Ctc bizer 3d printer software

Decent Slicing software for CTC Bizer (Dual Extruder) - 3D Printers - Talk Manufacturing

Alessandro_Jarv

#1

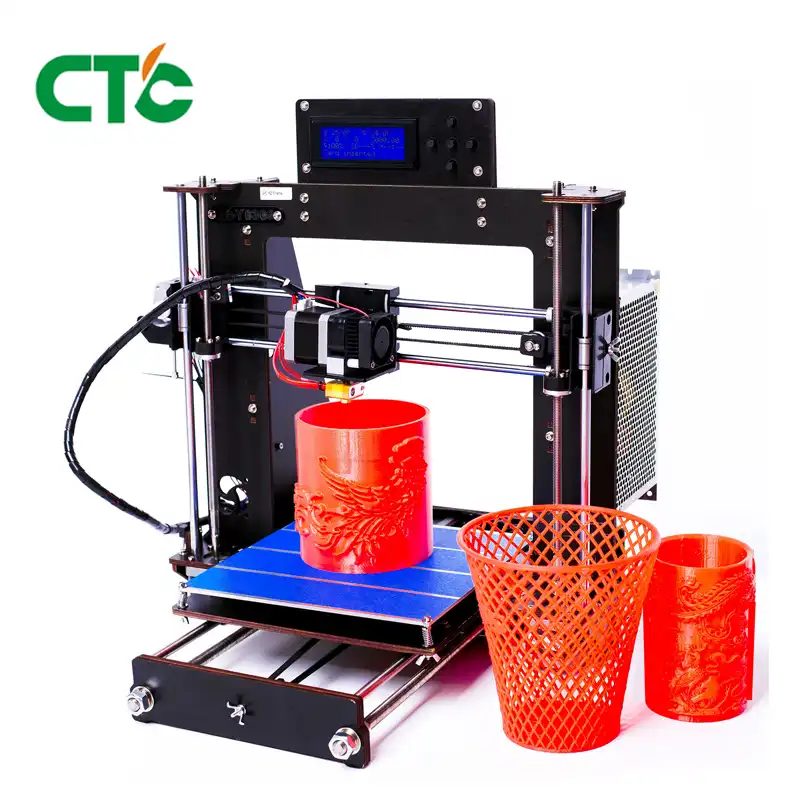

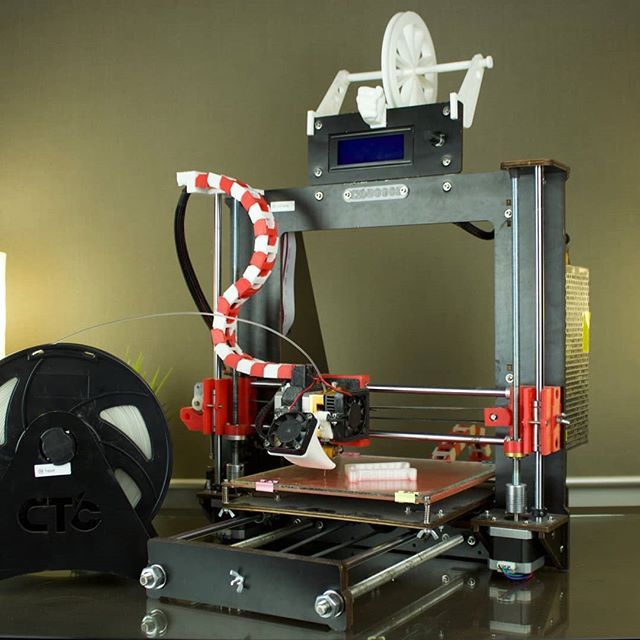

I have a CTC Bizer (Clone of Replicator 1 Dual Extruder), everything works fine, the printer works, the issue is with the slicer.

The given SD had ReplicatorG and MakerWare. MakerWare doesn’t work, it says that the background service is not running, if I try to restart it, it simply won’t start, so no slicing at all. I also downloaded MakerBot Desktop, which seems to be the latest version of MakerWare, it simply doesn’t slice files over a certain size. I tried to print the 10MB 3DBenchy.stl from http://www.thingiverse.com/thing:763622/#files - it simply won’t slice it. I have another 16MB part and it won’t slice that too. MakerBot Desktop simply shows an empty view in the “Preview” screen, stating there are 0 layers and exports a 0B (empty) x3g file. Smaller files get sliced without issues, but top and bottom layer are underextruded, so it leaves giant holes in the prints. Also, MakerBot Desktop leaves gaps between the filling and the shell.

I also tried Cura and Slic3r post-processing gcode files with ReplicatorG or GPX in order to make x3g files out of them (as that printer doesn’t read plain gcode files), I can’t get it to work, if I print something, the build plate goes down and down, then it starts vibrating as soon as it reachs the printer ground (like if it’s trying to go even further down).

I’m attaching some pictures of the Makerbot Desktop with the 3DBenchy and empty preview, and also two photos of the CTC Bizer spool holder I tried to print (which show underextrusion - so gaps of course - and gaps between shell and infill).

Is there anyone who can help?

Thank you

1 Like

Eduardo_Garcia

#2

Spend the money on simplify 3d. It’s the best thing you’re going to do. Also, update to sailfish before you burn out your board. After that look online for mod for ctc and do the main ones to get much nicer prints.

It’s the best thing you’re going to do. Also, update to sailfish before you burn out your board. After that look online for mod for ctc and do the main ones to get much nicer prints.

wirlybird

#3

I am using S3d also and even though it is for pay it was worth it to me. I can’t really comment of the other slicers since I have not used them really. RepG a bit and it was ok for what it is.

Alessandro_Jarv

#4

Does Simplify3D save to x3g? I already have Sailfish 7.7, and I was also wondering: is there any firmware capable of reading the standard gcode?

I hear lots of people telling to buy S3D but I use it for hobby, so spending $150 for a professional program is something I’d like to avoid, if not really necessary. Also, S3D doesn’t have a trial version, which would be really useful to test its potential before deciding to pay that amount.

Also, S3D doesn’t have a trial version, which would be really useful to test its potential before deciding to pay that amount.

Croft3r

#5

I use Matter Slice (Matter Control) as my slicer. However, I agree with the other posts, if you can spend the money for simplify3d then do it. With Matter Slice you can actually connect to your printer via USB if you want or export to SD card. It allows you to export straight to x3g. When I get home later tonight, I can upload my configuration file for my printer. However, for now they have a profile for the flashforge creator pro that works just fine. My profile just has a few tweaks to work better with my printer.

To get the slicer, go to mattercontrol.com.

I had the same problem that you are having right now with my prints. Again, when I get home, I will see what I can do to help you out.

Again, when I get home, I will see what I can do to help you out.

Eduardo_Garcia

#6

Yes it does. I also 3d print as a hobby aND I used makerware at first with proftweak. I learned alot then after 3 month I got s3d and it’s worth the cost even for a hobbyst. I know there is no trial, but look at YouTube videos, get familiar with it from videos and make a decision.

Alessandro_Jarv

#7

Thanks, I’ll wait! Do you have the same printer?

