New 3d printing technology 2023

First 20 VLM printers to be shipped by BCN3D in Spring 2023

3D Printer Hardware3D Printing ProcessesAutomationHigh Speed 3D PrintingMaterials

These elite customers will be the first to acquire the commerical systems, to be installed in their own facilities

Edward WakefieldJune 30, 2022

3 minutes read

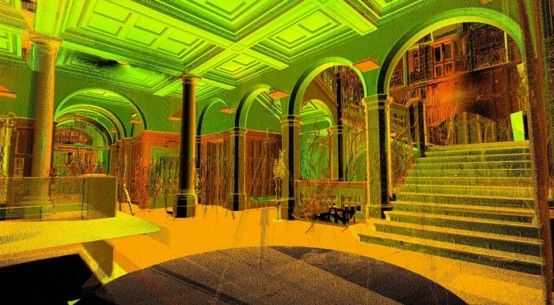

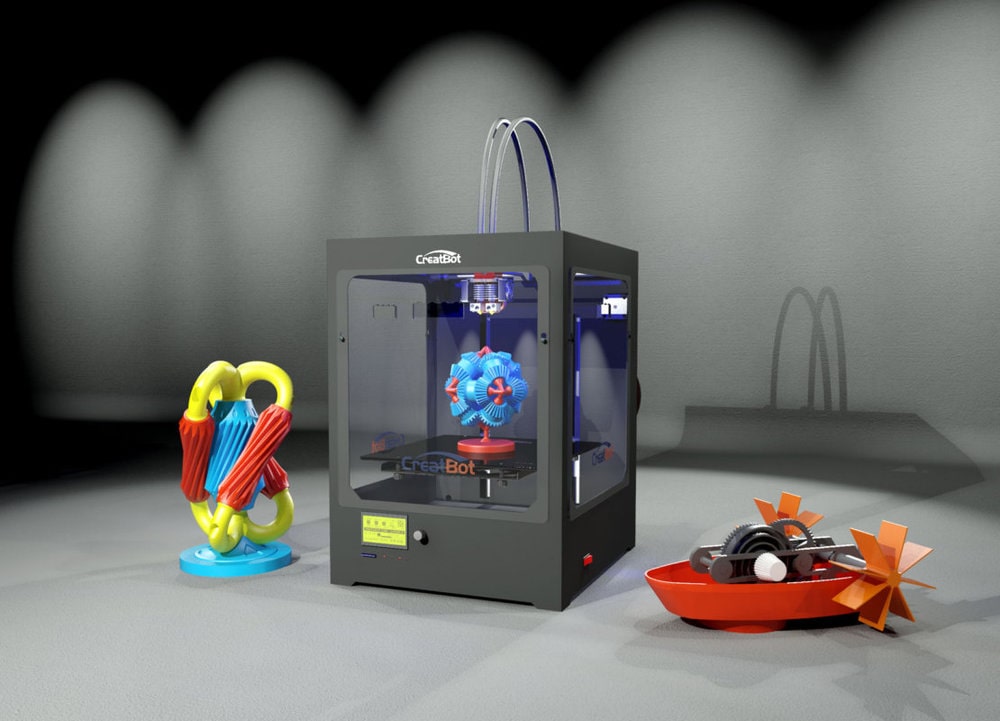

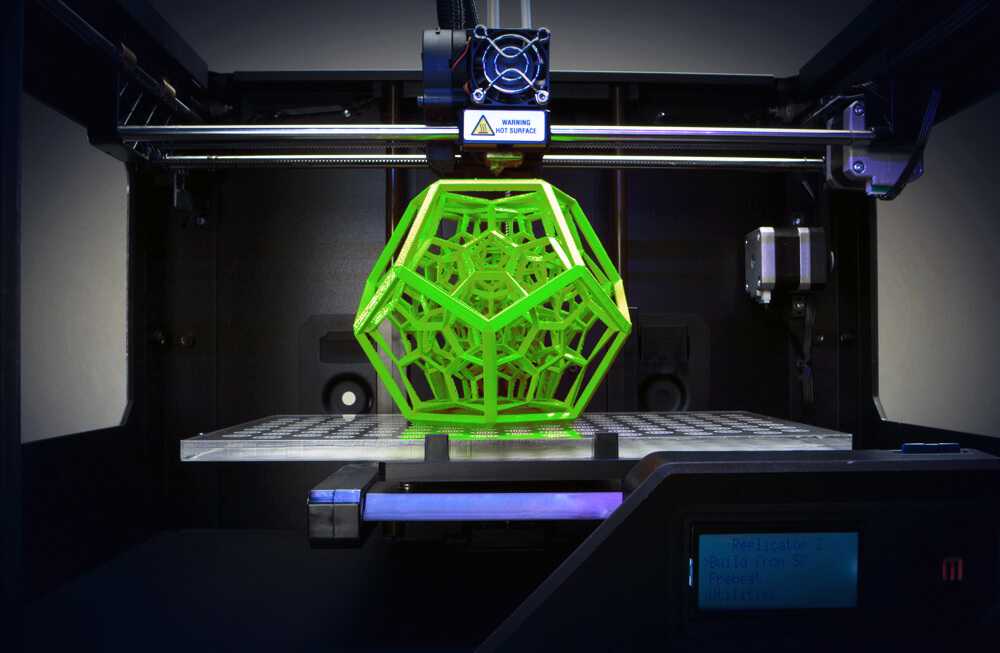

A multi-material rigid and flexible part printed with a VLM printer, as shown behindStay up to date with everything that is happening in the wonderful world of AM via our LinkedIn community.

Earlier this year, BCN3D Technologies announced that its strive for innovation had led its 3D printing experts to never-before-seen 3D printing technology, using high viscosity resins. Developed over the last three years, the patented Viscous Lithography Manufacturing (VLM) provoked mass interest worldwide, with more than 500 companies registering to become early adopters of the development of this ecosystem. BCN3D, in a response to the demand, has partnered with Arkema, and Henkel, to obtain material properties and applications otherwise unreachable with other resin-based technologies, and has committed to delivering 20 VLM printers to 20 of the companies currently enlisted in its Technology Adoption Program, during Spring 2023.

The Technology Adoption Program has been inundated with registrations. Applicants have come around the world, with the United States dominating the majority, followed by Germany and other European countries. BCN3D began rolling out local operations in North America in late 2021, and in April use cases with VLM were publicly presented during the Rapid+TCT show in Detroit, resulting in a peak in the Technology Adoption Program registrations.

The initial premise for this accumulation of early adopters was to orientate the go-to-market through gathering market information across a wide scope of vertical markets. Through this approach, BCN3D was able to see the real needs of customers, especially those within manufacturing, automotive, engineering, dental, prosthetics & orthotics, jewelry, product design, 3D printing services, and footwear.

