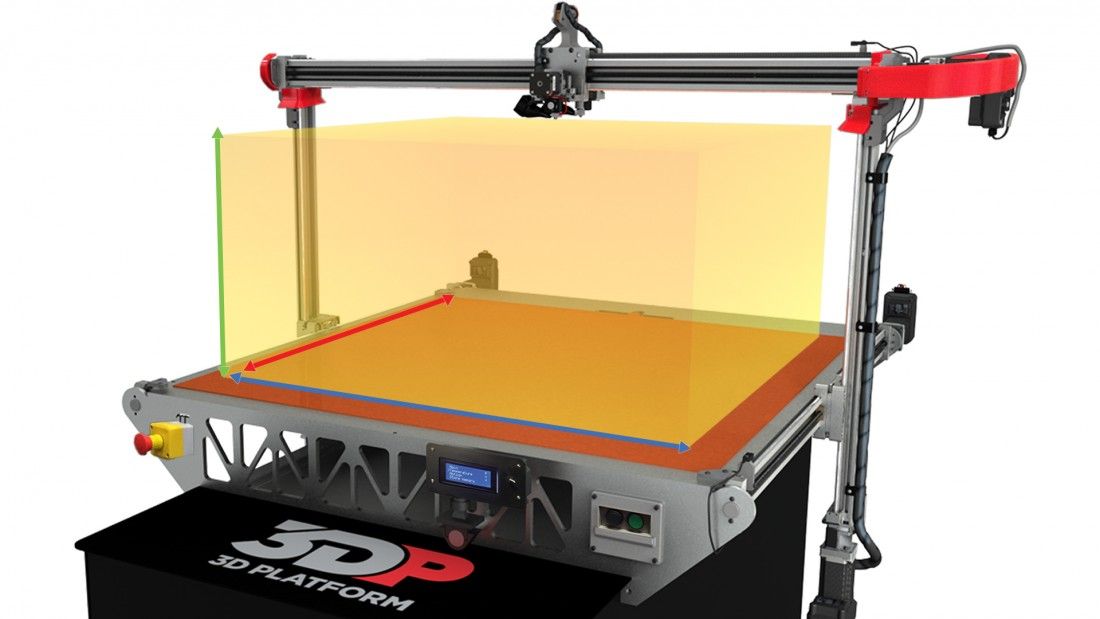

Large format 3d scanner

3D Laser Scanner Artec Ray

Ultra-high precision, fast laser 3D scanner with submillimeter precision to ensure you capture every detail

Cleanest 3D data capture for minimum post-processing time

Ideal for reverse engineering, inspection and construction. Scan large objects both indoors and outdoors!

Easy 3D scanning

Lightweight and user-friendly, Artec Ray was especially designed to ensure you get the most out of this powerful 3D laser scanner, whether it is getting the 3D measurements for quality control of a large industrial object or creating an accurate 3D model for heritage preservation. With no need for any lengthy preparations, you can 3D scan almost anything by simply mounting your Artec Ray on a tripod in front of your object and pressing a button!

Accessible and convenient 3D data capture

Portable and compact, this versatile long-range LIDAR solution is the latest in 3D laser scanning. An inbuilt battery lets you scan both indoors and outdoors for up to 4 hours, without a need for a power source nearby, making this a perfect solution for onsite 3D scanning.

Advanced software compatibility

3D scan and process data directly in the powerful Artec Studio software with a wide range of comprehensive tools available, then seamlessly export to Geomagic Design X at the touch of a button to make the most out of your 3D laser scanning experience.

Control Artec Ray 3D scanner with your phone or tablet

Using the Artec Remote app, you can easily scan all angles of a large object without being tethered to a computer. The scanning process can be controlled by any mobile device or tablet via WiFi. The Artec Remote is available for iOS and Android.

Artec Studio for professional processingProcessing your data in Artec Studio is the next step for your 3D scanning process. With our software, you have easy access to an advanced autopilot mode and the most accurate algorithms for quick and easy data processing, as well as HD Mode and high accuracy used to create the most true-to-form 3D models possible. Power up your workflow as you save time and get excellent results!

The full 3D scanning package

Pair Artec Ray with an Artec handheld 3D scanner, such as Eva or Spider, to effortlessly capture difficult to reach areas, e. g. the interior of a car, or to add intricate detail to a large-scale 3D model. The smart combination of Ray’s long-range 3D scanning capabilities along with the convenience and precision of all of Artec’s handheld 3D scanners ensures limitless 3D scanning potential.

g. the interior of a car, or to add intricate detail to a large-scale 3D model. The smart combination of Ray’s long-range 3D scanning capabilities along with the convenience and precision of all of Artec’s handheld 3D scanners ensures limitless 3D scanning potential.

Achieving maximum accuracy with your 3D laser scanner

Combine Artec Ray with a laser tracker and professional target units for the best possible alignment and registration of scanned data. Get the highest possible accuracy and tight tolerance results for your project.

Quality inspection of large objects right at your fingertips

Looking for a professional solution to do quick quality inspections of big industrial objects? Look no further. With Artec Ray, you can scan large complex parts with metrological accuracy and then import your models into Artec Studio software to carry out basic quality control, and compare it to the original CAD file all in one place. For advanced operations, you can also export the model to Control X and other full package inspection software.

