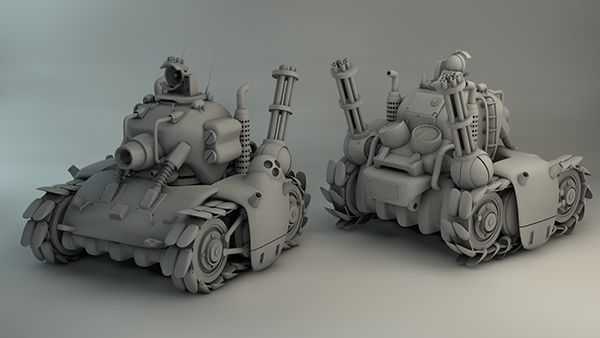

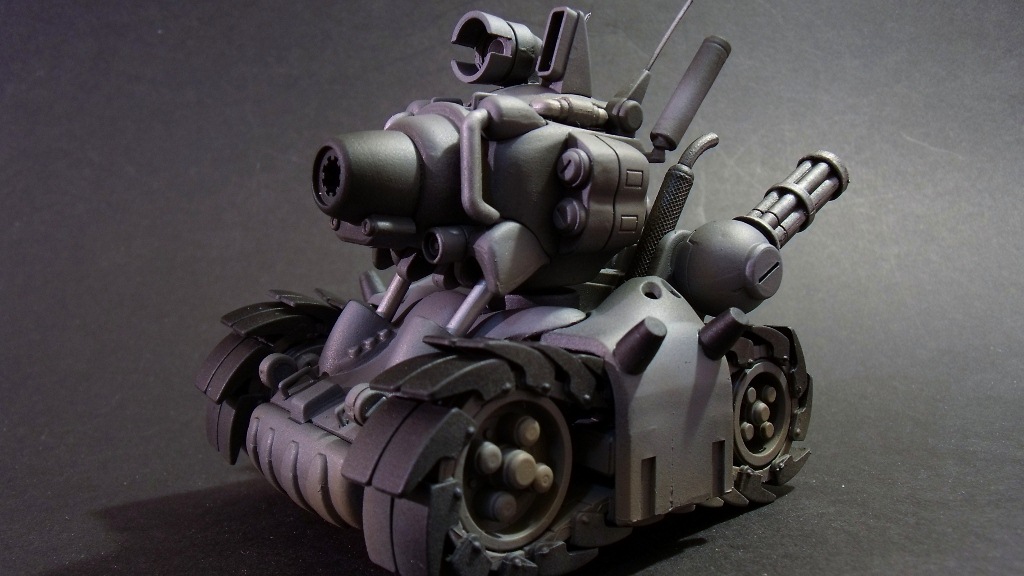

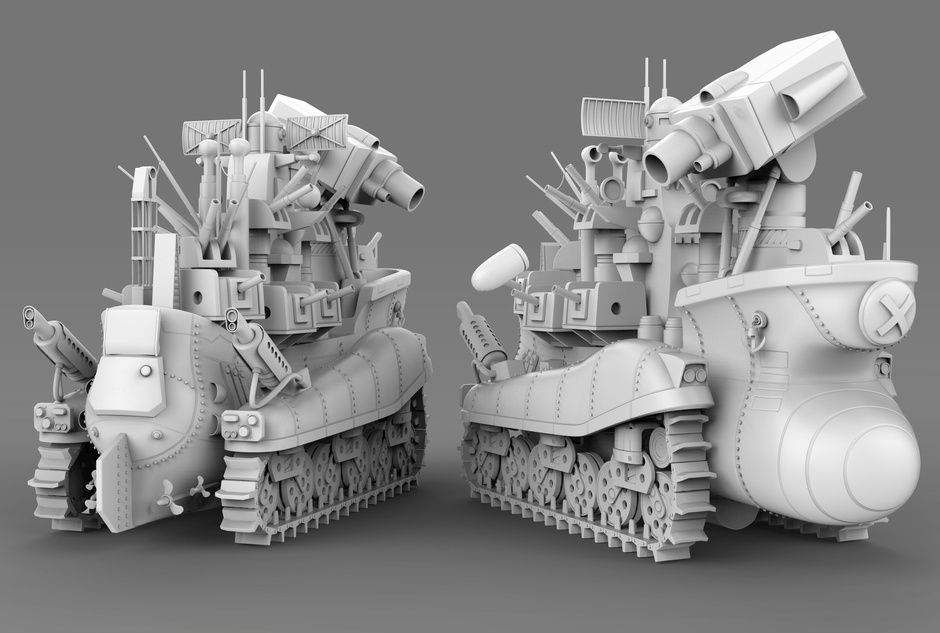

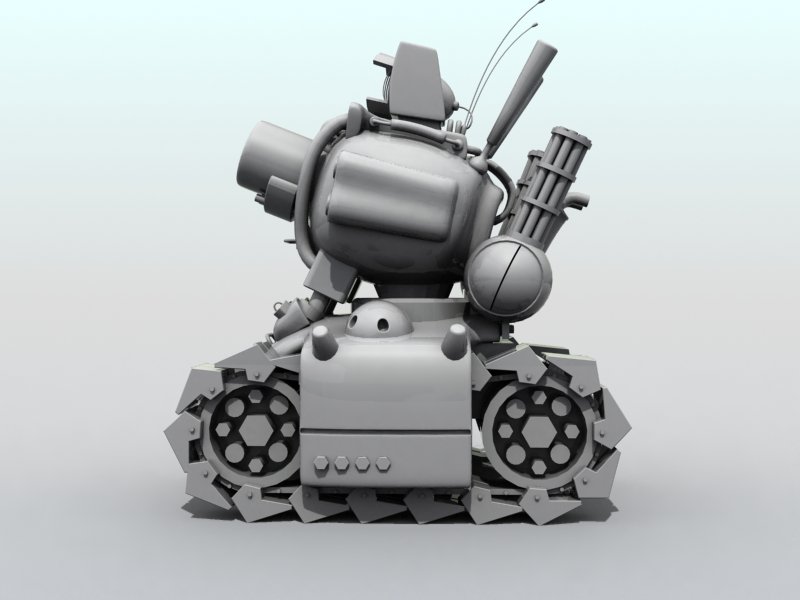

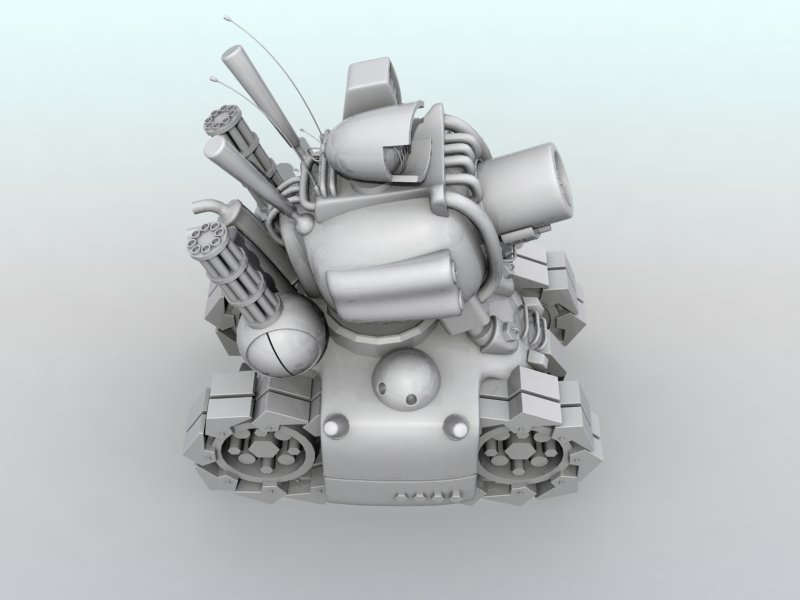

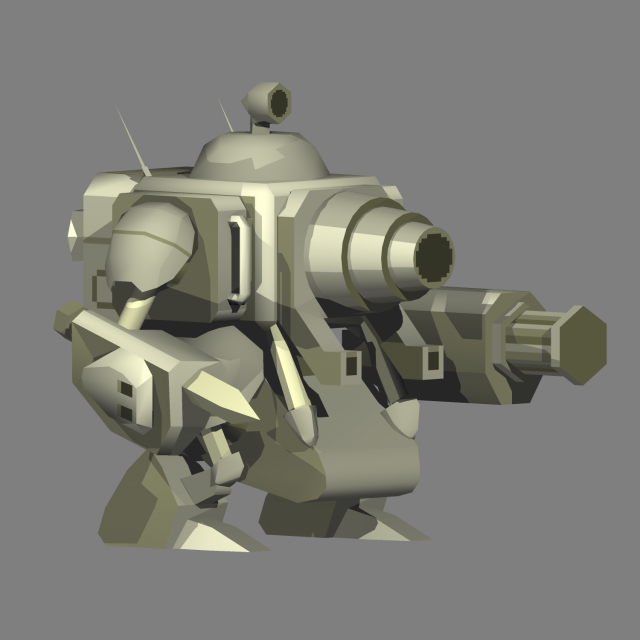

Metal slug 3d print

Metal Slug Tank – Download Stl Files

3D Objects, 3D Printing and CNC Tank

E-Mail : [email protected]

Note : 'Metal Slug Tank' is the free 3D Art file you will download, the 3D Art file is stealthed in the .zip .rar .7z file to help you download files faster . Please use the Winrar or 7Zip software to open and Extract files 3D model.

Note: We created this website system because of our passion and not for profit. Maintaining the system with limited funding is very difficult. We look forward to receiving your support. If you feel my system is beneficial to you, please help us share this website with your friends.That will give us the incentive to do better. thank you !

Free design 3D Art, 3D Model file download for CNC : Metal Slug Tank

Code file: H004569

Tank

Keywords : File Metal Slug Tank, File Metal Slug Tank for CNC cutting machine, File Metal Slug Tank for Laer cutting machine, File Metal Slug Tank for plasma cutting machine, File Metal Slug Tank for 3d printer, File Metal Slug Tank for cnc engraving machine, File Metal Slug Tank for laser engraving machine, File vector Metal Slug Tank, File artcam Metal Slug Tank, File dxf, File 3D model Metal Slug Tank, File cdr, File stl Metal Slug Tank, File obj Metal Slug Tank, File CNC Metal Slug Tank, File laser Metal Slug Tank, File 3d printer Metal Slug Tank, File plasma Metal Slug Tank, Design files Metal Slug Tank, Wood carving file Metal Slug Tank, cnc router files for sale, cnc router files free download, cnc router files furniture, cnc router files stl, cnc router files for wood, cnc router file format, cnc router file sharing, cnc router design files, cnc router files free, cnc router art files, free 3d cnc router, artcam files download, cnc router cut files, cnc router cad files, cnc router carving files, cnc router cabinet files, cnc router g code files free cnc router g code files, cnc router files download, cnc router dxf files for sale, cnc router dwg files, free cnc router files, cnc router engraving files, cnc engraving files, cnc router engraving software, free cnc engraving files, cnc routing file format, 3d cnc router files free, cnc router gcode files, cnc router guitar files, gcode files for cnc router, free gcode files for cnc router, files for cnc router, cnc router g code, cnc router g code software, military cnc router files, military cnc files, free military cnc files, cnc router project files, free cnc router project files, cnc router project, cnc router project downloads, cnc router svg files, cnc router sample files, cnc router stl files free, cnc router sign files, cnc router file types, cnc router test files, cnc router table files, cnc router file, file type for cnc router, file format for cnc router, cnc router vector files, free cnc router vector files, vector files for cnc router, free vector files for cnc router, vector images for cnc router, cnc files for wood, wood cnc files, cnc router 3d files, fusion 360 cnc router files, cnc router 3d models, 3d files for cnc router, file corel, file dxf, file cdr, file laser, file cut laser, file plasma, laser engraving filen, free