The diversity of the early adopters brings BCN3D valuable insights – current AM limitations can be detected with precision, industry and material trends can be identified, and the company has personal contact with the engineers operating the 3D printing labs in a variety of companies. VLM’s versatility makes it capable of covering the entire fabrication life-cycle, from product design to fabrication. BCN3D believes that the benefits will be made extremely apparent in prototyping and end-use parts.

VLM was devised to simultaneously accomplish the three main pillars of providing superb part performance, a high production capacity, and accessible and frictionless operation – thus, unlocking complete manufacturing autonomy. Since all manufacturers equipped with this technology can experience full control over every stage in their production processes with AM solutions, the findings from the Technology Adoption Program point to some interesting applications that are on the rise.

Some of the main applications taken from this research include low emission end-use parts, elastomeric components, biocompatible parts, and the mass-customization of high-temperature and high-resistance parts. Furthermore, multi-property opportunities in the medical sector range from the need for different biocompatibility requirements in dental, to complex combinations of rigid and flexible parts in prosthetics and orthosis. Last but not least, regarding the mass production of functional parts, the obvious applications include nesting strategies with water-soluble supports without manual polishing or overmolding solutions. Among this wide variety of applicants are those participating in material development. These elite AM users are testing and furthering new ways to utilize the high viscosity resins that make VLM so unique.

“The overwhelming initial reception for our most recent innovation has surpassed our expectations and set the tone for the onset of the distribution of our first VLM commercial systems. We’ve been able to hone in on what really matters to each individual company by gathering real, tangible information from experienced engineers. We’re aware of special interest regarding multi-material, and thus multi-property and water-soluble applications. Of course, functional materials also hold huge potential,” said Xavier M. Faneca, CEO of BCN3D.

