Mechanical properties of 3d printed materials

What are Mechanical Properties in 3D Printing?

When it comes to determining the suitability of a 3D printing material for a project, you need to know how hard, how strong and how flexible that material is. These things are referred to as the ‘mechanical properties’ of a material.

The phrase “good mechanical properties” is widely used in the 3D printing industry. However, it is a generic phrase that fails to describe the unique characteristics of a material. It is also important to consider that “good” does not mean “suitable”, since all materials have different properties for different applications.

Pictured above: A snapshot of the mechanical properties of Ultimaker CPE+, taken from the material’s technical data sheet.

You can find out the mechanical properties of a 3D printing material, by downloading its ‘data sheet’. Data sheets, or technical data sheets, provide data on the mechanical and thermal properties of a material. However, they don’t make it clear what each data set means. With that in mind, we have provided some useful information about mechanical properties below, to help you better understand what they are and how they translate to a material’s character.

Material Hardness

The hardness of a 3D printing material is usually measured using the Rockwell scale, or the Shore durometer. For instance, Ultimaker CPE+ has a hardness of 111 on the Rockwell scale, while Ultimaker ABS has a hardness of 97 on the Shore durometer. Both tests measure the hardness of a material, by testing its resistance to indentation. The harder a material is, then the more resistant it will be to changes in shape when a compressive force is applied.

The hardness of a material is measured using the Rockwell scale, or the Shore hardness scale.

Tensile strength at yield

Tensile strength at yield refers to the amount of stress a material can withstand before permanent deformation. A good example of this is if you imagine a rubber tube that is being stretched out. If you removed the pressure on the tube, then it would return to its original shape. However, if the stress on the tube kept increasing, then it would reach a point of deformation, rendering it incapable of springing back to its original shape.

The tensile strength at yield of a material is measured in megapascals (MPa).

Tensile strength at break

Tensile strength at break refers to the amount of force that can be applied to an object or material before it breaks. Coming back to our rubber tube example, if you kept increasing the pressure on it, then it would go beyond the point of deformation and break, because the molecules of the material would be unable to counter the external forces being applied. The force required to break the rubber tube is then used as that material’s tensile strength at break rating.

The tensile strength at break of a material is measured in megapascals (MPa).

In the video below, you can see a carbon fibre chain link printed by a Markforged 3D printer being put to the test. If you watch the video closely, you can see the chain link slowly deform, before breaking.

Elongation at yield

Elongation at yield, or tensile elongation at yield, refers to the ratio between the initial length and the increased length of a material at its yield point (which as we covered above, is the point that a material deforms – but does not break). In the simplest terms, elongation at yield is a measurement of a material’s ability to resist changes in shape before it deforms permanently. A good example would be if you stretched an elastic band out. Eventually, the band would deform.

The elongation at yield rating of a material is measured as a percentage.

Elongation at break

Elongation at break, or tensile elongation at break, refers to the ratio between the initial length and the increased length of a material at its break point. So, this is a measurement of a material’s ability to resist changes in shape before it breaks. For example, if you were to stretch an elastic band out as far as you could, it would eventually break. With both elongation at break and elongation at yield ratings, the more flexible a material is, the higher its elongation will be.

The elongation at break rating of a material is measured as a percentage.

Flexural strength

Flexural strength, also known as bend strength, is a measurement used to define a material’s tendency to bend. It is a ratio of stress to strain in flexural deformation. This measurement is widely used with materials that deform significantly, but will not break. It is a useful measurement to know, since it defines a material’s ability to resist failure in bending. An example of a test to find a material’s flexural strength, would be to bend a plastic stick with your hands until it deformed.

The flexural strength of a material is measured in megapascals (MPa).

Guide to 3D Printing Materials: Types, Applications, and Properties

3D printing empowers you to prototype and manufacture parts for a wide range of applications quickly and cost-effectively. But choosing the right 3D printing process is just one side of the coin. Ultimately, it'll be largely up to the materials to enable you to create parts with the desired mechanical properties, functional characteristics, or looks.

This comprehensive guide to 3D printing materials showcases the most popular plastic and metal 3D printing materials available, compares their properties, applications, and describes a framework that you can use to choose the right one for your project.

Interactive

Need some help figuring out which 3D printing material you should choose? Our new interactive material wizard helps you make the right material decisions based on your application and the properties you care the most about from our growing library of resins.

Recommend Me a Material

There are dozens of plastic materials available for 3D printing, each with its unique qualities that make it best suited to specific use cases. To simplify the process of finding the material best suited for a given part or product, let’s first look at the main types of plastics and the different 3D printing processes.

There are the two main types of plastics:

-

Thermoplastics are the most commonly used type of plastic. The main feature that sets them apart from thermosets is their ability to go through numerous melt and solidification cycles. Thermoplastics can be heated and formed into the desired shape. The process is reversible, as no chemical bonding takes place, which makes recycling or melting and reusing thermoplastics feasible. A common analogy for thermoplastics is butter, which can be melted, re-solidify, and melted again. With each melting cycle, the properties change slightly.

-

Thermosetting plastics (also referred to as thermosets) remain in a permanent solid state after curing. Polymers in thermosetting materials cross-link during a curing process that is induced by heat, light, or suitable radiation. Thermosetting plastics decompose when heated rather than melting, and will not reform upon cooling. Recycling thermosets or returning the material back into its base ingredients is not possible. A thermosetting material is like cake batter, once baked into a cake, it cannot be melted back into batter again.

The three most established plastic 3D printing processes today are the following:

-

Fused deposition modeling (FDM) 3D printers melt and extrude thermoplastic filaments, which a printer nozzle deposits layer by layer in the build area.

-

Stereolithography (SLA) 3D printers use a laser to cure thermosetting liquid resins into hardened plastic in a process called photopolymerization.

-

Selective laser sintering (SLS) 3D printers use a high-powered laser to fuse small particles of thermoplastic powder.

