Hemera 3d printer

E3D Hemera Dual Drive Extruder and Hotend Full Kit (12v)

- Home

- Store

- 3D Printer Accessories

- 3D Printer HotEnds

- Hotends by Voltage

- 12v 3D Printer Hotends

The Hemera hotend and extruder from E3D is one of the shortest and most well-constrained filament paths ever produced for 3D printers. This enables ultra-fast printing speeds but also improves performance during retractions and overall usage of flexible materials like MatterHackers PRO Series Flex.

- Ultra-fast printing speeds

- Improved performance with flexible materials

- Short and well-constrained filament path

Remove from wishlist Add to wishlist loading...

Product No. loading...

Notify me when this item becomes available Success You will be notified when .To learn about available discounts, training, and maintenance options, please use the form below and a MatterHackers Expert will contact you within one business day. Alternatively, you can always feel free to give us a call at +1 (800) 613-4290 or email [email protected].

To get an instant quote, add everything you need to your cart, and click "Download as quote".

Product(s)

Email *

Phone

Full Name

Company/Organization

Questions

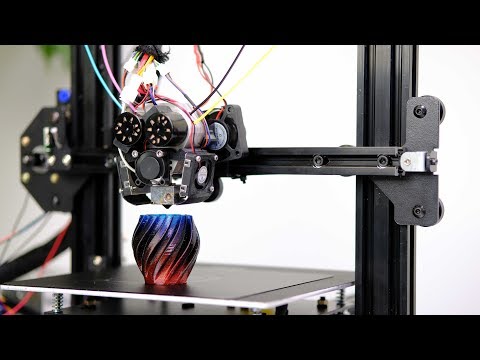

Success Thank you for your request. We will be in touch shortly. Hemera lets you print faster than ever before with rigid and flexible materials alike3D printing is a revolutionary and ever-evolving technology that is changing the nature of production for people around the world all the way from initial prototypes to final production of end-use parts. No matter what step of the production process you find yourself utilizing desktop additive manufacturing for, we can all agree that the ability to print faster is better. The Hemera hotend and extruder from E3D achieves this goal with one of the shortest and most well-constrained filament paths ever produced for 3D printers. Material is pulled from your spool with dual-drive hobbed gears and fed immediately into the top of the v6-ecosystem compatible heat break. This not only enables ultra-fast printing speeds but also improves performance during retractions and overall usage of flexible materials like MatterHackers PRO Series Flex. Flexible materials will find any and all opening in the filament path to wander out and ruin prints. Hemera eliminates each and every spot where other extruder designs see these issues.

No matter what step of the production process you find yourself utilizing desktop additive manufacturing for, we can all agree that the ability to print faster is better. The Hemera hotend and extruder from E3D achieves this goal with one of the shortest and most well-constrained filament paths ever produced for 3D printers. Material is pulled from your spool with dual-drive hobbed gears and fed immediately into the top of the v6-ecosystem compatible heat break. This not only enables ultra-fast printing speeds but also improves performance during retractions and overall usage of flexible materials like MatterHackers PRO Series Flex. Flexible materials will find any and all opening in the filament path to wander out and ruin prints. Hemera eliminates each and every spot where other extruder designs see these issues.

E3D has spent years developing an entire ecosystem of hotend components that make it possible to utilize 3D printing for almost any production workflow. V6 is a compact heater block with nozzle sizes all the way down to 0.15mm to extreme high detail FFF 3D printing projects, while Volcano takes advantage of a larger heater block for a longer melt zone and therefore larger nozzles up to 1.2mm for higher speed printing of larger, stronger parts. The new Hemera heat break interfaces perfectly with these and also the E3D SuperVolcano - a massive heater block with nozzles up to 1.4mm for huge production printing. The Hemera enables all of these much-loved hotend designs to now function with ultra-precise dual-drive extrusion for higher performance than ever before.

V6 is a compact heater block with nozzle sizes all the way down to 0.15mm to extreme high detail FFF 3D printing projects, while Volcano takes advantage of a larger heater block for a longer melt zone and therefore larger nozzles up to 1.2mm for higher speed printing of larger, stronger parts. The new Hemera heat break interfaces perfectly with these and also the E3D SuperVolcano - a massive heater block with nozzles up to 1.4mm for huge production printing. The Hemera enables all of these much-loved hotend designs to now function with ultra-precise dual-drive extrusion for higher performance than ever before.