We’ve been able to hone in on what really matters to each individual company by gathering real, tangible information from experienced engineers. We’re aware of special interest regarding multi-material, and thus multi-property and water-soluble applications. Of course, functional materials also hold huge potential,” said Xavier M. Faneca, CEO of BCN3D.

According to BCN3D, the response to the VLM technology release has exceeded the company’s expectations, and BCN3D’s VLM agenda is to now make the jump to a fully-fledged hardware system to serve the world’s most experienced additive manufacturing teams. BCN3D is selecting 20 elite customers to become the first to acquire these VLM printers which will be installed in their own facilities during the Spring 2023. This will grant each company in-house accessibility while still maintaining continuous contact and support from the dedicated materials and applications engineers at BCN3D that make up the application development service.

All in all, VLM’s increasing popularity stems from its way of solving manufacturing autonomy otherwise unachievable by existing ways in the current AM market. Following on from the success of the release and registration to the VLM Technology Adoption Program, BCN3D has set out to implement a powerful go-to-market strategy for the commercialization of VLM printers. In November 2022, users and enthusiasts can expect even more updates regarding VLM at the international Formnext exhibition and conference in Frankfurt, Germany.

Following on from the success of the release and registration to the VLM Technology Adoption Program, BCN3D has set out to implement a powerful go-to-market strategy for the commercialization of VLM printers. In November 2022, users and enthusiasts can expect even more updates regarding VLM at the international Formnext exhibition and conference in Frankfurt, Germany.

The VLM Technology Adoption Program is still open for new applications, as well as the opportunity to be one of the companies to apply for one of the 20 VLM printers during Spring 2023. Following on from the high volume of applications, BCN3D is putting a strong focus on granting extended access to the dedicated VLM Printing Center and to develop its application service with more dedicated materials and application engineers.

Related Articles

Back to top button

Amazon to Ban the Sale of 3D Printers by 2023

Published on April 1, 2022 by Madeleine P.

At 3Dnatives, we like April Fools’ Day! So this article was just a little joke for the occasion, Amazon remains supportive of 3D printing development!

You have almost certainly heard of Amazon. The American online retailer currently makes more than 12 million products available for purchase at lower prices. On this platform, you can find video games, clothing, household appliances, and of course 3D printing solutions – until now! That’s because Amazon is planning to make non-company 3D printers disappear from the platform very soon. Amazon has announced plans to ban all 3D printers by 2023. A slap in the face for major 3D printing companies offering their technologies on the popular online portal. Considering that Amazon receives more than 2 billion website visits per month, it’s easy to see why so many 3D printing companies sell their printers there.

Thankfully, Amazon did not keep its customers in the dark for long regarding their decision to ban 3D printers on the website. In fact, apparently the company is working internally to launch production and soon the sale of its own 3D printer line, including software, expected to be on the market starting in 2024. This is a large step from the conglomerate, as it dares to take in an industry that has proven to enjoy increasing popularity and acceptance.

In fact, apparently the company is working internally to launch production and soon the sale of its own 3D printer line, including software, expected to be on the market starting in 2024. This is a large step from the conglomerate, as it dares to take in an industry that has proven to enjoy increasing popularity and acceptance.

The company’s own 3D printer should be available for sale on the website from 2024 (photo credits: Amazon)

Amazon: A New Top 3D Printer Manufacturer in the Future?

Though of course the plan to ban 3D printers from Amazon is shocking, the first questions that spring to mind are probably: What can we expect from Amazon’s 3D printer? What innovative and ingenious features will this technology come with? Fortunately, Andy Jassy, CEO of Amazon and successor to the famous Jeff Bezos, cleared some doubts in a recent press release, making it clear that the plan is to take Amazon to the next level. In order to realize Amazon’s vision, the company has decided to put itself forward in the 3D printing sector. Internally, the board is already convinced that Amazon will have made a name for itself in the additive manufacturing market in just a few years. Already it seems that the board of the U.S. company expects the company to become one of the big players among 3D printing manufacturers in the future.

Internally, the board is already convinced that Amazon will have made a name for itself in the additive manufacturing market in just a few years. Already it seems that the board of the U.S. company expects the company to become one of the big players among 3D printing manufacturers in the future.