laser cutting files, acrylic laser cutting files, laser cutting files free download, free svg files for laser engraving, laser cutting templates, laser engraving files download, free 3d laser engraving files, svg laser cut files, laser cutting files free download, free laser engraving clipart, free vector files for laser engraving, free svg files for laser engraving, laser engraving images download, laser engraving vector files, free laser engraving patterns, laser engraving file format, free 3d laser engraving files, free cnc project files, cnc file download, tap file cnc, file cnc router, 3d cnc files, cnc laser files, cnc router file sharing, cnc svg files, wood design free download, cnc 2d design free download, free dxf files, cnc dxf files, cnc files 3d, dxf downloads, free dxf files download, 2d dxf files free download, cnc dxf files free download, free dxf files 3d, free alphabet dxf files, free dxf files for laser engraving, house dxf file download, dxf files for laser cutting, flex design cdr file free download,urdu cdr file download, panaflex cdr file free download, template design cdr file free download, cdr vector graphics free download, graphic design cdr file free download, coreldraw banner design cdr file download, corel draw 9 cdr files free download, cdr file to pdf, coreldraw document, coreldraw file format converter, cdr file opener, how to open cdr file in photoshop, Kho file Corel, open cdr file online, how to open cdr file without coreldraw, free cnc project files, free cnc router files for wood, 3d files for cnc router, free gcode files for cnc router, svg files for cnc router, free dxf files for cnc router, cnc router dxf files for sale, 3d router files, Download file 3d CNC, free 3d cnc files, 3d model to cnc, free 3d carving files, 3d cnc files for sale, stl files for cnc, free cnc models, cnc stl files for sale, free 3d models obj, 3d model download, free 3d models blender, free 3d model sites, 3d max model free download architecture, high quality 3d models free download, 3d models online, sketchfab, 3d models free download, 3d models download, free 3d models obj, free 3d models blender, 3d model sketchup, 3d model maker, high quality 3d models free download, cgtrader, stl file download, 3d printer models free, free stl files for cnc router, 3d stl files, stl file software, free 3d printer g-code files, buy stl files, 3d printer files, 3d printer models free, 3d printer stl files, free 3d printer g-code files, free stl files for 3d printing, buy stl files, 3d printing ideas, 3d print websites, 3d printer software, evangelion 3d model, evangelion 3d google, evangelion 3d model free, eva 01 stl, eva 01 3d model, evangelion stl, thingiverse evangelion, eva 02 3d model, artcam 3d relief files free download, artcam 3d model free download, artcam 3d door designs free download, cnc router 3d models free download, artcam 2d files free download, artcam file format, 3d relief downloads, artcam 3d design training, 3ds max blocks free download, 3ds max models free download interior, free 3d model sites, free 3d models download, 3d max model free download architecture, free 3d models obj, high quality 3d models free download, 3ds max models library, file autocad, open file dwg online, open autocad files, open autocad bak file online, reading file cad online, autodesk file download, autocad reader free

