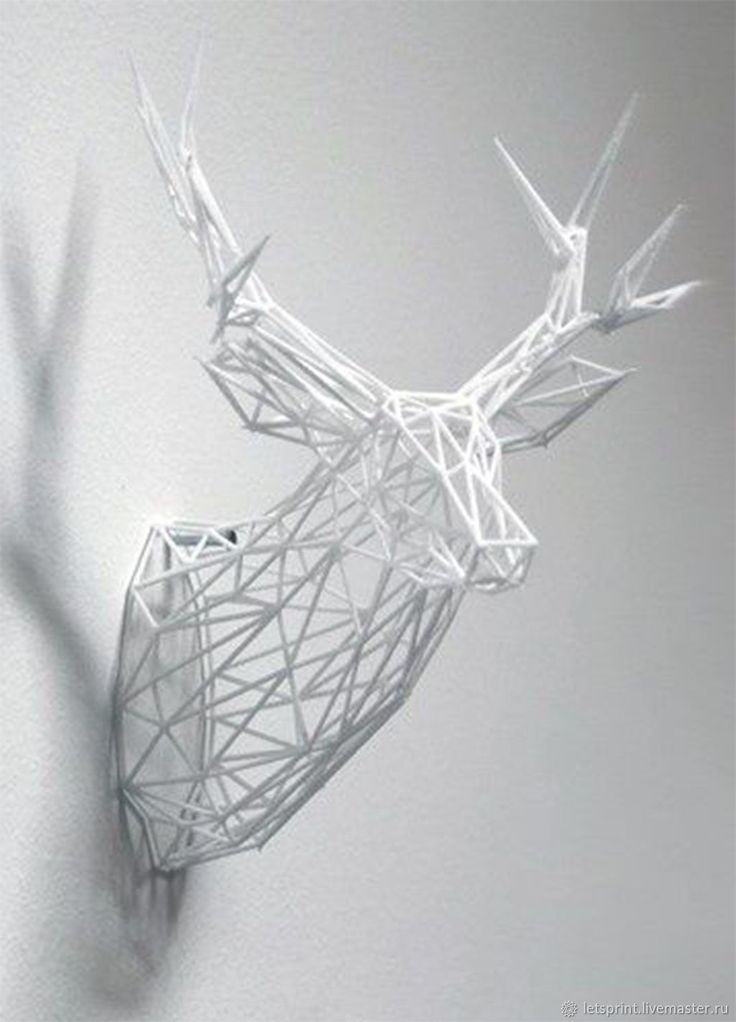

3D print beholder

▷ beholder 3d models 【 STLFinder 】

beholder

thingiverse

made a beholder in a vr cad program

Beholder

thingiverse

I will be very grateful to you if you post a photo of a printout. It is very important for me to improve the models. ... Also dream to see models painted News https://www.instagram.com/onmioji/ You can support me at Patreon: ...

Beholder

thingiverse

My fisrt Dnd model! ...Beholder

Beholder

thingiverse

Customized version of https://www. thingiverse.com/thing:1038261 Created with Customizer! ...https://www.thingiverse.com/apps/customizer/run?thing_id=1038261

