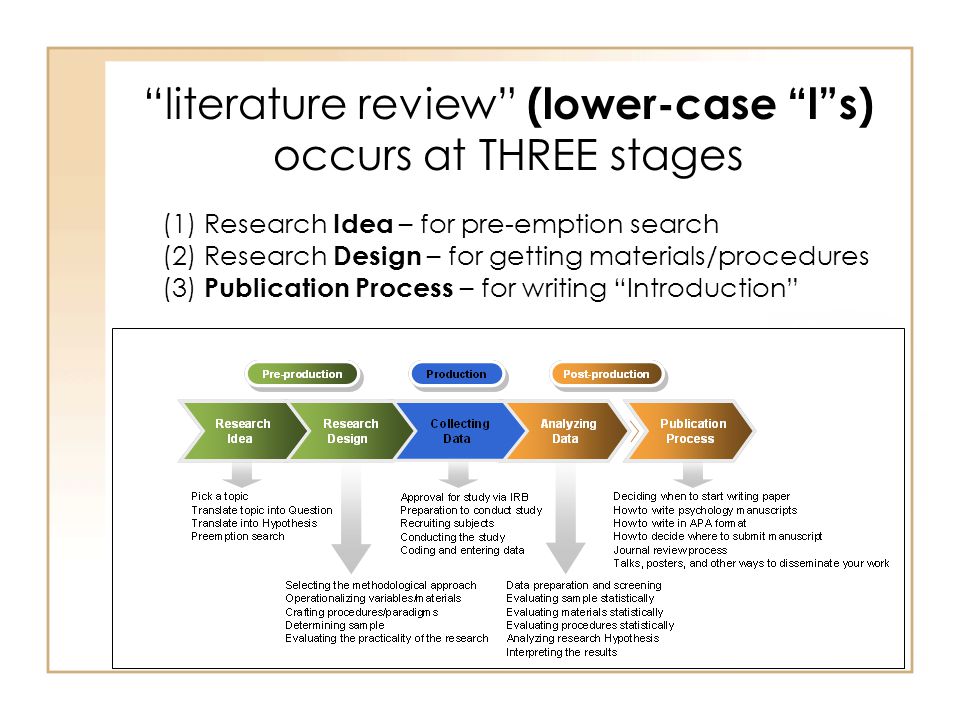

3D printing literature review

Literature Review - 3-D Printing

Abstract

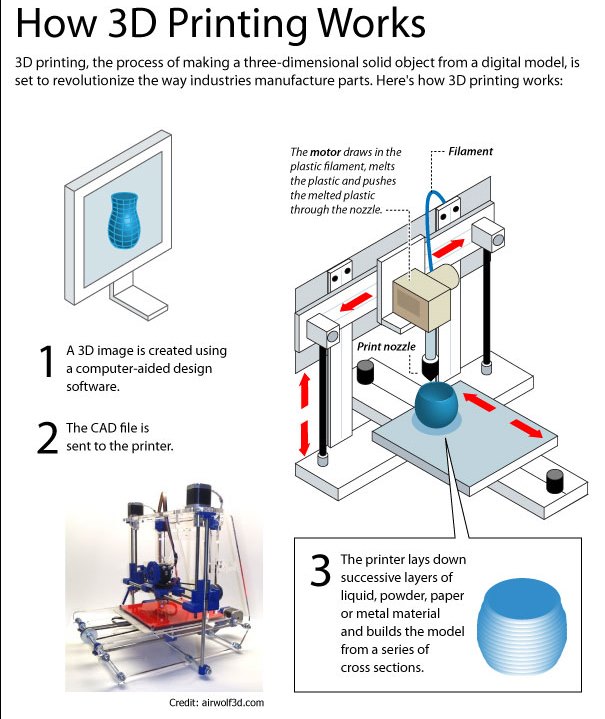

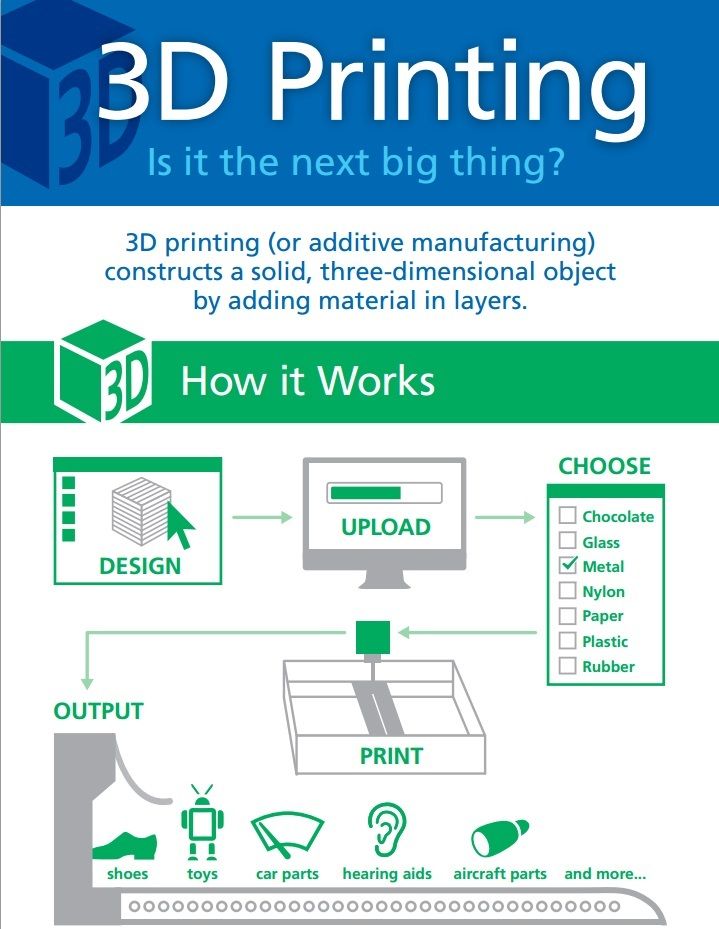

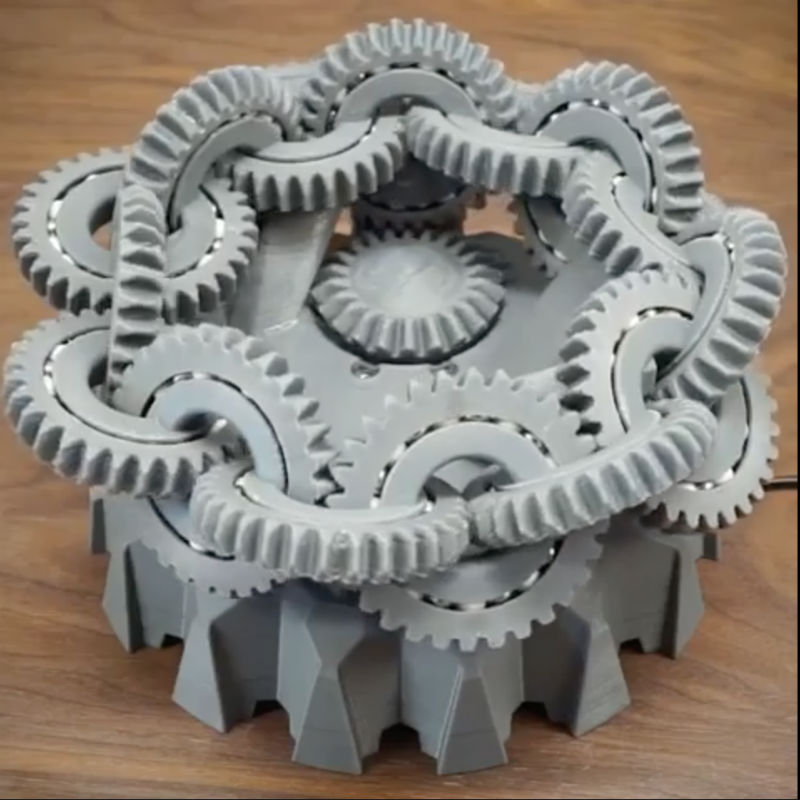

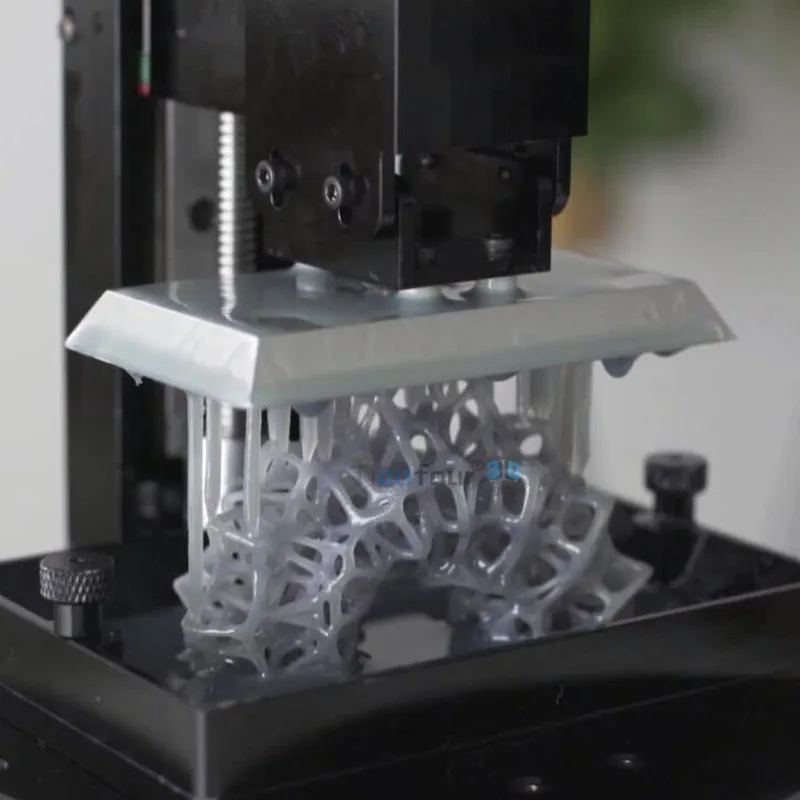

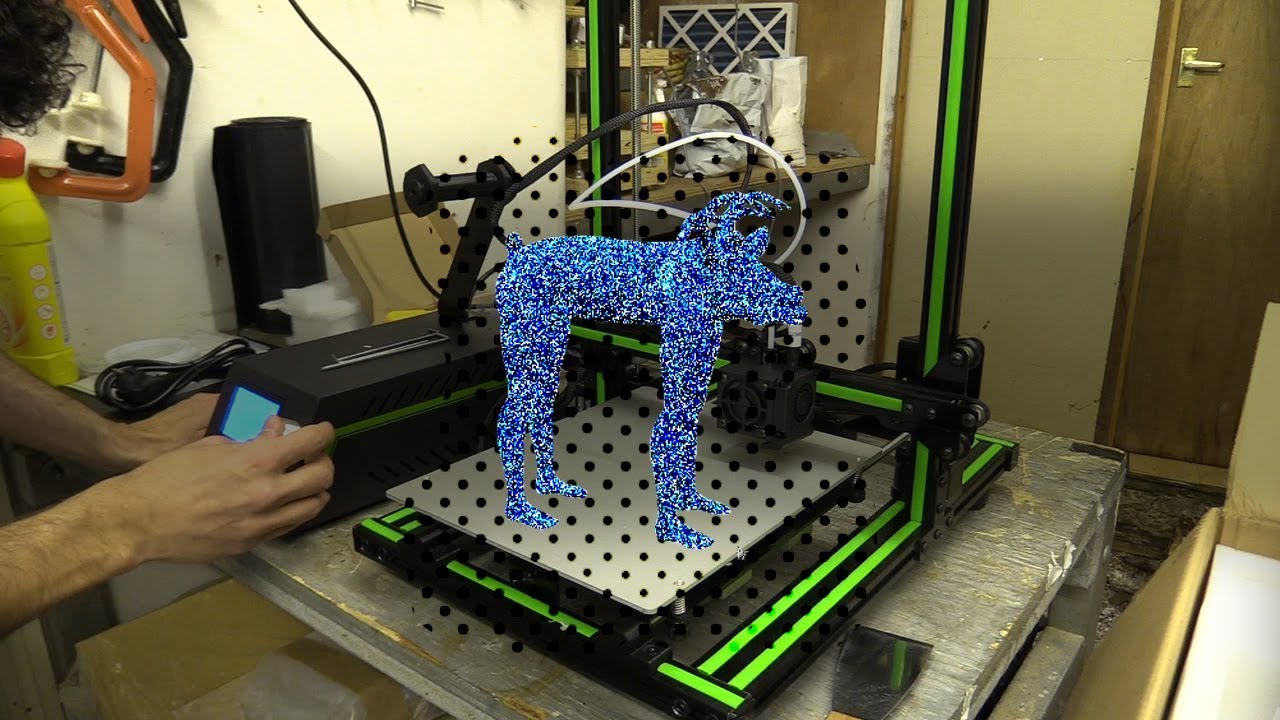

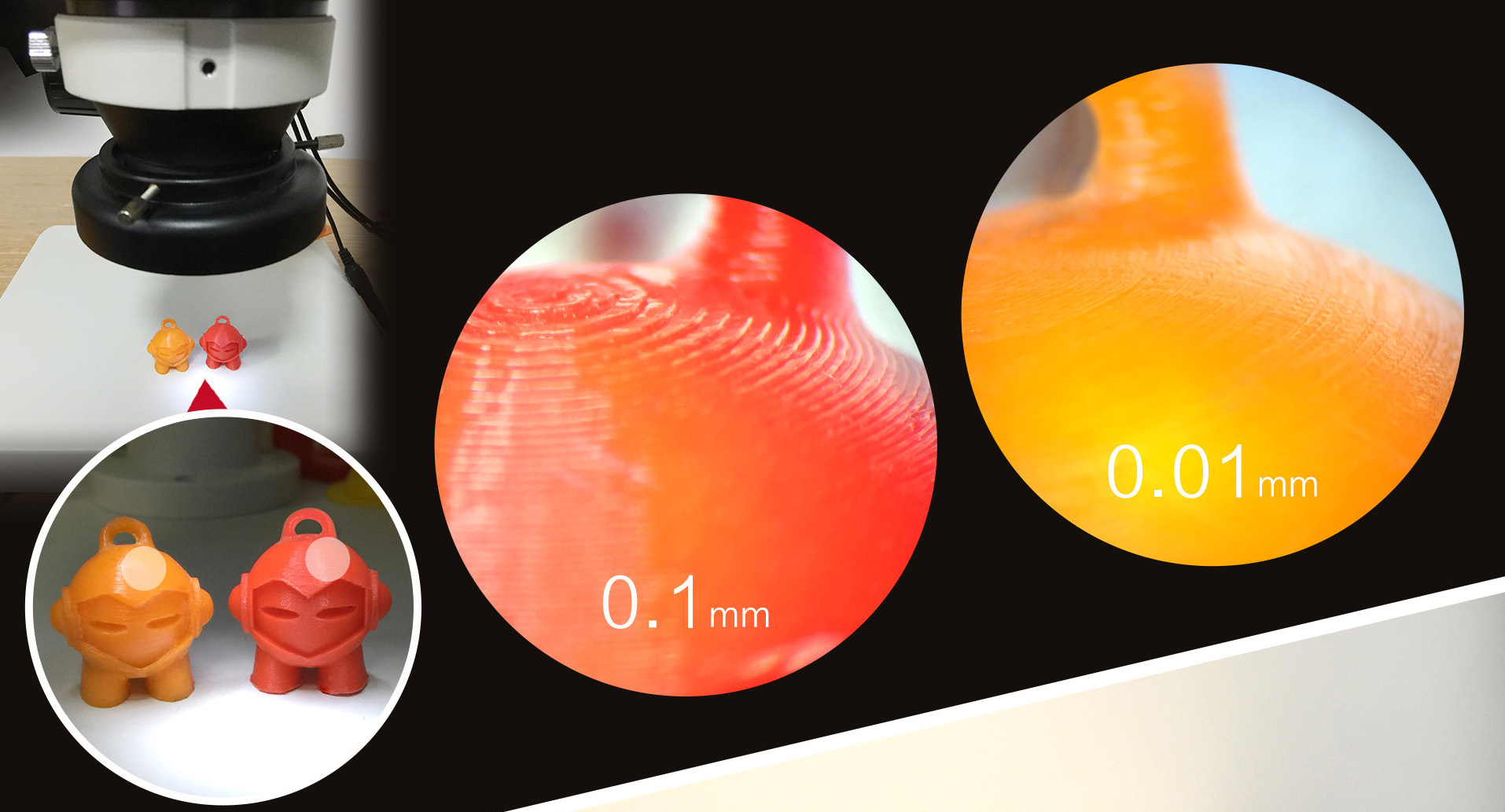

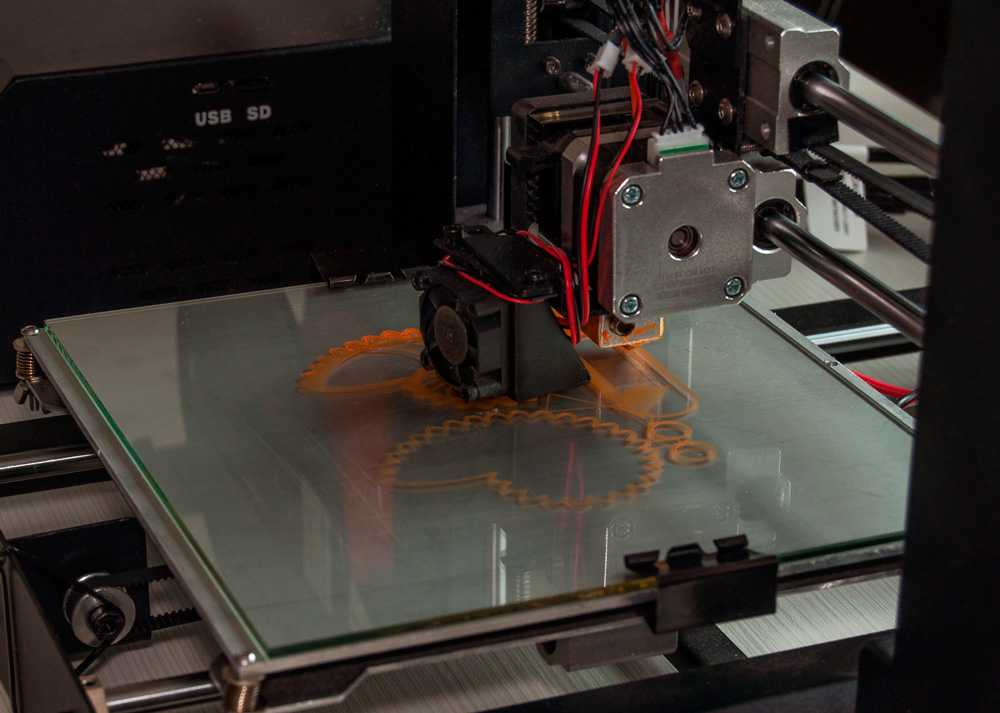

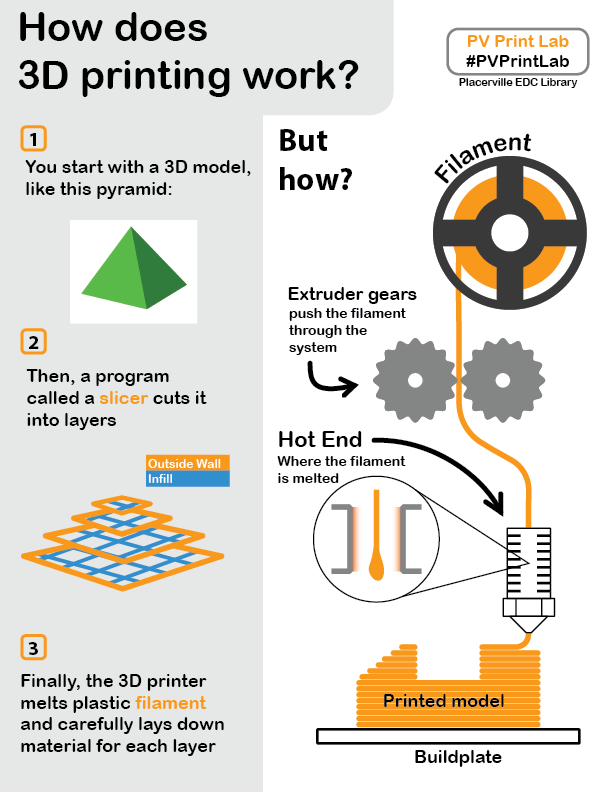

3D printing is a technology in which three dimensional objects can be created using many very thin layers stacked on top of each other. While the technology is becoming more and more practical, it has been around since 1984, when it was invented by Charles Hull using something called stereo lithography in which a perforated platform is place under a vat of photo polymer. A laser then traces layers of the object causing the photo polymer to harden, and is repeated until finished. (3D Printing. Cover story. 2012)Since then, there have been many improvements on the technology and it has evolved into using something called material jetting. In which photo polymer is emitted using a multi-nozzle print head. After every layer is placed a UV light is then used to harden the material. This of course can only be used to print plastic like materials and while printing metal alloys is possible it is still very expensive and experimental.

