Strong 3d printing material

What is the Strongest 3D Printing Filament That You Can Buy? – 3D Printerly

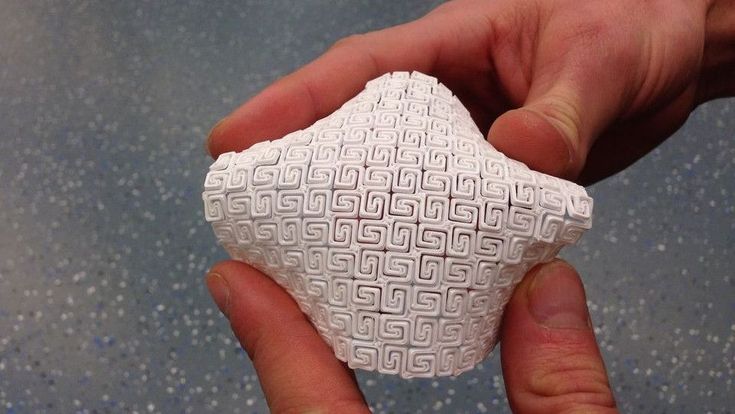

People used to consider 3D printed objects weak and brittle, but we have made some serious strides in the durability of these models.

We can create a strong 3D printer filament that stands up to very harsh conditions. This made me wonder, what is the strongest 3D printer filament that you can actually buy?

The strongest 3D printer filament you can buy is polycarbonate filament. Its mechanical structure is unlike many others, where strength tests have shown the excellent resilience and strength of this filament. Polycarbonate is widely used for engineering and has a PSI of 9,800 compared to PLA’s 7,250.

I will describe some interesting details about 3D printer filament strength, as well as give you a researched list of the top 5 strongest 3D printing filament, plus more, so keep on reading.

What is the Strongest 3D Printer Filament?

Polycarbonate (PC) filament is the strongest filament of all the known printing materials in the market. It is used for bullet-proof glass, riot gear, phone & computer cases, scuba masks and much more. The durability and rigidity of PC outweighs other printing materials easily.

The glass transition temperature rate offered by Polycarbonate filament is much higher than most other plastics filaments, meaning it has a high temperature resistance.

One of the tough competitors is ABS filament but you will be amazed to know that Polycarbonate filament can withstand 40°C more than ABS, making it a very strong filament.

Even at room temperature, thin PC prints can be bent without cracking or bending. Wear and tear doesn’t affect it as much as other materials, which is great in many 3D printing applications.

PC has amazing impact strength, higher than that of glass and several times higher than acrylic materials. On top of its incredible strength, PC also has transparent and lightweight qualities which make it a serious contender for 3D printing materials.

The Polycarbonate filament has a tensile strength of 9,800 PSI and can lift weights of up to 685 pounds.

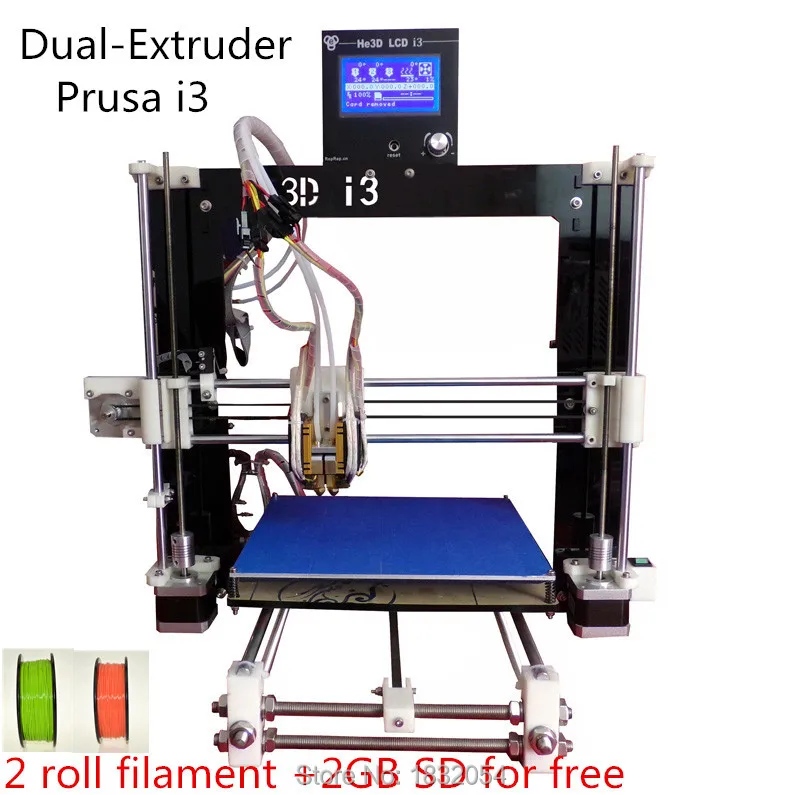

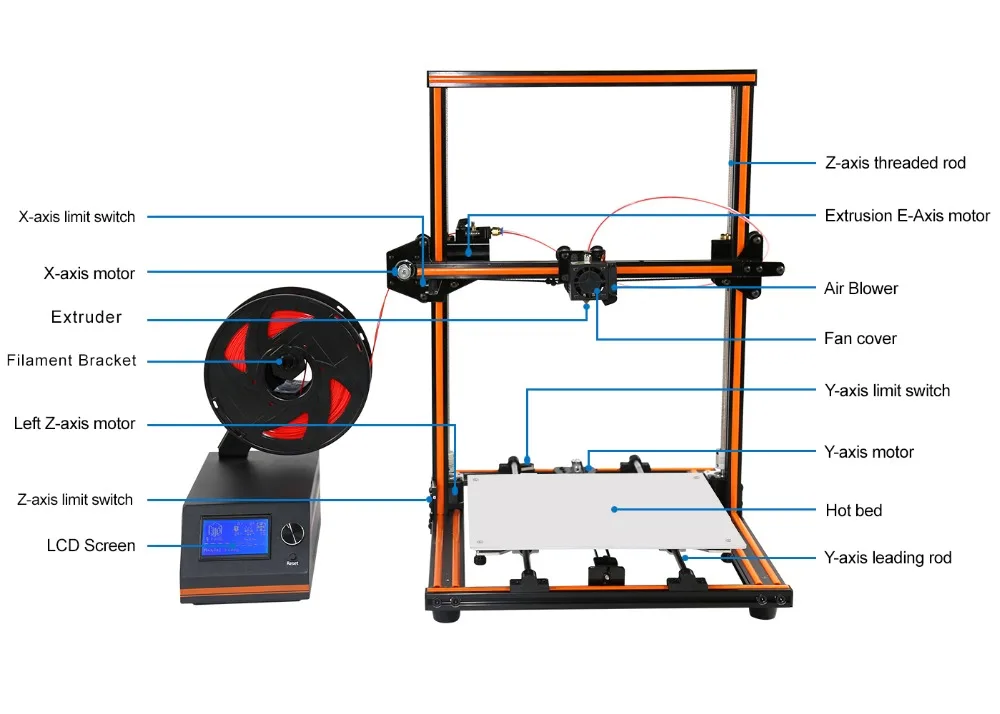

Depending on the different types of 3D printers and its components, Polycarbonate filament has an extruding temperature of almost 260°C and requires a heated bed of around 110°C to print properly.

