3D print composite

Composite Materials for 3D Printing: What Should You Know?

Published on July 26, 2021 by Madeleine P.

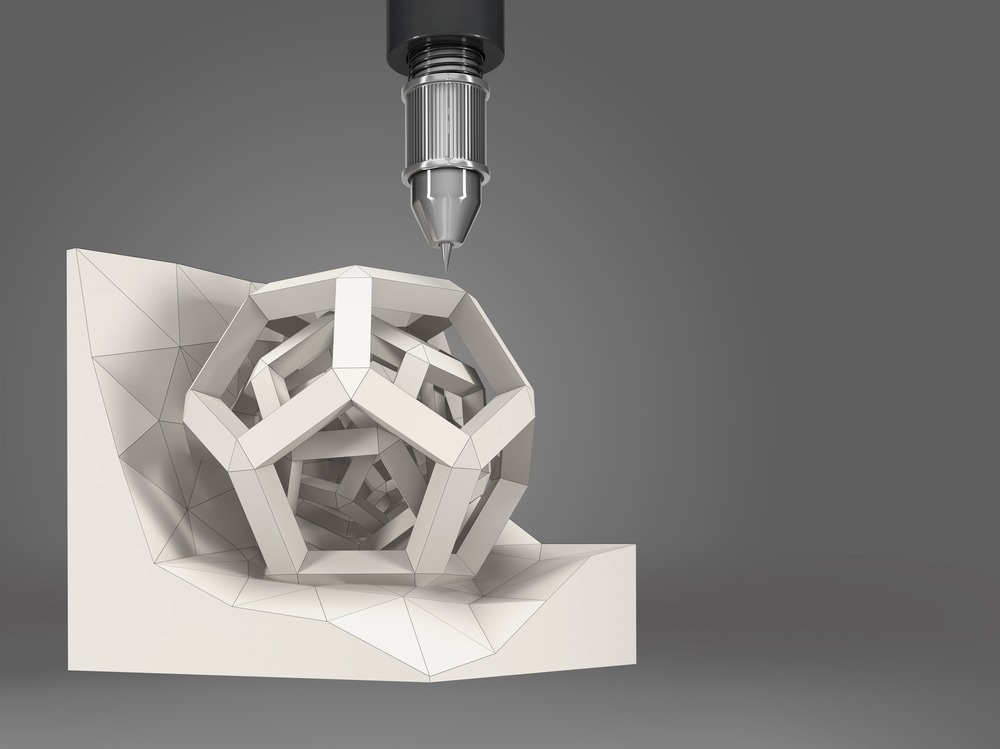

In recent years, composite 3D printing has become increasingly popular. One of the youngest branches of 3D printing, this technology is now used by many players in additive manufacturing, such as Impossible Objects, a company specializing in the field. In fact, it has become so popular that some studies estimate that the composite 3D printing market will reach $1.73 billion by 2030. Logically, when we talk about composite 3D printing, we think of composite printers, but also of composite materials, which are at the heart of this process. Composite materials are made of at least two components and have special properties, making them uniquely suited to various industries that use 3D printing.

Most of the time, in order to manufacture these materials, it is necessary to mix a plastic, which we will call the matrix, with fibers. Today, there are many different kinds of fibers, but three are mainly used for 3D printing: carbon fiber, which is probably the most popular, fiberglass, and PPD-T, also known as Kevlar. Depending on the requirements, either short or long fibers can be used. Short fibers are integrated into the entire matrix and will reinforce the entire part; this type of material is compatible with a wide variety of 3D printers. Long fibers are placed during the printing process itself and are not cut into small pieces, allowing reinforcement only where it is needed. They are only compatible with certain machines at this point in time.