Video Guide

Having trouble finding the best 3D printing technology for your needs? In this video guide, we compare FDM, SLA, and SLS technologies across popular buying considerations.

Watch the Videos

Fused deposition modeling (FDM), also known as fused filament fabrication (FFF), is the most widely used form of 3D printing at the consumer level, fueled by the emergence of hobbyist 3D printers.

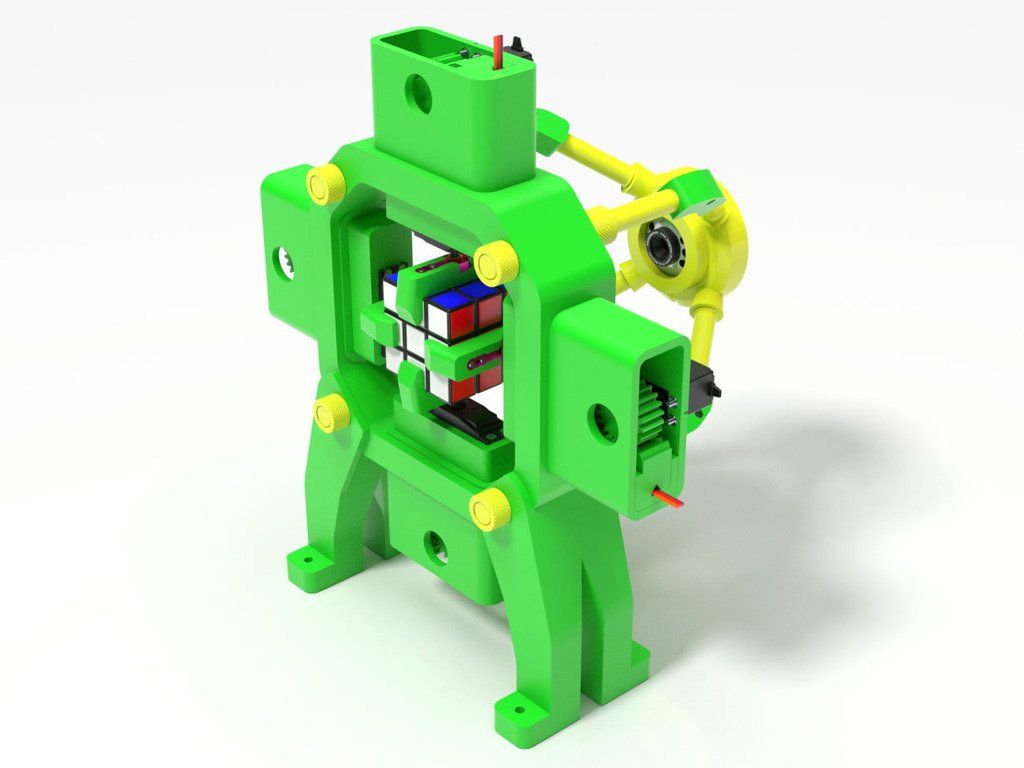

This technique is well-suited for basic proof-of-concept models, as well as quick and low-cost prototyping of simple parts, such as parts that might typically be machined.

Consumer level FDM has the lowest resolution and accuracy when compared to other plastic 3D printing processes and is not the best option for printing complex designs or parts with intricate features. Higher-quality finishes may be obtained through chemical and mechanical polishing processes. Industrial FDM 3D printers use soluble supports to mitigate some of these issues and offer a wider range of engineering thermoplastics or even composites, but they also come at a steep price.

As the melted filament forms each layer, sometimes voids can remain between layers when they don’t adhere fully. This results in anisotropic parts, which is important to consider when you are designing parts meant to bear load or resist pulling.

FDM 3D printing materials are available in a variety of color options. Various experimental plastic filament blends also exist to create parts with wood- or metal-like surfaces.

The most common FDM 3D printing materials are ABS, PLA, and their various blends. More advanced FDM printers can also print with other specialized materials that offer properties like higher heat resistance, impact resistance, chemical resistance, and rigidity.

| Material | Features | Applications |

|---|---|---|

| ABS (acrylonitrile butadiene styrene) | Tough and durable Heat and impact resistant Requires a heated bed to print Requires ventilation | Functional prototypes |

| PLA (polylactic acid) | The easiest FDM materials to print Rigid, strong, but brittle Less resistant to heat and chemicals Biodegradable Odorless | Concept models Looks-like prototypes |

| PETG (polyethylene terephthalate glycol) | Compatible with lower printing temperatures for faster production Humidity and chemical resistant High transparency Can be food safe | Waterproof applications Snap-fit components |

| Nylon | Strong, durable, and lightweight Tough and partially flexible Heat and impact resistant Very complex to print on FDM | Functional prototypes Wear resistant parts |

| TPU (thermoplastic polyurethane) | Flexible and stretchable Impact resistant Excellent vibration dampening | Flexible prototypes |

| PVA (polyvinyl alcohol) | Soluble support material Dissolves in water | Support material |

| HIPS (high impact polystyrene) | Soluble support material most commonly used with ABS Dissolves in chemical limonene | Support material |

| Composites (carbon fiber, kevlar, fiberglass) | Rigid, strong, or extremely tough Compatibility limited to some expensive industrial FDM 3D printers | Functional prototypes Jigs, fixtures, and tooling |