Rigid.Ink has a great article detailing how to print with Polycarbonate filament.

All these statistics are far better and efficient than any other filament tested until now. In a nutshell, Polycarbonate filaments is the king of the 3D printing filament when it comes to strength.

Top 5 Strongest 3D Printing Filament

- Polycarbonate Filament

- Carbon Fiber Filaments

- PEEK Filaments

- ABS Filament

- Nylon Filaments

Polycarbonate Filament

When it comes to the strongest filaments, polycarbonate filament will always be seen at the top of the list as described above. Many amazing features and reasons are contributing to making it to float above the other filaments but some of the most appreciated features of Polycarbonate filaments include:

Many amazing features and reasons are contributing to making it to float above the other filaments but some of the most appreciated features of Polycarbonate filaments include:

- PLA usually begins to deform at a minor temperature of about 60°C but Polycarbonate filament can resist the heat up to amazingly 135°C.

- It is durable with impact and high shatter resistance.

- Electronically, it is non-conductive.

- It is transparent and highly flexible.

You can’t go wrong with some PRILINE Carbon Fiber Polycarbonate Filament from Amazon. I’d thought it would be a lot pricer but it actually isn’t too bad! It also has great reviews that you can check out.

One user actually tested how much carbon fiber was in the PRILINE Carbon Fiber Polycarbonate Filament and they estimated it was around 5-10% carbon fiber volume to plastic.

You can print this on an Ender 3 comfortably, but an all-metal hotend is recommended (not required).

Carbon Fiber Filament

Carbon fiber is a thin filament composed of fiber that contains carbon atoms. The atoms are in a crystalline structure that provides high strength which makes it an ideal choice for industries like automotive.

Markforged state that their carbon fiber filament has the highest strength-to-weight ratio, where in their flexural strength three-point bending test, illustrated that it is 8x stronger than ABS and 20% stronger than the yield strength of aluminum.

Their carbon fiber has a flexural strength of 540 MPA, which is 6 times higher than their nylon-based onyx filament and it’s also 16 times stiffer than their onyx filament.

You can purchase 2KG of carbon fiber PETG for around $170 from 3DFilaPrint which is very premium for 3D printer material, but a great price for high quality filament.

It is light and has excellent resistance to chemical degradation and corrosion. Carbon fiber has better dimensional stability because of its strength that helps in mitigating the chances of colliding or shrinking.

Carbon fiber has better dimensional stability because of its strength that helps in mitigating the chances of colliding or shrinking.

The stiffness of carbon fiber make it a top contender for the aerospace and automotive industries.

PEEK Filament

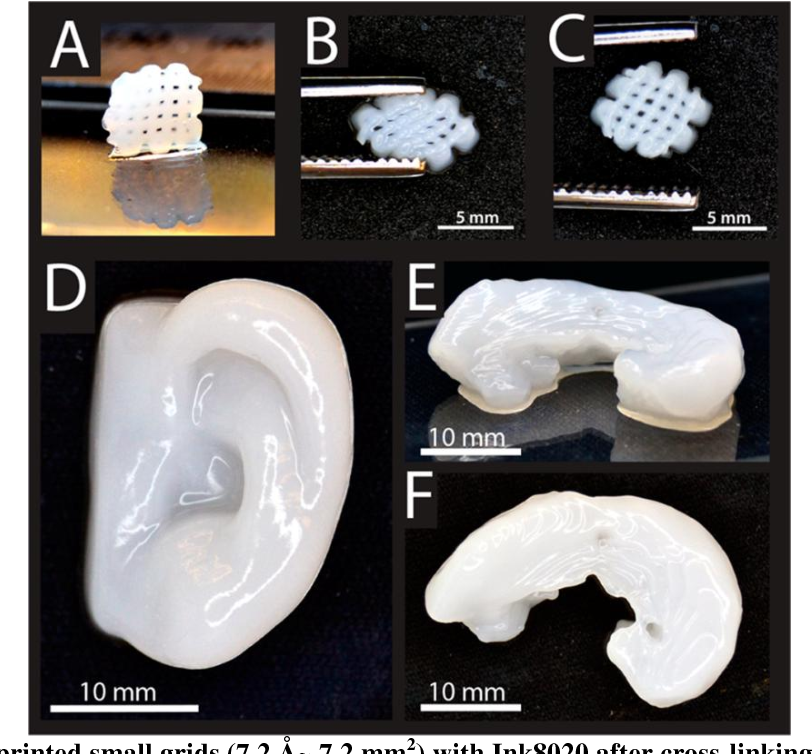

PEEK filament is one of the most reliable and trusted materials in the huge 3D printing industry. PEEK stands for its composition which is Polyether Ether Ketone, a semi-crystalline thermoplastic.

It is well known for its excellent strength and high-end chemical resistance. During its manufacturing, a process is followed known as phased polymerization at a very high temperature.

This process makes this filament highly resistant to organic, bio, and chemical degradation in any type of environment with a useful operating temperature of 250°C.

As PEEK filaments reduce the amount of moisture absorption and make the process of sterilization easy, medical fields and industries are adopting PEEK filaments for 3D printer rapidly.

It does get pretty pricey so keep that in mind!

ABS Filament

ABS comes in the list of the strongest filaments because it is a hard thermoplastic material that can resist impact gracefully.

This filament is widely used in printing processes such as engineering purposes, technical printings, etc. It is one of the most cost-effective as compared to other major types of fiber filaments.

This is the fact that makes this filament ideal for the users who are bound to a budget but want to have a high-quality strong filament for 3D printing.

ABS is a perfect choice if you are going to print things that will have the stress of will include high functionality. As this filament is heat and water-resistant, it provides users with a smooth and attractive finish to the product.

You also have the ability to easily work with the material, whether that’s sanding, acetone smoothing, or painting.

Nylon Filament

Nylon is an excellent and strong material that is used in most of the 3D printers. It has an amazing tensile strength of almost 7,000 PSI which is more than most of the other 3D filaments.

