3D point cloud laser scanner

The most popular laser scanners for creating point clouds

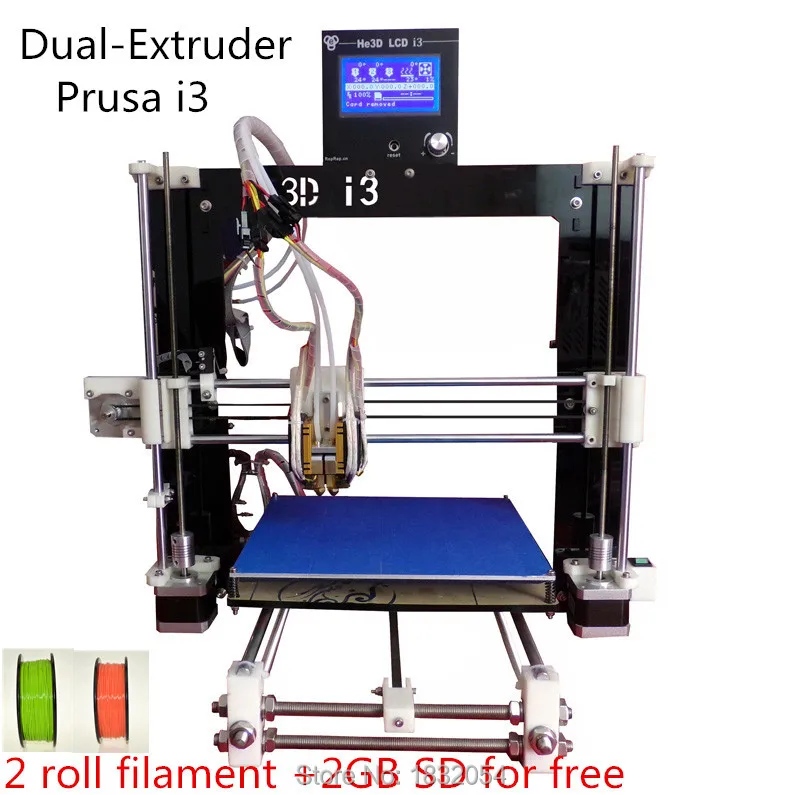

Although there are a number of ways surveyors can collect the data needed to create a point cloud, laser scanners remain the most popular and precise instrument. The pairing of aerial drones with laser scanner technology is increasing. Here, however, we will focus on terrestrial laser scanners, giving you a quick rundown of the options in the market and what to expect from different manufacturers.

Faro: A flexible scanning solution

Faro offers a range of popular and widely used laser scanners, some of which are generalists, while others are focused on specific use cases. Faro offers its own processing software (Scene), but its scanners pair easily with third-party options. This versatility, and the relative affordability of their hardware is one reason for the popularity of the company. Combined with the small size, fast scan speeds, ease of use, and often multi-purpose capabilities of their scanners, Faro has been a long time staple of the surveying community.

Founded in 1981, Faro has an annual revenue of over $360 million and is considered an industry leader in 3D measurements, imaging and realisation technology. Faro technology is popular with manufacturers as well as surveyors. Many of their scanners are focused on delivering precise models of objects, rather than surveying.

The Faro Focus series is their main product line for indoor and outdoor surveying. The Focus S 350 is the flagship scanner, specifically designed to overcome the challenges of outdoor scanning. It comes with an integrated GPS receiver, is lightweight and maximised for range. Capable of +/-1mm measurements at 25m, the FocusS 350 can deliver accurate measurements between 0.6m to 350m. The scanner comes pre-calibrated to accommodate dust, rain or direct sunlight and has internal compression technology to maximise the number of scans you can collect.

The Focus S 150 is a pared down version of the 350, lacking the GPS receiver and with a range limited to 150m. It is more suited to indoor spaces where neither of these factors will have a practical impact. The same goes for the Focus S 70, but with a further diminished maximum range of 70m. The Focus M 70 is the budget model, also delivering a maximum range of 70m, but with an accuracy calibration only capable of +/-3mm at 25m.

It is more suited to indoor spaces where neither of these factors will have a practical impact. The same goes for the Focus S 70, but with a further diminished maximum range of 70m. The Focus M 70 is the budget model, also delivering a maximum range of 70m, but with an accuracy calibration only capable of +/-3mm at 25m.

Leica: Scanning, processing and 3D modelling in one place

Leica Geosystems is a ‘premium player’ in the surveying industry. They create high-quality products with a number of diversified specialisations, and focus on delivering an end-to-end user experience. Rather than depending on third-party integrations, Leica encourages users of their scanners to rely on their in-house processing software. In fact, with the exception of a few limited partnerships, Leica scanners are only compatible with Leica processing software.

Leica’s main processing solution is ‘Cyclone’. Cyclone can be used with third-party scanners, and exports point clouds that can be paired with different 3D modelling software. Cyclone also offers 3D modelling capabilities. Cyclone, like Leica scanners, is high-quality, accurate and robust.

Cyclone also offers 3D modelling capabilities. Cyclone, like Leica scanners, is high-quality, accurate and robust.

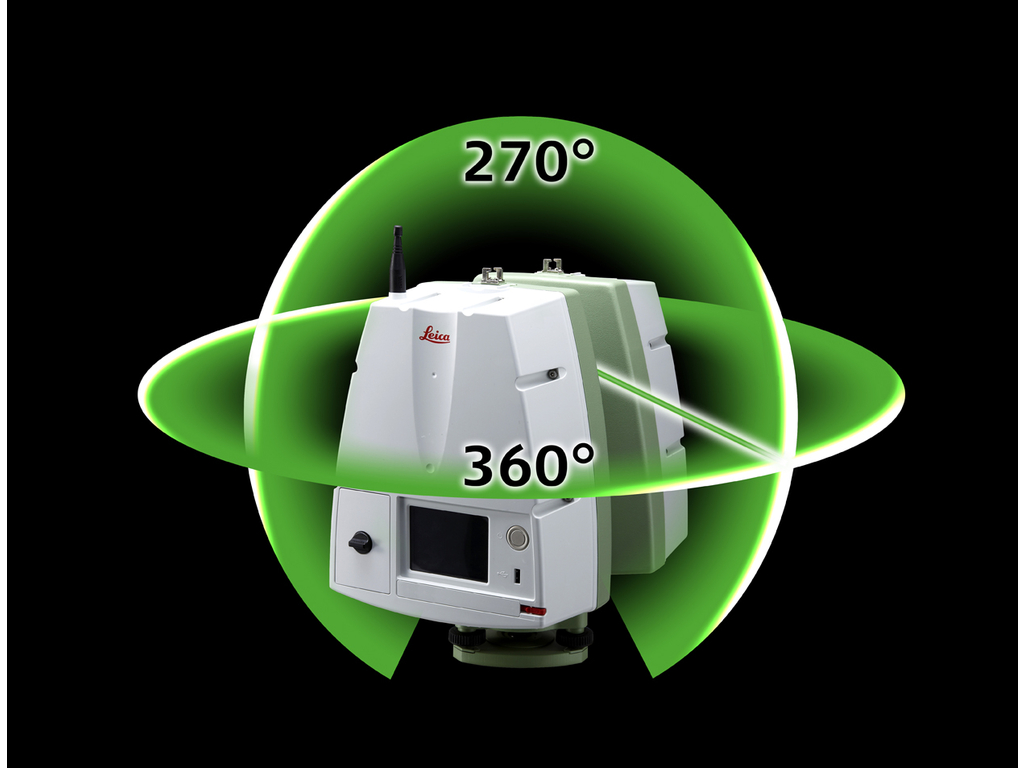

Leica products can be expensive, but users are buying into a complete ecosystem, and are guaranteed high-quality hardware and intuitive software. You can think of Leica as the Apple of laser scanners, restricting your total number of choices, but restricting them to only quality options. Their scanners excel at scan speeds, angular accuracy and limited range noise.

The staple Leica laser scanners are the Leica ScanStation P50/P40/P30. The P50 is the long-range model, capable of making high-quality measurements at distances up to 1 kilometre. ‘Range noise’ is limited to 0.4mm rms at 10m and 0.5mm rms at 50m. Range accuracy is 1.2mm + 10 ppm over the full range. It has a scan rate of 1 million points per second and delivers industry-leading angular accuracy paired with survey-grade dual-axis compensation.

The P40 and P30 scanners are optimised for closer range. The P40 caps out at 270m, and the P30 is effectively limited to 120m. However, for indoor scans, this limitation does not matter, and they both bring the same range noise metrics and angular accuracy as the P50.

The P40 caps out at 270m, and the P30 is effectively limited to 120m. However, for indoor scans, this limitation does not matter, and they both bring the same range noise metrics and angular accuracy as the P50.

All three scanners deliver colour information, making each a great choice where a highly realistic 3D colour model is the end goal.

Leica also offers the BLK360 and RTC360. The BLK360 claims to be the smallest imaging laser scanner in the world. It is compact and easy to use, however, it is limited in range to 60m and has an accuracy rate of 6mm at 10m.