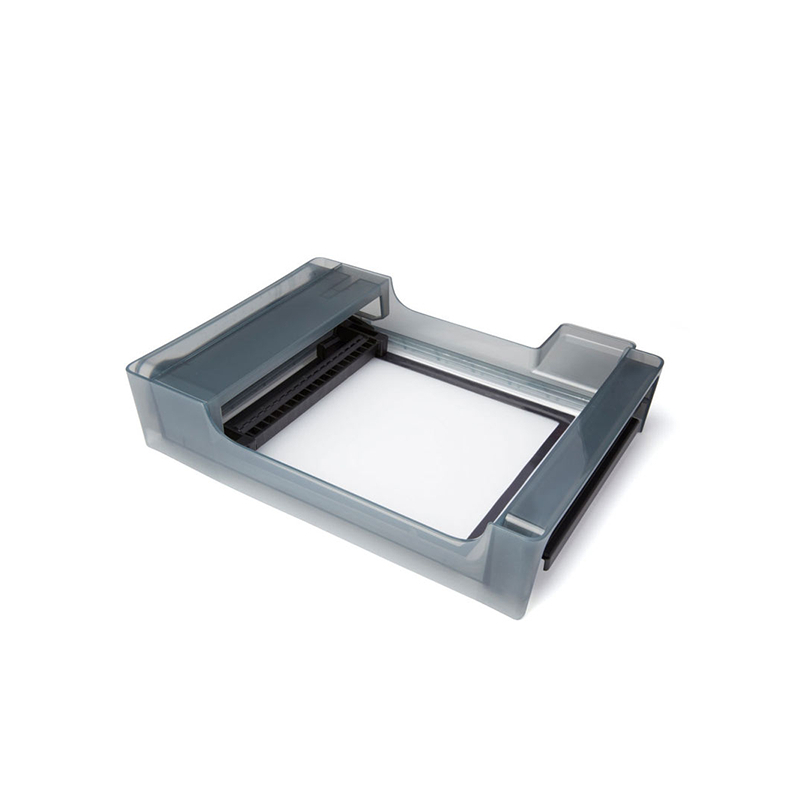

Stereolithography was the world’s first 3D printing technology, invented in the 1980s, and is still one of the most popular technologies for professionals.

SLA parts have the highest resolution and accuracy, the clearest details, and the smoothest surface finish of all plastic 3D printing technologies. Resin 3D printing is a great option for highly detailed prototypes requiring tight tolerances and smooth surfaces, such as molds, patterns, and functional parts. SLA parts can also be highly polished and/or painted after printing, resulting in client-ready parts with high-detailed finishes.

Parts printed using SLA 3D printing are generally isotropic—their strength is more or less consistent regardless of orientation because chemical bonds happen between each layer. This results in parts with predictable mechanical performance critical for applications like jigs and fixtures, end-use parts, and functional prototyping.

SLA offers the widest range of material options for plastic 3D printing.

SLA 3D printing is highly versatile, offering resin formulations with a wide range of optical, mechanical, and thermal properties to match those of standard, engineering, and industrial thermoplastics.

| Formlabs Materials | Features | Applications |

|---|---|---|

| Standard Resins | High resolution Smooth, matte surface finish | Concept models Looks-like prototypes |

| Clear Resin | The only truly clear material for plastic 3D printing Polishes to near optical transparency | Parts requiring optical transparency Millifluidics |

| Draft Resin | One of the fastest materials for 3D printing 4x faster than standard resins, up to 10x faster than FDM | Initial Prototypes Rapid Iterations |

| Tough and Durable Resins | Strong, robust, functional, and dynamic materials Can handle compression, stretching, bending, and impacts without breaking Various materials with properties similar to ABS or PE | Housings and enclosures Jigs and fixtures Connectors Wear-and-tear prototypes |

| Rigid Resins | Highly filled, strong and stiff materials that resist bending Thermally and chemically resistant Dimensionally stable under load | Jigs, fixtures, and tooling Turbines and fan blades Fluid and airflow components Electrical casings and automotive housings |

| Polyurethane Resins | Excellent long-term durability UV, temperature, and humidity stable Flame retardancy, sterilizability, and chemical and abrasion resistance | High performance automotive, aerospace, and machinery components Robust and rugged end-use parts Tough, longer-lasting functional prototypes |

| High Temp Resin | High temperature resistance High precision | Hot air, gas, and fluid flow Heat resistant mounts, housings, and fixtures Molds and inserts |

| Flexible and Elastic Resins | Flexibility of rubber, TPU, or silicone Can withstand bending, flexing, and compression Holds up to repeated cycles without tearing | Consumer goods prototyping Compliant features for robotics Medical devices and anatomical models Special effects props and models |

| Medical and dental resins | A wide range of biocompatible resins for producing medical and dental appliances | Dental and medical appliances, including surgical guides, dentures, and prosthetics |

| Jewelry resins | Materials for investment casting and vulcanized rubber molding Easy to cast, with intricate details and strong shape retention | Try-on pieces Masters for reusable molds Custom jewelry |

| ESD Resin | ESD-safe material to improve electronics manufacturing workflows | Tooling & fixturing for electronics manufacturing Anti-static prototypes and end-use components Custom trays for component handling and storage |

| Ceramic Resin | Stone-like finish Can be fired to create a fully ceramic piece | Engineering research Art and design pieces |

Explore Formlabs SLA Materials

Sample part

See and feel Formlabs quality firsthand. We’ll ship a free sample part to your office.

Request a Free Sample Part

Selective laser sintering (SLS) 3D printing is trusted by engineers and manufacturers across different industries for its ability to produce strong, functional parts. Low cost per part, high productivity, and established materials make the technology ideal for a range of applications from rapid prototyping to small-batch, bridge, or custom manufacturing.

As the unfused powder supports the part during printing, there’s no need for dedicated support structures. This makes SLS ideal for complex geometries, including interior features, undercuts, thin walls, and negative features.

Just like SLA, SLS parts are also generally more isotropic than FDM parts. SLS parts have a slightly rough surface finish due to the powder particles, but almost no visible layer lines.

SLS 3D printing materials are ideal for a range of functional applications, from engineering consumer products to manufacturing and healthcare.

