Optical cmm 3d scanner

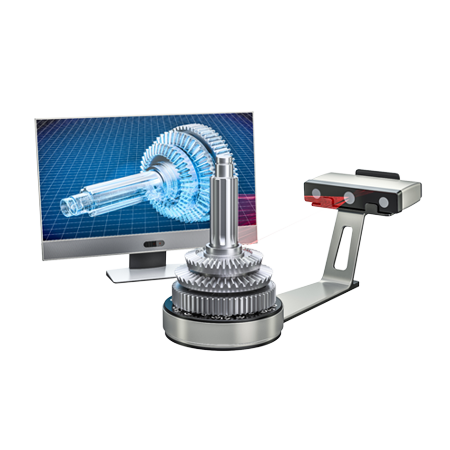

MetraSCAN 3D | Handheld [Optical CMM 3D Laser Scanner] by Creaform

Discover the fastest and most accurate 3D scanner and portable CMM for shop floor environments

Speed and accuracy combined with versatility

Faster 3D scanning

The MetraSCAN 3D features 15 laser crosses and a high measurement rate to accelerate 3D scanning processes. Thanks to quick setup and onboarding, real-time scans and ready-to-use files, your 3D scanning workflow will never have been faster.

- High measurement rate

1,800,000 measurements/second - Large scanning area for all types of parts

15 laser crosses - Ultra-quick setup

No warm-up time; users can be up-and-running in less than 5 minutes

Impressive shop floor accuracy

Free from any rigid measurement setup requirements, the MetraSCAN 3D is designed specifically for use on shop floors. It delivers accurate results, regardless of the measurement setup quality and user experience level. Thanks to the C-TrackTM optical tracker that enables dynamic referencing, the scanner, the part and the optical tracker can move during inspection and still provide accurate measurements.

- Accuracy

0.025 mm (0.0009 in) - Volumetric accuracy

0.064 mm (0.0025 in) - Reliable acceptance tests

Based on VDI/VDE 2634 Part 3 standard

ISO 17025 accredited laboratory - Shop floor accuracy with dynamic referencing

Measurement accuracy insensitive to environmental instabilities

High resolution

Measures all types of complex and highly detailed parts

Unmatched versatility

Highly versatile, the MetraSCAN 3D can be used to scan various part sizes and surface finishes in real time—all with the same device.

With its extendable measurement volume, parts of any shape, complexity, and geometry can be measured easily without loss in accuracy or requiring leapfrog.

- Blue laser technology

Ideal for shiny and reflective surfaces - Large and easily extendable measurement volume

Wider than other portable CMMs

No leapfrog required - Optional HandyPROBE

Combination of both 3D scanning and probing

No targets required

Get the ultimate portable metrology-grade 3D scanner for product development and quality control.

Learn how the MetraSCAN 3D can accelerate your time to market and mitigate costly quality control issues.

Request more information

3D scanning solutions designed for manufacturers’ unique needs

Creaform’s 3D scanning solutions address the 3D measurement requirements for each stage of the manufacturing process

Product development and design

Launch innovative products to your market faster

Quality control and quality assurance

Reduce costs and ensure the quality your customers expect

Reverse engineering

Quickly extract dimensional information from existing components to produce new CAD reference models

Explore all of Creaform’s 3D measurement solutions

You’ll be amazed at the world of opportunities our 3D scanning solutions offer ahead-of-the-curve manufacturers.

3D scanning software

3D scanning software

VXelements™

The MetraSCAN 3D seamlessly operates with VXelements, a fully integrated, user-friendly 3D scanning software platform. VXelements’s range of advanced modules let you leverage all the dimensional information captured by MetraSCAN 3D in a simplified, feature-rich data processing environment.

Software Module

Compatible Software

3D Optical CMM | KEYENCE America

First Name (required)

Last Name (required)

Newsletter

YES! Email with the latest product news, tips, and application guides.

