What lies ahead for 3d printing

What Lies Ahead for 3-D Printing? | Science

The Wake Forest Institute for Regenerative Medicine prints ear, nose and bone scaffolds that can be coated with cells to grow body parts. Laurie RubinWandering the brightly lit halls of the 3D Systems’ plant in Rock Hill, South Carolina, I gaze upon objects strange and wondrous. A fully functioning guitar made of nylon. A phalanx of mandibles studded with atrocious-looking teeth. The skeleton of a whale. A five-color, full-scale prototype of a high-heeled shoe. Toy robots. And what appears to be the face of a human fetus. “That was made from an ultrasound image,” Cathy Lewis, the company’s chief marketing officer, tells me, shrugging.

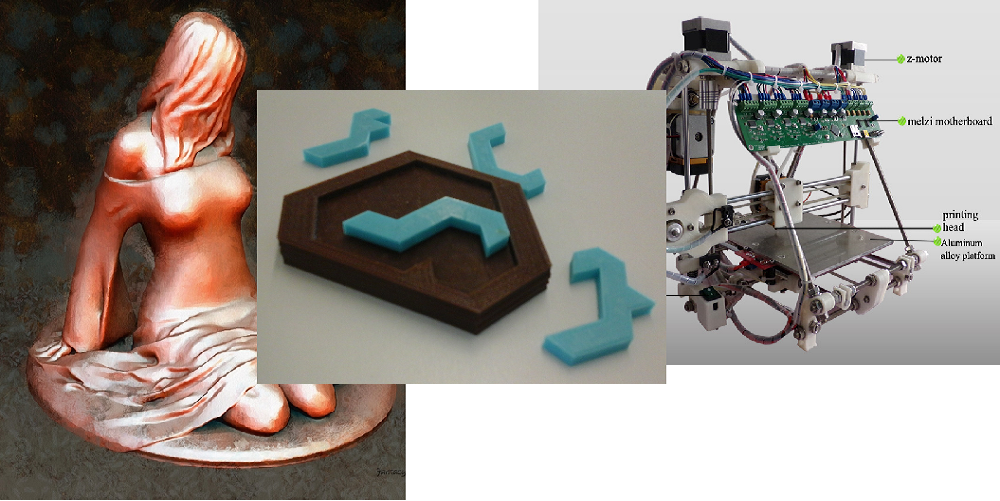

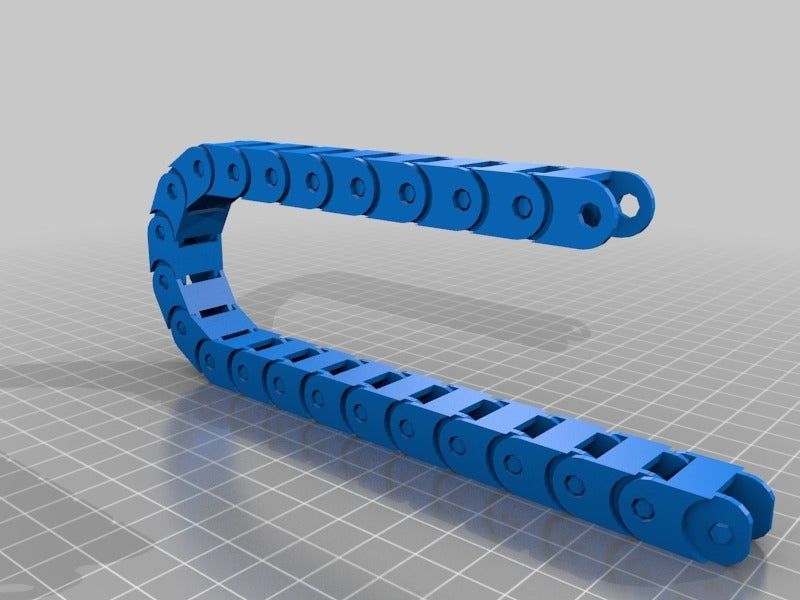

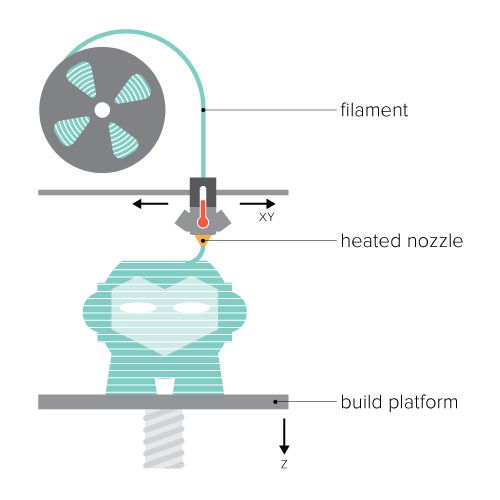

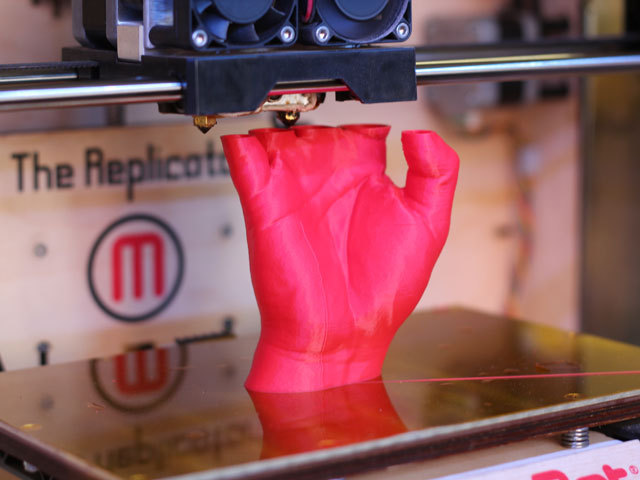

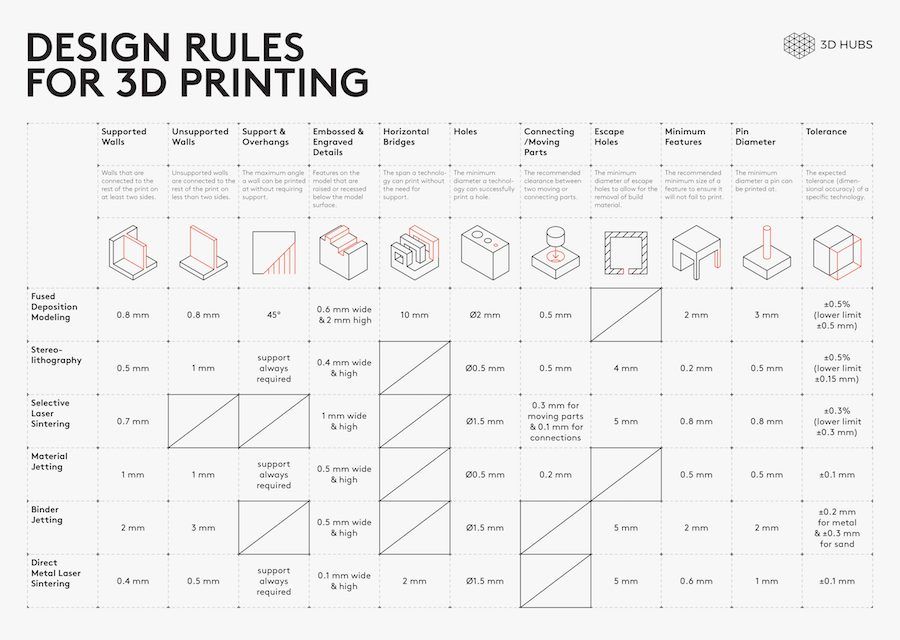

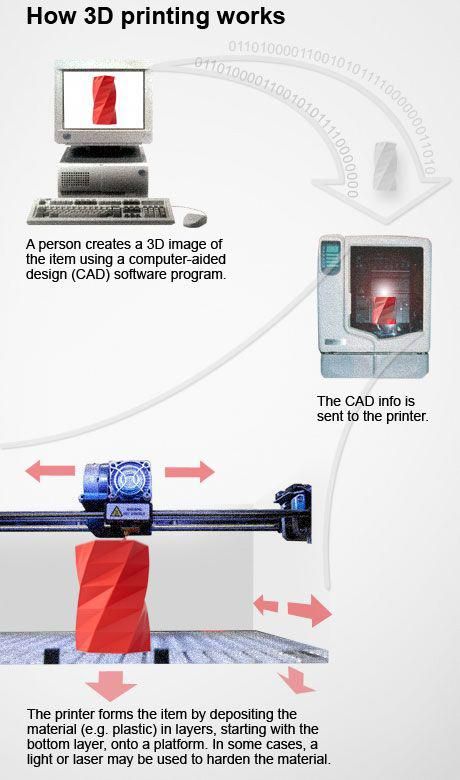

This collection of objects shares one feature: All were “printed” by machines that, following instructions from digital files, join together layer upon layer of material—whether metals, ceramics or plastics—until the object’s distinctive shape is realized. The process is called 3-D printing (or additive manufacturing, in industrial parlance) and if you haven’t heard of it by now, you haven’t been paying enough attention to scores of breathless news stories and technology blogs—or to President Barack Obama, who declared in his most recent State of the Union address that 3-D printing “has the potential to revolutionize the way we make almost anything.”

