huge audience

- Running ads are cheaper compared to Google

List of 3D printed products that you can sell on Etsy:

D&D miniatures

Planters

Vase

Freezing Bernie

How do you choose which products to sell?

On Etsy, you will see a lot of people selling different variations of the same thing - planters, iphone holder, headphone holder, etc.

Why?

Because these things sell!

Like it or not, Etsy will be full of copycats and originality doesn't matter. If your product sells, people will copy it. (And vice versa)

How can you stand out on Etsy?

There's a lot you can do to stand out, but here are some of the common ones that we hear over and over again.

Offer something unique that differentiates your product. Whether that's offering higher quality 3D print (resin), custom finishing, etc.

Avoid competing for price. It becomes

Ask your happy clients to leave a review

Take high quality product photos

2. Offer a specialized 3D printing

This comes down to finding a niche that you're comfortable to work with or if there's enough margin for you to be profitable.

Here's a list of niches you can offer your 3D printing services to:

Tabletop Miniatures

Toy Designers

Jewelry Designers

Architecture firms

Engineering firms for prototyping services

Pros

- You can standardize your process

- Repeatable business

- Easier to master one industry than be a jack of all trades

- You can become a known expert in that industry

3.

Start a 3D printing business in your local area

Start a 3D printing business in your local areaWe'll start off by saying that starting a 3D printing business is the most difficult thing to do out of all the other ideas on this list.

Pros

- Potential for high profits

- Local advantage over online only 3D printing companies

We were fortunate that we were located in NYC, where there is huge demand for 3D printing, and that we started in the early days when 3D printing was still new.

We're not saying this because we don't want you to compete with us, but we're saying this because we want you to know the risks involved in the 3D printing business. Many 3D printing companies have gone out of business because they could not make a sustainable profit to keep the lights on.

The amount of work that you have to put in on fulfilling custom orders is a lot. If you don't opt for an automated system, you end up doing a lot of back and forth with clients. And if you do opt in for these instant quoting systems, you can get a lot of low end jobs and lose out on clients with a very custom need.

The real money in offering a 3D printing service, especially if your a small business, is if you can differentiate yourself from merely becoming a commodity.

For us, we had to become more than just a 3D printing service. It sounds corny, but that was the reality. We had to offer other services that would add value to 3D printing. For example, a marketing agency came to us for 3D printed trophy in 24k gold. But we know that we can't 3D print gold. We can either tell them to take it to a metal plating shop or we can do it ourselves and charge on top of it.

We can charge a lot more because:

We're taking all the risk. If that metal plating fails, we have to 3D print again.

We're making their lives so much easier by being an expert at this field.

And if they're on a really tight deadline, we can charge even more because we're guaranteeing results.

Clients who care more about their time and results are willing to pay you a lot if you can deliver.

So we've partnered with a local metal plating company and later on started offering metal plating services for 3D printing.

Having capabilities more than 3D printing will allow you to charge more than just the 3D print by itself.

Whether that's painting, or creating molds. Whatever it is, you need to find the right clients.

Bonus: Offer 3D scanning services

3D scanning and printing services are perfect way to increase money you can make from owning 3D printer. Although this would require buying a 3D scanner, it's a good option to think about when increasing your chances of landing a 3D printing client.

4. Sell your 3D printing designs

Making money with 3D printing isn't only limited to running your 3D printer 24 hours a day. You can also make money from selling 3D models!

This might be hard if you don't have any design skills. You can either learn or hire a designer on Fiverr or Upwork.

Pros

- You can make money while you sleep

- More scaleable than running a 3D printing business

Patreon Business Model

Here's how it works. People pay you an X amount every month for you to publish 3D models for them.

People pay you an X amount every month for you to publish 3D models for them.

This business model is very popular among the tabletop miniature community.

The above picture is from LordOfThePrint's Patreon. They're one of the popular designers focused on building 3D designs for tabletop gaming. They currently have 1,933 subscribers as of this writing. Assuming only 5% of that is merchants, (about 100) that's $3,866 of monthly recurring revenue!

Take this WallStreetBets 3D model by ChaosCoreTech for example. We spent $50 to have the rights to sell their design for a month. Imagine having 10 Etsy sellers wanting to sell your 3D model. That's have $500 of passive income every month for a few hours of design work!

Merchants/Etsy sellers are great target to sell your 3D models to because:

They'll use it to make more money

They know that your 3D model would print properly because you also know how to 3D print. You might also include supports to make it easier for them

You can show them how it would like 3D printed, thus, making it even easier to sell.

Marketplace Business Model

Some prefer to sell their designs as one-off product that people can just buy online without having to subscribe monthly.

Places where you can sell your 3D models

MyMiniFactory

CGTrader

TurboSquid

5. Start a YouTube Channel

We know that this is easier said than done. Creating content requires time, effort and consistency. With the amount of 3D printing related youtube channels out there, it might be hard to stand out.