This filament is highly resistant to the chemicals and heat which makes it one of the ideal options to use in industries and major organizations.

It is strong but comes after ABS although, the nylon industry is moving forward to bring improvements using mixtures of particles from fiberglass and even carbon fiber.

These additions can make the nylon filaments more strong and resistant.

NylonX by MatterHackers is a perfect example of this composite material for some amazing 3D printed strength. The video below shows a great visual of this material.

TPU Filament

Although TPU is a flexible filament, it has some serious strength in the impact-resistance, wear and tear resistance, chemical and abrasion resistance, as well as shock absorption and durability.

As shown in the video titled ‘The Ultimate Filament Strength Showdown’ above, it showed to have amazing material strength and flexibility. The Ninjaflex Semi-Flex withstood 250N of pulling force before snapping, which in comparison with Gizmodork’s PETG, gave a force of 173N.

Which Filament is Stronger ABS or PLA?

When comparing the strength of ABS and PLA, the tensile strength of PLA (7,250 PSI) is greater than the tensile strength of ABS (4,700 PSI), but strength comes in many forms.

ABS has more flexible strength since PLA is brittle and doesn’t have as much ‘give’. If you expect your 3D printer part to bend or twist, you would rather be using ABS over PLA.

If you expect your 3D printer part to bend or twist, you would rather be using ABS over PLA.

The all-famous Legos are made from ABS, and those things are indestructible!

In hotter environments, PLA doesn’t hold its structural strength very well so if heat is a factor in your area, ABS is going to hold up better. They are both strong in their own rights but there is another option.

If you want a filament which meets in the middle of the two, you want to look towards using PETG, which is easy to print like PLA, but has a little less strength than ABS.

PETG has more natural flex than PLA and should keep its shape longer.

PETG can also withstand higher temperatures than PLA, but you want to make sure your 3D printer has the correct capabilities to reach the necessary temperatures to print it.

What is the Strongest 3D Printer Resin?

Accura CeraMax is considered as the provider of the strongest 3D printer resin. It guarantees full capacity temperature resistance as well as the highest strength for heat and water resistance.

It can be used efficiently to print the perfect composite like prototypes, ceramic-like components, jigs, tools, fixtures, and assemblies.

What is the Stiffest 3D Printing Material?

PLA filament is also known as Polylactic Acid and is one of the most used filaments in 3D printers.

It is considered as a standard filament material that is widely being used because it can print clearly at a very low temperature without requiring a high heated bed.

It is the stiffest 3D printing material and is ideal for the beginners because it makes 3D printing easy as well as it is very inexpensive and produces parts to be used for a variety of purposes.

After being the stiffest 3D printing material it is also known as the most environmentally friendly material to be used in 3D printers. As an amazing property, PLA emits a pleasant smell while printing.

What is the Weakest 3D Printing Filament?

As it is mentioned above that simple nylon or some PLA filaments are considered as the weakest 3D printing filaments in the 3D industry. This fact is only valid for previous or old versions of the nylon filaments.

However, the new updates such as filled nylon filaments with Onyx or nylon carbon fiber filaments come in the list of top strongest filaments for the 3D printers.

Choosing between PC, nylon, TPU, and others

Good 3D printing materials tend to offer a mix of desirable characteristics. These characteristics can include printability, durability, chemical resistance, temperature resistance, and flexibility, to name just a few. Chief among these desirable properties, however, is strength: nobody wants their 3D printed parts to break, and material strength is one of the best ways to ensure this doesn’t happen.

Take a look at the filament market and it’s easy to see that the strongest 3D printer filaments out there command a higher price than their weaker counterparts. This is partly due to the cost of the stronger raw materials, and partly due to the increased use of 3D printing as a tool for end-use manufacturing, with real functional parts requiring greater strength than prototypes. Demand for high-strength materials is growing, and many manufacturers have been happy to provide solutions.

This article looks at some of the strongest 3D printer filaments available for users of FDM 3D printers. It is by no means an exhaustive guide to high-strength materials, but it takes a look at some of the most popular high-strength filaments in the consumer sphere, while also touching on some professional-grade materials reserved for advanced users.

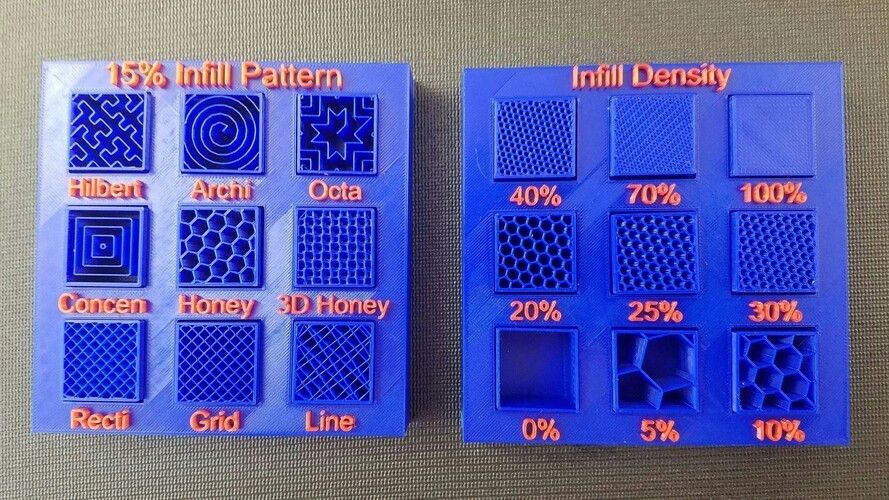

Strong 3D printing filament is in high demand, but “strength” can actually mean a few different things in this context. When comparing filaments, you’ll see terms like tensile strength, impact strength, tear strength, and flexural strength — all of which can be measured using standardized strength tests — in addition to more general terms like durability and toughness.

When comparing filaments, you’ll see terms like tensile strength, impact strength, tear strength, and flexural strength — all of which can be measured using standardized strength tests — in addition to more general terms like durability and toughness.

These different terms are needed because materials can be strong or weak in different ways. For example, try to imagine the relative strength of a glass bottle and a piece of chewing gum. If you were to hurl the two objects at a wall, the glass would obviously break and the chewing gum would survive almost unscathed. But you could much more easily pull the chewing gum apart with your hands than you could the glass bottle.

All of the various strength-related attributes are important when it comes to choosing and buying 3D printer filament. However, two types of strength are generally prioritized over any other. These are tensile strength and impact strength.

Tensile strength

Used to indicate the ultimate strength of a material or part, tensile strength can be defined as the ability to resist breakage when under tension, i. e. when being pulled or stretched.

e. when being pulled or stretched.