Croft3r

#8

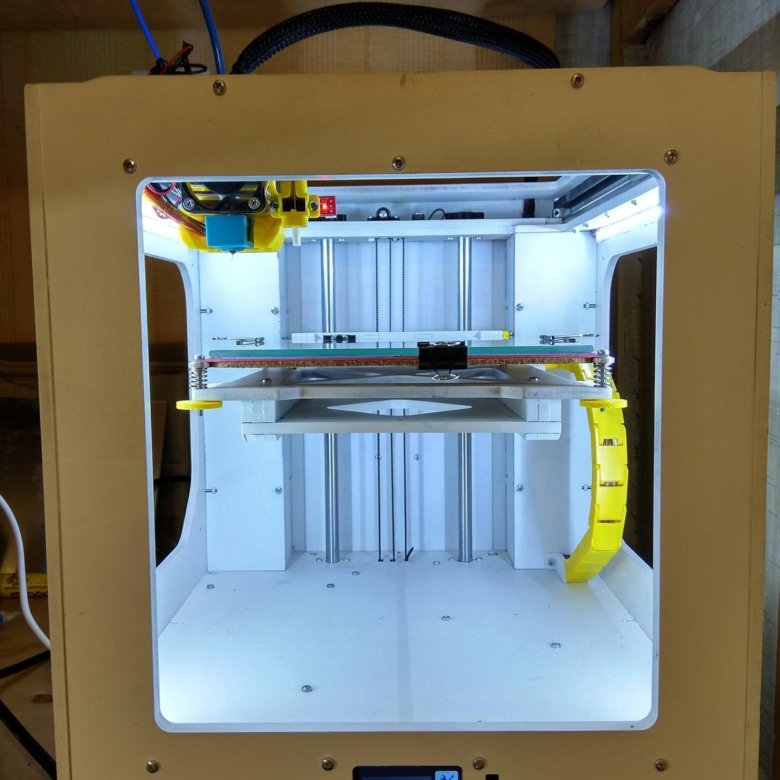

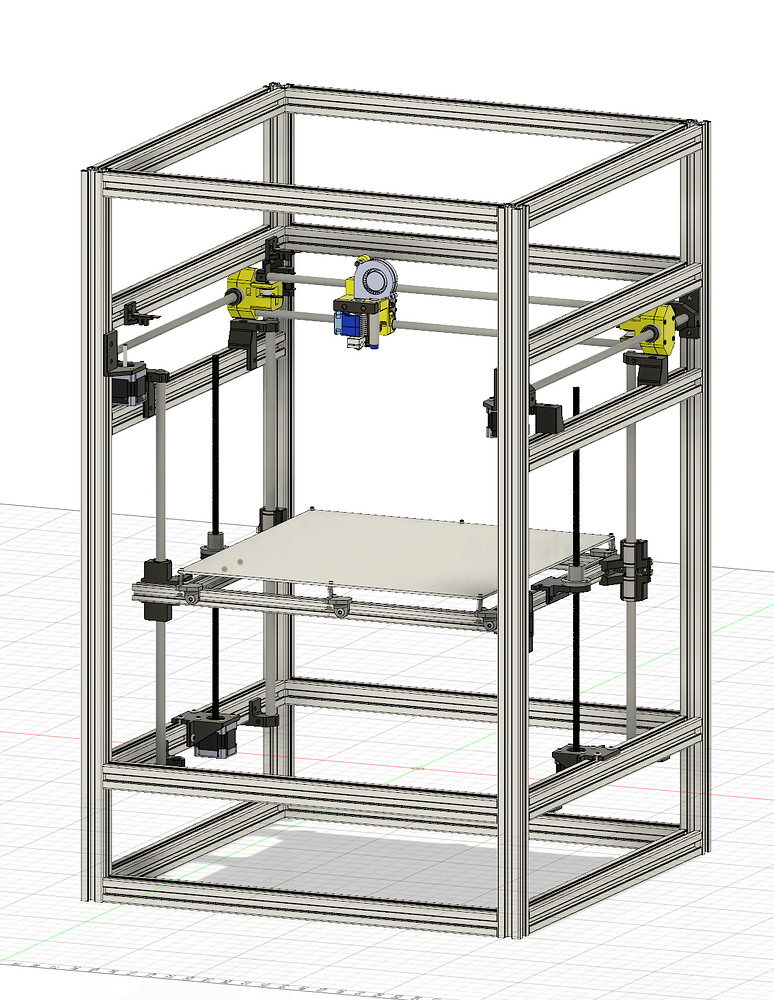

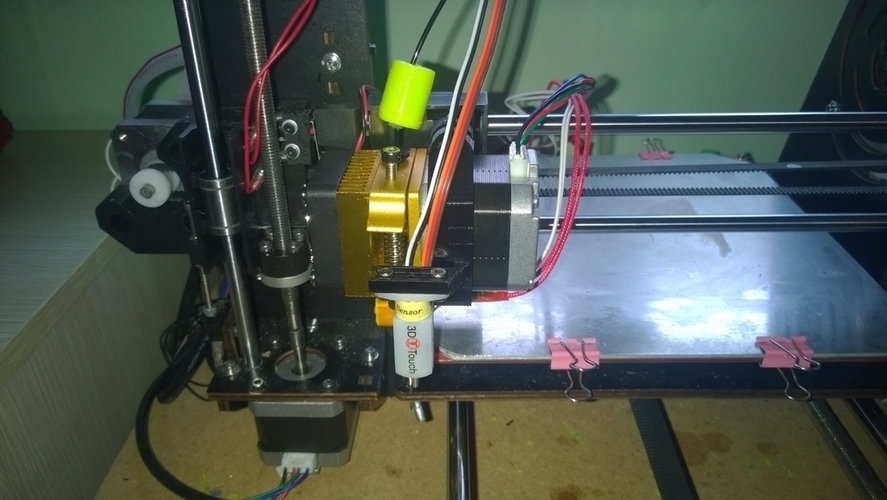

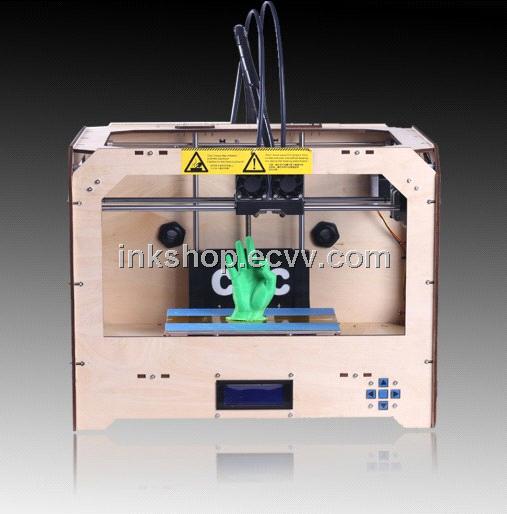

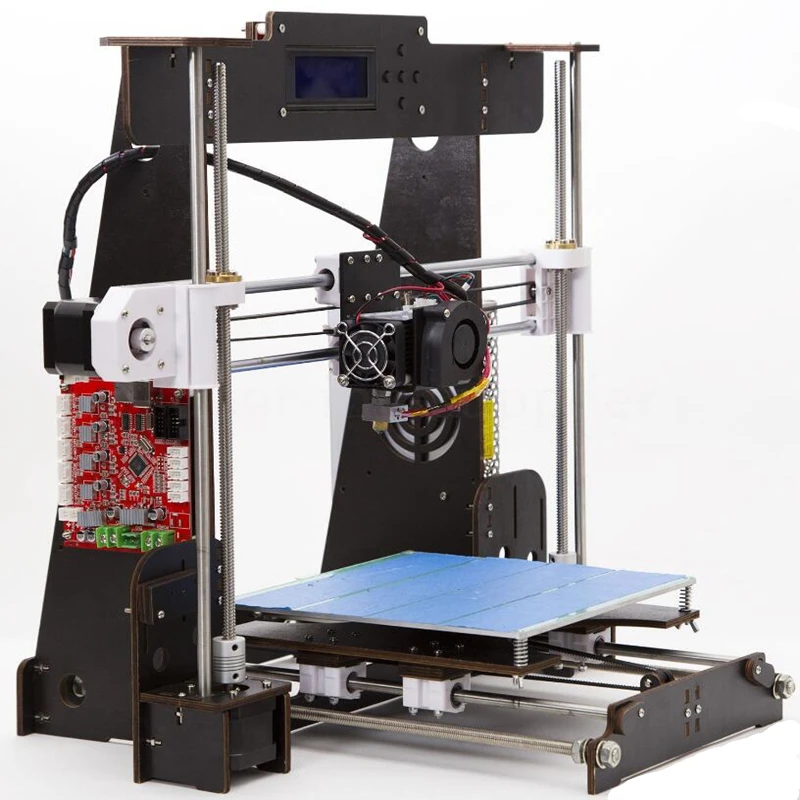

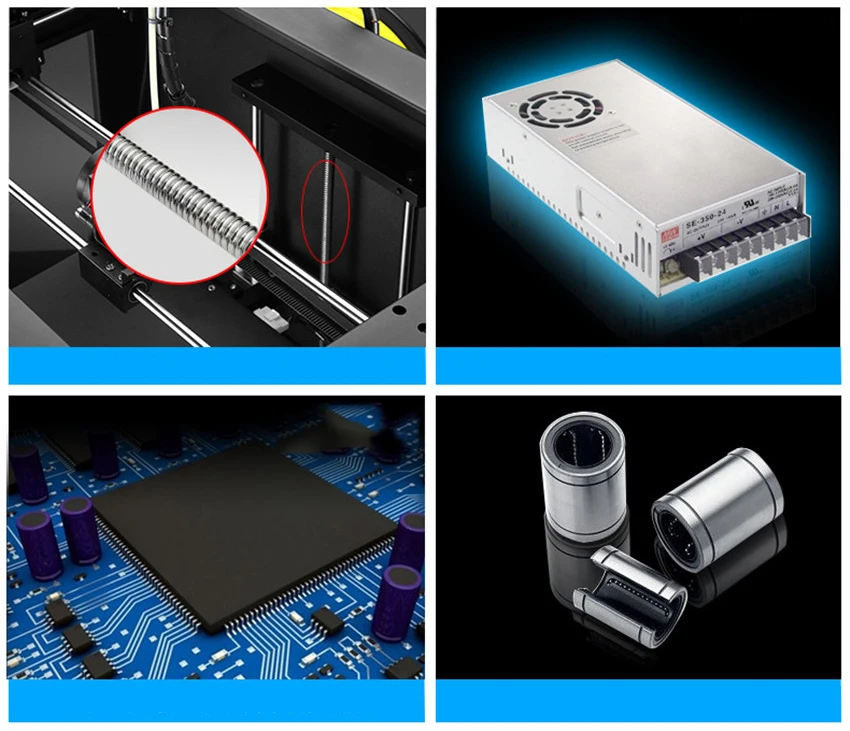

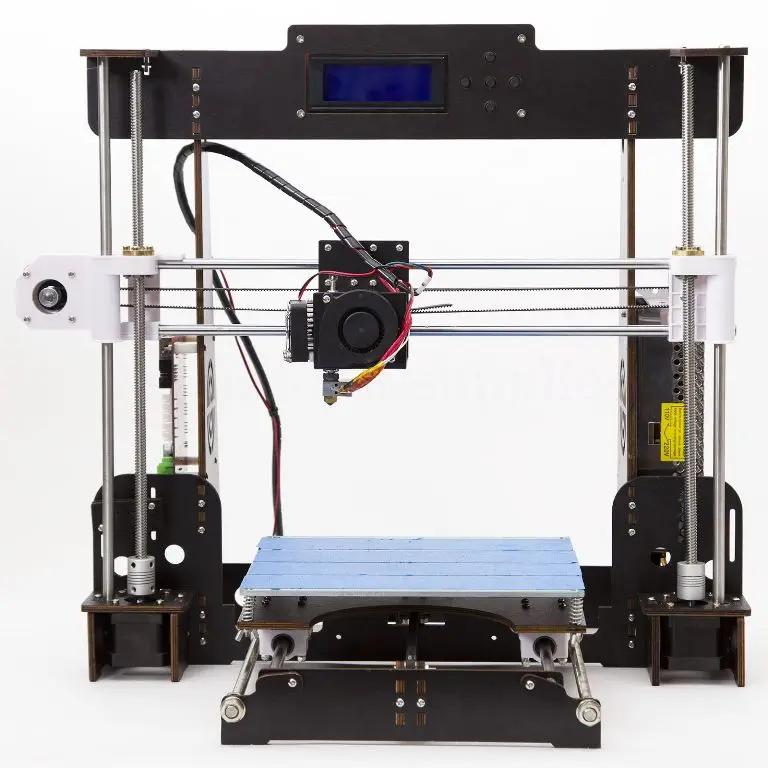

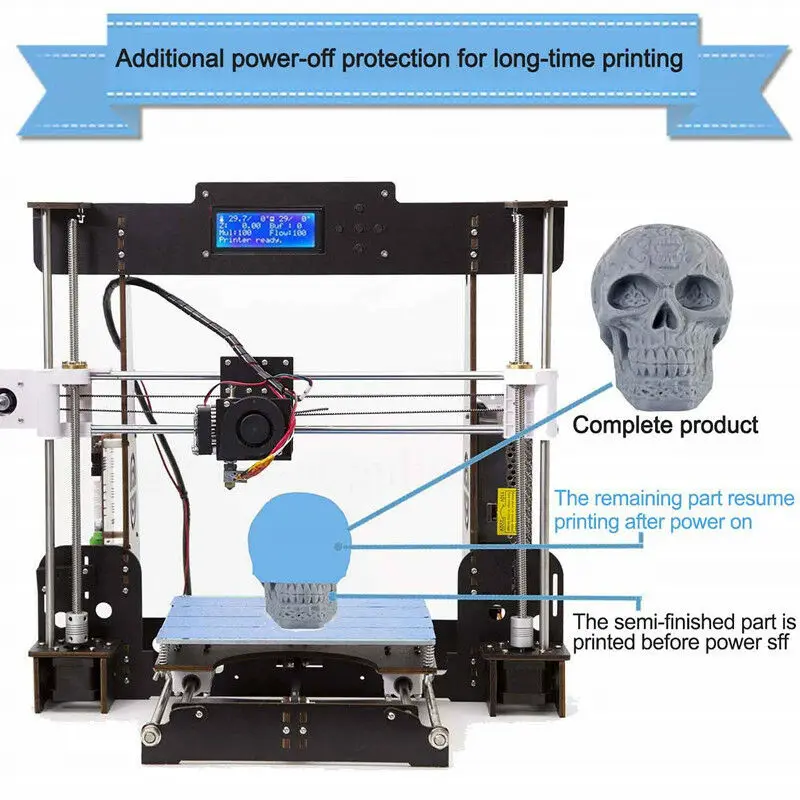

I have the same printer. However, I think I have a different version because mine is just unpainted laser cut wood and everyone else has one that is metal or painted wood. These are the settings I am using to control my printer. With this slicing software, you can use Cura, Slic3r, or Matter Slice. I use Matter Slice. I would play around the settings that I have attached. You are going to want to tune this to fit your printer better.

However, I think I have a different version because mine is just unpainted laser cut wood and everyone else has one that is metal or painted wood. These are the settings I am using to control my printer. With this slicing software, you can use Cura, Slic3r, or Matter Slice. I use Matter Slice. I would play around the settings that I have attached. You are going to want to tune this to fit your printer better.

I have been getting some pretty good prints with these settings. You may want to change around layer height to fit what you need though. If you are trying to go for something that needs a lot of detail, try lowing the speeds of the print and increasing layer height. As for layer height. The lowest I have gone so far is 50 Microns. I have printed several prints at that quality and it is difficult to see the lines in the print.

The problem you are having is that the top faces are not closing. I have this set to 8 layers on the top and bottom and that has been working. You may be able to cut down on layers if you have a cooling fan that you can blow directly on the print. You may also want to try increasing infill to support the top layer.

You may also want to try increasing infill to support the top layer.

With the configuration file, I need to let you know a few things. Under the Printer tab, and under Features. You can turn parts of the printer on and off. My heated build plate is currently not working so I have it turned off. If you have a heated build plate turn it on here. Also, please be careful on this screen. You may be able to do some damage to the printer on this screen.

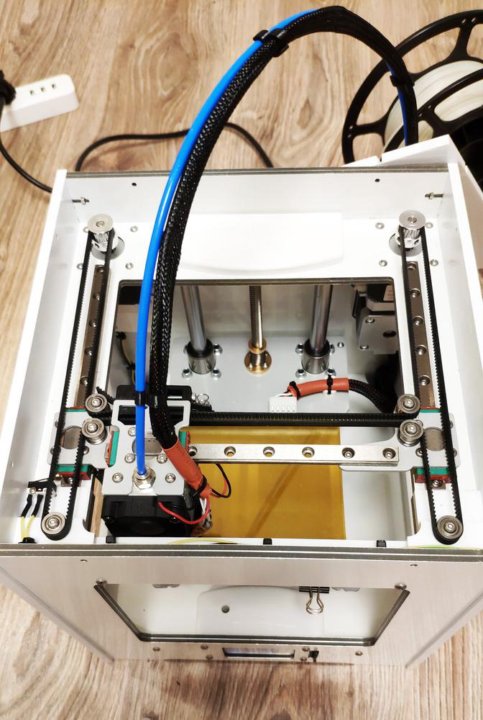