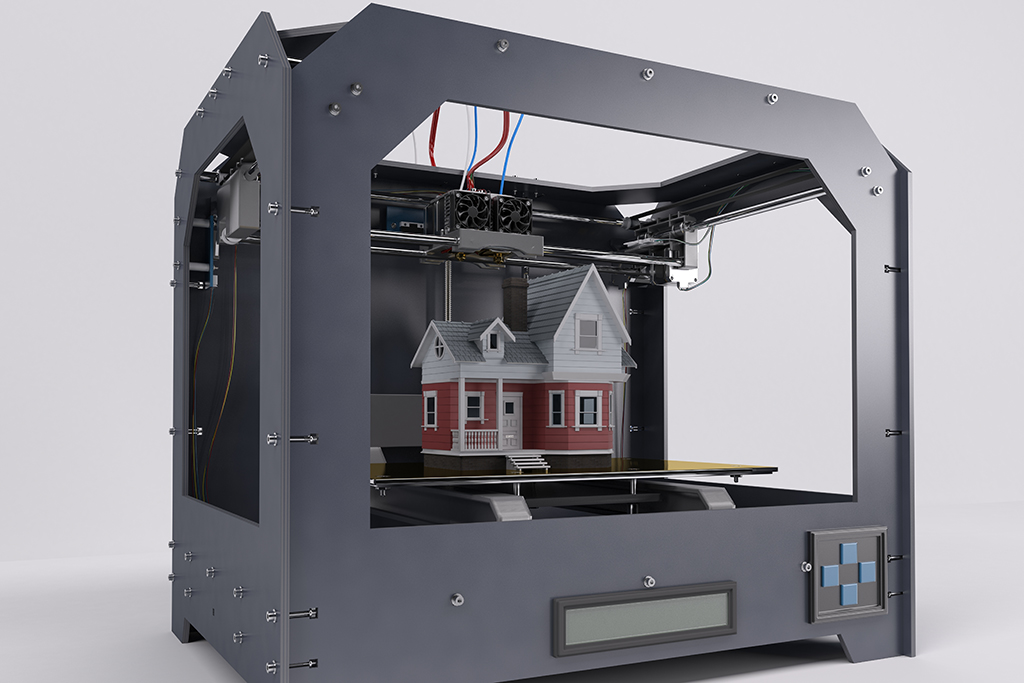

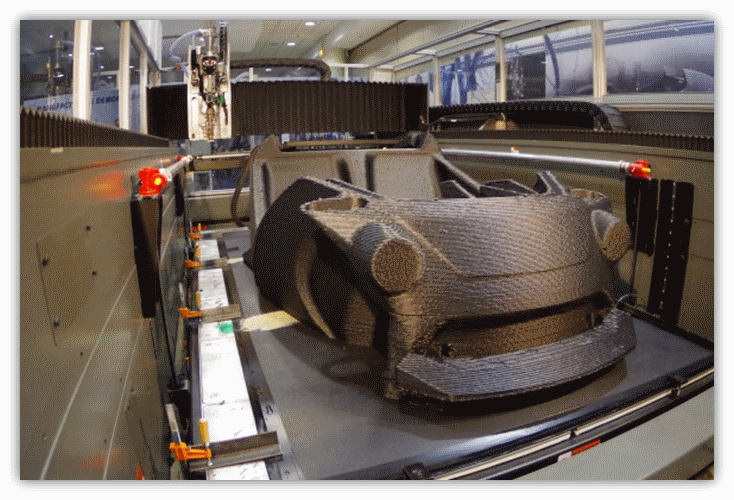

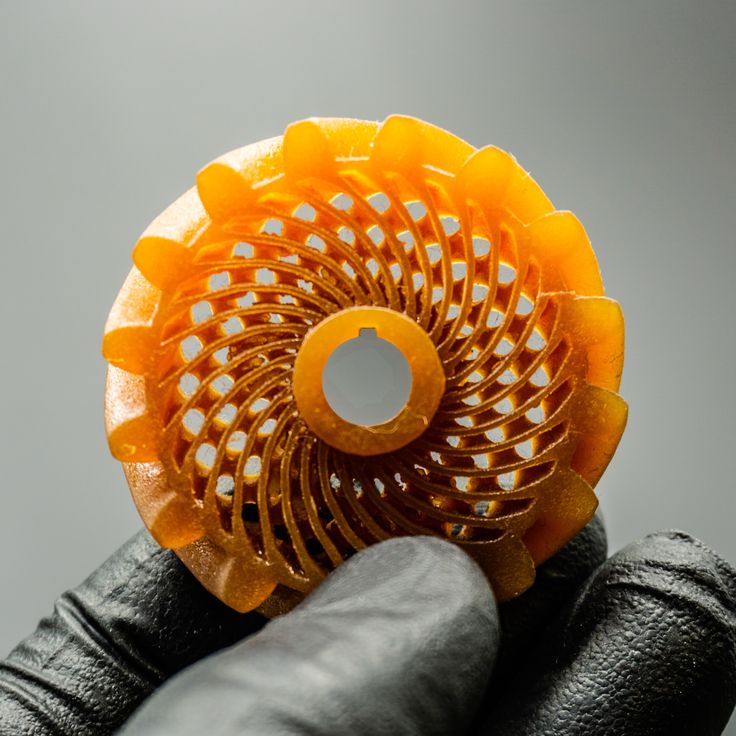

Printing a composite material (photo credits: SABIC)

Carbon fiber-filled materials

As previously stated, composites made from carbon fiber are the most common in the additive manufacturing market. First produced in 1860 by chemist Joseph Swan, carbon fiber, as the name suggests, is composed of many carbon atoms bonded together. It is considered by many to be the most efficient fiber for creating composite materials. Indeed, materials made from this fiber have high stiffness, high tensile strength and good chemical resistance. In addition, these composite materials are characterized by their low weight and high temperature tolerance – they are especially known for their weight/strength ratio, which is twice as high as that of aluminum, for example.

Carbon fiber composites can be found in many fields, such as aerospace, automotive, civil engineering and many others. Matrix materials such as PLA, PETG, nylon, ABS or polycarbonate become stronger and lighter when it is added, and carbon fiber can also be mixed with ceramics. The creation of these composite materials has led to the development of new applications in the printing industry, such as the first 3D printed electric scooter made of carbon fiber.

3D printed part made from carbon-filled nylon (photo credit: Stratasys)

Fiberglass-filled composite materials

Patented in 1930, fiberglass is, like carbon fiber, used to reinforce many polymers. However, compared to carbon fiber-filled materials, materials made from fiberglass are less rigid but also less brittle. It is mainly for these reasons that fiberglass-filled materials are mostly less expensive. Nevertheless, fiberglass offers good mechanical properties. In addition, it is considered to be a good electrical insulator and has low thermal conductivity. It is more comparable to other polymers: for example, it is 11 times more rigid than ABS.

It is more comparable to other polymers: for example, it is 11 times more rigid than ABS.

Whether in the construction, marine or even sports sectors, this composite material is now widespread. For example, in collaboration with Autodesk, Catmarine, Micad and Owens Corning, Moi Composites has created the MAMBO boat, the first 3D printed boat made of fiberglass.

Prototype of a bridge part printed using fiberglass (photo credits: CEAM)

Kevlar-filled materials

As with the other fibers mentioned above, Kevlar is regularly found mixed with several types of plastic to obtain composite materials. Kevlar is a registered trademark of the DuPont de Nemours company, first commercialized in 1971 and invented by Stephanie Kwolek. A member of the aramid fiber family, Kevlar is one of the most wear-resistant materials, known best perhaps for being one of the first materials used for bulletproof vests. With good mechanical properties in traction and fatigue, Kevlar is mainly used to manufacture parts exposed to strong vibrations and needing to resist abrasion. It is five times stronger and lighter than steel, and also has high heat resistance – it can withstand temperatures up to 400°C. Kevlar also has a low density.

It is five times stronger and lighter than steel, and also has high heat resistance – it can withstand temperatures up to 400°C. Kevlar also has a low density.

As far as additive manufacturing is concerned, Kevlar is mainly used in the automotive industry, although, like all composite materials, it can be used to 3D print any object. Aptera Motors, an American company, has partially 3D printed a car using this composite material. We are also thinking of test parts, which have to resist to important shocks

Kevlar filled ABS filament (photo credits: Markforged)

What do you think of these composite materials? Let us know in a comment below or on our Facebook and Twitter pages. Don’t forget to sign up for our free weekly newsletter, with all the latest news in 3D printing delivered straight to your inbox!

3D Printing Carbon Fiber and Other Composites

Composite materials, on the other hand, are parts made up of more than one material that, when combined, have properties different from their original materials. Materials like concrete and particleboard can be considered composites, because they are mixtures of a variety of materials. However, when we talk about composites from an engineering standpoint, we usually refer to composites with reinforcing fibers. Carbon fiber, fiberglass, and Kevlar are three of the most common fiber materials used for composites in industry. As we covered in the Physics of 3D Printing, the fibers are like spaghetti - thin, brittle, and easy to snap if bent. These fibers are almost never used by themselves - they are woven into sheets, wrapped into rods, or formed into custom molded shapes with the help of a matrix material to harden the fibers into an optimized shape. When many fibers are bound together to create larger structural elements, forces can distribute and disperse loads along the lengths of all of the fibers.

Materials like concrete and particleboard can be considered composites, because they are mixtures of a variety of materials. However, when we talk about composites from an engineering standpoint, we usually refer to composites with reinforcing fibers. Carbon fiber, fiberglass, and Kevlar are three of the most common fiber materials used for composites in industry. As we covered in the Physics of 3D Printing, the fibers are like spaghetti - thin, brittle, and easy to snap if bent. These fibers are almost never used by themselves - they are woven into sheets, wrapped into rods, or formed into custom molded shapes with the help of a matrix material to harden the fibers into an optimized shape. When many fibers are bound together to create larger structural elements, forces can distribute and disperse loads along the lengths of all of the fibers.

Fiberglass strands being laid down in a mold and cured with a thermoset resin.

Carbon fiber has one of the highest strength-to-weight ratios out there, making it very valuable for creating lightweight, strong parts. The fibers themselves are made up of carbon atoms whose crystal structure is aligned into strands, making the strands incredibly strong in tension. Traditionally, thermoset resins are used as the bonding agent to set these fibers into a designated shape, cured around a matrix material like foam. So you can create a sandwich panel by “sandwiching” the foam between to sheets of fiber weave, and curing it all with resin. In the context of 3D printing, the fiber can take two different forms:

The fibers themselves are made up of carbon atoms whose crystal structure is aligned into strands, making the strands incredibly strong in tension. Traditionally, thermoset resins are used as the bonding agent to set these fibers into a designated shape, cured around a matrix material like foam. So you can create a sandwich panel by “sandwiching” the foam between to sheets of fiber weave, and curing it all with resin. In the context of 3D printing, the fiber can take two different forms:

Chopped Fibers are short-length fibers chopped into segments less than a millimeter in length and mixed into traditional thermoplastics to form what is called a filled plastic. These can be printed with an FDM printing process.