The material selection for SLS is limited compared to FDM and SLA, but the available materials have excellent mechanical characteristics, with strength resembling injection-molded parts. The most common material for selective laser sintering is nylon, a popular engineering thermoplastic with excellent mechanical properties. Nylon is lightweight, strong, and flexible, as well as stable against impact, chemicals, heat, UV light, water, and dirt.

| Material | Description | Applications |

|---|---|---|

| Nylon 12 | Strong, stiff, sturdy, and durable Impact-resistant and can endure repeated wear and tear Resistant to UV, light, heat, moisture, solvents, temperature, and water | Functional prototyping End-use parts Medical devices |

| Nylon 11 | Similar properties to Nylon 12, but with a higher elasticity, elongation at break, and impact resistance, but lower stiffness | Functional prototyping End-use parts Medical devices |

| TPU | Flexible, elastic, and rubbery Resilient to deformation High UV stability Great shock absorption | Functional prototyping Flexible, rubber-like end-use parts Medical devices |

| Nylon composites | Nylon materials reinforced with glass, aluminum, or carbon fiber for added strength and rigidity | Functional prototyping Structural end-use parts |

Explore Formlabs SLS Materials

Sample part

See and feel Formlabs SLS quality firsthand. We’ll ship a free sample part to your office.

Request a Free Sample Part

Different 3D printing materials and processes have their own strengths and weaknesses that define their suitability for different applications. The following table provides a high level summary of some key characteristics and considerations.

| FDM | SLA | SLS | |

|---|---|---|---|

| Pros | Low-cost consumer machines and materials available | Great value High accuracy Smooth surface finish Range of functional materials | Strong functional parts Design freedom No need for support structures |

| Cons | Low accuracy Low details Limited design compatibility High cost industrial machines if accuracy and high performance materials are needed | Sensitive to long exposure to UV light | More expensive hardware Limited material options |

| Applications | Low-cost rapid prototyping Basic proof-of-concept models Select end-use parts with high-end industrial machines and materials | Functional prototyping Patterns, molds, and tooling Dental applications Jewelry prototyping and casting Models and props | Functional prototyping Short-run, bridge, or custom manufacturing |

| Materials | Standard thermoplastics, such as ABS, PLA, and their various blends on consumer level machines. | Varieties of resin (thermosetting plastics). Standard, engineering (ABS-like, PP-like, flexible, heat-resistant), castable, dental, and medical (biocompatible). | Engineering thermoplastics. Nylon 11, Nylon 12, and their composites, thermoplastic elastomers such as TPU. |

Beyond plastics, there are multiple 3D printing processes available for metal 3D printing.

-

Metal FDM

Metal FDM printers work similarly to traditional FDM printers, but use extrude metal rods held together by polymer binders. The finished “green” parts are then sintered in a furnace to remove the binder.

SLM and DMLS printers work similarly to SLS printers, but instead of fusing polymer powders, they fuse metal powder particles together layer by layer using a laser. SLM and DMLS 3D printers can create strong, accurate, and complex metal products, making this process ideal for aerospace, automotive, and medical applications.

-

Titanium is lightweight and has excellent mechanical characteristics. It is strong, hard and highly resistant to heat, oxidation, and acid.

-

Stainless steel has high strength, high ductility, and is resistant to corrosion.

-

Aluminum is a lightweight, durable, strong, and has good thermal properties.

-

Tool steel is a hard, scratch-resistant material that you can use to print end-use tools and other high-strength parts..

- Nickel alloys have high tensile, creep and rupture strength and are heat and corrosion resistant.

Compared to plastic 3D printing technologies, metal 3D printing is substantially more costly and complex, limiting its accessibility to most businesses.

Alternatively, SLA 3D printing is well-suited for casting workflows that produce metal parts at a lower cost, with greater design freedom, and in less time than traditional methods.

Another alternative is electroplating SLA parts, which involves coating a plastic material in a layer of metal via electrolysis. This combines some of the best qualities of metal—strength, electrical conductivity, and resistance to corrosion and abrasion—with the specific properties of the primary (usually plastic) material.

Plastic 3D printing is well-suited to create patterns that can be cast to produce metal parts.

With all these materials and 3D printing options available, how can you make the right selection?

Here’s our three-step framework to choose the right 3D printing material for your application.

Plastics used for 3D printing have different chemical, optical, mechanical, and thermal characteristics that determine how the 3D printed parts will perform. As the intended use approaches real-world usage, performance requirements increase accordingly.

| Requirement | Description | Recommendation |

|---|---|---|

| Low performance | For form and fit prototyping, conceptual modeling, and research and development, printed parts only need to meet low technical performance requirements. Example: A form prototype of a soup ladle for ergonomic testing. No functional performance requirements needed besides surface finish. | FDM: PLA SLA: Standard Resins, Clear Resin (transparent part), Draft Resin (fast printing) |

| Moderate performance | For validation or pre-production uses, printed parts must behave as closely to final production parts as possible for functional testing but do not have strict lifetime requirements. Example: A housing for electronic components to protect against sudden impact. Performance requirements include ability to absorb impact, housing needs to snap together and hold its shape. | FDM: ABS SLA: Engineering Resins SLS: Nylon 11, Nylon 12, TPU |

| High performance | For end-use parts, final 3D printed production parts must stand up to significant wear for a specific time period, whether that’s one day, one week, or several years. Example: Shoe outsoles. | FDM: Composites SLA: Engineering, Medical, Dental, or Jewelry Resins SLS: Nylon 11, Nylon 12, TPU, nylon composites |

Once you’ve identified the performance requirements for your product, the next step is translating them into material requirements—the properties of a material that will satisfy those performance needs. You’ll typically find these metrics on a material’s data sheet.