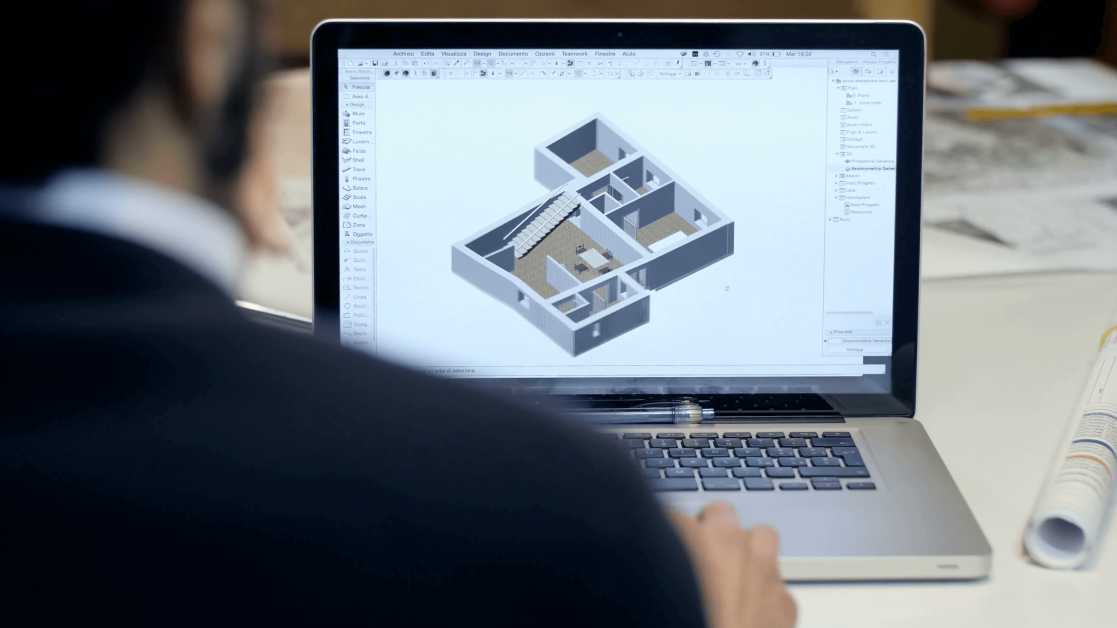

While many people only now are hearing about the technology, engineers and designers have been using large and expensive 3-D printers for nearly three decades, making rapid prototypes of parts for aerospace, defense and automotive companies. Over the years, however, digital design software has matured, scanners have become ubiquitous and affordable desktop printers have come within reach of self-starting entrepreneurs, schools and home tinkerers. Technologists boisterously proclaim that 3-D printing will democratize design and free us from the hegemony of mass manufacturing.

But just because anybody’s ideas can take shape doesn’t necessarily mean they should—a notion that struck me in 3D Systems’ lobby, where I saw shelf after shelf of what some people try very hard not to describe as cheap plastic crap: brightly colored miniature vases, phone cases, jewelry, dolls and, inevitably, skulls. (On just one 3-D file-sharing site, I found 101 designs for skull rings and pendants.) The creator of these lobby tchotchkes? The Cube, manufactured by 3D Systems.

(On just one 3-D file-sharing site, I found 101 designs for skull rings and pendants.) The creator of these lobby tchotchkes? The Cube, manufactured by 3D Systems.

“This is our consumer strategy,” Lewis explains to me, pointing toward a group of pink, turquoise and lime-green printers. The Cubes are the size of a Mr. Coffee machine, shiny and smooth, and have an on-off switch, a port for a thumb drive and a price tag of $1,299. Cubes create objects through a material extrusion process, in which a print head deposits and stacks thin layers of molten plastic onto a platform. The process begins when users load their digital design into the Cube, whose software helps them scale their model up or down and automatically adds support structures if they’re needed. (Supports are made of the same plastic as the machine prints, and they pop off.) Then the Cube “slices” the digital object into microns-thick horizontal layers, creating a blueprint that the print head will follow, moving on x and y axes.

The Cube can create objects in 16 different colors, but it can print only one color at a time (no cartridge switching mid-print). To make a toy robot or a skull ring in more than one color during a single printout, you’ll need a CubeX Duo, which costs more than twice as much but has two print cartridges that automatically turn colors off and on—a great leap forward in the eyes of desktop printing aficionados.

Perhaps sensing my ambivalence toward this device, Lewis leads me into a glass-walled manufacturing room to see the company’s big guns: a brace of refrigerator-size machines fronted with small windows and surrounded by monitors, keypads and CPUs. Electrical cables snake overhead, Shop-Vacs are ubiquitous and the floor is slippery with powdered nylon. Squinting and shielding my eyes from glare, I stare through the small window of a stereolithography machine, in which a vat filled with a photosensitive polymer is repeatedly blasted by a laser, triggering a chemical reaction that causes a thin layer of the viscous dark blue liquid to harden. Seconds pass, horizontal lightning flashes and a wiper distributes another layer of the resin.

Seconds pass, horizontal lightning flashes and a wiper distributes another layer of the resin.

Each layer is 50 microns thick, which is equal to one-twentieth of a millimeter. (The thinner the layers, the finer the resolution and the crisper the details.) The finished object rises while its build bed, or platform, sinks. What was this printer—which costs $170,000—producing? Lewis consults a monitor and surmises it’s jewelry, a ring of intricate design. I note that it’s a lot of machine to make a bauble, but Lewis assures me that technicians usually build more than one bauble at a time.

She shows me another windowed machine. This time the vat is filled not with dark blue liquid but white powdered nylon. A wiper smoothes the vat’s surface, upon which a laser lightly etches the outlines of four rings and a miniature boomerang by fusing together the powdered material (a process known as sintering). The wiper swipes again, erasing the shapes, the laser flashes, and another layer of rings and a boomerang is sintered. The monitor tells us this project is four inches high after 26 hours of sintering, with many hours to go. The “reveal” won’t come until the excess powder is excavated and the product exhumed. It might be a drone, it might be a cast for an engine block. Lewis can’t say (it’s definitely not a boomerang). But she knows this part will be as durable as whatever traditionally manufactured part it’s replacing.

The monitor tells us this project is four inches high after 26 hours of sintering, with many hours to go. The “reveal” won’t come until the excess powder is excavated and the product exhumed. It might be a drone, it might be a cast for an engine block. Lewis can’t say (it’s definitely not a boomerang). But she knows this part will be as durable as whatever traditionally manufactured part it’s replacing.

My tour ends where it began, among the plastic robots and phone cases. In two hours, the history of additive manufacturing has passed before my eyes, starting with technical applications and ending in homes and offices—not unlike the trajectory of computers and laser printers. With the ability to replicate or create such objects on demand, says Dale Dougherty, publisher of Make magazine—part of the burgeoning DIY “Maker Movement” that privileges customization over commodities—the 3-D printer is “Wal-Mart in the palm of your hand.”

***

That notion may thrill or horrify you, but the business model—on-demand printing of customized products—has significant advantages over traditional retailing models. If you can quickly and cheaply replace a broken cabinet handle by printing it at home (or scanning what you want and e-mailing those specs to a print shop), you needn’t travel to a store and stores needn’t keep millions of everything on hand. Shoe designs could be encoded as digital templates that could be manipulated and printed to perfectly fit any customer’s feet. Inventories would shrink, along with transportation, handling and storage costs. (Retail shops might even disappear if orders can be fulfilled directly by manufacturers who deliver to their customers’ homes.) And if supply lines are less dependent upon manufacturing centers abroad, they’re also less vulnerable to interruption.

If you can quickly and cheaply replace a broken cabinet handle by printing it at home (or scanning what you want and e-mailing those specs to a print shop), you needn’t travel to a store and stores needn’t keep millions of everything on hand. Shoe designs could be encoded as digital templates that could be manipulated and printed to perfectly fit any customer’s feet. Inventories would shrink, along with transportation, handling and storage costs. (Retail shops might even disappear if orders can be fulfilled directly by manufacturers who deliver to their customers’ homes.) And if supply lines are less dependent upon manufacturing centers abroad, they’re also less vulnerable to interruption.

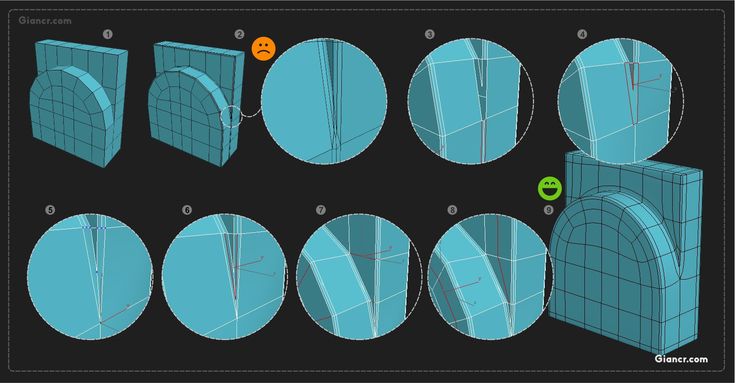

In conventional manufacturing, every increase in design complexity costs money and time. With additive manufacturing, it’s as easy to print a simple tube as it is to print, say, a double helix wrapped in a spiral staircase draped by a spider web. High-resolution printers can even make products with gears and hinges.