Country (required)

AfghanistanAlbaniaAlgeriaAmerican SamoaAndorraAngolaAntigua and BarbudaArgentinaArmeniaAustraliaAustriaAzerbaijanBahamasBahrainBangladeshBarbadosBelarusBelgiumBelizeBeninBermudaBhutanBoliviaBosnia and HerzegovinaBotswanaBrazilBruneiBulgariaBurkina FasoBurundiCambodiaCameroonCanadaCape VerdeCentral AfricaChadChileChinaColombiaComorosCongo, Democratic Republic ofCosta RicaCroatiaCubaCyprusCzech RepublicDenmarkDjiboutiDominicaDominican RepublicEast TimorEcuadorEgyptEl SalvadorEquatorial GuineaEritreaEstoniaEthiopiaFederated States of MicronesiaFijiFinlandFranceFrench GuianaGabonGambiaGeorgiaGermanyGhanaGreeceGrenadaGuatemalaGuineaGuinea BissauGuyanaHaitiHondurasHong KongHungaryIcelandIndiaIndonesiaIranIraqIrelandIsraelItalyIvory CoastJamaicaJapanJordanKazakhstanKenyaKiribatiKoreaKuwaitKyrgyzLaosLatviaLebanonLesothoLiberiaLibyaLiechtensteinLithuaniaLuxembourgMacauMacedoniaMadagascarMalawiMalaysiaMaldivesMaliMaltaMarshall IslandsMauritaniaMauritiusMexicoMoldovaMonacoMongoliaMontenegroMoroccoMozambiqueMyanmarNamibiaNauruNepalNetherlandsNew ZealandNicaraguaNigerNigeriaNorth KoreaNorwayOmanPakistanPalauPanamaPapua New GuineaParaguayPeruPhilippinesPolandPortugalPuerto RicoQatarRepublic of CongoRepublic of KosovoRomaniaRussiaRwandaSaint LuciaSamoaSan MarinoSao Tome and PrincipeSaudi ArabiaSenegalSerbiaSeychellesSierra LeoneSingaporeSlovakiaSloveniaSolomon IslandsSomaliaSouth AfricaSpainSri LankaSt. Christopher and NevisSt.Vincent and the GrenadinesSudanSurinameSwazilandSwedenSwitzerlandSyriaTaiwan R.O.C.TajikistanTanzaniaThailandTogoTongaTrinidad and TobagoTunisiaTurkeyTurkmenistanTuvaluUgandaUkraineUnited Arab EmiratesUnited KingdomUnited StatesUruguayUzbekistanVanuatuVatican CityVenezuelaVietnamYemenZambiaZimbabwe

Christopher and NevisSt.Vincent and the GrenadinesSudanSurinameSwazilandSwedenSwitzerlandSyriaTaiwan R.O.C.TajikistanTanzaniaThailandTogoTongaTrinidad and TobagoTunisiaTurkeyTurkmenistanTuvaluUgandaUkraineUnited Arab EmiratesUnited KingdomUnited StatesUruguayUzbekistanVanuatuVatican CityVenezuelaVietnamYemenZambiaZimbabwe

Company Name (required)

Address (required)

City (required)

Zipcode (required)