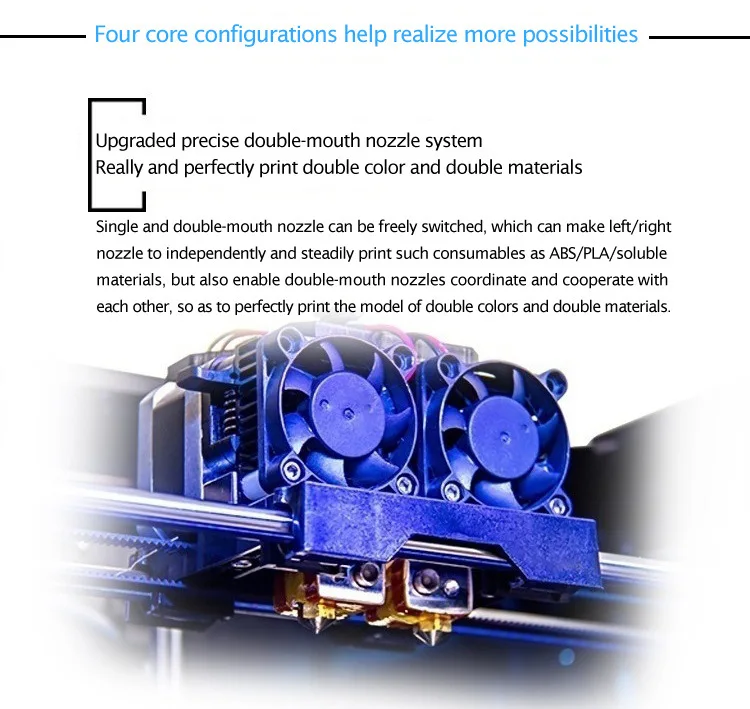

Also, with the dual extrudes I am having some difficulty with them lining up. I think I have the offset set properly but I am not sure. The left extruder on my printer is jammed so I can’t really test it. However, I think I have the offset set properly. To change this got to the Printer tab, then to Extruder. Also, if you want to do an extended build plate with your printer, you can change that under the print area options.

If you have any problems with this file please let me know and I will help you out. To load this file you first need to add the FlashForge Creator Pro Dual printer using the add printer menu. Then click Settings & Controls, then click Options then import. This should change all your settings to match the file. Also, you will want to change your settings from Basic to Advanced to change some of the things I talked about previously.

Then click Settings & Controls, then click Options then import. This should change all your settings to match the file. Also, you will want to change your settings from Basic to Advanced to change some of the things I talked about previously.

For connecting to the printer, I can’t really help to much. I export my files to SD card and print directly from the printer. I do this because the USB connection on my printer does not work at all. So no Sailfish upgrade :(. Anyways, I have connected over USB with my M3D Micro and it works fairly well. You can set prints to email, and text you when they finish and you can monitor them online.

However, I would use this software to get you by. When you get a chance I recommend that you pickup Simplify3D. They do have a 30 day money back guarantee if you do not like the software. I agree though, I trial would give me a lot more trust in their software.

Also, here is the link to the config file. I had to put it in a zip because everywhere I uploaded it, it wanted to display as text instead of a file. Anyways, here is the link: https://dl.dropboxusercontent.com/u/229079674/CTC%20Bizer%20Config.zip

Anyways, here is the link: https://dl.dropboxusercontent.com/u/229079674/CTC%20Bizer%20Config.zip

Alessandro_Jarv

#9

You say I can use Cura too… How? As far as I know Cura is not capable of exporting x3g files… I have tried Matter Slice too, imported the model, clicked on “generate” button and a window saying “NullReferenceException” popped up…

Croft3r

#10

Sorry for the delay.