Shapeways, a 3-D printing service, has built its business upon the assumption that a sizable demographic is willing to pay more for customized products than for mass-manufactured goods. The company fulfills design orders from tens of thousands of customers, or “community members,” at plants in the Netherlands and in Long Island City, New York, using printers that handle a variety of materials, including ceramics, sandstone, plastics and metals.

“We’re giving people access to million-dollar machines,” Elisa Richardson, Shapeways’ PR and social media manager, says. “We’re enabling them to run businesses through our company.” And what do those businesses sell? “Mostly cultish things, like Minecraft models and Dungeons & Dragons dies.” Ah, I think: We’re back to the skull rings. “Are customers requesting prints of anything truly surprising?” I ask. Richardson pauses, then says, “It’s amazing how unsurprising the stuff we make is. It’s a doorknob or a crib part from a mom in suburbia. ”

”

Clearly, 3-D printing is a boon to personal consumption, but the machines can potentially provide great social value as well. Imagine villages in the developing world printing parts for farm equipment or water pumps, and the solar panels that drive them. Imagine mobile production plants quickly deployed in disaster zones, printing out anything from arm splints to tent stakes.

In the future, suggests Peter Friedman, publisher of the Innovation Investment Journal, car dealers might include free printers with vehicles, so that owners can make their own parts, replacing and redesigning forever. “3-D printing is not just the future of making things you don’t have,” he wrote in a column. “It’s the future of making things that you do have immortal.”

One of those things might even be the human body—or at least some of its parts.

***

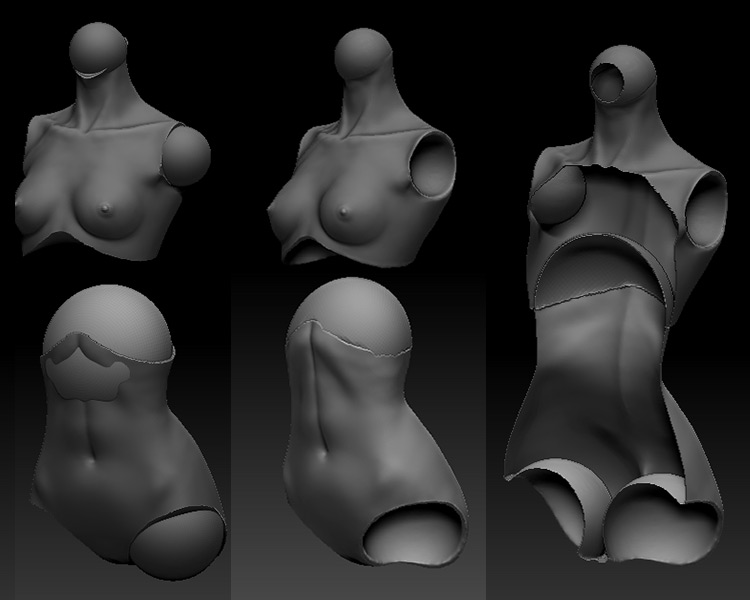

Carlos Kengla, a slim young man wearing statement eyeglasses and a four-inch-long soul patch, could easily pass for a hipster Maker of small-batch bourbon or bespoke bicycles. But Kengla has spent the last few years focusing on the production of ears, which he prints using cells that are taken from human ear cartilage and then propagated in the lab. Kengla’s fellow scientists at the Wake Forest Baptist Medical Center’s Institute for Regenerative Medicine are developing, in collaboration with other labs, processes to systematically print muscle tissue, skin, kidneys, cartilage and bones. For years, researchers have been building organs by hand, pipetting progenitor cells—which have the capacity to differentiate into specific types of cells—onto degradable scaffolds. They’ve had varying levels of success: Handmade bladders have been functioning in a handful of patients for many years; a miniature kidney implanted in a cow successfully excreted urine. But constructing organs by hand is laborious and plagued by human error. Rapid prototyping, with cartridges of cells squirting from a print head and guided by a computer, Kengla says, “is faster and more precise, to the micron.

But Kengla has spent the last few years focusing on the production of ears, which he prints using cells that are taken from human ear cartilage and then propagated in the lab. Kengla’s fellow scientists at the Wake Forest Baptist Medical Center’s Institute for Regenerative Medicine are developing, in collaboration with other labs, processes to systematically print muscle tissue, skin, kidneys, cartilage and bones. For years, researchers have been building organs by hand, pipetting progenitor cells—which have the capacity to differentiate into specific types of cells—onto degradable scaffolds. They’ve had varying levels of success: Handmade bladders have been functioning in a handful of patients for many years; a miniature kidney implanted in a cow successfully excreted urine. But constructing organs by hand is laborious and plagued by human error. Rapid prototyping, with cartridges of cells squirting from a print head and guided by a computer, Kengla says, “is faster and more precise, to the micron. It allows us to place different types of cells in specific shapes and in intricate patterns.”

It allows us to place different types of cells in specific shapes and in intricate patterns.”

Kengla stares into a computer monitor, clicks through what seems like a hundred menus and initiates three cartridges loaded into a print head that hovers over a petri dish atop a small platform. One cartridge contains cartilage cells, another contains biodegradable scaffold material and the third contains a water soluble gel, which temporarily provides support until it’s later washed away. Back and forth the print head shuttles with a pneumatic whoosh, switching between the cartridges, constructing the organ in stacked, successive layers, each 150 microns thick. A high-intensity light and microscope allow Kengla to follow the machine’s progress on a monitor. After 45 minutes, the shape of an ear begins to emerge.

Perfection remains a few years in the future. Still, the printing of organs—and cartilage and skin and tissue—holds great promise for transforming health care and extending longevity. Transplanted organs created from a patient’s own tissues won’t be rejected. Waiting times for kidneys and other donor organs will decrease, and organ traffickers could be put out of business (the World Health Organization estimates there were almost 11,000 organs sold on the black market in 2010). Prescription drug companies are eager to test drugs and other therapies on rapidly prototyped organs or tissue, instead of on animals or human beings.

Transplanted organs created from a patient’s own tissues won’t be rejected. Waiting times for kidneys and other donor organs will decrease, and organ traffickers could be put out of business (the World Health Organization estimates there were almost 11,000 organs sold on the black market in 2010). Prescription drug companies are eager to test drugs and other therapies on rapidly prototyped organs or tissue, instead of on animals or human beings.

Anthony Atala, who leads the Institute for Regenerative Medicine, predicts that it’s only a matter of years before hospitals have machines that can print skin—from subcutaneous fat up through keratinocytes to hair follicles, oil glands and melanocytes—directly onto a patient’s body. “Skin is the least complex organ,” Atala says. “Then we’ll see tubular structures, then hollow and then non-hollow organs.” Including, eventually, a heart? “I hope in my lifetime,” he says, laughing. “And I’m still very young.” (Atala is 54.)

***

Dealing with complexity is what additive manufacturing is best at. Engineers for Lotus Renault GP, in pursuit of lighter, faster and more fuel-efficient Formula 1 race cars, use stereolithography and laser sintering to experiment with cooling ducts and fins, eliminating material that’s inessential to function. And the process is quick. Pat Warner, Lotus Renault GP’s advanced digital manufacturing manager, says he can turn around parts in two days instead of ten weeks.

Engineers for Lotus Renault GP, in pursuit of lighter, faster and more fuel-efficient Formula 1 race cars, use stereolithography and laser sintering to experiment with cooling ducts and fins, eliminating material that’s inessential to function. And the process is quick. Pat Warner, Lotus Renault GP’s advanced digital manufacturing manager, says he can turn around parts in two days instead of ten weeks.

It’s high-end applications like this that have raised 3-D printing’s public profile. “The aviation industry has more than 22,000 printed parts flying right now, and people are walking on 3-D printed orthopedic implants,” says Terry Wohlers, the president of the independent consulting firm Wohlers Associates. “These are very regulated, very demanding industries and these parts are performing well.”

