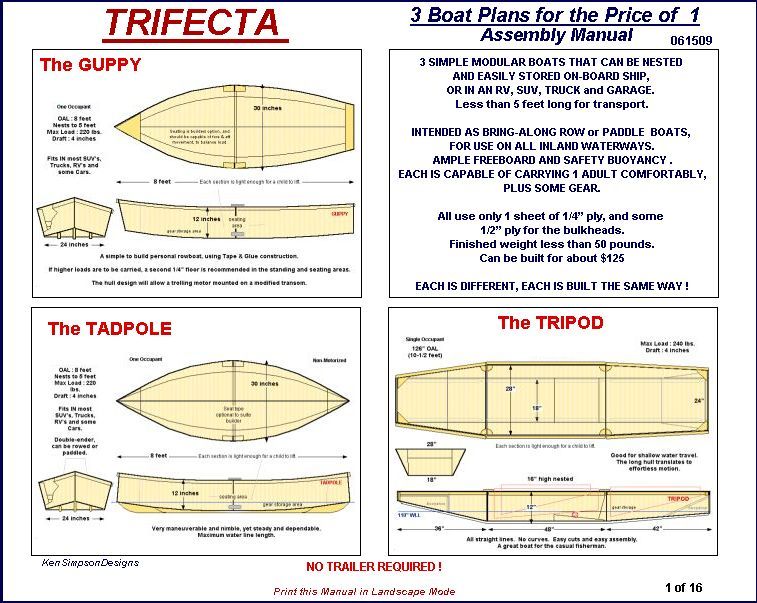

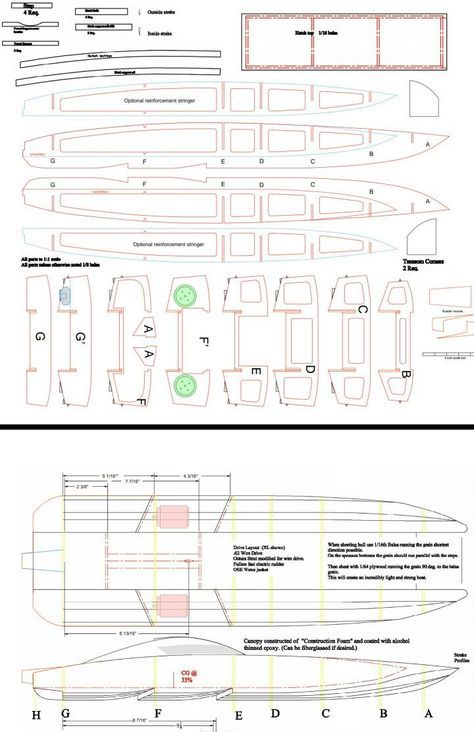

3D printed rc boat plans

Rc Boat best 3D printer files・Cults

RC-scale-yacht Nordhavn 52

€17.79

Vizibusz - RC ship 1:32

€15

2002 Hasbro jeep locking Tailgate

€4.20

Scale welding cart

€0.90

1/10 Garage cart

€0.90

Tiny Transformer: Tiny Ship

Free

RC Airboat Trailer

€1.95

RC boat gear

€5

HEAVY CASTING (FISHING) RC BAIT BOAT - 85cm Hull Length

€20 -50% €10

FT012 Spoiler

Free

Lifeboat Deck

Free

poupito2.