Phi | Metal Slug Wiki

in: Characters, Female characters

View source

Phi

Aliases

No information

Gender

Female

Origin

AI created by Regular Army

Occupation

Artificial intelligence

Height

Unknown (hologram and tank body)

Weight

Unknown (hologram and tank body)

Special Skills

3D Printing

Phi is a new character introduced in Metal Slug Attack.

Contents

- 1 Character Summary

- 2 Story

- 2.1 Extra Ops

- 3 Gallery

Character Summary

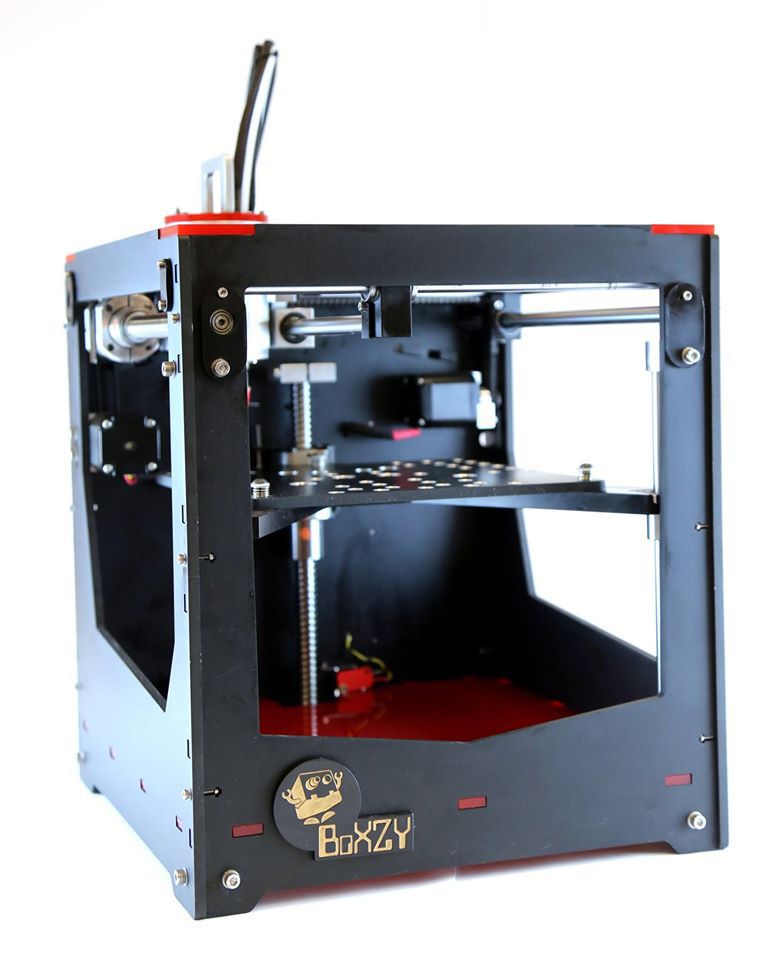

An AI created by the Regular Army, Phi operates an unnamed tank that has a 3D printer attached to it. The printer allows her to create anything that she thinks of in an instant, making her a valuable asset to MS-Alice's unmanned division.

Despite the massive power she possesses, Phi is an AI with an ego; she is extremely shy and dislikes being damaged. This shyness makes her reluctant to fight, but she becomes terrifying when angered, venting it out on nearby entities regardless of affiliation. She also possesses an unusual attachment to the Iron Fortress for reasons unknown, as she herself admits that she doesn't know why she's fathomed with her.

Story

Extra Ops

First appearing in "Accidental Coincidence", Phi takes part in a mission to stop a train loaded with a missile. However, she shows no interest in participating until Alice promises to bake her a cake and that she would eventually meet the Iron Fortress if she kept fighting. She saves Whip from Rapid, who thanks her for the rescue. When Whip states that her attacks felt like love at first sight, she mistakenly believes that Whip loves her and unintentionally harms her allies.