Hemera heat break interfaces with any E3D heater block design

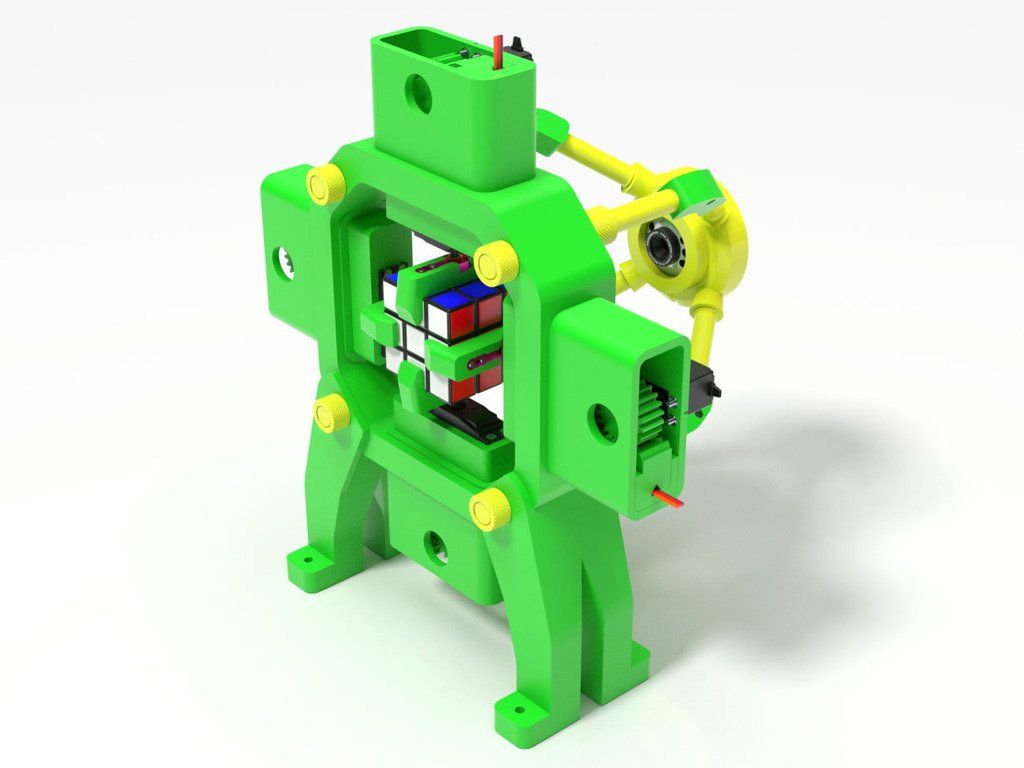

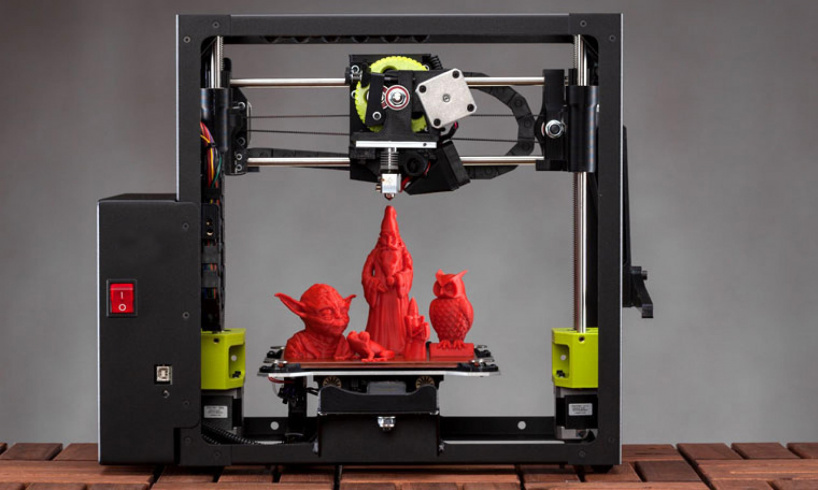

Hemera is modular and versatile, ready to be installed on almost any 3D printerE3D set out to change everything about the direct-drive extruder ideal with Hemera, and to that end that didn't stop with just the drive system. The extruder utilizes a custom-built stepper motor with T-Slot nuts everywhere that support any mounting system you can design. No matter what kind of 3D printer you operate, there is a way to factor in this incredible extruder for improved performance. Along with the modular nature of installing this extruder on any printer, each component is also available stand-alone from the extruder to hotend components for later growth and further refinement.

No matter what kind of 3D printer you operate, there is a way to factor in this incredible extruder for improved performance. Along with the modular nature of installing this extruder on any printer, each component is also available stand-alone from the extruder to hotend components for later growth and further refinement.