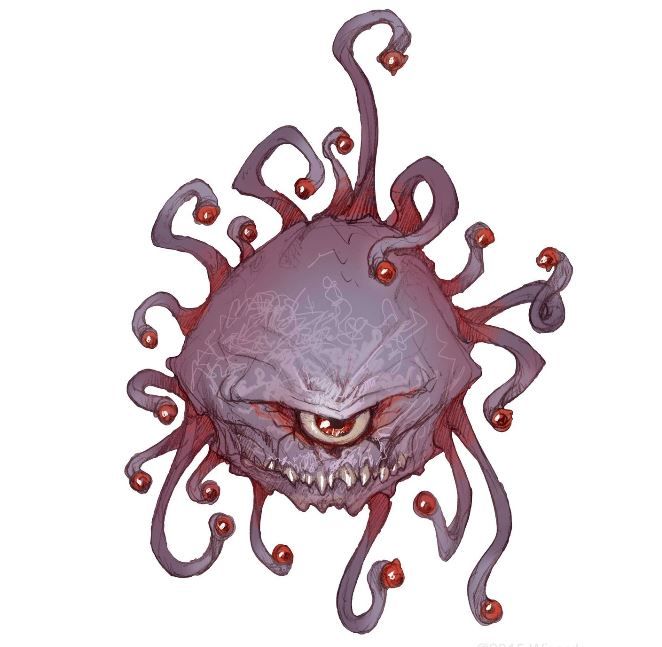

Beholder

thingiverse

This is a miniature I have modeled in Zbrush for tabletop gamers. There are 17 .STL files (Main Body, Tongue, 6 for the Tentacles/antennas and 9 for the Teeth) with custom holes and pins modeled in for easier assembling. Enjoy! ... Please consider...

Beholder

thingiverse

Customized version of https://www.thingiverse.com/thing:1038261 Created with Customizer! ...https://www.thingiverse.com/apps/customizer/run?thing_id=1038261

Beholder

thingiverse

The beholder has long been one of the most terrifying creatures in all fantasy role playing games. Print is in 3 pieces for easier printing. You will need support, but automatically generated support is easily removed. ...Visit us at...

Print is in 3 pieces for easier printing. You will need support, but automatically generated support is easily removed. ...Visit us at...

Beholder

myminifactory

Free Model Pre-supportedMultiple version, with sculpted eyes and blanked eyes1 inch base

beholder

myminifactory

Simple stylized floating eye monster figure for tabletop roleplaying games.

Beholder

thingiverse

beholder from dnd in 30s cartoon style. ...print stand a few percentages smaller to fit in hole.

Beholder

thingiverse

Your party has been traversing a dank, slimy dungeon for what feels like weeks. The dim flicker of a torch is the only light for which to see. You notice a gated opening at the end of a hall, but a shadowy mass seems to block the way. The mage...

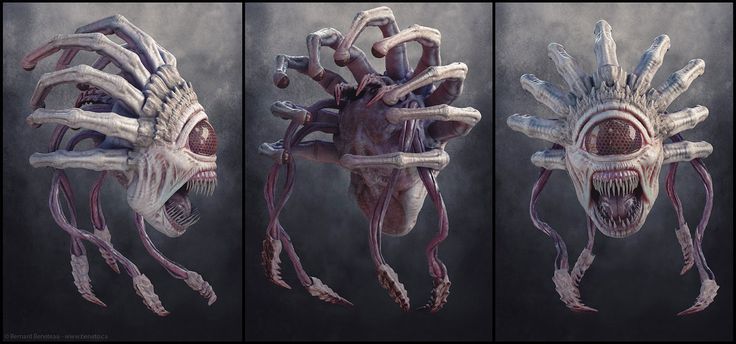

Beholder

thingiverse

Beholder (Fan-Made) Beholder, the Mad story was created by Critical Role (https://critrole.com/). This is a unofficial Fan Content permitted under the Fan Content Policy. Not approved/endorsed by Wizards. Portions of the materials used are...

Beholder

thingiverse

Getting into DnD and 3D printing at once..jpg) ...Beholder's have always been fun and I thought I'd try one myself.

...Beholder's have always been fun and I thought I'd try one myself.

Beholder

thingiverse

Beholder. ... Sculpted in Blender

Beholder

thingiverse

My first attempt at an actual mini, this is my take on the ever popular beholder. Slotted for use with the base, this model is also able to stand on its lower tentacles for freedom of choice. Any comments and constructive criticism are always...

Beholder

thingiverse

A beholder i made in under an hour, exept i forgot the mouth :P

Beholder

thingiverse

A beholder from Dungeons and Dragons.

Beholder

myminifactory

BeholderMultiple file inside, splited and unsplited version.

Beholder

thingiverse

Its an eye beast!!! The files may be uploaded already hollowed, I am not 100% on this model if I hollowed and saved or not. ... You can find me on facebook at: https://www.facebook.com/tjhenry3d/ I am also on Patreon: <a...