Tensile strength is the most widely used indicator of strength for 3D printed parts, because it indicates a material’s suitability for load-bearing or mechanical applications. It is expressed in megapascals (MPa) or, in the United States, in pounds per square inch (psi), and values are determined by performing a tensile test: literally pulling a piece of the material apart and using a tensometer to record the exact degree of tension at which the material breaks. It is a key metric for almost any functional printed part.

At the low-cost consumer level, the strongest 3D printer filaments in terms of tensile strength include polycarbonate (PC), polyethylene terephthalate glycol-modified (PETG), and polylactic acid (PLA). Weak materials include thermoplastic polyurethane (TPU) and acrylonitrile butadiene styrene (ABS).

Materials with good tensile strength are harder to break when pulled

Impact strength

Another key indicator of strength is impact strength. Synonymous with toughness, impact strength is the ability of a material or part to absorb shock and sudden impact without breaking. It is an important material property for items like safety equipment and children’s toys.

Synonymous with toughness, impact strength is the ability of a material or part to absorb shock and sudden impact without breaking. It is an important material property for items like safety equipment and children’s toys.

Impact strength is defined as the amount of energy — generally expressed in kilojoules per square meter (kJ/m2) — that the material is able to absorb without breaking. Brittle materials have a low level of impact strength and can break more easily when subjected to sudden impact. However, materials can have a high impact strength and a low tensile strength, and vice versa.

Unfortunately, due to the many different ways of testing for impact strength, it can be difficult to compare the exact toughnesses of two different filaments side by side. Two different filament manufacturers might use different testing methods and even different units of measurement.

At the consumer level, the strongest 3D printer filaments in terms of impact resistance include ABS filament, PETG filament, PC filament, and flexible filaments like TPU. One very weak material in terms of impact strength is PLA, which can easily shatter if it is dropped or struck.

One very weak material in terms of impact strength is PLA, which can easily shatter if it is dropped or struck.

Other strength metrics

Beyond tensile strength and impact strength, some notable terms you might find on a material’s data sheet include:

Flexural strength: Refers to how well a material can resist breakage when it is bent or under load; expressed in megapascals (MPa)

Tear strength: Refers to how well a material can resist the growth of cuts when it is under load; expressed in kilonewtons per meter (kN/m)

Elongation at break: Relates to tensile strength and refers to how much a material stretches before it breaks when under tension; expressed as a percentage

Recommended reading: 5 options to get strong parts with 3D printing

Approx tensile strength: 70 MPa

One of the strongest FDM 3D printing materials — in terms of both tensile[1] and impact strength — is polycarbonate (PC). In fact, polycarbonate filament would likely be one of the most popular printing materials were it not so difficult to print.

In fact, polycarbonate filament would likely be one of the most popular printing materials were it not so difficult to print.

Advantages of polycarbonate, besides its excellent tensile and impact strength, include its temperature resistance and its suitability for printing transparent parts. An obstacle to the printing of PC is its very high melting point and the very high temperatures required to print it. Extruder temperatures of at least 260 °C are required, with some formulations needing more than 300 °C, which is beyond the capabilities of consumer-level desktop 3D printers. A bed temperature of around 100 °C is recommended.

Some brands of PC contain additives that reduce the material’s melting point, but these additives can also compromise the material’s strength and heat resistance, making them less suitable for end-use parts such as automotive components.

PC 3D printing is usually limited to non-budget systems that can print at high temperatures and extract the best strength properties from the material. However, even these systems can struggle to control the material’s proneness to warping.

However, even these systems can struggle to control the material’s proneness to warping.

Popular PC filaments include Raise3D Premium PC, Polymaker PolyMax, and 3DXTech 3DXMax PC.

Approx tensile strength: 50–80 MPa

Another strong filament in both the tensile and impact departments is nylon (PA). Although not as robust as PC, nylon filament is marginally easier to print, requiring an extruder temperature of around 250 °C and a heated bed set to around 80 °C.

Nylon is perhaps more often associated with selective laser sintering (SLS), where it is used in powder form to make industrial parts and prototypes. However, nylon FDM 3D printer filament is widely available and typically comes at a lower price point than PC. Compared to PC, it is slightly more flexible, which may be desirable for certain functional parts. Other advantages of nylon filament include its excellent durability, surface smoothness, and layer adhesion.

Although most desktop printers can process nylon filament, the high-strength material has drawbacks. For example, it is highly hygroscopic and prone to absorbing moisture, which can cause a variety of printing issues, such as the formation of bubbles in the nozzle. Like PC, nylon is also susceptible to warping as it cools down.

Popular nylon filaments include MatterHackers Pro Series Nylon, Ultimaker Nylon, and ColorFabb PA.

Approx tensile strength: 20–50 MPa

Though not usually thought of as high-strength materials due to their very low tensile strength, flexible filaments like thermoplastic polyurethane (TPU) actually offer a very high level of impact strength, making them suitable for shock-absorbing printed objects and functional parts like protective enclosures. Naturally, TPU has a very high elongation at break compared to more rigid materials, and the material also has good abrasion resistance and chemical resistance. Its tensile strength, however, is very low, making it unsuitable for mechanical parts.

Its tensile strength, however, is very low, making it unsuitable for mechanical parts.