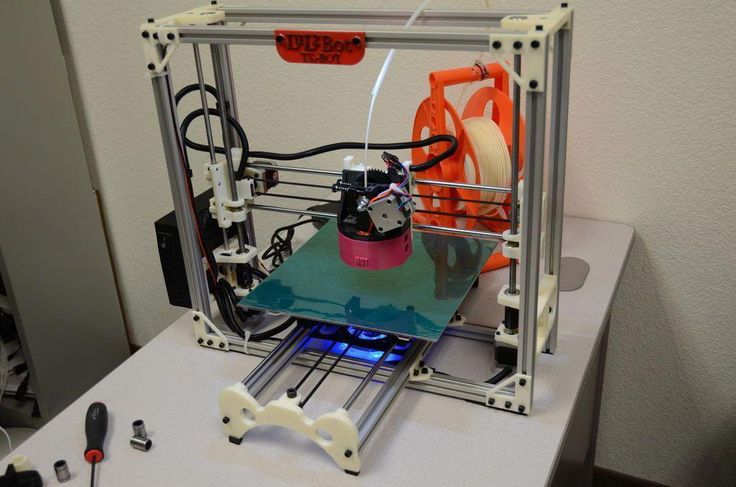

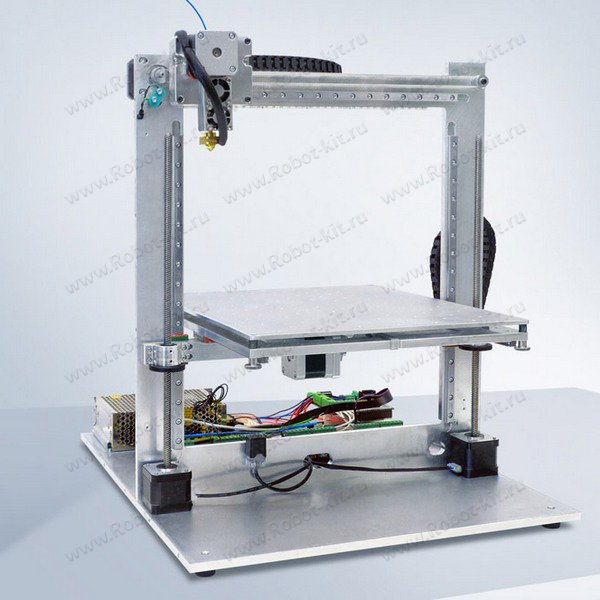

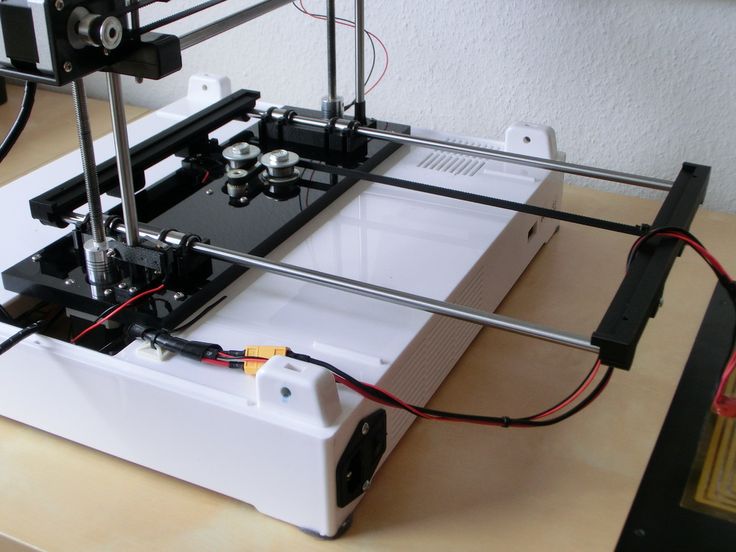

Example of a custom Hemera installation

What's in the box?- 12V or 24V 30W Heater cartridge

- Thermistor cartridge

- Molex cable

- 40 x 40 x 10 mm 12V or 24V Fan

- Cable tie

- Hemera heat sink

- Idler

- Idler slide block

- Idler spring block

- Thumbwheel

- Idler shaft

- Drive hobb

- Idler hobb

- V6 Heater Block

- E3D Hemera motor

- Motor cable

- E3D Hemera fixings kit

- V6 fixings kit

- E3D Hemera heatbreak

- Brass 1.75mm, 0.4mm nozzle

- V6 sock

- Thermal compound

Custom made stepper motor and beautifully engineered drive shaft

Key changes in the Hemera offering 2021:- Gear material changed and new heat treatment processes have been modified to increase toughness and elongation to break by nearly 10x

- Grease has been added to gear assembly to prevent wear, significantly increasing each unit’s

lifecycle

Read more about Hemera through our Tech breakdown article here.

This item cannot be shipped to a PO Box or APO/FPO/DPO address. This item takes longer to ship due to its size and/or weight.

E3D Hemera – E3D Online

E3D Hemera is the best extrusion system we’ve ever made. It combines our market leading V6 hotend with an all new filament drive to form a highly responsive direct drive extrusion system - providing unrivaled performance with flexible filaments. Hemera is also available as a bowden extruder.

Featuring a dual-drive, hardened stainless steel drive train with a fully constrained, super-short filament path and an E3D-V6 Hot-Side, E3D Hemera provides an unrivalled precision extrusion experience: excellent control over stops and starts; greatly reduced stringing and blobbing; and greater filament traction means slipping and grinding are a thing of the past. We print flexibles at 50mm/s.

You're probably wondering why at the last minute everything that you were expecting to be called 'Hermes' is now called 'Hemera'. Unfortunately, less than 24 hours before launch, we received a legal challenge from a company much larger than us, and with significantly more legal resources. They objected to us naming our product after a Greek god from the Mycenaean era, as they feel that name belongs to them.

Unfortunately, less than 24 hours before launch, we received a legal challenge from a company much larger than us, and with significantly more legal resources. They objected to us naming our product after a Greek god from the Mycenaean era, as they feel that name belongs to them.

Unfortunately, we don't have the time or resources to resolve this through a long legal process and we just want to get on with making incredible extrusion systems. Therefore we've had to undergo a rapid unscheduled rebranding, and have settled on Hemera, a somewhat less fashionable Greek god, yet still in keeping with our other mythological names, and our first female one too.

Please do excuse us if some of the content is slightly less polished than usual, it's been a long hard night. If you see any instances of the old name hanging around please do let us know too. Thanks in advance for your understanding.

For E3D Hemera, we opted for a dual-drive arrangement which provides a huge boost in grip over single drive systems. We are able to push filament with up to 10kg of force. The secondary gear shaft is on a moveable, sprung idler which allows the user to adjust filament tension. All the gears are hardened stainless steel.

We are able to push filament with up to 10kg of force. The secondary gear shaft is on a moveable, sprung idler which allows the user to adjust filament tension. All the gears are hardened stainless steel.

Sharp teeth - with a round bottomed profile - provide excellent grip and strongly resist filament debris wedging into the drive gear and in almost all cases it’s self-cleaning as any debris simply falls off the teeth. (Look familiar? You may remember this self-cleaning tooth profile in the Titan extruder.)

Hemera drive gear closeup - individually CNC cut teethWe achieve this profile by individually CNC cutting each tooth, allowing us to provide the round-bottomed root, with a tooth that curves upwards to a robust, sharp tip.

E3D Hemera’s compact, hardened, stainless steel drive trainAs a result of opting for an all-metal hardened stainless steel drivetrain, we were able to reduce the size of the gears. This enables the drivetrain to fit within the frame of a Nema 17 stepper motor - more on compactness in the next section. With the drive train being made from hardened stainless steel, we can maintain the operation of the Hemera gearbox. For bearings we make use of an igus® bushing and shielded ball-bearings. Older Hemera's (pre Jan 21) had a dry-running system but we have since changed the material of the gears and also greased them for greater improved wear performance, see here for more details.

With the drive train being made from hardened stainless steel, we can maintain the operation of the Hemera gearbox. For bearings we make use of an igus® bushing and shielded ball-bearings. Older Hemera's (pre Jan 21) had a dry-running system but we have since changed the material of the gears and also greased them for greater improved wear performance, see here for more details.

When designing Hemera’ dual-drive hobbs, we took a ground-up approach starting with a specification of dual-drive, researching and testing material combinations and implementing our tooth profiles. Dual drive is an established concept within the industry (going all the way back to 2011 with Steves Extruder used on the SeeMeCNC h2) and it is clear that dual-drive provides considerably more grip when compared to single drive systems. Fundamentally, the entire extrusion system is just better.