3D printing has grown dramatically in the last 20 years and is now being incorporated into many big manufacturer names such as Ford, Mattel, and General Electric. It is expected that 3D printing will be the next game changing technology but since it is still fairly new, it is uncertain. Many people still have doubts about 3D printing because it still has many unexplored horizons, and the technology has recently raised questions about safety and issues dealing with piracy.

3D Printing

As the world keeps evolving, new technologies begin emerging. But only a few new technologies, change the world completely and deeply impact people’s lives. Three dimensional printing is one of these technologies. But with every new technology, comes an unknown horizon. For three dimensional printing to make in an impact there has to be further research done in order to better understand what its capabilities are and whether it can make the impact it is predicted to make. In order to further analyze this technology the following questions must be addressed:

In order to further analyze this technology the following questions must be addressed:

1. What are the primary uses (whether intended or not) for 3D printers?

2. Who is already implementing this new technology?

3. Can people use a 3D printer to construct working weapons from home?

4. Is there a way to restrict the 3D printing?

In order further understand the current expected growth in the field of 3D printing, a survey was conducted to show the areas people thought the technology would grow in. (Figure 1 below)

What are the primary uses (whether intended or not) for 3D printers?

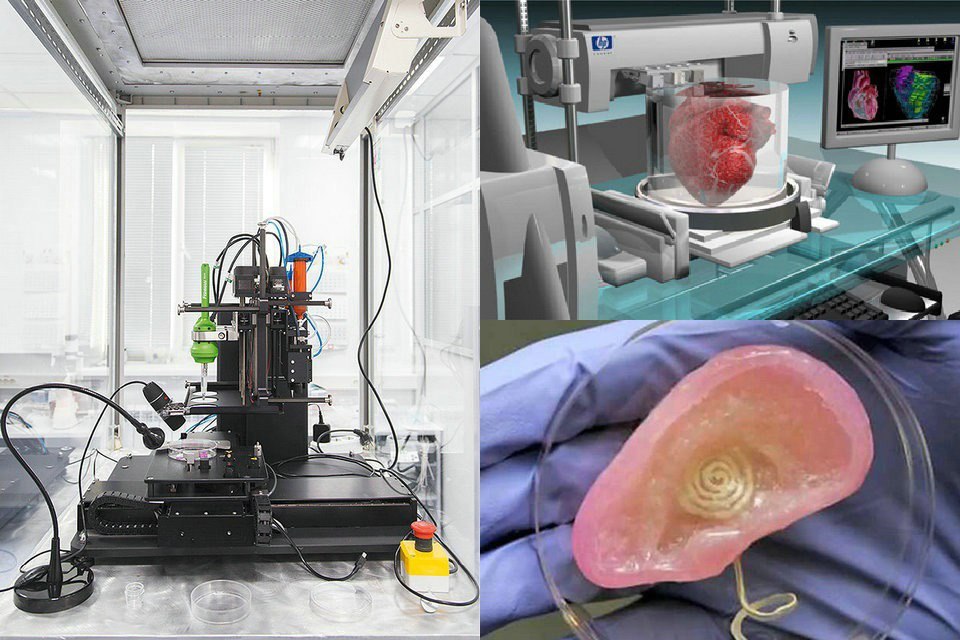

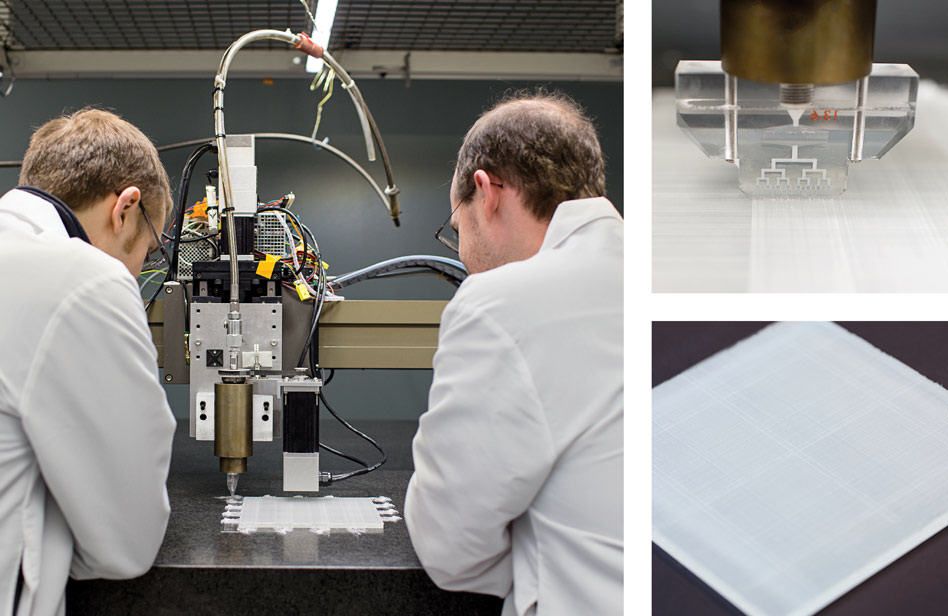

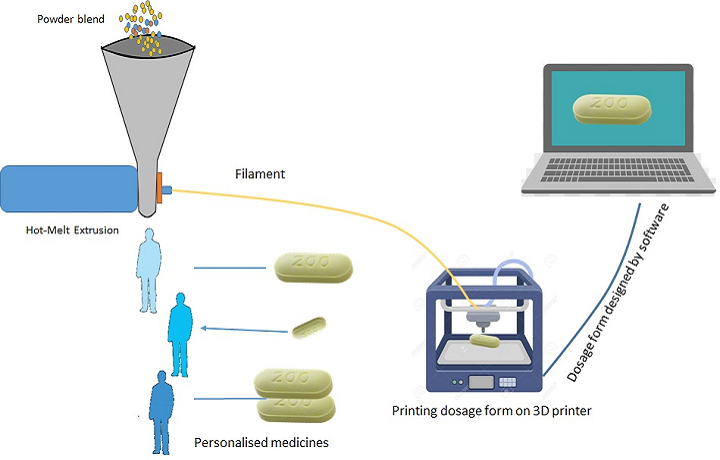

One of the most important uses for 3D printing is within the medical industry. With the power of 3D printing, surgeons and doctors can produce a mockup of parts from patient’s bodies which need to be operated on. 3D printing makes it possible to make a part from a computer program in just a couple of hours. There have been huge advancements in the medical field with the help of 3D printing. One area in which the technology has helped is skin transplants. Bio-printers are used to print fake skin, which can be used on burn patients and other patients who need a skin graft. Another huge advancement has allowed scientist to successfully print a transplantable, working kidney in which 90% of the cells are living. (Greenemeier, L. 2013)