I am not 100% sure but I think MatterControl uses Java. Try updating your Java and see if that works. Also, the MatterControl community is very helpful. They can help you get it running if you keep having problems.

They can help you get it running if you keep having problems.

Also, for Cura you can generate the files in GCode then use ReplicatorG to convert it to x3g. However, I have never got this to work. Maybe you will have better luck.

When I mentioned Cura and Slic3r. I meant that MatterControl comes packaged with three slicing engines. Cura, Slic3r, and MatterSlice. Got into the settings of your printer, then click options, then you can change the slice engine there. Then your options will change to suite the engine.

Also, you can export x3g from Cura with a plugin but I can not find the plugin. I have found something that works along side Cura to convert Gcode to x3g but I have never got any of that to work.

Alessandro_Jarv

#11

No, a NullReferenceException comes from a . NET application, Java has a similar one but it’s called NullPointerException. I already have .NET up to date. I never got gcode to x3g conversion to work neither, as I stated in the post.

For the error: I checked the settings, fill density was set at 0.3%, I changed it to 15% and it sliced, I think this was the messy option. I also found the setting to use CuraEngine to slice, I’m trying it now Thank you! Anyway, I think we have the same printer, I have the wood one too.

Alessandro_Jarv

#12

Weird thing. I tried to slice the same model with Cura and MatterControl using CuraEngine.

Cura settings:

50mm/s print speed

50mm/s infill speed

30mm/s outer wall speed

40mm/s inner wall speed

15mm/s bottom layer speed

20% infill

MatterControl settings:

130mm/s infill speed

130mm/s inside perimeters

120mm/s outside perimeters

150mm/s travel speed

15mm/s first layer speed

20% infill

Cura says it takes 1 hour for the model to print (with lower speeds than MatterControl)

MatterControl (with CuraEngine) says it takes 2:41 hours to print - with significantly higher speeds.

Something is going wrong here, is it ignoring my settings??

Perry_1

#13

I am going to agree with the others here that simplify3d is the answer to all your ills. It is the best investment you can make in your printer.

That being said, it is so easy to put my hand in your pocket and tell you to spend the money. But sometimes folks are just not in a position to do so.

As such, I would recommend flashforges flashprint as an alternative. It will get you good prints, but not give you the control of s3d in getting to great prints.

It is free.

Daniel_Pass

#14

I can’t help with everything else, but are you using makerware on ubuntu 16. 10 by any chance? I was getting the same background service issue and after emailing makerbot they said that they support 16.04 LTS but not 16.10. Not a great help, but I have the same issue. Been dual booting into windows just for it.

10 by any chance? I was getting the same background service issue and after emailing makerbot they said that they support 16.04 LTS but not 16.10. Not a great help, but I have the same issue. Been dual booting into windows just for it.

Croft3r

#15

Sorry for not getting back to you sooner, been busy. Were you able to get x3g export working in MatterControl?

conorm125

#16

I use simplify 3d and i is a lot better than mb’s software

mbroen

#17

Could you be persuaded to reupload the settings above? (if you still have them)

I am having similar problems and can’t seem to figure out the correct settings for my printer (also a CTC Bizer Dual Extruder).

CTC FDM printer software installation problem? - 3D Printers - Talk Manufacturing

j3dj3d

#1

Hi,

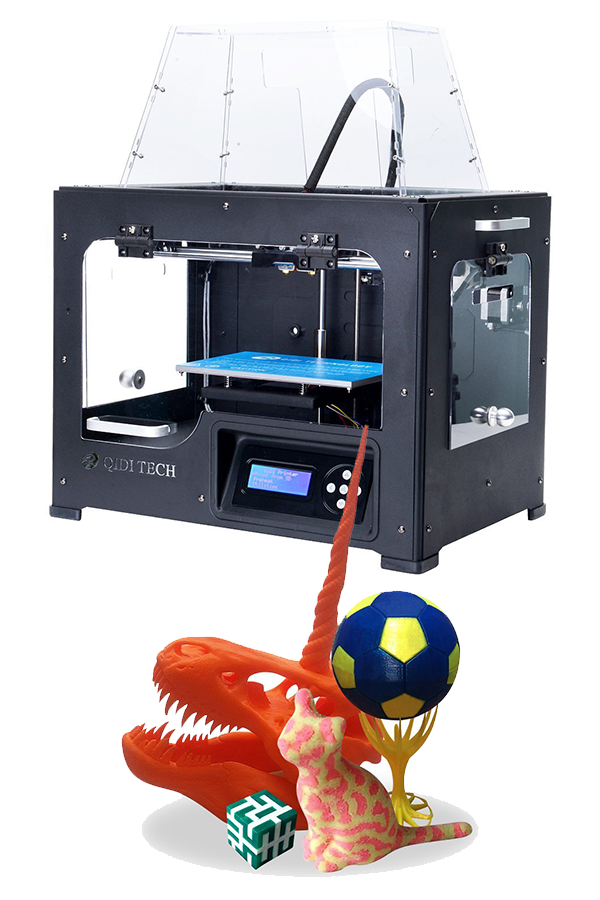

I bought this 3D Printer:

https://www.amazon.co.uk/gp/product/B01CU2MCM4/ref=oh_aui_search_detailpage?ie=UTF8&psc=1

When I install the ReplicatorG 0040 Installer that is on the disk that came with the

I get the following error messages:

arduino LCC (www.arduino.cc)(usbser) Ports (11/15/2007 5.1.2600.0) Status: Install Failed

Makerbot Industries (usbser) Ports (11/15/2007 5.1.2600.0) Status: Install Failed

Makerbot Industries (usbser) Ports (11/15/2007 5.1.2600.0) Status: Install Failed

Then when I start Replicator All the menus are in Chinese.

I am using Windows 10 64bit.

Should I try installing version 3. 1 Beta from here:

support.makerbot.com

Download | MakerBot Desktop (Software) | MakerBot Support

Download | MakerBot Desktop (Software) | MakerBot Support

Thank you for any advice?

TralanJr

#2

Did you ever find a solution to the install? I’ve been unable to even install with compatibility mode. I’m resorting to installing the linux version on a raspberry pi to get the sailfish firmware update

j3dj3d

#3

You need to forget about the Replicator on the disk and download Makerbot Desktop from here:

support. makerbot.com

MakerBot Desktop Release Notes | MakerBot Desktop (Software) | MakerBot Support

MakerBot Desktop Release Notes | MakerBot Desktop (Software) | MakerBot Support

Set it to Replicator Dual

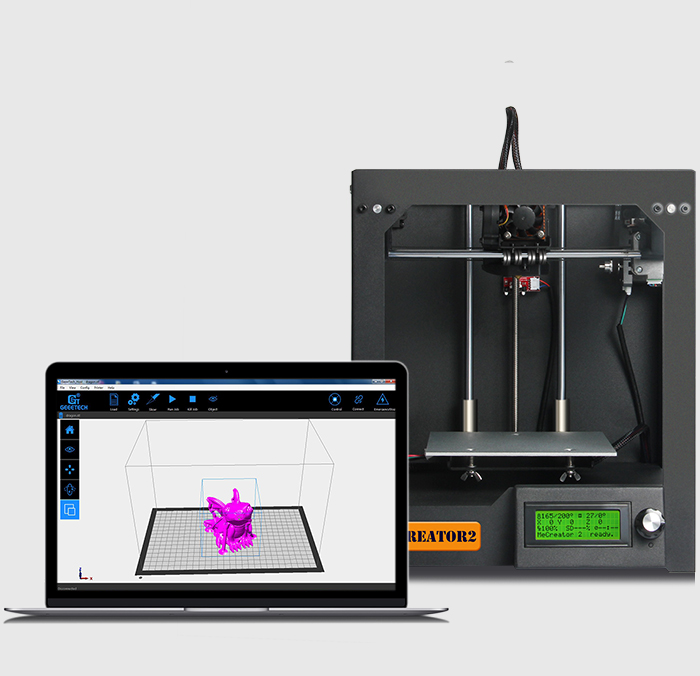

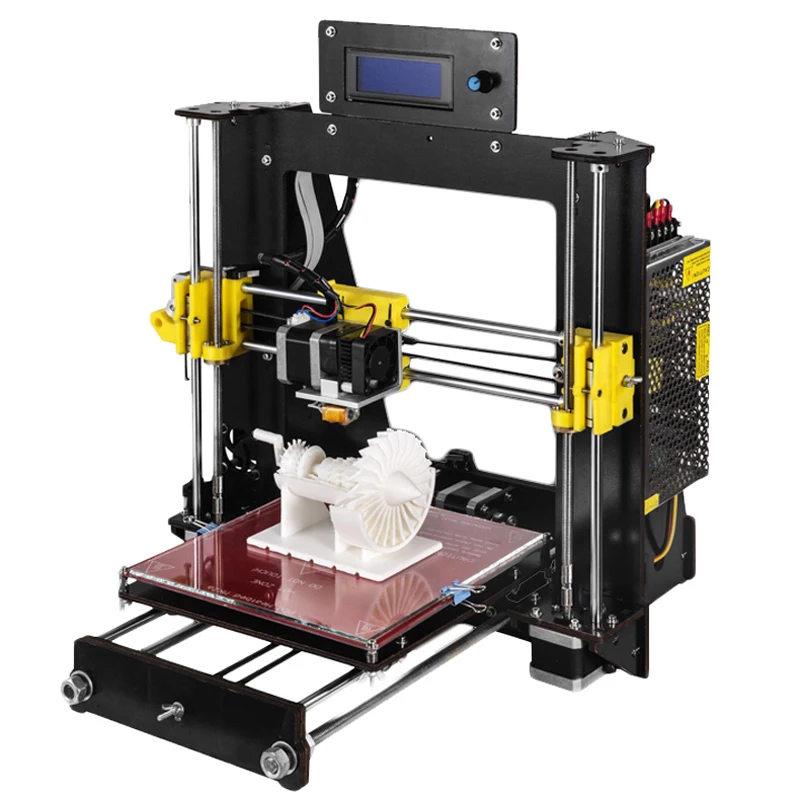

Makerbot Desktop works okay but personally think it is well worth splashing out on Simplify 3D which has a profile for the CTC Bezier which works well and can be tweaked. The printer usually prints better with output from this software:

https://www.simplify3d.com/

TralanJr

#4

So, to be clear, you didn’t need the Sailfish firmware update for your printer? The program mentioned above worked?

j3dj3d

#5

and have followed what he recommended buying the nozzle that he recommended and adding the active cooling mod and adding the glass bed and using the filament that he recommended:

Cooling mod:

thingiverse.com

Active Cooling Fan Duct v2 for Replicator 1 / Duplicator 4 / FlashForge / CTC by...