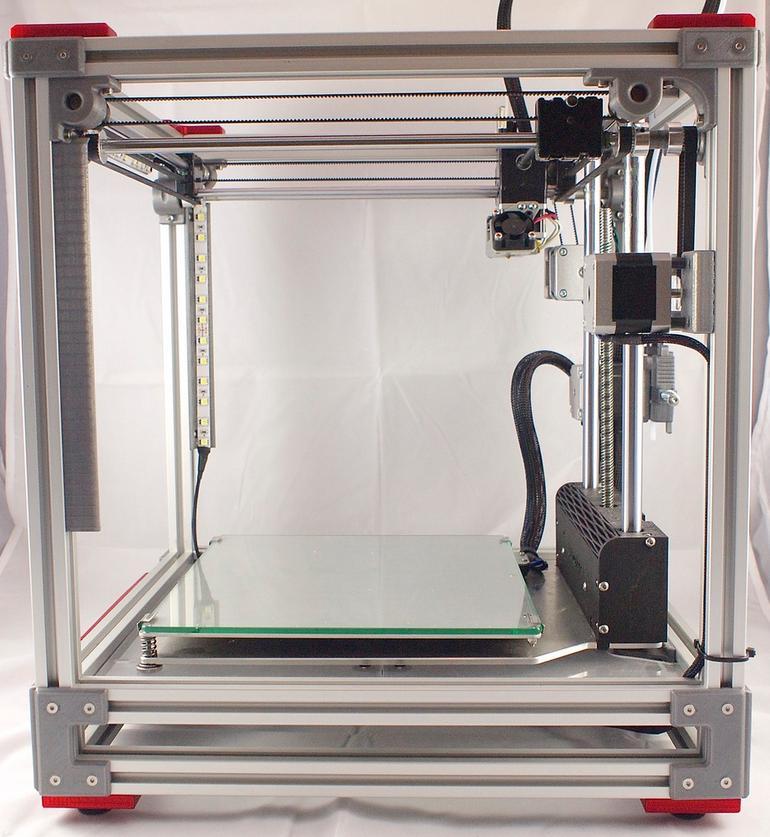

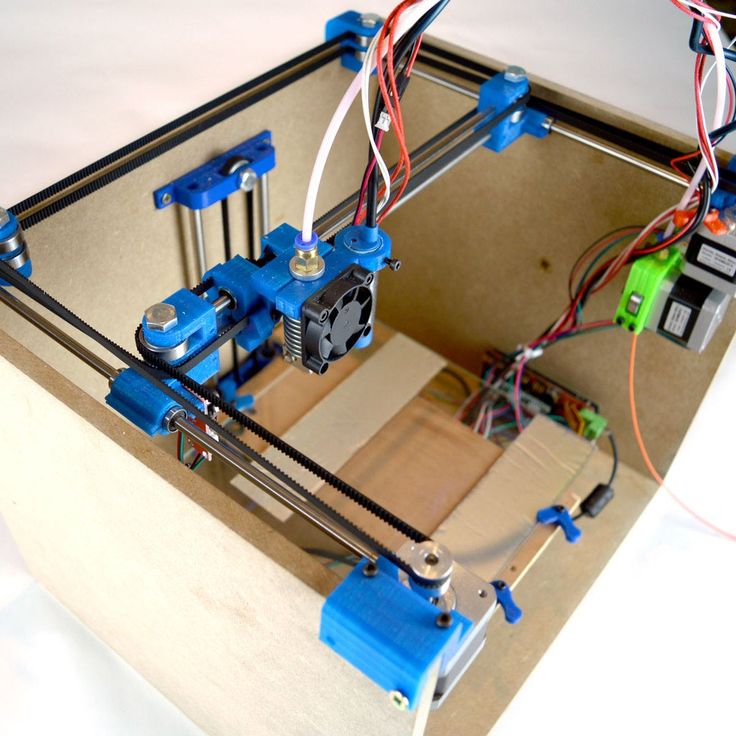

We set out to develop a compact extruder and HotEnd system with a reduced part-count. Hemera is a system of components designed to work seamlessly together as a single product.

To achieve this, we have developed a custom motor, based on a NEMA 17 frame, with our own faceplate designs. This is neat as it allows us to use the motor itself as part of the assembly and to add our own features for the user’s convenience, such as the mounting T-Slots.

The custom motor for E3D Hemera: not just a pretty faceplate, but useful tooHemera constrains your filament like no other extrusion system. You won’t truly ‘get’ the impact of the optimised constraint that Hemera provides until you’ve printed flexibles with it. But trust us - the performance is second to none and also has a significant impact on printing normal materials such as PLA or PETG.

Flexible Dragon model printed in ninjatek cheetah https://www.thingiverse.com/thing:1624412

A flexible example we like to show is the famous “retraction performance test” model by MAKE (a model with many retractions, short stop/start extrusions, and travel moves) we are able to show off incredibly defined results with no stringing or oozing, indicating how unbelievably responsive the system is. Just look at this TPU print:

Just look at this TPU print:

Model: https://www.thingiverse.com/thing:2755063

If you were impressed, then wait until we tell you that we printed the TPU print using typical PLA settings. We didn’t change anything except the filament. 50mm/s with a 0.2mm layer, with a 0.4mm nozzle.

You asked to see #E3DHermes printing and you shall receive. Here's #Hermes printing #NinjaFlex on the #ToolChanger at a whopping 100mm/s #GottaPrintFast

Benchies - PLA vs. TPU - printed with same settings

Model: https://www.thingiverse.com/thing:763622

How did we achieve this wizardry? Firstly, Hemera was designed to be compact which allows us to attain a very short distance from drive-wheels to melt-zone. This has a number of benefits, primarily reducing the length of filament under compression when being pushed into the melt zone, improving responsiveness.

This has a number of benefits, primarily reducing the length of filament under compression when being pushed into the melt zone, improving responsiveness.

Secondly, we carefully toleranced all the components after the drive gear. There is a clearance gap between drive gears and heatbreak of approximately 100µm. The filament is tightly constrained in the heatbreak with only 250µm of clearance (enough to allow for slight inconsistencies in filament, but not so much that we introduce a big filament-spring into your system!)

E3D Hemera offers no way out for flexibles

These two improvements together mean that the filament has only one place to go - into your nozzle, and that when you apply a force - it responds.

An additional benefit of this arrangement is that there are zero transitions after the drive gears, filament proceeds directly to the melt. This ensures reliable operation.