There have been huge advancements in the medical field with the help of 3D printing. One area in which the technology has helped is skin transplants. Bio-printers are used to print fake skin, which can be used on burn patients and other patients who need a skin graft. Another huge advancement has allowed scientist to successfully print a transplantable, working kidney in which 90% of the cells are living. (Greenemeier, L. 2013)

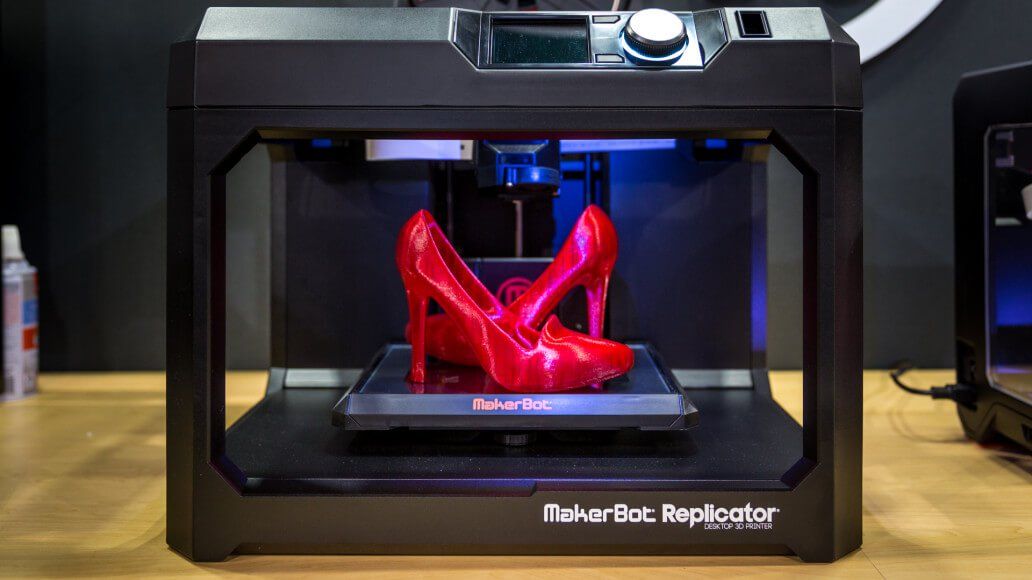

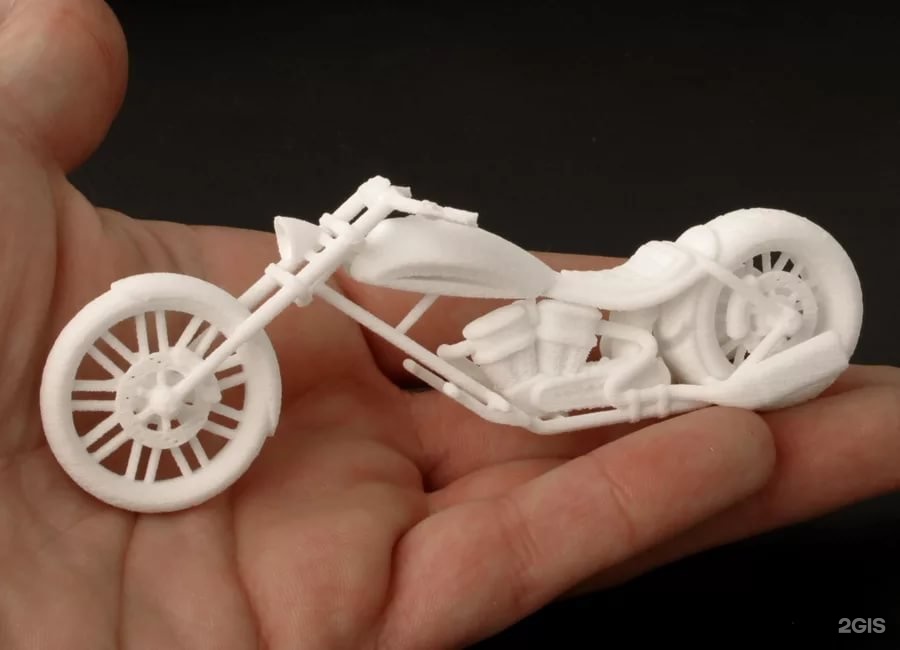

3D printing can also be implemented in many other fields. It allows designers and developers to go from flat screen 2D images, to exact to exact parts and very precise scales this allows 3D printers to create things that other machines can’t. It allows artist to create the unimaginable but have also been used to replicate near perfect art forgeries. (Greenemeier, L. 2013). Almost everything from aerospace components, manufacturing parts, and even toys are getting built with the help of 3D printers. 3D printing can also be used for jewelry and architecture, fashion design, and interior design. It essentially revolutionizes the concept of interchangeable parts by making it less expensive and more efficient.

It essentially revolutionizes the concept of interchangeable parts by making it less expensive and more efficient.

What companies are implementing this new technology?

Some of the big names actually already using 3D printing are companies such as Ford, General Electric, and Mattel. Ford is already beginning mock trials in which customers use 3D printers to get on-demand replacement parts for their cars. But while that may still be a while a way, for now they use the technology to make prototypes parts, which makes their testing process more efficient and cheaper. “Using 3-D printing, Ford saves an average of one month of production time to create a casting for a prototype cylinder head for its Eco-Boost family of engines, designed for better fuel efficiency. This complex part includes numerous ports, ducts, passages and valves to manage fuel and air flow.” (3D Printing. Cover story. 2012). The traditional casting method takes four to five months. With 3D printing it takes three.

With 3D printing it takes three.

General Electric, 3D printing isn’t just helping them in the design process. They have already started experimenting with 3D printed plane parts. General Electric Aviation’s new LEAP jet engine will use the additive manufacturing process because it uses less material and will make the engine extremely lighter, helping aircrafts save on fuel costs and increase speeds. It is expected to be used worldwide by new Airbus jets and Boeing starting as early as 2016. Mattel, the popular toy company is using it to create product prototypes from wax and clay. The process is much more efficient with 3D printing and makes for cheaper and more innovative toys. NASA has also decided to implement 3D printing. One of their current projects involves implementing a 3D printer inside future shuttles in order to easily replace broken parts and build objects that might be needed in outer space. They have also begun testing on 3D-printed rocket injectors.

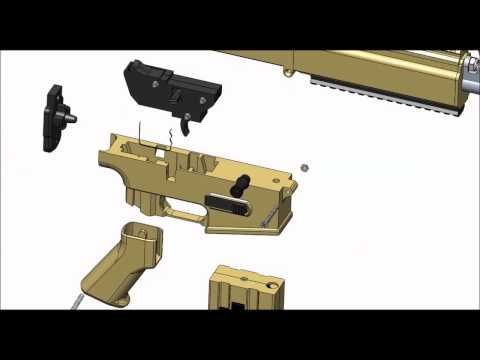

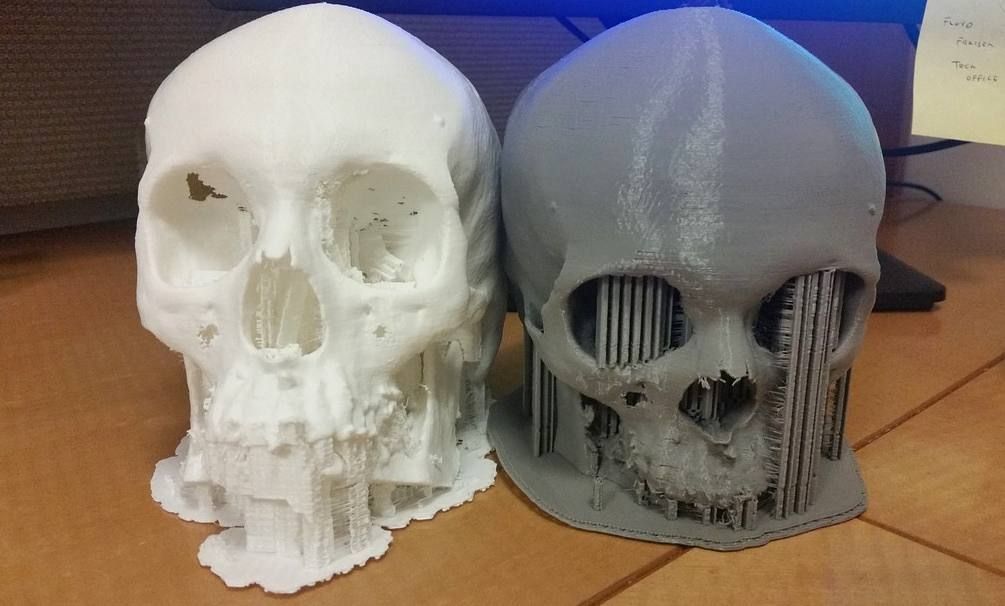

Can people use a 3D printer to construct working weapons?