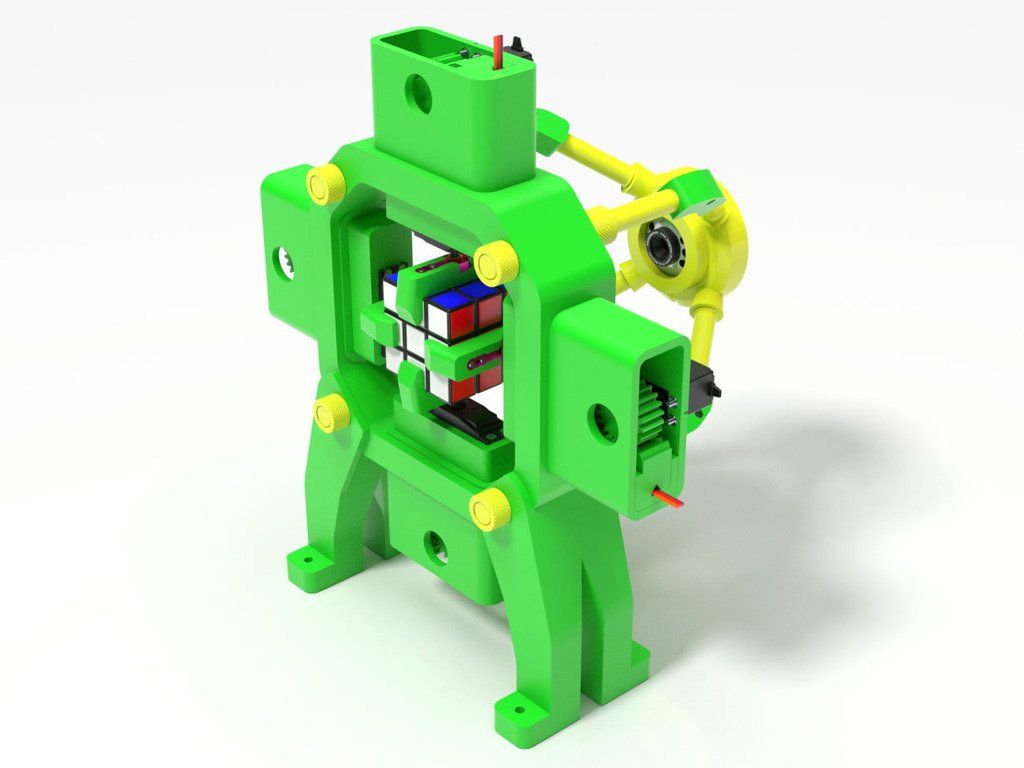

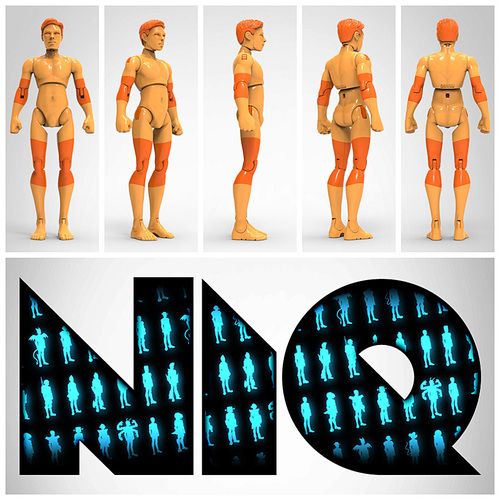

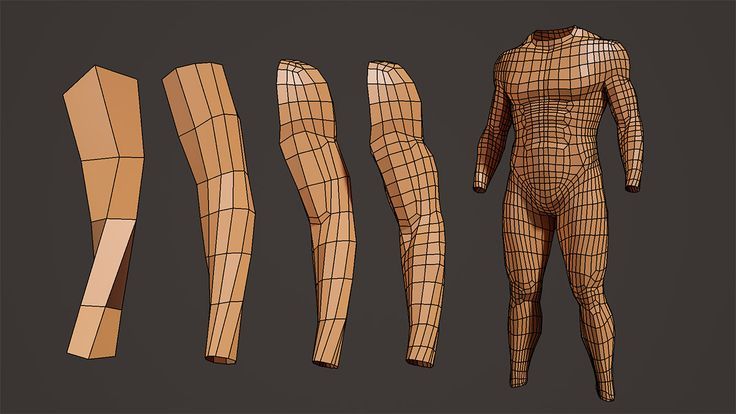

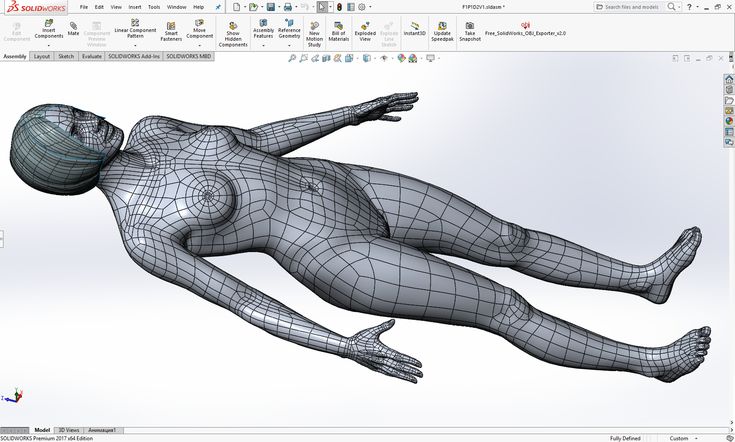

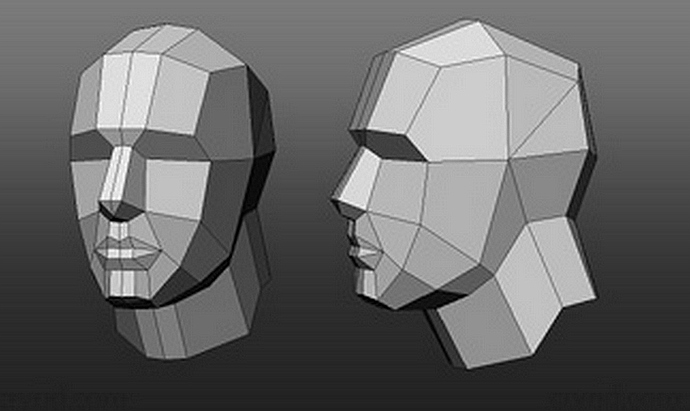

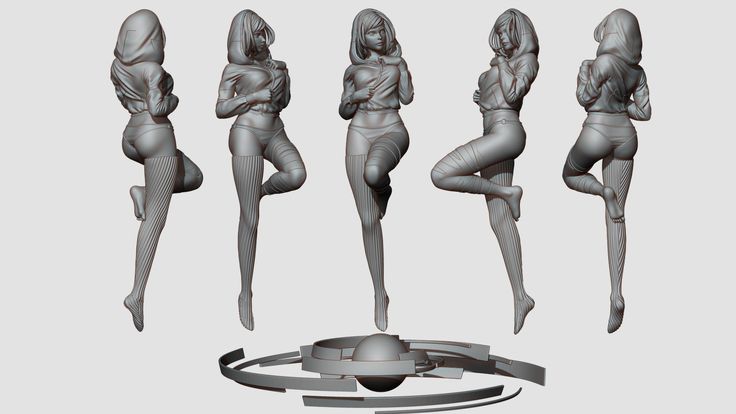

Canadian designer Jim Kor is building a three-wheeled, teardrop-shaped car that weighs just 1,200 pounds. Kor shaves weight by combining multiple parts. The dashboard, for example, is printed with ducts attached, eliminating the need for multiple joints and their connecting plastic and metal parts. Somewhat less dramatically, bakers are extruding icing from print heads to decorate cakes; stop-motion animators are using rapid-prototyping 3-D printers to create thousands of nuanced facial expressions for film characters; mathematicians use the technology to model complex geometric shapes; and 3-D photo booths are scanning people and printing miniature replicas of their heads or entire bodies.

Somewhat less dramatically, bakers are extruding icing from print heads to decorate cakes; stop-motion animators are using rapid-prototyping 3-D printers to create thousands of nuanced facial expressions for film characters; mathematicians use the technology to model complex geometric shapes; and 3-D photo booths are scanning people and printing miniature replicas of their heads or entire bodies.