Continuous Fibers require a slightly different 3D printing method, in which continuous fiber strands are coated in a curing agent and laid down into a thermoplastic matrix extruded via a secondary print nozzle. This process is called Continuous Fiber Fabrication (CFF).

Two forms of 3D printed carbon fiber: on the top is a chopped fiber 3D printing filament, and below is a continuous strand of carbon fiber.

Either way you add fiber, the addition of the fibers boosts part strength and other material properties, but the amount it helps differs depending on the way that fiber is used, and what fiber it is. Generally speaking, a continuous carbon fiber 3D print is stronger than chopped carbon fiber 3D because the continuity distributes any applied loads.

Chopped Fiber 3D Printing Materials

Chopped fiber filled plastics are the most common type of composite 3D printed plastics. The most widely used chopped composite 3D printing material is chopped carbon fiber - where carbon fiber pieces are mixed with traditional 3D printing plastics like nylon, ABS, or PLA. Adding this “filling” to thermoplastics is a material booster pack. The fibers take on some of the stresses of the part, like how concrete is added to cement to boost its strength. The fibers handle some of the applied stresses on the part, boosting the properties of typically lower-grade materials. The addition of carbon fiber also improves the thermal stability of mechanical properties, which widens the range of operating temperatures and improves predictability of material behavior in both high and low temperatures.

The fibers handle some of the applied stresses on the part, boosting the properties of typically lower-grade materials. The addition of carbon fiber also improves the thermal stability of mechanical properties, which widens the range of operating temperatures and improves predictability of material behavior in both high and low temperatures.

A close-up of chopped carbon fibers used in 3D printing, taken on an SEM.

These fibers are chopped up into fine pieces and mixed into the plastic before it gets extruded into a spool for use with material deposition-based 3D printers. In this case, the 3D printing process remains the same, because the fibers are just suspended in the thermoplastic - so it gets heated, extruded, and cooled into the part just like any other FFF style 3D printed. Chopped composite 3D printing materials take normal plastic that may be lacking in certain properties and boost it. In the case of carbon fiber, the fibers boost the strength, stiffness, and dimensional stability of the part to make it higher-performing than its base plastic.

Chopped carbon fiber 3D printing materials can be used like normal 3D printing plastics, boosting some material properties.

The quantity of fibers and the length of chopped segments impacts the strength and quality of the part. Different vendors blend different amounts of fiber into their plastic, yielding materials with different strengths. Below a certain threshold, and the fibers boost surface finish, print quality. Above that threshold, mixing in a large quantity of longer fibers, and you get a stronger material, but you sacrifice surface finish and part accuracy because there is a smaller percentage of plastic in the material overall. The thermoplastic is essential to the mixture because it makes the printing process work well, so your parts can only get so strong.

Continuous Fiber 3D Printing

Continuous fiber 3D printing adds continuous strands of fiber reinforcement to the part (think back to fiber strands), to achieve metal-strength properties at a fraction of the weight. Using two print nozzles, the printer builds the matrix material out of a thermoplastic, and irons down continuous strands of continuous fibers into the part. This process is called Continuous Fiber Fabrication (CFF).

Using two print nozzles, the printer builds the matrix material out of a thermoplastic, and irons down continuous strands of continuous fibers into the part. This process is called Continuous Fiber Fabrication (CFF).

Continuous Kevlar strands are ironed into this part to increase its impact resistance with a composite fiber printing nozzle. A thermoplastic matrix material forms the skin and core of the part.

The power of CFF comes from the continuity of the strands. Unlike chopped fibers, continuous strands can absorb and distribute loads across their entire length. When placed within a thermoplastic matrix, the part can handle higher loads and absorb larger impacts. This allows these parts to achieve the strength of metal at a fraction of the weight.

Continuous fibers form the backbone of a 3D printed part, because the loads distribute along their length, rather than into the plastic.

The CFF 3D printing process consists of two steps per layer - first, a thermoplastic is extruded to form the infill and shells of the part - this serves as the “matrix” material of the composite. Next, the continuous fiber is ironed into that matrix, fusing with the thermoplastic by use of a compatible resin coating. This process repeats layer by layer, forming the fibers into the backbone of the 3D printed part, while the thermoplastic acts as a skin. This process is also similar to how rebar can be laid down inside concrete to reinforce it.

Next, the continuous fiber is ironed into that matrix, fusing with the thermoplastic by use of a compatible resin coating. This process repeats layer by layer, forming the fibers into the backbone of the 3D printed part, while the thermoplastic acts as a skin. This process is also similar to how rebar can be laid down inside concrete to reinforce it.

The fibers form the "backbone" of the part and can be laid down in specific patterns to optimize a part’s strength for its weight and material consumption. You can place fiber in specific areas based on how the part will experience load, putting the strength exactly where you need it. This is very different from standard deposition-based 3D printers, including with chopped fibers, because these methods have an even distribution of properties throughout the entire part. Different fiber reinforcement options can be used for different loading conditions and behaviors. You can learn more about the different reinforcement strategies in Fiber Reinforcement Strategies.

A variety of different fibers can be used for reinforcement as well, depending upon what material properties your part needs to have. Markforged 3D printers offer a few different fiber materials so that you can choose the strength behavior of the reinforcement:

Carbon Fiber is a stiff and strong fiber that behaves like 6061 Aluminum, so it can be used for lightweight components that support heavy loads.

This 3D printed carbon fiber can match the strength of aluminum when continuous. Both are supporting a 27.5 lb load.

Fiberglass is a sturdy, cost-effective reinforcing material with some compliance to it. It boosts part strength above that of plastics and is a good starting point for printing with reinforcement.

Fiberglass is a robust 3D printing fiber option, exceeding the strength of chopped fiber, ABS, and PLA when supporting a 7.5 lb weight.

Kevlar has high toughness and shock resistance, making it ideal for shock-loading and high-impact conditions. It bends instead of breaking.

It bends instead of breaking.

PLA, ABS, and Kevlar reinforced 3D printed parts getting shock-loaded with some big hammer hits!

High Strength High Temperature (HSHT) Fiberglass maintains its strength and stiffness at high temperatures because of its high heat-deflection temperature. Its heat resistance allows it to hold up in more extreme environments.

This test was performed after heating each beam to 300 degrees Fahrenheit in an oven. HSHT does not lose strength at high temperatures, so it still supports the 5 lb load.

So between selecting different fiber types for certain material needs, and controlling where the fiber can be placed layer by layer, you can control the behavior and performance of your parts. This is one of the primary advantages continuous 3D printed composites have over chopped fiber materials. Not only do you get stronger parts, but you also can produce parts optimized for their application.