The RTC360 is a premium, multi-purpose product. Easy to use and fast, the RTC360 is a great choice for mid-range scanning. Uniquely, it comes with a video-enhanced inertial measuring system (visual SLAM) that tracks the relative movement of scan positions in real-time. Together with more traditional GNSS receivers and an altimeter, these features improve workflows and ease registration. The RTC360 can make measurements up to 130m at speeds of 2 million points per second. It has an accuracy rate of 1.9mm at 10m and 5.3mm at 40m.

It has an accuracy rate of 1.9mm at 10m and 5.3mm at 40m.

Riegl: Long-range point cloud laser scanners

For long-range scanners, Riegl is really second to none. They dominate the aerial market and are used heavily in the mining sector. But their products are expensive. Whether or not range is a priority is one of the main decisions you should make if thinking about investing in top quality Riegl hardware.

The Riegl terrestrial laser scanner mainstays are the VZ-Series. The VZ-6000 and VZ-4000 are their ‘standard’ products. They are both, however, capable of scan distances far in excess of other scanners on the market — 6km and 4km respectively. Even by Riegl standards, these are long-range specialist scanners. They deliver a respectable scan rate of 222k points per second, have built-in digital cameras, integrated GPS receivers and multi-target capabilities. At 150m, both deliver an accuracy rate within 15mm.

The Riegl VZ-400i and Riegl VZ-2000i are the cutting-edge Riegl products. They have a smaller range, 800m and 2500m. But that is still greater than most high-end, long-range specialist products on the market. What these products deliver is a multi-purpose workflow.

They have a smaller range, 800m and 2500m. But that is still greater than most high-end, long-range specialist products on the market. What these products deliver is a multi-purpose workflow.

Both come with “innovative processingarchitecture for data acquisitions and simultaneous georeference in real-time”. Further, these pair with Riegl’s own processing software to execute on-site registration in real-time. The system is highly flexible, capable of bringing on peripherals to augment your processes, and are fully compatible with the Riegl VMZ mobile laser mapping system. At 100m, both are capable of an accuracy rate of 5mm.

Trimble: An American giant in surveying

Trimble is the American leader when it comes to both point cloud processing software and hardware production. Founded in 1978, they have an annual revenue stream nearing $3 billion. Trimble develops laser rangefinders, UAVs, inertial navigation systems and GNSS receivers. Their technology has a reputation for being fast, clean and consistent.

The two standard Trimble laser scanners are the TX8 and TX6. The TX8 has a standard maximum range of 120m, with the ability to upgrade to 340m. The TX6 has a standard range of 80m, with the ability to upgrade to 120m. Both the TX8 and TX6 have a systematic error rate of less than 2mm between 10m and 100m and an angular accuracy of 80 µrad.

Both have integrated cameras that can help colourise scans, and integrated WLAN technology to enable the wireless and remote operation of their scanners using standard computers. The TX8 delivers a scan rate of 1 million points per second, while the TX6 operates at half that speed. Both are great scanners that deliver for most medium-sized projects.

Trimble also offers the SX10, which brings together the capabilities of a total station with 3D laser scanning. This is great for picking up survey targets and detail in the scene while also scanning, and is one of the leading hybrid products on the market.

There are significant distinctions between products, but think about processing software as well

Riegl specialises in long-range scanners while Faro scanners offer affordable and versatile options. Both Trimble and Leica deliver accurate and robust measurements at medium distances. None of these scanners, however, are a bad choice.

Both Trimble and Leica deliver accurate and robust measurements at medium distances. None of these scanners, however, are a bad choice.

You could consider Riegl to be the industry outlier with their high prices and extreme range capabilities. These ranges are why the scanners are so popular in the mining sector and the oil and gas industry. For a lot of construction purposes, however, teams are working in confined spaces in which those types of distances don’t matter. The accuracy of any scanner starts to depreciate at those distances, and complete scene coverage becomes difficult. Neither of these things are significant issues for a lot of purposes. But they are a problem in construction. There is a reason that Riegl scanners aren’t often seen on construction sites but dominate other markets.

Between the three big medium-range scanners (Faro, Leica and Trimble) Leica stands out because of their closed ecosystem. They deliver high-quality products, but your software choices are limited. There are benefits to this — compatibility guarantees, access to knowledgeable technical support that understands your software and hardware, and quality assurances — however, it makes it harder to access cutting edge solutions.

There are benefits to this — compatibility guarantees, access to knowledgeable technical support that understands your software and hardware, and quality assurances — however, it makes it harder to access cutting edge solutions.

The point cloud processing market is maturing, and startups have entered the field offering software specialised for processing or modelling that delivers features unmatched by the legacy and ‘end-to-end’ solutions. For example, there are new options for multi-stage, vector-based processing software that delivers targetless registration speeds 40%-80% faster than traditional methods. There is also software that enables the front-loading of manual processing procedures, allowing scans to be queued up for hands-off processing.

These types of advances deliver substantial efficiencies to surveyors and allow for targetless registration techniques to be undertaken in the field without creating problems in the office. This is a powerful option that should be taken advantage of no matter what scanner is used. Spend time picking the best scanner for the job, but also make sure you have the capabilities to efficiently transform that data into a completed survey.

Spend time picking the best scanner for the job, but also make sure you have the capabilities to efficiently transform that data into a completed survey.

Popular Laser Scanners for Creating Point Clouds

Point cloud scanners and reality capture are going through a renaissance. Stable and mature technology has contributed to an expansion in use cases. The result is that more people across a broader range of industries are innovating new solutions and helping drive forward both hardware and software capabilities.

There are many new types of scanners on the market. However, more fundamentally, we are at a tipping point with regards to how scanners are used. Multi-scanner workflows are critical to getting the job done, allowing the right scanner to be used at the right time within a single operation.

There are two main ways of looking at different scanners:

- By brand

- By scanner type

Rather than solely focusing on a particular brand or scanner, it’s important to think about how all of your scanners work together. Realistically, that has as much to do with software choices as the specific hardware you use. It also makes focusing on “scanner type” a more productive option for actually deciding what capabilities are missing from your workflow.

Realistically, that has as much to do with software choices as the specific hardware you use. It also makes focusing on “scanner type” a more productive option for actually deciding what capabilities are missing from your workflow.

The diagram below demonstrates how different scanners line up with use cases — primarily dictated by distance and accuracy considerations. What this graphic doesn't show is additional components of cost or ease of integration of those scans.

The most popular laser scanners will be those that deliver outcomes — not just scans. A multi-scanner workflow (tied together by advanced point cloud processing software) is crucial to ensuring flexible and optimised results. Here, we’re going to look at the main scanner types, the use-cases they are popularly deployed to execute, and how you can use this information to improve outcomes.

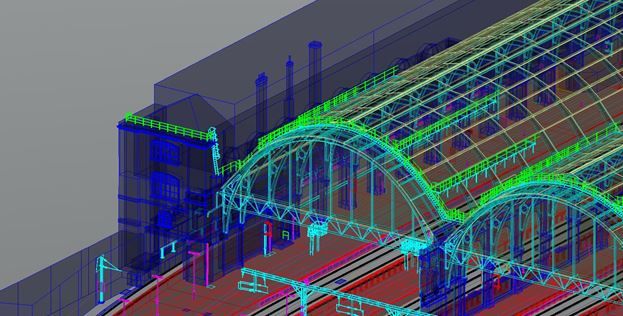

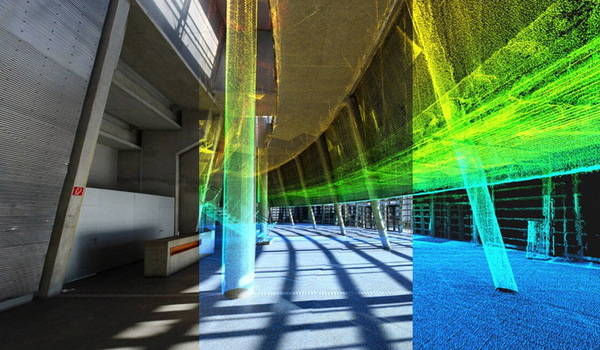

Terrestrial laser scanners (TLS) are the bread-and-butter of reality capture. Particularly when deploying 3D reality capture for building construction, or other contexts where engineering-grade measurements need to be made, these are the core scanners able to deliver scene coverage and high-detail accuracy.

Particularly when deploying 3D reality capture for building construction, or other contexts where engineering-grade measurements need to be made, these are the core scanners able to deliver scene coverage and high-detail accuracy.

TLS systems generate multiple static scans based on line of sight measurements to provide detailed and accurate mapping indoors and outdoors. Arguably, they are the most cost-effective and versatile scanners available. The question generally isn’t whether or not you need a terrestrial laser scanner, it’s what other types of scanners you should be using to augment the capabilities of your TLS.

Pros

- Well understood and accepted.

- Wide range and good accuracy.

- Versatile and robust.

Cons

- Limited by physical scan positions.

- Multiple scan positions generally needed for scene coverage.

- Can be time-consuming to deploy.

The differences between TLS systems (in terms of cost and functionality) mostly comes down to accuracy and range.