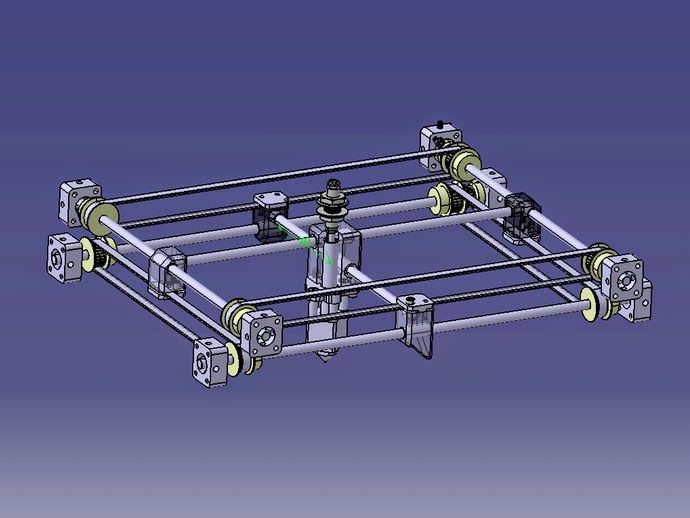

Scanning technologies

- home

- Directory

- Scanning technologies

Laser based 3D Scanners use a process called trigonometric triangulation to accurately display a 3D shape as millions of points. Laser scanners work by projecting a laser line or lines onto an object and then picking up its reflection using one or more sensors. The sensors are located at a known distance from the source of laser radiation. Accurate point measurements can be made by calculating the angle of reflection of the laser light. Laser scanners are very popular and come in many designs. These include handheld devices, manipulator-based devices, CMM-based devices, long-range devices, and long-range single-point devices. Advantages of 3D laser scanners. Ability to scan complex surfaces, such as shiny or dark. Less sensitive to changes in lighting conditions and ambient light. Often more portable. A simpler design is easier to use and cheaper.

Laser scanners work by projecting a laser line or lines onto an object and then picking up its reflection using one or more sensors. The sensors are located at a known distance from the source of laser radiation. Accurate point measurements can be made by calculating the angle of reflection of the laser light. Laser scanners are very popular and come in many designs. These include handheld devices, manipulator-based devices, CMM-based devices, long-range devices, and long-range single-point devices. Advantages of 3D laser scanners. Ability to scan complex surfaces, such as shiny or dark. Less sensitive to changes in lighting conditions and ambient light. Often more portable. A simpler design is easier to use and cheaper.

Projected or Structured Light 3D Scanners . Historically known as "white light" 3D scanners, most structured light 3D scanners today use blue or white LED projected light. These 3D scanners project a pattern of light onto an object, consisting of stripes, blocks, or other shapes. A 3D scanner has one or more sensors that look at the edges of these patterns or structural shapes to determine the 3D shape of an object. Using the same trigonometric triangulation method as in laser scanners, the distance from the sensors to the light source is known. Structured light scanners can be mounted on a tripod or hand held.

A 3D scanner has one or more sensors that look at the edges of these patterns or structural shapes to determine the 3D shape of an object. Using the same trigonometric triangulation method as in laser scanners, the distance from the sensors to the light source is known. Structured light scanners can be mounted on a tripod or hand held.

Laser pulse-based 3D scanners . Laser pulse scanners, also known as time-of-flight scanners, are based on a very simple concept: the speed of light is known very precisely. Thus, if the time required for the laser to reach the object and reflect from the sensor is known, then the distance from the sensor to the object is also known. These systems use picosecond-accurate circuitry to measure the time it takes millions of laser pulses to return to the sensor and calculate the distance. By rotating the laser and sensor (usually with a mirror), the scanner can scan around itself 360 degrees.

Laser Phase-shift 3D Scanners . Laser phase-shifting systems are another type of time-of-flight 3D scanner technology, and they work conceptually similar to pulsed systems. In addition to the pulsed laser, these systems also modulate the power of the laser beam, and the scanner compares the phase of the laser light sent and returned to the sensor. Phase shift measurements are typically more accurate and quieter, but not as flexible for long range scanning as pulsed 3D scanners. Laser pulsed 3D scanners can scan objects up to 1000m away, while phase shift scanners are better suited for scanning objects up to 300m or less.

Laser phase-shifting systems are another type of time-of-flight 3D scanner technology, and they work conceptually similar to pulsed systems. In addition to the pulsed laser, these systems also modulate the power of the laser beam, and the scanner compares the phase of the laser light sent and returned to the sensor. Phase shift measurements are typically more accurate and quieter, but not as flexible for long range scanning as pulsed 3D scanners. Laser pulsed 3D scanners can scan objects up to 1000m away, while phase shift scanners are better suited for scanning objects up to 300m or less.