Cody R. Wilson a 25 year old law student at the University of Texas at Austin, has answered this question. Wilson was successfully able to construct a CAD prototype of a working 3D printing gun using only $25 of material. The gun he constructed is nothing close to being as powerful as current guns, but it is capable of shooting 9 shots before breaking.Wilson has recently been under heavy criticism for his development of the weapon, and has since then created a site called “Wiki Weapon Project” in which he is fighting for his cause. Wilson has also gone as far as uploading the blueprints for his gun which were download by hundreds of thousands of people, before being taken down by the United States government. But since 3D printing is still fairly new, there is not much that the government can do from a legal stand point. Some others have also had similar success by printing knives, but have come short as plastic is not very sharp and while 3D printing from metal alloys is possible, it is still very expensive and inconvenient.

Wilson a 25 year old law student at the University of Texas at Austin, has answered this question. Wilson was successfully able to construct a CAD prototype of a working 3D printing gun using only $25 of material. The gun he constructed is nothing close to being as powerful as current guns, but it is capable of shooting 9 shots before breaking.Wilson has recently been under heavy criticism for his development of the weapon, and has since then created a site called “Wiki Weapon Project” in which he is fighting for his cause. Wilson has also gone as far as uploading the blueprints for his gun which were download by hundreds of thousands of people, before being taken down by the United States government. But since 3D printing is still fairly new, there is not much that the government can do from a legal stand point. Some others have also had similar success by printing knives, but have come short as plastic is not very sharp and while 3D printing from metal alloys is possible, it is still very expensive and inconvenient.

Is there a way to restrict the uses of 3D printing?

Though there are many people who have looked into this issue, there is one individual who is already making plans to restrict 3D printing. Steve Israel, a congressman for the United Sates. Israel understands the possibilities that come with the new technology and instead of regulating the technology itself. He aims to target specific individuals instead. A big factor that comes into play here, is the use of piracy. The government could go ahead and institute regulations on specific companies and alter digital rights of the blue prints, but with piracy hackers could always find a way around it and that would be critical for safety matters. Instead Israel plans to not put a single finger on blue prints, manufacturers, or even the piracy community. But instead wants to focus on targeting specific individuals, “I just want to be clear. I’m not seeking to regulate or reduce the use of 3D printers at all. This isn’t about 3D printers. It’s about the use of a 3D printer to manufacture a weapon that can’t be detected by metal detectors.” (Kaur, S. 2012) .While not much else has been said on plans to regulate 3D printing, there are many political and law enforcement officials looking into this issue. Over time many experimental regulations may be enforced in order to make this technology as safe as possible.

This isn’t about 3D printers. It’s about the use of a 3D printer to manufacture a weapon that can’t be detected by metal detectors.” (Kaur, S. 2012) .While not much else has been said on plans to regulate 3D printing, there are many political and law enforcement officials looking into this issue. Over time many experimental regulations may be enforced in order to make this technology as safe as possible.

Conclusion

Though 3D printing is still a growing technology, it already has many benefits and drawbacks. While many people agree that this technology could change the world, there are also those who believe it could have extreme consequences if it is not researched and tested thoroughly. As the technology beings to grow more and more throughout the next couple of years there will be more information and data that will determine whether it is a technology that is here to stay or it is something that will simply not make it. For now it is something that has to be further looked into in order to fully understand its extents whether good or bad.

3D-Printing Technology in Construction: Results from a Survey

Abstract

Purpose

The purpose of this paper is to study the introduction of 3D-printing of concrete in the construction sector.

Design/Methodology/Approach

A survey was conducted to collect professional view on ongoing innovations in the construction sector, including 3D-printing. Participants were selected among the members of Norwegian networks for project and construction management research.

Findings

The survey highlighted effective leadership, collaboration with partners and industry-academia collaboration as primary enablers of innovation. Few of the respondents to the survey have used 3D-printing technologies.

Research Limitations/Implications

It is difficult to obtain representative samples in this type of research, including this study. The study can be seen as a snapshot of attitudes in the sector.

The study can be seen as a snapshot of attitudes in the sector.

Practical Implications

3D-printing appear as a potentially interesting technology, especially for unstandardized construction components. Further work is needed to materialise the expectation for technological development in the construction sector.

Originality/Value

Most research on 3D-printing has focused on demonstrating technical potential. This study adds a practitioners’ perspective, with a large dose of pragmatism.

Keywords

- 3D-printing

- Concrete

- Implementation

- Additive

- Hybrid additive/Subtractive manufacturing

- HINDCON

Citation

Olsson, N. O.E., Shafqat, A., Arica, E. and Økland, A. (2019), "3D-Printing Technology in Construction: Results from a Survey", Lill, I. and Witt, E. (Ed.) 10th Nordic Conference on Construction Economics and Organization (Emerald Reach Proceedings Series, Vol. 2), Emerald Publishing Limited, Bingley, pp. 349-356. https://doi.org/10.1108/S2516-285320190000002044

O.E., Shafqat, A., Arica, E. and Økland, A. (2019), "3D-Printing Technology in Construction: Results from a Survey", Lill, I. and Witt, E. (Ed.) 10th Nordic Conference on Construction Economics and Organization (Emerald Reach Proceedings Series, Vol. 2), Emerald Publishing Limited, Bingley, pp. 349-356. https://doi.org/10.1108/S2516-285320190000002044

Publisher

:Emerald Publishing Limited

Copyright © 2019, Nils O.E. Olsson, Ali Shafqat, Emrah Arica, Andreas Økland.

License

Published in the Emerald Reach Proceedings Series. Published by Emerald Publishing Limited. This article is published under the Creative Commons Attribution (CC BY 4.0) licence. Anyone may reproduce, distribute, translate and create derivative works of this article (for both commercial and non-commercial purposes), subject to full attribution to the original publication and authors. The full terms of this licence may be seen at http://creativecommons.org/licences/by/4.0/legalcode

The full terms of this licence may be seen at http://creativecommons.org/licences/by/4.0/legalcode

1. Introduction

This paper studies 3D-printing of concrete in the construction sector. As an innovative technology, 3D-printing offers interesting opportunities for the construction industry, such as increased flexibility and reduced operational costs. However, it is important to analyse and use the previous innovation experiences to increase the success potential of implementing the 3D-printing technology in the construction industry. The study is a part of the EU-funded research project HINDCON (2018).

The aim of this study is to investigate the implementation of 3D-printing in the construction sector. The following research questions are set up:

2. On 3D-printing as an innovation in construction

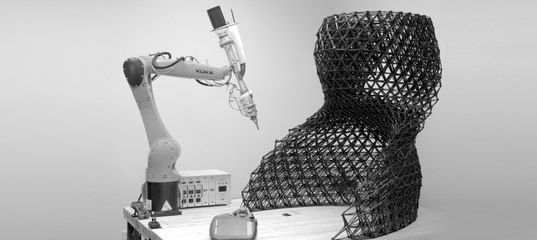

The construction industry has evolved from a craftsmanship to an industrialised and service-oriented business, owing to the significant efforts in development and implementation of technological and organisational innovations over the past 70 years. Nevertheless, it is questionable if the introduced innovations have yielded their full potential and promises in the construction industry. Many studies show that construction industry has failed to adopt innovations to improve its performance as in other industries (World Economic Forum, 2016). The lack of stakeholder's involvement, high initial innovation costs, lack of risk funding, inherent conservative behaviour of organisations and initial non-profitability of innovations are some examples of barriers leading to fails in innovation (Ozorhon et al., 2013). As an innovative technology, 3D-printing and hybrid additive/subtractive manufacturing offers significant opportunities for the construction industry, such as increased flexibility and reduced operational costs. However, it is important to analyse and use the previous innovation experiences to increase the success potential of implementing the 3D-printing technology in the construction industry.

Nevertheless, it is questionable if the introduced innovations have yielded their full potential and promises in the construction industry. Many studies show that construction industry has failed to adopt innovations to improve its performance as in other industries (World Economic Forum, 2016). The lack of stakeholder's involvement, high initial innovation costs, lack of risk funding, inherent conservative behaviour of organisations and initial non-profitability of innovations are some examples of barriers leading to fails in innovation (Ozorhon et al., 2013). As an innovative technology, 3D-printing and hybrid additive/subtractive manufacturing offers significant opportunities for the construction industry, such as increased flexibility and reduced operational costs. However, it is important to analyse and use the previous innovation experiences to increase the success potential of implementing the 3D-printing technology in the construction industry.