Examples of TLS

| Short-range TLS | Price point | Accuracy | Instrument Range |

| £15k - £30k | +/- 5mm - 10mm | <30m | |

| Use cases: Capture targets like facades, crash sites, crime scenes and minor construction sites. Examples: Faro Focus 70, Leica BLK360 | |||

| Medium-range TLS | Price point | Accuracy | Instrument Range |

| £40k - £65k | +/- 2mm - 10mm | 100m - 400m | |

| Use cases: These all-purpose work-horse scanners are ideal for gathering high-detail information in indoor and outdoor spaces and in most contexts. Examples: Faro Focus 150/350; Leica P30/40/RTC360; Z+F Imager 5016 | |||

| Long-range TLS | Price point | Accuracy | Instrument Range |

| £85k - £150k | +/- 5mm - 15mm | 1km - 6km | |

| Use cases: The go-to solution for civil engineering, topography and mining. Long-range scanners are used to measure large areas — e.g. forests and urban areas — especially if obstacles prevent operators from setting up near the scanned object. Examples: Riegl VZ-2000i, VZ-4000, VZ-6000; Maptek XR3, LR3; Leica P50 | |||

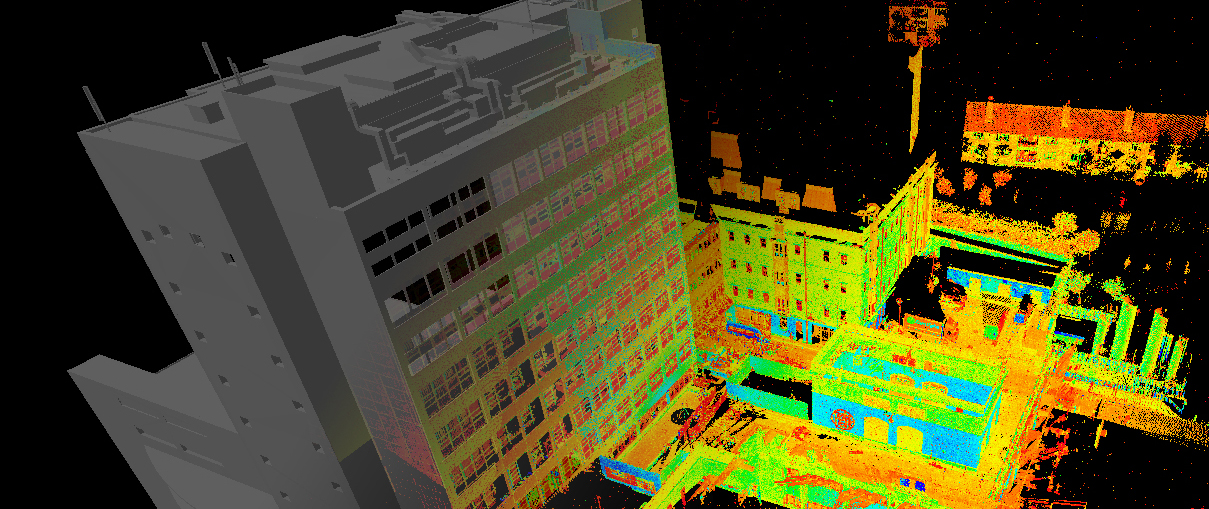

Mobile mapping systems provide more flexibility and faster reality capture capabilities than static scanners, making them great for taking a large number of scans. There are three main components in MMS:

There are three main components in MMS:

- Camera(s)

- LiDAR

- Positioning system (e.g. SLAM, IMU, GNSS, or combination).

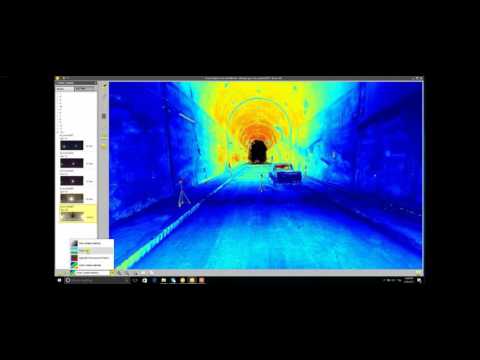

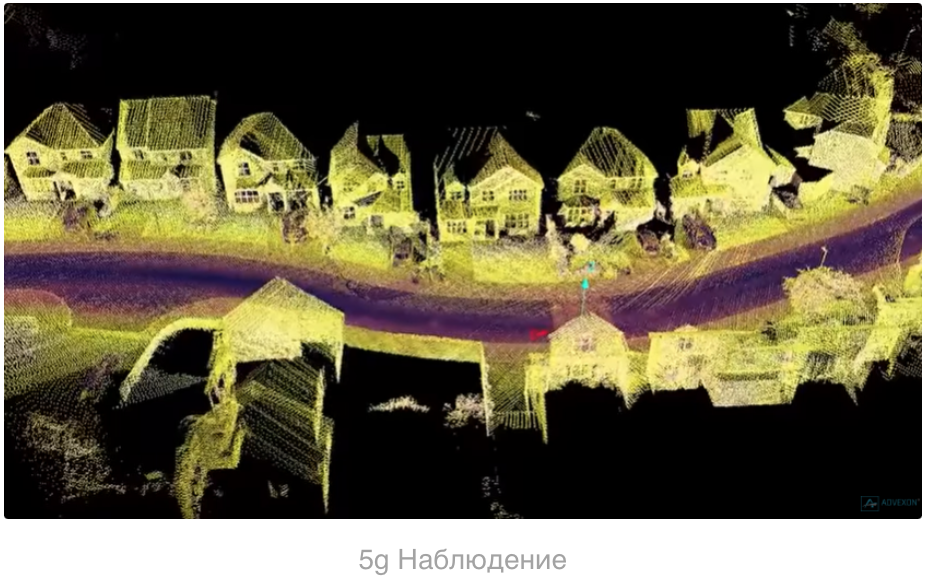

Traditional MMS features laser sensors mounted onto cars, aircraft or drones, trains, and boats to capture vast terrains or landscapes. However, SLAM is increasingly being used in 3D laser scanning for mobile mapping and surveying applications, allowing for the proliferation of wearable MMS. Such 3D scanners are part of the iMMS (indoor Mobile Mapping Systems) category, which belongs to the broader MMS (Mobile Mapping Systems) ecosystem.

iMMS are optimised for indoor mapping and large infrastructures, construction sites, mines, or even forests. In terms of capabilities and use cases, there are significant variations.

Pros

- Allows for rapid scanning across small and large distances.

- Requires very little technical expertise to operate once set up.

- A great complement to TLS, helping add mobility and rapid scene coverage within a mixed scanner workflow using static scans to capture detail where needed.

Cons

- Potential mobility and site limitations.

- Limited accuracy can restrict suitability for specific types of job.

Examples of MMS

| Vehicle scanners | Price point | Accuracy | Instrument Range |

| £250k - £500k | +/- 20mm - 40mm | 120m - 360m | |

| Use cases: Vehicle mounted scanners are ideal for mobile and large-scale registration. Often used for auditing and monitoring road and rail assets; checking telecommunication asset inventories; creating and verifying elevation models; creating 3D city models. Examples: Riegl VMX-2HA, Trimble MX-9, Pegasus II | |||

| Trolly scanners | Price point | Accuracy | Instrument Range |

| £50-100k | +/- 2mm - 10mm | 30m - 360m | |

| Use cases: Trolly scanners bundle sensors on a platform that can be pushed or propelled around a scene. These are valuable for indoor and outdoor scanning, but have some mobility and site limitations. Often used for railway track checking and BIM build progress monitoring. Examples: Leica ProScan, Faro Focus Swift, NavVis M6 | |||

| Wearable scanners | Price point | Accuracy | Instrument Range |

| £20k - £60k | +/- 6 - 30mm | 25m - 100m | |

| Use case: Designed to be held or worn, these scanners enable rapid indoor scanning for small to medium-sized spaces. Examples: Leica BLK2GO, NavVis VLX, GeoSLAM Zeb Horizon | |||