Coordinate Measuring Machine (CMM) . They are mainly used to control details. The machine can be controlled manually or autonomously by software and computers. Measurements are determined by attaching a sensor to the machine. The sensor usually has a small ball at the end of a shaft of known diameter. The CMM is then programmed to make contact with the part. When the machine senses contact with the probe tip, a value in XYZ space is measured. The most common type of CMM is the bridge type, which has 3 axes X, Y, and Z. The sensor system, which is mounted multiple times, can rotate to provide an additional 3 axes for a total of 6 degrees of freedom (DOF). For very precise measurement of parts to within a few microns, CMMs are typically installed in a control room with a reinforced floor, controlled humidity and temperature, and isolated from vibration and other forces that can affect accuracy. In addition, most CMMs have a large granite table with a perfectly flat surface. Details are fixed on a granite table in such a way as to exclude their movement during the measurement process.

The most common type of CMM is the bridge type, which has 3 axes X, Y, and Z. The sensor system, which is mounted multiple times, can rotate to provide an additional 3 axes for a total of 6 degrees of freedom (DOF). For very precise measurement of parts to within a few microns, CMMs are typically installed in a control room with a reinforced floor, controlled humidity and temperature, and isolated from vibration and other forces that can affect accuracy. In addition, most CMMs have a large granite table with a perfectly flat surface. Details are fixed on a granite table in such a way as to exclude their movement during the measurement process.