Beholder

myminifactory

If you enjoy my work, subscribe to my Patreon and get access to a full library with all of my models (no matter if those models are free on MyMiniFactory or not) patreon. com/YourNeighborKnight

com/YourNeighborKnight

Beholder

cults3d

Do they always have to be so huge? heres a beholder who seems to be missing a tentacle. I have included a sliced version that can be printed on fdm printers and assembled, I have sucessfully printed it but I would recommend to print it on SLA unless...

Beholder

myminifactory

Beholder

thingiverse

If you enjoy my work, subscribe to my Patreon and get access to a full library with all of my models (no matter if those models are free on MyMiniFactory or not) patreon. com/YourNeighborKnight

com/YourNeighborKnight

Beholder

myminifactory

My version of a beholder from the Dungeons and Dragons table top game. This version does require supports and has a hole at the bottom for an addition of a stand if you so wish to add one. ... Tips would be appreciated as more are to come and would...

Beholder

sketchfab

No description provided.

Beholder

sketchfab

No description provided.

Beholder

sketchfab

No description provided.

Beholder

sketchfab

No description provided.

Beholder

sketchfab

A Beholder from Dungeons and Dragons

beholder

sketchfab

Designed by Cool_monsters with Cubik Studio - https://cubik.studio Made with Cubik Studio 2.8.445 Beta

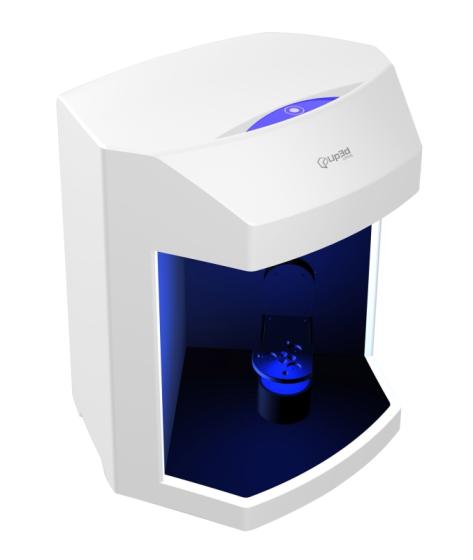

Beholder | Photogrammetry in the cloud

Beholder | Photogrammetry in the cloud Automatically convert photos

of an object into a 3D model

Build Model Now

Works with objects of any size

Focus on just the part of a scene that you're interested in

Build lots of 3D models, integrate Beholder into your pipeline

If you have photos of an object that you want to 3D print, or include in a game or film, but don't have the budget to hire a 3D artist, then Beholder can build the model for you. You'll need 20 or more high quality photos, taken in a ring around the object of interest.

You'll need 20 or more high quality photos, taken in a ring around the object of interest.

Step 1

Drag and drop the photos into the browser

Step 2

Click align images to get camera images and an initial point cloud

Step 3

If the point cloud looks good, click 'Construct Mesh' to build a detailed textured mesh

Step 4

And you're done! Download your 3D model in STL, OBJ or GLB format

Works with objects of any size. Build models of buildings using a drone, or capture smaller objects using your phone

Focus on just the part of a scene that you're interested in by using a bounding box to cut out unnecessary detail

If you need to build lots of 3D models, integrate Beholder into your pipeline by using our easy to use REST API

Build for 3D printing by exporting to STL, build for import to 3D packages such as Blender or Maya by exporting to OBJ, build for the web by exporting to GLB

1 Credit = Reconstruction of 1 image

$0

per month

- Storage for 2 models

- 100 credits per month that expire at month end

- Jobs run in a shared queue

- Purchase extra credits at a cost of 500 credits for $10.

With paid for credits, your jobs will run in a priority queue

With paid for credits, your jobs will run in a priority queue

Sign Up

Popular

$9

per month

- Storage for 25 models

- 500 credits per month. Unused credits rollover up to a max of 2500 credits while subscription is active

- Jobs run in a high priority queue

- API access

- Purchase extra credits at a cost of 500 credits for $9

Subscribe

$49

per month

- Storage for 100 models

- 5000 credits per month. Unused credits rollover up to a max of 25000 credits while subscription is active

- Jobs run in a high priority queue

- API access

- Purchase extra credits at a cost of 500 credits for $7

Subscribe

$Custom

per month

- Custom storage

- Custom credits

- Jobs run in a high priority queue

- API access

- Custom SLA

Contact Us

What kind of objects can I build models of?