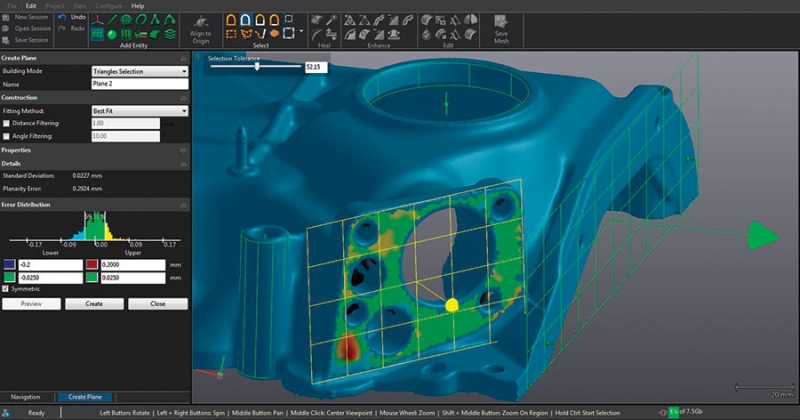

2.1. About 3D-printing and additive manufacturing

3D-printing is an automated, additive manufacturing process for producing 3D solid objects from a digital (i. e. CAD) model, where the 3D CAD model is sliced into a series of 2D layers that are later deposited by the printer to construct the model (Boothroyd, 1994). A more recent definition for 3D-printing is "the fabrication of objects through the deposition of a material using a print head, nozzle, or another printer technology" (American Society for Material and Testing 2009). The term "additive manufacturing" (AM) is more generally defined as: "the process of joining materials to make objects from 3D model data, usually layer upon layer" (American Society for Material and Testing, 2009). Additive manufacturing can deliver parts of intricate and complex geometries, built from tailored materials with near-zero material waste, while being applicable to a variety of materials (Bikas et al., 2016).

e. CAD) model, where the 3D CAD model is sliced into a series of 2D layers that are later deposited by the printer to construct the model (Boothroyd, 1994). A more recent definition for 3D-printing is "the fabrication of objects through the deposition of a material using a print head, nozzle, or another printer technology" (American Society for Material and Testing 2009). The term "additive manufacturing" (AM) is more generally defined as: "the process of joining materials to make objects from 3D model data, usually layer upon layer" (American Society for Material and Testing, 2009). Additive manufacturing can deliver parts of intricate and complex geometries, built from tailored materials with near-zero material waste, while being applicable to a variety of materials (Bikas et al., 2016).

Three important aspects of additive manufacturing are: material, process, and design. The main categories of 3D-printing have been detailed by (Labonnote et al. 2016) solid-like, viscous-like, powder-like and liquid-like. More complete overviews on previous and current additive construction experiences can be found in (Perkins and Skitmore, 2015; Labonnote and Rüther, 2016 and Wu, Wang et al., 2016).

More complete overviews on previous and current additive construction experiences can be found in (Perkins and Skitmore, 2015; Labonnote and Rüther, 2016 and Wu, Wang et al., 2016).

PWC (2014) did a general about use of 3D-printing in manufacturing. It showed that about 25% of the companies were involved in prototyping using 3D-printing and 29% were experimenting how they can use it.

2.3. Drivers and barriers to use of 3D-printing in construction

A driver that supports the use of 3D-printing in construction is the significant customisation opportunities (Labonnote et al. 2016). Minimisation of waste (Berman, 2012) and improved carbon footprint (Achillas et al., 2015) are also interesting possibilities. There is a potential for cost-efficiency through high automation and reduced manpower requirement (www.3ders.org, 2014). Automation such as 3D-printing can reduce danger for human workers in harsh environments (Millsaps, 2015). 3D-printers also have quick deployability (Peter, 2015).

Issues that may serve as barriers include uncertainty regarding the size of demand for mass customisation and availability of high-strength printing materials. The literature also find it unclear whether 3D-printing could lead to reduced or increased construction cost (Wu, Wang et al., 2016). Owing to size limitation of existing 3D printers, it is difficult to print a multi-story building at a time (Gibson et al., 2002). However, users can print structural components piece-by-piece and then assemble them together as a real-scale building (Feng and Yuhong, 2014). Intellectual property issues have been raised in particular in connection with concerns that digital objects (including a digital file describing the construction of a given structure) can easily be copied and re-sold (Berman, 2012). There are also cyber security risks (Campbell et al., 2014).

3. Research approach

The paper presents findings from a questionnaire on use and expectations for 3D-printing in construction industry. Based on initial literature studies, the first version of the questionnaire was developed, which involved several workshops with the authors and the HINDCON team members. The result presented here is related to the 3D-printing experiences and expectations in the construction sector. In the second phase of the survey, the questionnaire was piloted in three companies with follow-up interviews. The questionnaire was adjusted after the feedback. The third phase of the survey was to collect an e-mail list of potential respondents. Survey participants were mainly selected among the members of Norwegian networks for project and construction management research. The types of companies involved in the survey are engineering and construction management consultants, clients, building owners, architects and suppliers of pre-assembled modules. The list of potential respondents included 235 persons. The fourth stage of the survey was to launch the final version of the questionnaire. A total of 36 valid responses were received.

Based on initial literature studies, the first version of the questionnaire was developed, which involved several workshops with the authors and the HINDCON team members. The result presented here is related to the 3D-printing experiences and expectations in the construction sector. In the second phase of the survey, the questionnaire was piloted in three companies with follow-up interviews. The questionnaire was adjusted after the feedback. The third phase of the survey was to collect an e-mail list of potential respondents. Survey participants were mainly selected among the members of Norwegian networks for project and construction management research. The types of companies involved in the survey are engineering and construction management consultants, clients, building owners, architects and suppliers of pre-assembled modules. The list of potential respondents included 235 persons. The fourth stage of the survey was to launch the final version of the questionnaire. A total of 36 valid responses were received. The results of the survey are entered in Excel format for analysis and graphical presentation.

The results of the survey are entered in Excel format for analysis and graphical presentation.

The formal response rate was 15%. However, it was not realistic to receive answers from all as several organisations had more than one person listed, and the list covered a wide array of actors. We estimate that the response rate among realistic respondents was between 25 and 30%. The results are largely based on Norwegian companies, with a bias towards large actors in the construction industry and those with an interest in research and development. Reliability can be influenced by the selection criteria of respondents. However, the study can hopefully give indications of present thinking about 3D-printing, even though the quantifications are not based on a representative sample. Validity in the study was a main concern in the development for the survey and in the piloting with three companies.

4. Results about the use of 3D-printing

The results address two aspects of 3D-printing in construction. The first aspect is about present and expected degree of implementation, while the second aspect is about expected cost issues.

The first aspect is about present and expected degree of implementation, while the second aspect is about expected cost issues.

4.1. Implementation of 3D-printing

The questionnaire addressed the use and implementation of 3D-printing. Figure 1 indicates that most of the respondents had not used 3D-printing. Those who had used the technology had mainly used it for piloting and prototyping.

Figure 1

Is your company involved in 3D-printing technology? N = 36 (more than one alternative could be selected)

Figure 2 shows the expected areas of application of 3D-printing. Most respondents expected that 3D-printing would mainly be applied for small or complex parts, including decorations. However, some also believed in the production of building blocks.

Figure 2

In the near future (5 to 10 years), what do you expect to be the primary area for application of 3D-printing products in your company? N = 36 (more than one alternative could be selected)

Figure 3 indicate collaboration within the construction sector as a key success factor for implementation of 3D-printing, along with R&D funding.

Figure 3

How can 3D-printing technology be successfully implemented in the construction industry? N = 34 (more than one alternative could be selected)

Most of the respondents expect that it will take more than eight years for 3D-printing to be widely in use, as shown in Figure 4.

Figure 4

In how many years do you expect 3D-printing technology to be used widely in construction projects? N = 36

4.2. Cost issues

The survey also included questions about cost issues of 3D-printing. Figure 5 show that most respondents expected a high initial investment related to 3D-printing.

Figure 5

Do you think 3D-printing technology involves high initial investment? N = 35

In spite of the expected high investment, a majority of the respondents believed that 3D-printing would eventually be cost efficient (see Figure 6).

Figure 6

Do you think the use of 3D-printing technology in construction projects will be cost -efficient? N = 35

5.

Conclusions

Conclusions We have investigated the implementation of 3D-printing in the construction sector. The first research question addressed the status of implementation of 3D-printing technology in construction industry. Despite the positive expectations from 3D-printing technology, it has so far only been applied to a limited extent in the Norwegian construction industry, and mainly for piloting and prototyping. The study shows that 20% of the respondents use 3D-printing for prototyping, while a smaller part of the companies uses 3D-printing for ordinary production. In terms of materials, plastic and ceramic are now not only widely used in 3D-printing, but also a big development in 3D-printing of metals. In comparison, the study by PWC (2014) found that some years ago, 25% of manufacturing companies were involved in prototyping using 3D-printing. Our results imply that the Norwegian construction industry is behind but still on somewhat the same level as for manufacturing.

The second research question is related to expectations for 3D-printing in construction industry. The respondents expected not only high initial investments, but also that 3D-printing would prove to be cost efficient in the long run, with an implementation time of more than eight years. The reviewed literature was not conclusive about the future cost efficiency of 3D-printing (quite naturally, as the technology is in an early stage of development).

The respondents expected not only high initial investments, but also that 3D-printing would prove to be cost efficient in the long run, with an implementation time of more than eight years. The reviewed literature was not conclusive about the future cost efficiency of 3D-printing (quite naturally, as the technology is in an early stage of development).

The companies in the survey believe that research and development funding for the 3D-printing technology along with collaboration between suppliers and contractors will facilitate its wide future implementation of 3D-printing in the construction sector. Regarding future use, the survey pointed to production of small or complex parts, including decorations as key potential applications of 3D-printing. This is in accordance to the literature, which highlighted the significant customisation opportunities, even though the literature also addressed uncertainty regarding the size of demand for mass customisation. Overall, the study conveys the impression of 3D-printing as a potentially interesting technology, especially for unstandardized construction components. The technology appears to still be at a testing stage. However, there is interest in the industry and we expect to hear more as the technology matures, and we gain more experiences.