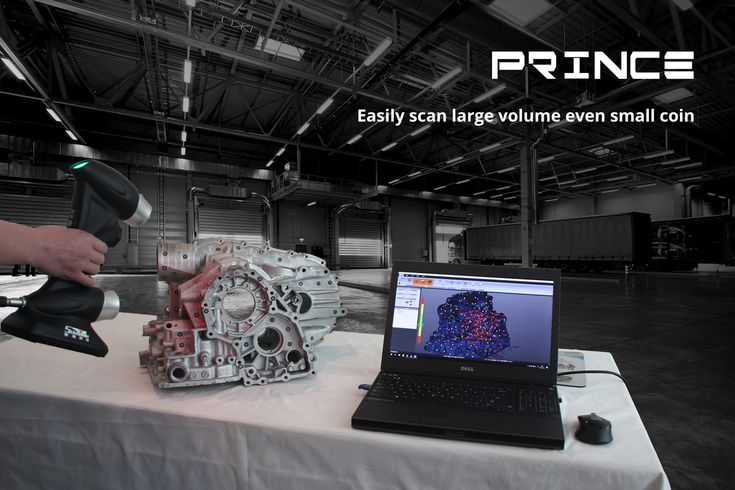

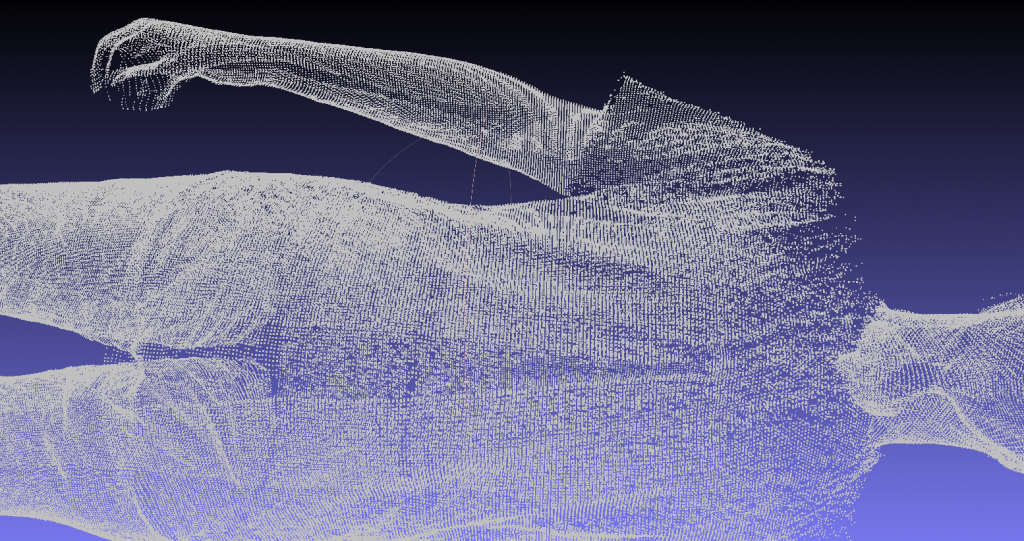

Type 3: Metrology scanners

Metrology scanners deliver high-accuracy and repeatable measurements. They are mainly used for 3D geometrical surface inspection. Mobile metrology grade scanners can use structured light measurements to provide less accurate (although still very accurate) results within a limited range. Popular within manufacturing and archaeological contexts, metrology scanners are finding an increasing number of use cases. However, they remain a relatively niche type of reality capture.

Pros

- Excellent for automating quality checking processes or reverse engineering.

- Increasingly used within multi-scanner workflows and stitched into more extensive scene coverage using advanced software registration.

Cons

- Range usually limits use within broader reality capture contexts

Examples of metrology scanners

| Arm scanners | Price point | Accuracy | Instrument Range |

| > £100k | 0.004mm | max 2m - 3m | |

| Use case: Ideal for cross-checking manufacturing production with planning with high accuracy. For example looking for defects in an automated quality checking process or reverse engineering. Examples: Faro Quantum Scan Arms, Faro Super 6DoF TrackArm | |||

| Structured light scanners | Price point | Accuracy | Instrument Range |

| £10k - £27k | +/- 0. | 0.1-10m | |

| Use case: Widely used within heritage restoration and archaeology, their range limits use within broader reality capture contexts. However, it’s possible to stitch location-specific data from white light scanners into more comprehensive reality capture data sets of an entire scene — if you deploy the right software solution. Examples: Faro Freestyle 2, Artec Eva, Creaform HandyScan 3D | |||

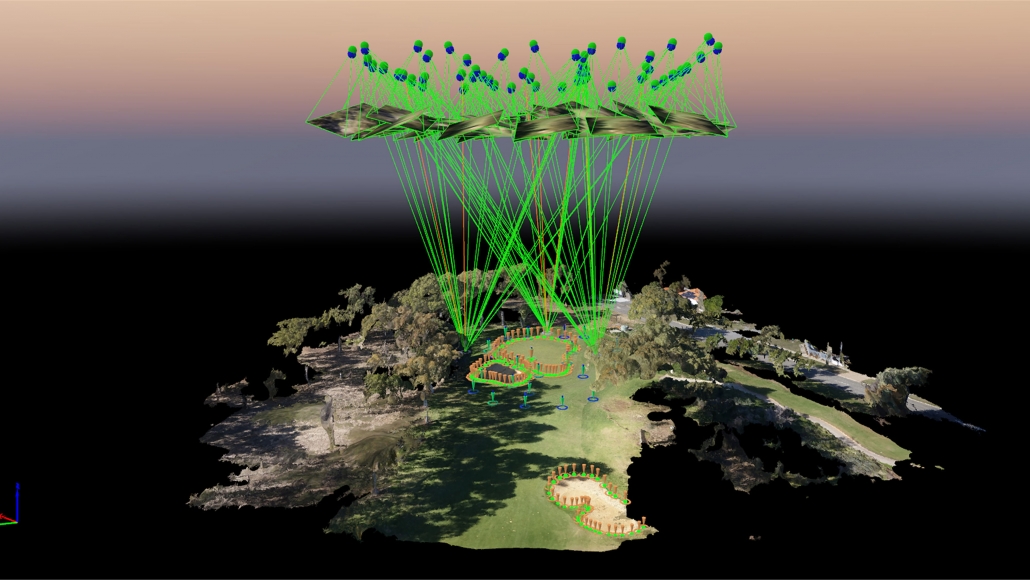

Type 4: Aerial scanners

Aerial scanners are long-range, sophisticated and expensive devices. They combine data from multiple inputs and are often used for global mapping — mounted to both drones and conventional aircraft. For most users, they are usually best rented rather than purchased.

Pros:

- Enables scanning on an incredibly large scale

- Rapid scene coverage

Cons:

- Cost of scanners

- Complexity of deployment

- The need for aircraft or drones

Examples of aerial scanners

| Aerial (long-range) | Price point | Accuracy | Instrument Range |

| > £1m | +/- 0. | Kilometres | |

| Use case: Can deliver rapid and vast scene coverage, best suited to large-scale outdoor mapping, including use in navigation, meteorology, land surveys and cartography. Examples: Riegl VQ-1560 II, Leica CityMapper 2 | |||

| Aerial (short-range) | Price point | Accuracy | Instrument Range |

| £45k - £100k | +/- 30mm | Kilometres | |

| Use cases: Short-range aerial scanners provide similar capabilities on a smaller scale and lower price point. This makes them great for city planning, area mapping, ecological surveys and more. Examples: Emesent Hovermap, mdLiDAR1000-aaS | |||

The major 3D scanner manufacturers and brands

Thinking about the specific type of scanner you need should be your number one priority. However, it then becomes important to consider brands. Within that context, there are a number of core names you’ll see in the market. A quick overview of each will help you orientate yourself and make the right choice. This list focuses on terrestrial laser scanner manufacturers.

However, it then becomes important to consider brands. Within that context, there are a number of core names you’ll see in the market. A quick overview of each will help you orientate yourself and make the right choice. This list focuses on terrestrial laser scanner manufacturers.

Faro: A flexible scanning solution

Faro offers a range of popular and widely used laser scanners, some of which are generalists, while others are focused on specific use cases. Faro offers its own processing software (Scene), but it's scanners pair easily with third-party options. This versatility, and the relative affordability of their hardware is one reason for the popularity of the company. Combined with the small size, fast scan speeds, ease of use, and often multi-purpose capabilities of their scanners, Faro has been a long-time staple of the surveying community. The Faro Focus series is their main product line for indoor and outdoor surveying.

Founded in 1981, Faro has an annual revenue of over $360 million and is considered an industry leader in 3D measurements, imaging and realisation technology. Faro technology is popular with manufacturers as well as surveyors. Many of their scanners are focused on delivering precise models of objects, rather than surveying.

Faro technology is popular with manufacturers as well as surveyors. Many of their scanners are focused on delivering precise models of objects, rather than surveying.

Z+F: German engineering and third-party compatibility

The German company Z+F delivers a range of robust and sophisticated hardware and software solutions for reality capture. Founded as an engineering company in 1963, they developed their first laser scanner for railway measurements in 1994 and their first scanner for the 3D documentation of objects in 1996. There has been a Z+F subsidiary in the US since 1998 and in the UK since 2001.

Their flagship static scanners are the IMAGER series, providing a range of capabilities in a number of different packages. The Z+F scanners offer high quality data, and with integrated HDR cameras they offer arguably best in class imagery. The Z+F IMAGER 5016 model is compact and lightweight with an integrated LED enabled camera with the benefit of additional internal positioning sensors. Conversely, the IMAGER 5006EX is the only explosion-proof laser scanner in the world — delivering robust capabilities for volatile environments. Z+F also offers to the market a number of 2D profiler laser scanners which can be utilised on both trolley and vehicle mobile mapping systems.

Conversely, the IMAGER 5006EX is the only explosion-proof laser scanner in the world — delivering robust capabilities for volatile environments. Z+F also offers to the market a number of 2D profiler laser scanners which can be utilised on both trolley and vehicle mobile mapping systems.

Leica: Scanning, processing and 3D modelling in one place

Leica Geosystems is a ‘premium player’ in the surveying industry. They create high-quality products with a number of diversified specialisations, and focus on delivering an end-to-end user experience. Rather than depending on third-party integrations, Leica encourages users of their scanners to rely on their in-house processing software. In fact, with the exception of a few limited partnerships, Leica scanners are only compatible with Leica processing software. The staple Leica laser scanners are the Leica ScanStation P50/P40/P30.

Riegl: Long-range point cloud laser scanners

For long-range scanners, Riegl is really second to none. They dominate the aerial market and are used heavily in the mining sector. But their products are expensive. Whether or not range is a priority is one of the main decisions you should make if thinking about investing in top quality Riegl hardware.