Best-in-class industrial laser scanner

A large working facility, an airplane, an oil rig, or even an outdoor space — whatever industrial object or scene you need to scan, Ray has you covered. Versatile and portable, this industrial 3D scanner is perfect for digitizing and measuring large structures with metrology-grade accuracy at any time and place — day or night, indoors or outdoors.

LiDAR 3D scanner for exact 3D measurements

Thanks to built-in LiDAR 3D scanning technology, Artec Ray allows you to capture precise long-range 3D measurements of complex objects and shapes from up to 110-meters.

Perfect long-range 3D scanner

Capture complex constructions such as warehouses, factories, airports, and apartment buildings to get precise and clean 3D data about the building, such as its size, structure, facade, and more. Thanks to Ray’s extreme accuracy and cleanliness of data, you don’t need to spend much time on processing. Put the scanned material to work right away!

Artec Ray technical specs:

| Range | Up to 110 m |

| Ranging error | <0. 7 mm @ 15 m 7 mm @ 15 m |

| Angular accuracy | 25 arcseconds |

| Range Noise, 90% reflectivity | 0.12 mm @ 15 m |

| Range Noise, 10% reflectivity | 0.3 mm @ 15 m |

| Color | Two fully integrated 5 megapixel cameras |

| Weight | Under 5 kg |

Reverse engineering

- Product design

- Customisation

- 3D documentation

Industrial design and manufacturing

- Reverse engineering

- Quality control

- Rapid prototyping

- Aerospace

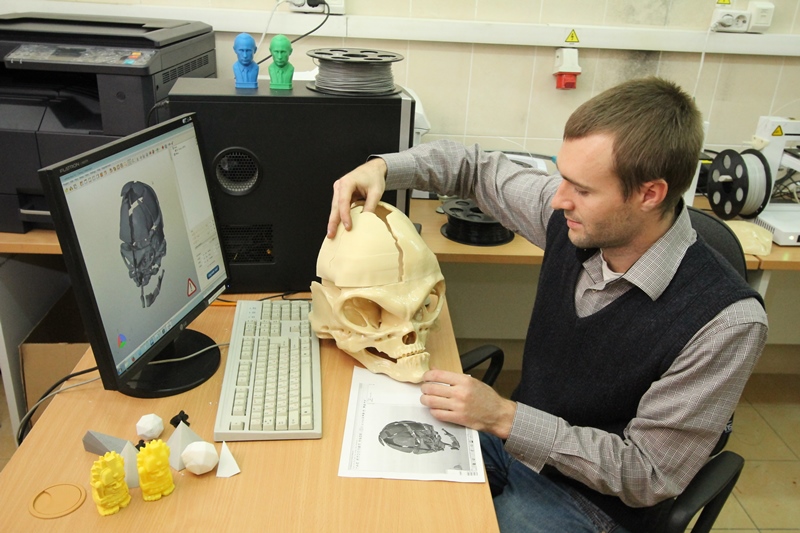

Healthcare

- Orthopedics

- Prosthetics

- Plastic surgery

- Custom wheelchairs

Science and education

- Research

- Training

- Online museums

Art and design

- Heritage preservation

- Architecture

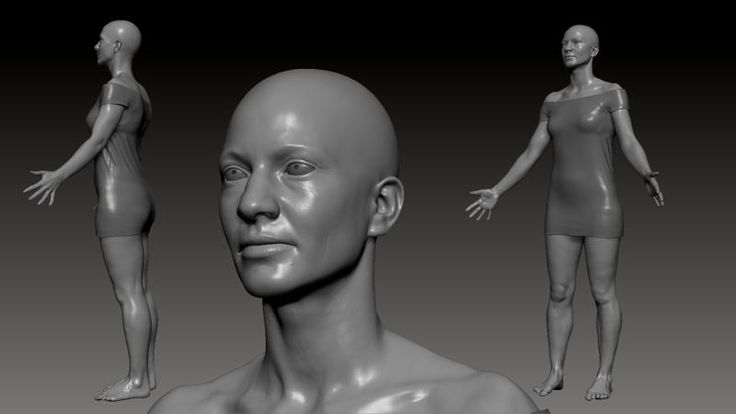

- CGI

- Fashion

Learn more about Artec Ray

Got a question about Artec Ray 3D scanner?

Can the Artec Ray be controlled remotely?

Yes. You can control the scanner remotely via the Artec Remote mobile application.

What size objects is Artec Ray able to scan?

We recommend using Ray to capture large objects such as wind turbines, ship propellers, airplanes, warehouses, and buildings.

What's the difference between Artec Ray and other long-range laser 3D scanners?

The most distinguishing difference and advantage of Artec Ray is that it’s much more accurate. The scanner is able to capture objects and scenes with submillimeter accuracy over long distances. This feature makes Ray a perfect, precise solution for reverse engineering, dimensional control, forensics, and more.

Another difference is that Ray captures much cleaner 3D data than other laser scanners. This means that you can spend significantly less time on processing and cleaning up the noise to get a final 3D model.