| Requirement | Description | Recommendation |

|---|---|---|

| Tensile strength | Resistance of a material to breaking under tension. High tensile strength is important for structural, load bearing, mechanical, or statical parts. | FDM: PLA SLA: Clear Resin, Rigid Resins SLS: Nylon 12, nylon composites |

| Flexural modulus | Resistance of a material to bending under load. | FDM: PLA (high), ABS (medium) SLA: Rigid Resins (high), Tough and Durable Resins (medium), Flexible and Elastic Resins (low) SLS: nylon composites (high), Nylon 12 (medium) |

| Elongation | Resistance of a material to breaking when stretched. Helps you compare flexible materials based on how much they can stretch. Also indicates if a material will deform first, or break suddenly. | FDM: ABS (medium), TPU (high) SLA: Tough and Durable Resins (medium), Polyurethane Resins (medium), Flexible and Elastic Resins (high) SLS: Nylon 12 (medium), Nylon 11 (medium), TPU (high) |

| Impact strength | Ability of a material to absorb shock and impact energy without breaking. Indicates toughness and durability, helps you figure out how easily a material will break when dropped on the ground or crashed into another object. | FDM: ABS, Nylon SLA: Tough 2000 Resin, Tough 1500 Resin, Grey Pro Resin, Durable Resin, Polyurethane Resins SLS: Nylon 12, Nylon 11, nylon composites |

| Heat deflection temperature | Temperature at which a sample deforms under a specified load. Indicates if a material is suitable for high temperature applications. | SLA: High Temp Resin, Rigid Resins SLS: Nylon 12, Nylon 11, nylon composites |

| Hardness (durometer) | Resistance of a material to surface deformation. Helps you identify the right “softness” for soft plastics, like rubber and elastomers for certain applications. | FDM: TPU SLA: Flexible Resin, Elastic Resin SLS: TPU |

| Tear strength | Resistance of a material to growth of cuts under tension. Important to assess the durability and the resistance to tearing of soft plastics and flexible materials, such as rubber. | FDM: TPU SLA: Flexible Resin, Elastic Resin, Durable Resin SLS: Nylon 11, TPU |

| Creep | Creep is the tendency of a material to deform permanently under the influence of constant stress: tensile, compressive, shear, or flexural. | FDM: ABS SLA: Polyurethane Resins, Rigid Resins SLS: Nylon 12, Nylon 11, nylon composites |

| Compression set | Permanent deformation after material has been compressed. Important for soft plastics and elastic applications, tells you if a material will return to its original shape after the load is removed. | FDM: TPU SLA: Flexible Resin, Elastic Resin SLS: TPU |

For even more details on material properties, read our guide to about the most common mechanical and thermal properties.

Once you translate performance requirements to material requirements, you’ll most likely end up with a single material or a smaller group of materials that could be suitable for your application.

If there are multiple materials that fulfil your basic requirements, you can then look at a wider range of desired characteristics and consider the pros, cons, and trade-offs of the given materials and processes to make the final choice.

Try our interactive material wizard to find materials based on your application and the properties you care the most about from our growing library of materials. Do you have specific questions about 3D printing materials? Contact our experts.

Recommend Me a Material

Steel 3D Printing - A Quick Guide / Sudo Null IT News

Any metal 3D printing technology can print with steel. This is the most popular material. But which steel grades and which technology is best for your application? Will printed steel parts really be as strong and durable as traditionally made parts? nine0003

Let's see how a 3D printed steel part is revolutionizing manufacturing and opening doors to new applications in aerospace, medical equipment, automotive, tool making, heavy industry, architecture and more. In addition, more affordable desktop printers are expanding the scope and scope of real steel 3D printed parts.

Strength of steel printed parts. nine0009 Cast steel part (left), 3D printed version (center).

The most common question when it comes to a 3D printed metal model is "Will it be as strong as a forged or cast part?" ?". The short answer is yes... and no.

3D printed steel parts can be just as strong, and sometimes even stronger, than those made in the traditional way. It depends on many factors such as: end use, type of steel, choice of 3D printing method, post-processing and shape of the part. Also, the comparison depends on which of the strength characteristics you focus on: tensile strength, static load strength, fatigue strength, etc. nine0003

Parts printed from steel are used in the aerospace industry, for the military, and also, for example, for the manufacture of a footbridge, shown below. Therefore, the strength of printed products is beyond doubt, but let's take a closer look.

Queen Maxima of the Netherlands officially opens a 3D printed metal bridge. Photo by Adriaande Groot (Source: MX3D) A 3D printed or laser powder sintered (LPBF) steel part has a finer grain structure than cast metal products. This provides better tensile strength characteristics, but in other respects the cast parts are currently still stronger. Most often, LPBF 3D printing is used to replace cast components, but in some cases, 3D printed components can replace forged parts. nine0003

One study showed that, under certain conditions, stainless steel parts made using LPBF 3D printers were three times stronger than parts made from the same steel using the traditional method.

In experiments comparing 3D printed steel parts to traditionally made steel parts, researchers create identical parts using two methods and compare their performance. However, head-to-head comparison of details is only part of the big picture. nine0003

The main advantage of printing with steel is not only its strength, but also the unique ability to create internal channels and lattice fillings in parts, which is impossible using traditional manufacturing methods. Metal 3D printing makes it possible to produce parts faster than traditional production, since this method does not require the use of special equipment and tools, it allows you to create assemblies as a whole, eliminating the need for subsequent assembly and welding. Designing a printed part usually means that less metal is needed to make it, and therefore less weight, for the same strength. nine0003 MX3D Wire Arc Additive Manufacturing (WAAM) printed steel architectural support (Source: MX3D)

Steel 3D printing is also more stable and cost effective as it reduces waste. When using subtractive manufacturing methods, such as CNC machining, you make a part by cutting it out of a large one, with a lot of waste. With additive manufacturing, you only use the material you need to make the finished product. nine0003

Steel 3D printing is not intended to replace traditional methods in all areas, but it may be a better choice for a wide range of applications. Particularly when the required parts are unique and designed for specific applications, such as rocket engines, racing cars or the oil and gas industry. 3D printing is the fastest and most flexible technology for mass production and prototype production. For military and industrial applications, steel 3D printing is a faster and more efficient way to create individual parts for vehicles and machines. Stainless steel 3D printing is rapidly finding applications in medicine to create unique surgical instruments and implants. nine0003

If you know what characteristics your final product should have (tensile strength, compressive strength, hardness, density, etc.), then all these parameters can be incorporated into the product at the production stage.