They dominate the aerial market and are used heavily in the mining sector. But their products are expensive. Whether or not range is a priority is one of the main decisions you should make if thinking about investing in top quality Riegl hardware.

The Riegl terrestrial laser scanner mainstays are the VZ-Series. The VZ-6000 and VZ-4000 are their ‘standard’ products. They are both, however, capable of scan distances far in excess of other scanners on the market — 6km and 4km respectively. Even by Riegl standards, these are long-range specialist scanners. They deliver a respectable scan rate of 222k points per second, have built-in digital cameras, integrated GPS receivers and multi-target capabilities. At 150m, both deliver an accuracy rate within 15mm.

Trimble: An American giant in surveying

Trimble is the American leader when it comes to both 3D point cloud processing software and hardware production. Founded in 1978, they have an annual revenue stream nearing $3 billion. Trimble develops laser rangefinders, UAVs, inertial navigation systems and GNSS receivers. Their technology has a reputation for being fast, clean and consistent.

Trimble develops laser rangefinders, UAVs, inertial navigation systems and GNSS receivers. Their technology has a reputation for being fast, clean and consistent.

The three standard Trimble laser scanners are the TX8, TX7 and TX6. The TX8 has a standard maximum range of 120m, with the ability to upgrade to 340m. The TX6 has a standard range of 80m, with the ability to upgrade to 120m. Both the TX8 and TX6 have a systematic error rate of less than 2mm between 10m and 100m and an angular accuracy of 80 µrad.

How to make the right choice

What makes a scanner popular is going through a bit of shift change at present. It may be worth forgetting the brands you have loyally used for years. Instead, focus on choosing the right type of scanner and think about brands later.

The first task in your purchasing decision is to align use cases with scanners. This will help you understand the scanning required to get the job done. Then you must figure out how your different types of scanners best work together — and then you can create a holistic workflow that matches the best scanners for the best jobs.

Closed vs open ecosystems

Although we strongly believe in the importance of thinking about outcomes, there is one brand difference that you critically need to keep in mind — how well those scanners work with other types of scanners. Some manufacturers limit the ability of their scanners to integrate with third-party software. This severely limits your ability to flexibly deploy these scanners within a multi-scanner workflow, and need to be kept in mind when making purchasing decisions.

Focusing on outcomes and use cases

Each main type of laser scanner has a central use case, but they are increasingly beginning to overlap. Indeed, at the extremes of very high accuracy or vast range — your decisions are made for you — the middle ground is becoming less clear cut.

Effective reality capture is increasingly dependent on the merging of multiple types of scan outputs. You have to combine scanning techniques, each with its own strengths and weaknesses, to maximise the tools at your disposal. However, your ability to make this kind of workflow possible has more to do with your software choices than the scanners you deploy.

However, your ability to make this kind of workflow possible has more to do with your software choices than the scanners you deploy.

Modern scanner developments now are, fundamentally, dependent on software innovation. For example, your ability to leverage technology such as point cloud data classification and point cloud feature extraction is entirely software-based. To improve outcomes, you need to think about workflows first, including both the scanning process and downstream deliverables. Processing software, modelling tools, and file-sharing capabilities dramatically impact workflows and need to be considered simultaneously to hardware decisions.

At Vercator, we believe in driving hardware-based outcomes using software — something we see as a significant LiDAR mapping trend. Get in touch if you want to learn more about how Vercator Cloud can transform the use of your existing laser scanners and impact which scanners to invest in for the future.