In usual and unsurprising Amazon fashion, the first concrete plans are already in place from the R&D team to ensure that the company’s entry into the 3D printing industry is guaranteed. David Stafford, as head of the R&D department at Amazon Lab126, is playing a key role in the design and manufacture of the Amazon 3D printer. They plan to offer an affordable 3D printer based on FDM technology that is not only aimed at individuals, but also businesses; priced at under $100, this 3D printer will be found in Amazon Basics’ own product line and reinforces the idea of making 3D printing accessible to everyone.

Features and characteristics of the 3D printer

To ensure that the entry into the field of 3D printing with the future FDM printer is also a complete success for the US company, the printer will have important and practical features: for example, the device, which is to be supplied with a closed power supply unit, is to have an build volume of 1200 x 600 x 450 mm and will be able to offer its users many interesting . The incredible thing is that it does not plan to just stick to using FDM as a printing technology, but they will be launching an all-in-one FDM/SLA combined machine! As unrealistic as this may sound, Amazon has said that they are very confident in their idea. If it is done successfully, it will also give Amazon even more of an edge as often those looking for cheap printers must choose between SLA and FDM for their needs. With this machine, they could get everything at an incredibly affordable price, even if they are very tight-lipped about the specific details of how the printer will work. What is also known is that with a total weight of 19.4 kg, the printing speed is expected to be 320 mm per second, though whether that is just for FDM or for both is still unknown.

The incredible thing is that it does not plan to just stick to using FDM as a printing technology, but they will be launching an all-in-one FDM/SLA combined machine! As unrealistic as this may sound, Amazon has said that they are very confident in their idea. If it is done successfully, it will also give Amazon even more of an edge as often those looking for cheap printers must choose between SLA and FDM for their needs. With this machine, they could get everything at an incredibly affordable price, even if they are very tight-lipped about the specific details of how the printer will work. What is also known is that with a total weight of 19.4 kg, the printing speed is expected to be 320 mm per second, though whether that is just for FDM or for both is still unknown.

It is still unclear which software the Amazon printer will be compatible with. However, Stafford gave some small insights, setting his team and himself up for great expectations from the public. They want to use this type of software that will combine user-friendliness, efficiency and cost savings in one cheap package. Great words, which will hopefully be followed by great deeds. However, what exactly this project means for the banning of the current 3D printers and the companies behind them, is still not clear. But we will be watching the news closely and inform you of any new developments. If you want to learn more about the new Amazon technology, you can find more information from the US company HERE.

Great words, which will hopefully be followed by great deeds. However, what exactly this project means for the banning of the current 3D printers and the companies behind them, is still not clear. But we will be watching the news closely and inform you of any new developments. If you want to learn more about the new Amazon technology, you can find more information from the US company HERE.

David Stafford gives great reason to be excited about the advancement of 3D printing

Did you fall for the prank? Let us know if you believed our April Fool’s Day article in a comment below or on our Facebook, Twitter and LinkedIn pages! Sign up for our free weekly Newsletter here, the latest 3D printing news straight to your inbox!

*Cover Photo Credits: Amazon

Construction 3D printing is waiting for a breakthrough

3D printing technology originated in the 80s of the XX century, but construction 3D printing appeared much later. The first construction projects using this technology appeared only in 2014. First of all, we are talking about the so-called small architectural forms (benches, flower beds, fences). They have not yet dreamed of building houses. But already in 2015, the Russian startup Apis Cor made a splash - it printed a whole house in the Moscow region. Since then, news about new 3D printed houses has periodically appeared. However, despite the fact that the technology proved to be very promising in terms of the speed of construction of housing and the reduction in the cost of construction, no mass implementation followed.

First of all, we are talking about the so-called small architectural forms (benches, flower beds, fences). They have not yet dreamed of building houses. But already in 2015, the Russian startup Apis Cor made a splash - it printed a whole house in the Moscow region. Since then, news about new 3D printed houses has periodically appeared. However, despite the fact that the technology proved to be very promising in terms of the speed of construction of housing and the reduction in the cost of construction, no mass implementation followed.

Construction is the world's number one market. And, if many technological innovations are being introduced in the field of high-rise construction, then little has changed in the field of low-rise construction over the past decades. The last 30 years have seen the availability of the internet, mobile phones, mobile internet, robotics have risen to new levels, etc., but when you get to a house construction site, you are unlikely to find many technological innovations. Automation is practically non-existent, and manual labor prevails. 2020 was a test of strength for the whole world, and also led to the highest level of inflation, which, first of all, hit the construction market, there was a dramatic change in prices for metals, cement, wood and much more.

