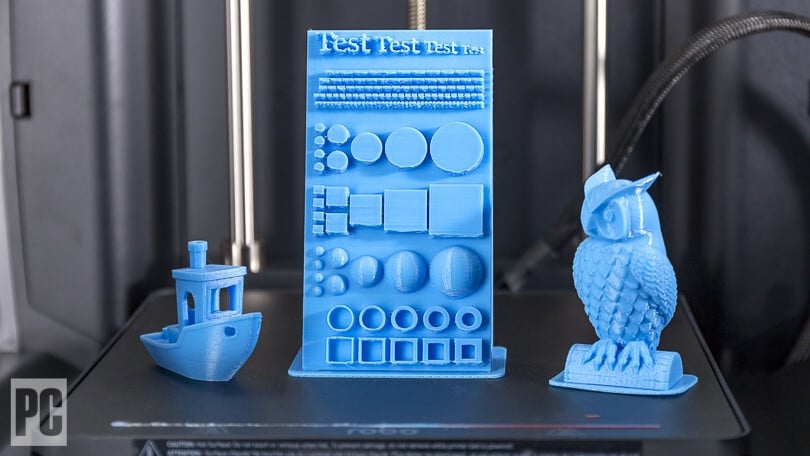

3D printer item

67 Cool Things to 3D Print

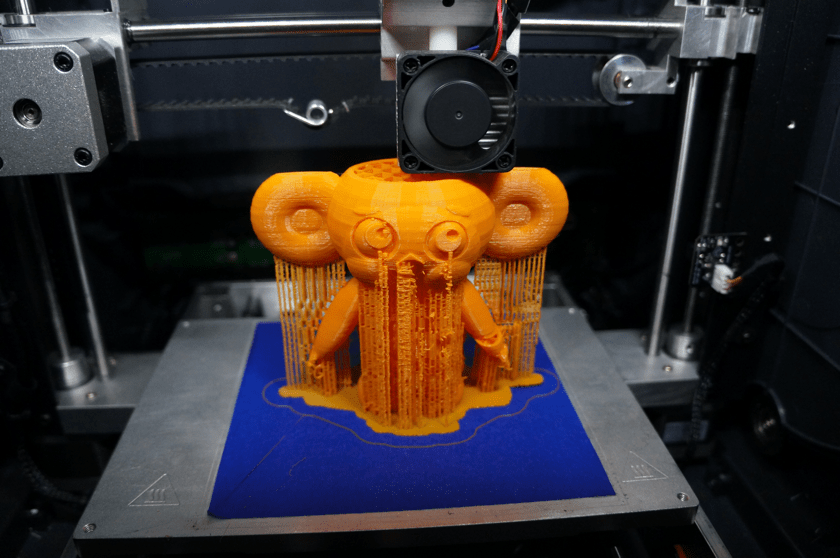

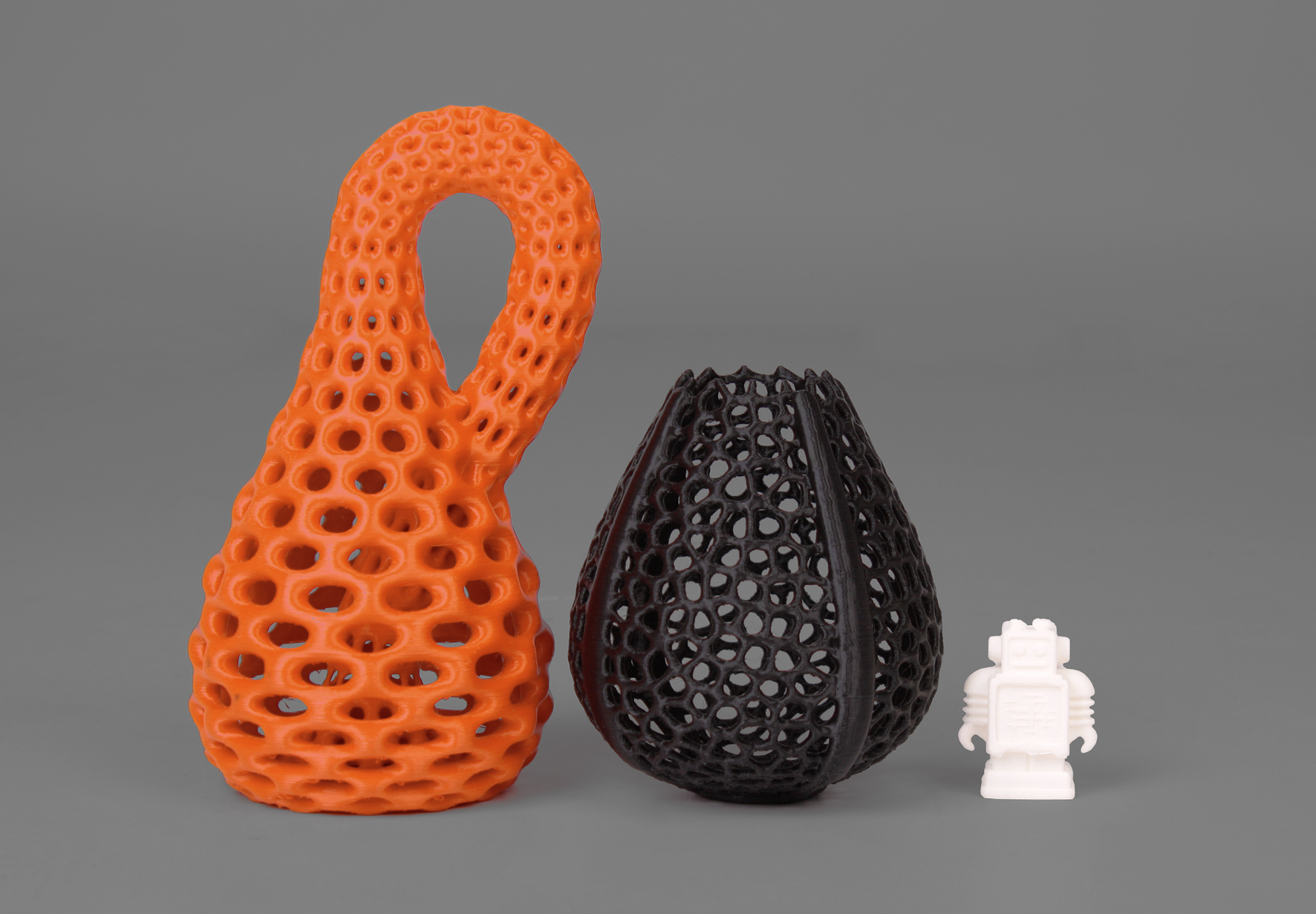

3D printing is such a fun way to produce creative work—and it has totally taken off. Now, creators are using this amazing new technology to create all kinds of wild and wonderful 3D printer projects that were previously all but impossible to make at home.

These 3D printer projects are a great addition to your online design portfolio. This is such a hot space that shows your mastery of this chic craft could win you some big new clients. You can showcase a collection of cool things to 3D print and some of your best 3D printings too.

Want to get in on this cool 3D prints trend? We’ve compiled a list of 67 inspiring 3D printing ideas to fuel your next 3D printer design. So, what can you make with a 3D printer? Well, there’s something cool for everyone!

Next in our list of cool things to 3D print is a simple project that can be completed in approximately one hour and will produce a whistle. It can produce an eye-popping 118db sound, perfect for camping or sporting events.

If there’s one thing we can all agree on, it’s that earbud cords are a pain in the butt to keep organized. They constantly get tangled and eventually produce the dreaded earphone-crackle, rendering your treasured music-makers useless. This is a great example of what you can make with a 3D printer that can improve your everyday life.

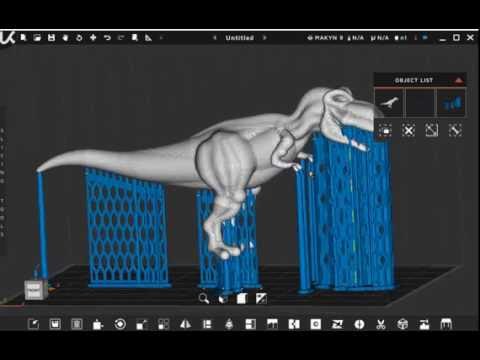

A simple toy originally created for Settlers of Catan, this project is durable and (in our opinion) cute. This is one of those 3D printer projects you could use in a few ways: gaming, office desk decoration, children’s toy, you name it! Plus, T-Rexes are (always!) cool.

Organize your desk, and add a little flair at the same time! With these simple 3D printer designs, you’ll have all you need to generate truly unique desktop organizers that not only keep your stuff where it needs to be but look cool as well. You can 3D print a pencil holder that is unique to your own personality and have others mistaking your pencil holders again.

You can 3D print a pencil holder that is unique to your own personality and have others mistaking your pencil holders again.

With a 3D printer you’ll be able to replace your dinnerware with new and original 3D printer designs in no time at all. Take this blueberry-themed bowl, for example. Why stop there? There are numerous other designs for plates and bowls out there to make eating at home a unique experience.

One of the cool things to 3D print is an abstract planter for your succulents and cacti. Why use traditional planters to hold your plants? There are cool 3D prints out there that don’t allow you to skip the traditional clay pots. These modular little guys are modern and fresh and guaranteed to make your mini-garden more attractive.

Get rid of those 72 measuring spoons from your utensil drawer and replace them all with a single implement! One of the most immediately useful and cool 3D prints in this list, it’ll make for an interesting tool that others will want when they see it.

Stop the tyranny of cords taking over your desk and entertainment unit and 3D print some space-saving cable management devices. You’ll cut back on desk clutter and all that cord-related aggravation. These are the blessed 3D printed objects that make life a little less annoying!