But we're not here to stop you from starting your own channel. We're just here to tell you that you can make money with it.

Pros

- Potential for high earnings

- You can use your audience to make more money aside from YouTube Ads

6. Sell an online 3D printing course

If your confident enough with your 3D printing skills and you have knack for teaching others, then selling an online course about 3D printing can

What should you teach?

Again, you need to find a problem where people are willing to pay money for. If you search "3D printing" on Udemy, you'll find 3D printing courses that people are paying for.

If you search "3D printing" on Udemy, you'll find 3D printing courses that people are paying for.

It doesn't have to be "how to operate a 3D printer", it can be a course on "how to operate a profitable 3D printing business". With this strategy, you'll attract clients who are willing to pay money to make more money.

Pros

- Passive income

The following ideas are not so good

So you can probably skip to the end if you wish to.

7. Rent your 3D printer for events

With the pandemic and all, this is probably not a good idea. But it's still an idea right?

The business is very similar to a photo booth. A bar mitzvah will hire you for 3 hours to 3D print keychains for them.

But 3D printing takes a long time. They are going to complain that you didn't 3D print for everyone.

Yup, bad idea.

8. Sell your 3D printer

You can quickly make money if you sell the 3D printer you just bought. Guaranteed.

Guaranteed.

All jokes, aside

9. 3D print the word "money"

You will literally make "money" with a 3D printer with this strategy.

In summary

Yes, you can make money with a 3D printer. And there are a lot of ways that you can do it, whether that's selling 3D printed items, digital goods, or even offering a 3D printing service in your local area. Is it easy to make money 3D printing? It's not. You still need to work hard(and smart) to become successful in the 3D printing business.

Let's talk about the beginning of earnings? Business model with 3D printer

Business

Subscribe to the author

Subscribe

Don't want

9

Good day to all.

Quite often I see questions about "starting a 3D printing business". Therefore, I would like to share my thoughts on this issue. The article will not have a ready-made business plan, but there will be ground for reflection on it (I hope). In order not to be unfounded, below are the Yandex search statistics. These statistics are only from Yandex, so you can safely multiply by 2.

In order not to be unfounded, below are the Yandex search statistics. These statistics are only from Yandex, so you can safely multiply by 2.

Actually what I'm talking about. Many people buy 3D printers in the hope of additional income from the provision of 3D printing services. Often, thoughts like: "I'll post an ad on Avito and orders will go through people's heads." Many of these businessmen simply remain alone with the printer or sell it afterwards. The competition in this area is already simply colossal and is only growing. Therefore, climbing into the service sector of this format without investing in advertising seems to me not the best idea. Moreover, almost two printer costs will have to be invested in advertising in this direction. Generally not an option. There is one way out for stuffing the client base - this is price dumping with its subsequent increase. But here, let everyone decide for himself whether he is ready, filling the base, at first to print "for 0" or even in the minus.

The second option is already less common, but still relevant in this matter. 3d modeling + 3d printing. This format of the service is in great demand and you can already earn at least on modeling, and at the same time spend only time. Everyone should determine the price of their time for themselves, since we are all different. But even here there is more than enough competition.

Well, now actually what I want to talk about. At the time of purchase of the 3D printer, I already knew what I was going to do with it. For me, it was initially a tool to a greater extent, and not earnings. Noah understood that I could print, which would bring me some kind of income. Of course, I will not say what my projects are, but I want to share the logic of thought, or, if you like, the business model.

1st version

The beauty of a 3D printer is that there is no need to create a batch on it, to make molds or molds for casting parts. You can get by with a sample. And I think that a person who buys a 3D printer for business needs to know what he will do on it. At least roughly calculate the cost of production and the real demand for the product on the market. As an example, I can cite the sale of handles for a metal detector on Avito. I didn’t go deep into this issue, but I suspect that this thing is useful. In general, one of the options is to take as a basis a part that is in demand (perhaps some kind of automotive) on the market, learn how to print it at least well, and already post an ad on Avito or on specialized forums. This behavior can kill two birds with one stone. There is no need for advertising, since this product is already needed by someone, and Avito itself will give your ad on the Internet, including if you format it correctly (I advise you to watch a video on this topic), and there will also be no need to fight with competition, since with the right choice of product it will either not be, or will be in a minimal amount. The same wordstat from Yandex can help you with the choice.

And I think that a person who buys a 3D printer for business needs to know what he will do on it. At least roughly calculate the cost of production and the real demand for the product on the market. As an example, I can cite the sale of handles for a metal detector on Avito. I didn’t go deep into this issue, but I suspect that this thing is useful. In general, one of the options is to take as a basis a part that is in demand (perhaps some kind of automotive) on the market, learn how to print it at least well, and already post an ad on Avito or on specialized forums. This behavior can kill two birds with one stone. There is no need for advertising, since this product is already needed by someone, and Avito itself will give your ad on the Internet, including if you format it correctly (I advise you to watch a video on this topic), and there will also be no need to fight with competition, since with the right choice of product it will either not be, or will be in a minimal amount. The same wordstat from Yandex can help you with the choice. And the number of such goods is limited only by your busyness.