She saves Whip from Rapid, who thanks her for the rescue. When Whip states that her attacks felt like love at first sight, she mistakenly believes that Whip loves her and unintentionally harms her allies.

Gallery

Idle

Story illustration

Design sheet

| Characters | ||

| Heroes | Main Series | Marco Rossi • Tarma Roving • Eri Kasamoto • Fio Germi • Trevor Spacey • Nadia Cassel • Ralf Jones • Clark Still • Leona Heidern |

|---|---|---|

| Spin-Offs | Walter Ryan • Tyra Elson • Hero • Gimlet • Red Eye • Tequila | |

| Mobile | Roberto Nicola • Nathalie Neo • Alisa Stewart • Helton • Tilde • Nikita • Matilda • Amir • Whip • Heidern • Merris | |

| Support | Hyakutaro Ichimonji • Rumi Aikawa • Madoka Aikawa • Utan • Navel • Selina • Issenman Tarou • Eris • Hyakumantaro • Pupipi | |

| Villains | Main Series | Donald Morden • Allen O'Neil • Abul Abbas • Rootmars • Doctor • Avatar of Evil • Invader King |

| Spin-Offs | Allen Jr. • Oguma • Macba • Lt. Wired • Kanan • Hilde Garn • Oguma • Macba • Lt. Wired • Kanan • Hilde Garn | |

| Mobile | Unknown Alien • Victor • Ptolemaios • Anubis the Chained • Nanook • Dalia | |

| Instructors | Sophia Greenville • Margaret Southwood • Riviera von Wittenberg • Maryell von Wittenberg • Cynthia Hartnett • Anne | |

| NPC | Announcer • POWs • Duke Koudou • Satiko Suzuki • Gerhardt City Civilians • Chris Key • Alexander Suvorov • Baby • Scott Amundsen Jr. • Miner • Genie of Lamp • Orca • President • Survivors • Fishman • Lumberjack • Sailor • Chinese Soldier | |

| Crossover | KOF Team • Battle Cats | |

| Unused | Phil Gene • Michiko Nakajima • Angry Man • "Achilles" • "Tabomba" | |

| Metal Slug: Awakening | Goddess Ancor • Catherine | |

| Metal Slug Attack | ||

| Regular Army | Associates | MS-Alice • Anna Wiese • Midori Schumann • Mello • Rita Lewinsky • Amber • Nikita • Reika Bradford • Louise • Gisee • MS-Heart • Ashley • Rocky • Growl • Jephet • Victoria • Claudia • Kanae • Howell • Phi • Elizabeth Mariani • Undo • Charlotte • Nayutaro Ichimonji |

| Metal Device Project | Perche • Ami • Molly • Menzel • Ulala • Maggie • Avvio • Quaith • Karen | |

| Rebel Army | Associates | Rapid • Julia • Chloe • Izabella • Edda • Growth & Cline • Naomi • Alesha • Jane Doe |

| ACE | Abigail • Dion • Romy • Kriemhild • Katalina | |

| "Frozen Brigade" | Beatriz • Vicky • Dolores | |

| Blaze Brigade | Grazia • Loretta • Norah | |

| Allen Platoon | Destrade • Huracan • Conny • Nantes • Padwah • Olga • Virginia | |

| Science Department | Vita • Navy • Nova • Emma • Millefie • Sylfie • Fluffy • Eight Eight | |

| Arabian Army | Shizuka • Aisha | |

| MRAW | Extra Raven | |

| Ptolemaic Army | Rebellion | Dragunov • Yoshino • Caroline • Veronica • Sisilia • Towa • Simon • Miharu • Chunyan • Owen • Sho • Lucy • Phoebe • Josette • Mizuna • Matilda • Little Lady Black • Svetla • Humphrey • Lithos • Yutong • Tatyana • Cica • Linhua • Valette |

| Cultists | Mira D. Genesis • Maria • Damian • Achetto • Sally • Cara • Oao-One • Sorceress Genesis • Maria • Damian • Achetto • Sally • Cara • Oao-One • Sorceress | |

| Secret Sect | Anastasia IV • Believers • Beecham • Melvina • Anastasia I • Zahara | |

| Others | Reverse Trinity | |

| Space Army | Martians | Professor "Aionion" • Mars People Neo • Percier • Clone Abby • Clone Betty • Mars People Rangers • Ariadna • Gemini Twins • Halle • Bonny • Clario • Harriot • Code Marionette:Un • Pauline • Leone • Claris • Draco • Raubtier • Malkuth |

| Invaders | Odette • Annette • Lydia • Nowan • Schwarz Metzelei • Fedeln Metzelei • Rillacle • Franke • Teleko • Bloom Metzelei • Odile • Bersek • Geweih Metzelei • Purple King • Barbeln • Biene Goldenes • Swordeist • Drache Goldenes • Eis Monstrum • Ai Agate • Lieben • Goldenes Krieger • Pictura | |

| Unaffiliated | Unsigned • Li Lin | |

| Independent Army | Amadeus Syndicate | White Baby • Alma • Otto • Iron Fortress • Valerian Bears • First Baby • Type:Ant-Lion • Sweet Baby • Melk |

| Red Goblin Society | Scotia Amundsen • Red Goblin • Vatn • Jin • Aileen • Elena • Licht • Ichima • Wendy • Bushin Tenzan • Maki | |

| Mummy Army | Pharaoh • Cleopatra • Hemet • Arsinoe • Hathol • Sharifa • Ramal • Sekhat • Wepset | |

| Vampires | Aswang • Agalia • Sharl • Grace | |

"World Military Corp. " " | Kelly • Maya • Mirror Mantis | |

| Mirage Circus | Cocatrix • Bunny • Flan | |

| Unaffiliated | El Dorado • Elysion • Esther • Teresa • Minerva • Yang Dao • Yuki Tsuki Hana • Ido • Philia • Hisui | |

Community content is available under CC-BY-SA unless otherwise noted.

Metal 3D Printing - The Essential Guide

There is no hotter trend in 3D printing today than metal. We will talk about metal printing at home, how it is done on an industrial scale, about technologies, applications, printers, processes, prices and materials.