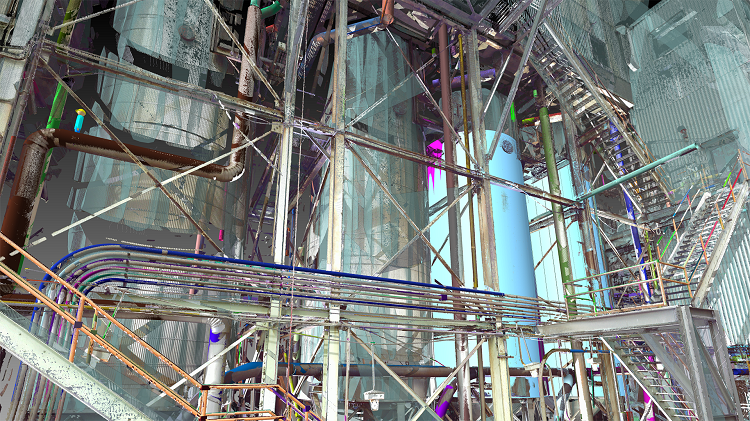

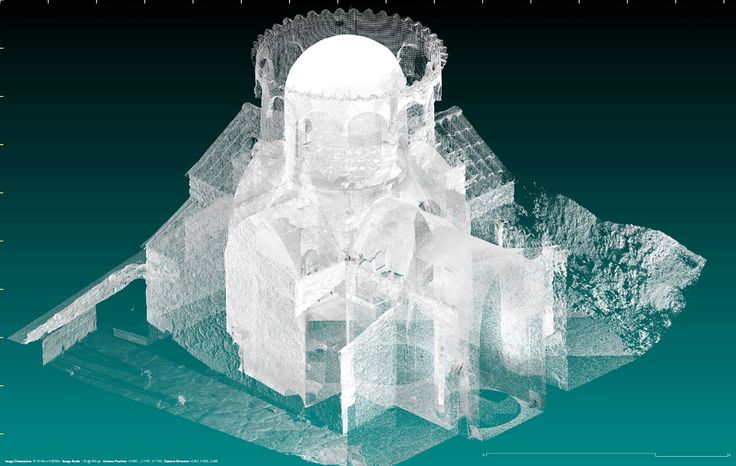

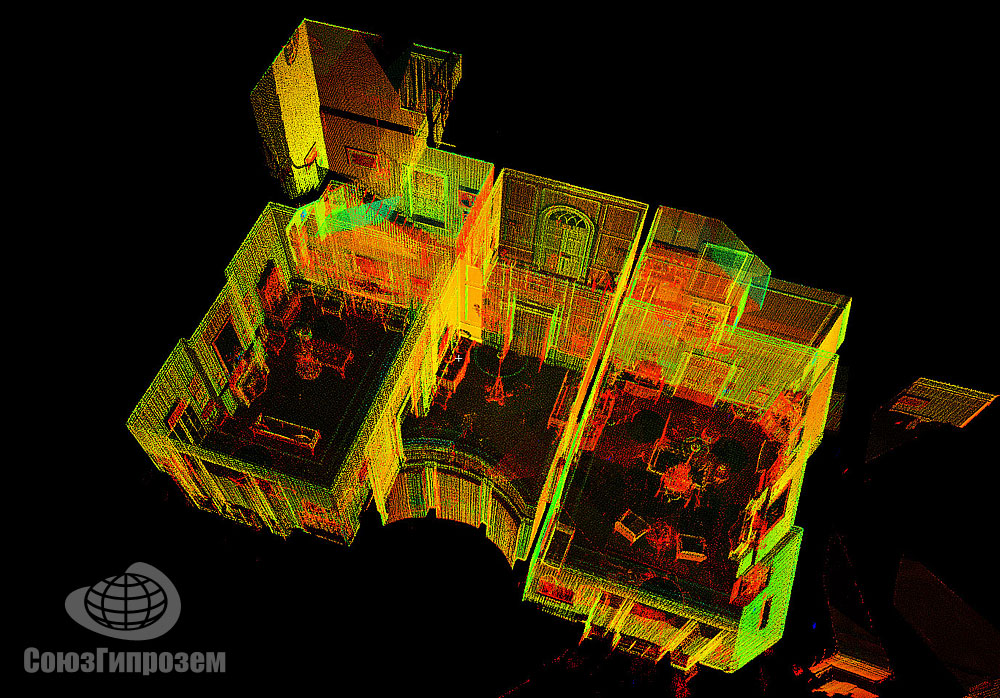

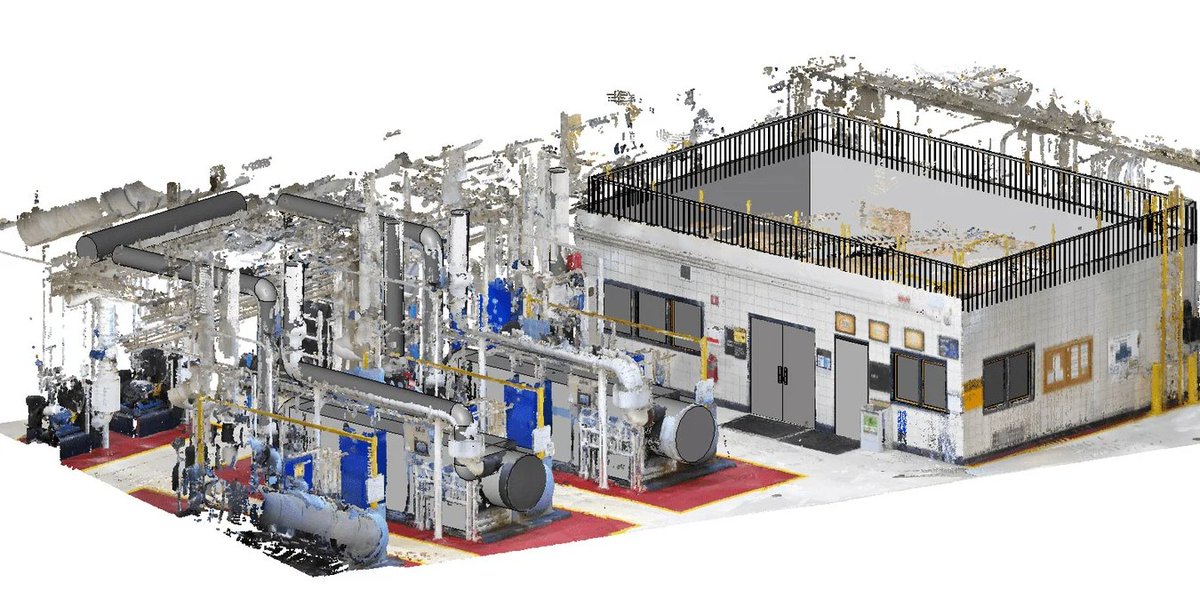

3D ground laser scanning

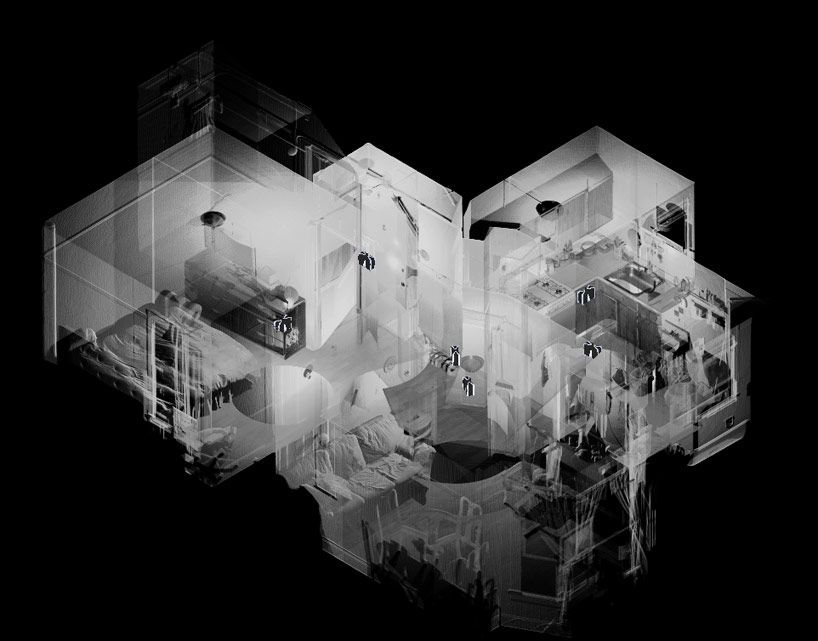

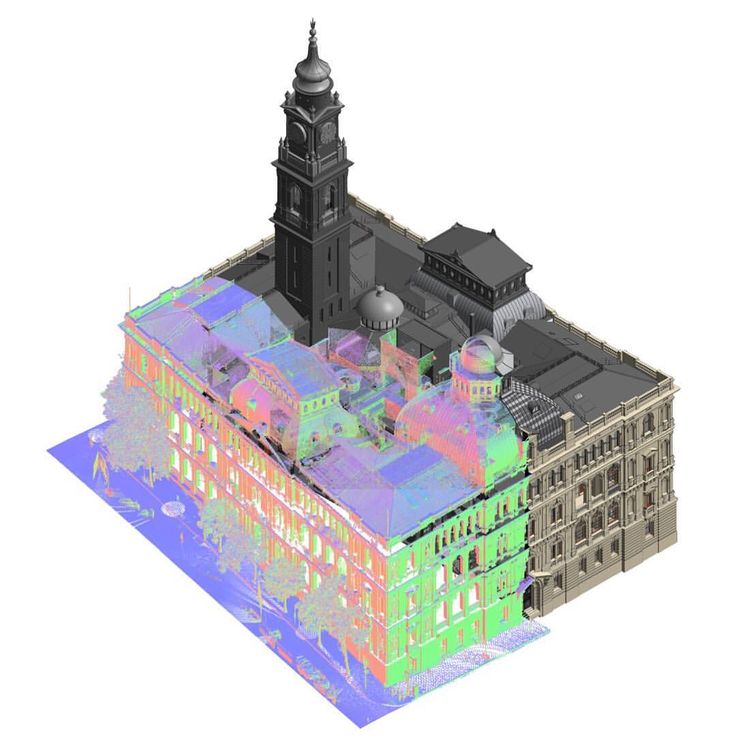

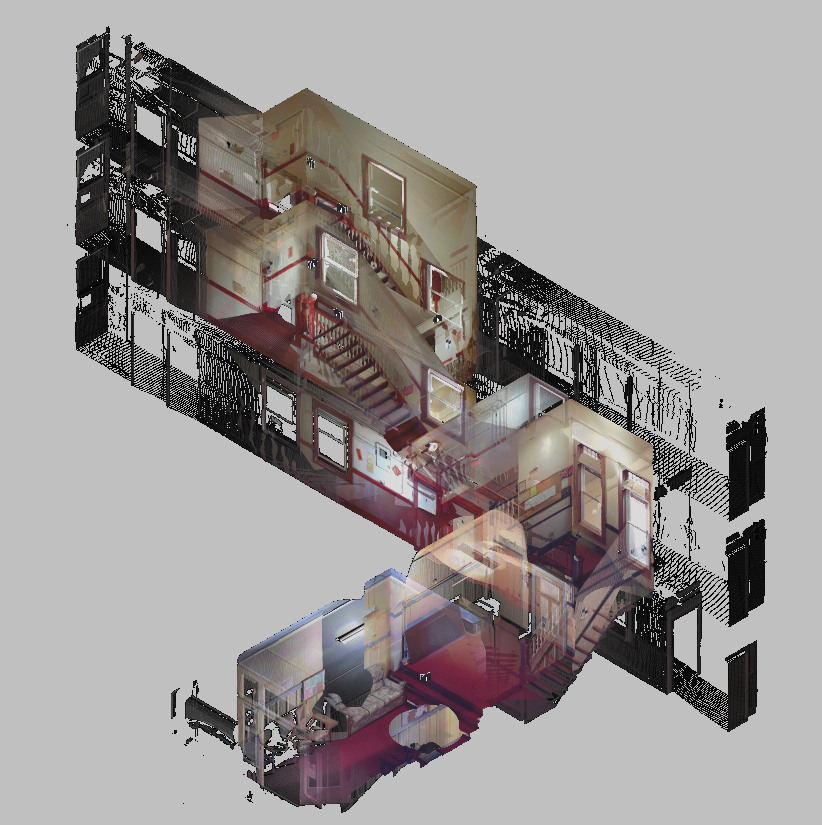

Point cloud examples

Despite the fact that the first terrestrial 3D scanners appeared in the last century, there is no reason to state that 3D laser scanning technology is widely used in geodesy. The main reasons, probably, are the still high cost of such systems and the lack of information on how to use them effectively in various applications. Nevertheless, interest in this technology and its demand in the market of geodetic equipment are growing exponentially every year.

The main reasons, probably, are the still high cost of such systems and the lack of information on how to use them effectively in various applications. Nevertheless, interest in this technology and its demand in the market of geodetic equipment are growing exponentially every year.

What is a 3D laser scanner?

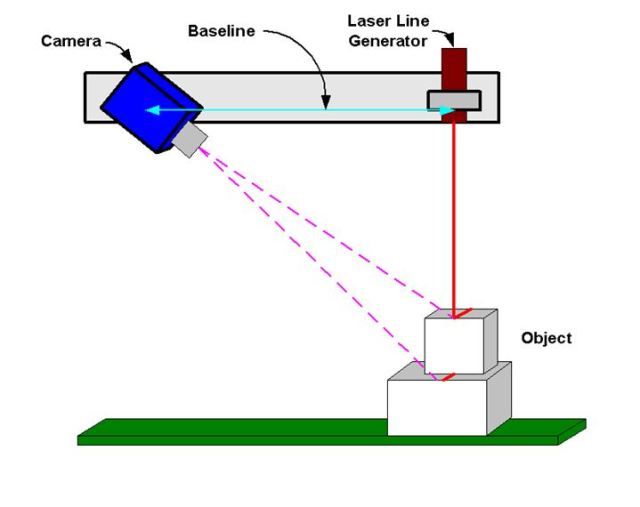

According to the type of information received, the device is in many ways similar to a total station. Similar to the latter, the 3D scanner uses a laser range finder to calculate the distance to an object and measure vertical and horizontal angles to obtain XYZ coordinates. The difference from a total station is that daily shooting with a ground-based 3D laser scanner is tens of millions of measurements. Obtaining a similar amount of information from a total station will take more than one hundred years ...