Nearly everyone these days has a smartphone, and we’ve likely all had moments where we wanted to prop up our phones for viewing video or photos and had to resort to piled books or whatever else is on hand. And it rarely works out as well as we hope! That makes this tiny project one of the coolest 3D printed objects on the list. Plus, they look like cats. Cats are good.

A perennial childhood favorite, kids love them just as much today. Of course, adults can enjoy these toys, too. They could be just the ticket to break through some creative block!

A truly inspiring 3D printing idea, these pop-out business cards allow you to speak to clients in a way they won’t have experienced many times (if ever) before! Rather than a drab piece of cardboard, hand them a toy they can assemble that speaks much louder than a traditional printed card.

Can’t sit still? Searching for a 3D printer project to help you focus? Look no further. Fidget spinners are an excellent way to occupy your mind, and this 3D printed object will definitely do the trick.

This is probably one of the most fun and cool things to 3D print, these gimmicky little toys are quite literally affixed to food items found in your house. A lemon helicopter? A banana-car? Why not! Easy to print and awesome for providing hours of enjoyment to restless rainy-day kiddos.

Definitely among the most interesting and cool things to 3D print in this list (and showcasing a bit more complexity than other entries), the dragonfly is a tiny little flying machine you can whip up in a short time. It’s perfect for providing a little entertainment for your kids on a rainy day.

Why settle for boring cutlery in your drawer? With minimal effort, you can produce some decorative handles for your eating utensils and wow visitors to your humble abode. When they inevitably ask “so, what can you print with a 3D printer?”, you can tell them they’re eating with it!

When they inevitably ask “so, what can you print with a 3D printer?”, you can tell them they’re eating with it!

Drop your phone into these useful little devices to amplify the sound from its speakers. They offer surprisingly high-quality sound—and now you don’t need to lug portable speakers around on picnics or at the beach.

If you’re looking for some more simple and cool 3D printing ideas, consider 3D printing a set of drink coasters. Thanks to simple 3D printer designs like this, we won’t need to spend our hard-earned cash on flimsy little discs anymore. Make your own coasters with whatever designs you want, and say goodbye to tacky freebies and over-priced novelty ones. This idea makes for one of the cool things to 3D print as gifts!

If you’re an audiophile, you’ll truly appreciate this entry as one of the best things to 3d print. By converting audio files, you can create your own records that will play on turntables. Why limit it to music? Record your own special messages to loved ones and send out the love!

By converting audio files, you can create your own records that will play on turntables. Why limit it to music? Record your own special messages to loved ones and send out the love!

Simple 3D printer designs like this are great to have on hand. Hinges are always useful, and come in handy all over the house. These particular designs are super-simple, even by 3D printing standards, requiring just a single step!

With a sliding clasp, these unique chip clip designs work quite well and are fantastically simple things to 3D print.

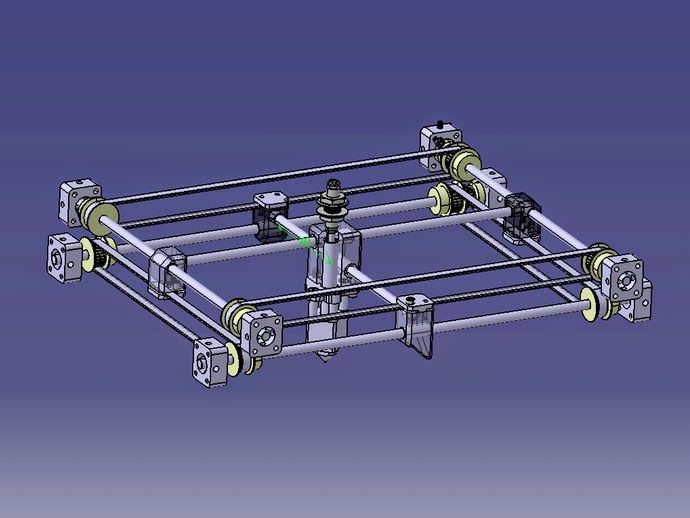

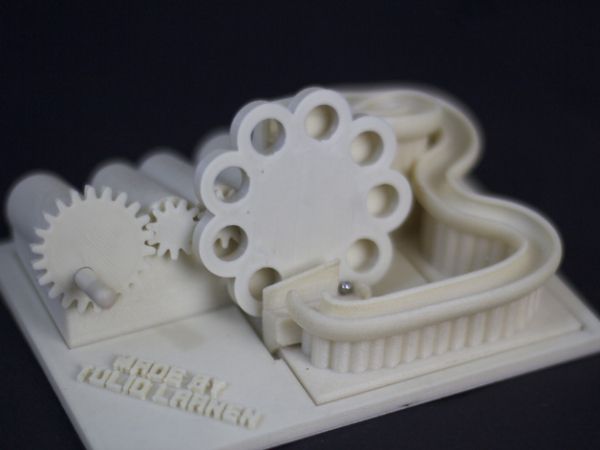

A larger-scale project than other 3D printing ideas, the Drawing Machine is quite unique: attach a pen and create works of art from files on your computer. This 3D printer project can help you produce invitations, cards or any other manner of drawings.