Please read this text completely before printing! This is an improved version of thing 295317 Goals Fine detailed parts of your prints (PLA and ABS) normally don't show up well and and bridging only works for small distances if you use your...

https://www.ebay.co.uk/itm/Active-Cooling-Fan-Kit-for-Replicator-Wanhao-FlashForge-CTC-Dual-Extruder/322381439384?hash=item4b0f6e6198:m:maHMk0j-O5L55EIS6RvYDSg .

Best fans although a bit noisey:

https://www.amazon.co.uk/dp/B01CZFUOD0/ref=pe_3187911_185740111_TE_item

Which I actually bought as part of this whole upgrade package from Gearboy on Ebay:

eBay

CTC Dual Extruder 3D Printer Flagship Upgrade Kit | eBay

LED Lighting kit for CTC. 1.Y-axis upgrade part. 3.Z-axis Stabilizer upgrade part. Active Cooling Fan Kit. Appropriate length of wire(around 120cm,attached to fan and 2-Way Plug-In). 1pcs x 300mm LED Light for front top (attached to wire).

All these mods help the printing. It is possible to make this cheap machine print as well as a more expensive machine doing all this and doing + lots of testing at each stage.

The Rigid Ink PLA filament recommended in the videos was this which worked well:

https://www.amazon.co.uk/rigid-ink-Reliable-Filament-Printing-Tolerance/dp/B00QIPVRH6/ref=sr_1_55_sspa?keywords=pla&qid=1556012153&s=gateway&sr=8-55-spons&psc=1

Nozzle: http://www. ebay.co.uk/itm/32236704004…

ebay.co.uk/itm/32236704004…

Kapton Tape: http://www.ebay.co.uk/itm/11178056659…

Glass Bed: http://www.ebay.co.uk/itm/3D-Printer-…

These extruders work better than the plastic ones and help the filament keep being fed in. Can put spacers in where the springs go to make them give more pressure too:

eBay

MK8 Dual Head Extruder - CTC Upgrade Extruder Full Kit - 3D Printer Part...

This Kit Transforms Your 12 v or 24v Extruder Into The Strong MK8, lose The Thin Ptfe And Experience Less Blockages, Strong Feed System, A Top Quality Upgrade For A CTC And Many Others. Help & Support.

Hope that helps.

Top 20 Free 3D Printing & 3D Printing Software

Looking for 3D printing software? We've rounded up the top 20 software tools for beginners and professionals alike. Most slicers are free.

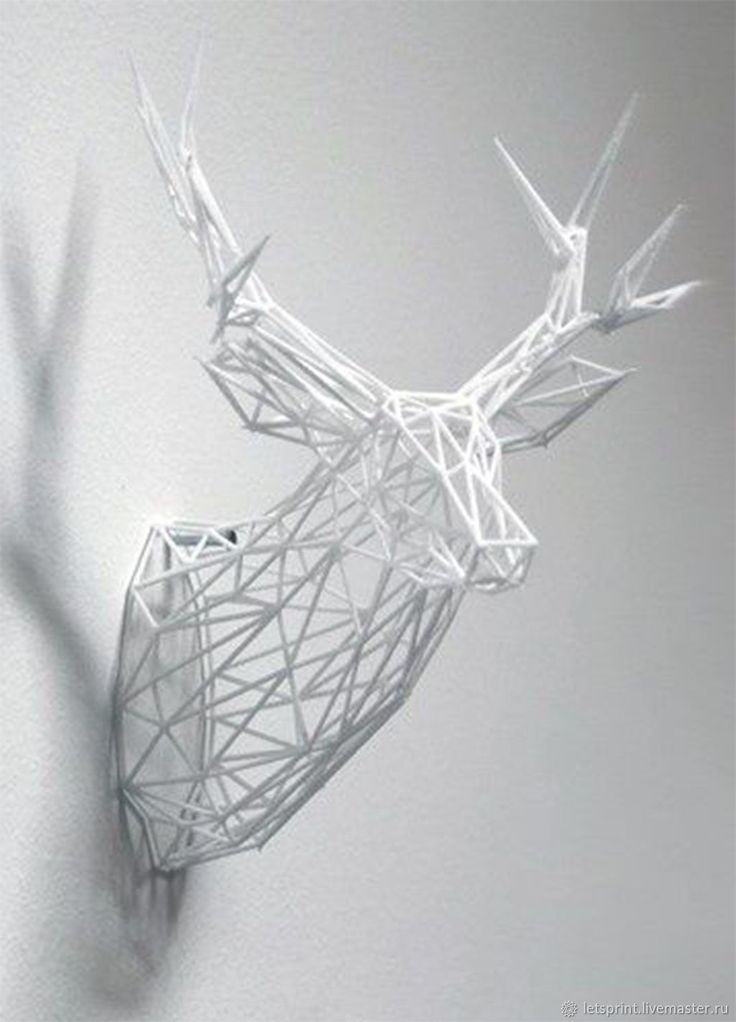

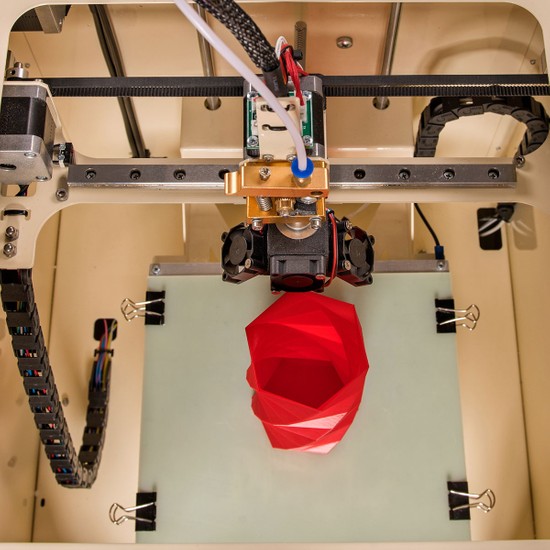

What is a slicer? This is a program for preparing a digital model for printing. Models for 3D printing are usually distributed in STL files. To turn an STL file into G-code (a language that a 3D printer understands), a slicer program is required. It is called a slicer because it cuts (to slice - English) a 3D model into many flat two-dimensional layers, from which a 3D printer will add a physical object.

To turn an STL file into G-code (a language that a 3D printer understands), a slicer program is required. It is called a slicer because it cuts (to slice - English) a 3D model into many flat two-dimensional layers, from which a 3D printer will add a physical object.

Which slicer should I choose? In this article, we will tell you which slicer is best for 3D printing for each stage of your work. Which one is better for preparing a 3D model for printing? But what if you need to create a 3D model from scratch? And if you are only taking the first steps in 3D?

Don't be afraid: we've answered all of these questions, including the required skill level for each program and where you can download it. The great thing is that most of these programs are completely free and open source.

- Cura

- CraftWare

- 123D Catch

- 3D Slash

- TinkerCAD

- 3DTin

- Sculptris

- ViewSTL

- Netfabb Basic

- Repetier

- FreeCAD

- SketchUp

- 3D Tool

- Meshfix

- Simplify3D

- Slic3r

- Blender

- MeshLab

- Meshmixer

- OctoPrint

#1: Cura

For beginners who need a slicer to prepare STL files for 3D printing

Cura is the default slicer software for all Ultimaker 3D printers, but can be used with most others , including RepRap, Makerbot, Printrbot, Lulzbot and Witbox. The program is completely open source, its capabilities can be extended using plugins.

The program is completely open source, its capabilities can be extended using plugins.

This program is very easy to use and allows you to manage the most important 3D printing settings through a clear interface. Start in Basic mode to quickly get up to speed and change print quality settings. If finer control is required, switch to Expert mode.

Cura can also be used to directly control the printer, but then the printer and computer must be connected to each other.

Download: Cura

Price: Free

Systems: PC, Mac, Linux

#2: CraftWare

3D printers by the Hungarian startup CraftUnique to support their CraftBot crowdfunding machine. However, the program works with other printers.