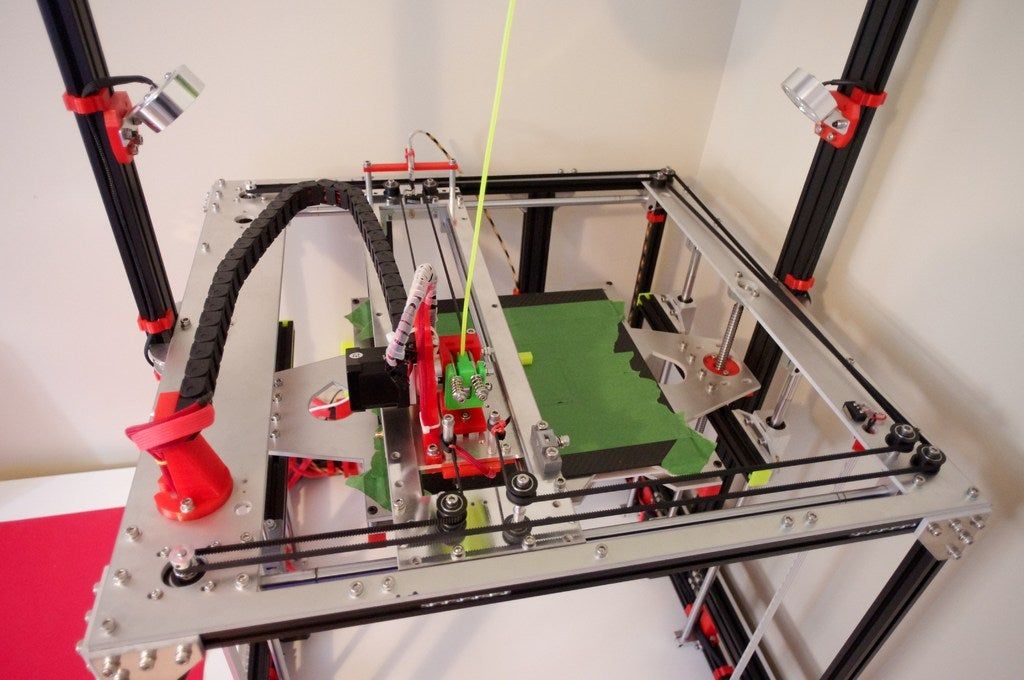

The T-Slots on the custom motor faceplates allow for easy mounting solutions to pre-existing machines, as well as providing a more compact, stable platform for printer manufacturers to integrate onto their machine.

Hemera T-Slot mounting system

Each side of the motor has 4 T-Slots holes. One side can be used for mounting to the carriage, leaving the opposing face free for mounting whatever you need, part cooling fans, bed levelling probes, or other accessories.

The heatsink isn’t just a visually striking aspect of Hemera (or inspired by Sanjay’s hair). As a result of in-depth testing with a hot wire anemometer setup, we have optimised the airflow of the die-cast fins. Airflow is directed up and away from both the HotEnd and the heated bed, meaning airflow does not disrupt the print envelope. This reduces the risk of warping and uneven stresses forming in the printed part.

Optimised Hemera Heatsink airflow

All interaction with Hemera is from the top. To set filament tension the user simply twists a thumbscrew and a cam slider mechanism with a captive nut compresses a spring and loads the idler. Filament tension is increased by rotating clockwise and decreased by rotating counterclockwise.

Hemera is designed to auto-load filament exceptionally reliably, no matter what you throw at it. With the drive wheels turning, you can literally drop filament onto the hobbs and it will be sucked in, and you will be ready to print.

Although we have implemented self-cleaning drive-teeth, there may one day be the need to disassemble Hemera for maintenance. If maintenance is required, the internal mechanisms are easily accessible by removing the fan, and undoing the two faceplate screws. Full access is available to clean and replace parts even while filament is loaded. When you pop off the faceplate the filament, idler and spring all come along too, as one neat assembly.

Hemera - maintenance made easy allow easy servicing

Here at E3D, we strive for excellence by putting emphasis on developing rigorous quality control. As part of our focus on traceability, we are laser engraving QR codes onto the Hemera motor, allowing us to tie the QC data we already collect, to the unit in your hand.

In order to quality control the complex 3D geometries of the Hemera heatsink and motor we purchased dedicated new and upgraded inspection equipment that combines optical measurement and probing.

Eventually, we aim to have this serialised data, along with sensor and heater data available to every customer via our website.

Hemera motor with laser-engraved QR code

The Hemera cold side (heatsink & extruder) is compatible for use in both direct and bowden modes. In direct, we make use of an E3D-V6 hotside (with a custom heatbreak).

In bowden, we simply replace the hotside with the Hemera bowden adaptor (or “bowdaptor” as we like to call it).

Note that the cooling fan is required in direct mode, but not in bowden mode.

The bowdaptor allows you to attach a length of PTFE tube via the same collet and collet clip as you’d come to expect with the rest of our ecosystem.

We are happy to be able to offer a really competitive price for Hemera; the retail price for a fully-fledged direct system is just £90. This is inclusive of an all in one Extruder, HotEnd, and Motor. A Bowden-only Hemera unit is also available with a retail price of £70. Assembled units will also be available post-launch (pricing TBC).

With Hemera our goal was to raise the performance bar of extrusion and hotend systems. We have the advantage of scale, and so have also paid heavy attention to the manufacturing processes being used to keep costs low. Die-casting of the heatsink and motor faceplates are incredibly efficient ways to produce precise aluminium parts in high volumes. We touch this up with a minimal amount of post-machining to achieve a perfect balance of cost and quality (whilst also getting some sexy bare metal highlights.)

Optimised Hemera HeatsinksHemera features a new heatbreak with an M4 thread on the coldside to improve heat transfer.

The flange on the heatbreak ensures a precise mate between the heatbreak and the heatsink. This guarantees perfect positioning of the break between the drive gears, giving that fantastic constraint.

The hot side makes use of the standard M6 thread which maintains full compatibility with the E3D ecosystem of nozzles, heater blocks, temperature sensors, and heater cartridges.

Hemera heatbreak (left) V6 heatbreak (right) Hemera heatbreak with V6, Volcano and Super Volcano heater blocksE3D Hemera, is a powerful, advanced extrusion system, we truly believe is the best product that we’ve ever brought to market and can’t wait for you to get your hands on it.