And the number of such goods is limited only by your busyness.

2nd option.

Here you have to turn on your imagination. We must set ourselves the task of inventing a new product and promoting it. In this matter, one must understand that there is no competition at all, but there is also no advertising. Will have to look for it. Without investment, or almost without, it's real. I'll give you an example. Suppose you want to sell mini boxes with video game symbols, why not?

Let's say something like this. This idea has not been brought to mind at all and most likely it will not come to life in my hands, so you can take this idea, bring it to mind, learn how to print, make a collapsible box (that's exactly what I wanted to do), and start promoting. As marketers say, "sow demand." As an option, send it as a gift to some streamer (s), having previously made a website with possible models. Making a website as a whole is not so long and difficult. You just have to really put in the time for it. And with due diligence, you will bring a completely new product to the market, and you will receive money for it.

And with due diligence, you will bring a completely new product to the market, and you will receive money for it.

Personally, my projects worked in both cases, and I don't take printing to order (although I was just asked to do it a couple of times), but I don't rely on the orders themselves and purposefully don't look for them.

In general, this is very crumpled, and I would like to describe more, but people do not like to read long articles here)

Thank you for your attention, I will not mind discussing the article in the comments)

Even more interesting articles

28

Follow author

Subscribe

Don't want

Today we would like to present to your attention a new model of 3D Printer in our product line - Vo...

Read more

3

Subscribe to the author

Subscribe to the author

Don't want to

Today we want to present to your attention a new 3D Printer model in our product line - Vo. ..

..

Read more

avtor

Loading

06/04/2017

22709

240

Subscribe to the author

Subscribe

Don't want

Good evening, dear residents of the portal. I present to you the completed finished project of the bench model t...

Read more

How to make money on 3D printing: an overview of promising niches

The heyday of 3D printing was in 2010-2015. Additive technologies have rapidly burst into the market, making possibilities that previously existed only in science fiction films a reality. Even the most pessimistic critics had no doubts that very soon approaches to the production and customization of goods will change dramatically.

However, the revolution did not happen. Mass-produced products are still mass-produced without the use of 3D printing, and the idea of moving production closer to the consumer has not been realized, despite billions in investments and the active participation of the world's largest players from various industries. What's the matter?

What's the matter?

A global failure

In 2015, Amazon applied for a patent for using car-mounted 3D printers to print ordered items at a nearby pickup location. A patent was obtained, but the idea was never implemented.

During the same period, UPS deployed 100 CloudDDM (now Fast Radius) start-up 3D printers to one of its logistics hubs in the United States to create full-cycle automated manufacturing.

The site could operate 24/7 under the control of just one operator. UPS resources made it possible to deliver manufactured goods to another continent the very next day. All conditions were created for the success of the project, but it also did not receive development.

Global retailers Tesco, Walmart and Carrefour tried to introduce 3D printing as a service, but they also stopped at the testing stage. Just like toy manufacturers Mattel, Lego and Toys "R" Us - with 3D printing projects.

New strategy

The lack of rapid and large-scale results excluded 3D printing from the list of hype topics, but did not kill the idea itself. The market got rid of the excess of those who want to change the world and become famous, clearing the way for those who really want to work.

Over the past five years, favorable conditions have developed in the industry for the development of projects in the field of additive technologies.

To take advantage of the situation, the new wave of businessmen should abandon large-scale ideas and focus on narrow niches and specific customers. Of course, it does not sound as incendiary as the presentations of Amazon and Google, but it can bring real money.

This is exactly the path followed by the founders of Align Technology (USA), who created and patented the Invisalign dental alignment system with caps, having previously received FDA approval and a $140 million investment. In 2015, the company shipped 583.2 million 3D printed caps to customers and generated a net profit of $144 million at a 17% margin.

In 2015, the company shipped 583.2 million 3D printed caps to customers and generated a net profit of $144 million at a 17% margin.

The success of the American startup was repeated by the Russian company 3D Smile, which uses 3D printing to produce removable transparent mouthguards for bite correction. In terms of cost, they are comparable to braces, but much more convenient to use. In August 2014, 3D Smile was certified by Roszdravnadzor, launched sales in October, and reached operating profit in December.

SOLS (USA) has raised $23.7 million in investments and implemented the technology of 3D printing of custom-made orthopedic insoles. The service was tested in partnership with 50 orthopedists, from whose patients up to a hundred orders were received per week. At the launch stage in 2014, the cost of a pair of personal insoles was 300-500 dollars (for analogues in pharmacies, you had to pay 500-1000 dollars). Two years later, we managed to reduce the price to 9$9 for a pair and increase your order flow many times over.