Some nostalgic old-timey engineering comes into play with these uber-neat 3D printing ideas. Relive the past and have your desk decorated with a sign that uses something other than LED or LCD displays!

Relive the past and have your desk decorated with a sign that uses something other than LED or LCD displays!

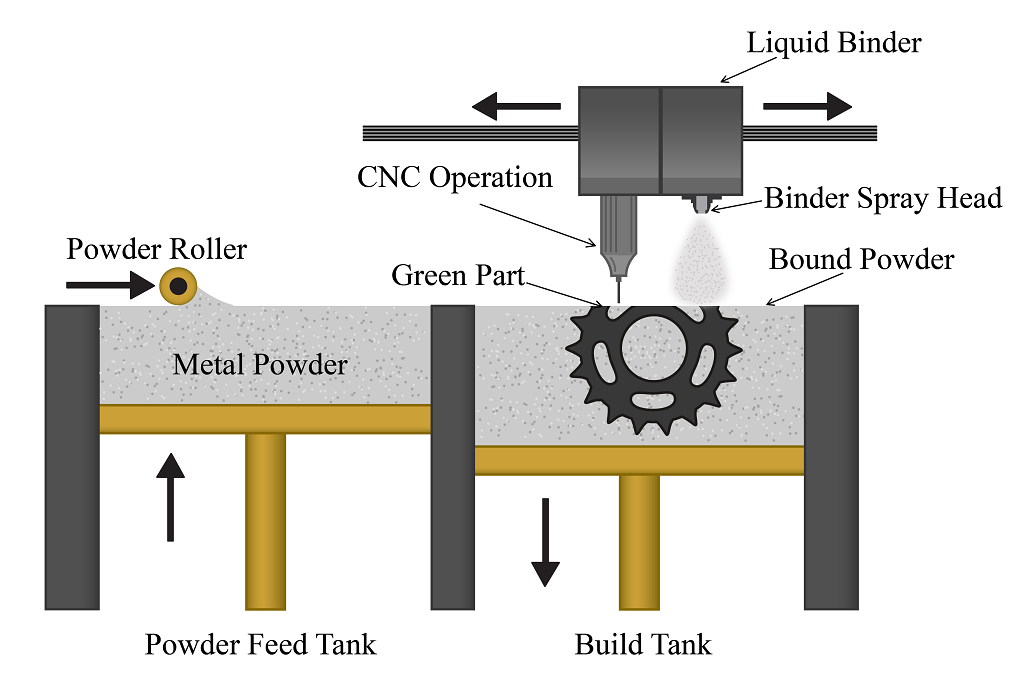

When it comes to 3D printing metal, there are people who may choose to use a laser cutter instead. The reason is that 3D printed projects using metal can be costly and time-consuming. However, the two are quite different. 3D printing is an additive process, while laser cutting is a subtractive process. Depending on your needs, those that are looking to create multiple pieces at a quicker pace may choose the laser cutter as it can conveniently cut multiple materials and larger size.

With digital trends of raw and rustic design, you might be considering 3D printing cool things at home with metal. However, printing metal is extremely costly due to its process and the machinery required. If you’re looking for cool things to 3D print at home with a metal-looking finish, we recommend using materials on the market that can create metal-like 3D printed objects instead. These materials give the illusion that your 3D printed pencil holder or camera mount is made out of metal but without the actual cost.

These materials give the illusion that your 3D printed pencil holder or camera mount is made out of metal but without the actual cost.

Thanks to 3D printing, it has also made highly-customizable prosthesis possible. One of the coolest things about 3D printed prosthesis is that they can create custom fits for the patient and also a much lower cost. Instead of creating static designs that are “one size fits all”, 3D print gives companies the opportunity to create products that are affordable and personalized. What would have cost lots of money to create is now more accessible thanks to 3D printed prostheses.

Beyond science, 3D printed homes and shelters have also become one of the cool things to 3D print across the world. To address the housing issue around the world, companies have been using this technology to print emergency shelters and 3D printed homes. With this technology, companies and cities can build a community in a much shorter amount of time and for a cost cheaper than traditional home building methods. Each home inside the community can then be purchased at a more affordable cost.

Each home inside the community can then be purchased at a more affordable cost.

If you love architecture and buildings, companies have created kits that allow people to replicate architectural structures and other cool things with a 3D pen. For boardgame lovers, you 3D print your own figurines by drawing it with your 3D pen. You can also turn your favorite cartoon show characters or movie heroes into 3D. While a 3D pen allows you to draw 2D things to 3D, their limitation tends to be the size of the project you can make. If you’re looking to 3D print a life-size chair, it may be easier to use a printer because 3D pens may not be able to create something as durable.