3D printing with thermoplastic polymers: 12 domestic projects

Implementation stories

Rapid prototyping

Experts recommend

Author: Semyon Popadyuk

Author: Semyon Popadyuk

Thermoplastics and composites - what is it? | How are composites made? | Who are the main consumers of 3D printing resins? | What plastics are the most popular? | How is 3D printing with thermoplastics and composites applied? Examples of finished products nine0003

We are often asked the question: do they make high-quality, reliable and safe materials for 3D printing in Russia? Of course, there are such manufacturers, moreover, significant experience and know-how have been accumulated in this area. One of the pioneers in the domestic market for the production of plastics for the additive industry was REC. It is directly involved in the production of filaments, and its 3D Solutions division conducts R&D on the creation of composite materials.

One of the pioneers in the domestic market for the production of plastics for the additive industry was REC. It is directly involved in the production of filaments, and its 3D Solutions division conducts R&D on the creation of composite materials.

REC and 3D Solutions in facts and figures: nine0003

-

8 years of work with thermoplastics in the field of additive technologies;

-

22 different types of FFF filament material are mass-produced;

-

in 2020 and 2021, more than 130 different compositions based on thermoplastics were produced and tested;

-

own production equipment and laboratory complexes for the production and testing of thermoplastic compositions both in molding and in 3D printing; nine0003

-

the most recognizable brand in the field of FDM printing materials.

Dmitry Miller © youtube.com / JsonTV

Today, in our blog, REC and 3D Solutions Executive Director Dmitry Miller shares his experience in the development and application of thermoplastics and composite materials and talks about the most interesting FDM technology implementation projects.

Check if a 3D printer will solve your problems - order a free test 3D printing service from iQB Technologies!

Thermoplastics and composites - what is it?

A thermoplastic is a polymer that can become plastic when subjected to temperature. Based on thermoplastics, composites are produced - pure plastics in combination with other materials, for example, ABS with polycarbonate or reinforced with carbon fiber. There can be a huge number of such variations. nine0003

For eight years on the market, we have managed to work with most of the existing plastics, including ABS, ASA, SBS, SEBS, PA, PP, PSU, PPSU, PEEK, PC, TPU, TPEE, PET, PETG, PEI, PLA, PS, PTFE, PVA, PMMA, PBT. And this is not a complete list - some materials, such as PVC, could not be brought to an adequately usable state, because there are all sorts of difficulties with processing.

How are composites made?

We take the necessary polymer base and, depending on the task and the required properties of the material, we modify it with certain components. These include: nine0003

These include: nine0003

A wide range of fillers with different properties is also used. These are the most familiar carbon fibers, and fiberglass, and basalt fiber, and Kevlar fibers. To obtain certain properties, it is possible to fill the polymer with hollow glass spheres and carbon nanotubes.

We also have metal-filled polymers used in MIM (Metal Injection Molding) molding technology. It is more correct to call them metal-polymer compositions, since they contain more than 93% metal and at least 7% binder. A product is molded from such a composite material using casting or 3D printing, then the binder is chemically etched, the resulting model is baked in an oven, and finally we get an all-metal part.

In addition, compositions exhibiting ferromagnetic properties can be obtained. They are in demand in tasks related to radiography and radio electronics.

iQB Technologies experts recommend the article: Additive Manufacturing of Molding Tooling from Polymer and Composite Materials nine0044

Who are the main consumers of 3D printing resins?

Our main consumer is production, since additive methods create either the final product, or some part of it, or tooling for its production. A large number of orders is due to the regularity, systematic repetition and stability of the production process.

A large number of orders is due to the regularity, systematic repetition and stability of the production process.

Slightly more than a quarter of the volume of production is engineering companies that are engaged in 3D printing of prototypes for assembly testing, visual models and the like. nine0003

A large layer, accounting for 25%, is the sphere of education. Thanks to federal programs such as "Point of Growth", 3D printers are supplied to many educational institutions, and additive technologies are an educational subject. Teaching the basics of 3D printing makes a huge difference as it helps students change the way they think. When we use classical subtractive technologies - turning a blank or cutting it with a laser, cutting something out of a flat sheet - this is one way of thinking. Additive manufacturing removes many restrictions, thinking is completely different, and the next generation will think in technical terms much more freely. nine0003

The next segment is occupied by personal consumption, which can affect absolutely any area.:quality(80)/images.vogel.de/vogelonline/bdb/779600/779668/original.jpg) These are people, as well as small businesses, using 3D printers for their own purposes, hobbies.

These are people, as well as small businesses, using 3D printers for their own purposes, hobbies.

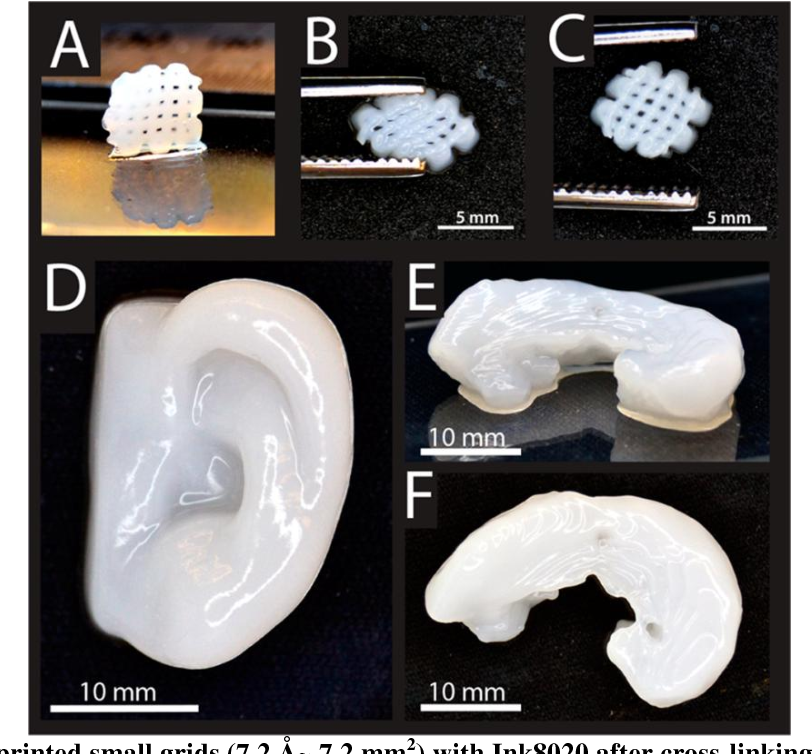

And finally, medicine. So far, the amount of work we have in this area is small, but there are precedents for application. Polymers are used for the additive production of orthoses (devices for fixing limbs), prosthetics, and, together with educational institutions, for the manufacture of anatomical models for various medical needs. nine0003

What plastics are the most popular?

For clients of REC and 3D Solutions, PLA occupies the first place in terms of consumption. This is well deserved, as it is easier to print than any other plastic, and it is the least demanding on equipment. Any simplest personal 3D printer will work fine with this material, and there will be no difficulties.

The second place is approximately equally divided by ABS and PETG materials. They are used in functional prototyping, where PLA is far from always applicable due to its extremely low heat resistance: at 50 degrees it is already soft. nine0003

nine0003

Next come various composite materials, and this segment is growing from year to year. In the next five years, they are likely to come out on top due to the ability to achieve any desired properties.