Types of steel for 3D printing

Metal powder is the most used metal material for 3D printing (Source: GKN Additive)There are thousands of different grades of steels and alloys with different mechanical properties, used in traditional manufacturing but in 3D printing there are only a few dozen of them, and some of them are unique, created specifically for this technology. Among the steel options, the following can be distinguished:

-

Stainless steel (316L, 304L , 17-4PH, 15-5PH, 420, 254, Ph2, GP1, 630, 410).

-

Tool steel (D2, M2, h23, h21, MS1, 1.2709).

-

Low alloy steel (4140).

-

Structural alloyed (20MnCr5).

Recently, unique alloys have been developed specifically for 3D printing, designed to solve the problems that occur with classical production methods. nine0003

For example, 3D printer manufacturer Desktop Metal released a patented stainless steel in 2022 that the company says combines the tensile strength, ductility, and corrosion resistance of 13-8 PH stainless steel, combined with the hardness low alloy steel like 4140. The company says customers can go to market with this material and skip the galvanizing step to protect products from corrosion.

ExOne offers two special blends of steel and bronze that the company says allows 3D printed steel parts to achieve increased corrosion resistance while being easy to machine and polish. nine0003

While most of the metal powders used in 3D printing are similar to those used for other manufacturing methods, their numbers are on the rise as more companies adopt the technology. Some metal powder manufacturers, such as GKN, also make custom powders for specific 3D printing applications.

How to print with steel

The strength, properties and applications of 3D printed steel products largely depend on which 3D printing technology you use. Some methods produce stronger parts, other methods provide better hardness or abrasion resistance, and some technologies are simply very fast. nine0003

Below are the main metal 3D printing methods, their properties and some of the most common application examples.

Fused Deposition Printing (FDM)

BCN3D's Epsilon printer extrudes metal filament from stainless steel (Source: BCN3D) as more printer manufacturers certify metallic filaments for use on their printers, such as Ultimaker, BCN3D, Makerbot, Raise3D. Raise3D has recently released a complete metal printing suite - Metalfuse (3D printer, debinding oven and sintering oven). This method is still much more popular for printing plastics, but with new plastic filaments filled with stainless steel powder, strong metal parts can be produced.FDM media was once limited to thermoplastics. Companies like BASF Forward AM and The Virtual Foundry now offer metal filaments that can be used on almost any FDM printer as long as it has a hardened steel nozzle for abrasive media.

These materials are approximately 80% metal and 20% plastic. After printing, the post-processing process removes the plastic, resulting in 100% metal parts. nine0003

Due to the removal of the bonding plastic, FDM metal parts shrink during post-processing. The amount of shrinkage is constant and can be taken into account in CAD systems, which allows to obtain relatively accurate finished parts.

Forward AM's 316L Stainless Steel Ultrafuse filament produces finished parts with material properties that the company claims are comparable to injection molded metal parts. nine0003 (Source: BCN3D)

While 3D printing with metallic materials may not be suitable for demanding applications such as aerospace, the economics of producing simple metal components without critical loads on an affordable FDM printer can outweigh the impossibility of applying them in some areas.

Metal prototype parts and finished parts that will not be subjected to extreme stress are ideal uses for this technology. nine0003

Bound Metal Deposition (BMD)

Desktop Metal's Studio System 3D printer used bonded metal bars that were extruded layer by layer to form a metal part (Source: Desktop Metal)Similar to FDM, Metal mesh deposition method (BMD) or bonded powder extrusion (BPE) is a 3D printing process based on extrusion. This method uses bonded metal rods or bonded powdered metal filaments, which consist of a much higher percentage of metal powder than the filaments used in FDM. As with FDM, post-treatment to remove the binder and heat treatment in a final sintering oven are required. nine0003

There are only a few 3D printers using this method such as Desktop Metal, Markforged and more recently 3DGence, but more companies are entering this market, so stay tuned. These printers are valued as a convenient solution for office 3D metal printing, they are more expensive than most FDM printers, but cheaper than the powder-based metal 3D printing technologies described below.

These printers use their own proprietary filament. Desktop Metal and Markforged offer four types of steel. nine0003

Ideal niches for this technology are metal prototype parts, where it is necessary to test the functionality of a part before mass production using traditional methods. Popular applications are molds, punching dies, nozzles, impellers, fasteners and heat exchangers.

For example, Shukla Medical uses Markforged's Metal X printer to print steel prototypes of its orthopedic implant removal tools. nine0003

Laser powder sintering.

Laser powder sintering technology uses one or more lasers to melt powdered metal into a desired shape layer by layer (Source: GE Additive) metal printing. This technology is used by 80% of all metal 3D printers on the market.This method uses powerful lasers to selectively sinter metal powder layer by layer. nine0003

LPBF 3D printers are available in a wide range of sizes, prices and laser powers. These and other characteristics affect the properties of the finished part, print speed and other parameters of the finished products.

Steel and steel alloys are the most popular material for LPBF equipment and, unlike FDM and BMD, metal powders are commercially available as they are most commonly used in traditional production methods.

LPBF is a technology that maximizes the quality of a 3D printed part. Applications include aerospace components such as monolithic thrust chambers, rocket engine components and heat exchangers, molds, tools and other applications, as well as high wear parts and surgical instruments. nine0003

Binder Jetting

Binder 3D printing technology uses metal powder and a binder to form metal parts (Sorrce: ExOne) binder, and not with a laser. During post-processing, the binder is removed.Binder application stands out for its high printing speed compared to other 3D printing methods or traditional manufacturing, and metal parts made with this technology have material properties equivalent to those made by metal injection molding. nine0003

The number of manufacturers producing metal-bonded inkjet 3D printers is much smaller than that of LPBF machines. Leading manufacturers include ExOne, Desktop Metal, Digital Metal, GE Additive and HP.

Binder blasting is ideal for medium to high volume production of metal tools and spare parts.

In fact, HP claims that its Metal Jet 3D printer was designed specifically for mass production of 316L stainless steel products. HP has partnered with Parmatech to produce metal parts for the medical industry. Pennsylvania-based ExOne uses this technology to manufacture hard metal cutting tools and tool steels. nine0003

Electron Beam Melting (EBM)

(Source: GE Additive)Electron Beam Melting (EBM) is another powder cladding technology. It works in a similar way to selective laser melting (SLM), but instead of using a laser as the energy source, it uses a much more powerful beam of charged particles.