€10

RC Bait Boat

€10 -95% €0.50

RC Guardian class patrol boat

€35.59

USCG Cutterboat OTH

Free

Sentinel Class Fast Response Cutter

Free

1/18 brushless motor mount for rc boat

€0.96

33" Jet Boat for Mjet30 jet drive

Free

#TrollingBot propeller

Free

RC Shaft coupling

Free

Strut Tool RC Boat

Free

Mini RC Fishing Boat CAD Files

€12. 18

18

Carp boat hull, bait boat

€25

RC Fishing Boat Pole Replacement

Free

Springer Pusher Tug

Free

Kort Nozzle

Free

Robotic Gripper for RC Boat

Free

Boat stand for design "Mini RC Jet Boat 200 Mono"

€1.02

Astroms RC Jetboat One - easy to print

€2.22

Mini rc fishing boat

€9.64

#TrollingBot semi-autonomous fishing/cinematic rc boat - datachable propeller guard

Free

TinyJetSki Trim Tabs

Free

FPV Cover for Tiny JetSki - micro rc twin jet boat

Free

Fenders and fenders for boats

€0. 80

80

Ship Propeller

€1

RC Plane Stand

Free

thumb control rc car, boat

€0.57

rc boat

€2.54

jet rc boat

€2.54

Speed Gear L

€1

Speed Gear S

€0.50

RC Speedboat Hydroplane

€14.21

Trawlers Bridge

€5.66

Oerlikon 20 mm cannon stepped Tub

€3.40

4in gun platform for armed trawlers and Merchant ships WW2

€11.24

SMS S33 RC torpedo boat

€5

Outline windows Trawler 1/25

Free

Boat cabin dome

Free

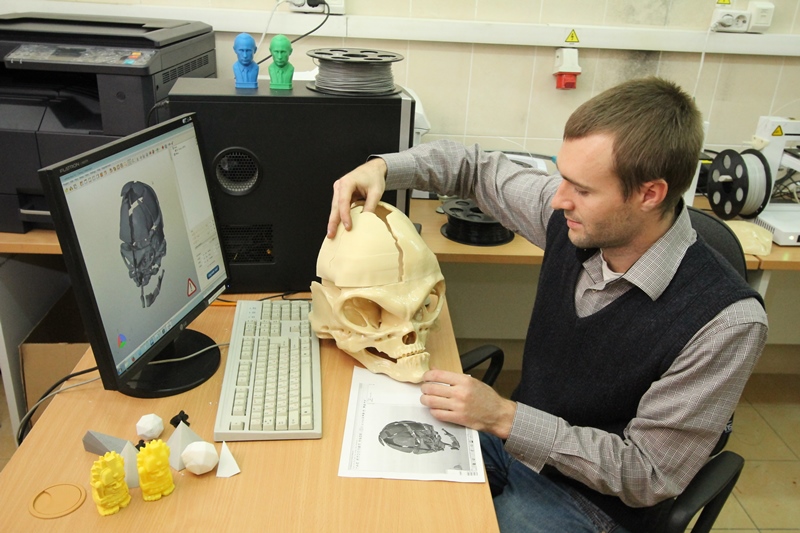

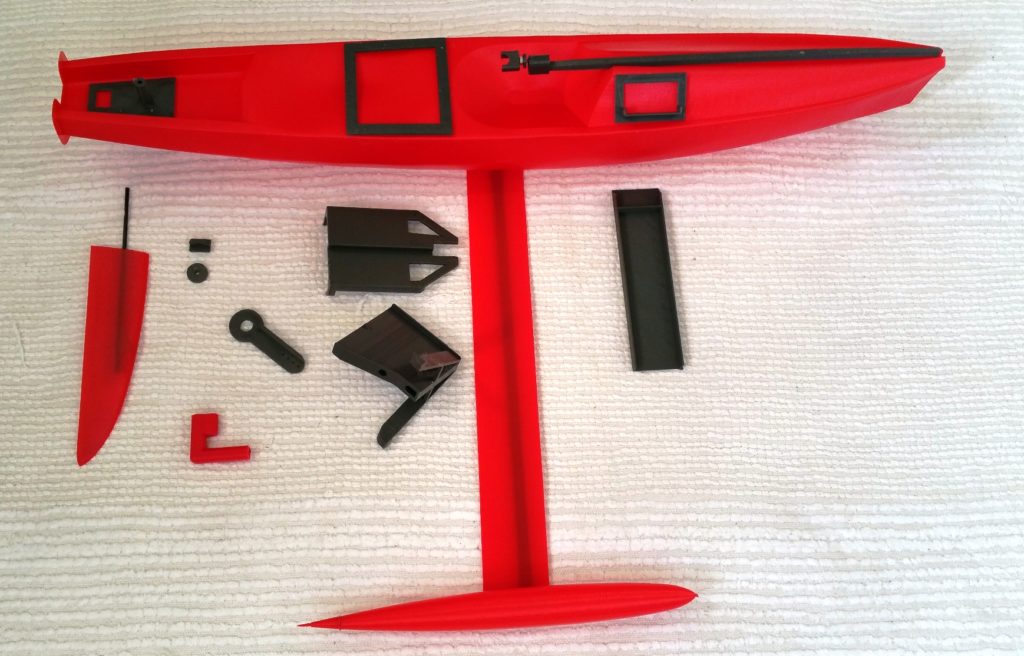

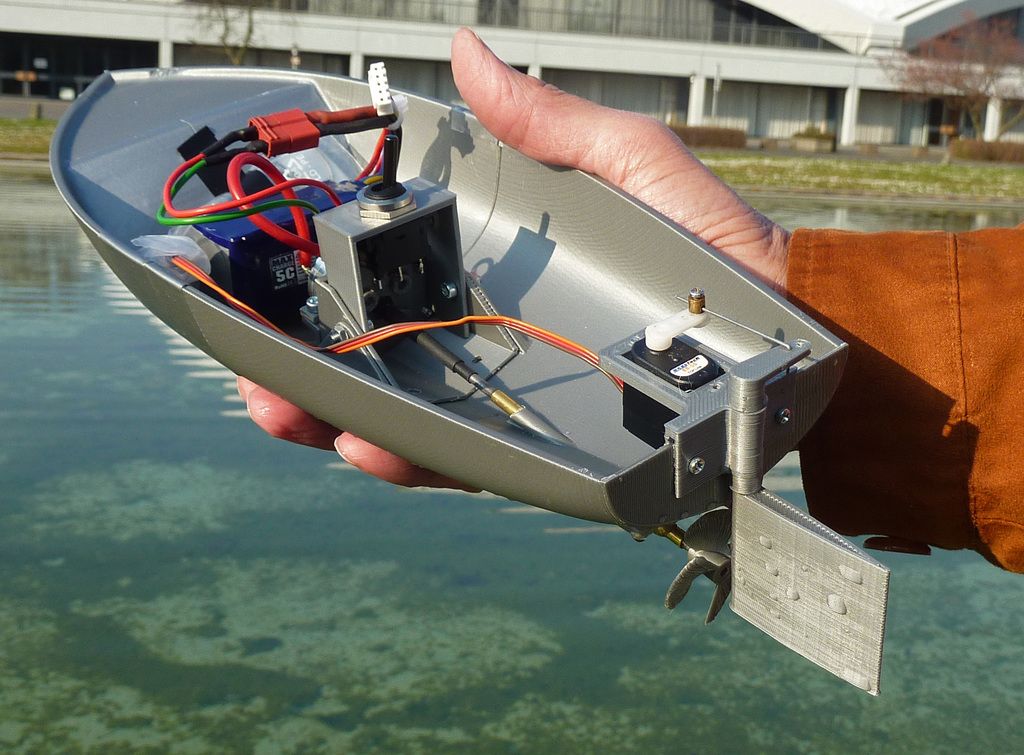

Improve Your Hobby with CNC and 3D Printed RC Boats

RC boating is a fascinating hobby. Whether you’re driving powerful RC speed boats around a lake or just interested in driving a smaller one around your local pond, RC boats can be a fun hobby for the summer months.

Whether you’re driving powerful RC speed boats around a lake or just interested in driving a smaller one around your local pond, RC boats can be a fun hobby for the summer months.