Beholder works best with photos of objects with a non-reflective surface that have a clear texture on them, which luckily includes a lot of man made and natural materials. Beholder does not work well on objects that are highly reflective (cars, shiny metal) or which are translucent, such as glass or liquids.

Beholder does not work well on objects that are highly reflective (cars, shiny metal) or which are translucent, such as glass or liquids.

How many photos will I need?

Beholder will work with as few as 6 images if you just want to model one side of an object, but in general we would recommend at least 20 to 50 images of an object. Try to take photos evenly spaced in one or two rings around the object of interest.

Can I build models of moving objects?

Unfortunately no. At the moment objects need to be still and to not move between photos for Beholder to be able to build a model of them.

Can I use my phone to take photos?

Yes. Modern phone cameras, produced by the likes of Apple, Samsung and Google are very high quality, and so with care can be used to build 3D models. If you have a DSLR with a tripod though, you will likely get even better results.

If you have a DSLR with a tripod though, you will likely get even better results.

What if I pay for a subscription or credits and I'm not happy with the result?

In the first instance, please contact us so we can try to help and offer advice. If after that Beholder is not performing as you want then we offer a 14 Days Money Back Guarantee.

Practical search for maximum, acceptable and optimal print speeds.

Consumables

Subscribe to the author

Subscribe

Don’t want

22

Hello, last time I talked about the results of an experiment to find the speed of printing with PLA plastic, if you haven’t seen that material, then I advise you to familiarize yourself with them.

The conclusions were quite unexpected, but for many, and for me in particular, everything fell into place.

How about the ABS? - we'll find out right now.

The testing procedure is the same as last time, we take the G-code files for the 1.75 mm bar and the installed nozzle, load the bar, run the file for each temperature in turn, get ten pieces of thread, measure the deviations of the diameter of the pieces from the diameter of the installed nozzle, after which we write all the data in the corresponding table.

- If the diameter of the bar, nozzle or layer height differs from those stated in the code, we correct the code according to the table from article "How to find the maximum print speed of a 3D printer."

Traditional video:

All tests were done on calibrated e3d v5 extruders with 0.4 and 0.6 mm nozzles installed.

So, in fact, the results for ABS type plastic from esun and a 0.4 mm nozzle:

The results you see in the table, they turned out to be so interesting that I had to repeat the test three times, and even call an outside observer to confirm what he saw.

Nozzle 0.4 mm is practically unsuitable for printing ABS!

Of course, it prints, but, as you can see from the table, with an excess of the diameter of the extruded thread, except for the temperature range of 240-250 degrees (at these temperatures, the plastic begins to emit an unpleasant odor) and in a very limited speed range.

On the other hand, we have a wide "yellow" range, conditionally fit for printing, which everyone uses - this is obviously an abnormal mode that they try to compensate through Linear Advance or the flow settings in the slicer.

I strongly do not recommend touching the flow setting in the slicer without a clear understanding of how it works.

These properties alone make ABS a "difficult to print" and "terrible smelling" plastic.

But what about the 0.6 mm nozzle?

As we can see, the 0.6 mm nozzle handles ABS easily and naturally over the entire temperature range and in a larger speed range.

Compare this with the PLA result on the 0.6 nozzle from the previous experiment.

It is obvious that ABS has a lower maximum print speed from the "green" range than PLA, as well as the conditionally allowable speed from the "yellow range".

However, ABS completely lacks the minimum allowed print speed, at which plastic flows out of the nozzle uncontrollably, and it can be printed on both an all-steel thermal barrier and a barrier with a Teflon tube.

As in the previous test, the 0.6 mm nozzle performed well, which cannot be said for the 0.4 mm nozzle.

And that's all for me, I wish you a good print, and constructive criticism for yourself in the comments.

ABS typing speed

Follow author

Follow

Don't want

22

More interesting articles

DrProg

Loading

09/13/2022

2429

eleven

Follow the author

Subscribe

Don't want

Having received the deepest disappointment from the so-called "composite" and even "reinforced" carbon plates. ..

..