And a very small segment (4%) is made up of polyurethanes, ester elastomers - any flexible and elastic polymers. They are used by customers of all other materials, but for certain tasks that require elasticity and flexibility. nine0003

How is 3D printing with thermoplastics and composites applied? Examples of finished products

1. The prototype of an unmanned taxi and its components printed using FDM technology

Before you (Fig. 1) is a functional prototype of an unmanned taxi, containing a huge number of details. To make each of them by classical factory methods is quite difficult, expensive and time consuming. Thanks to 3D printing, the manufacturing company has optimized the process of creating many parts - reflectors for front optics, brackets, holders, decorative elements, etc. Models drawn on a computer were immediately printed and installed on the spot - so, as quickly and simply as possible, project of a fully functional working prototype vehicle. nine0003

Models drawn on a computer were immediately printed and installed on the spot - so, as quickly and simply as possible, project of a fully functional working prototype vehicle. nine0003

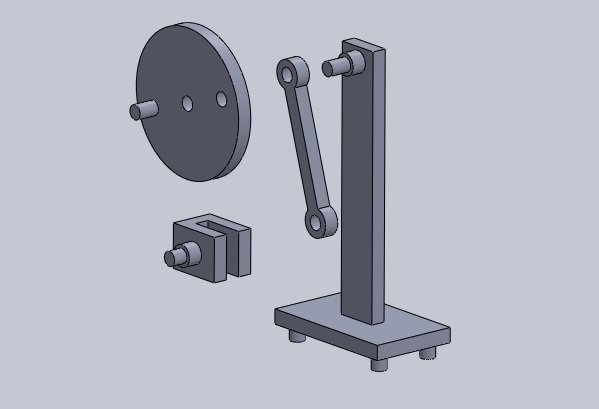

2. Grip for the robotic arm

An interesting example is when materials are combined for 3D printing. In the photo above, you can see the grip for the arm of the robotic arm. The claws themselves are printed from hard PETG plastic, while the inner pads are made from elastic material. It ensures that objects will not slip out of the manipulator's hand.

3. Model of the fuel system of the Angara rocket. Printed from ABS plastic, used to test the assembly of a complex device nine0003

Let's move on to complex systems. Figure 3 shows a real layout of the Angara space rocket power supply system, printed from ABS plastic, on which the assembly was checked. It was necessary to test whether the developed device with a large number of components can be assembled without damage.

4. Elements of LED lamps (medium runs)

And here you see how it is possible to produce complete end products using 3D printing. The company is engaged in the manufacture of LED lamps in small series. Some models have plastic elements - plugs, light diffusers. All products are designer, original, it turns out to be more expensive to make a thousand pieces by casting into silicone, not to mention the classic casting of molds: in such a run, the mold will not pay off at all, the parts will turn out to be “golden”. In this case, 3D printing is an extremely profitable solution. Unlike casting in silicone, additive manufacturing allows more freedom in geometry and a batch can be produced very cheaply and quickly. nine0003

The production speed is determined by the capacity of the 3D printer farm. As a rule, when we integrate 3D printing into production, we do not limit ourselves to one machine and create a farm. This is a whole fleet of identical additive installations to which the job is sent, and they immediately start printing together. In this way, we can significantly increase productivity. It is easily scalable and quite cheap, especially if FDM is used - the most affordable of all 3D printing technologies. nine0003

In this way, we can significantly increase productivity. It is easily scalable and quite cheap, especially if FDM is used - the most affordable of all 3D printing technologies. nine0003

5. Pots for levitating plants (small runs)

A curious startup project that specializes in levitating plants (Fig. 5). A tree in a pot flies over a wooden block, a magnet device works. So, the task was to make a planter. It should be light, not clay, so that it is easier to make a magnet, and not be afraid of such environment as earth, fertilizers and water. At first, there were attempts to produce wooden pots, but the wood, even with protective coatings, eventually deteriorated from the internal environment. Therefore, it was decided to introduce 3D printing with plastics. The company ordered 3D printing from us, but when it became clear that the production was profitable, it purchased equipment and materials and began to produce pots of various designs on its own. nine0003

6. Model of the foot, made according to CT

Model of the foot, made according to CT

Medicine cannot be overlooked. The photo shows a model of the foot printed from white plastic based on the results of computed tomography. The 3D model was obtained from CT and sent to the 3D printer. The product has two uses:

-

students with the help of such realistic models can practice, identify pathologies, since the use of real bones is very limited; nine0003

-

using this model, it is much easier for surgeons to plan an operation strategy and make it more accurate on the patient.

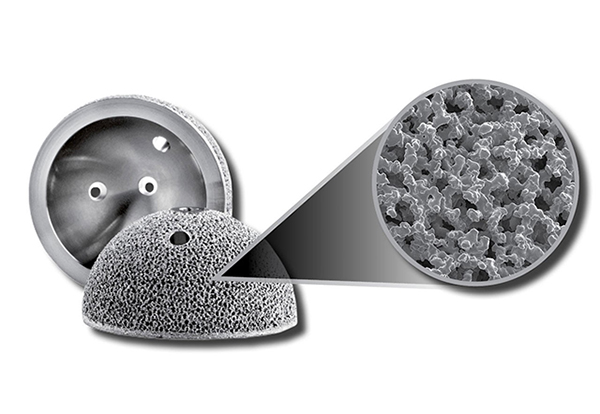

7. Prototype of endoprosthesis

Another medical device is a prototype endoprosthesis (Fig. 7). This is a preliminary model made of plastic, which is used to check the accuracy and correctness of the prosthesis. The final product is also created on a 3D printer, but already from metal, using SLM technology, obtaining a high-precision model of an individual endoprosthesis on the first attempt. Medical metal has a high cost and, in order to eliminate errors, prostheses are initially printed from plastic. nine0003

Medical metal has a high cost and, in order to eliminate errors, prostheses are initially printed from plastic. nine0003

Read on: Plastic works wonders: how a 3D printer imitates human organs

8. Figures in the Olympic Museum in Sochi, printed on a 3D printer

Now let's see what benefits you can get using large format resin 3D printing. One of the most common areas of application today is the production of small architectural forms: sculptures, statues, decorative elements, architectural decorations (Fig. 8). Using a 3D printer, such models are created easily and quickly, and this is one of the cheapest ways to manufacture. In addition, there is the possibility of a wide choice of materials, adding optical effects, translucency (for example, to build a luminous element inside the sculpture for a greater effect). nine0003

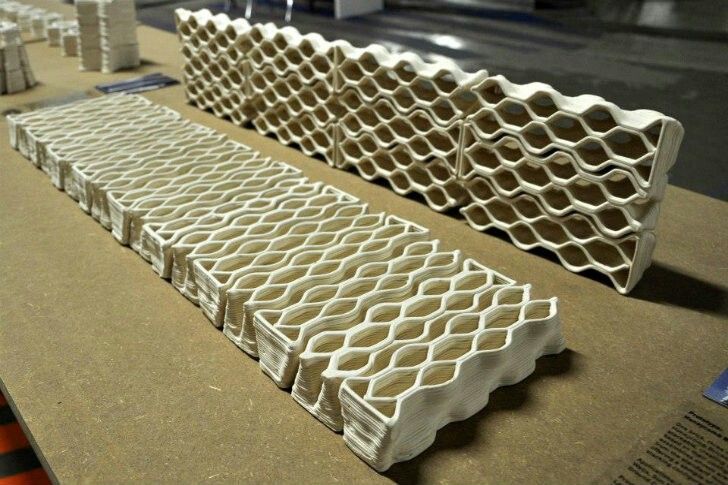

9. An example of the texture of a printed product of large dimensions

As you know, FDM printing has one feature: due to the layered construction, the parts are “striped”. However, this disadvantage can be turned into an advantage and interesting textures can be created using a large-format 3D printer, as in Fig. 9. Of course, first of all, this is the production of designer furniture and various decorative elements and architectural forms.