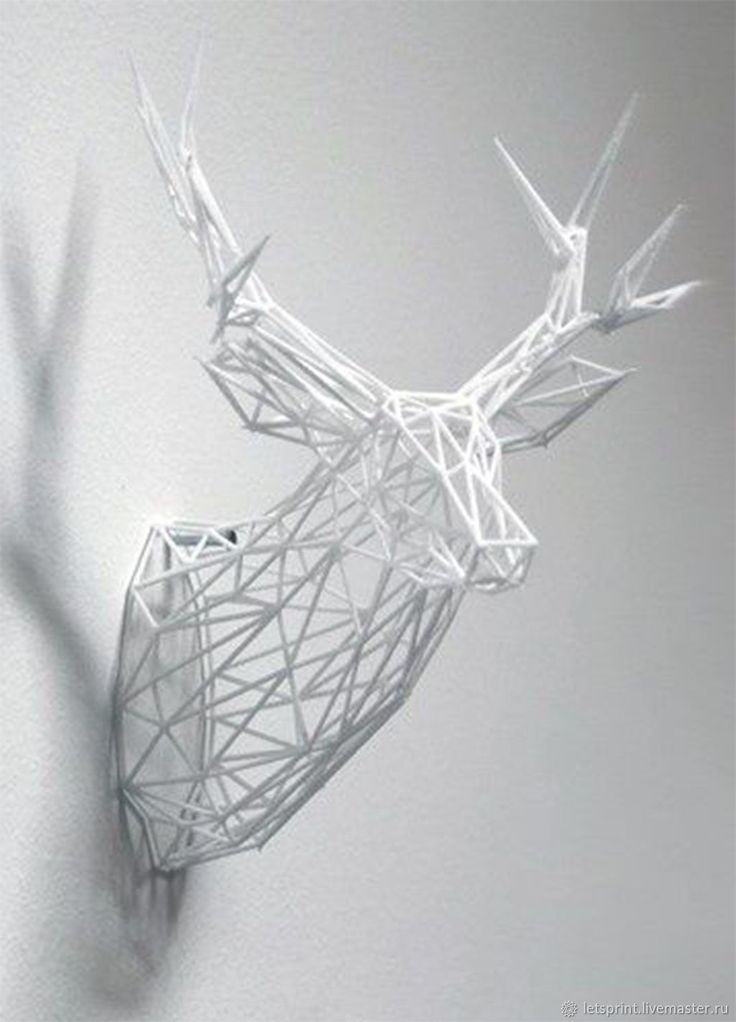

Metal 3D printing has grown in popularity over the past few years. And this is quite natural: each material offers a unique combination of practical and aesthetic qualities, can be suitable for a wide range of products, prototypes, miniatures, decorations, functional details and even kitchen utensils.

The reason metal 3D printing has become so popular is because the printed objects can be mass-produced. In fact, some of the printed parts are just as good (if not better) than those made with traditional methods.

In fact, some of the printed parts are just as good (if not better) than those made with traditional methods.

In traditional production, working with plastic and metal can be quite wasteful - there is a lot of waste, a lot of excess material is used. When an aircraft manufacturer makes metal parts, up to 90% of the material is simply cut off. 3D printed metal parts require less energy and waste is reduced to a minimum. It is also important that the final 3D printed product is up to 60% lighter than a traditional part. Billions of dollars could be saved in the aviation industry alone—mainly through weight savings and fuel savings.

So, what do we need to know about metal 3D printing?

Metal 3D printing at home

If you want to make objects at home that will look like metal, your best bet is to look at metalized PLA filaments (Photo: colorFabb)

Where to start if you want to print metal objects at home ? Given the extreme heat required for true metal 3D printing, a conventional FDM 3D printer will not be able to do this.

It is unlikely that in this decade it will be possible to print with liquid metal at home. Until 2020, you probably will not have a printer specialized for this purpose at home. But in a few years, as nanotechnology advances, we may see significant developments in new applications. This can be 3D printed with conductive silver, which will emit in much the same way as it does in 2D home printers. It will even be possible to mix different materials like plastic and metal in one object.

Materials for metal 3D printing at home

Even though you can't print actual metal objects at home, you can turn to plastic filament that has metal powders added to it. ColorFabb, ProtoPasta and TreeD Filaments all offer interesting metal-PLA composite filaments. These filaments, containing a significant percentage of metal powders, remain pliable enough to be printed at low temperatures (200 to 300 Celsius) on virtually any 3D printer. At the same time, they contain enough metal to make the final object look, feel, and even weigh like metal. Iron-based filaments even rust under certain conditions.

Iron-based filaments even rust under certain conditions.

But you can go further. Typically, up to 50 percent metal powder is added to 3D printing filament. Dutch company Formfutura says they have achieved 85 percent metal powder with 15 percent PLA. These filaments are called MetalFil Ancient Bronze and Metalfil Classic Copper. They can be printed even at "moderate" temperatures from 190 to 200 degrees Celsius.

Metallic 3D Printing Filament Spools, in this case from SteelFill and CopperFill colorFabb (Steel and Bronze), Ancient Bronze (Ancient Bronze) from Formfutura

Here are the key points about metal printing at home

- Gets a unique metal surface and look

- Ideal for jewelry, figurines, housewares, replicas

- Durability

- Objects are not flexible (structure dependent)

- Objects do not dissolve

- Not considered food safe

- Typical print temperature: 195 - 220°C

- Extremely low shrinkage on cooling

- No table heating required

- Printing complexity is high, requires fine tuning of nozzle temperature, feed rate, post-processing

Preparing Your Home Printer for Metal 3D Printing

Since getting metal 3D prints is more difficult than usual, you may need to upgrade your 3D printer nozzle, especially if you are an entry-level printer. The metal filament wears it out quickly. There are hard-wearing hot-ends (like the E3D V6) that are themselves made of metal. They can withstand high temperatures and fit most printers. Be prepared for the fact that the nozzles will have to be changed frequently, because the metal filament is very abrasive.

The metal filament wears it out quickly. There are hard-wearing hot-ends (like the E3D V6) that are themselves made of metal. They can withstand high temperatures and fit most printers. Be prepared for the fact that the nozzles will have to be changed frequently, because the metal filament is very abrasive.

You will also need to take care of the final finishing of the surface (cleaning, grinding, oiling, waxing or priming) so that the printed metal object shines as it should.

How much does metal filament for 3D printing cost?