- Tangram: A super easy and fun game to play with your kids or friends. If you’re going on a road trip or simply trying to pass time, this 3D printed tangram makes for portable entertainment.

- Klöts (Quick shoe ties): Some cool things to 3D print for your kids are these quick shoe ties.

With this project, you’ll spend less time worrying about their shoelaces being undone and risking a fall.

With this project, you’ll spend less time worrying about their shoelaces being undone and risking a fall. - Puzzle Keychain: This heart puzzle is perfect as a gift or personal use. If you’re tight on schedule for an anniversary or valentine’s day gift, this heart puzzle is one of the quickest things to 3D print.

- Door Stop: Some things to 3D print for practical uses are these door stops. Whether you’re using it at home or for your office, printing them is super easy and fast.

- Light Switch Locks: This definitely tops for cool things to 3D print, especially for parents. This awesome tool can prevent your kids from turning the lights on and off at home. Keep certain lights off to save energy.

Ready to build a design portfolio website that captures clients’ attention? From gorgeous themes to a built-in proofing tool, we’ve got designers covered. Start your free trial with Format today!

Now get out there, get creative, and start turning heads with amazing 3D creations!

Need some more design project inspiration?

How to Start a Creative Project by ADAMJK

5 Ways to Fund Your Personal Project

10 Steps to Building Your Perfect Online Portfolio

3d Printed Objects - Etsy.

de

deEtsy is no longer supporting older versions of your web browser in order to ensure that user data remains secure. Please update to the latest version.

Take full advantage of our site features by enabling JavaScript.

Find something memorable, join a community doing good.

(1,000+ relevant results)