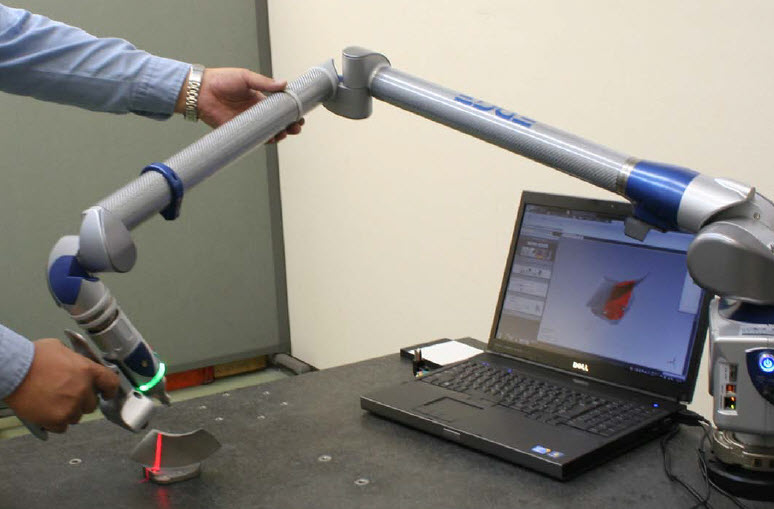

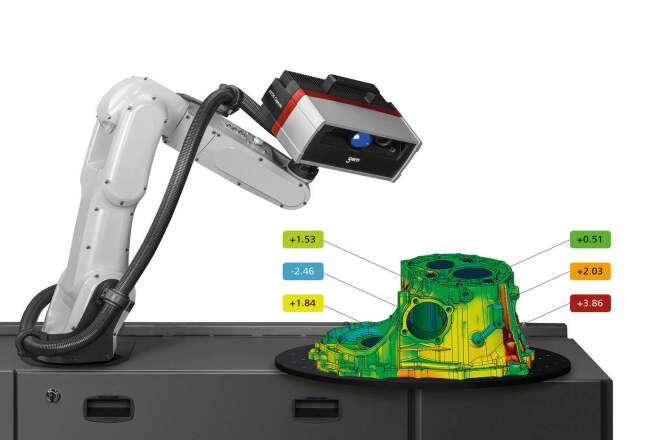

Arm based 3D Scanners and Probe systems . A manipulator-based 3D scanning or probing system is similar to a coordinate measuring machine (CMM) in that a touch probe can be used to measure the part. In addition to the sensor, many manipulator-based systems are also equipped with an attachable 3D laser scanner to collect a large number of points. The software tracks the movement of the hand's joints to know where it is in 3D space at any given time. Manipulator-based systems work by attaching an articulated arm to a table or a solid base. The hand is then held onto the handle at the end and moved to probe or scan. The main advantage of these systems is that they are much more portable than CMMs and can be used in the shop floor.

The software tracks the movement of the hand's joints to know where it is in 3D space at any given time. Manipulator-based systems work by attaching an articulated arm to a table or a solid base. The hand is then held onto the handle at the end and moved to probe or scan. The main advantage of these systems is that they are much more portable than CMMs and can be used in the shop floor.

Optically tracked 3D Scanners and Probe Systems . 3D scanning and optical tracking probing systems use a set of cameras to track the location of a 3D scanner head or probe in 3D space. These systems have advantages over manipulator-based systems, including freedom of movement, better distance accuracy, and the ability to enable "dynamic referencing". Dynamic referencing systems work by attaching targets or LED indicators to the scanned or probed object. This allows the camera system to track the part and the scanning or measuring head separately from each other. As a result, the part can move even during scanning, without loss of accuracy or data quality. In addition, the camera system can be moved, allowing large parts to be scanned in a single setup.

In addition, the camera system can be moved, allowing large parts to be scanned in a single setup.

Portable coordinate measuring machines (ARM Based) (also called "manipulators" or "arms") are mobile metrological measuring systems with 6 and 7 degrees of freedom (axes). They are ideal for fast and accurate measurements of objects, geometric dimensions, shape deviations and the relative position of the surfaces of parts in any place convenient for you due to the mobility and ease of installation of the system. The measuring arm consists of articulated segments (shoulder and forearm) made of carbon fiber (for lightness and thermal stability), as well as a built-in counterweight, control unit and power source. Determining the position of each link of the manipulator is carried out using built-in high-precision angular sensors (encoders) in each axis. Measuring manipulators can work both with contact (tactile) sensors and non-contact laser scanners. When using contact sensors, the coordinate of the center of the probe ball is determined when touching the measured surface. When using a laser scanner, the coordinates of the set of points of the measured surface are determined within the scanner's field of view. The obtained coordinates of the points are processed by specialized software, the geometric dimensions, the parameters of the deviation of the shape and the relative position of the surfaces and elements of the parts are calculated. Software available for use: PolyWorks, Verisurf, Metrolog, Geomagic, etc. To control the geometry of products and their elements, measuring arms are installed either on tripods or on a flat hard surface through special bases (magnetic, vacuum, fixed with bolts). These systems are not automated, data collection is performed manually by the operator.

When using contact sensors, the coordinate of the center of the probe ball is determined when touching the measured surface. When using a laser scanner, the coordinates of the set of points of the measured surface are determined within the scanner's field of view. The obtained coordinates of the points are processed by specialized software, the geometric dimensions, the parameters of the deviation of the shape and the relative position of the surfaces and elements of the parts are calculated. Software available for use: PolyWorks, Verisurf, Metrolog, Geomagic, etc. To control the geometry of products and their elements, measuring arms are installed either on tripods or on a flat hard surface through special bases (magnetic, vacuum, fixed with bolts). These systems are not automated, data collection is performed manually by the operator.

Photogrammetry is a scientific and technical discipline that deals with determining the shape, size, position and other characteristics of objects from their photographic images. There are two main directions in photogrammetry: creating maps and plans of the Earth (and other space objects) from images (phototopography), and solving applied problems in architecture, construction, medicine, forensics, etc. (terrestrial, applied photogrammetry).