Read more

0

Subscribe to the author

Subscribe

Don't want

In this article we will tell you about new photopolymer resins from our catalog!

Se...

Read more

136

Follow author

Follow

Don't want

Foreword (which you don't have to read)

Despite the KDPW, this article does not set its own...

Read more

Printer items | Director of information service

Despite the continued air of mystery and exoticism, 3D printing is becoming a reality in our lives. As experts predict, the development of this technology, together with unmanned vehicles, will be among the most destructive in terms of its impact on many industries, reducing the need for blue-collar jobs. Indeed, the development of technology can give rise to the problem of "extra people" being forced out by robotic production. The Da Vinci Institute estimates that more than 2 billion “traditional” jobs will disappear by 2030.

Indeed, the development of technology can give rise to the problem of "extra people" being forced out by robotic production. The Da Vinci Institute estimates that more than 2 billion “traditional” jobs will disappear by 2030.

Gartner estimates that the 3D printer market grew nearly 50% in 2013 to $412 million, of which $325 million was in the enterprise segment. As analysts are sure, the demand for 3D printers will grow along with the growth of the quality and performance of devices. By 2015 sales will double. The 3D printer market is at a turning point. Although the market is still in its infancy and advertising exaggerates the capabilities of the technology, the speed of development and the rise in user interest are pushing hardware manufacturers and software developers to improve the quality and ease of use of printers. As 3D printing technology improves, it will be used more and more in product development and manufacturing.

Garbage housing

Industrial 3D printing of houses has begun in Shanghai. Thus, the government hopes to reduce the cost of building buildings. It is important to note the high speed of construction: a small house is being built in a day.

Thus, the government hopes to reduce the cost of building buildings. It is important to note the high speed of construction: a small house is being built in a day.

The giant 3D printer can work around the clock without an observer. The material is a mortar of cement and recycled construction waste. House of 200 sq. m costs about 5 thousand dollars. However, a printer that needs factory conditions to work is not mobile, and transporting a finished house to the right place will cost more.

Despite the common name, the term "3D printing" covers nine different technologies that differ in the techniques and materials used. The four most common are stereolithography, photopolymerization, extrusion (Fused Deposition Modeling, FDM) and sintering (Selective Laser Sintering, SLS). Depending on the printing method, the device can be either monochrome or color. At the CES-2014 exhibition held at the beginning of the year, there were several dozen booths of companies producing 3D printers. The best known are 3D Systems, Stratasys, Makerbot, and Solid Concepts, each operating in a different hardware segment.

The best known are 3D Systems, Stratasys, Makerbot, and Solid Concepts, each operating in a different hardware segment.

The 3D printing market is currently in chaos - the players are diverse, the technologies are extremely immature, and they are sorely lacking in standardization. Experts pin great hopes on market consolidation: sooner or later IT giants should pay attention to this industry. At a minimum, we can expect interest from related industries - manufacturers of PLM systems, in which digital product layouts will be designed, and players in the traditional printing market.

For example, HP is working in this direction. The company recently announced that they have overcome two major problems with 3D printing - slow print speeds and poor surface quality. At the same time, HP's plans are primarily aimed at the corporate market. As for ordinary consumers, it is possible that a 3D printing service will be created for them, accepting tasks and issuing finished products.

Autodesk also announced its entry into the 3D printing market a month ago with the launch of two products: Spark, an open 3D printing software platform, and its own 3D printer capable of working with a wide range of materials. Documentation on them will be available to everyone for further development and experiments.

New Features

The advent of affordable 3D printers could completely change the balance of power in many industries. The reason is simple: 3D printing has the potential to undermine the economies of scale that are central to modern industry and drive mass production. As a result, a kind of “renaissance era” may come in the manufacturing sector, because even small companies will be able to produce high-quality products without the need to build factories.

Major changes in logistics are also likely. Now the cost of shipping goods from places of production is a significant part of their value. In the case of 3D printing, the production of many goods will become mobile and it will be reasonable to move it closer to consumers.