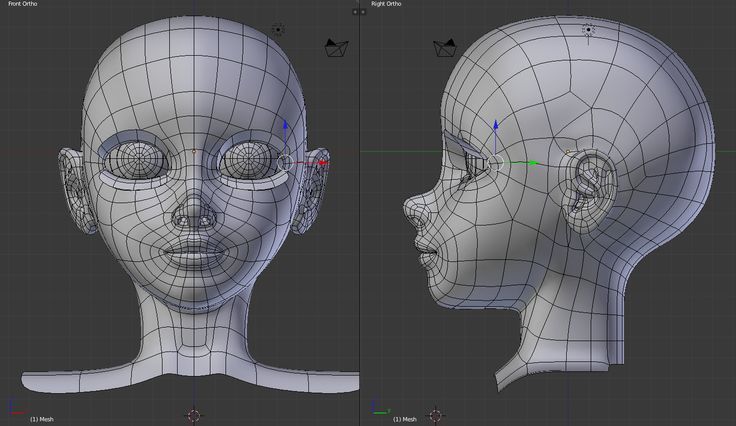

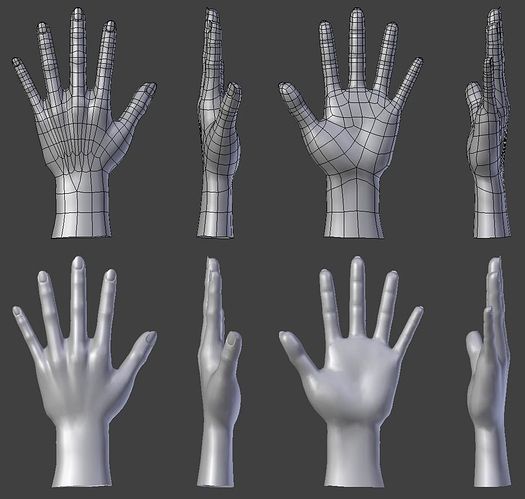

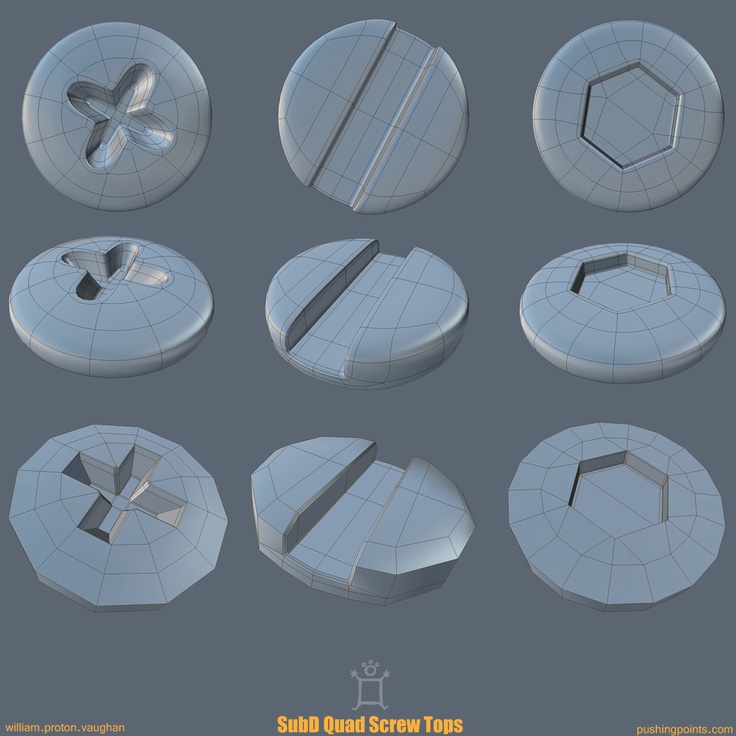

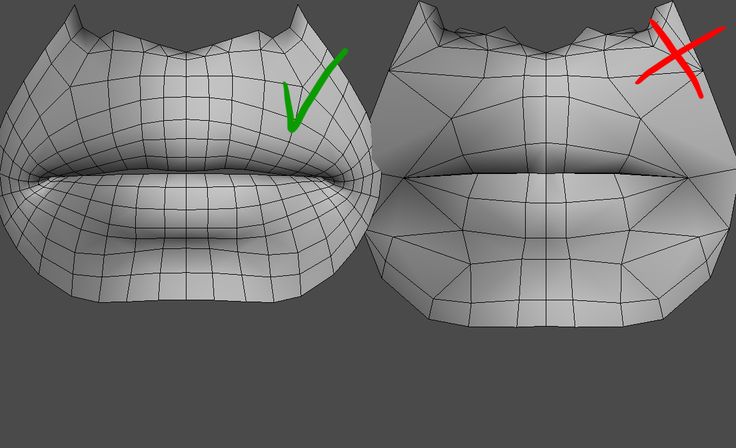

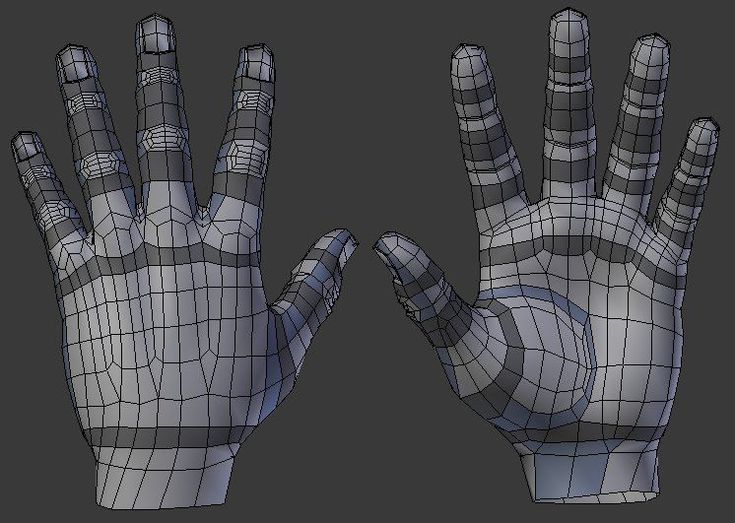

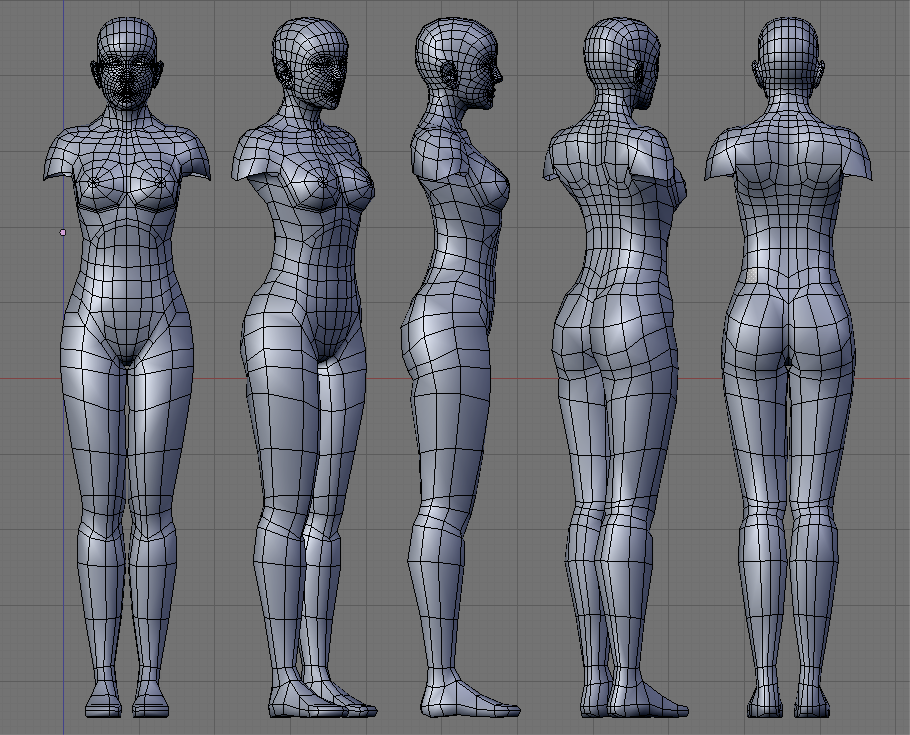

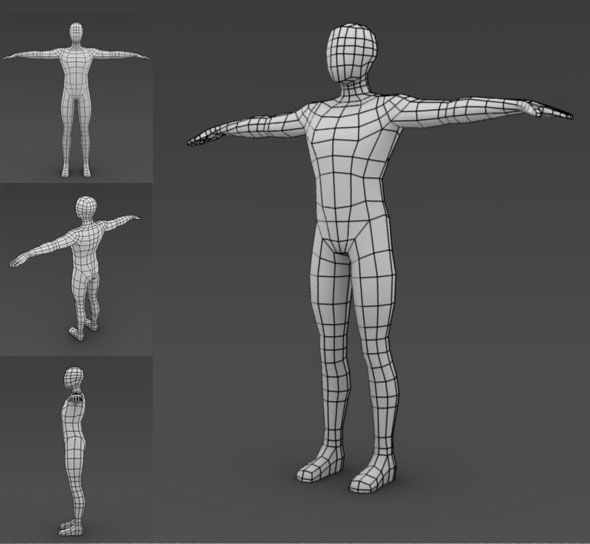

Additive manufacturing would not have flowered without major advances in computer-directed modeling. A decade ago, it took weeks to generate a digital 3-D model; now it takes only hours. Design software has become more accessible, and scanners, too, have become more powerful and easier to use—even at home. This past March, Microsoft announced a forthcoming software release that will endow its Kinect for Windows computer sensor with the ability to quickly create detailed 3-D models of people and objects.