There are two main directions in photogrammetry: creating maps and plans of the Earth (and other space objects) from images (phototopography), and solving applied problems in architecture, construction, medicine, forensics, etc. (terrestrial, applied photogrammetry).

In short, it is the process of creating 3D models from multiple images of the same object, photographed from different angles. This technique is not new at all, it is much older than the modern process, and it has been widely used in cartography and geodesy. It became more popular due to its affordability due to the increasing power of computers, which allowed it to spread to other areas such as game development, video effects, and model building for various tasks.

Industrial computed tomography (Tomography) scan - any computer - an auxiliary tomographic process, usually X-ray computed tomography, which uses radiation to create three-dimensional internal and external representations of the scanned object. Industrial computer scanning is used in many industries for the internal control of components. Some of the main applications of industrial CT scanning are defect detection, failure analysis, metrology, assembly analysis, and reverse engineering. As with medical imaging, industrial imaging includes both non-tomographic radiography (industrial radiography) and computed tomographic radiography (computed tomography).

Industrial computer scanning is used in many industries for the internal control of components. Some of the main applications of industrial CT scanning are defect detection, failure analysis, metrology, assembly analysis, and reverse engineering. As with medical imaging, industrial imaging includes both non-tomographic radiography (industrial radiography) and computed tomographic radiography (computed tomography).

HandySCAN 3D laser scanners | Creaform

HandySCAN 3D Handheld Scanners are optimized for the needs of pipeline integrity engineers and provide the most efficient and reliable way to obtain 3D measurements of physical objects.

Creaform's flagship metrology scanners have been redesigned. They're lighter and deliver high-resolution 3D scans faster, while still being just as easy to use.

The Creaform Pipecheck system offers a choice of two models of 3D laser scanners depending on the required level of accuracy.

A COMBINATION OF PRECISION AND PORTABILITY. INTRODUCING HANDYSCAN 3D SCANNERS.

INTRODUCING HANDYSCAN 3D SCANNERS.

Looking for the most efficient way to accurately quantify material loss and mechanical damage ? The HandySCAN 300 is a reliable tool that will solve this problem.

HandySCAN 700 provides high accuracy and resolution. It is the most versatile 3D scanner for inspection available on the market. The data collection speed of the HandySCAN 700 will pleasantly surprise you.

- Benefits

- Operating sequence

- Applications

- Accessories

- features

TRUaccuracy (True Accuracy)

- Dynamic coupling between tube and scanner maintains accuracy and resolution in all conditions, including high vibration conditions.

- The system generates accurate, reproducible high resolution 3D data (0.040-0.050 mm).

- Improved virtual level gauge capabilities. The transmitter is configured to provide the most accurate measurements close to welds.

- Comparison of Internal Pipe Condition Data : Access inspection results by comparing internal pipe inspection data and data from tools with data from the Pipecheck system. This helps operators to more accurately identify areas where earthworks need to be done.

- Depth of Corrosion Within a Mechanical Fault : Unique and innovative tools for determining the depth of corrosion within a mechanical fault.

TRUsimplicity : very simple 3D scanning process

- Scanning and analysis are accurate, intuitively easy to use and independent of operator skill.

- Very fast learning, regardless of user experience.

- Start up and start in less than 2 minutes.

- Simplicity: simple and fast learning.

- The ability to change the working distance allows access to isolated areas.

- Visualization of the scanned surface in real time.

TRUportability : 3D scanning where you need it

- Portable from place to place and used both indoors and outdoors.

- Weight 0.85 kg; possibility of use in limited spaces. Fits in a portable case.

- The mass of the scanner is about 1 kg.