However, this disadvantage can be turned into an advantage and interesting textures can be created using a large-format 3D printer, as in Fig. 9. Of course, first of all, this is the production of designer furniture and various decorative elements and architectural forms.

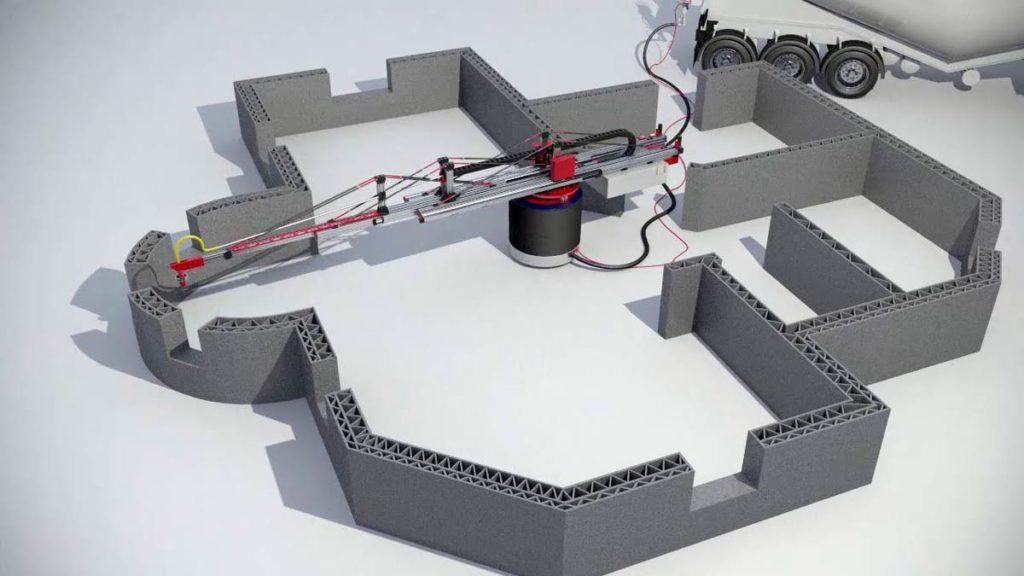

For 3D printing of large objects using FGF technology using polymer granules, there is a separate layer of composite materials. On fig. 10 shows the process of printing with a material resembling polyurethane foam. The similarity is not accidental - a foaming composite is used here. One cubic meter of raw material yields 25 cubic meters of foamed material. And, as you can see, this technology allows you to achieve very large layer heights, and the thicker the layer, the faster the 3D printing. And a slight decrease in density facilitates the entire structure as a whole. nine0003

Learn more about large-format 3D plastic printing: solutions, challenges, case studies

FDM/FGF printing has a very low accuracy. Moreover, materials have different shrinkage, and in the case of different geometry of parts, shrinkage will be non-linear, unequal simply because of the peculiarities of the technology itself - because of how the material is laid, what temperature loads are applied. In the case of tooling production, as a rule, hybrid technologies are used - the model is printed, and then the working surface is milled. In this way, we obtain the desired roughness and precision. nine0003

Moreover, materials have different shrinkage, and in the case of different geometry of parts, shrinkage will be non-linear, unequal simply because of the peculiarities of the technology itself - because of how the material is laid, what temperature loads are applied. In the case of tooling production, as a rule, hybrid technologies are used - the model is printed, and then the working surface is milled. In this way, we obtain the desired roughness and precision. nine0003

Different equipment requires different materials. Somewhere high heat resistance is needed, somewhere high strength, and somewhere the lowest possible price is a priority. There is an optimal material for each task.

And there is a huge field for optimizing production in order to produce large enough objects cheaply and in an incredibly short time - literally in a matter of hours.

Screensaver photo © zbulvar.ru nine0044

Article published on 11/12/2021, updated on 09/20/2022

Additive technologies for composite materials

How it all began

3D printing, as you know, refers to additive technologies, which initially, long before 3D, included the production of composites. Anisoprint has developed a composite 3D printing technology that combines these two areas, but at the same time is completely new for both of them. nine0003

Anisoprint has developed a composite 3D printing technology that combines these two areas, but at the same time is completely new for both of them. nine0003

First of all, let's talk about CFRP, the king of composites. Unidirectional carbon fiber is several times stronger and lighter than aluminum, much lighter than steel with similar strength characteristics. At one time, it was very popular in the production of highly loaded critical structures - rockets and aircraft. The peculiarity is that its high strength lies along the fibers, along the direction of reinforcement. In transverse directions, the properties are much lower. For some reason, this was considered a drawback and began to be corrected. Layers of unidirectional CFRP began to be stacked on top of each other at various angles to form what is known as a quasi-isotropic laminate, which engineers in the field like to call "black aluminium." nine0003

Its properties are similar to sheet aluminum, it is used in approximately the same structures: aircraft fuselage, wing, rocket body. After the properties of carbon fiber "smeared" in different directions, its strength became about 10 times less, that is, it approached ordinary aluminum. Thus, all the advantages of unidirectional carbon fiber were lost, but at the same time, many problems appeared related to technology, impact strength, fracture features, and connections of such nodes to each other. Because of this, in the last generation of civil aircraft there were 50–60% of composites, and in the next one, two times less is expected. Boeing had a Dreamliner program that failed for just that reason. They tried to "fix" carbon fiber and make it "omnidirectional", but nothing worked. nine0163

After the properties of carbon fiber "smeared" in different directions, its strength became about 10 times less, that is, it approached ordinary aluminum. Thus, all the advantages of unidirectional carbon fiber were lost, but at the same time, many problems appeared related to technology, impact strength, fracture features, and connections of such nodes to each other. Because of this, in the last generation of civil aircraft there were 50–60% of composites, and in the next one, two times less is expected. Boeing had a Dreamliner program that failed for just that reason. They tried to "fix" carbon fiber and make it "omnidirectional", but nothing worked. nine0163

New approach

We saw in the unidirectionality of the composite not a disadvantage, but an advantage. It is very efficient to make mesh structures from composites.

For fig. 1 shows the payload adapter of the Proton-M launch vehicle, which is made of carbon fiber, but not of black aluminum, but in the form of a mesh structure with ribs of a certain direction and a certain density.

Fig. Fig. 1. Payload adapter of the Proton-M launch vehicle

2. Carbon fiber sandwich analog

3. Aluminum analogue

The part weighs about 50 kilograms and can withstand a load of 200 tons. A similar part made from CFRP sandwich weighs 30 percent more and can withstand less stress ( fig. 2 ). Aluminum demonstrate even lower performance ( fig. 3 ).