Another critical advantage is that data scanned with Ray can be easily paired with the data from other Artec scanners, all-in-one software — Artec Studio. For example, a large and complex object such as an airplane or a ship can be scanned with Ray to capture the shape and all the bigger elements, while other smaller parts can be scanned with a different Artec scanner such as Leo, Eva, or Space Spider and in even higher resolution.

| Recommended work range | 1-50 m | 1-110 m |

| Ranging error | 0.7 mm @ 15 m | <0.9 mm @ 15 m |

| Angular accuracy | 25 arcsecs | |

| Range noise, 90% reflectivity | 0.12 mm @ 15 m | 0.25 mm @ 15 m |

| Range noise, 10% reflectivity | 0.3 mm @ 15 m | 0.7 mm @ 15 m |

| Speed, points/second | 208,000 | |

| Scanning modes | Autonomous or via USB | |

| Color | Two fully integrated 5-megapixel cameras | |

| Horizontal (maximum) | 360° | |

| Vertical (maximum) | 270° | |

| Scanner type | Phase-shift, hemispherical scanner with 360° × 270° field of view | |

| Distance measurement method | Phase shift | |

| Laser wavelength | 1550 nm | |

| Laser type | Continuous wave | |

| Laser class: (IEC EN60825-1:2007) | Class 1 | |

| Internal coordinate representation unit | 0. 001 mm 001 mm | |

| Beam diameter at aperture | 3 mm | |

| Internal angular representation unit (vertical/horizontal) | 1 arcsec | |

| Min. vertical point density | 20 points/degree | |

| Min. horizontal point density | 20 points/degree | |

| Max vertical point density | 80 points/degree | |

| Max horizontal point density | 80 points/degree | |

| Weight with battery | 5.74 kg | |

| Dimensions L × H × W | 287 × 200 × 118 mm | |

| External power supply voltage | 14-24 V DC, 30 W | |

| Internal battery power supply | Two Li-Ion 14 V, 49 Wh batteries, powers the scanner for up to 4 hours | |

| Power consumption | 30 W | |

| Supported OS | Windows 7, 8 or 10 – x64 | |

| Minimum computer requirements | Intel Core i5, i7 or i9, 32GB RAM, GPU with 2 GB VRAM | |

Best 3D Scanner - The Top 10 3D Scanners for 2022 [Reviews]

Much like a regular scanner, laser scanning 3D uses various methods to analyze a physical object and then relay that data to a computer to create digital 3D models. The 3D digitizer process might be automatic or users might need to complete the model to their requirements by using software. The aim is usually to get an accurate model to the right standard and format, ready for 3D printing, for virtual reality applications or other purposes.

The 3D digitizer process might be automatic or users might need to complete the model to their requirements by using software. The aim is usually to get an accurate model to the right standard and format, ready for 3D printing, for virtual reality applications or other purposes.

Such scanners are used in many professional industries, but with advances in home 3D printing, there are now also a good variety of home options. They are sometimes called portable 3D scanners or handheld scanners if they’re designed as such. These allow you to easily scan small to medium-sized objects for 3D printing.

Some come completely assembled while others, like 3D printers themselves, you’ll have to put them together by yourself. The benefit for those that are good with that type of thing is it reduces the price and allows for easier upgrades and modifications.

Scanning is typically done using laser triangulation or various forms of structured light to surround the object and measure its 3D dimensions or ‘geometry’. High-quality 3D scanner camera lenses also capture the color and surface texture of the object. Using accompanying or third-party software, the model can then be scaled up or down, or completely modified.

High-quality 3D scanner camera lenses also capture the color and surface texture of the object. Using accompanying or third-party software, the model can then be scaled up or down, or completely modified.

It’s never been easier to scan 3D objects!

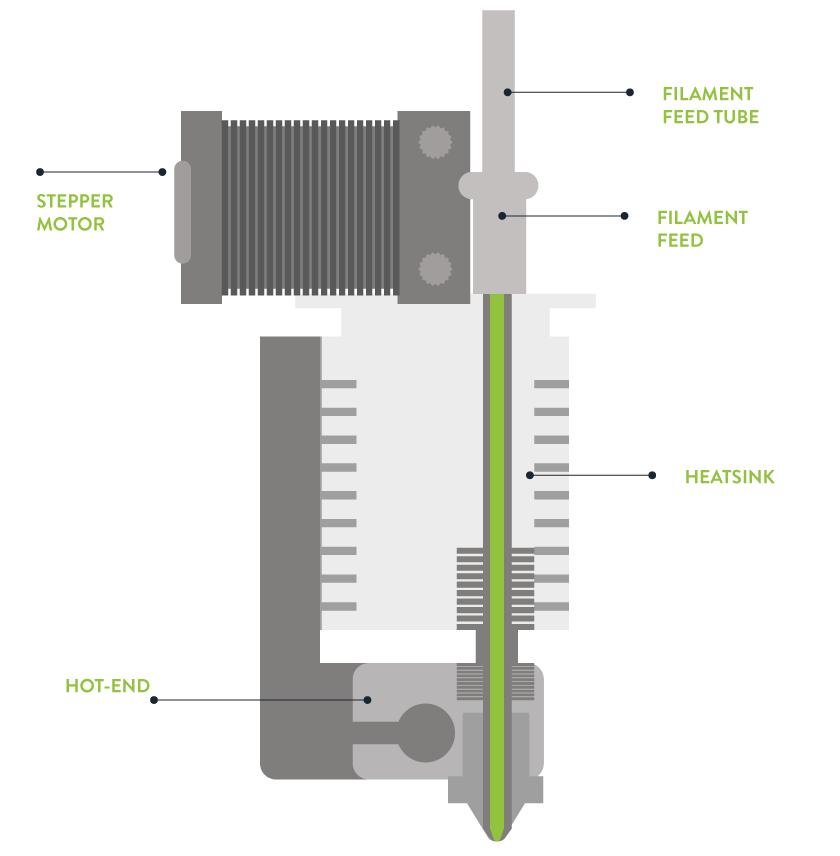

How Do 3D Scanners Work?So, how do you scan 3D objects into a computer? Whether it’s on an industrial scale, at a small business, or on a desk at home, 3D scanners all share similar characteristics in the way they work.