Automation is practically non-existent, and manual labor prevails. 2020 was a test of strength for the whole world, and also led to the highest level of inflation, which, first of all, hit the construction market, there was a dramatic change in prices for metals, cement, wood and much more.

This Internet meme clearly shows what happened to the cost of building materials in just a year. And the process is still going on. At the same time, there is a serious rise in the cost of labor, and there is an acute shortage of it. All this leads to a sharp rise in the cost of building houses. No matter how strange it may sound, statistics show that the growth of automation does not occur when everything is fine, but precisely in crisis situations, during increased competition, reduced demand and the need to urgently look for new technologies to increase production efficiency. This happened this time too, and after some stagnation, construction 3D printing received a new impetus for development.

Preparing to write an article, I turned to the founder of Arkon - Boris Kozlov . Arkon was established in 2020 and is engaged in the production of construction 3D printers, both a workshop type for creating prefabs (prefabricated houses) and a portal type capable of printing a two-story house. I asked Boris the key, in my opinion, question:

— Construction 3D printing appeared in 2014, but no mass adoption of this technology followed for 7-8 years. Why do you think this happened and why is there a surge of new projects right now?

- It seems to me that the reason is the "snowball" effect. The technology had to mature, grow from a hypothesis to a pilot implementation, and finally to commercialization and scaling (what is happening now). In addition, it should be taken into account that construction is one of the most conservative industries, where, unlike even aviation and the automotive industry, there is still an extremely low introduction of digital solutions and automation in the field of the production process itself - the construction itself.

The issue of regulation and certification also plays an important role - this process is long and creates an additional lag.

2014–2016 the first samples of building 3D printers and prototypes of printed buildings appeared. The concepts of various form factors of 3D construction printers and types of printing materials were tested.

In 2017-2018 in the world, the first notable investments were made in a number of construction 3D printing start-ups. Further, by 2020, these investments "rolled" in the form of reaching a certain level of technology maturity - the first commercial products (3D printers and houses) appeared.

Finally in 2020-2022 it became clear that the hypotheses of the effectiveness of construction 3D printing were justified (cheaper, faster, more environmentally friendly), and large investments began in the industry. A vivid example is the investment of GE (the French division of General Electric) in the Danish COBOD or the achievement of a capitalization of $ 2 billion by the American company ICON.

In 2022-2023 over 1,000 buildings will be printed worldwide already, scaling from individual buildings/pilot projects to entire villages and major infrastructure/reinforced concrete implementations. In addition, in a number of countries, by now, a regulatory framework has been created or is being actively created for the introduction of additive technologies in the construction industry.

Thus, I believe that the specified time period is a fairly natural cycle of the formation of technology, which is likely to experience exponential growth in the next decade.

According to a ResearchAndMarket report, the global construction 3D printing market is valued at $354.3M in 2022 and is projected to reach $11,068.1M by 2027, up 99.04%.

Various market processes affect the prices and behavior of participants in the global 3D construction printing market. They create price signals that are the result of changes in the demand and supply curves for a product or service. They can be associated with both macroeconomic and microeconomic factors. Even human emotions can also drive decisions, influence the market, and create price signals.

They can be associated with both macroeconomic and microeconomic factors. Even human emotions can also drive decisions, influence the market, and create price signals.

Now let's take a quick look at what is the construction 3D printer. Without delving too deeply into the technology, we can say that construction 3D printers are very similar to classic FDM/FFF printers that print with plastic, but instead of plastic, the material here is a cement mixture, which is fed directly into the nozzle and forms an object by layer-by-layer overlay. Printers can also be gantry, on the basis of a flying boom, with a robotic arm.

Shown on the left is a construction printer based on a boom. In the figure on the right, a portal construction 3D printer

In the figure, a construction 3D printer in the form of a robot arm installed on a mobile platform.

Everything changed completely when, in the summer of 2021, the American company ICON, which was trying to introduce 3D printing into the construction of various auxiliary facilities, signed a contract with one of the largest American developers - the Lennar company - to build a village of 100 houses in Texas and immediately became a unicorn , having received $200 million in investments from several investment funds.

Pictured are 3D printed houses in Austin, Texas.

At the same time, the Danish company COBOD, formed by the world's largest construction formwork company PERRI, began selling its 3D portal construction printers and participating in construction projects around the world. In the photo below, a modern two-story house built in Germany and a school building in Malawi, built in record time with a minimal budget.