Like human-sized boats, RC boats are subject to a lot of wear and tear on parts thanks to water. Machinery that is exposed to water often quickly corrodes and begins to develop problems. If you’re out for a day at the lake, this can stop your RC boating in its tracks if you don’t have replacement parts on hand.

Fortunately, CNC and 3D printing technology can provide you with ready-made RC boat parts for when you need them. You can even use these awesome manufacturing techniques to design and build your own custom RC boat.

CNC RC Boats

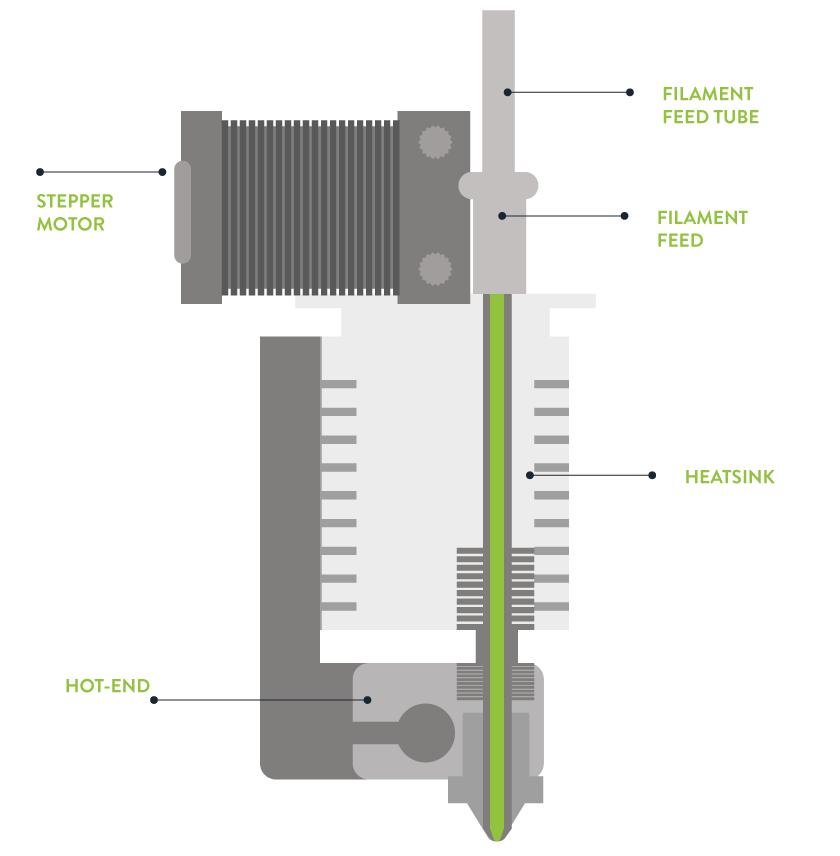

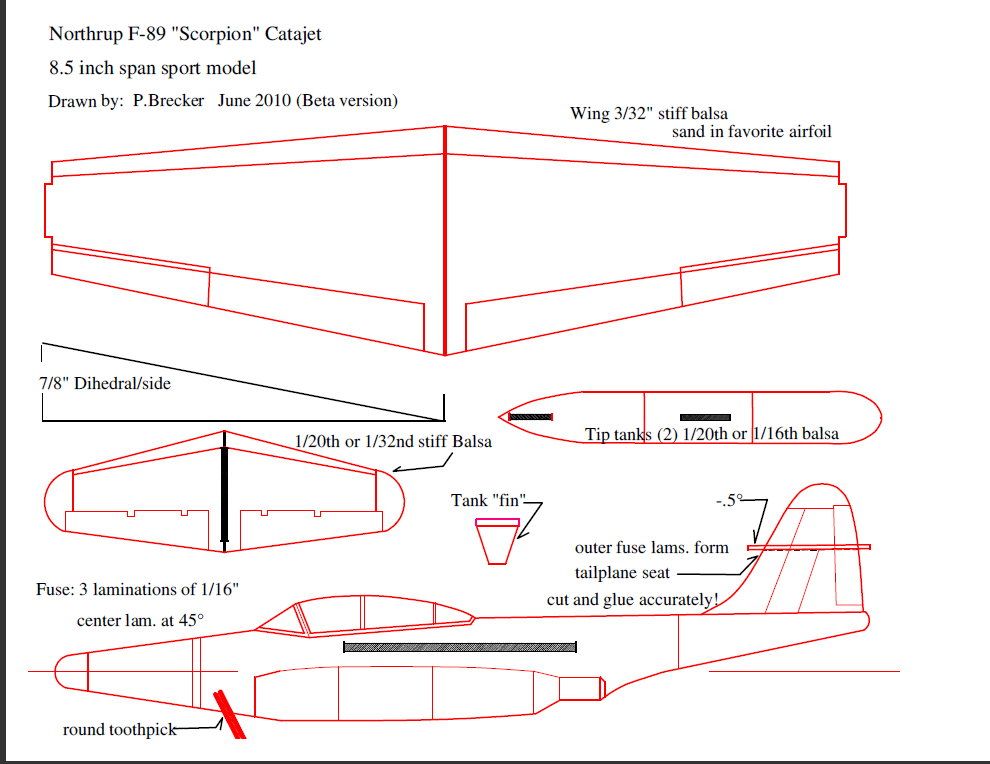

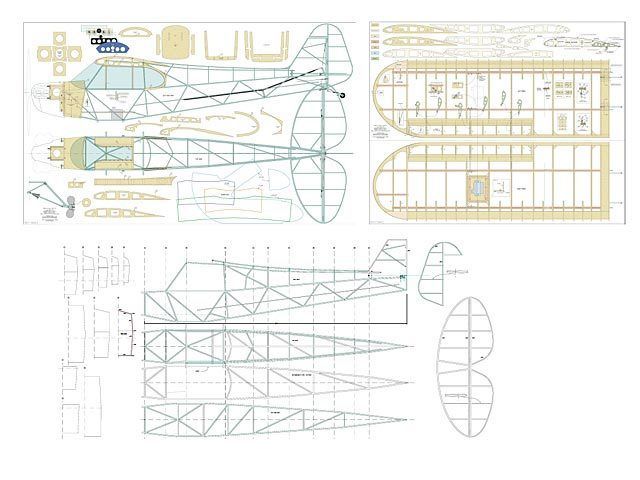

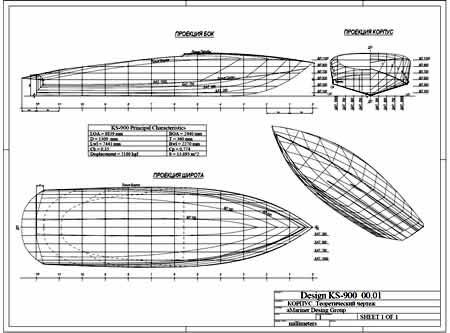

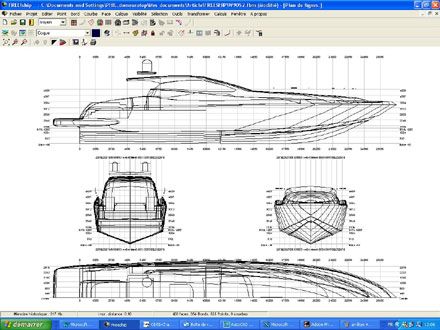

CNC, short for Computer Numerical Control, is a kind of manufacturing where a machining tool such as a lathe, mill, press, laser cutter, or any of many other tools moves according to a set of computerized directions. These directions usually take the form of a 3D model in a CAD file for most modern CNC machines.