The majority use laser and/or white light technology and cameras. The physical object is placed in a bed, tray, or suitable location. Electromagnetic light bounces off the object, measuring its circumference, full dimensions, and all its finer details.

Depending on the scanner it may use multiple light sources, cameras, and other tech to aid this process. The collected data is called a point cloud, which refers to the number of points captured by the laser.

The more points collected the more accurate the scan. A high-resolution scanner can capture hundreds of thousands of points in seconds and reach millions overall. The whole process only takes a few minutes.

While the light tends to be a measure of the object’s geometry, HD cameras tend to capture the surface detail and color.

The data recorded can then be fed into a computer-aided design program or similar software for inspection and manipulation. E.g. if you’re planning to use it for 3D printing, the model might need scaling up or down, hollowing, have added support structures, be re-colored or have brightness/contrast changes, etc.

There are, of course, different types of 3D scanner and scanning technology. So, let’s take a closer look at each one:

Types of 3D ScannersThere are several 3D scanner types. Before making your decision check out the section below:

Handheld vs StationaryHandheld and stationary 3D scanners often use the same technology and can overlap in their functions. The difference lies mainly in the design.

The difference lies mainly in the design.

A handheld scanner has a grip and lets the user move around the object themselves to capture it at every angle.

A stationary scanner has to be positioned in front of the object, which is typically placed on a rotating plate and captures it as it spins 360 degrees. The user may have to reposition the object several times to capture every angle.

Newer designs are becoming smaller and more easily portable.

Laser TriangulationThe most common technology used in 3D scanning is laser trigonometric triangulation. It records millions of different points on the surface of the object to build an accurate overall polygon mesh. These are common in handheld options and industrial-grade scanner machines. They can also work long-range and for laser-tracking objects.

Structured-Light 3D ScannersSimilar and often used interchangeably with laser triangulation, structured light or ‘white light’ projects itself in a grid-like pattern over an object. It can then measure the structure of that grid as it applies to the object by using sensors/3D scanner cameras and triangulation.

It can then measure the structure of that grid as it applies to the object by using sensors/3D scanner cameras and triangulation.

Longer range scanners use phase shift or pulse technology that can capture millions of points while rotating 360 degrees with the aid of mirrors. This is more commonly used to scan large objects like cars or buildings.

They might also use ‘time of flight’ technology that measures the distance of an object in relation to the speed of light and the time it takes for it to return to a sensor.

This is less relevant for everyday 3D scanning and printing.

3D Scanning ApplicationsThere are many different applications for 3D laser scanning - from those for 3D printing at home, to prototyping, industrial scale medical supply production and even architecture.

Hobbyist 3D printingCheaper 3D scanners are typically used by home users for scanning simple objects and 3D printing them for fun.

The medical field and dentistry commonly use 3D scanning to create implants and aids to serve their patients’ needs. For example, scanning people’s feet with a high-quality 3D scanner allows for the creation of orthotics (shoe inserts). It is also used in the creation of prosthetics.

Virtual EngineeringIndustrial 3D scanners are used both in the creation and quality control of cars, planes, and even aerospace. It ensures existing parts are as accurate as their original models and that new viable parts are made.

Reverse Engineering and RepairsFrom the home computer desk to the manufacturing floor, 3D scanning allows users to reverse engineer or copy existing objects. Saved models also allow for the reconstruction of damaged objects.

Virtual RealityFrom creating realistic 3D worlds to the people that occupy them, 3D scanning devices are integral to the growing virtual reality industry. This ranges from AAA video games, virtual cinematography, and computer-generated imagery (CGI), to virtual tours and office meetings. It is also a side industry to motion capture.

This ranges from AAA video games, virtual cinematography, and computer-generated imagery (CGI), to virtual tours and office meetings. It is also a side industry to motion capture.

CSI has come a long way. Forensic experts nowadays don’t just have to rely on memory, photos, and evidence of a crime scene. They can capture the entire location in a full 3D model for closer inspection and for running through different scenarios.

Archeology and ArchivingFrom museums to libraries, 3D scanning is being used to log and preserve everything from artifacts to digitizing books. This also gives experts and the public remote access.

Architecture3D scanning can also help architects map the areas they will be designing their buildings in, take inspiration from existing architecture, and aid in building miniatures/prototypes.

What Should I Know Before Buying a 3D Scanner?Before you buy a 3D scanner, there are several things to consider:

- your budget

- what you’ll actually be using it for

- it’s speed and accuracy

- the device’s other features.

3D laser scanner price ranges vary greatly. On the cheaper end, you may be able to pick one up for home for just shy of $300, like the XYZprinting 3D Scanner 1.0 A. However, if you want the highest overall quality and the ability to scan small and large objects. Or, if you’re a professional and need a 3D part scanner in a field like medical implants or automotive parts, you’re looking at anywhere between $3,000 and $35,000.