In mesh construction, the composite works only along the fibers. It does not have the ability to work across, so all its anisotropic properties are used most effectively.

Fiber steering

There is another interesting direction besides mesh structures called fiber steering. The fibers are laid not at fixed angles in a straight line, but along curvilinear trajectories in such a way that the directions of the fibers at each point correspond to the directions of the principal stress vectors in the part. nine0003

nine0003

Consider an aircraft fuselage panel with an inspection hole, made by automated laying out along curved trajectories. Now this method is sometimes also called 3D printing, although this technology is several decades old and has long been actively used to make parts from composites.

Fig. Fig. 4. Trajectories of laying fibers in layers

5. Test results of the aircraft fuselage panel with different fiber placement methods

Comparative tests have been carried out on these black aluminum parts ( fig. 5 ). The fiber-stering panel, with the same weight and nature of the loads, can withstand a 30 percent higher compressive load (105 tons). In this case, a completely different character of destruction is observed.

One of our main ideas was to enable design engineers to fabricate, manufacture and design truly efficient composite structures. Moving away from black aluminum and making the anisotropy of the material from a disadvantage, as many believed, became the main advantage. We wanted to make composites in which you can arbitrarily control the direction of anisotropy and the degree of anisotropy at each point in the material. nine0003

We wanted to make composites in which you can arbitrarily control the direction of anisotropy and the degree of anisotropy at each point in the material. nine0003

Knowing how the part works, knowing the loading conditions, design cases, internal forces and stress, it would be possible at each point to focus the properties of the material in exactly the direction in which it is needed. Thus, there is a whole extra space for optimization. We can optimize not only the shape of parts, but also their internal structure.

Unfortunately, traditional automated manufacturing techniques for manufacturing composite parts do not allow random placement of fibers at every point. Then we turned to 3D printing. nine0163

Composites in the world of 3D printing

When we say that we print with carbon fiber, we hear that everyone prints with it. But usually this is plastic filled with chopped fibers, in fact - ordinary plastic with a filler - an isotropic material in which we do not control any direction of these fibers. There are no properties even close to those of real composites. The material turns out to be two to three times more rigid than ordinary plastic, sometimes it can be a little stronger, but this approach does not give anything new in terms of design and technology in general. This is the usual FDM or, as in this case, SLS, when we add finely chopped fiber to the polyamide powder. nine0163

There are no properties even close to those of real composites. The material turns out to be two to three times more rigid than ordinary plastic, sometimes it can be a little stronger, but this approach does not give anything new in terms of design and technology in general. This is the usual FDM or, as in this case, SLS, when we add finely chopped fiber to the polyamide powder. nine0163

Continuous fibers: prepreg winding and laying

In addition to chopped fibers, there is an interesting option with long fibers, for example, lamination technologies.

Sheets of carbon fabric pre-impregnated with thermoplastic, so-called "prepregs" are taken. In one zone, this sheet is cut along the contour of the layer, possibly by ultrasound, then in another zone it is rolled, laminated, thus forming a layer. It turns out pure black aluminum, only made on a special machine. That is, it is such a quasi-isotropic material that has all the disadvantages of black aluminum, such as fiber rupture and, as a result, stress concentration and edge effects, which lead to holes and joints becoming very weak points. nine0003

nine0003

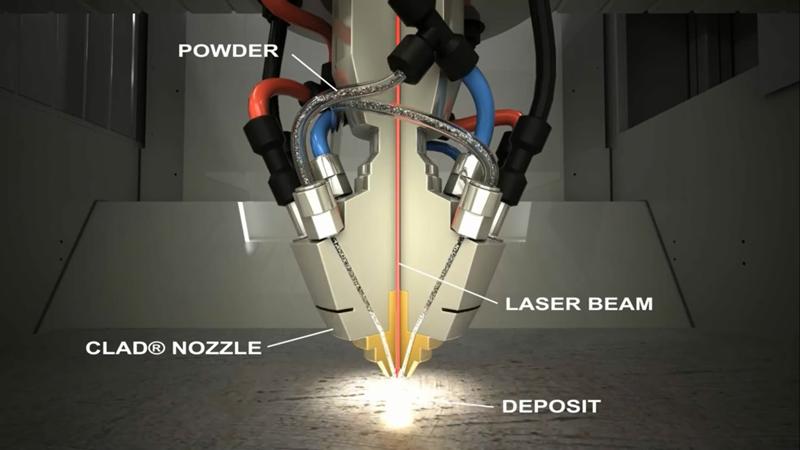

The next step, a little closer to what we started doing, is the extrusion of a continuous fiber thermoplastic. In fact, this is FDM technology, only during the printing process, reinforcing fiber is continuously added to the nozzle. Quite a few scientific groups around the world are doing this sort of thing.

The problem here is that the engineering fibers are not monofilament, they are made up of hundreds or thousands of micron filaments, and if we just add this fiber to a melt of viscous plastic, it does not get inside, it does not impregnate the fiber and form a composite. And in the composite there must be a reinforcing fiber and a binder that connects all the components together, forcing them to work together. In this case, this does not happen. Therefore, although the tensile strength can be quite large, there are no special characteristics in compression in such materials. If you look at microscopy, there are a lot of pores inside between the fibers. nine0003

The second approach, a little more successful, the so-called "prepreg lay-out" is when we take the same fiber, for example, carbon or glass, and in advance, on a special installation, we impregnate it with viscous plastic under high pressure or soak it in a solution and then we evaporate it and stretch it through a spinneret. That is, we are trying to pre-place this viscous plastic inside the fiber. At the output, we get an impregnated thread, which is traditionally called a prepreg in the composite industry. This is a semi-finished product for the manufacture of a composite. And then we heat this “prepreg” through the nozzle and form the part by extrusion or laying out. nine0003

That is, we are trying to pre-place this viscous plastic inside the fiber. At the output, we get an impregnated thread, which is traditionally called a prepreg in the composite industry. This is a semi-finished product for the manufacture of a composite. And then we heat this “prepreg” through the nozzle and form the part by extrusion or laying out. nine0003

Probably the most famous example in the world of continuous fiber 3D printing (layouts of prepegs) is the systems offered by the American company Markforged for a long time. These systems also have carbon fiber pre-impregnated with nylon and a nozzle in which it is heated and laid out. In addition, there is also an additional nozzle for printing with just plastic. Markforged printers have pretty good specs. The strength is already over 700 megapascals. There is a choice of types of reinforcing fibers. But, judging by the many studies of the microstructure of these materials, they contain a very large number of pores. Perhaps this is due to insufficient impregnation or the property of nylon to take on water and boil when printed. nine0163

nine0163

Co-extrusion technology (composite fiber co-extrusion - CFC)