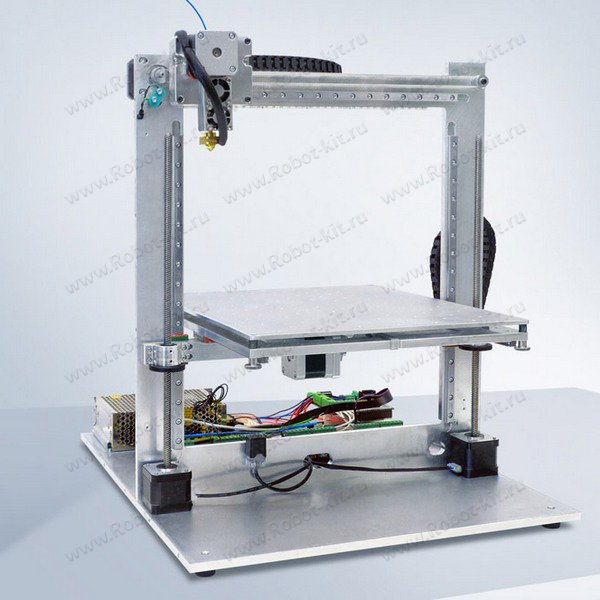

Techno Print 3D Company

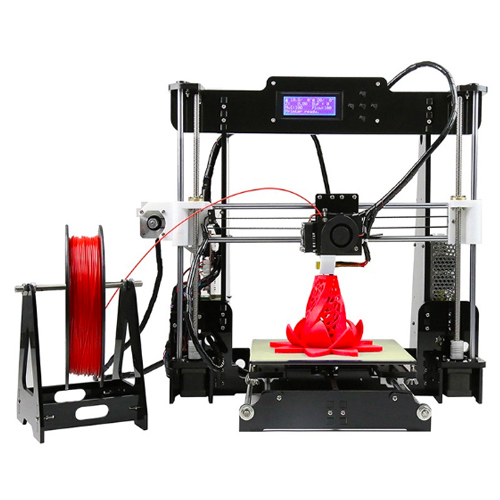

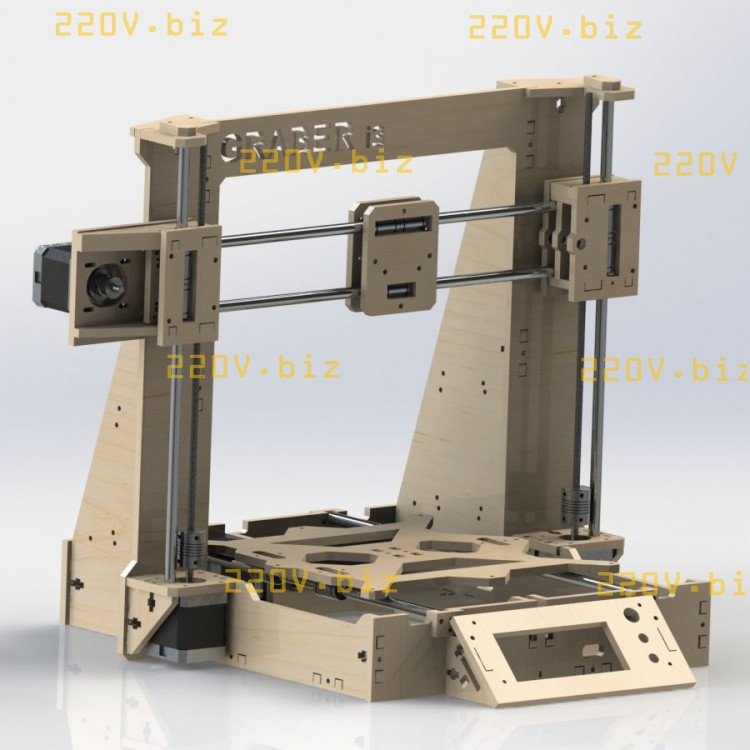

This is our first review of the most popular and inexpensive 3D printers for 2020. The list will include the best-selling devices in two price ranges (up to 30 tr and up to 60 tr). Printers working with both plastic filament (FDM) and photopolymers (LCD/DLP) will be presented. This list will always be up to date, as it is periodically updated and supplemented. Read more→

The list will include the best-selling devices in two price ranges (up to 30 tr and up to 60 tr). Printers working with both plastic filament (FDM) and photopolymers (LCD/DLP) will be presented. This list will always be up to date, as it is periodically updated and supplemented. Read more→

The Chinese company Dazz3D announces the launch of the project on KickStarter and accepts pre-orders for Dazz3D Basic and Dazz3D Pro 3D printers. These revolutionary new devices are aimed at both the professional and amateur markets. Read more→

We all know that precise calibration of the 3D printer desktop is the foundation and the key to successful printing on any FDM printer. In this article we will talk about the main and most popular ways to level the "bed". So, as mentioned above, 3D printing without desktop calibration is impossible. We face this process Read more→

It's hard to go through a day today without hearing about 3D printing technology, which is bursting into our lives at an incredible speed. More and more people around the world are becoming addicted to 3D printing technology as it becomes more accessible and cheaper every day. Now almost anyone can afford to buy a 3D printer, and with the help of Read more→

More and more people around the world are becoming addicted to 3D printing technology as it becomes more accessible and cheaper every day. Now almost anyone can afford to buy a 3D printer, and with the help of Read more→

The FormLabs Form 2 and Ultimaker 3 are perhaps the most popular 3D printers today, capable of high quality printing with incredible surface detail. Moreover, these two devices use completely different technologies, and therefore, there are a lot of differences between them. Many will say that it is wrong to compare them or Read more→

XYZprinting, best known for its daVinci line of desktop 3D printers, is bringing five new devices to the professional and industrial environment. One will use laser sintering technology, the second full color inkjet printing and three DLP machines. First of all, the novelties will be of interest to dentists and jewelers. Read more→

Cleaning the nozzle of a 3D printer is a fairly common process that any user of such a device has to deal with. This is not at all a complicated procedure that anyone can handle. You can complete this task in 15 minutes, using only handy tools and accessories. Read more→

This is not at all a complicated procedure that anyone can handle. You can complete this task in 15 minutes, using only handy tools and accessories. Read more→

Acetone steam polishing of ABS plastic is a process for smoothing the surface of 3D printed models. The result of this treatment makes your printed products look as if they were made by a professional mold casting method. If you want to understand how this is done correctly, then read this article. Aceto Read more→

3D Printing: All about Heatle

The heating of plastic filaments in specialized printers equipped with heated extruders and print beds creates the basis for the formation of products from molten filaments, also known as 3D printing.