Typically, it’s best to look for 3D scanners for sale online where you can find the best selection and prices.

3D PrintingWhile a dual 3D printer scanner combo is rare, if you want to scan models for 3D printing, you will need to make sure it has good accuracy and resolution. The software also must be able to export to a usable format. You will need to check your 3D printer and its own software to see what file types it accepts and then choose your scanner accordingly.

Fortunately, almost all of our 3D scanner reviews include devices that can export in common file types like OBJ and STL.

It’s typically only the more expensive scanners that are good for other applications, like VR, full-body scanning, architecture, and engineering.

Handheld vs StationaryWe already explained the difference, but basically, a handheld scanner is mobile, while the stationary one will require you to move and adjust the object. Neither is necessarily better than the other, it’s all down to your needs.

SpeedHow fast is the scanner? Do you have a lot of spare time or require the job to be done as fast as possible? All 3D scanners will take a few minutes to complete, while many scanning complex objects in high resolution can talk half an hour or longer.

Accuracy and ResolutionAccuracy refers to how close to the object being scanned your digitized model will be, measured in millimeters. Therefore, the smaller the better. The term resolution may be used interchangeably with accuracy or refer to the resolution of any cameras being used as part of the scanning process.

Therefore, the smaller the better. The term resolution may be used interchangeably with accuracy or refer to the resolution of any cameras being used as part of the scanning process.

Generally, the lower the millimeter, the better. Other factors also play a role in overall quality, such as lighting conditions, color, and depth.

Object Size and SpaceSome types of 3D scanners excel at scanning small objects while others are better at medium to large. Others are all-rounders. Before buying a scanner, you should decide the general size of the items you will be scanning.

You will also need to make room for the scanner. Although all the products on our list are small and relatively portable, stationary scanners at least need a table to work from. Likewise, there will be a minimum and maximum distance the scanner must be in relation to the object being scanned.

You’ll need more room when scanning larger objects in full.

All 3D scanners need to be connected to a computer or device to help monitor the process and for saving the digital model. This is usually done via a USB or HDMI cable. You will need to check that your computer or laptop meets the minimum requirements for the scanning and modeling software. Also, make sure that you have a tablet to make real-time monitoring easier.

SoftwareYour device will either come with its own software or a popular third-party program to aid the process and to help touch-up the model once it’s scanned. Different 3D printing software is better suited to different skill levels. Some programs have a lot of features for experienced users and others do most of the basic tasks automatically. Check our 3D scanner reviews to see the software each device comes with and how advanced and easy to use it is.

Wrap UpWhether you’re looking for a tool for your home or something more on an industrial scale for your business, our 3D scanner reviews have something for everyone. From handheld devices to structured lightboxes with turntables, you’ll be creating 3D models or reverse engineering parts in no time. Perhaps you’ll even do a 3D selfie or two!

From handheld devices to structured lightboxes with turntables, you’ll be creating 3D models or reverse engineering parts in no time. Perhaps you’ll even do a 3D selfie or two!

If you’re still unsure about 3D printing after reading our reviews and guides, check out our answers to your most commonly asked questions below.

we choose the best in 2022 in our direction

In order to expand the user audience, SHINING3D offers universal solutions - the same 3D scanner is able to satisfy the needs of ordinary consumers and be in demand in industrial production. Based on the feedback and reviews of device owners, the developers have improved the line of models, making 3D digitization and additive technologies even more accessible.

Contents:

- EinScan 3D scanners

- For beginners, designers or education

- Scanners for objects of various sizes

- 3D scanning of people and their faces

- EinScan Pro 2X 3D scanner 2020 900 Transcan0

- 3D-scanner 8 C007 indicators need to be understood in order to choose what you need

- Accuracy

- The use of professional 3D scanners in metrology

- The use of 3D scanners in mechanical engineering

- Reverse engineering

- Quality Control

- Laser 3D scanner Freescan UE

- High-precision stationary 3D scanner Autoscan Inspec

- OptimScan-5M Metrological 3D scanner 9000 EinScan Series 3D Scanners

For Beginners, Designers or EducationalScanning small objects requires precision and advanced settings in the capture software.

The first thing users are guided by is the scanning area. Using two models - EinScan-SP and EinScan-SE - it will be possible to scan an object from 30 × 30 mm.

The first thing users are guided by is the scanning area. Using two models - EinScan-SP and EinScan-SE - it will be possible to scan an object from 30 × 30 mm. EinScan-SP and EinScan-SE are useful for beginners, designers and educational users. Desktop scanners SE and SP are the easiest to learn.

Key benefits:

- Easy device setup with Plug and Play technology;

- Russian software interface;

- the ability to scan objects of different sizes - from small to large; nine0008

- texture tracking.

- 1 second per shot;

- Russified software;

- automatic and fixed operation;

- Aligns scanned data with marks.

- 1 second per shot;

- 45 seconds for 360-degree scanning in AutoScan mode;

- Russified software;

- automatic alignment of multiple scans; nine0008

- API access service for 3D printers of any brand.

Scanners for objects of various sizes

aIn this category, models with the “H” index successfully demonstrated their capabilities: EinScan H , EinScan HX from the line of hybrid devices.

The portable EinScan H is the most affordable for the price.