Like Cura, CraftWare allows you to switch from "Easy" to "Expert" mode, depending on how confident you feel. It's a colorful app that features a visual G-code visualization with each function represented by a different color. But the most outstanding feature is the individual support service. As far as we know, only the paid program Simplify3D has this.

As far as we know, only the paid program Simplify3D has this.

Please note, however, that this program is still in beta, so bugs may occur.

Download: CraftWare

Price: Free

Systems: PC, Mac

#3: 123D Catch

-systems, smartphones and tablets, which allows you to convert images of objects into a 3D model. Pictures can be taken with a smartphone/tablet or digital camera.

You need many photos of an object from different angles - the more the better - after which they will be compiled into a 3D model.

123D Catch is more of a fun app than a professional 3D printing tool, but after some tambourine dancing, you can get good results, especially when paired with an STL editor like MeshLab or Meshmixer.

Price: Free

Systems: PC, Android, iOS, Windows Phone

#4: 3D Slash

and surprisingly simple, and refreshingly new. With 3D Slash, you can design 3D models using your dice skills.

You can start with a large block and, like a virtual sculptor, remove small cups from it with tools such as a hammer or drill, or start from empty space and build a model from cubes and other shapes. You can paint with flowers or use template pictures.

Other features worth mentioning are tools for creating logos and 3D text. The Logo Wizard imports an image and creates a 3D model, while the Text Wizard allows you to enter and format text, and then turn it into 3D.

Recommended!

Download: 3dslash.net

Price: Free

Systems: PC, Mac, Linux, Browser

#5: TinkerCAD

- A computer-aided design (CAD) system for 3D printing, which is a good starting point for beginners. Since its capabilities are limited compared to Blender, FreeCAD and SketchUp, many users switch to more powerful tools after some time.

As in 3D Slash, here you can build models from basic shapes. At the same time, unlike 3D Slash, TinkerCAD allows you to create vector shapes in 2D and convert them into three-dimensional models.

Come in: Autodesk TinkerCAD

Price: Free

Systems: Browser

#6: 3DTin

For beginners who want to create 3D printable models

another easy and intuitive online tool choice for beginners in 3D modeling. All you need is a Chrome or Firefox browser with WebGL enabled.

Choose from a huge library of 3D shapes and add them to your sketch. All sketches are stored in the cloud, access to them is free if you honor the Creative Commons license. Everything can be exported to STL or OBJ formats.

Enter: 3DTin

Price: Free

Systems: Browser

#7: Sculptris

For beginners who want to create 3D printable models

clay. This is a fantastic 3D modeling program if figurines are your main task. For example, you can make a bust of your favorite video game or comic book character. Sculptris is completely free and bills itself as a stepping stone to the more complex (and expensive) ZBrush tool.

Download: Pixologic Sculptris

Price: Free

Systems: PC, Mac

#8: ViewSTL

For beginners who want to view STL files

ViewSTL is the easiest way to view STL files . Simply open a web page and drag the STL onto the dotted box.

The STL online viewer allows you to display the model in one of three views: flat shading (for a quick view), smooth shading (for a high-quality image), and wireframe.

Enter: ViewSTL

Price: Free

Systems: Browser

#9: Netfabb Basic

some nice features that allow you to analyze, "repair" and edit STL files before moving on to the model cutting stage.

A good choice if you need more than just a slicer and want to be able to quickly fix STL files without having to learn programs like MeshLab or Meshmixer.

Don't let the 'Basic' in the title fool you, Netfabb Basic is actually a very powerful 3D printing tool. It's "basic" only in the sense that it doesn't cost €1,500 like Netfabb Professional!

Download: netfabb. de

de

Price: Free

Systems: PC, Mac, Linux

No. 10: Repetier

For advanced to prepare STL files for 3D printing

9002 the next level of 3D printer slicer software, but if you want to stay open source, you should look into Repetier. It is the great grandfather of 3D printing software and a favorite of the RepRap community.To date, the program is moving by leaps and bounds from the level for beginners to advanced users. Packaged in an all-in-one configuration, it supports up to 16 extruders, multi-slicing via plug-ins, and virtually every fusing 3D printer on the market. Get ready to tinker!

What's more, Repetier Host works remotely via Repetier Server, so that the 3D printer can be controlled via a browser, tablet or smartphone.

Download: Repetier

Price: Free

Systems: PC, Mac, Linux

#11: FreeCAD

The program is a great option for developing your design skills. More technically, this parametric 3D modeling program allows you to easily change the project by rolling back through the history of the model and editing the parameters.

Download: freecadweb.org

Price: Free

Systems: PC, Mac, Linux

#12: SketchUp

For beginners who want to create 3D printable models

SketchUp is the perfect combination of simplicity and the perfect combination functionality, with a user-friendly interface and a relatively flat learning curve (i.e., as experience grows with the time spent), the ideal program for developing three-dimensional models.

The Make SketchUp version is free and will include everything you need for 3D modeling if you also download and install the free STL exporter. There is also a professional edition for architects, interior designers and engineers.

Download: sketchup.com

Price: Free (SketchUp Make), $695 (SketchUp Pro)

Systems: PC, Mac, Linux

#13: 3D-Tool Free Viewer

view and validate STL files

3D-Tool Free Viewer is a sophisticated tool that, among other things, allows you to check the structural integrity and printability of your file. With the Cross-Section function, for example, you can look at the model from the inside and check the wall thickness. Very useful if you want to check your STL file for killer errors before printing.

With the Cross-Section function, for example, you can look at the model from the inside and check the wall thickness. Very useful if you want to check your STL file for killer errors before printing.

Download: 3D-Tool

Price: Free

Systems: PC

#14: Meshfix

your model for errors.

Price: Free

Systems: Browser

#15: Simplify3D

For professionals to prepare STL files for 3D printing print. A flexible algorithm checks the model for problems, fixes them, shows a preview of the printing process (ideal for identifying potential problems), and then slices it.

This slicer offers the best infill pattern options in the competition. For models that require supports, Simplify3D will create the appropriate structures on its own and give you full control over their placement. For printers with a dual extruder, when printing with different materials, the Dual Extrusion wizard will help, as a result of which, for example, it will be easier to remove the dissolving filament.

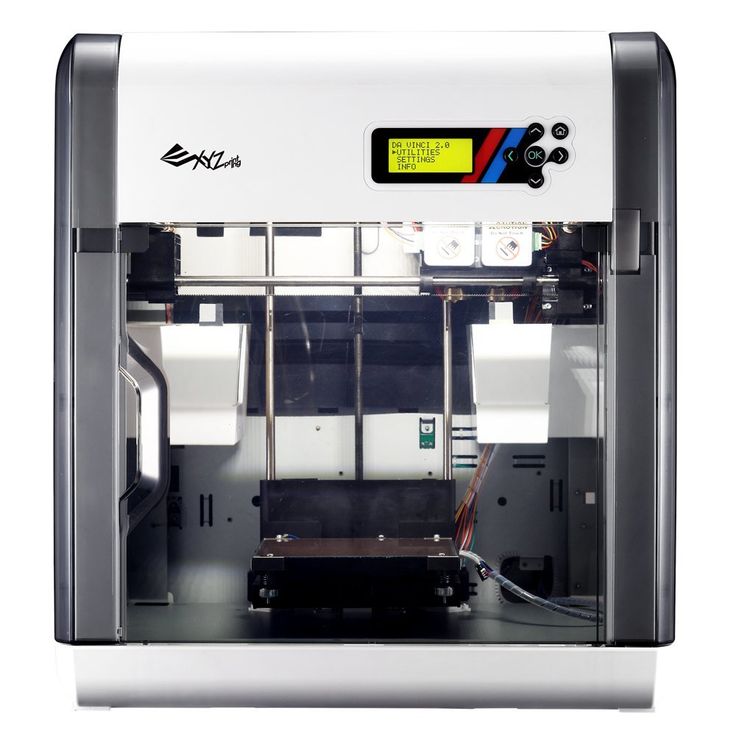

Simplify3D supports 90% of today's commercially available desktop 3D printers and is compatible with Marlin, Sprinter, Repetier, XYZprinting, FlashForge, Sailfish and MakerBot firmware. Simplify3D can also be used to directly control the printer, but then the printer and computer must be connected to each other.

Download: simplify3d.com

Price: $149

Systems: PC, Mac, Linux

#16: Slic3r

source code, which has a reputation as a carrier of super new functionality, which you will not find anywhere else. The current version of the program is able to show the model from multiple angles, so that the user gets a better preview experience.

There's also an incredible 3D honeycomb infill, the first of its kind that can extend over multiple layers rather than repeating itself like a stamp. This significantly increases the strength of the internal filling of the model and the final printout.

Another option is direct integration with Octoprint. Once the files on the user's desktop are sliced, they can be directly uploaded to Octoprint with one click.

Once the files on the user's desktop are sliced, they can be directly uploaded to Octoprint with one click.

Download: Slic3r

Price: Free

Systems: PC, Mac, Linux

#17: Blender

For professionals who want to create 3D printable models

Blender is a popular computer-aided design (CAD) system with a steep learning curve. Not at all the best choice for beginners, but what you need if you are quite experienced and need something more complex for modeling and printing.

In short, Blender is one of the most powerful tools out there. Its community is always ready to help, there are a lot of educational materials. It's also open source, so enthusiasts often write extensions to make it even better and more powerful.