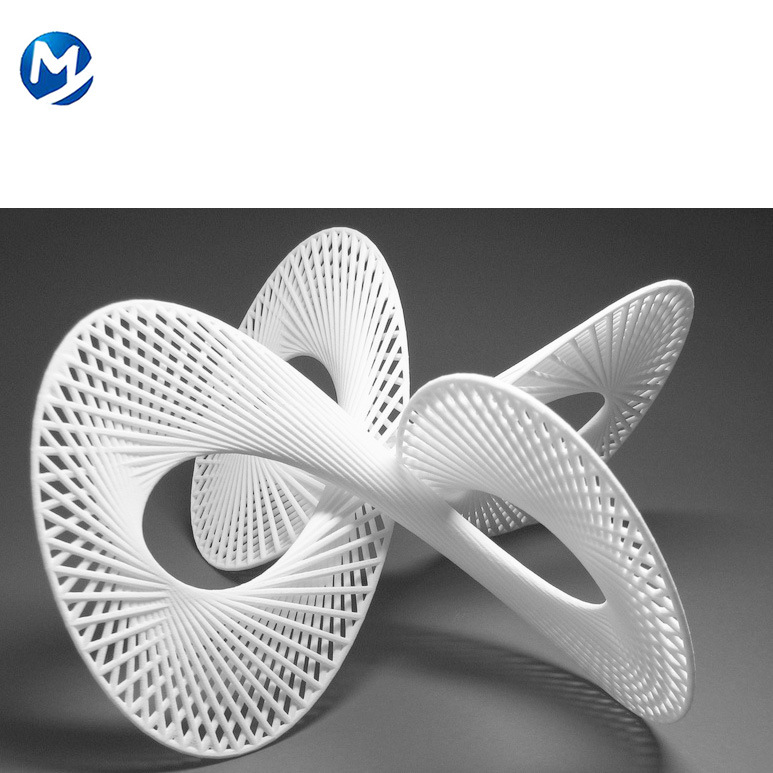

Currently, 3D printers are being used to create tools, camera equipment, medical models, phones and tech accessories, home decor items, toys, and fashion, just to name a few. The applications for 3D printing are almost limitless.

Since 2009, when the main patent for portable 3D printers expired, 3D printing has grown into an industry of its own. As a result, 3D printers are one of the defining products of our time.

As a result, 3D printers are one of the defining products of our time.

3D printers are now being used to create just about anything you can imagine - tools, camera equipment, medical models, phone and personal technology accessories, home decor, toys, and fashion, just to name a few. Its applications are almost endless. Theoretically, any solid object can be made with 3D printing. Although some limitations in technology prevent printing in certain sizes and materials, research and development is rapidly expanding the possibilities.

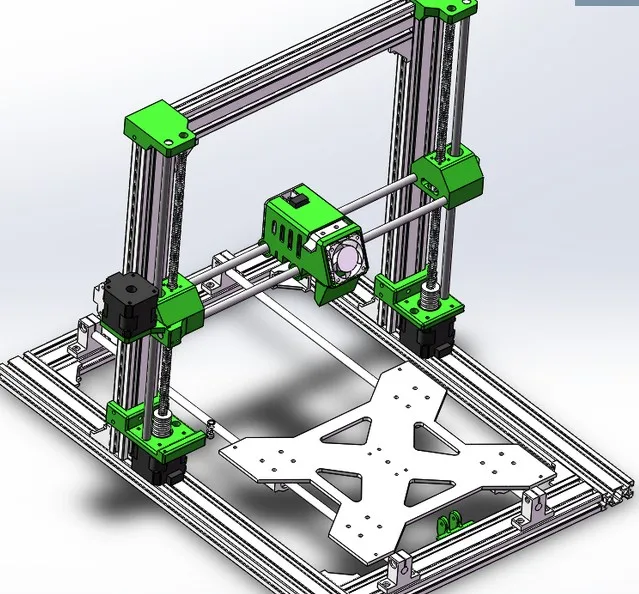

The most popular type of 3D printing is Fused Deposition Modeling (FDM). Modeling the product on the printer is done by melting and extruding a spool of plastic filament through the nozzle as it moves up, down and across the specified XYZ coordinates.

Creating a product using the FDM process looks something like this:

- 3D model created using software.

- The model is exported as a stereolithography file (.

stl format) and then imported into the slicing software.

stl format) and then imported into the slicing software. - The file is split into product layers and specific tool paths are generated.

- The design is sent to the printer.

Within minutes - or possibly hours or days, depending on the size and complexity of the part - the part is made by additive manufacturing.

3D printing heater

3D objects are made by melting, molding and cooling plastic.

Several key components create and manage heat in an FDM printer:

- Extruder.

- Work table.

- Multi-layer cooling fan.

A closer look at each of them will explain how they affect the print result.

Extruder.

The extruder is where most of the printer technology resides. It consists of a cold end that pulls the filament through the system and a hot end that melts the filament as it is extruded.

Inside the hot end of the extruder is a heating block. As a rule, this is an aluminum element with a hole for a cartridge heating element. The heating element melts the filament as it passes through the heat pipe and reaches the nozzle.

As a rule, this is an aluminum element with a hole for a cartridge heating element. The heating element melts the filament as it passes through the heat pipe and reaches the nozzle.

The extruder also has a fan heatsink. This cooling element helps prevent heat from entering parts of the extruder that need to be kept at cooler temperatures.

Another element of the extruder worth mentioning is the thermistor or thermocouple. This temperature sensor detects and helps regulate the temperature of the hot end.

Work table.

The desktop is the surface on which the filament is deposited in a given shape during the printing process. Most PCBs are heated to prevent the plastic from cooling too quickly and deforming the product. Printtables typically maintain temperatures somewhere between 50 and 100°C. Specific temperature requirements depend on what type of plastic is being used.

Some printers do not have heated stages. These machines are limited in the materials they can print with. Also, materials may not adhere to these layers and melted parts are more likely to pop out of the middle of the print.

Also, materials may not adhere to these layers and melted parts are more likely to pop out of the middle of the print.

Multilayer cooling fan.

The cover fan cools the plastic after exiting the nozzle. This element helps the created product to keep its shape when printed.