0066

- EinScan H - an infrared emitter has been added to the LED illumination;

- EinScan HX - white LED light combined with a blue laser.

- Structured radiation of the LED source and scanner laser;

- In Laser Scan mode, object scan accuracy is 0.04 mm; nine0008

- Minimum point distance 0.05 mm;

- High efficiency in fast scan mode - 1,200,000 points/s;

- Full color copy.

- Two scanning technologies - LED and invisible infrared light, combined in one device;

- Scanning people (portrait, full-length) and other living objects;

- High accuracy of scanned data up to 0.05 mm and volumetric accuracy of 0.1 mm/m;

- Fast scanning and large FOV scanning 420*440 mm.

- The new principle of 3D scanning of the device in manual HD mode, which allows scanning without the use of markers (as Einscan Pro HD does).

The old model could not scan without markers in this mode. The quality and detail of scans have also been improved. nine0008

The old model could not scan without markers in this mode. The quality and detail of scans have also been improved. nine0008 - Higher device scanning accuracy in manual HD mode, improved volumetric accuracy for scanning large objects

- Higher scanning speed in manual HD mode

- Increased 3D scanning area

- Added alignment modes in manual HD mode: alignment by markers, alignment by geometry , hybrid alignment. This expands scanning capabilities and efficiency in a wider range of tasks and areas.

- Color Pack 3D scanning module - an additional camera that allows you to scan with color and texture; nine0008

- Industrial Pack - turntable and tripod. Suitable for high quality scanning of small objects in the studio.

- characteristics of the object;

- user qualification; nine0008

- scanner settings.

- the highest accuracy;

- the ability to upload scans to processing programs; nine0008

- compatible with CAD/CAM technologies;

- work with objects of various sizes and shapes, including those with complex geometry;

- texture tracking and color imaging.

- reverse engineering;

- ultra-precise 3D quality control;

- implementation of intermediate stages of the technological chain of additive manufacturing; nine0008

- faster prototyping and other operations.

- high speed;

- ultra-precise measurement and digital copy saving;

- processing of objects regardless of the size and complexity of the form;

- possibility of integration into automated production systems. nine0008

- reverse engineering, or reverse engineering;

- metrological control;

- test measurements of geometrical parameters for the purpose of quality control and detection of defects;

- creation of archives of digital models.

- Absolutely accurate data for reference comparison;

- measurement of millions of surface points;

- high speed operation;

- possibility of automatic operation. nine0008

- user friendly interface;

- the accuracy of the 3D model reaches the metrological level with an error of 10 µm; nine0008

- the device can be used for non-contact measurement and quality control;

- the process is fully automated.

- accuracy - 15 microns; nine0008

- two 5-megapixel cameras;

- high processing speed;

- blue light scanning technology.

- Light weight, only 240g;

- Fast 3D scan, 25 sec single jaw, 1 min full arch;

- 2 tip sizes, suitable for adults and children;

- AI Scan - speed up the scanning process;

- Powerful software, ortho modeling and oral health report. nine0008

- scanning speed of one jaw - 13 seconds;

- high accuracy - 7 µm;

- data export to virtual articulator;

- the ability to work with non-separable objects; nine0008

- own fully Russified Dental Scan software compatible with most CAD/CAM solutions.

- Quadruple resolution: The device captures the finest details and scans large objects using a unique and versatile combination of high quality optics and multiple blue lasers.

- 3x measurement speed and instant meshing: The scan area has been expanded with 11 blue laser crosses (22 lines) capable of up to 1,300,000 measurements per second. This allows you to get a ready-to-use file based on scanned data much faster.

nine0008

nine0008 - More precise and traceable measurements: volumetric accuracy of 0.020 mm + 0.040 mm/m according to VDI/VDE 2634 part 3 and ISO 17025 – reliable measurements and full linkage with international standards of measurement procedures.

- Two models to choose from - BLACK and BLACK|Elite: customers can choose from two models, depending on the complexity of parts, speed and accuracy of measurements, etc.

- Improved VXelements 7.0 software: The interface has been updated and many features have been added that are as impressive as the new 3D scanner itself. Working with the scanner has become much more convenient and easier. nine0008

- And much more! Visit the Creaform website and our blog to learn more about innovative technologies that provide high accuracy, simplicity, portability and speed for applications such as product development and quality control.

- Plug and play: No setup required. Reliable positioning based on geometry, color or labels.

nine0008

nine0008 - Quadruple resolution: Stunning 3D scan quality with flawless color texture and geometry tracking.

- 3X measurement speed and instant ready-to-use files: The scan area includes 99 swaths at up to 1.5 million measurements per second, resulting in a ready-to-use polygon mesh much faster. The mesh file can be imported into 3D modeling and 3D printing software without any additional processing. nine0008

- Twice as accurate: Reliable measurements with an accuracy of 0.050 mm.

- Smart design: multi-position handle provides excellent ergonomics.

- Improved VXelements 7.0 software: The interface has been updated and many features have been added that are as impressive as the new 3D scanner itself. Working with the scanner has become much more convenient and easier.

- Access to metrology: the new SPARK is the first from the Go!SCAN line to be entered into the State Register of SI, will receive a metrological Certificate and can be used in the tasks of controlling the geometric parameters of products.

Learn more

This high-tech solution makes it possible to use these two professional scanners. Manual mode allows you to scan objects of different sizes - medium and large.