And what about metal filament for 3D printing? - you ask. Here are a few examples:

- ColorFabb's 750 gram Bronzefill spool is $56.36

- ColorFabb 750g Copperfill Coil $56.36

- Protopasta's Polishable Stainless Steel PLA Composite is $56 for 56 grams of

- Protopasta's Rustable Magnetic Iron PLA Composite is $34.99 for 500 grams of

Industrial metal 3D printing

But what if you want a better result or even full metal 3D printing? Should a real "metal" 3D printer be purchased for business needs? We wouldn't recommend it - unless you're going to be doing it every day. A professional metal 3D printer is expensive: EOS or Stratasys devices will cost you 100-500 thousand dollars. In addition, the costs will be even greater, since you will have to hire an operator, a worker to maintain the machine, as well as to finalize the printouts (polishing, for example). Just a note: In 2016, an affordable metal 3D printer didn't exist.

A professional metal 3D printer is expensive: EOS or Stratasys devices will cost you 100-500 thousand dollars. In addition, the costs will be even greater, since you will have to hire an operator, a worker to maintain the machine, as well as to finalize the printouts (polishing, for example). Just a note: In 2016, an affordable metal 3D printer didn't exist.

Lowering Metal 3D Printing Costs

If you are not going to start a metal 3D printing business, but still need a professionally 3D printed metal part, it is best to contact the appropriate company that provides such services. 3D printing services like Shapeways, Sculpteo and iMaterialise offer direct metal printing.

They currently work with the following metal materials in 3D printing:

- aluminum

- steel

- brass

- copper

- bronze

- sterling silver

- gold

- platinum

- titanium

If you are a jeweler, you can also order wax models for casting in precious metals.

If we talk about wax models, then in most cases they (with subsequent melting) are used when printing with metals (including gold and silver). Not all orders are carried out directly by these firms. They usually turn to other metal 3D printing companies to complete the order. However, the number of such services around the world is growing rapidly. In addition, metal 3D printing techniques are becoming more and more common in companies that offer such services.

The reason big companies love 3D printing so much is that it can be used to build fully automated lines that produce "topologically optimized" parts. This means that it is possible to fine-tune the raw materials and make the components thicker only if they must withstand heavy loads. In general, the mass of parts is significantly reduced, while their structural integrity is preserved. And this is not the only advantage of this technology. In some cases, the product turns out to be significantly cheaper and affordable for almost everyone.

Please note that metal 3D printing requires special CAD programs for modeling. It is worth paying attention to the recommendations of Shapeways - 3D printing metal guidelines. To delve further into the topic, check out Statasys’ information on related 3D printers and the nuances of metal 3D printing.

Here are some examples of Benchy test model prices for metal 3D printing:

- Metal plastic: $22.44 (former alumide, PLA with aluminium)

- Stainless steel: $83.75 (plated, polished)

- Bronze: $299.91 (solid, polished)

- Silver: $713.47 (solid, mirror polished)

- Gold: $87.75 (gold plated, polished)

- Gold: $12,540 (solid, 18K gold)

- Platinum: $27,314 (solid, polished)

As you might expect, solid metal 3D printing prices are quite high.

Metal 3D printing. Applications

GE LEAP aircraft engine parts 3D printed at Avio Aero (Photo: GE)

There are several industries already using 3D printers to make everyday objects - you may not even know that these objects are printed.

- The most common case is surgical and dental implants, which are considered the best option for patients today. Reason: they can be tailored to individual needs.

- Another industry is jewelry. Here, most manufacturers have abandoned resin 3D printing and wax casting, switching directly to metal 3D printing.

- In addition, the aerospace industry is becoming more and more dependent on 3D printed metal objects. The Italian company Ge-AvioAero was the first to do all-metal 3D printing. It manufactures components for LEAP aircraft engines.

- Another industry targeting metal 3D printing is the automotive industry. BMW, Audi, FCA are seriously considering this technology, not only for prototyping (3D printing has been used for this for quite some time), but also for making real parts.

Before metal 3D printing really takes off, however, there are some hurdles to overcome. And first of all, this is a high price, which cannot be made lower than during molding. Another problem is the low production speed.

Metal 3D printing.

Technologies

Most metal 3D printing processes start with an “atomized” powder

You can talk a lot about “metal” 3D printers, but their main problems remain the same as any other 3D – printers: software and hardware limitations, material optimization and multimateriality. We won't talk too much about the software, we'll just say that most of the major specialized software companies, such as Autodesk, SolidWorks and solidThinking, try to emphasize as much as possible the fact that as a result of the 3D metal printing process, you can get any shape you want.

In general, printed metal parts can be as strong as parts made by traditional processes. Parts made using DMLS technology have mechanical properties equivalent to casting. In addition, the porosity of objects made on a good "metal" 3D printer can reach 99.5%. In fact, manufacturer Stratasys claims that 3D printed metal parts perform above industry standards when tested for density.

Parts made using DMLS technology have mechanical properties equivalent to casting. In addition, the porosity of objects made on a good "metal" 3D printer can reach 99.5%. In fact, manufacturer Stratasys claims that 3D printed metal parts perform above industry standards when tested for density.

3D printed metal can have different resolutions. At the highest resolution, layer thickness is 0.0008 - 0.0012" and X/Y resolution is 0.012 - 0.016". The minimum hole diameter is 0.035 - 0.045". formed layer)

The metal 3D printing process used by most relevant large companies today is called Powder Bed Fusion. This name indicates that some source of energy (a laser or other energy beam) melts an "atomized" powder (i.e., a metal powder that is carefully ground into spherical particles), resulting in layers of a printed object.

There are eight major manufacturers of metal 3D printers in the world that already use this technology; while we are talking here, there are more and more such companies. Most of them are in Germany. Their technologies are called SLM (Selective Laser Melting - selective laser fusion) or DMLS (Direct Metal Laser Sintering - direct metal laser sintering).

Most of them are in Germany. Their technologies are called SLM (Selective Laser Melting - selective laser fusion) or DMLS (Direct Metal Laser Sintering - direct metal laser sintering).

Metal 3D-printing process No. 2:

Binder Jetting (spraying the binder)

under 3DP technology EXONE Metal objects are printed due : ExOne)

Another professional approach that also uses a powder base is called Binder Jetting. In this case, the layers are formed by gluing metal particles together and then sintering (or fusing) them in a high-temperature furnace, just like it is done with ceramics.