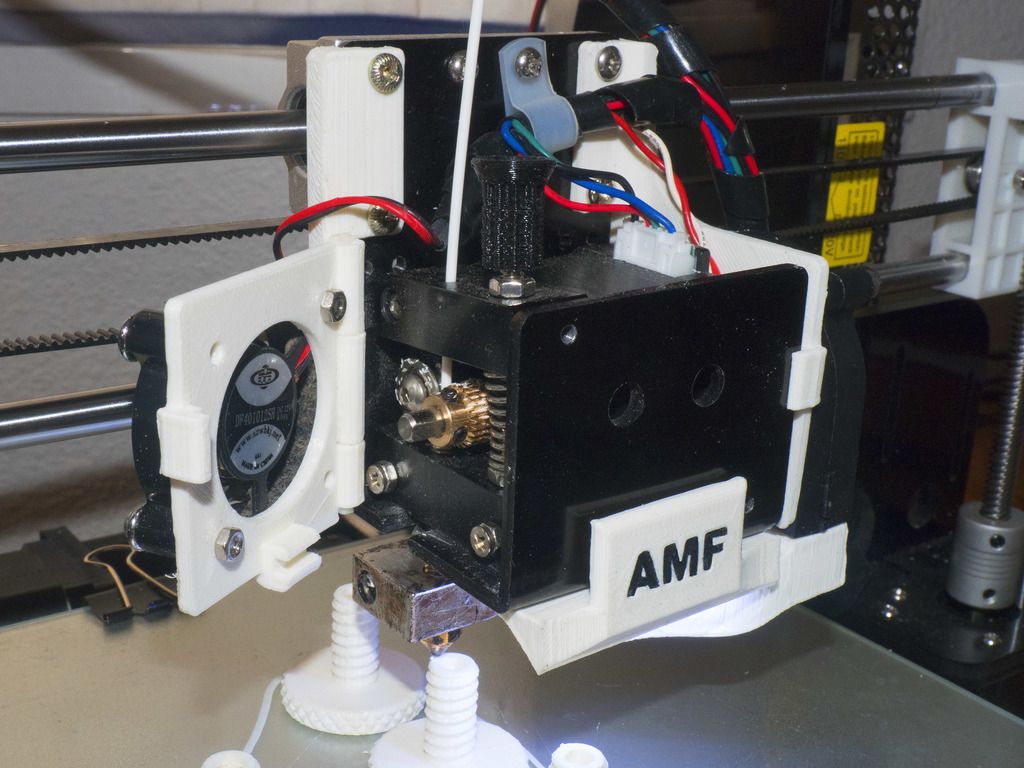

Most desktop 3D printers can print TPU and other varieties of thermoplastic elastomer (TPE), with a hot end temperature of around 230 °C required. However, note the best 3D printers for printing flexible filaments have direct-drive extruders, as Bowden extruders can suffer filament tangles.

Popular TPU filaments include NinjaTek Cheetah TPU, Polymaker PolyFlex, and Fillamentum Flexfill.

Recommended reading: TPU print settings explained

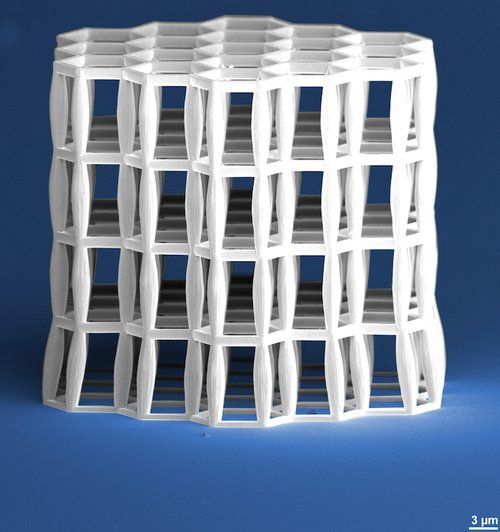

In professional and industrial settings, many FDM users are now turning to high-performance materials like PAEK (PEEK and PEKK) and PEI (ULTEM) for the production of end-use parts, especially in demanding industries like automotive and aerospace. When filament strength is the highest priority, these engineering-grade materials are far better than ordinary products like PLA filament.

High-performance plastics offer a very high level of tensile strength. PEEK filament, for example, can have a tensile strength as high as 100 MPa, notably higher than PC filament and significantly higher than ABS filament. Materials in the PAEK family also have very good impact strength; PEI is slightly less tough, but is typically much more affordable than PAEK filament.

The obvious drawback of high-performance polymers is that they cannot be printed on beginner-level printers or even mid-level desktop machines. They demand much higher temperatures (nozzle, bed, and enclosure) than regular materials, are more expensive, and sometimes require annealing to maximize their mechanical performance.[2]

Popular high-performance filaments include 3DXTECH ThermaX PEEK and Markforged ULTEM 9085.

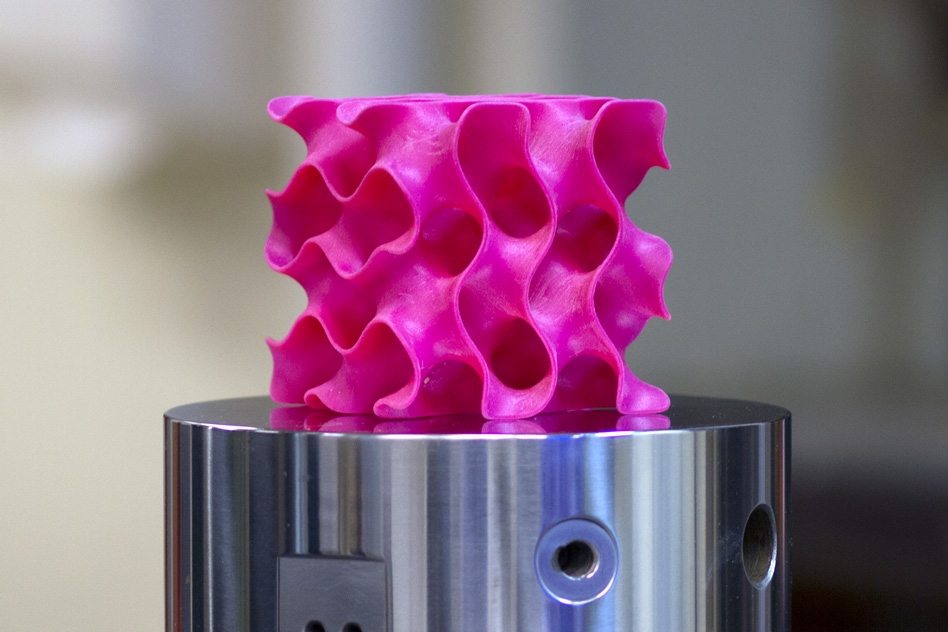

The strength and stiffness of thermoplastics can be increased by mixing them with reinforcing additives, creating what is called a composite filament. Common additives include chopped carbon fiber and fiberglass.

Common additives include chopped carbon fiber and fiberglass.

Composites are popular in FDM 3D printing because they enable users to incorporate strong materials like carbon fiber without adjusting the printing process. Because there is a greater amount of thermoplastic than additive in the composite, the material can still be melted and extruded like an ordinary filament.

Reinforced composites can have a high level of tensile strength. For instance, MatterHackers NylonX (a composite of nylon and carbon fiber) has a tensile strength of 100 MPa.

Note, however, that FDM carbon fiber filaments have limits on their strength, because the chopped fibers mixed into the material are randomly oriented. Advanced composite printing technologies, such as those developed by Markforged and Desktop Metal, are able to print continuous fibers, resulting in much stronger parts.[3]

Choosing the strongest 3D printer filament for your needs comes down to two key factors: the type of strength required and the level of strength required (that is feasible with the printing hardware available).

If the parts need to withstand constant loads and stresses, then materials with a high tensile strength should be prioritized. These include PLA and PETG at the cheaper end, materials like PC in the middle, and composites or high-performance polymers — offering the very highest levels of tensile strength — at the premium end.