The recoater moves the powder onto the printing plate and an electron beam selectively melts each layer of powder. After each layer is printed, the plate is lowered and another one is applied on top of the previous layer. nine0003

EBM can be much faster than SLM, but SLM produces smoother and more accurate pieces. The electron beam is wider than the laser beam, so EBM cannot produce the same precise parts as SLM. Another difference is that the manufacturing process takes place in a vacuum chamber, which reduces the amount of impurities in the material that can lead to defects. That is why EBM is often chosen for printing components for the aerospace, automotive, defense, petrochemical and medical implant industries. nine0003

Titanium is the most popular metal for most EBM applications, however steel can be used.

Cold Spray

(Source: Impact Innovations)Cold spray 3D printing is done by injecting metal powders through a jet nozzle into a supersonic stream of pressurized gases such as air, nitrogen or helium. The process is called "cold" because the metal particles do not melt, but hit the metal substrate and adhere to its surface during the so-called plastic deformation. nine0003

Cold spray printed products are not prone to porosity, thermal cracking and other defects associated with melt-based technologies. This method has several advantages over other production methods. The technology is used in the military and aerospace industries around the world. For example, the US Army uses cold spray to repair the mounts of a worn Bradley 25mm steel turret gun.

In the automotive industry, cold spray steel is used for crash repairs because the high strength steel substrates in cars can be susceptible to thermal repair methods such as welding. nine0003

Direct Energy Deposition (DED) and Wire Arc Additive Manufacturing (WAAM)

WAAM Steel Parts from MX3D (Source: MX3D) Direct Energy Deposition (DED) uses welding powder or wire that enters through a nozzle and is fed into the power source to melt the metal. A melt region is created and applied to the substrate. DED is a new process, reminiscent of an old building technology known as "cladding", in which a coating is applied to a substrate, often for thermal insulation or weather resistance. DED is useful for fabricating large objects as a whole, as well as complex geometries that require extensive machining. DED can get such parts much closer to finished than traditional CNC machining. nine0003

Because DED uses a coating process, it can be used to add complex geometries to existing steel parts, thus combining complexity with cost reduction. For example, the French company AddUp advertises a rocket nozzle that uses a preformed large 304 stainless steel hopper cone printed with an isogrid structure, usually made from a larger piece by traditional methods.

A technology related to DED is wire-arc additive manufacturing (WAAM). Instead of powder, WAAM uses a metal wire that is melted by an electric arc. The process is controlled by robotic arms. WAAM is also capable of producing large-sized metal parts, as demonstrated by the Dutch company MX3D and its nine thousand-pound 41-foot stainless steel bridge in Amsterdam, as well as an oil and gas equipment repair part, proving that parts can be made in the field. nine0003

Micro 3D printing

Micro parts printed from steel (Source: 3D MicroPrint) Micro scale additive manufacturing, or micro 3D printing, can produce products with a resolution of a few microns (or less). There are three micro 3D printing methods to produce metal parts.

LMM (lithography-based metal fabrication) is a light-based technology that creates tiny parts from raw materials, including stainless steel, for applications such as surgical instruments and micro-mechanical parts. nine0003

Electrochemical deposition is the latest micrometal 3D printing process developed by the Swiss company Exaddon. In this process, the printing nozzle applies liquid with metal ions, creating details at the atomic level.

A third micrometal 3D printing method is microselective laser sintering, in which a layer of metal nanoparticle ink is applied to a substrate, then dried to produce a uniform layer of nanoparticles.

German researchers have successfully tested micro SLS printing of hollow microneedles using 316L stainless steel. nine0003 Metal parts from 3D Systems, Desktop Metal, MX3D and Materalise.

How metal 3D printers work. Overview of SLM and DMLS technologies. additive manufacturing.

Metal 3D printing. Additive technologies.

SLM or DMLS: what's the difference?

Hello everyone, Friends! 3DTool is with you!

BLT metal 3D printer catalog

Selective laser melting ( SLM ) and direct metal laser sintering ( DMLS ) are two additive manufacturing processes that belong to the family of 3D printing , using the powder layer method. The two technologies have much in common: they both use a laser to selectively melt (or melt) metal powder particles, bonding them together and creating a pattern layer by layer. In addition, the materials used in both processes are metals in granular form. nine0003

The differences between SLM and DMLS come down to the basics of the particle bonding process: SLM uses metal powders with a single melting point and completely melts the particles, while in DMLS the powder consists of materials with variable melting points.

In particular:

SLM produces single metal parts while DMLS produces metal alloy parts.

Both SLM and DMLS technologies are used in industry to create final engineering products. In this article, we will use the term "metal 3D printing" to summarize the 2 technologies. We will also describe the main mechanisms of the manufacturing process that are necessary for engineers to understand the advantages and disadvantages of these technologies. nine0158 There are other manufacturing processes for producing dense metal parts, such as electron beam melting (EBM) and ultrasonic additive manufacturing (UAM). Their availability and distribution is rather limited, so they will not be presented in this article.

How metal 3D printing SLM or DMLS works.

How does metal 3D printing work? The basic manufacturing process for SLM and DMLS is very similar.

1. The printing chamber is first filled with an inert gas (such as argon) to minimize the oxidation of the metal powder. It then heats up to the optimum operating temperature. nine0158 2. A layer of powder is spread over the platform, a powerful laser makes passes along a predetermined path in the program, fusing the metal particles together and creating the next layer.

3. When the sintering process is completed, the platform moves down 1 layer. Next, another thin layer of metal powder is applied. The process is repeated until the entire model is printed.