Download: blender.org

Price: Free

Systems: PC, Mac, Linux

#18: MeshLab

For professionals to prepare STL files for 3D printing

MeshLab - advanced editor. It allows you to remove parts of a 3D model, merge two models into one, patch holes. If you need a program to modify models for 3D printing or some kind of "repair" work, MeshLab is the right choice.

It allows you to remove parts of a 3D model, merge two models into one, patch holes. If you need a program to modify models for 3D printing or some kind of "repair" work, MeshLab is the right choice.

Price: Free

Systems: PC, Mac, Linux

#19: Meshmixer

For professionals to prepare STL files for 3D printing files. It's especially good for identifying potential problems and fixing them automatically. For example, it will show paper-thin walls that can lead to problems with 3D printing. Meshmixer is part of the Autodesk family of 3D printer software, so it should work well with tools like TinkerCAD.

Price: Free

Systems: PC, Mac

#20: OctoPrint

start, pause or interrupt 3D print jobs. Combined with Wi-Fi capable devices, it makes for a great monitor for remotely monitoring the 3D printing process.

Octoprint understands the G-codes of almost all 3D printers and slicers and includes a gCodeVisualizer to visualize this code before or during printing.

If you want to work away from your 3D printer and control it remotely, Octoprint is the best you can find.

Download: octoprint.org

Price: Free

Systems: PC, Mac, Linux

Source

REC Wiki » Best 3D printing software in 2022

you need to design a 3D model, check it for errors, convert it to machine code, and only then the 3D printer comes into play. In this article, we will share examples of programs that can help at every stage of preparatory work and directly during 3D printing.

Contents:

2. Editing and repairing STL files:

- Meshmixer

- MeshLab

3. Slicers:

- Cura

- PrusaSlicer

- ideaMaker

- ChiTuBox Basic

- Lychee Slicer

- Kiri:Moto

- IceSL

4. Control programs:

Control programs:

- OctoPrint

- MatterControl 2.0

- AstroPrint

5. Programs for visualizing G-code

- UVTools

- WebPrinter

- Gcode Analyzer

- Design Software

1. 3D modeling software

If you are ready to create from scratch, you will have to learn special 3D modeling software. Many of them, especially professional computer-aided design systems, can be expensive investments, but on the other hand, there are plenty of quite capable and at the same time free offers on the market.

Tinkercad

Tinkercad is a browser-based application from Autodesk that is great for no-experience users, even kids, because of its simplicity. In this program, 3D models are built on the basis of basic blocks - simple geometric shapes that are joined together and then "filed" to the finished look. You can also convert 2D vector images into 3D models. Of course, you have to pay for simplicity - in the case of Tinkercad, rather primitive functionality that makes it difficult to create truly complex models. But such a task is not worth it: having gained basic skills on Tinkercad, you can always move on to more complex and more capable programs on our list.

Of course, you have to pay for simplicity - in the case of Tinkercad, rather primitive functionality that makes it difficult to create truly complex models. But such a task is not worth it: having gained basic skills on Tinkercad, you can always move on to more complex and more capable programs on our list.

ZBrushCoreMini official website

ZBrushCoreMini

ZBrushCoreMini is primarily a 3D sculpting tool, especially popular among those who create figures of people and animals, computer games and comics characters, and the like. This software is mainly aimed at beginners and users with moderate experience, but at the same time, it is full of impressive features that make the work easier. For example, dynamic tessellation algorithms constantly analyze the surface of the working model and automatically add polygons so that detail is not violated.

ZbrushCoreMini is offered free of charge and billed as an entry-level program for learning and gradually moving up to the more capable and sophisticated options ZBrush and ZbrushCore.

Official website

3D Builder

Developed by Microsoft, this program was originally bundled with Windows 10, although now it needs to be downloaded and installed separately. 3D Builder allows you to edit models in STL, OBJ, and 3MF formats, as well as create models from scratch. In this regard, the program is quite primitive, but it is simple and understandable even for novice modelers.

One of the interesting features of 3D Builder is the ability to simplify meshes by reducing the number of polygons, file weight and processing time in the slicer - useful in cases where the original designer obviously went too far with polygons. Additionally, you can import models from the library and even use Kinect sensors to 3D scan and import models of physical objects.

Official website

SketchUp

SketchUp is a web application with a great combination of simplicity and functionality. The user-friendly interface is intuitive and greatly facilitates learning, and the set of tools is quite diverse even for advanced users - hence the wide popularity of this program.

The free version was formerly called SketchUp Make, but is now simply called SketchUp Free. It includes everything you need for 3D modeling for 3D printing, just don't forget to download the module for exporting STL files - it's also free. The kit comes with 10 GB of storage for projects in the cloud and access to the 3D Warehouse, a repository with open source user-generated content.

Official site

Fusion 360

Professional CAD developed by Autodesk and famous for its ease of use and advanced functionality. This includes parametric modeling and mesh analysis and load distribution tools, including through generative design with topological optimization. The program is great for those who are engaged in 3D printing of functional products, for example, for industrial applications.

Some versions of Fusion 360, such as hobby and student versions, are even available free of charge. FreeCAD FreeCAD The program relies on a parametric approach: at any point in history, you can scroll back and make changes to the parameters. The program even includes finite element analysis and a robotic system simulator.

The program even includes finite element analysis and a robotic system simulator.

Official site

Blender

One of the most popular 3D modeling programs, but quite difficult to master. Not the best choice for a novice designer, but a great tool for those who have already gotten their hands on simpler editors. Fortunately, the popularity of Blender has led to a huge number of guides, tutorials, and visual examples published by experienced users for beginner colleagues.

Developers are trying to make the program more convenient without sacrificing functionality: the interface has recently been updated, rendering has been improved, and 3D design and animation capabilities have been expanded. And yes, it's open source and freeware, so you don't risk anything.

Official website

2. Editing and repairing STL files

If you find an interesting 3D model on the Internet, this does not mean that it can be immediately sent to a 3D printer. Many models are created for completely different needs, such as animations or video games, and in principle are not intended for 3D printing. But there is a solution: before processing such models into G-code, they must first be repaired so that the slicer can do its job well. The following programs on our list will help you cope with the repair.

Many models are created for completely different needs, such as animations or video games, and in principle are not intended for 3D printing. But there is a solution: before processing such models into G-code, they must first be repaired so that the slicer can do its job well. The following programs on our list will help you cope with the repair.

Meshmixer

Meshmixer is an advanced and free program from Autodesk that allows you to view and check 3D models for errors in polygonal meshes that can ruin 3D printing. If such problems are detected, the program can automatically repair meshes. One example of an application is finishing 3D scans to a state suitable for 3D printing.

Additional functionality includes mesh blending, 3D sculpting, surface writing, cavity creation, support branching, mesh smoothing, and more.

Official website

MeshLab

MeshLab is another open source program for editing polygonal meshes. MeshLab has the necessary tools for editing, checking, cleaning and converting meshes with the ability to combine meshes into one model and patch holes that can lead to incorrect processing of models into G-code.

MeshLab has the necessary tools for editing, checking, cleaning and converting meshes with the ability to combine meshes into one model and patch holes that can lead to incorrect processing of models into G-code.

Official website

3. Slicers

Having received a 3D model, it must be converted into machine code - a series of commands understandable to CNC machines, including 3D printers. Slicers are responsible for this task - programs that accept digital models (usually in the form of files with STL, OBJ or 3MF extensions), analyze their structure, and then compile lists of actions for 3D printers, called G-code (Gcode). Such lists contain all the information necessary for the equipment: to what temperature to warm up the extruders and tables, whether to use airflow, along what trajectory and at what pace to lay the plastic.

Cura

Cura is a slicer from the Dutch company Ultimaker, designed primarily for proprietary 3D printers, but open source and compatible with most other FDM/FFF systems. The program is easily customizable with various plugins. Since this is a very popular program, the chances are that it already has a profile with optimal settings for your 3D printer. If not, then nothing prevents you from creating a profile manually or using profiles prepared by other users.

The program is easily customizable with various plugins. Since this is a very popular program, the chances are that it already has a profile with optimal settings for your 3D printer. If not, then nothing prevents you from creating a profile manually or using profiles prepared by other users.

The program has several levels of difficulty depending on the level of training - basic, advanced, expert and complete. The higher the level, the more access to customizable options. At a basic level, the program takes the bulk of the work on itself, helping inexperienced users.

Cura is constantly being developed and improved through regular updates and is also offered free of charge, although a paid version of Cura Enterprise is available to professional users with licensed plug-ins from the Ultimaker Marketplace, technical support and additional security measures.

In addition to converting 3D models to G-code, Cura can also take on the role of a control program, but this will require a constant connection between the 3D printer and the computer throughout the 3D printing. Professionals appreciate another feature of Cura - seamless integration with professional computer-aided design systems such as SolidWorks and Siemens NX.

Professionals appreciate another feature of Cura - seamless integration with professional computer-aided design systems such as SolidWorks and Siemens NX.

In general, Сura is suitable even for novice users, especially since a huge number of training videos and step-by-step guides are available for this program from both developers and enthusiasts.

Official website

PrusaSlicer

3D printer manufacturer Prusa Research, under the leadership of the legendary Czech engineer Josef Prusa, whose designs are copied and refined around the world, has developed its own open source software based on the Slic3r slicer. PrusaSlicer quickly gained popularity as it not only retains the original program's extensive customizations, but also adds a number of useful features not found in Slic3r.