Several Russian projects have been successfully launched in a similar niche. The most famous of them is the Motorika children's traction prostheses, which have now evolved into bioelectric prostheses with built-in gadgets. The company's turnover for 2018 is about one million dollars.

We can also mention the Zdravprint service - 3D printing of individual orthoses that replace plaster and its alternatives, as well as used in complex fractures after plaster removal. They are printed on a custom printer. At the product creation stage, the founders invested $50,000 in the project, and then raised another $100,000 from Maxfield Capital venture fund.

Not just printing

Not only manufacturers of goods, but also equipment sellers make money on the wave of popularity of 3D printers.

After the expiration of the first patents, the price of the printer dropped from $20,000 to $2,000. This was taken advantage of by several Russian companies, which now make up the main pool of sellers of such equipment.

Each manufacturer has developed its own technological solution with unique elements, which helped to divide niches and not create heat in the competitive field.

One of the first manufacturers in the Russian Federation was PICASO 3D, ApisCOR created the first really working construction 3D printer, 3D SLA is responsible for printing metal products.

There are also desktop 3D printer vendors on the market (TOP 3DSHOP, 3D REP) that rely on import and distribution. In addition, they are engaged in 3D modeling and custom printing, and offer CNC machines and robotic systems.

For new players, the entrance to a clearly segmented business that operates in each of the listed niches is still open. At the same time, to start, it is not necessary to have a unique technology or idea, it is enough to identify your client and focus on demand.

In addition, there are a sufficient number of empty niches on the market that you can enter and work in.

Open niches

Jewelry

The jewelry market is stagnating, buyers are increasingly trying to save money and get an interesting design, so they choose jewelry not from gold, but from silver, as well as bijouterie.

Manufacturers are responding by reducing the weight of precious metals and introducing cheaper substitutes.

3D printing gives the market the missing element - personalization of jewelry.

This allows you to "drop" the cost of production under the order, reduce lead times and meet real demand. There is no need to invent technology, any jewelry shape can be easily found on the Internet and adapted in a 3D editor.

Characters and artifacts for gamers

3D printing of artifacts or game characters (Warcraft, DotA, GTA) is an interesting and promising niche, not just printing children's toys.

In the USA there are examples of cases with high turnover. For example, the WhiteClouds company offers fans and lovers of computer games to create a personalized figure of their favorite game character.

The demand from gamers for such products is stable and will grow. According to Newzoo forecasts, this solvent audience will reach 28.2 million people by the end of 2019. And most of them like the idea of printing out their sword, armor, or an entire character from the game.

Orthopedics

In Russia, this niche is practically not occupied. Individual players are engaged in insoles and orthoses, however, this market is much wider and includes everything that is made of plastic, rubber, requires a certain level of rigidity and individual settings.

Today, the main sellers of such goods buy them in bulk from China. The use of 3D printing will help to abandon this in favor of small-scale production on site on demand. The result is cost savings, simplification of logistics, and an increase in turnover. For the client, this is an opportunity to quickly, right at the medical center, get what the doctor has prescribed. No need to search, order and wait.

The result is cost savings, simplification of logistics, and an increase in turnover. For the client, this is an opportunity to quickly, right at the medical center, get what the doctor has prescribed. No need to search, order and wait.

There are successful cases in this market, they can be studied and “tried on” for other groups of orthopedic products.

Auto parts

3D printing of automotive parts is an idea that has been successfully implemented by a number of companies in the US. Moreover, we are not talking about the nodes of running systems, but about simple spare parts that constantly break down.

Door handles, sun visors and blinds, disk covers are all products of steady demand. They can be printed on a 3D printer, make a markup of 400-500%, and at the same time successfully compete with official dealers who are not interested in selling "trifle".

Owners of used cars often look for such parts at dismantling sites, since it is not possible to order a new one or the price is not acceptable. The range can be expanded with plastic elements for tuning and car customization.

The range can be expanded with plastic elements for tuning and car customization.

Also, 3D printing can be used in auto tuning and more globally. For example, the RingBrothers company is engaged in the creation of unique "custom" cars. At some point, the team decided that it was too expensive to constantly make metal parts, figure out how they would look on the car, and then make a new version. Therefore, I began to use 3D printers to create cheaper prototypes.

Another example is the collaboration between MINI (BMW) and Belgian personalization software provider Twikit. The automaker has brought in Twikit so that car buyers can use the platform to create their own interior and exterior elements using 3D modeling. These models were sent to BMW's additive manufacturing center, where customer-designed parts are 3D printed and then integrated into the ordered car.

Consumables manufacturing

A fairly simple business that requires one Chinese machine and a pack of plastic granules to start.