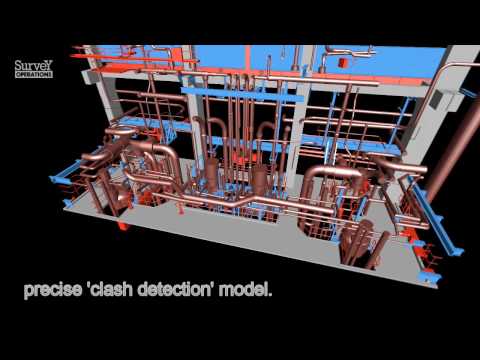

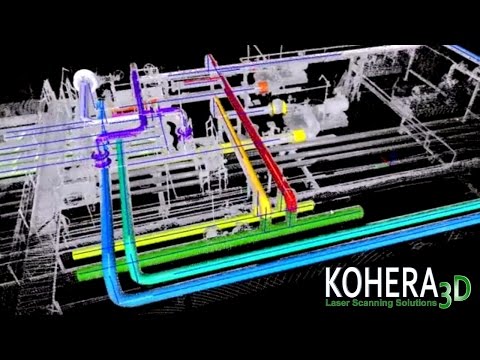

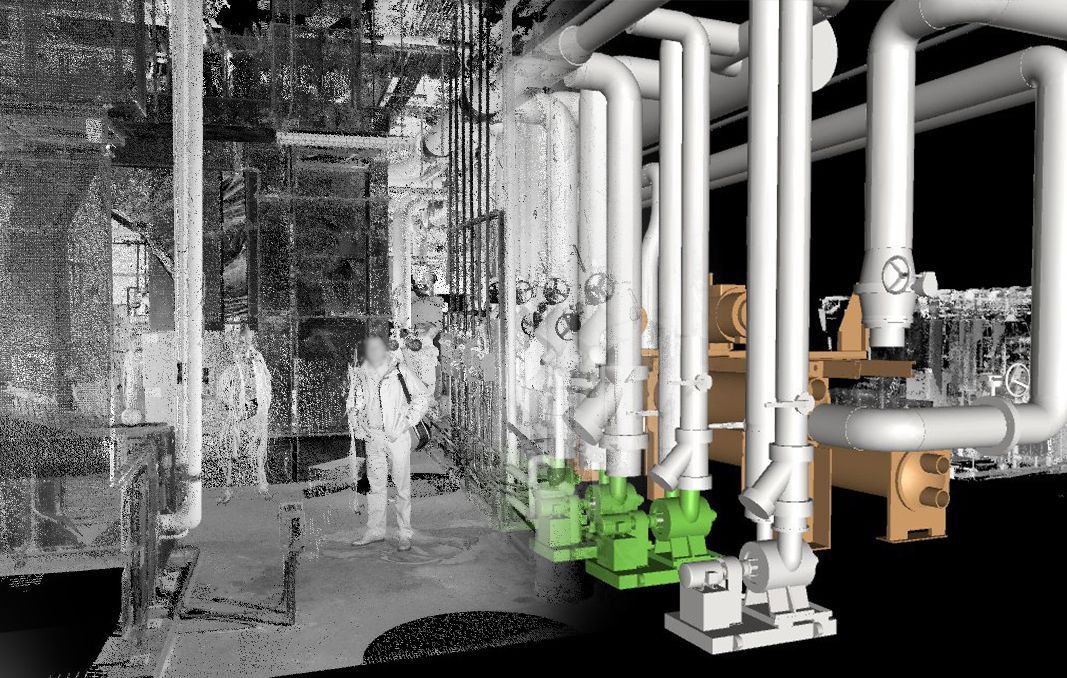

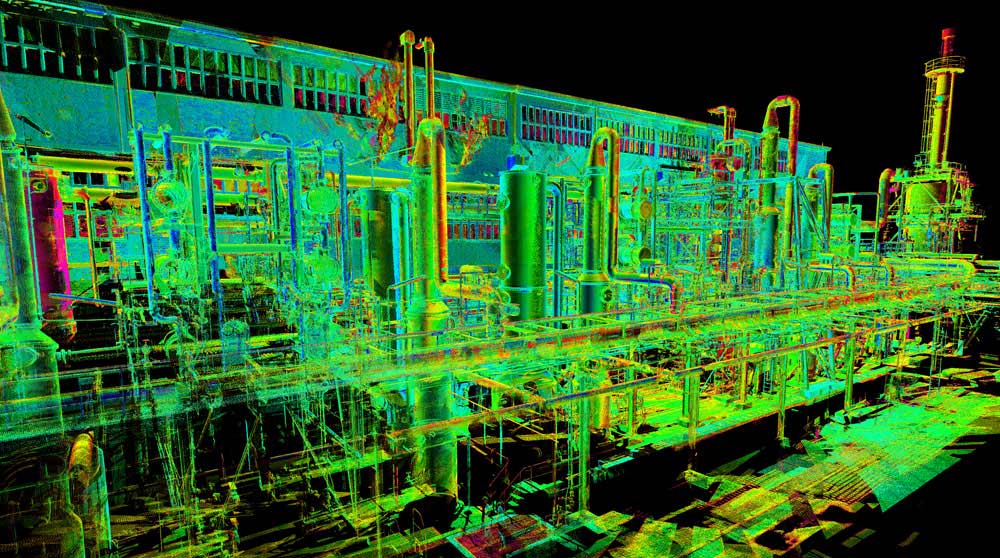

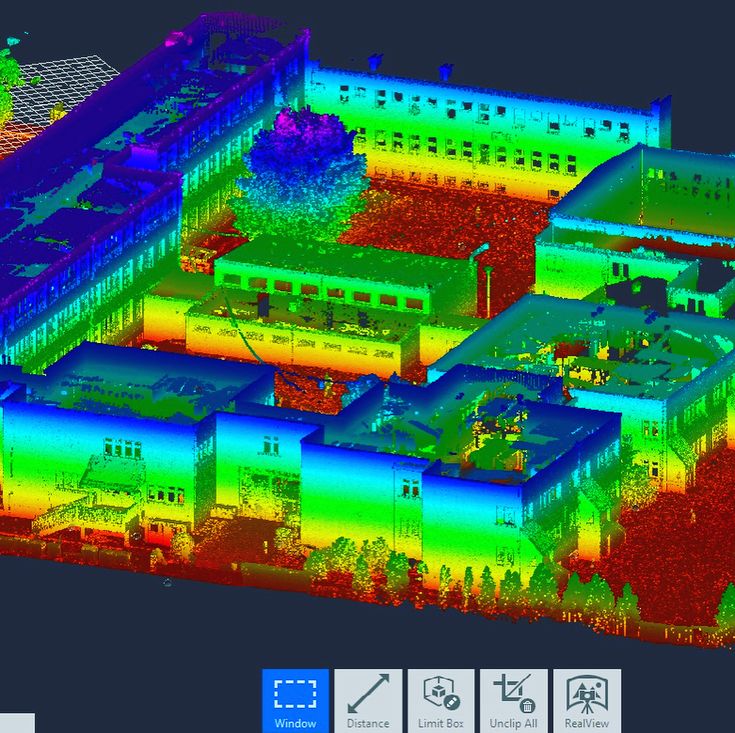

The initial result of the 3D laser scanner is a point cloud. In the process of shooting, three coordinates (XYZ) and a numerical indicator of the intensity of the reflected signal are recorded for each of them. It is determined by the properties of the surface on which the laser beam falls. The point cloud is colored depending on the degree of intensity and after scanning looks like a three-dimensional digital photo. Most modern models of laser scanners have a built-in video or photo camera, so that the point cloud can also be painted in real colors.

It is determined by the properties of the surface on which the laser beam falls. The point cloud is colored depending on the degree of intensity and after scanning looks like a three-dimensional digital photo. Most modern models of laser scanners have a built-in video or photo camera, so that the point cloud can also be painted in real colors.

In general, the operation of the device is as follows. The laser scanner is mounted opposite the object to be filmed on a tripod. The user sets the required point cloud density (resolution) and survey area, then starts the scanning process. To obtain complete data about an object, as a rule, it is necessary to perform these operations from several stations (positions).

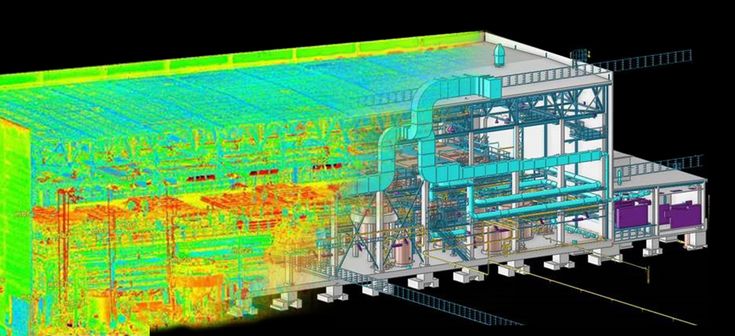

Then the initial data received from the scanner is processed and the measurement results are prepared in the form in which they are required by the customer. This stage is no less important than field work, and is often more time-consuming and complex. Profiles and sections, flat drawings, three-dimensional models, calculations of areas and volumes of surfaces - all this, as well as other necessary information, can be obtained as the final result of working with a scanner.

Where can laser scanning be used?

Main applications of 3D scanning:

- industrial enterprises

- building and architecture

- road shooting

- mining

- monitoring of buildings and structures

- documentation of emergencies

This list is far from complete, since every year users of laser scanners perform more and more unique projects that expand the scope of technology.