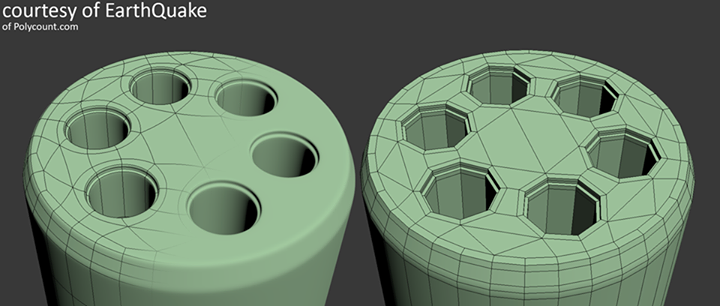

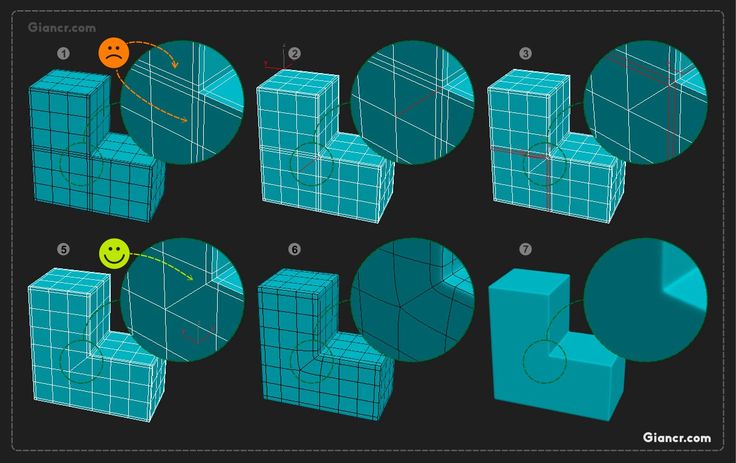

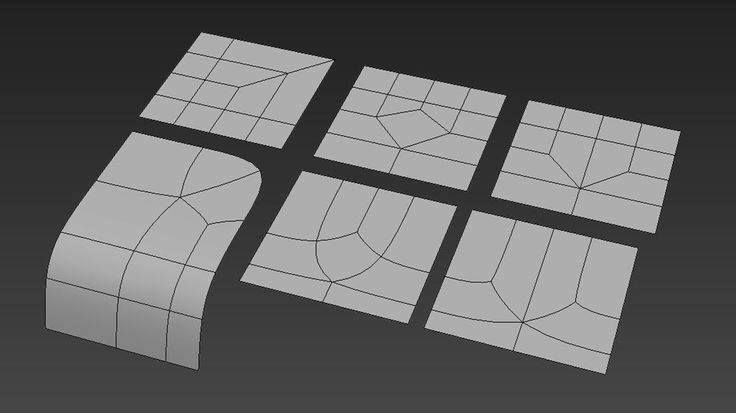

Engineers and product designers scan an existing object or contour by shooting thousands of points of light at it and loading the “point cloud”—a 3-D ghost image of the original—into a computer. Multiple scans are aligned and filtered, points are connected to their near neighbors to form polygons, holes are filled and blemishes removed. Finally, with a click of the mouse, the surface of the image is smoothed to form a shrink-wrapped version of the original. Off to the printer the digital file goes.

Multiple scans are aligned and filtered, points are connected to their near neighbors to form polygons, holes are filled and blemishes removed. Finally, with a click of the mouse, the surface of the image is smoothed to form a shrink-wrapped version of the original. Off to the printer the digital file goes.

And if the client doesn’t like the finished print? Not a big deal: The supply chain is a computer file, not parts from around the world, and there’s no need to retool machines to make design changes. The trajectory from idea to approval to manufacturing to marketing to sale is, again, vastly accelerated.

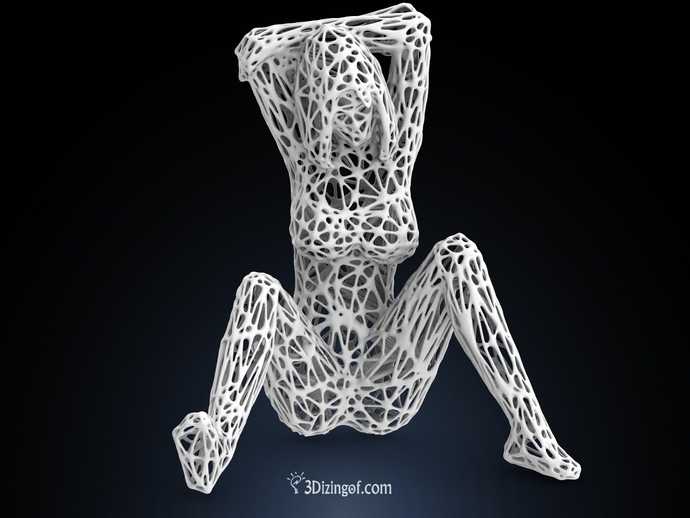

“Once a shape is in a usable 3-D format, the sky’s the limit,” says Rachael Dalton-Taggart, director of marketing communications for Geomagic, a pioneer in sculpting, modeling and scanning software. The company’s products include software that gives digital designers tactile feedback. Wielding a penlike, haptic device—which has motors that push back against the user’s hand—designers can trace the contours of a digital model, feel its surface textures and carve shapes. “It’s like working in digital clay,” says Dalton-Taggart. “The program lets designers create particularly complex and highly detailed organic shapes,” whether for sculptural jewelry or patient-specific medical implants, such as a perfectly modeled prosthetic nose.

“It’s like working in digital clay,” says Dalton-Taggart. “The program lets designers create particularly complex and highly detailed organic shapes,” whether for sculptural jewelry or patient-specific medical implants, such as a perfectly modeled prosthetic nose.

The opportunities for customization have long made additive manufacturing appealing to the medical community. Biomedical companies commonly use 3-D modeling and printing to produce personalized hearing aids as well as dental restorations, orthodontic braces—and most recently, skulls. This past March, after FDA review, an unnamed patient had 75 percent of his skull replaced by a plastic implant printed by the Connecticut-based Oxford Performance Materials.

***

From organs to O-rings, 3-D printing has prognosticators buzzing over its transformative, and even disruptive, potential. If the technology fulfills the predictions of its most ardent cheerleaders, supply lines that connect mass manufacturers in cheap labor markets with consumers in the developed world will be shortened. Mass manufacturing in low-wage countries will decline and markets will be re-localized. With a lower bar between innovating and producing, thousands of new businesses are expected to blossom.

Mass manufacturing in low-wage countries will decline and markets will be re-localized. With a lower bar between innovating and producing, thousands of new businesses are expected to blossom.

But the growth of this technology raises a thicket of legal questions. Who is liable if a home-printed design fails to perform? Who owns the intellectual property of codes and the objects they produce? (Physical objects can be trademarked and patented, and digital 3-D files can be copyrighted, but in the Maker universe this is considered uncool and counterproductive to innovation.) Three-D printing is bound to encourage counterfeiting, with serious consequences for brand owners. Disney, whose characters are widely copied by Makers, is so far ignoring infringements, but that may change.

Then there are security concerns. Using blueprints downloaded from the Internet, people already have begun printing gun parts. Hackers have stolen personal banking information after creating a widget that fits inside an ATM. As ever, tools can be used for good as easily as for ill. It will be up to myriad government agencies to address the wide spectrum of legal and criminal concerns.

As ever, tools can be used for good as easily as for ill. It will be up to myriad government agencies to address the wide spectrum of legal and criminal concerns.

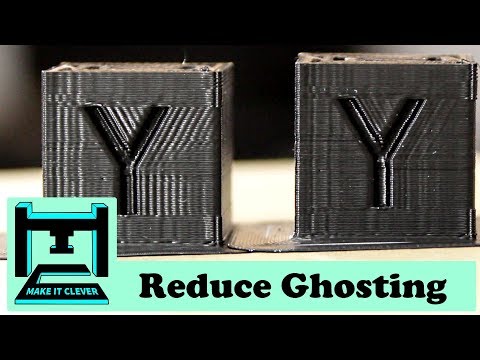

And all new technology produces winners and losers. Additive manufacturing will create new industries and new jobs. But it may also displace skilled craftspeople, artisans and designers who work with raw materials, just as Amazon displaced bookstores, and desktop printers eviscerated mom and pop copy shops. Thanks to the Internet, we are all writers, photographers, filmmakers, publishers and publicists. Soon, we may all be Makers, too. Those who rue that day can take some comfort, for now, in 3-D printing’s weaknesses: The printers can produce objects only as big as their build platforms; and most desktop machines print only in one or two materials, which are fragile compared with those produced by the high-end industrial machines. And, unlike industrial printers, desktop models lack standardization, so different machines using the same design files won’t necessarily produce identical objects. (The National Institute of Standards and Technology is currently helping to develop standards for the industry.)

(The National Institute of Standards and Technology is currently helping to develop standards for the industry.)

***

Throughout my travels in 3-D, cognitive dissonance stalked me. One can intuitively grasp that additive manufacturing has a smaller resource footprint than subtractive manufacturing, in which designs are chipped or cut away from larger blocks of material. Shorter supply chains have smaller carbon footprints, and printing on demand could reduce the waste of closeouts, overstocks and other products that never get bought. But the feedstock of 3-D printers—whether plastics or gypsum powders or metals—still needs to travel the world. Moreover, ABS plastic, the principle feedstock of desktop printers, is derived from oil or gas, which are both finite, polluting resources. (PLA, another common feedstock, is made from corn, which also has a sizable environmental footprint since it requires fertilizer, pesticides and irrigation.) 3D Systems’ Cathy Lewis stresses the recyclability of ABS and PLA, but most communities don’t accept or collect these materials for processing, and I doubt that many customers are likely to mail their unwanted Cube creations to South Carolina for re-milling.

More important, I worry that the ease and relative affordability of making niche or customized products—with the exception of medical and some industrial applications—is just as likely to speed their disposal: Easy come, easy go. When new sneaker designs move from idea to retail shelves in weeks instead of months, design fatigue may set in sooner as well. The result? Ever more sneakers on the trash heap of fashion obsolescence, and a devaluing of the creativity that went into producing them.