Heat control: solving heating problems

Since 3D printing is so dependent on heating temperature, any temperature issues can easily disrupt the entire process. Common problems encountered in 3D printing include

- Thermal creep

- Deformation and bending.

- Melted or deformed articles.

- Cracks on the sides of the taller item.

- Slope or bend at the bottom (elephant foot).

- Blurry or undefined first layer.

Manufacturers can face such problems due to non-ideal temperatures.

As 3D printing research and development continues, advanced technology offers even more precise control over higher temperatures, producing high-quality printed products from difficult-to-work materials.

Thermal creep

Heat creep occurs when heat is distributed unevenly through the hot end of the extruder. This happens when the filament cools as it is extruded and heat travels up the thermal barrier tube. This will cause the filament to heat up and swell too early and stick to the walls of the thermal barrier tube. Heat creep can cause clogs that stop printing, and such clogs are difficult to remove.

As a result, thermal barrier tubes are often designed to prevent thermal creep. The teeth or filaments in the pipe help prevent heat from entering places where it is not needed. In addition, there are several preventive measures that can be taken to prevent a negative effect.

- First, ceramic insulation tape must be added around the heater block.

- Second, when the printer is not printing, do not leave it hot.

- Third, avoid using low quality filament that may expand unevenly.

- Finally, if possible, always unload the filament when you finish printing.

Deformation and bending.

Product distortion occurs when the plastic is cooled too quickly after extrusion. Because the plastic shrinks slightly when cooled, rapid cooling can cause the plastic to bend as it solidifies.

Warping can be prevented by keeping the plastic just below its melting point on the print bed. If warping occurs, the temperature of the print engine may need to be increased.

Melted or deformed seal.

Excessive heat is to blame when printed pieces look droopy. FDM printing requires a precise balance between a temperature that allows good flow and a temperature that ensures fast curing.

To fix melted prints, adjust the temperature settings . First, make sure the temperature is within the appropriate parameters for the material. Then try decreasing the nozzle temperature by 5°C at a time.

Cracks on sides of higher prints.

Sometimes when the higher pieces are 3D printed, cracks can appear between some of the higher layers. This is because these layers too far away from the heat of the printed layer . After extrusion, the filament cools too quickly and is not as tacky as it should be. This results in small spaces or cracks between the layers.

This is because these layers too far away from the heat of the printed layer . After extrusion, the filament cools too quickly and is not as tacky as it should be. This results in small spaces or cracks between the layers.

To prevent the filament from cooling too quickly, try to increase the temperature of the extruder by about 10°C.

Slope or bend at the base.

Bending or warping near the base of printed objects occurs when the weight of the model presses on the lower layers before they cool down properly.

This deformation of the lower layers is eliminated by faster cooling. This can be achieved by lowering the platen temperature by 5°C at a time until the desired results are achieved.

Blurry and undefined first layer.

Sometimes the first layer can be blurry. When this happens, the corners feel vague and the filaments look messy. This usually happens because0066 The print bed is too hot and this causes the plastic to lose its shape.

The solution to this problem is probably pretty obvious. It may be necessary for to reduce the temperature of the platen by 5°C at a time until the desired results are achieved.

The threads come in a variety of colors and textures and offer effects ranging from glow in the dark to the look and smell of wood.

Material temperature limits

There are several filament options for . The threads come in a variety of colors, textures and offer effects ranging from glow in the dark to the look and smell of wood. An important part of mastering the use of these different materials is understanding the specific temperature requirements for each material. Failure to comply with these parameters may result in any of the temperature related problems mentioned.

Higher temperatures equals more capability . When 3D printers can maintain higher temperatures during production, more filament options become available. However, working at higher temperatures requires special technology in a 3D printer.

However, working at higher temperatures requires special technology in a 3D printer.

For example, it is not uncommon for extruder hot ends to be made up of both metal and polyetheretherketone (PEEK) or polytetrafluoroethylene (PTFE). While PEEK and PTFE provide excellent insulation, they limit the hot end temperature to no more than 240°C. However, when all-metal hot ends are used, temperatures can be effectively maintained above 300°C. This opens the door to the use of a range of different materials.

New developments in FDM technology are paving the way for even higher temperatures during 3D printing. Last year, a 3D printer manufacturer introduced a line of high-temperature printer components that allow the hot ends of an extruder to reach temperatures in excess of 400°C. Printtables on the same devices can reach temperatures in excess of 200°C.

Ideal temperatures for various materials:

Polylactic acid (PLA)

Acrylonitrile butadiene styrene (ABS)

Polyamide (nylon)

Polyethylene terephthalate (PET / PETG / PETT)

Acrylonitrile styrene acrylate (ASA)

Polypropylene (pp)

Thermoplastic elastomer (TPE)

Thermoplastic polyurethane (TPU)

Wooden Threads

Polycarbonate

Polyvinyl alcohol (PVA)

As 3D printing research and development continues, the improved technology continues to offer even finer control over higher temperatures.