We’ve spent a huge amount of time ensuring that this product is as compatible, universal and user friendly as it can possibly be for the end user. As such, to make things as easy as possible for you guys, we’ve collaborated with some of the industry’s most loved content creators (MakerNoob, CNC Kitchen, Toms3DP, Maker’s Muse & Ivan Miranda to name a few) to bring you upgrade guides and videos for the most popular printers on the market.

To make upgrading as easy as possible, we've teamed up with some community favourites to create printer specific upgrade guides:

| Printer Name | Written Guide | Video Guide | Printable Mounts |

|---|---|---|---|

| Artillery Sidewinder X1 | by Joe Casha (3D Maker Noob) | N/A | by Joe Casha (3D Maker Noob) |

| Artillery Genius | by Joe Casha (3D Maker Noob) | N/A | by Joe Casha (3D Maker Noob) |

| Creality CR-10s Pro | by Joe Casha (3D Maker Noob) | N/A | by Joe Casha (3D Maker Noob) |

| Creality CR-10s Max | by Joe Casha (3D Maker Noob) | N/A | by Joe Casha (3D Maker Noob) |

| Lulzbot Mini | by Joe Spanier (Maker's on Tap) | N/A | by Joe Spanier (Maker's on Tap) |

| Lulzbot Taz Printers (Taz 4, Taz 5, Taz6) | by Joe Spanier (Maker's on Tap) | N/A | by Joe Spanier (Maker's on Tap) |

| Creality Ender 3 | by Dan Rock (E3D) | by Joe Casha (3D Maker Noob) | by Joe Casha (3D Maker Noob) |

| Creality CR-10 Printers (CR-10, CR-10S, CR-10 4S, CR-10 5S) | by Dan Rock (E3D) | by Joe Casha (3D Maker Noob) | by Joe Casha (3D Maker Noob) |

| Anet A8 | by Tom Sanladerer (Tom's 3D) | by Tom Sanladerer (Tom's 3D) | by Tom Sanladerer (Tom's 3D) |

| Prusa i3 MK3 | by Dan Rock (E3D) | N/A | N/A |

Have we missed your favourite printer? Let us know via facebook, twitter or email us at support@e3d-online.

com.

com.Free 3D file of Mount Gemera・3D printer design for download・Cults

Mario Kart Item Box Lantern

0,99 €

Pink Floyd Lithophane Lamp

Free

Ikea RIBBA Led Frame

Free

TMNT mask

Free

nine0003 TAE MountFree

The best files for 3D printers in the Tools category

Pointy painters pyramids (and blunt ones too)

Free

LEAD HOLDER - MINX1 MECHANICAL PENCIL

Free

simple pocket caliper

Free

Functional Gas Mask V2

Free

Breadboard Bits - Modularize your breadboard.

Free

TOOLBOX FOR PRUSA I3 HEPHESTOS

Free

Micro control cases: for micro SD cards and other miniature items

1 €

nine0003 Spinning Filament Holder1.38 €

Bestsellers in the Tools category

'ELEGANCE' Bambu lab set and general 3d printers

5 €

Quick print stackable parts containers / storage boxes

2.85 €

Fire Hydrant Storage Container

1.84 €

Cut-Man - PET bottle cutter with handle!

5 € -thirty% 3. 50 €

50 €

UNIVERSAL BED LEVELING INDICATOR FOR VERY ALL PRINTERS

2,31 €

Ender 3 S1 BEST cable guide - vertical

2.50 €

ENDER 3 S1, S1 PRO, SPRITE, V3 AIR DUCT FAN 5015, ACCELEROMETER, LED strip

€2.64 -20% 2.11 €

PRECISION CALIPER 3D PRINT DIY

3,10 €

Phone Holder

2.57 €

telephone ring holder

0,90 €

SUPERBOX

1,50 €

Tool holder for 3D printer V3.0

1.01 €

gb-22 mini

0,90 €

Printer boxes for Ikea Lack Table

1. 99 €

99 €

Fan duct Sovol SV06 5015 - CFD optimized

3.75 €

ENDER 3 S1, S1 PRO, SPRITE, HOT END DUCT 4020 OR 5015 FAN, NON-OFFSET Y PROBE, ABL BETA ADAPTER

€2.24 -20% 1.79 €

Do you want to support Cults?

Do you like Cults and want to help us continue our journey on our own ? Please note that we are a small team of 3 people, so supporting us in maintaining activities and creating future developments is very easy. Here are 4 solutions available to everyone:

-

AD: Disable your AdBlock banner blocker and click on our banner ads. nine0006

-

AFFILIATION: Shop online with our affiliate links here Amazon.

-

DONATIONS: If you want, you can donate via PayPal here.

-

* INVITE FRIENDS: * Invite your friends, discover the platform and great 3D files shared by the community!

The show must go on: the car dealership that never happened

This year's Geneva Motor Show was an example of an unforeseen but inevitable switch to advanced technology. The old auto industry exhibitions (the same auto show in Switzerland was supposed to open for the 90th time) have long been predicted to end in real life and move to the digital space, but they resisted until the last - more precisely, until the advent of a new type of coronavirus.

Vasily Beloborodov

The organizers of the exhibition announced its cancellation just a couple of days before the start of press screenings, when automakers were already finishing the installation of stands. The largest brands managed to reorganize over the weekend and organize online premieres for the media or public live broadcasts, others simply posted photos and technical descriptions of new products on the Web. And most likely, this approach will be forced to repeat all the auto shows of the coming months that are in global quarantine. Whether you like it or not, you will remember Freddie Mercury's famous song The Show Must Go On, but I would like to add on my own: on the Internet. nine0006

And most likely, this approach will be forced to repeat all the auto shows of the coming months that are in global quarantine. Whether you like it or not, you will remember Freddie Mercury's famous song The Show Must Go On, but I would like to add on my own: on the Internet. nine0006

Traditionally "in Geneva" - although the car companies broadcast from their headquarters around the planet - there was something to see. First of all, the Swiss Motor Show is the main vanity fair of the year in the automotive world, which means that it showed a lot of supercars that competed with each other in juggling the most advanced technological solutions. Electric vehicles of all segments and their alternatives based on other energy sources were prepared, as well as cars from our reality with you, in which they also found something to modernize or at least note with some unworn solution in ergonomics or design. Of more than a hundred world premieres, we will discuss the most interesting ones. nine0006

nine0006

Mega-hypersupercars

The most daring and therefore costly innovative technologies are most easily found in the latest supercars.