While 3-D printing offers the promise of democratizing design, it does so by letting Makers off the intellectual hook as they bypass deep knowledge of materials and process. As Chris Anderson, the former editor of Wired Magazine, writes in his book Makers: The New Industrial Revolution, “You don’t need to know how the machines do their work, or how to optimize their toolpaths. Software figures all that out.” That might not bode well for the future. Designing and producing only on computers, says Scott Francisco, an architectural theorist and designer who teaches at Parsons The New School for Design in New York, has the potential “to drown human learning, creative skills and even basic productivity with its information and numerical-technical approach to problem solving. ” Sure, the machines themselves are innovative, but they reduce the need for designers to work face to face with collaborators—crafting and refining, one slow iteration after another. The next generation of designers, Francisco fears, will know little about how real materials look, feel and interact with each other, leaving people ill-prepared to be innovators in their own right.

” Sure, the machines themselves are innovative, but they reduce the need for designers to work face to face with collaborators—crafting and refining, one slow iteration after another. The next generation of designers, Francisco fears, will know little about how real materials look, feel and interact with each other, leaving people ill-prepared to be innovators in their own right.

Such worries may be premature, for 3-D printing has yet to reach either its “killer app” moment—which makes it as ubiquitous as home computers—or its “rubber ducky” moment, when it supplants mass manufacturing. Traditional methods of production in low-wage countries are still far faster and cheaper than additive manufacturing when large numbers of parts are needed, says Innovation Investment Journal’s Peter Friedman. And while Geomagic co-founder and CEO Ping Fu has predicted that “mass customization” will replace mass production, even matching it in costs, one can’t help feeling, gazing at a set of metal mixing bowls (to name just one household item), that customization isn’t always called for.

Yes, additive manufacturing is being used to create prosthetics and aircraft components—products that epitomize the technology’s sweet spot of low volume and high complexity. But for the vast majority of people, 3-D printing may remain an upstream, out-of-sight industrial process. Only the technorati, with cash to burn and a burning desire to Make, are likely to pursue desktop printers. Anyone else compelled to own a 3-D-printed skull ring will find easy satisfaction perusing the many on offer through print bureaus. Some of them are even anatomically correct.

Facial replicas at 3D Systems. Animators have begun using the technology to create faces with multiple expressions. Laurie Rubin A 3-D printer can construct nose scaffolding—simultaneously embedding it with cells that will later grow into tissue. Laurie Rubin Prêt-à-printer? A dress made from 17 printed parts, designed by Michael Schmidt and Francis Bitoni. Shapeways The Wake Forest Institute for Regenerative Medicine prints ear, nose and bone scaffolds that can be coated with cells to grow body parts. Laurie Rubin

Laurie Rubin Prêt-à-printer? A dress made from 17 printed parts, designed by Michael Schmidt and Francis Bitoni. Shapeways The Wake Forest Institute for Regenerative Medicine prints ear, nose and bone scaffolds that can be coated with cells to grow body parts. Laurie Rubin Recommended Videos

What Lies Ahead for 3D Printing?

3D design and printing technology has advanced at an alarming rate. We can now print complex objects from different materials, in different colors, in rapid time — even in the comfort of our own homes.

Then there’s the varied commercial applications for 3D printing (3DP). One survey of US manufacturers found that two out of three companies are already adopting 3DP in some way. Some of these companies include General Electric, Nike, Airbus, Amazon, Hasbro, Hershey’s, Boeing, and Ford. And we hear countless stories of 3D-printed houses, cars, aircraft components, musical instruments, shoes, robots, and body parts, just to give a few examples.

Some of these companies include General Electric, Nike, Airbus, Amazon, Hasbro, Hershey’s, Boeing, and Ford. And we hear countless stories of 3D-printed houses, cars, aircraft components, musical instruments, shoes, robots, and body parts, just to give a few examples.

Given these developments, the question arises: What lies ahead for 3D printing?

As 3D printing becomes a common tool to the next generation, we will see more design that use 3D printing to optimize products.

3D Printing: An Alternative (or Accessory) to Conventional Mass Production

Barack Obama is quoted as saying that 3D printing “has the potential to revolutionize the way we make almost anything.” That is certainly true. And a lot has changed in the five years or so since those words were uttered. In fact, improvements in 3D print efficiency, and the reduction of associated costs, means that 3D printing is now a powerful competitor to conventional mass production.

As an article published by Forbes highlights: “3D printing is an unstoppable force. Not too long ago, the printing speed and limited output of 3D printers made them suitable only for rapid prototyping. But in the coming years, 3D printers will be at the heart of full-scale production capabilities in several industries… Manufacturing as we know it will never be the same.”

Not too long ago, the printing speed and limited output of 3D printers made them suitable only for rapid prototyping. But in the coming years, 3D printers will be at the heart of full-scale production capabilities in several industries… Manufacturing as we know it will never be the same.”

Consider an example. According to an article by The Economist, the sporting goods manufacturer Adidas intends to make 3D-printed soles for its shoes at two new, highly automated factories, so it can bring their shoes to market faster and keep up with fashion trends. This is a significant improvement because, as the article relates, “getting a design to the shops can take months. The new factories, each of which is intended to turn out up to 500,000 pairs of trainers a year, should cut that to a week or less.”

As this example shows, the limitations normally associated with commercial 3D printing, namely, high production costs and slow turnover, are being eliminated as technology improves.

Of course, whether 3D printing meets a company’s manufacturing needs depends on the specific design and application. Nevertheless, all indications are that the use of 3D printing will continue to grow. The materials used are getting more diverse, costs are going down, and new approaches to 3D printing are leading to further improvements.

SelfCAD is cloud-based CAD software that works towards wide adoption of user-friendly drafting.

3D CAD an Integral Part of Manufacturing

Whether it be using traditional or state-of-the-art technologies, 3D CAD is at the heart of the manufacturing industry. Why? Because the 3D design process and prototype testing occur well before full-scale production takes place. So, having the 3D CAD skill set is certainly an asset.

Some CAD companies are creating user friendly, easy-to-learn, cloud-based, all-in-one 3D design and printing software packages for students and home learners. As 3D printing will continue to grow, acquiring 3D CAD skills with these easy-to-access, free or affordable CAD packages is a worthwhile venture.

Tyler Berrigan is a professional writer specializing in 3D printing, STEM, and education.

prospects, development and future of 3d printers

3D printing is an extremely promising technology that can change the way many things are made. In addition, the use of 3D printers will significantly reduce the production time of various products and reduce their final cost. Let's consider in which areas the use of 3D printing is most promising, what is the future of this technology and how quickly it will develop.

Relevance of 3D printing

3D printing technology is relevant due to its ease of use and saving time spent on the production of various types of products.

Printing of 3D objects also provides high-precision reproduction of the necessary shapes and details of a particular object. At the same time, manual labor is practically reduced to zero, which means that the cost of the operator and maintenance of the 3D printer will be minimal. Subsequently, this will reduce the cost of the finished product. nine0003

Subsequently, this will reduce the cost of the finished product. nine0003

Thanks to these advantages, 3D printing is successfully used in many industries and in everyday life.

The future of 3D printers in various fields

3D printing technology has a lot of potential if applied correctly. The following areas of activity are most in need of 3D printing services:

- Construction. In the construction industry, 3D printing can be a powerful addition to traditional construction methods. Since this technology does not require the involvement of a large number of people to perform hard work. A few operators and craftsmen are enough to service the construction 3D printer. The first successful experiments in the manufacture of building parts and the construction of houses have already been carried out in China and the United Arab Emirates. nine0020

- Electronics. In the manufacture of digital devices, 3D printing will reduce the time for the manufacture of labor-intensive parts, microcircuits and hardware electronics.

In particular, 3D printing is already developing the first samples of graphene batteries that have an unlimited service life.

In particular, 3D printing is already developing the first samples of graphene batteries that have an unlimited service life. - Mechanical engineering and automotive industry. In this area, with the help of three-dimensional printing, experimental models of future spare parts and parts are created, which later allow the production of products of perfect quality. This is possible due to the detailed study of a three-dimensional object during its creation and printing of a finished computer model, which has a high level of detail. nine0020

- Aerospace industry. The use of 3D printing in this industry is explained by the ability to create innovative designs of any complexity. Details of satellites, rockets and other space objects are printed from metal, polymers and other types of heavy-duty materials.

- Medicine and pharmaceuticals. In medicine, 3D printing technology is extremely important. Therefore, in this industry it is studied in great detail. With the help of a 3D printer, it is possible to print prototypes of human organs, prostheses, bone tissue implants.

Even the first steps are being taken to develop and print real organs that will take root well in the human body. In the pharmaceutical industry, 3D printing is mainly used to create tablets that will gradually release active substances after ingestion. nine0020

Even the first steps are being taken to develop and print real organs that will take root well in the human body. In the pharmaceutical industry, 3D printing is mainly used to create tablets that will gradually release active substances after ingestion. nine0020 - Advertising. For advertising purposes, 3D printers print prototypes of various products, demonstration and handouts.

- Food industry. 3D food printers are especially interesting because they allow you to create edible objects from familiar foods. 3D printing makes it possible to create unique decorations and complex multi-color objects with high detail.

The future of 3D printing

3D printing, if properly developed and explored, will be more accessible in the future. Since 3D printers will be common as a work unit in many areas. At the same time, prices for such equipment are likely to fall. Since they will be produced by various companies in large quantities to satisfy the demand of all buyers. nine0003

nine0003

The growing demand for 3D printing will lead to the development of new types of 3D printers and materials for creating products.