When the printing process is completed, the metal powder already has strong bonds in the structure. Unlike the SLS process, parts are attached to the platform via support structures. The support in metal 3D printing is created from the same material as the base part. This condition is necessary to reduce deformations that may occur due to high processing temperatures. nine0158 When the 3D printer's chamber cools down to room temperature, excess powder is removed manually, such as with a brush. The parts are then typically heat treated while they are still attached to the platform. This is done to relieve any residual stresses. They can then be further processed. The removal of the part from the platform occurs by means of sawing.

Scheme of operation of a 3D printer for metal.

In SLM and DMLS, almost all process parameters are set by the manufacturer. The layer height used in metal 3D printing varies from 20 to 50 microns and depends on the properties of the metal powder (fluidity, particle size distribution, shape, etc. ). nine0158 The basic size of the print area on metal 3D printers is 200 x 150 x 150 mm, but there are also larger sizes of the working area. Printing accuracy is from 50 - 100 microns. As of 2020, metal 3D printers start at $150,000. For example, our company offers 3D metal printers from BLT.

Metal 3D printers can be used for small batch production, but the 3D printing capabilities of such systems are more like those of mass production on FDM or SLA machines. nine0158 The metal powder in SLM and DMLS is recyclable: typically less than 5% is consumed. After each impression, the unused powder is collected and sieved, and then topped up with fresh material to the level required for the next production.

Waste in metal printing, are supports (support structures, without which it will not be possible to achieve a successful result). With too much support on the manufactured parts, the cost of the entire production will increase accordingly. nine0158

Adhesion between coats.

3D metal printing on BLT 3D printers

SLM and DMLS metal parts have almost isotropic mechanical and thermal properties. They are hard and have very little internal porosity (less than 0.2% in 3D printed condition and virtually non-existent after processing).

Metal printed parts have higher strength and hardness and are often more flexible than traditionally made parts. However, such metal becomes “tired” faster. nine0003

3D model support structure and part orientation on the work platform.

Support structures are always required when printing with metal, due to the very high processing temperatures. They are usually built using a lattice pattern.

Supports in metal 3D printing perform 3 functions:

• They form the basis for creating the first layer of the part.

• They secure the part to the platform and prevent it from deforming.

• They act as a heat sink, removing heat from the model. nine0003

Parts are often oriented at an angle. However, this will increase the amount of support required, the printing time, and ultimately the overall cost.

Deformation can also be minimized with laser sintering templates. This strategy prevents the accumulation of residual stresses in any particular direction and adds a characteristic surface texture to the part.

Since the cost of metal printing is very high, software simulations are often used to predict how a part will behave during processing. These topology optimization algorithms are otherwise used not only to increase mechanical performance and create lightweight parts, but also to minimize the need for supports and the likelihood of part distortion. nine0003

Hollow sections and lightweight structures.

An example of printing on a BLT 3D printer

Unlike polymer powder melt processes such as SLS, large hollow sections are not typically used in metal printing as the support would be very difficult to remove, if at all possible.

For internal channels larger than Ø 8 mm, it is recommended to use diamond or teardrop cross-sections instead of round ones, as they do not require the construction of supports. More detailed recommendations on the design of SLM and DMLS can be found in other articles on this topic. nine0003

As an alternative to hollow sections, parts can be made with sheath and cores, which in turn are machined using different laser power and pass speeds, resulting in different material properties. The use of sheath and cores is very useful when making parts with a large solid section, as it greatly reduces printing time and reduces the chance of warping.

The use of a lattice structure is a common strategy in metal 3D printing to reduce part weight. Topology optimization algorithms can also help design organic lightweight shapes. nine0003

Consumables for 3D metal printing.

SLM and DMLS technologies can produce parts from a wide range of metals and metal alloys, including aluminum, stainless steel, titanium, cobalt, chromium and inconel. These materials meet the needs of most industrial applications, from aerospace to medical applications. Precious metals such as gold, platinum, palladium and silver can also be processed, but their use is of a minor nature and is mainly limited to jewelry making. nine0003

The cost of metal powder is very high. For example, a kilogram of 316 stainless steel powder costs approximately $350-$450. For this reason, minimizing part volume and the need for supports is key to maintaining optimal manufacturing cost.

The main advantage of metal 3D printing is its compatibility with high-strength materials such as nickel or cobalt-chromium superalloys, which are very difficult to process with traditional methods. Significant cost and time savings can be achieved by using metal 3D printing to create a near-clean shape part. Subsequently, such a part can be processed to a very high surface quality. nine0158

Metal post-processing.

Various post methods. treatments are used to improve the mechanical properties, accuracy and appearance of metal printed products.

Mandatory post-processing steps include the removal of loose powder and support structures, while heat treatment (heat annealing) is typically used to relieve residual stresses and improve the mechanical properties of the part.

CNC machining can be used for critical features (such as holes or threads). Sandblasting, plating, polishing, and micro-machining can improve the surface quality and fatigue strength of a metal printed part. nine0003

Advantages and disadvantages of metal 3D printing.

Pros:

1. Metal 3D printing can be used to make complex custom parts, with geometries that traditional manufacturing methods cannot provide.

2. Metal 3D printed parts can be optimized to increase their performance with minimal weight.

3. Metal 3D printed parts have excellent physical properties, metal 3D printers can print a wide range of metals and alloys. Includes difficult-to-machine materials and metal superalloys. nine0003

Cons:

1. Manufacturing costs associated with metal 3D printing are high. The cost of consumables is from $ 500 per 1 kg.

2. The size of the working area in metal 3D printers is limited.

Conclusions.

• Metal 3D printing is most suitable for complex, one-piece parts that are difficult or very expensive to manufacture using traditional methods, such as CNC.

• Reducing the need for building supports, will significantly reduce the cost of printing with metal. nine0158 • 3D printed metal parts have excellent mechanical properties and can be made from a wide range of engineering materials, including superalloys.

And that's all we have! We hope the article was useful to you.

Catalog of 3D printers for metal BLT

You can purchase metal 3d printers, as well as any other 3d printers and CNC machines, by contacting us:

• By email: Sales@3dtool.