If the parts need to withstand sudden impact, then materials with a high impact strength or toughness should be prioritized. Such materials include ABS and TPU at the consumer end and high-performance polymers at the premium end.

In general, materials like nylon and polycarbonate are favored by many FDM users because they offer a good balance between affordability, tensile strength, and impact strength.

[1] Tanikella NG, Wittbrodt B, Pearce JM. Tensile strength of commercial polymer materials for fused filament fabrication 3D printing. Additive Manufacturing. 2017 May 1;15:40-7.

[2] Yi N, Davies R, Chaplin A, McCutchion P, Ghita O. Slow and fast crystallising poly aryl ether ketones (PAEKs) in 3D printing: Crystallisation kinetics, morphology, and mechanical properties. Additive Manufacturing. 2021 Mar 1;39:101843.

Slow and fast crystallising poly aryl ether ketones (PAEKs) in 3D printing: Crystallisation kinetics, morphology, and mechanical properties. Additive Manufacturing. 2021 Mar 1;39:101843.

[3] Yang C, Tian X, Liu T, Cao Y, Li D. 3D printing for continuous fiber reinforced thermoplastic composites: mechanism and performance. Rapid Prototyping Journal. 2017 Jan 16.

What is the most durable material for 3D printing?

3DPrintStory 3D printing process What is the most durable material for 3D printing?

While the 3D printing process seems like a great alternative to traditional manufacturing methods, the parts produced can be fragile and unusable. As a rule, this is the result of using standard materials that are not designed for strength and durability. But there is a solution: use durable materials! Durable 3D printing materials can greatly enhance your options, as you can print parts and assemblies for small projects without fear of breakage.

But there is a solution: use durable materials! Durable 3D printing materials can greatly enhance your options, as you can print parts and assemblies for small projects without fear of breakage.

In this article, we'll take a look at the three most durable types of 3D printing materials. However, before that, we will take a closer look at what strength means in terms of filament materials.

What is strength and how do we evaluate it?

The strength of a material can be measured and evaluated in different ways. In this article, we will mainly use tensile strength (stress before something breaks). We will list the tensile strength of each 3D printing material in pounds or pounds per square inch (PSI).

Despite the obvious number of pounds the material can support, there is still a margin of error depending on how the part was printed. We've compiled research from a variety of sources to make sure these three materials are the strongest.

You must also understand that the material itself is not the only factor that affects the strength of the finished product. The design itself, post-processing and the 3D printing process also affect the strength of the part.

The design itself, post-processing and the 3D printing process also affect the strength of the part.

Polycarbonate

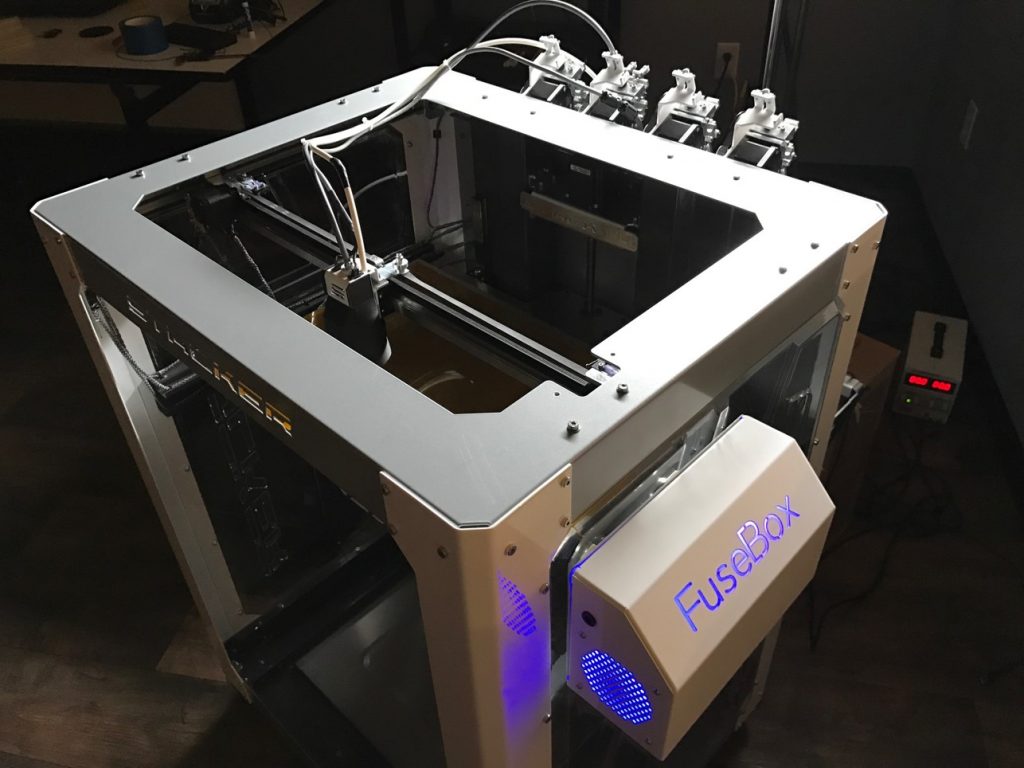

Polycarbonate (PC) is considered by many manufacturers and reviewers to be the strongest 3D printing filament available. In particular, it is possible to achieve high strength of polycarbonate products by 3D printing with an all-metal hot end and a 3D printer in a case that is isolated from the influence of the external environment.

Some Numbers

Airwolf 3D has come to the conclusion after many filament tests that polycarbonate is the best choice of durable filaments for desktop 3D printers. They were able to hang up to 685 pounds on a polycarbonate printed hook and found that this material had a tensile strength of 9800 psi. In contrast, the same part printed in PLA could only support 285 pounds.

Using a similar test, MatterHackers studied the tear strength of this type of thread, as well as a number of other materials. They were able to hang an average of 409 pounds on the polycarbonate hook, while the PLA parts had a significantly lighter average weight of just 154 pounds.

They were able to hang an average of 409 pounds on the polycarbonate hook, while the PLA parts had a significantly lighter average weight of just 154 pounds.

Finally, renowned 3D printing YouTuber Thomas Sunladerer reviewed several polycarbonate materials and gave very positive feedback on the strength of the material.

3D printing with polycarbonate

It is worth noting that the quality of 3D printing with polycarbonate is not very good. Compared to other materials, protrusions and small details may not turn out as well as using the same PLA.

According to Rigid.Ink, polycarbonate is mostly sold in clear. This 3D printing material has excellent heat resistance as well as impact resistance. But note that you will have to print at high temperatures. As mentioned above, it is better to use an enclosed 3D printer and a solid metal hotend.