Another option, which is similar to working with ceramics, is mixing metal powder into metal paste. A pneumatically extruded 3D printer (similar to a syringe bioprinter or an inexpensive food printer) forms 3D objects. When the required shape is reached, the object is sent to the furnace, i.e. in the mountains

This approach is used in the Mini Metal Maker, apparently the only inexpensive "metal" 3D printer.

Metal 3D printing process #3: 9Metal Deposition This is not entirely true. Of course, on some desktop device, simply fusing metal threads onto the base will not work. However, very large steel companies can do it. And they do. There are two options for working with "metal surfacing".

One is called DED (Directed Energy Deposition) or Laser Cladding. Here, a laser beam is used to melt the metal powder, which is slowly released and solidifies as a layer, and the powder is fed using a robotic arm.

Normally the whole process takes place in a closed chamber, but the MX3D project used conventional 3D printing techniques to build a full-size bridge. Another option for metal fusion is called EBAM (Electron Beam Additive Manufacturing - additive electron beam technology), which is essentially soldering, in which a very powerful electron beam is used to melt 3 mm titanium wire, and the molten metal forms very large finished structures. As for this technology, its details are known so far only to the military.

Metallic 3D printing. Metals

3D Printing Metal #1: Titanium

Pure titanium (Ti64 or TiAl4V) is one of the most commonly used metals for 3D printing and is definitely one of the most versatile, strong and lightweight. Titanium is used both in the melting process in a preformed layer and in the process of spraying a binder and is used mainly in the medical industry (for the manufacture of personal prostheses), as well as in the aerospace industry, automotive and machine tools (for the manufacture of parts and prototypes). But there is one problem. Titanium is very reactive and explodes easily in powder form. Therefore, it is necessary that titanium 3D printing takes place in a vacuum or in an argon environment.

3D printing metal #2: Stainless steel

Stainless steel is one of the cheapest 3D printing metals. At the same time, it is very durable and can be used in a wide range of manufacturing and even artistic and design applications. The type of steel alloy used also contains cobalt and nickel, is very difficult to break, and has a very high elasticity. Stainless steel is used almost exclusively in industry.

The type of steel alloy used also contains cobalt and nickel, is very difficult to break, and has a very high elasticity. Stainless steel is used almost exclusively in industry.

3D Printing Metal #3: Inconel

Inconel is a superalloy manufactured by Special Metals Corporation and is a registered trademark. The alloy consists mainly of nickel and chromium and is very heat resistant. Therefore, it is used in the oil, chemical and aerospace (for black boxes) industries.

3D Printing Metal #4: Aluminum

Due to its lightness and versatility, aluminum is very popular in 3D printing. Aluminum alloys are commonly used.

3D Printing Metal #5: Cobalt Chrome

gap). It is most commonly used in the manufacture of turbines, dental and orthopedic implants, where 3D printing has become the dominant technology.

3D printing metal #5. Copper and bronze

With some exceptions, copper and bronze are used in wax melting processes, rarely in layer melting. The fact is that these metals are not very suitable for industry, they are more often used in the manufacture of works of art and crafts. ColorFabb offers both metals as the basis for a special metal filament.

The fact is that these metals are not very suitable for industry, they are more often used in the manufacture of works of art and crafts. ColorFabb offers both metals as the basis for a special metal filament.

3D printing metal #6. Iron

Iron, incl. magnetic, also mainly used as an additive to PLA-based filaments, which are produced, for example, by ProtoPasta and TreeD.

3D printing metal #7. Gold, Silver, and Other Precious Metals

Most preformed layer companies can 3D print precious metals such as gold, silver, and platinum. Here, along with the preservation of the aesthetic properties of materials, it is important to achieve optimization of work with expensive starting powder. Precious metal 3D printing is required for jewelry, medical applications and electronics.

Metallic 3D printing. Printers

Do not hesitate - the purchase of a metal 3D printer will not pass without a trace on your budget. It will cost at least 100-250 thousand dollars. Here is a list of a variety of "metal" printers, some of which can be found in firms providing 3D printing services.

It will cost at least 100-250 thousand dollars. Here is a list of a variety of "metal" printers, some of which can be found in firms providing 3D printing services.

Metal 3D Printer #1:

Sciaky EBAM 300 - Metal Filament Printing

If you need to print really large metal structures, Sciaky's EBAM technology is your best bet. By order, the device can be built in almost any size. This technique is used mainly in the aerospace industry and the military.

Sciaky's largest production printer is the EBAM 300. It prints objects in a volume of 5791 x 1219 x 1219 mm.

The company claims the EBAM 300 is also one of the fastest industrial 3D printers on the market. A three-meter-sized titanium part for an aircraft is printed on it in 48 hours, while the material consumption is about 7 kg per hour. In general, forged parts that usually take 6-12 months to complete can be made in 2 days with this 3D printer.

The metal layers are first cut and then ultrasonically welded. The largest Fabrisonic 7200 printer operates in a volume of 2 x 2 x 1.5 m. The metal powder 3D printer is the Concept Laser XLine 1000. It has a modeling volume of 630 x 400 x 500 mm and is the size of a house.

Its German company, one of the main suppliers of 3D printers for aerospace giants like Airbus, recently introduced a new machine, the Xline 2000.

This machine uses two lasers and has a working volume of 800 x 400 x 500 mm. Uses LaserCUSING laser technology (a variant of selective laser fusion) from Concept Laser, which allows you to print alloys of steel, aluminum, nickel, titanium, precious metals and even some pure substances (titanium and stainless steel).

Metallic 3D printing. Services

There are more than 100 companies worldwide offering metal 3D printing services. We list the most popular services for consumer needs.

Metal 3D Printing Service #1: Shapeways

The world's most popular 3D printing service, Shapeways offers two types of services. As a consumer, you can choose from a wide range of professionally designed objects, customize them, and then have them printed to your specifications. Like other 3D printing services, Shapeways offers a platform for designers to sell and print their work. Shapeways is also a good place for rapid prototyping: customers benefit from industrial-grade printers (EOS, 3D Systems) and personal technical support.

As a consumer, you can choose from a wide range of professionally designed objects, customize them, and then have them printed to your specifications. Like other 3D printing services, Shapeways offers a platform for designers to sell and print their work. Shapeways is also a good place for rapid prototyping: customers benefit from industrial-grade printers (EOS, 3D Systems) and personal technical support.