The technology appears to still be at a testing stage. However, there is interest in the industry and we expect to hear more as the technology matures, and we gain more experiences.

References

Achillas, Aidonis, Iakovou, Thymianidis, and Tzetzis, 2015Achillas, C., Aidonis, D., Iakovou, E., Thymianidis, M. and Tzetzis, D. (2015). “A methodological framework for the inclusion of modern additive manufacturing into the production portfolio of a focused factory.” Journal of Manufacturing Systems 37(1): 328–339.

American Society for Material and Testing, 2009American Society for Material and Testing (2009). “Standard terminology for additive manufacturing technologies”. West Consholhocken, US, ASTM International. F2792-12a.

Berman, 2012Berman, B. (2012). “3-D printing: The new industrial revolution.” Business horizons 55(2): 155–162.

Bikas, Stavropoulos, and Chryssolouris, 2016Bikas, H. , Stavropoulos, P. and Chryssolouris, G. (2016). “Additive manufacturing methods and modelling approaches: a critical review.” The International Journal of Advanced Manufacturing Technology 83(1-4): pp. 389–405.

, Stavropoulos, P. and Chryssolouris, G. (2016). “Additive manufacturing methods and modelling approaches: a critical review.” The International Journal of Advanced Manufacturing Technology 83(1-4): pp. 389–405.

Boothroyd, 1994Boothroyd, G. (1994). “Product design for manufacture and assembly”. Computer-Aided Design, 26(7), pp 505–520.

Campbell, Tibbits, and Garrett, 2014Campbell, T. A., Tibbits, S. and Garrett, B. (2014). “The next wave: 4D printing - Programming the material world”. Atlantic Council, Washington DC.https://www.researchgate.net/publication/262818283_The_Next_Wave_4D_Printing_-_Programming_the_Material_World/download (accessed on 20 August 2018).

Feng, and Yuhong, 2014Feng, L. and Yuhong, L. (2014). “Study on the status quo and problems of 3d printed buildings in china.” Global Journal of Human-Social Science Research.

Gibson, Kvan, and Wai Ming, 2002Gibson, I., Kvan, T. and Wai Ming, L. (2002). “Rapid prototyping for architectural models.” Rapid prototyping journal 8(2): pp 91–95.

HINDCON, 2018HINDCON (2018) “Hybrid INDustrial CONstruction” http://www.hindcon3d.com, (accessed on 20 August 2018).

Labonnote, Rønnquist, Manum, and Rüther, 2016Labonnote, N., Rønnquist, A., Manum, B. and Rüther, P. (2016). “Additive construction: State-of-the-art, challenges and opportunities.” Automation in Construction 72, Part 3: pp. 347–366.

Labonnote, and Rüther, 2016Labonnote, N. and Rüther, P. (2016). “Additive manufacturing: an opportunity for functional and sustainable constructions”, Smart and Sustainable Manufacturing. Lisbon, Portugal. https://www.researchgate.net/publication/309430330_Additive_manufacturing_An_opportunity_for_functional_and_sustainable_constructions, (accessed on 20 August 2018).

Millsaps, 2015Millsaps, B. B. (2015). “The Swarmscapers: Students create 3D printing robots capable of building in outlying areas”. www.3DPrint.com, (accessed on 20 August 2018).

Ozorhon, Abbott, and Aouad, 2013Ozorhon, B., Abbott, C. and Aouad, G. (2013). “Integration and leadership as enablers of innovation in construction: Case study”. Journal of Management in Engineering, 30(2), pp. 256–263.

Perkins, and Skitmore, 2015Perkins, I. and Skitmore, M. (2015). “Three-dimensional printing in the construction industry: A review.” International Journal of Construction Management 15(1): pp 1–9.

Peter, 2015Peter, B. J. (2015). “Spiderbot: Large Scale 3D Printer.” Retrieved November 2015, from http://www.bnpeters.com/spiderbot.html (accessed on 20 August 2018).

PWC, 2014PWC (2014). “Technology forecast: The future of 3-D printing”, http://usblogs.pwc.com/emerging-technology/the-road-ahead-for-3d-printing/pp (accessed on 20 August 2018).

“Technology forecast: The future of 3-D printing”, http://usblogs.pwc.com/emerging-technology/the-road-ahead-for-3d-printing/pp (accessed on 20 August 2018).

World Economic Forum, 2016World Economic Forum (2016). “Shaping the future of construction a breakthrough in mindset and technology”. http://www3.weforum.org/docs/WEF_Shaping_the_Future_of_Construction_full_report__.pdf (accessed 20 August 2018).

Wu, Wang, and Wang, 2016Wu, P., Wang, J. and Wang, X. (2016). “A critical review of the use of 3-D printing in the construction industry.” Automation in Construction 68: pp. 21–31.

www.3ders.org, 2014www.3ders.org. (2014). “Loughborough University teams up with Skanska to build commercial 3D concrete printing robot.” http://www.3ders.org/articles/20141121-loughborough-university-skanska-to-build-commerical-3d-concrete-printing-robot.html, (accessed on 20 August 2018).

Encyclopedia of 3D printing

Welcome to the help section of our portal!

As you can see, the world of 3D printing deserves the title of "mysterious". The rapid development of technology gives rise to a lot of all kinds of terms, concepts and designs, whose essence is far from obvious to a simple layman. The main task of our website is to acquaint you with the latest news from the world of 3D printing, tell you about technological innovations and help you with the purchase of the necessary equipment.

The task is complicated by the fact that currently in Russia there is no official standard for terms related to 3D printing. As a result, many of them are differing translations of the originals, somewhat confusing to the reader. In addition, 3D printer manufacturers themselves often try to monopolize parts of the market by making fairly minor changes to existing technologies in order to obtain a patent, and supplying “new” products with new names, thereby only exacerbating the confusion.

But don't despair. In this section, we will try to explain all the nuances of the world of 3D printing: the technologies used, how they work, terminology options, and so on. Keep in mind that the world of 3D printing does not stand still, and therefore we will constantly update and supplement our help section with new information.

Reference sections:

- 1 3D printing

- 2 3D printing technologies

- 3 Consumables for 3D printers

- 4 3D equipment

- 5 SLISERS

- 6 Articles about 3D printing

- 7 Our reviews about 3D printers and about 3D printing

- 9 Literature

- 10 Work with a 3DTODAY portal. Reference

3D printing

- What is a 3D printer.

- All about 3D printing. additive manufacturing. Basic concepts.

- 3D printing for dummies or "what is a 3D printer?"

- How to build a 3D printer with your own hands"

- 3D Printer & 3D Printing FAQ"

3D Printing Technologies

- Mask Stereolithography (SGC)

- Multi-Jet Modeling Technology (MJM)

- Color Inkjet (CJP)

- Digital LED Projection (DLP)

- 3D Inkjet Printing (3DP)

- Selective Laser Sintering (SLS)

- Selective laser melting (SLM)

- Stereolithography (SLA)

- Selective heat sintering (SHS)

- Lamination Object Manufacturing (LOM)

- Electron Beam Melting (EBM)

- Direct Metal Laser Sintering (DMLS)

- Electron Beam Fusion Manufacturing (EBFȝ)

- Fused Deposition Modeling (FDM)

- Selective Deposition Lamination (SDL) Technology

3D Printer Consumables

- FDM/FFF Consumables

- 3D Printing Consumables Chart.

Melting Points and Extrusion Rates

Melting Points and Extrusion Rates - Photopolymer consumables

- PLA plastic for 3D printing

- ABS plastic for 3D printing

- Printable PVA

- PET plastic for printing

- 3D Printable Nylon

- Laywoo-D3 for 3D printing

- NinjaFlex for 3D printing

- Laybrick for 3D printing

- Stratasys Photopolymer Resins

- 3D Ink Photopolymer Resins

- Photopolymer resins Asiga

- Photopolymer Resins Digital Wax Systems

- RapidShape 9 Photopolymer Resins0021

- MadeSolid Photopolymer Resins

- 3D Systems Photopolymer Resins

- Fun To Do Photopolymer Resins

- Polystyrene for 3D printing

- 3D printed polycarbonate

- Portable bar extruders.

Filament manufacturing. How To Make Your Own 3D Printing Consumables

Filament manufacturing. How To Make Your Own 3D Printing Consumables

3D equipment

- 3D pen

- 3D printer FDM

- Catalog of DIY and OpenSource 3D printers

- Photopolymer 3D printer

- Metal 3D printing

Slicers

- All versions of CURA - download

3D printing articles

- How to avoid deformation of models when 3D printing

- How to choose high quality filament

- Processing of 3D printed models

- How to clear a clogged extruder nozzle

- "Rescue" of the product using the Repetier-Host program when 3D printing is stopped

- 3 Commandments to make 3D printed products cheaper

- Photoshop CS6 modeling and 3D printing tutorial

Our reviews about 3D printers and 3D printing

- We bought a 3D printer and decided to make money.

What's next?

What's next? - Cheap 3D printers for every taste

- Household 3D printers for your home

- Jewelry 3D printers or what to give your beloved man

- Metal 3D printing on a home 3D printer. Technology Today and Immediate Prospects

- 3D printer and metal - the present and future of metal 3D printing

- ChefJet Confectionery 3D Printers – The End of the Sugar Cube Era

- MBot Home 3D Printer Review

- 3D printing with chocolate or how to organize your sweet business

- 3D Printers for Jewelers - Unparalleled Print Quality

Technical

- Set up the Marlin firmware and upload it to the 3D printer

- We print with ABS plastic without cracks and heat chambers

Literature

- Book: 3D printing - short and clear

Working with the 3Dtoday portal.