3D printer supercar: Czinger 21C

The debut hour of the startup Czinger (the name reads “Zinger”, as the same sewing machine), scheduled for GIMS 2020, has not arrived. It's a pity: in California, another team of specialists, scientists and businessmen came up with a serious supercar. The creators promised that the novelty will break the world speed record, accelerating to 400 km / h and braking to a complete stop in just 29c - now the best indicator in this discipline belongs to the Swedish Koenigsegg.

The developers of the 21C hypercar, "designed for the 21st century", decided to demonstrate the advancement on the production method: the car is built from parts printed on a 3D printer.

Alcohol fuel cells: Roland Gumpert Nathalie

Natalie. So the former Audi manager Roland Gumpert named his new hypercar in honor of his daughter. The main source of energy in Nathalie is a T-shaped battery with a capacity of 190 kWh, and the “spare” generator is an electrochemical generator operating on fuel cells. It seems to be an actively exploited approach, although it has not reached the mass consumer. But there is a peculiarity in Natalie: not hydrogen, but methanol is used as a fuel for generating electricity through a chemical reaction.

So the former Audi manager Roland Gumpert named his new hypercar in honor of his daughter. The main source of energy in Nathalie is a T-shaped battery with a capacity of 190 kWh, and the “spare” generator is an electrochemical generator operating on fuel cells. It seems to be an actively exploited approach, although it has not reached the mass consumer. But there is a peculiarity in Natalie: not hydrogen, but methanol is used as a fuel for generating electricity through a chemical reaction.

Composite Wheels: Zenvo TSR-S

Few people know that Denmark can build cars too, but wealthy fans of the exclusive car industry keep a close eye on Zenvo's limited hypercars. The next modification of the TSR-S has a rear wing capable of changing the angle of inclination when turning the steering wheel to stabilize the car in turns, as well as interesting experiments with carbon fiber. Body panels received a multidirectional combination of fibers that create a geometric pattern; the logo is designed in the same way, which can be colored at the request of the buyer or left neutral. nine0006

nine0006

At the heart of the Zenvo TSR-S are the unique 21" rims made from sliced carbon, each handcrafted within a week! But the savings is 15 kg, and the weight is critical for any sports car.

Fuel cocktail for Greta: Koenigsegg Gemera

In Koenigsegg, the new four-seat (!) Gemera is traditionally called a megacar, since the power of the car exceeds one megawatt - in the usual equivalent for motorists, this means at least 1360 hp. With. The unique engine is capable of running on second-generation bioethanol, Vulcanol methanol and any of their blends, as well as on E85 blends and regular gasoline. When using ethanol, a powerful car turns out to be as innocent in the face of the stern face of Greta Thunberg as an electric car. nine0006

Nanopaint: Bentley Mulliner Bacalar

Looks like more than one car designer has been dreaming about barquettes this year. In the special workshops of the Bentley brand, a division of Mulliner, which has not recently pleased with serious projects, they created another car with this rare type of body. The Continental GT-based Bacalar convertible with luxurious Schedoni panniers in place of the rear seats literally dazzles thanks to the Yellow Flame paint, which has been added with nanoparticles that create a radiant effect. nine0006

In the special workshops of the Bentley brand, a division of Mulliner, which has not recently pleased with serious projects, they created another car with this rare type of body. The Continental GT-based Bacalar convertible with luxurious Schedoni panniers in place of the rear seats literally dazzles thanks to the Yellow Flame paint, which has been added with nanoparticles that create a radiant effect. nine0006

A bag instead of a glove compartment: Aston Martin V12 Speedster

It is even difficult to decide whether this handbag in a British supercar is considered an advanced technological solution or, conversely, a step into the past. But the fact is clear: instead of a glove box, the new Aston Martin supercar has a removable leather handbag.

The designers also made a mistake with the luggage compartment, namely, they divided it into two containers hidden behind the backs of the passengers. It is supposed to remove the included helmets there. There are two riders, and each has a separate cockpit, separated by an impressive wall. In the era of coronavirus, a very thoughtful decision. nine0006

There are two riders, and each has a separate cockpit, separated by an impressive wall. In the era of coronavirus, a very thoughtful decision. nine0006

Formula 1 Roll Bars: Bandini Dora Concept

First of all, this prototype has an incredibly beautiful body: it has no roof, and the windshield is devoid of framing. The resulting design is reminiscent of sports cars from the 1950s. But what about modern approaches to security? The notorious Italians, father and son named Giugiaro, who developed this barchetta under the revived Bandini brand, transferred the load to the front pillars, imitating the safety arcs of formula cars and not connected with the glass itself. Looks very cool. nine0006

Chips in concepts

Concept cars of different car companies, with rare exceptions, use the same chips for many years: now it is an interior without a steering wheel, voice and gesture control, a transformable interior or body, augmented reality instead of a windshield. However, there are some original inventions in the "Geneva" premieres of 2020.

However, there are some original inventions in the "Geneva" premieres of 2020.

Crystal ball: Aiways U6ion

A prototype electric crossover from the Chinese startup Aiways, which the company aimed at Europe, was supposed to be one of the show-stoppers of the exhibition, but it did not work out. The most unusual thing about it is the interaction interface (you can’t just say “control” these days) with a multimedia system. On the front panel, under the windshield, there is a ball that is responsible for recognizing voice commands, face recognition and monitoring driver fatigue and emotional states. nine0006

The rest of the tricks of the interior developers affect mainly the design. As a gear selector, instead of the usual lever, the U6ion has a switch, like on fighters, and the steering wheel has been replaced with a steering wheel.