There is little in common between developed, developing and poor countries, everywhere their problems and challenges, but the lack of affordable housing is a global agenda . If in poor countries the issue of increasing the number of homeless due to lack of housing as such is acute, then in developing countries it is necessary to dramatically accelerate the number of new housing being built to meet the needs of a growing population. In developed countries, the problem is primarily in the cost of housing, which has risen in price to such an extent that it has become practically inaccessible to young people. And with the simultaneous increase in life expectancy in these countries, this problem is only getting worse.

In developed countries, the problem is primarily in the cost of housing, which has risen in price to such an extent that it has become practically inaccessible to young people. And with the simultaneous increase in life expectancy in these countries, this problem is only getting worse.

At the same time, the trend towards "green agenda " is developing, reducing CO emissions 2 , building from more environmentally friendly materials, etc. But, unfortunately, so far the construction industry is the absolute leader in CO emissions 2 , and also by the amount of garbage that each construction site leaves behind. This is not to say that construction 3D printing solves all these problems, but at least it is moving in the right direction. Let's look at this with a few illustrative examples.

The photo shows the walls printed by a construction 3D printer.

Today, when we talk about 3D printing houses, we are talking about printing walls. Everything else (foundation, windows, doors, ceilings and roof) is done in the traditional way. 3D printed walls are erected as fixed formwork, which significantly saves the amount of cement used, which in turn reduces construction costs and reduces the environmental impact of cement production. In addition, with this method of construction, no additional waste is produced, the strength of the structure does not suffer. It can be reinforced, as shown in the photo on the left, and engineering communications can be laid immediately, as shown in the photo on the right, which also affects the final speed of the construction of the object. At the same time, the total weight of the structure is reduced, the remaining cavities can be filled with lightweight foam concrete, insulation, straw, or any other available material. Such a lightweight design can use a lighter foundation. The construction method itself is more economical in terms of material, and therefore environmentally friendly.

Everything else (foundation, windows, doors, ceilings and roof) is done in the traditional way. 3D printed walls are erected as fixed formwork, which significantly saves the amount of cement used, which in turn reduces construction costs and reduces the environmental impact of cement production. In addition, with this method of construction, no additional waste is produced, the strength of the structure does not suffer. It can be reinforced, as shown in the photo on the left, and engineering communications can be laid immediately, as shown in the photo on the right, which also affects the final speed of the construction of the object. At the same time, the total weight of the structure is reduced, the remaining cavities can be filled with lightweight foam concrete, insulation, straw, or any other available material. Such a lightweight design can use a lighter foundation. The construction method itself is more economical in terms of material, and therefore environmentally friendly.

Ecoconcrete with the addition of polymers is currently being actively developed, the production of which reduces CO emissions 2 from 30% to 100%. The Apis Cor company mentioned at the beginning of the article, which built a house in the Moscow region in 2015, is now based in hot Florida, plans to start using this material in its projects.

Another startup from Russia, Mighty Buildings, headquartered in California, initially relied on a polymer with the addition of mineral chips. And while the company doesn't build entire houses, it only makes wall panels, it has received numerous design awards, as well as a $400 million valuation in several investment rounds.

In summary, with a rough calculation, we can say that the total savings on the construction of walls can reach 30%, and the total cost of the house can be reduced by 10%. This is true for houses designed for conventional construction. And if you initially design with 3D printing, you can improve this ratio by optimizing the laying of communications, the ability to immediately print interior walls, laying niches for bathrooms, fireplaces, built-in wardrobes and kitchens, as was done in the house built by COBOD in Germany.

"There are spots on the sun." Despite all the advantages of construction 3D printing, has several significant disadvantages of . The main one is layering, which cannot be avoided at the current level of technology development.

The photo shows the layering of the 3D printed walls.

This task can be worked in several directions:

1. Ribbed walls can be plastered, painted and played with as a design element. This is what ICON does in the USA. For example, their latest project, House Zero, did just that and won a number of design awards.

Pictured is House Zero in the USA built by ICON.

2. Use special "shutters" on the printhead to smooth layers, as COBOD and other manufacturers do. The photo below shows that this does not ensure the complete absence of layering.

3. Fully sand the surface to get the usual smooth wall for plastering, painting, wallpapering or other finishing. It is possible, but it will require huge labor costs, which can reduce the overall efficiency of using 3D printing.