Laser Scanning from Leica Geosystems - History of Laser Scanners

The history of Leica laser scanners began in the 90s of the last century. The first model 2400, then under the Cyra brand, was released in 1998. In 2001, Cyra entered Leica Geosystems into the HDS (High-Definition Surveying) division. Now, after 14 years, Leica Geosystems introduces a line of two scanning systems on the market.

As mentioned above, 3D laser scanning is used in completely different areas, and there is no universal scanner that would effectively solve all problems.

For shooting industrial facilities where a long range is not required, but the model must be very detailed (that is, an accurate high-speed device is needed), the laser scanner Leica ScanStation P30 will be optimal: range up to 120 m, speed up to 1,000,000 points per second.

Completely different requirements are imposed on the scanner when it comes to shooting opencast mines and storages of bulk materials in order to calculate volumes. Here, centimeter accuracy of the rangefinder is enough, and the shooting range and protection from weather conditions and dust come to the fore. The ideal tool for scanning in such conditions - Leica HDS8810 with a range of up to 2,000 m and IP65 dust and water resistance. In addition, this device is the only one on the market of scanning systems that operates in the temperature range from -40 to +50 degrees. That is, the HDS8810 is a laser scanner that works in all weather conditions.

The key model of Leica Geosystems' HDS division is the Leica ScanStation P40 . The famous and most popular ScanStation line in the world, whose history began in 2006, was replenished in April 2015 with the P40 scanner. The P40 inherited the accuracy and speed from the previous model, but has become more long-range, and the data quality has become even better. In terms of the range of tasks to be solved, this device is truly a leader in its segment. It is no coincidence that despite the "youth" of this model, it has already gained wide popularity in the world.

The famous and most popular ScanStation line in the world, whose history began in 2006, was replenished in April 2015 with the P40 scanner. The P40 inherited the accuracy and speed from the previous model, but has become more long-range, and the data quality has become even better. In terms of the range of tasks to be solved, this device is truly a leader in its segment. It is no coincidence that despite the "youth" of this model, it has already gained wide popularity in the world.

Software for processing laser scan data (point clouds)

It is impossible not to say a few words about the software for processing data received from the scanner. Potential customers pay undeservedly little attention to this component of the 3D laser scanning system, although data processing and obtaining the final result of the work are no less important stages of the project than field work. The range of Leica HDS software is truly the widest on the laser scanning market.

The main element of the spectrum is, of course, the Cyclone complex. This modular software system is rightfully considered the most popular in the world and has a large package of tools for processing data obtained using a scanner. Leica also has a number of more highly specialized programs. For those who are accustomed to working in traditional CAD, there is a series of software products Leica CloudWorx embedded in AutoCAD, MicroStation, AVEVA and SmartPlant, which allows users of these programs to work directly with point clouds. 3DReshaper builds high-quality triangulation models of object surfaces and allows you to monitor deformations by comparing object surveys taken at different times. The Leica HDS line of software even includes software for processing scan data in forensics.

This modular software system is rightfully considered the most popular in the world and has a large package of tools for processing data obtained using a scanner. Leica also has a number of more highly specialized programs. For those who are accustomed to working in traditional CAD, there is a series of software products Leica CloudWorx embedded in AutoCAD, MicroStation, AVEVA and SmartPlant, which allows users of these programs to work directly with point clouds. 3DReshaper builds high-quality triangulation models of object surfaces and allows you to monitor deformations by comparing object surveys taken at different times. The Leica HDS line of software even includes software for processing scan data in forensics.

Thus, laser scanning from Leica Geosystems is a whole complex of software and hardware solutions. For every, even a highly specialized task, Leica has a scanner + software combination that will help solve this problem as efficiently as possible.

Leica RTC360 3D Laser Scanner | Leica Geosystems

- home

- Products/Solutions

- Laser scanners

- Scanners

- Leica RTC360 3D laser scanner

Use automatic on-site pre-registration of point cloud data for real-time quality control, increased productivity and better decision making on site

Document and digitize your environment in 3D with the Leica RTC360 3D reality capture solution. Increase productivity on site and in the office with fast, accurate, portable and easy-to-use hardware and software. With the RTC360 3D Laser Scanner, a skilled technician can overcome any design challenge with accurate and reliable 3D models to unlock the full potential of any site.

- The compact, highly automated, intuitive and user-friendly RTC360 solution includes a high-performance 3D laser scanner, the Leica Cyclone FIELD 360 mobile app for edge computing, such as automatic registration of scanned data in real time, and Leica Cyclone REGISTER 360 software for office work , with which you can easily implement the resulting 3D model into your workflow.

- Capture scans, including stunning HDR images, in less than two minutes.

- Automatic recording of movements between survey points to pre-register scanned data in the field without manual intervention.

- Augment your collected data with informative tags with tips for optimal planning and real-world conditions on site to help your colleagues better understand the situation.

- Upload collected data from Cyclone FIELD 360 directly to Leica TruView Cloud to quickly share design data before import and registration.

Quick

The new Leica RTC360 laser scanner captures reality in 3D at a speed never seen before. Capturing up to 2 million points per second and using advanced HDR image capture, the scanner generates colorful 3D point clouds in less than two minutes.

Automated, labelless data logging in the field based on VIS technology and convenient automatic data transfer from site to office further speed up field work and increase productivity.

Automated, labelless data logging in the field based on VIS technology and convenient automatic data transfer from site to office further speed up field work and increase productivity.

Adaptive

Thanks to its portable design and foldable tripod, the compact and lightweight Leica RTC360 fits into a regular backpack. On the object, one click of a button is enough to scan the environment without any additional settings.

Fine

Low noise in the acquired data means better image quality – you get crisp, detailed scans that are ready for a variety of industries. Combined with the Cyclone FIELD 360 automated data logging software in the field, the Leica RTC360 delivers amazing accuracy that can be verified on site.

Pre-registration in the field

The Cyclone FIELD 360 app, part of the RTC360 solution, bridges the gap between on-site 3D data collection and on-site registration of laser scan data in the office with Cyclone REGISTER 360.

User can automatically capture, register, and control scan and image data on site . The easy-to-learn and user-friendly graphical interface offers visual aids for complex calculations, making it easy for even beginners to master.

User can automatically capture, register, and control scan and image data on site . The easy-to-learn and user-friendly graphical interface offers visual aids for complex calculations, making it easy for even beginners to master. Previous Next

Scanning options

The RTC360 3D Laser Scanner automatically captures movement between survey points to pre-register scanned data on the spot. Juergen Mayer spoke about the latest developments in an interview with The Reporter.

Introduction to the RTC360

The latest Leica RTC360 3D reality capture solution, unveiled at HxGN LIVE 2018, combines a high-performance laser scanner with a mobile application for capturing and pre-logging real-time scan data.

From hardware to software

Geosystems specialists optimize every link of the workflow in both software and hardware solutions to increase the efficiency and productivity of field work and data processing in the office.

Leica RTC360: 3D reality capture solution

Leica Cyclone FIELD 360 mobile-device app

Downloads

Videos

EXPERT ADVICE

Examples of using

Podcasts

Introducing the Leica RTC360 3D Laser Scanner

3D environments in a matter of minutes - an outlook on recent reality capture technology

3D reality capture - new opportunities, greater understanding

Transforming Ayacucho into a digital city

Services

myWorld Customer Portal

Active Customer Care

Customer Support Packages

Related products

Laser scanners

Leica BLK360 laser scanner

Leica ScanStation P40 / P30

Leica ScanStation P50

Software

Leica Cyclone

Leica Cyclone REGISTER

Leica Cyclone REGISTER 360

Leica CloudWorx

Leica TruView

Leica JetStream

Accessories

Accessories for 3D laser scanners 9003

contact-for-laser-scanning

As of v7. 0.1, Safari exhibits a bug in which resizing your browser horizontally causes rendering errors in the justified nav that are cleared upon refreshing.

0.1, Safari exhibits a bug in which resizing your browser horizontally causes rendering errors in the justified nav that are cleared upon refreshing.

As of v7.0.1, Safari exhibits a bug in which resizing your browser horizontally causes rendering errors in the justified nav that are cleared upon refreshing.

CONTACT US

The High-Definition Surveyor - Blog

Learn how Leica Geosystems laser scanning solutions are helping professional to shape the future of our world.

Learn how Leica Geosystems laser scanning solutions are helping professional to shape the future of our world.

Read More

Scanning power

Quality is a tradition, built deep within our DNA. We have a commitment to excellence and exceptional attention to detail.

Scanning power

Quality is a tradition, built deep within our DNA. We have a commitment to excellence and exceptional attention to detail.

WATCH NOW

Educational articles and analytics

What is 3D Reality Capture and how is it applied in your industry?

What is 3D Reality Capture and how is it applied in your industry?

learn more

Comparison table of laser scanners

Which laser scanner is right for you?

Which laser scanner is right for you?

download now

Reality Capture Newsletter

Click here to subscribe to our regular newsletter and stay up-to-date on all the latest reality capture news.

They are great for repetitive scanning or managing restricted access sites. However, the limited accuracy of mobile mapping (and SLAM specifically) means that these scanners are not suited to every job.

They are great for repetitive scanning or managing restricted access sites. However, the limited accuracy of mobile mapping (and SLAM specifically) means that these scanners are not suited to every job.  02mm - 0.11mm

02mm - 0.11mm 5m - 10m

5m - 10m