Music for the engine: BMW i4

Many motorists, even the most quiet and indifferent, like to say that they are excited in the car by the growing roar of the engine. And it is precisely this exciting feature, which is not characteristic of silent electric vehicles, that manufacturers of vehicles with electric motors are fighting for. In the development of the new i4 (the "prototype is still presented in Geneva, but already as close as possible to the conveyor version"), BMW did not leave this moment without attention and invited the composer Hans Zimmer to collaborate. He composed soundtracks for the i4, synthesizing the sounds of the internal combustion engine and the exhaust system, which are broadcast from special speakers. nine0006

And it is precisely this exciting feature, which is not characteristic of silent electric vehicles, that manufacturers of vehicles with electric motors are fighting for. In the development of the new i4 (the "prototype is still presented in Geneva, but already as close as possible to the conveyor version"), BMW did not leave this moment without attention and invited the composer Hans Zimmer to collaborate. He composed soundtracks for the i4, synthesizing the sounds of the internal combustion engine and the exhaust system, which are broadcast from special speakers. nine0006

Pixelated optics: Hyundai Prophecy Concept

Hyundai's prototype Prophecy makes the brain twitch in viscous abstract descriptions like "aesthetic harmony" and "benchmark for the electric vehicle segment of the future." However, this unconditionally beautiful car has an important design element that will go into series on regular Hyundai models almost in its original form. The matrix of LEDs in the optics is designed in the form of pixels, and it looks fresh. There are so-called pixel lamps in the headlights and huge taillights. But two joysticks (for both hands of the driver), which replaced the steering wheel in the prototype, will obviously remain only a fantasy of the interior designer for now. nine0006

The matrix of LEDs in the optics is designed in the form of pixels, and it looks fresh. There are so-called pixel lamps in the headlights and huge taillights. But two joysticks (for both hands of the driver), which replaced the steering wheel in the prototype, will obviously remain only a fantasy of the interior designer for now. nine0006

Salon made from wine waste: Polestar Precept

Swedish electric car startup Polestar, recently spun off from its parent brand Volvo, was about to showcase its first Precept concept car in Geneva. The car looks quite ordinary, if not faceless, even with rear-view cameras instead of side mirrors - such a solution is already found even in mass-produced cars in a number of markets, not to mention the trains of the Moscow Metro, where mirrors have long been replaced by lenses. Seat upholstery is made from winemaking waste and recycled plastic bottles, which is also not a curiosity for a long time. But floor mats woven from old fishing nets are something new. nine0006

But floor mats woven from old fishing nets are something new. nine0006

Two in one: transformer Renault Morphoz

Looking at the promo video of the French company Renault, you might think that a dream has come true: an ordinary crossover with a wave of the hand lengthens, simultaneously increasing the interior. That's how to use the modular platform!

Morphoz prototype electric car body transformation is not an advertising fiction, but the process does not occur as shown in the video. Due to the spacers at the front and rear fenders, the crossover expands in length: the front axle moves forward by 20 cm along with the hood, the rear overhang (and luggage space) is extended by the same 20 cm, that is, the transformation gives +40 cm to the base length 4, 4 m. However, the transformation can only be carried out in a service center, and along the way, the electric motor can be “rocked” from 136 to 218 hp. With. nine0006

With. nine0006

Surprises from stock cars

Due to the unprecedented speed of technology innovation, surprising the user - and the vehicle user in particular - is not at all easy now. It seems like just yesterday we changed the temperature in the cabin with the help of a simple regulator, and now we are flipping through the tracks almost by the power of thought. Moreover, before the implementation of some solutions in serial machines, as mentioned above, they are an eyesore for a long time in numerous extravagant concepts. It was all the more unexpected to discover unique approaches in the conveyor novelties of the failed car show, first of all, to production and repair. nine0006

Cheaper technologies: Citroen Ami

This car is unusual in itself, if only because it is not really a car. It does not require a driver's license to drive, and the minimum driver age is 14 years. The fact is that the budget Ami (6000 euros) is an analogue of scooters and mopeds, although it looks like a real, albeit very small, hatchback, and in terms of comfort it is closer to urban small cars than to two-wheeled ones. The electric motor, as required by local law, develops only 8 hp. With. nine0006

The fact is that the budget Ami (6000 euros) is an analogue of scooters and mopeds, although it looks like a real, albeit very small, hatchback, and in terms of comfort it is closer to urban small cars than to two-wheeled ones. The electric motor, as required by local law, develops only 8 hp. With. nine0006

The French are happy to describe how they managed to make Ami so accessible. Instead of an audio system, there is a holder for a smartphone, and this is still the easiest find! There are no power windows: half of the glass in the side windows of the two-door simply leans outward like a window. To simplify production and repair, both doors are exactly the same, and in order to place them in the car, they wised up with the configuration: the driver's door opens in the usual way, and the right passenger door opens in the opposite direction. The bumpers are also interchangeable, only the front headlights are inserted into the front, and the lights into the rear. nine0006

Seats made from old bottles: Audi A3

Audi A3 premium golf hatchback is one of the most “simple” models in the entire line of the German brand, despite its undeniable quality factor and pleasant character traits. Russian buyers are unlikely to be worried about this, but Europeans will appreciate the package, which provides seat upholstery made of recycled plastic. From old bottles (their share in the composition of the fabric reaches 89%), a coating was obtained that is comparable to textiles by touch and quality. True, the color is somehow not very successful - either yellow-gray or black-gray, but in the future they promise to expand the palette. nine0006

Russian buyers are unlikely to be worried about this, but Europeans will appreciate the package, which provides seat upholstery made of recycled plastic. From old bottles (their share in the composition of the fabric reaches 89%), a coating was obtained that is comparable to textiles by touch and quality. True, the color is somehow not very successful - either yellow-gray or black-gray, but in the future they promise to expand the palette. nine0006

The manufacturer emphasizes that at least 107 1.5-liter plastic bottles get new life in the cabin of one A3. And soon it will be available in all Audi models.

Alas, most of the planned premieres failed. Not all companies were able or willing to quickly organize online shows, and many simply did not begin to reveal their new products without spotlights and burning eyes of the public. We never saw the promised electric Mercedes-Benz EQA, Toyota's compact low-cost crossover based on the Yaris, the Aston Martin Vantage roadster with the fastest retractable roof on the planet.