3D printing metals: aluminium, brass, bronze, gold, platinum, precious metal plating, silver, steel. There are also wax molds for jewelry purposes.

Metal 3D Printing Service #2: Sculpteo

Like Shapeways and i.materialise, Sculpteo is an online 3D printing service that allows anyone to upload 3D models and send them to fabrication in a wide range of materials . Like its competitors, Sculpteo provides a platform for hobbyists and professionals to showcase and sell their designs. The stable of Sculpteo printers includes highly professional machines from 3D Systems, EOS, Stratasys and ZCorp. Extensive technical documentation will help identify design flaws and select the right material for the project.

Extensive technical documentation will help identify design flaws and select the right material for the project.

Metals for 3D printing: alumide (plastic with aluminum particles), brass, silver.

Metal 3D Printing Service #3: iMaterialise

Materialise is a company that works with industrial customers to prototyp 3D printed products. For casual users and designers, Materialize offers an online 3D printing service called i.materialise. As with Shapeways, this service allows anyone to upload their 3D designs and print them out. Once an object has been uploaded and successfully printed, a designer can list it for sale either in the gallery of the i.materalise online store or by embedding some code into their site.

3D printing metals: alumide (plastic with aluminum powder), brass, bronze, copper, gold, silver, steel, titanium.

Metal 3D Printing Service #4: 3D Hubs

Through 3D Hubs, you can search for individuals and companies that offer 3D printing services in your area, upload STL files (which are immediately evaluated for defects ) and contact service providers directly to get the job done. The online 3D printing service also allows you to sort offers by materials, customer rating, distance and many other parameters. Whatever object you wish to print, chances are there is someone nearby who can do it. A significant number of materials can be printed in industrial quality, such materials have an HD mark in the search field.

The online 3D printing service also allows you to sort offers by materials, customer rating, distance and many other parameters. Whatever object you wish to print, chances are there is someone nearby who can do it. A significant number of materials can be printed in industrial quality, such materials have an HD mark in the search field.

3D printing metals: aluminium, bronze, cobalt-chromium, stainless steel, titanium.

Precise 3D metal printing on order in Sprint 3D

Metal 3D printing - additive manufacturing of metal products, which is rightfully one of the most promising and rapidly developing areas in 3D printing as such. The technology itself originates from the conventional sintering of materials used in powder metallurgy. But now it has become more perfect, accurate and fast. And today SPRINT3D offers you metal printing on 3 D printer on really favorable terms. But first, a little information about the production process itself and its capabilities.

But first, a little information about the production process itself and its capabilities.

Selective Laser Fusion Technology

SLM or Selective Fusion Technology is a type of direct metal printing that achieves a density of 99.5%. The difference is especially noticeable when compared with models obtained by conventional casting. This indicator is achieved due to the introduction of the latest technologies in the hardware part:

- The use of special rollers for compacting powders and, as a result, the possibility of using powders with a particle size of 5 µm.

- Bulk density increase to help compact end products.

- Creates a rarefied atmosphere of inert gases, which ensures maximum purity of the material, no oxidation, and eliminates the risk of introducing third-party chemicals into the composition.

But most importantly, the modern 3 D metal printer makes it easy to customize the configuration for printing with a specific metal powder. Thus, even with inexpensive material, you can get a first-class result. But only if you use high-quality modern equipment. And here we are ready to surprise you too!

Thus, even with inexpensive material, you can get a first-class result. But only if you use high-quality modern equipment. And here we are ready to surprise you too!

Metal 3D printing B SPRINT 3D

3D printing with own 3D printers

The largest working area is 280x280x350 mm

layer thickness up to 15 microns

3D with various types of metals

Delivery throughout Russia and CIS countries

Installations for 3 9000 which we use

Production quality is a key requirement that we set ourselves. Therefore, in our work we use only professional equipment with wide possibilities for metal printing. Let's take a closer look at each of the production units.

Production unit SLM 280HL

SLM 280HL is a development of the German company SLM Solutions GmbH, which uses the technology of layer-by-layer laser melting of powder metal materials. The installation is equipped with a large working chamber and allows you to create 3D objects with dimensions of 280x280x350 mm. Among the main advantages of printing with this installation are:

Among the main advantages of printing with this installation are:

- Small minimum thickness of the applied layer - 20 microns.

- Filling the working chamber with inert gas, which allows you to work with various reactive metals.

- Print speed up to 35 cm/hour.

- Building layer thickness – 30 and 50 µm.

- Power - 400 W.

A special highlight is the patented powder feed system, which delivers significantly faster print speeds than most production machines in the same price range. We use the following materials in production:

- Stainless steel (domestic 07X18H12M2 (Polema), 12X18H10T and imported 316L).

- Tool steel (imported 1.2709).

- Heat-resistant alloys 08KhN53BMTYu (similar to Inconel 718, produced by Polem) and EP 741 (produced by VILS).

- Cobalt Chrome (COCR)

The SLM 280HL 3D printer can be used to create all kinds of metal components, prototypes and end products. If necessary, we can provide small-scale production.

If necessary, we can provide small-scale production.

ProX 100 production unit

ProX 100 is a compact 3 D metal printing unit developed by the American company 3D Systems. It uses direct laser sintering technology, which ensures high speed and precision of production. Among the main characteristics, it is worth highlighting:

- The size of the working chamber is 100x100x80 mm.

- Building layer thickness – 20 and 30 µm.

- Power - 50 W.

ProX 100 allows you to create prototypes that cannot be developed by standard methods, provides short lead times, guarantees the absence of material porosity and high part density. In addition, we note the standardized quality of all products, regardless of their structure. At the moment, the model is actively used in dentistry when creating high-precision prostheses, but it has found wide application in other industries:

- Manufacture of engines and their individual parts.

- Development of medical equipment.

- Printing jewelry and even contemporary art.

In printing we use the cobalt-chromium alloy KX28M6 (manufactured by Polem), originally developed for additive technologies when creating endoprostheses.

Metal 3D printing - current application

Many experts argue that 3D printing as such has not yet fully revealed its potential. For example, Elon Musk plans to use technology in the colonization of Mars to build administrative and residential buildings, equipment and technology right on the spot. And this is quite real, because already now the technology of three-dimensional metal printing is actively used in various industries: The high precision of production and relatively affordable price have made 3D printing very relevant in this industry.