The second problem is the required temperature. Ideally, printing should take place at temperatures between +5°C and +30°C. Humidity is also important. Using additives, you can push these boundaries, but not to infinity. At strong sub-zero temperatures, printing will be possible in the field only if the construction site is covered with a dome and the required temperature is reached inside with the help of heat guns. In conditions of extreme heat, it is preferable to print at night. Another solution could be to print wall panels in the shop and assemble them on site. Of course, each of these decisions will negatively affect the economic efficiency of the project.

Building 3D printing can be useful not only for the construction of houses . With its help, you can solve many other problems, and there its disadvantages will not matter. For example, the American concern GE uses COBOD printers to build towers for wind turbines in the shop. Ribbed surface and temperature restrictions in this case do not play any role. Construction takes place in the workshop, after which the object is transported to the installation site.

With its help, you can solve many other problems, and there its disadvantages will not matter. For example, the American concern GE uses COBOD printers to build towers for wind turbines in the shop. Ribbed surface and temperature restrictions in this case do not play any role. Construction takes place in the workshop, after which the object is transported to the installation site.

Pictured is a 3D printed wind turbine tower.

————————————

Construction 3D printing, or, as it is also called, additive construction, has just appeared, and I want to believe in its bright future. There are many prerequisites for this, but much still needs to be done for success. First of all, it is necessary to develop principles for designing houses for building 3D printing. Then it is necessary to attract top architects to create landmark projects, which can be followed by the mass introduction of a new and very promising technology. Construction 3D printing can help solve the global housing shortage and also bring more automation to other areas of construction.

Construction 3D printing can help solve the global housing shortage and also bring more automation to other areas of construction.

3D Technology Supplementary Education Program

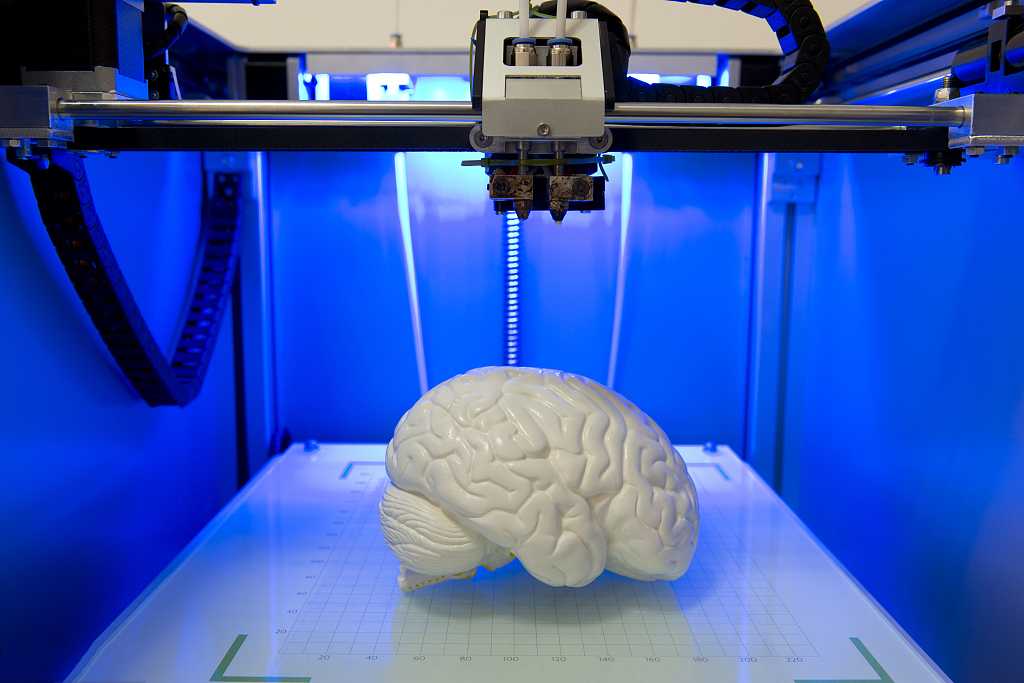

3D printing technology is quite new and it is developing really fast. More recently, rapid prototyping has been limited in children's educational settings due to the high cost of equipment and consumables. But layer-by-layer building technology appeared, and 3D printing became an accessible tool for students. They are happy to use this technology for rapid prototyping and small-scale production.