Photo of a 3d scanner EinScan HXCopying accuracy is so great that when scanning objects of works of art, it is possible to obtain a perfect replica. For medical institutions, this is also a worthy find. Separately, it should be noted the presence of a built-in color camera.

3D scanning of people and their faces

Living objects require special scanning technology. You can get a digital copy of a fragment of a human body, face and hair using EinScan H hybrid models - thanks to two light sources and a color camera, they produce an ideal 3D model with texture preservation. nine0003

HX is a universal scanner model, and Einscan Pro HD/Einscan pro 2x 2020 are multi-functional scanners that have the ability to perform tasks in various industries. nine0003

nine0003

The EinScan Pro HD is an upgraded scanner from the older Einscan Pro 2x series thanks to its ergonomic and high quality design. Models in this range can be used with a special tripod.

This professional 3D scanner provides high precision scanning of objects in both operating modes: up to 0.045+0.3 mm/m.p. in manual mode and up to 0.04 mm. in fixed scan mode.

Manual object scanning has two submodes: Rapid and HD, the latter providing a higher level of detail. nine0003

The maximum possible scanning speed for this scanner is 3 million points per second. Even aside from the specs, you can see that the device is extremely fast in real-life scenarios. For example, a 220 x 71 cm low relief sculpture can be fully digitized in color in less than a minute.

Scanning of human bodies is also possible with this device, it provides decent quality. Last but not least, the device can scan color materials, including even textured images. This feature is available as a paid option called the Color Pack. nine0003

nine0003

EinScan HX is more expensive than the EinScan H scanner, and professional scanners, which include the EinScan Pro HD, are traditionally more expensive than others of the "classmates" and therefore are available to large additive manufacturers.

EinScan Pro 2X 2020 3D Scanner

Portable and versatile handheld 3D scanner for high precision results

The EinScan Pro 2X 2020 3D scanner is an excellent option for scanning small, medium and large objects. nine0003 3D scanner EinScan Pro 2X 2020

The updated scanner model has improved the main characteristics, added new 3D scanning algorithms. Thus, Einscan Pro 2x 2020 has become a more affordable version of Einscan Pro HD, retaining the advantages and features of the old model.

The main improvements of the new model:

Einscan Pro 2x 2020 3D scanner is compact and lightweight, you can take it anywhere with you. It has a comfortable grip and is light weight, and if you need HD mode accuracy, put the scanner on a tripod. The scanner is connected via USB 3.0 to a computer or laptop. nine0003

The latest developments in data capture and optimized algorithms make the Einscan Pro 2x 2020 3D Scanner a true breakthrough with a scanning speed of up to 1,500,000 points per second (at 30 frames per second) in manual scanning mode.

If you need to expand the functionality of the scanner, Shining 3D offers several options:

Transcan C

3D ScannerThe Transcan C 3D Scanner is a professional scanning grade scanner capable of capturing “extraordinarily” accurate high-resolution scans of small to medium objects thanks to two 12-megapixel color cameras with adjustable scanning range and the ability to switch between multiple permission levels within a single project. nine0003

The 3D scanner has a sliding design that allows you to easily switch the scanning range between 150mm x 96mm and 300mm x 190mm to suit different sizes of objects. The multi-resolution fusion algorithm allows you to mix high, medium and low resolutions in the same project, making the scanner much more efficient, and its two cameras can capture a 24-bit color map for detailed 3D color data.

Transcan C features a structured light scanning mode with an automatic turntable that, in combination with the scanning software's stitching algorithm, allows “efficient 3D model acquisition without manual intervention. nine0003

What other indicators do you need to understand in order to choose what you need? - ease of setup and others. Of course, the properties are considered in a complex: the most important parameter is considered as a basic one, the rest are considered as auxiliary, but at the same time mandatory. nine0003

3D Scan Accuracy

The degree to which the copy matches the original is perhaps the most important indicator. The technical characteristics of scanners indicate the maximum allowable deviation of the scan size from the real object. The smaller the number, the more accurate the 3D scan will be. But the deviation in reality can be greater, since it is quite difficult to create ideal conditions for the device to work, the result is affected by:

The use of professional 3D scanners in metrology

3D scanners handle the process of measuring the dimensions and shapes of models in a matter of minutes, unlike traditional coordinate measuring machines. The non-contact mode of operation allows the device to scan surfaces of complex shapes (internal corners and edges), recesses and other hard-to-reach places.

After receiving all the necessary data, they are transferred to the computer for processing. The program performs a comparison of indicators in order to identify deviations - a mismatch in shape and size, the presence of chips, cracks and other deformations caused by mechanical stress or corrosion processes. nine0003

Innovatively adapted blue laser 3D scanning technology

For metrology purposes for scanning a small object, we recommend the OptimScan-5M, 3M and AutoScan Inspec Scanner-Inspector. All these devices to some extent belong to the same price niche, are multi-tasking, make it possible to obtain high-quality digital 3D models for comparison with reference samples, demonstrating:

Professional, they are also industrial, 3D scanners help to perform the following tasks:

3D scanning in mechanical engineering

The integration of 3D scanning technologies into production processes gives undoubted preferences. Properties of modern industrial scanners:

With the help of 3D scanners and specialized software, numerous processes can be performed:

Reverse engineering

Reverse engineering of complex shapes is one of the areas of industrial engineering. A physical sample is converted into a digital copy using a 3D scanner. The resulting polygonal model is converted into a CAD format. The digital copy is modified and modified to achieve the specified parameters. Unlike traditional design, work takes many times less working time. The finished object becomes the basis for serial production. nine0003

Quality control

Metrological 3D scanners make it possible to obtain a point cloud of the test sample, on the basis of which an ultra-precise 3D model of the part is formed. It is compared with a digital copy of a reference sample or with an existing CAD model.