Also for larger 3D printing, large-scale equipment will be created that will allow printing very large products for construction needs, engineering and other industries.

Unexpected possibilities of 3D printing

In addition to the standard creation of three-dimensional objects, the development and 3D printing of unique and customized products is also available on a 3D printer. Their shape, structure and design features are limited only by the user's imagination. It is possible to produce unusual products. For example, non-melting ice sculptures, curly perfectly fried pancakes or fine jewelry. nine0003

Who is the future of 3D printing?

First and foremost, the future of 3D printing depends on inventors who create new types of printers and develop new printing technologies depending on the type of material used. Most often, 3D printing novelties appear in research centers, industrial enterprises and technical departments of various universities. This is due to the fact that people working in such institutions are interested in the development of new technologies. Since innovation will help to improve and improve the processes of creating products in specific areas. In addition to researchers and students, a large number of developments are carried out by children and 3D printing enthusiasts. For example, the invention of the first 3D-printed prosthesis belongs to 17-year-old Easton LaChapelle. nine0003

Most often, 3D printing novelties appear in research centers, industrial enterprises and technical departments of various universities. This is due to the fact that people working in such institutions are interested in the development of new technologies. Since innovation will help to improve and improve the processes of creating products in specific areas. In addition to researchers and students, a large number of developments are carried out by children and 3D printing enthusiasts. For example, the invention of the first 3D-printed prosthesis belongs to 17-year-old Easton LaChapelle. nine0003

In addition to inventors, organizations that sponsor new developments are also responsible for the continued development and improvement of printing methods.

Help. Three companies are considered the most famous in the field of 3D printing: Shapeways, Sculpteo and Materialize. They are engaged in the professional development and release of new models of 3D printers, materials, as well as the improvement of existing technologies and the creation of new ones.

What's in store for 3D printing in the next few years? nine0005

3D printing experts in 2021 make the following forecasts for its development:

- The spread of 3D printing will be massive. Studios for creating three-dimensional objects will be distributed in much the same way as studios for photocopying and printing materials. 3D printing will be carried out both on standard models and on individual projects.

- Small-scale production of various products will completely switch to 3D printing technology. This will help to significantly reduce the price of finished products. nine0020

- Medical scientists will master the creation of full-fledged and fully compatible organs on a 3D printer, which will be printed from dividing human cells.

- With due diligence proving the safety of 3D printing for construction purposes, many companies in the industry will start using powerful industrial printers to create the necessary building elements.

At the same time, the time to build houses will be reduced and the proportion of hired workers who perform hard work will decrease. nine0020

At the same time, the time to build houses will be reduced and the proportion of hired workers who perform hard work will decrease. nine0020

A revolution in materials

The standard filament used in 3D printers is plastic materials. However, technology development continues at an accelerated pace. Thanks to this, innovative materials appear on the market, such as:

- Metal powder. This material is mixed with a polymer during printing and is used in the technology of laser sintering of metals. Products printed from a mixture of polymer and metal powder have increased strength comparable to real metal. nine0020

- Graphene. This carbon material is being used experimentally to develop a new composite. Ideally, a 3D-printed graphene sheet would be one molecule thick. By weight, the material will be lighter than air, but its strength properties will be very high - the sheet is ten times stronger than steel.

- Ceramic foam. Such material has flexible characteristics that can be changed depending on the purpose of use.

From ceramic foam on a 3D printer, you can print both a very light figure and a heavy monument. In theory, development already exists. But it requires a series of tests and stabilization of functional properties. nine0020

From ceramic foam on a 3D printer, you can print both a very light figure and a heavy monument. In theory, development already exists. But it requires a series of tests and stabilization of functional properties. nine0020

What are the unusual technology projects of the future?

Among the unusual 3D technologies of the future, special attention should be paid to:

- the creation of individualized clothing and footwear, which will be produced on the basis of 3D body scanning;

- makeup created by special handheld 3D printers, which is very fast and yet very precise in fine details;

- bioprinting with living cells and creation of tissues and organs from hydrogel. nine0020

3D printing has very great prospects in various fields of industry and human activity. The technology will replace the hard work of people, print cheaper products with consistently high quality. However, not all areas can immediately use 3D printing. This will require many years of testing and a series of examinations.

- April 19, 2021

- 11502

Get expert advice

what's next for 3D printing

The future of 3D printing

Already, the outlook for 3D printing is very promising. Scientists are actively developing existing 3D printing techniques, developing new technologies and types of materials, and finding new areas of application. Many call 3D printing the technology of the future, and for good reason. The technique is able to completely turn the usual way of life, changing the way most things are produced. In fact, a 3D printer is a real multifunctional factory, small and compact. Due to this, the future of 3D printing can definitely be called successful. nine0003

3D printers can significantly reduce production costs, thereby reducing the cost of products. Judging by the growing trend towards the popularization of 3D technologies, raw materials for 3D printing will become the main commodity unit in the future. In general, the prospects for 3D printing are defined for many areas. And now we will try to reveal them as much as possible.

In general, the prospects for 3D printing are defined for many areas. And now we will try to reveal them as much as possible.

The future of 3D printing

If you try to imagine the future of 3D printing, the imagination paints a rather interesting picture. Given the great interest of scientists in the 3D bioprinting technique, which is one of the most promising 3D printing technologies, the production of artificial organs on a 3D printer is not far off. It is also safe to say that the future of 3D printing will bring us dramatic changes in areas such as:

- Construction. 3D printing of houses, or contour construction, attracts many with its futurism and simplicity. The first steps in this direction have already been taken. The pioneers in 3D printing of houses were the Chinese, followed by the government of Dubai who discovered contour building. The first 3D printed office building has already been built in this city of the future, and an entire block is planned to be printed in the near future.

And just recently, the first printed house in Europe was created on a 3D printer; nine0020

And just recently, the first printed house in Europe was created on a 3D printer; nine0020 - Electronics. When listing the prospects for 3D printing, this point should be given special attention. Scientists believe 3D printing of electronics is the future of digital device manufacturing, and with good reason. Graphene properties and its application in additive manufacturing are currently being actively researched. A huge breakthrough in this area is the creation of a graphene battery with an unlimited service life on a 3D printer;

- Automotive and aerospace industry. The future of 3D printing is largely based on its ability to reproduce almost any element of varying complexity. In this regard, 3D printing is already widely used in the development of aircraft, machines and satellites. The ISS even has its own 3D printer, not to mention a number of successful 3D printing of cars. nine0020

- Pharmaceutical industry. Yes, yes, you can imagine. The future of 3D printing is in the manufacture of tablets and other medicines.

This is confirmed by epilepsy pills legalized in the USA, made according to a special technique. The essence of this perspective of 3D printing is the gradual release of active substances, so that instead of many tablets, you can drink just one.

This is confirmed by epilepsy pills legalized in the USA, made according to a special technique. The essence of this perspective of 3D printing is the gradual release of active substances, so that instead of many tablets, you can drink just one. - Food industry. 3D food printers are gradually gaining space in cafes and restaurants. While this is probably one of the most raw 3D printing technologies out there, it has potential. Food 3D printers are especially interesting for the possibility of making food for astronauts, as well as the freedom to display culinary talent. This is confirmed by the amazing 3D-printed desserts of our compatriot. nine0020

Other questions and answers about 3D printers and 3D printing:

- Finance Which 3D printer manufacturers are best?

- Finance Which 3D printer is better to buy?

The future of 3D printers

Now let's try to imagine the future of 3D printers. There are several important points to be noted here. Below we list the most likely scenarios for the future of 3D printers.

Below we list the most likely scenarios for the future of 3D printers.

- Improving the reliability and quality of instruments. Surely, many users are looking forward to this, because most of the existing models of 3D printers cannot boast of uninterrupted operation and the absence of printing errors; nine0020

- Large-scale distribution. It is certain that the future of 3D printers will please us with their popularization. Even now, one can observe a growing trend towards the use of 3D printing in almost all areas of industry. In parallel with the fact that more and more users learn about the possibilities of technology, the demand for desktop 3D printers is also growing;

- Availability. In continuation of the previous paragraph, it is worth noting that the growing demand for 3D printers will lead to lower prices for these devices. The use of 3D printing for domestic purposes is gaining momentum, which brings new equipment manufacturers to the market. Naturally, such a step will entail a reduction in the cost of devices; nine0020

- Enlargement of the construction area.

3D printing of large-sized objects has long occupied the minds of developers. Of course, this applies to industrial 3D printers, because the functionality of 3D printing at this scale will allow you to create full-fledged components, for example, cars and aircraft;

3D printing of large-sized objects has long occupied the minds of developers. Of course, this applies to industrial 3D printers, because the functionality of 3D printing at this scale will allow you to create full-fledged components, for example, cars and aircraft; - Expanding the range of available materials. The future of 3D printers depends a lot on 3D printing materials, because more means more possibilities. The development of special equipment and related materials is being carried out by many companies, and news about the release of new polymers is constantly appearing. nine0020

3D technologies of the future

Summing up, it remains to consider only 3D technologies of the future. These include various futuristic scenarios that, to one degree or another, are already beginning to develop today. These include the technique of virtual reality, 3D scanning to create the perfect clothes and shoes, 3D printed makeup, and more. In a way, 3D technologies of the future also include bioprinting.