A redesigned interface, support for Original Prusa branded 3D printers, and profiles with settings to work with many common polymers are just some of the improvements. Additionally, algorithms for generating support structures have been improved, support for multimaterial 3D printing and the ability to dynamically adjust the layer thickness have been added.

Additionally, algorithms for generating support structures have been improved, support for multimaterial 3D printing and the ability to dynamically adjust the layer thickness have been added.

PrusaSlicer can process models not only for FDM 3D printers, but also for stereolithographic systems printing with photopolymers. As with Cura, the user can select a difficulty level with appropriate access to fine-tuning.

Official website

ideaMaker

Raise3D's slicer is optimized for branded additive hardware in the same way that PrusaSlicer is optimized for Original Prusa 3D printers, and Cura is optimized for Ultimaker 3D printers, but this does not mean that it cannot be use with third party systems. The organization of workflows and the interface is somewhat more complicated than in Cura and PrusaSlicer, but on the other hand, ideaMaker allows you to set up individual layers and apply textures for product customization.

ideaMaker users can connect to the cloud platform and access hundreds of 3D printer profiles and materials created by other operators, or create their own library of settings.

Add the ability to customize support structures, split models for more efficient 3D printing of large parts, integrated mesh repair tools, and OctoPrint compatibility, and you have a flexible, versatile program to suit the needs of most 3D printers.

Official website

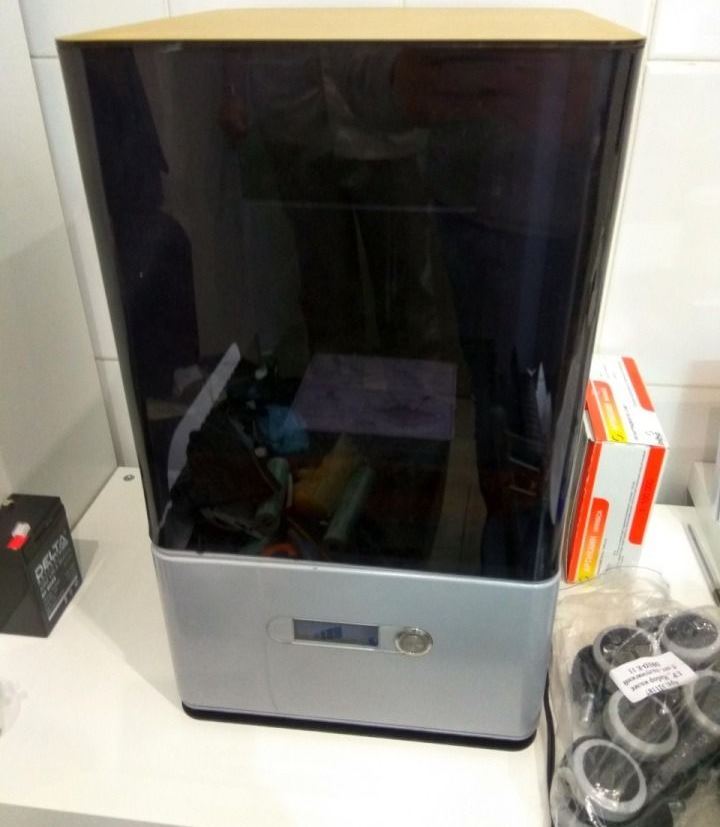

ChiTuBox Basic

This is a specialized slicer for those who use stereolithographic 3D printers that print with photopolymer resins. Most budget LCD masked stereolithography (MSLA) 3D printers rely on motherboards and firmware from ChiTu Systems, which also developed this software.

Users gain control over technology-specific parameters such as layer exposure time, as well as access to predefined profiles with settings for many popular 3D printers. The slicer takes into account such moments as the orientation of the model and the automatic construction of support structures with the possibility of manual optimization.

Official website

Lychee Slicer

A program from the independent Franco-Belgian team Mango 3D, not associated with 3D printer manufacturers, but with support for many popular stereolithographic 3D printers, including those from Elegoo, Anycubic, Phrozen and Creality.

One of the special features of this program is the high level of automation. If you wish, you can simply click on the "magic" button (it's called Magic), and the slicer will do everything by itself: it will orient the model on the platform, generate supports, and so on. Although, here you are lucky: the results are not always optimal, but usually adequate for relatively simple models. Otherwise, everything can be configured manually.

The program is offered in free and paid versions. The functionality of the free version is slightly reduced, but it has everything you need.

Official site

Kiri:Moto

Browser solution for those who lack computing power. Kiri:Moto can prepare 3D models for both 3D printing and laser engraving or milling. The settings are somewhat more primitive than in locally installed slicers, but are sufficient for most users.

Official website

IceSL

IceSL is a combination software that combines slicing with 3D modeling. In the left window, you can edit 3D models using scripts in the Lua language, which makes it possible to perform parametric modeling. On the right side, the 3D printing settings are displayed. For beginners, pre-configured settings are available, while experienced users can take advantage of features such as specific adjustment of parameters for individual layers with automatic gradation of intermediate areas. For example, this allows you to gradually reduce or, conversely, increase the filling density of the product as it is built, or gradually change the thickness of the layers.

In the left window, you can edit 3D models using scripts in the Lua language, which makes it possible to perform parametric modeling. On the right side, the 3D printing settings are displayed. For beginners, pre-configured settings are available, while experienced users can take advantage of features such as specific adjustment of parameters for individual layers with automatic gradation of intermediate areas. For example, this allows you to gradually reduce or, conversely, increase the filling density of the product as it is built, or gradually change the thickness of the layers.

Official website

4. Control programs

Control programs are designed for exactly this - managing workflows during 3D printing. Although you can insert a G-code drive into almost any 3D printer and press the start button, this is not always convenient, especially when you have to work with several 3D printers at the same time, and even more so when you do it remotely. This is where control programs come to the rescue. In addition, some of them offer additional functionality, including slicing and even editing 3D models.

In addition, some of them offer additional functionality, including slicing and even editing 3D models.

OctoPrint

A web-based hardware and software system that requires connection to a 3D printer via a microcomputer such as a Raspberry Pi equipped with a Wi-Fi module. This system allows you to control 3D printers remotely. OctoPrint accepts G-code from almost any slicer and provides the ability to visualize - view files before and during 3D printing. Alternatively, STL files can be loaded and processed directly in OctoPrint.

OctoPrint not only provides all the necessary tools for remote management, but also allows you to track the work in progress using notifications via various instant messengers.

This is a completely free, open source program with many plug-ins created by enthusiasts and available on the official website.

Official website

MatterControl

MatterHackers offers its own control program, slicer and 3D editor in one package. MatterControl allows you to directly control and observe 3D printing, slice, export G-code to SD cards for offline printing, and even create 3D models from scratch. The 3D printer will need a Wi-Fi or USB connection to run MatterControl.

MatterControl allows you to directly control and observe 3D printing, slice, export G-code to SD cards for offline printing, and even create 3D models from scratch. The 3D printer will need a Wi-Fi or USB connection to run MatterControl.

The interface is well structured: on the left side there is a file browser and a library of simple geometric shapes. Interestingly, these shapes can be dragged into the 3D model and used as support structures.

Basic functionality is available in the free basic version, advanced users can pay to upgrade to MatterControl Pro.

Official website

AstroPrint

AstroPrint is a cloud-based management platform that allows you to remotely monitor and control multiple 3D printers simultaneously, store files, convert 3D models to G-code, and track workflow statistics. The functionality ranges from basic in the free version to advanced with different levels of paid subscriptions.

The 3D printer will require a Wi-Fi module to fully work with AstroPrint. In conjunction with the Raspberry Pi, the system is similar in functionality to OctoPrint: you can process models and send the finished code to a 3D printer via a web interface without the need for additional software. Another plus is integration with popular repositories of 3D models Thingiverse and MyMiniFactory, as well as 3D editors 3D Slash and Leopoly.

In conjunction with the Raspberry Pi, the system is similar in functionality to OctoPrint: you can process models and send the finished code to a 3D printer via a web interface without the need for additional software. Another plus is integration with popular repositories of 3D models Thingiverse and MyMiniFactory, as well as 3D editors 3D Slash and Leopoly.

Official website

5. Programs for visualizing G-code

What to do if you find an old file with a G-code, but you have no idea what it is and why - maybe garbage, or maybe an excellent, but long-forgotten model without a clear marking in the file name? The programs in this section will help you visualize the contents of such files.

UVTools

This program combines file browsing with layer editing and even model repair for stereolithographic 3D printing. The program can also be used as a plug-in for PrusaSlicer, adding support for third-party photopolymer 3D printers - although PrusaSlicer is open source, support for stereolithographic systems is still limited to branded equipment. At the same time, UVTools allows you to print calibration samples to check the exposure time and other parameters, which can be useful, for example, when working with new photopolymers that have not yet been tested.

At the same time, UVTools allows you to print calibration samples to check the exposure time and other parameters, which can be useful, for example, when working with new photopolymers that have not yet been tested.

Official website

WebPrinter

A simple browser tool for quick G-code preview, developed by the same team that created the IceSL slicer and 3D editor. The application works very simply: follow the link, upload the file with the G-code and see how the 3D printer will grow the model according to the commands provided. Unfortunately, the functionality is limited: for example, the application does not provide information about temperature settings. On the other hand, you can quickly figure out what kind of model is hidden in a file with an incomprehensible name.

Official website

Gcode Analyzer

An old but still very capable and popular G-code analysis web application. The 3D simulation doesn't work very well, but the 2D and G-code previews work great.