“In recent years, the world has seen a significant breakthrough in understanding the role of 3D printing and related technologies from a business point of view,” said Frederic Vacher, director of strategic media marketing at Dassault Systemes. 3D printers are already being used extensively in the production of automobiles, consumer goods, and parts for aircraft and rockets to physically evaluate the parameters of objects being created before mass production begins. The foundation laid in recent years and the significant price reductions have resulted in an ever-wider range of 3D printing machines.

What is important, devices not only fall in price, but also acquire new features every year. For example, machines capable of printing titanium, aluminum and silver parts have revolutionized several industries. The creators of jewelry got the opportunity to develop products that are unique in shape, which could not be realized using traditional technologies. It became possible to show people in advance how this or that fruit of a design fantasy will look like, significantly reducing the risk of disappointment from the final product. Examples of 3D printing of buildings are already known.

Examples of 3D printing of buildings are already known.

Concept car - per year

So far, the use of 3D printing in industry has mostly been limited to printing prototypes in the development of new products. This seriously reduces the cost and speeds up the development and testing of products. Businesses quickly release physical samples of a product or print smaller copies for research or presentation to customers. The Bleu project, carried out by Dassault Systemes throughout 2013, is indicative. The main goal of the project is to create your own concept car from scratch to showcase the latest 3D modeling technologies. An important role was played by the use of an accurate 3D printer for multi-composite printing Stratasys Objet260 Connex.

The work was carried out by a team of a designer, two modellers, two visualization experts, two surface modelers and one mechanical modeller. At the first stage, miniature five-centimeter models were created. They were designed to identify the main design flaws. At the second stage, 3D models 10 cm long were already used to study and work out the proportions of the car. The printed models made sure that in terms of volumetric perception and proportions, all design elements are balanced and fit together.

They were designed to identify the main design flaws. At the second stage, 3D models 10 cm long were already used to study and work out the proportions of the car. The printed models made sure that in terms of volumetric perception and proportions, all design elements are balanced and fit together.

The third stage of the project, which is extremely important in the automotive and aerospace industries, is the production of an aerodynamic model. This model must be tested in a wind tunnel. The model of the car has already grown to 26 centimeters, it has new details - mirrors and bumpers. At the final stage of the project, a fully functional model of the concept car was printed.

To print structural elements (tires, chassis, windows) on a 3D printer, several types of materials were used.

Special mention should be made of new opportunities for the spare parts market. Many companies are required to provide their customers with spare parts for many years. The fulfillment of such obligations requires significant expenses for the storage of "dead" stocks. 3D printing technologies allow you to print parts on order and store only their digital models. Thus, suppliers have at their disposal a warehouse of virtual spare parts that are invisibly present and available at any time.

3D printing technologies allow you to print parts on order and store only their digital models. Thus, suppliers have at their disposal a warehouse of virtual spare parts that are invisibly present and available at any time.

One of the industries that are developing rapidly in Russia is construction. Despite common misconceptions, it is very receptive to new technologies, including 3D design and printing.

“Yes, with the development of 3D printing, the world will change beyond recognition, including the labor market. Some professions that do not require qualifications in the first place may disappear, while others, on the contrary, may appear,” admits Anastasia Morozova, Head of Architecture and Construction at Autodesk in Russia and the CIS.

According to Morozova, the development of 3D printing in construction will give rise to at least four new professions:

• BIM-manager - a specialist in building information modeling (Building Information Modeling). The demand for such specialists is already huge. In fact, such specialists appear at the intersection of two professions: a designer and a CAD manager - a system administrator responsible for technical support for the work of designers.

The demand for such specialists is already huge. In fact, such specialists appear at the intersection of two professions: a designer and a CAD manager - a system administrator responsible for technical support for the work of designers.

• Engineer of integrated digital control of construction - a specialist who works with a 3D model of an object directly at a construction site.

• Specialist in virtual reality. Modern 3D technologies make it possible to "visit" the object already at the design stage. In the future, stereo rooms may be created for this, where a client will be shown a virtual object using augmented reality technologies.

• Own 3D printer operator.

The advent of 3D printing technologies can be considered inevitable - it's only a matter of time. In any case, it makes sense for CIOs of manufacturing companies to prepare the ground in advance. 3D printing will be based on PLM and 3D modeling technologies. It is on them that you should pay special attention.