At present, 3D technologies are so accessible (both the purchase of the machine itself and consumables) that one can not only talk about this technology, but also actively use it in the classroom. The use of 3D printing opens up a fast path to iterative modeling. Students can design 3D parts in various CAD programs. The use of 3D technology inevitably leads to an increase in the share of innovations in student projects. Children are involved in the process of development and production of the part being created.

Children are involved in the process of development and production of the part being created.

Once students have drawn their idea on paper, modeled it in CAD software and printed it on a 3D printer, students will 3D print more and more.

Since 2018, our university in schools No. 645 of the Pushkinsky district of St. Petersburg, secondary school No. 547 St. Petersburg, secondary school No. 690 St. Petersburg has been implementing an exciting additional general educational program "3D Technologies". The program is aimed at introducing students to and mastering modern design technologies, three-dimensional modeling and manufacturing their own parts on a 3D printer.

Lessons in secondary school No. 645 of the Pushkinsky district of St. Petersburg

Lessons in secondary school No. 547 St. Petersburg

Classes in secondary school No. 690 St. Petersburg

Educational process for students contributes to the development of elements of technological culture, as important components of the culture of modern man. Children develop knowledge about the basic principles of design, three-dimensional modeling, and acquire practical skills in working with modern 3D equipment and various software.

Children develop knowledge about the basic principles of design, three-dimensional modeling, and acquire practical skills in working with modern 3D equipment and various software.

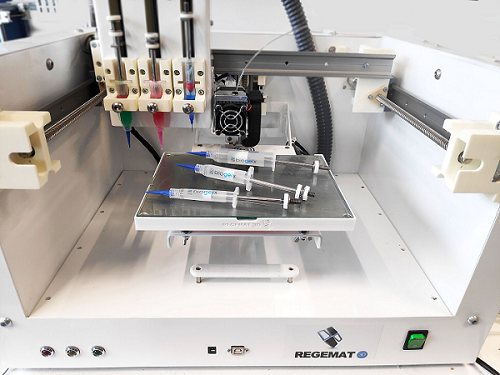

The student prepares the 3D printer for printing on the left, the printed structural element on the right. Making your own parts and using them in various designs demonstrates the visibility and reality of the application of the mental and creative abilities of the child in practice. Working with the latest design engineering tools (CAD and 3D printer) allows students to start mastering modern design and information technologies that contribute to the development of a person in a technical direction.

The program is designed for boys and girls aged 10-17 who have basic PC skills and want to learn how to implement their ideas using modern equipment.

The program is designed for two years of study. The total volume is 258 hours. Its purpose is to develop students' creative and design abilities based on the transformation of virtual ideas into material ones using 3D equipment.

During their studies, students not only successfully cope with the curriculum, but also prove the high level of knowledge gained. So schoolchildren of secondary school No. 645 are winners of the All-Russian Olympiad for schoolchildren in 3D technologies. Schoolchildren of secondary school No. 547 are preparing a project for the Lunakhod layout for participation in the XI All-Russian Conference with international participation "Information Technologies for the New School" as part of the St. Petersburg Educational Forum 2020. Team of schoolchildren of secondary school No. 690 took part in the CanSat Air Engineering School competition.

A team of schoolchildren from secondary school No. 645 became the winners of the All-Russian Olympiad in 3D technologies.

A team of schoolchildren from school No. 547 is preparing a project for an exhibition at the XI All-Russian Conference with international participation "Information Technologies for the New School" as part of the St. Petersburg Educational Forum 2020

Petersburg Educational Forum 2020

A team of schoolchildren from school No. CanSat School of Engineering"

The organizer of this additional general education program is the Reception Center (CSC) of BSTU "VOENMEH" named after. D.F. Ustinov with the active support of the Center for Scientific and Technical Creativity of Students (CNTTS).

The strategic goal of CNTTS is to create a self-organizing community of enthusiasts of different ages who accept the technological challenges of new markets and successfully cope with them.

DDOP "3D Technologies" is organized and successfully implemented thanks to the well-coordinated work of its main organizers:

Kuzmin A.M. - Director of the CSC, executive secretary of the selection committee.

Pobeliansky A.V. 1999-1999 - Head of the Central NTTS, Head of the Center for Additive Technologies and 3D Scanning "ATOS".

Dmitriev D.N. - Head of the student design bureau "Development of aircraft engines".