Pros of polycarbonate : extra strong, excellent thermal and impact resistance.

Cons of polycarbonate : does not cope well with protrusions and small details of a 3D model, requires a body and an all-metal hot end, a limited number of colors.

Nylon

Next on our list of durable 3D printing materials is nylon. This material is considered by many to be the most reliable for desktop 3D printers. Nylon is inferior in strength to polycarbonate, but still clearly stronger than other competitors such as PLA and ABS.

Some numbers

A hook printed with nylon (910) thread had a breaking strength of 7,000 psi, while the same ABS hook only had a strength of 4,700 psi, according to Airwolf 3D. Airwolf 3D also noted that the nylon filament-printed clip holds 485 pounds.

MatterHackers posted similar results and noticed that a hook printed with their NylonX material can hold an average of 364 pounds before it breaks. Rigid.Ink also reviewed some nylon threads and gave them a four out of five rating for strength and a five for durability. For comparison: the strength and durability of PLA is three conventional units.

Nylon 3D printing

Nylon is slightly easier to print than polycarbonate, but it's still not PLA. Nylon filament is quite hygroscopic, so it must be kept dry and requires a high printing temperature of 220-270°C. This material is prone to slight warpage, but is also resistant to impact, fatigue, and high temperature.

Nylon filament is quite hygroscopic, so it must be kept dry and requires a high printing temperature of 220-270°C. This material is prone to slight warpage, but is also resistant to impact, fatigue, and high temperature.

Nylon pros: impact resistance, fatigue resistance, heat resistance, easier to print than polycarbonate.

Nylon 9 cons0042 : hygroscopic, warping, very high hot end temperature required.

Composites

Finally, composite threads, although not essentially a single material, can be extremely strong. Composites are threads with certain additives that affect the properties of the material, including to increase strength. The names of these threads usually have the words "pro", "reinforced" (reinforced) or "infused" (infused), since they are usually a mixture of different materials.

For this reason, it is impossible to assess where the composite fibers are compared to the two previous materials. Some composites, such as Carbonyte, can compete with nylon threads for strength, while some composites are less durable.

It all depends on what the composite thread consists of. Durable is usually a high strength material such as nylon impregnated with another high strength material such as carbon fiber or glass.

Speaking of carbon fiber, this is also a very strong filament that is sometimes used for 3D printed bicycles. However, some composite fibers are stronger than many pure carbon fibers, so they are not in the top three, but deserve special mention as composite fibers.

Some numbers

We will use carbon fiber nylon and glass fiber nylon threads as examples. MatterHackers has determined that hooks printed on these materials can hold an average of 349and 268 pounds respectively.

Rigid.Ink gave the fiberglass nylon filament four out of five ratings for strength and five for durability. They also gave the carbon fiber nylon a five out of five rating for both strength and durability. In comparison, PLA and ABS were in the top three for strength.

3D printing with composites

Composites vary in the way they are 3D printed, but they are generally relatively similar to their base material. Durable composite fibers are usually made from nylon, so you'll have to print at fairly high temperatures. These threads are also quite expensive.

Durable composite fibers are usually made from nylon, so you'll have to print at fairly high temperatures. These threads are also quite expensive.

Advantages of composites : This is a combination of several materials to achieve the best possible properties, durable.

Cons of composites: Expensive, requires high 3D printing temperatures.

3D printing material comparison

3D printing material comparison

3dunitprint2022-02-07T14:43:04+03:00

3dunitprint Knowledge base 0 comments

ABS - PLASTIC

Acrylonitrile butadiene styrene (ABS) is one of the most popular plastics. It is an easily accessible, durable and lightweight material. ABS plastic comes in a wide range of colors. Its strength and ease of processing have led it to become the most popular of the engineering polymers.

Manufacturing techniques: FDM

- Rugged

- Flexible

- Easy to process

- Resistant to everyday chemicals

- Temperature resistant

- High print shrinkage

- Smell of “plastic” when printed

- Not suitable for food contact

Strength

90%

Cost

20%

Moisture resistance

70%

Stability to ultraviolet

9000%Chemical resistance

40%

PLA - PLASTIC

The raw material for the production of PLA plastic is corn starch (but you can also find varieties of sugar cane and tapioca), which makes it biodegradable. This is a simple material for 3D printing, when heated, it releases a pleasant sweet aroma. For this reason, many people prefer its ABS.

This is a simple material for 3D printing, when heated, it releases a pleasant sweet aroma. For this reason, many people prefer its ABS.

Manufacturing techniques: FDM

- Eco-friendly, biodegradable

- Food contact

- Hard, durable

- Low shrinkage

- High surface quality

- Low softening point 50°C

- Narrow temperature range (-20 to +40°C)

- Short-lived

- Fragile

Durability

75%

Cost

20%

Moisture resistance

20%

UV resistance

25%

Chemical resistance

45%

PETG, PET, PETT - PLASTIC water. This material is the second alternative to ABS, it does not emit caustic fumes when melted, while remaining strong and flexible.

Manufacturing techniques: FDM

- Odorless printing

- UV resistance

- Wide operating temperature range.

- Good slip and impact resistance

- Non-toxic, can be printed on articles intended to come into contact with food.

- Lower strength and softening point than ABS.

- High printing temperature quickly destroys the PTFE insert in the hot end

- Scratches more than ABS.

- Absorbs moisture from the air

Strength

90%

Cost

30%

Moisture resistance

75%

Ultraviolet

9000%Chemical resistance

9000,000 (polycarbonate) is a high strength material designed for harsh environments and engineering applications. It has extremely high thermal deflection and impact resistance. Polycarbonate also has a high glass transition temperature of -150° Celsius. This means that it will maintain its structural integrity up to this temperature, parts made with this material show significantly improved mechanical strength compared to ABS and PLA.Manufacturing techniques: FDM

- Impact resistance

- High temperature resistant

- Naturally transparent

- Flexibility

- Durability

- Tendency to warp

- Very high print temperature required

- High tendency to shrink during printing

- Absorbs moisture from the air, which can cause print defects

Strength

90%

Cost

45%

Moisture resistance

55%

Ultraviolet

9000%Chemical resistance

%HIPS - Plastic

HIPS (BDYARIROLRIL) is a dissolvable support material commonly used with ABS. When used as a support material, it can be dissolved in d-Limonene leaving the print free of any defects caused by the removal of supports. HIPS has many of the same printing properties as ABS, making it a logical partner for dual extrusion. This material is more stable and slightly lighter than ABS, making it an excellent choice for parts that wear quickly or are used to print lighter products.