Handbook

Handbook - 3Dtoday: portal visitor guide

What is a 3D printer?

Popular articles

printer's birthday

03/15/2023

2729

And they called it "QuAD"The kinematics was invented by me.Based on 12 mm round rails, on which...

PETG mousetrap

03/14/2023

2462

The title of the post was a joke, just because the result came out a bit like a mousetrap...

A simple calculator for printing costs, depreciation, accounting, and formulas. + new version

03/16/2023

2052

Hello %username%. Article - continuation of work on a simple calculator for the cost of home ...

3D pen

- 1 Description

- 2 History

- 3 Design

- 4 Materials

- 5 Application

- 6 Development

- 7 Interesting 3Dtoday blog posts about using 3D pens:

Description

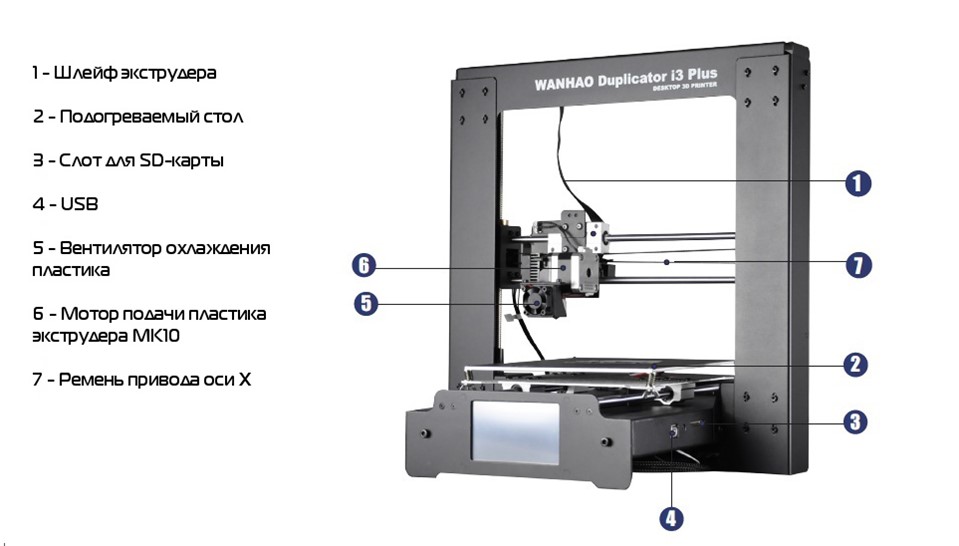

FDM printing is the logical evolution of CNC machines. The only fundamental difference was the use of a specialized nozzle (extruder) for melting and feeding plastic. By the same logic, hot glue guns, which are widespread in everyday life, have also been developed. The use of thermoplastics instead of thermoplastic adhesives allows devices like these, dubbed 3D pens, to be used as hand-held additive manufacturing devices.

The only fundamental difference was the use of a specialized nozzle (extruder) for melting and feeding plastic. By the same logic, hot glue guns, which are widespread in everyday life, have also been developed. The use of thermoplastics instead of thermoplastic adhesives allows devices like these, dubbed 3D pens, to be used as hand-held additive manufacturing devices.

Parts of the future model can be drawn on paper using templates and glued together

History

One of the latest developments is the Dim3W 3D pen

The pioneer of a new direction in the development of 3D printing was the pen from Wodoodleworksr.

The team turned to Kickstarter to raise the funds needed to bring the project to life.

With a $30,000 goal, Wobbleworks had raised over $2 million by the end of the campaign, indicating strong public interest.

Amid the success of 3Doodler, a competitive wave swept through. At the moment, the range of 3D pens includes actual 3Doodler clones like 3DYAYA or SwissPen, as well as more original designs including Dim3W and LIX.

At the moment, the range of 3D pens includes actual 3Doodler clones like 3DYAYA or SwissPen, as well as more original designs including Dim3W and LIX.

The basic principle of operation of all these devices is the same, but there are some design features aimed at improving a fairly young concept.

Construction

In essence, a 3D pen is nothing more than a manual extruder. The user himself acts as the CNC of the machine.

3Doodler disassembly. The nozzle at the bottom and the pull mechanism in the middle of the handle are clearly visible. and heating element.

Since almost all software functions of 3D printers are performed by the user, 3D pens do not require a connection to a computer or the creation of digital models. Only a power supply is required - as a rule, conventional power supplies with a 12V voltage converter are used.

As with FDM printers, it takes a few minutes for the nozzle to heat up, after which the pen is ready to print. The supply of material is carried out by pressing the corresponding button. Some models, such as the Dim3W, are equipped with a print speed control.

The supply of material is carried out by pressing the corresponding button. Some models, such as the Dim3W, are equipped with a print speed control.

Also available with reversible feeder. This feature allows you to quickly remove the plastic filament from the pen and replace it with a different color material.

Materials

3Doodler complete with colorful ABS plastic packs

Two of the most popular plastics in FDM 3D printing are currently used as materials for 3D pens - ABS plastic and organic, biodegradable polylactide (PLA plastic). Theoretically, it is possible to use other materials - polycarbonate, nylon, etc. At the same time, existing models do not provide the ability to accurately adjust the nozzle temperature, which is important when switching to other materials. Temperature characteristics are embedded in the firmware. In the future, we can expect more variety in the range of materials and the ability to fine-tune the temperature if there is a corresponding demand.

Like full-fledged FDM printers, 3D pens use thermoplastic filaments with a diameter of 1.75 or 3mm. For ease of use with the pen, the threads are usually supplied as scraps rather than spools, but it is ultimately up to the user to choose.

Applications

Similar voids formed during plastic delamination due to uneven cooling can be filled with a 3D pen

3D pens are positioned as a means for creative work, three-dimensional drawing. Although devices can indeed fulfill such a role, creating more or less decent-looking models requires serious skill.

However, initially 3D pens were conceived for a completely different purpose, similar to the purpose of their ancestors - hot glue guns. It's about repairs. The fact is that some types of plastics used in FDM 3D printing (for example, the very popular ABS plastic) have a high degree of shrinkage and a tendency to deform during uneven cooling. All this often leads to cracking of the manufactured models. 3D pens were supposed to be a tool for manually repairing printed models. These devices allow you to fill in missing layers or faults.

3D pens were supposed to be a tool for manually repairing printed models. These devices allow you to fill in missing layers or faults.

Particularly good results can be achieved by careful treatment of cracks with acetone, which dissolves ABS plastic. The surface softened in this way will adhere well to freshly applied plastic with a 3D pen.

3D pens allow you to draw in the air instead of paper

The surface of the repaired area can be leveled by sanding and gently working with the same acetone. Similarly, household products can be repaired - many of them are made from the same ABS plastic that has become widespread in the industry.

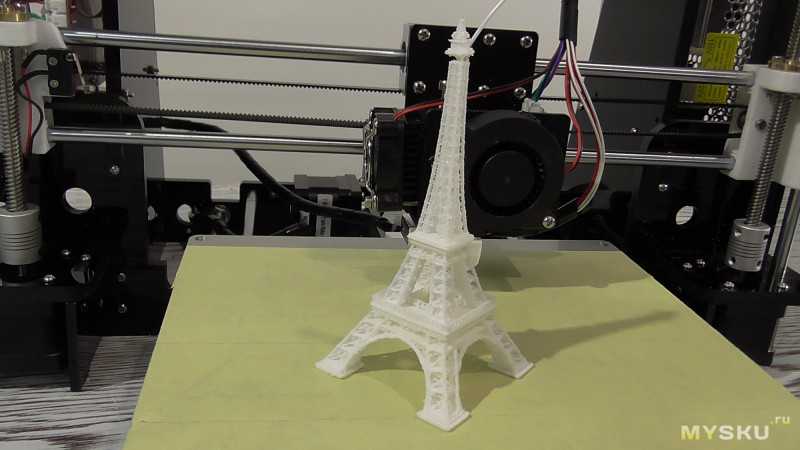

As for artistic applications, 3D pens will appeal to those who love to draw and want to move from 2D sketches to 3D physical models.

The main difficulty lies in purely human limitations - any unwanted hand movement will affect the quality of the model, especially when drawing the model "in the air".

One interesting way to improve the quality is to divide the models into their component parts, using sketches on paper as templates. Finished parts are simply glued together.

BioPen allows surgeons to “paint over” damaged areas of bone or cartilage tissue, contributing to its restoration

This method is quite possible to make a good reproduction of the Eiffel Tower.

Of course, the method is applicable only when creating parts of models with relatively flat surfaces.

Very promising is the possibility of using a variety of 3D pens in medicine.

Devices called "bio-pens" (BioPen) are being tested as tools for applying live cell layers mixed with biopolymers that act as support matrices and contain essential nutrients.

The original 3D BioPen was developed by Australian scientists at ASEC and is designed to repair cartilage and bone tissue.

During surgery, PioPen allows clinicians to “paint over” damaged areas of bone or cartilage, stimulating the recovery process.