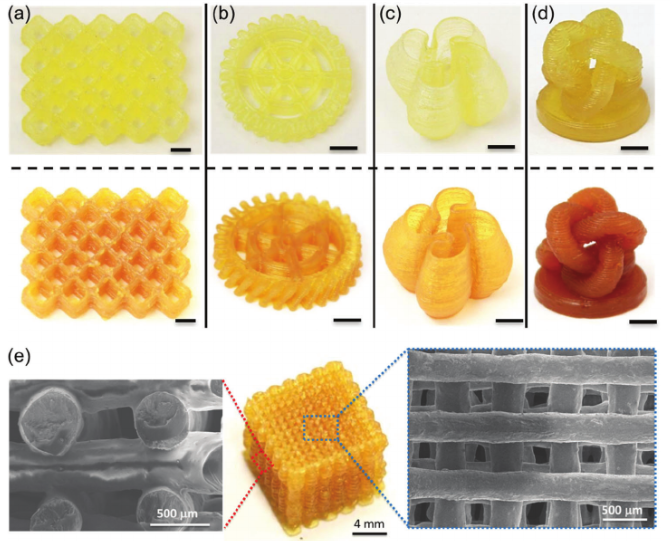

Unlike the methods described, in the Anisoprint technology we pre-impregnate the fiber, but not with a thermoplastic, but with a thermoplastic, which allows us to provide better, cheaper, more reliable impregnation. This process is called co-extrusion.

Since such a fiber cannot be melted, we add plastic to it separately during the printing process. And the output is a two-matrix composite, in which we have a non-meltable thermoplastic inside the fiber, which ensures the impregnation of the fiber, and between the fibers there is a thermoplastic that binds them. nine0003

In our case, plastic can be anything. Whether you need non-flammable plastic, or colored plastic, or plastic with resistance to certain chemical or temperature influences or the environment, you can choose the one that suits you. All the main surface properties of the material are determined precisely by the binder - the matrix.

Due to the fact that fiber and plastic are fed separately into one extruder, the volume fraction of fiber and plastic can be changed locally at each point. We can feed less plastic - then we increase the volume fraction of the fiber, we can feed more plastic - then it decreases. You can choose the optimal values for the expected loads without spending more material than necessary and without increasing the weight of the part. nine0003

We can control the degree of anisotropy and, more importantly, print mesh designs with fiber intersections within a single layer. That is, it is possible to stack reinforcing fibers on top of each other, at any desired angles, individually within each layer. At the same time, the layer thickness at the intersection does not increase, only the volume fraction of fibers in this very place changes.

Thanks to this technology, we obtain a material ten times stronger than plastic, stronger and lighter than metal analogues with the same properties. An important point for many companies and the future of technology: in addition to the outstanding material properties, the final parts are also cheaper than their counterparts from other materials. The introduction of Anisoprint technology allows to significantly reduce production costs, while obtaining an equally (and often more) effective replacement in a variety of areas from tooling on production lines to aircraft and car body parts. nine0163

An important point for many companies and the future of technology: in addition to the outstanding material properties, the final parts are also cheaper than their counterparts from other materials. The introduction of Anisoprint technology allows to significantly reduce production costs, while obtaining an equally (and often more) effective replacement in a variety of areas from tooling on production lines to aircraft and car body parts. nine0163

Application

Anisoprint technology has many applications, from aviation to consumer goods. With mass implementation, almost any company in the world could reduce production costs. Let's look at a closer to life example from the production of everyday goods.

Fig. 6. CFC printing scheme

A dairy brand production line needs a piston to form yogurt cups. When the original milled polyamide part is destroyed, a replacement must be ordered from a third-party company and wait 3 months. At this time, the production line stops: the company incurs losses due to a stop in the production of the product. You can increase the service life and reduce production downtime by replacing the part with an Anisoprint Composer 3D printed part. A carbon fiber composite piston can be printed in 24 hours, reducing production downtime from 3 months to 24 hours ( fig. 7).

At this time, the production line stops: the company incurs losses due to a stop in the production of the product. You can increase the service life and reduce production downtime by replacing the part with an Anisoprint Composer 3D printed part. A carbon fiber composite piston can be printed in 24 hours, reducing production downtime from 3 months to 24 hours ( fig. 7).

Fig. Fig. 7. An example of replacing a piston for a dairy production line

Co-extrusion technology involves reinforcing plastic directly during the printing process, and not before that, as in other cases. Thus, it is possible to obtain a material with special properties required for a specific situation and area. For example, for a production line where parts are washed with peroxide, we printed a plug using peroxide resistant PETG plastic ( fig. 8 ).

Fig. 8. An example of replacing the “fork” part for dairy production

The fork moves on a shaft along the production line, catches the bottle and takes it to the washing area, the part is washed with peroxide. The original part made of milled polyamide is made to order within 3 months. At this time, the production line stops, causing the company to incur losses. The part was replaced with one printed from peroxide-resistant PETG reinforced with composite carbon fiber. Printing time was 6 hours - production downtime was reduced by several months. In addition, thanks to peroxide resistance, the service life of the fork has been increased. nine0163

The original part made of milled polyamide is made to order within 3 months. At this time, the production line stops, causing the company to incur losses. The part was replaced with one printed from peroxide-resistant PETG reinforced with composite carbon fiber. Printing time was 6 hours - production downtime was reduced by several months. In addition, thanks to peroxide resistance, the service life of the fork has been increased. nine0163

Three products - one solution

Software

You can prepare a 3D model, set the reinforcement scheme and the volume fraction of reinforcing fibers in different parts of the part using the Aura slicer software developed by Anisoprint. It allows you to manage reinforcement, set plastic perimeter and plastic infill, composite perimeters, composite infill, supports - all the functionality of a conventional slicer + functionality for working with reinforcing fiber. nine0163 Storage, processing and print launch are fully automated and are performed from a local computer, which ensures the confidentiality and security of the data of the developed models.

Fig. 9. Design using Aura software

Material

Composite fiber created in Anisoprint is used for reinforcement. Initially, only carbon fiber was available, the company recently announced the emergence of composite basalt fiber. Parts made from the latter are even cheaper with similar strength characteristics: 15 times stronger than plastic, 5 times lighter than steel, 1.5 times stronger and lighter than aluminum. Composite basalt fiber is perfect for the production of hull non-conductive elements - basalt is radio transparent. nine0163

Printers

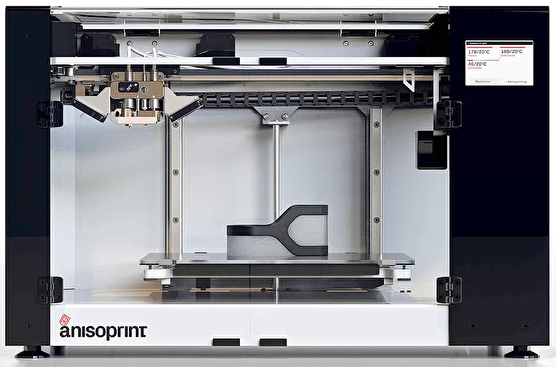

Printing is carried out on Anisoprint Composer printers ( fig. 10, 11 ), two models are now available: A3 with a printable area of 420 × 297 × 210 mm and A4 (297 × 210 × 147 mm).

Fig. 10. Printer Anisoprint Composer

11. Anisoprint print head on the Kuka robot

The main advantage of Anisoprint machines is the ability to print mesh structures, which ultimately reduces the weight of the part, and as a result, the time and cost of production (0161 fig.