When used as a support material, it can be dissolved in d-Limonene leaving the print free of any defects caused by the removal of supports. HIPS has many of the same printing properties as ABS, making it a logical partner for dual extrusion. This material is more stable and slightly lighter than ABS, making it an excellent choice for parts that wear quickly or are used to print lighter products.

Manufacturing techniques: FDM

- Low cost

- Impact resistant

- Waterproof

- Light

- Soluble with d-limonene

- Heated deck required

- Closed chamber recommended

- High Print Temperature

- Ventilation required

Strength

80%

Cost

10%

Moisture resistance

80%

Ultraviolet 60005

70%

Chemical resistance

25%

FLEXIBLE - plastic

FLEXIBLE (FLOOK FIRS) (TPE), which are a mixture of hard plastic and rubber.:quality(80)/images.vogel.de/vogelonline/bdb/1403700/1403729/original.jpg) This material is elastic in nature, which allows it to stretch and flex easily. There are several types of TPE, with thermoplastic polyurethane (TPU) being the most commonly used among 3D printing filaments. The degree of elasticity of the plastic depends on the type of TPE and the chemical composition used by the manufacturer. For example, some threads may be partially flexible, like a car tire, while others may be elastic and fully flexible, like a rubber band.

This material is elastic in nature, which allows it to stretch and flex easily. There are several types of TPE, with thermoplastic polyurethane (TPU) being the most commonly used among 3D printing filaments. The degree of elasticity of the plastic depends on the type of TPE and the chemical composition used by the manufacturer. For example, some threads may be partially flexible, like a car tire, while others may be elastic and fully flexible, like a rubber band.

Manufacturing techniques: FDM

- Flexible and soft

- Excellent vibration damping

- Long shelf life

- Impact properties

- Hard to print

- Difficulty removing supports

- Not suitable for all 3D printers

Strength

80%

Cost

60%

Moisture resistance

80%

Persistence to ultraviolet

70%

Chemical resistance

70%

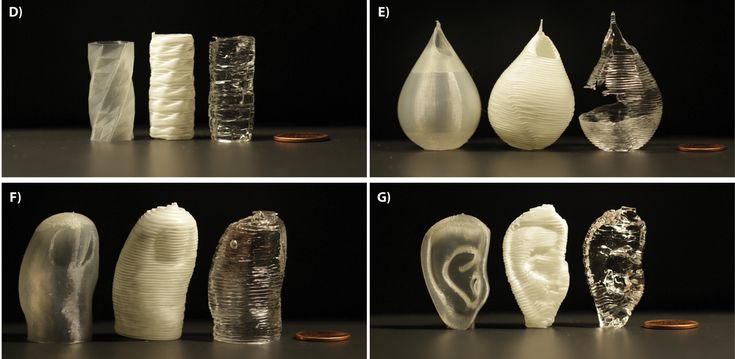

Photopolymers

Photopolymers are liquid resins, they usually consist of epoxy resin or a combination . When exposed to UV radiation, these monomers quickly form molecular bonds with each other and turn into a solid polymer. The main modern technologies where photopolymers are used are SLA/DLP and PolyJet. Resin 3D printing is also an additive process, just like FDM printing. This means that the process is based on a layer-by-layer building process, where one layer forms molecular bonds with the next layer. This process is repeated until the entire model is recreated.

When exposed to UV radiation, these monomers quickly form molecular bonds with each other and turn into a solid polymer. The main modern technologies where photopolymers are used are SLA/DLP and PolyJet. Resin 3D printing is also an additive process, just like FDM printing. This means that the process is based on a layer-by-layer building process, where one layer forms molecular bonds with the next layer. This process is repeated until the entire model is recreated.

Crafting Technologies: SLA/DLP , Polyjet

- High Detail

- Smooth surface

- Faster printing process

- Finished product uniform in all axes

- High material cost

- More labor-intensive removal of supports

- More limited choice of materials

Strength

80%

Cost

75%

Moisture resistance

80%

Ultraviolet

9000%Chemical resistance

9000%Polymide (powder)

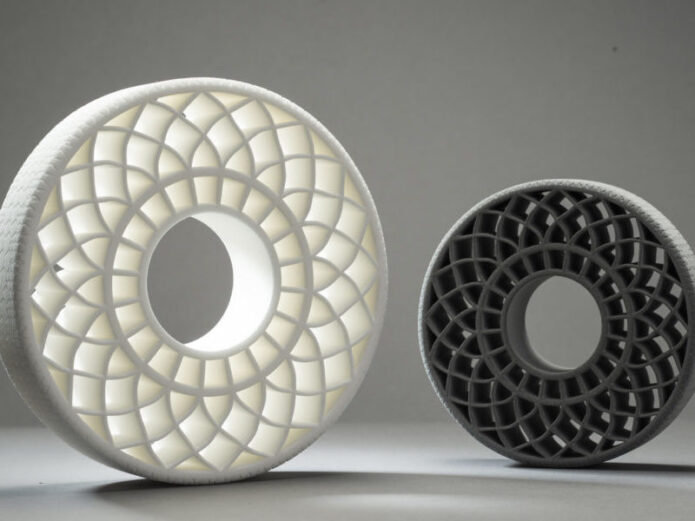

Poliamide (nylon) is one of the most popular 3D printing materials used by professional 3D printing companies. Polyamide is the reference material in the technology of SLS-laser sintering of plastic powder. This technology is used for rapid prototyping and rapid production. With this technology it is possible to create complex three-dimensional objects that can be used as prototypes or as functional parts.

Polyamide is the reference material in the technology of SLS-laser sintering of plastic powder. This technology is used for rapid prototyping and rapid production. With this technology it is possible to create complex three-dimensional objects that can be used as prototypes or as functional parts.

Given its flexibility and strength, nylon is an indispensable material for a wide range of applications from engineering to art. Nylon (polyamide) parts have a rough surface that can be polished to a smooth finish. Nylon is stronger than all other types of plastics, making it an ideal material for 3D printing products that require good tensile strength and mechanical strength.

Manufacturing techniques: SLS

- High detail

- High strength

- Finished part flat surface

- Supports not required

- Fast printing process

- High material cost

- Rough surface (can be removed with post-processing)

- Limited materials

- Available in one color (white)

Strength

90%

Cost

90%

Moisture resistance

65%

Ultraviolet resistance

80%

Chemical resistance

80%

Metals (powders)

Metal powder (steel, aluminum, aluminum, aluminum, aluminum, aluminums, aluminums, aluminums, aluminums, aluminums, aluminums, aluminums, and aluminums, aluminums, aluminums, aluminums nickel, titanium) are metals that are ground to particles and are pre-base materials for most 3D printing processes producing metal parts.