Pipecheck: Your best ally in all phases of your pipeline integrity program

SCAN

- Corrosion

- High definition image capture for all areas showing signs of corrosion

- Fast surface imaging for increased efficiency

- Improved scanning of fine details such as pitting

- Mechanical damage

- High resolution mesh files for analysis optimization

- Quick measurements to check any surface finish

- Comparison of pipe internal inspection data

- Skill-independent high-precision measurements for more accurate matched data

- Improved performance to cover more area and get more accurate statistical trends

ANALYSIS

- Corrosion

- Troubleshooting using real pipeline geometry

- Automatic application of interaction rules

- Estimated Burst Pressure Calculation

- Improved virtual level gauge for working near welds and obstacles

- Mechanical damage

- Automatic maximum depth detection

- Automatic creation of a 2D cross profile in both directions at maximum depth

- Measuring the maximum depth in both directions with straightedge

- Ledge section available

- Comparison of pipe internal inspection data

- Automatic detection of coincidences when overlapping surfaces

- Manual match function

- Axial and circular offset function for optimum overlap

REPORT

- Corrosion

- Excel report including worst case profile and predicted fault evolution

- Ability to export to CSV format for further analysis

- Ability to export coordinate grid

- Configurable Pass/Fail criteria

- Photographic device for 3D report

- Mechanical damage

- Excel report with ovality measurements

- Cross section details (axial and cylindrical)

- Depth mesh export to CSV format

- Ability to export coordinate grid

- Excel report with ovality measurement results (diameter measurement with caliper)

- Dat, maximum depth point

- Dat, 90° from the maximum depth point

- Dmax

- Comparison of pipe internal inspection data

- Visual overlay of pipe internal inspection data and faults detected by scan

- General Graph for Evaluating the Performance of Sizing, Maximum Depth and Estimated Burst Pressure Tools

- List of coordinated and inconsistent functions

- Piping corrosion assessment

- Assessment of mechanical damage to pipelines

- Assessment of the degree of hail damage to aircraft

- 3D simulation for phased array inspection - Aerospace

- 3D simulation for phased array inspection - Energy

Rugged field kit with wireless tablet

For companies looking for optimum performance in the field, Creaform has developed a complete package of accessories. Our rugged field kit includes a wireless tablet for real-time visualization of scanned surfaces.

Our rugged field kit includes a wireless tablet for real-time visualization of scanned surfaces.

It also offers a choice of three compatible power sources: Creaform battery with charger*, 110/220V direct input or car battery.

Package includes:

- Wireless tablet powered by VXremote

- Pelican rugged laptop case

- Creaform battery with charger

- Magnetic support for scanner

- Magnetic tablet support

- USB 3.0 cable, 8m

Accessories:

- Emergency power cables for car battery

*When used with a Creaform rechargeable battery, the rugged field kit provides 8 hours of battery life.

3D Scanner Power Bank: Takes portability to a whole new level

Lightweight 3D scanner power bank with three hours of battery life improves data acquisition efficiency. Ideal for short term projects and applications where the object is accessed with a tether and provides complete freedom of movement. Combined with HandySCAN 3D, you can use the scanner wherever you are. The small weight and size guarantee a new level of portability! Offered at a reasonable and affordable price, the rechargeable battery is ideal for working in confined spaces as well as outdoors!

Combined with HandySCAN 3D, you can use the scanner wherever you are. The small weight and size guarantee a new level of portability! Offered at a reasonable and affordable price, the rechargeable battery is ideal for working in confined spaces as well as outdoors!

- Autonomy: 3 hours continuous scan

- Dimensions: 180x110x20 mm / 7.1x4.3x0.8 inches.

- Weight: 0.52 kg / 1.14 lb

- Charging time: 4 hours

VXremote™: Remote Access Software

VXremote improves field efficiency by providing quick and easy remote access to Pipecheck. This software guarantees fast start-up and configuration without any hardware. All 3D scanner functions are at your disposal... Only available with Creaform Certified Rugged Tablets!

Complete solution includes:

- Handyscan 3D Laser Scanner

- Pipecheck software license

- Calibration plate

- Pointer needle with protective cover

- USB 3.

Learn more