Benefits of 3D quality control:

The obtained data can be used for reverse engineering.

Scanners from the metrological category are recommended for quality control.

FreeScan UE

Shining 3D Handheld Laser Scanner FreeScan UE is the latest addition to the FreeScan high performance 3D scanner line. The device uses the patented blue laser technology and features high accuracy and stable repeatability.

Sunny Wong, product manager of Shining 3D, states: “Innovative adaptation of blue laser 3D scanning technology, high precision and stable repeatability, and easy and convenient operation of hardware and software, enable FreeScan UE to efficiently and accurately upgrade digital workflows in engineering and inspection tasks”. nine0003

The metrology-grade FreeScan UE system delivers 0.02 mm accuracy and 0.02 mm + 0.04 mm/m volumetric accuracy. With a maximum scan area of 510 x 520mm, users get a field of view suitable for large-scale reverse engineering projects.

AutoScan Inspec High Accuracy Stationary 3D Scanner AutoScan Inspec

Works with native software developed by SHINING 3D programmers for industrial applications.

OptimScan-5M 3D metrological scanner

OptimScan-5MThe professional 3D metrological scanner OptimScan-5M shows the best consumer characteristics required just for 3D inspection:

AutoScan Inspec Desktop Scanner is a two-in-one scanner-inspector that works in automatic mode. The scanner performs 3D scanning with the highest precision and 3D inspection of objects. This is one of the best devices for working with parts of complex shape and the smallest elements:

Solutions for dentistry

In dental orthopedics, 3D scanners - intraoral and dental - have become indispensable assistants for orthopedists and dental laboratory specialists. The former are used for scanning, creating digital impressions and then manufacturing perfectly fitting prostheses, crowns, veneers and other dental restorations using a 3D model using CAD / CAM technology. The second digitizes plaster casts or abutments with tiny elements. nine0003

The second digitizes plaster casts or abutments with tiny elements. nine0003

Aoralscan 3

The Aoralscan 3 is a compact, powerful device with simple, user-friendly controls and an updated algorithm:

AutoScan-DS-MIX 3D Dental Scanner

AutoScan-DS-MIXAutoScan-DS-MIX is an exceptional performance dental scanner with two 5 megapixel cameras and advanced blue light 3D scanning technology :

SHINING 3D's 3D modeling and additive manufacturing products make it easy to find the right equipment for solving tasks in industry, medicine, education and everyday life.

3 times faster, 2 times more accurate!

You are here

Home

nine0002 Creaform, the world leader in portable and automated 3D measurement solutions, today announced the release of the heavily redesigned and enhanced versions of the HandySCAN 3D™ and Go!SCAN 3D™ 3D scanners.HandySCAN BLACK: A new benchmark in portable metrology

HandySCAN BLACK is Creaform's third generation of metrology class devices. The novelty is characterized by the use of improved optics, blue lasers and powerful algorithms that allow you to perform measurements much faster and more accurately. The release of this 3D scanner is the result of over 15 years of technology development to meet the growing needs of the manufacturing and engineering industries. HandySCAN BLACK is designed for professionals who need the most efficient and reliable tool on the market to accurately measure physical objects. nine0003

HandySCAN BLACK is designed for professionals who need the most efficient and reliable tool on the market to accurately measure physical objects. nine0003

HandySCAN BLACK combines high-quality 3D scanning with advanced optics and 14 or 22 blue laser lines with an elegant, ergonomic design that won the 2019 Red Dot Design Award. Creaform product line. As the company's flagship handheld 3D metrology scanner, the HandySCAN BLACK sets a new measurement standard by enabling scanning in seconds, anywhere, no matter the size, material, or complexity of objects. nine0003

“Over the past decade, Creaform technologies have become the standard for high-precision devices that provide reliable measurements for informed decisions at all stages of product lifecycle management,” says Simon Côté, Product Manager at Creaform. “HandySCAN BLACK combines the strengths of its predecessors and takes quality control to the next level on the shop floor, at the machine, in production – wherever customers need it.” nine0003

“HandySCAN BLACK combines the strengths of its predecessors and takes quality control to the next level on the shop floor, at the machine, in production – wherever customers need it.” nine0003

Go!SCAN SPARK: a powerful tool to accelerate your time to market

Creaform's second big hit is Go!SCAN SPARK. The third generation of professional 3D scanners, Go!SCAN 3D, features unparalleled measurement speed and ease of use. The new scanner is designed specifically for product designers and engineers who need the most efficient portable tool to digitize physical objects virtually anywhere. nine0003

Go!SCAN SPARK has four built-in cameras for faster 3D scanning and color data acquisition. It also features an ergonomic design, allowing you to use different hand positions. The Go!SCAN SPARK 3D scanner can measure a wide range of surfaces and textures at various stages of product development right in the factory.