What CNC means for CNC RC boat parts is that you will get the exact dimensions you need every time the machine is run with the instructions for it. There is little to no variability. CNC boat parts can also be made at odd and precise angles that are difficult for a human machinist to pull off. This makes CNC RC boat props or a CNC clutch bracket for a marine engine very possible to make, even in multiples and small sizes.

You can also custom design RC boat parts or even RC boat hulls. All you need to do is provide the machine with a viable CAD file. This is a great option if you want to custom design an RC boat, or if you are looking for hard-to-find or expensive parts. You can design CNC boat plans in a program and then have them made just to order.

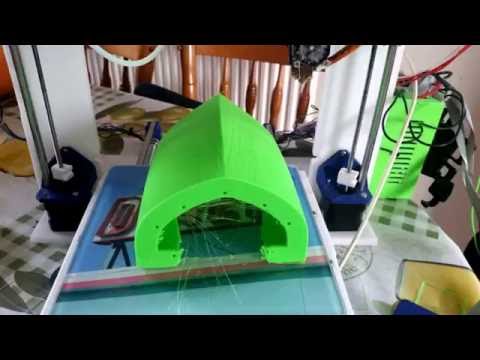

3D Printed RC Boats

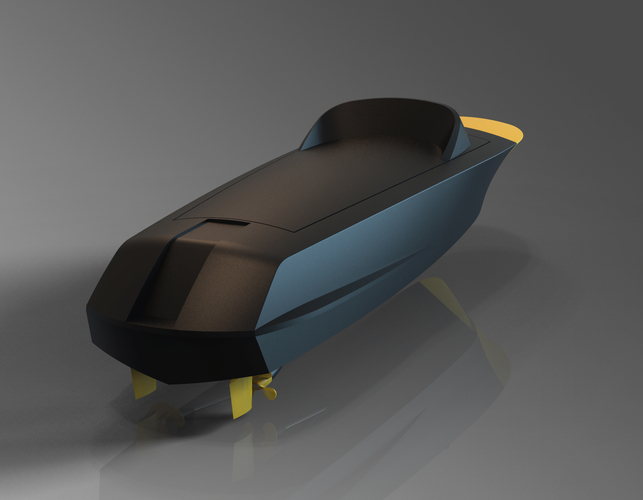

As customizable as CNC RC boats are, 3D printing opens up even more possibilities. 3D printing technology has been in the news often and the industry is using it to create all sorts of things, from aerospace parts to medical devices. This technology is not just useful for large and serious subjects though; it offers great and affordable options for RC boats.

This technology is not just useful for large and serious subjects though; it offers great and affordable options for RC boats.

A 3D printed RC boat is limited only by your own design skills and the size of the 3D printer. Like with CNC, 3D printing is all based on a CAD model and it will follow your CAD model exactly.

There are a wide variety of materials available for use with 3D printing, including numerous kinds of plastics, metal, and rubber. Whether you want to create 3D printed RC boat parts or full 3D printed RC boat plans, there are good options to optimize your design and make sure it performs how you want.

3D printing is cost-friendly, especially if you are experimenting with new designs. Unlike many other manufacturing methods, 3D printing has a much lower set-up cost. There are no molds or large machinery to retool. This allows for rapid prototyping on a fairly small budget. It also means that anyone who wants to create a CAD model can likely afford to create their own custom 3D printed RC boat.

At Jawstec, we provide top-of-the-line CNC and 3D printing services. We can help you from the very first stages of design all the way through the finishing of your custom RC boat or RC boat parts. Our expert team is here to help you! Contact us today for a CNC quote or a 3D printing quote!

⛵ Best Boat 3D Models・Cults

⛵ Best Boat 3D Models

3D Printable Boats

On this page you will find a large number of free or paid 3D files for boat lovers. Some boats are purely decorative, while others can easily navigate the water. There are sailboats, catamarans, fishing boats and even huge cargo ships.

#3DBenchy - fun 3D printing torture

Free

BEN floating BENCHMARK (Benchy)

Free

Caravel Columbus "Nina" (1492)

Free

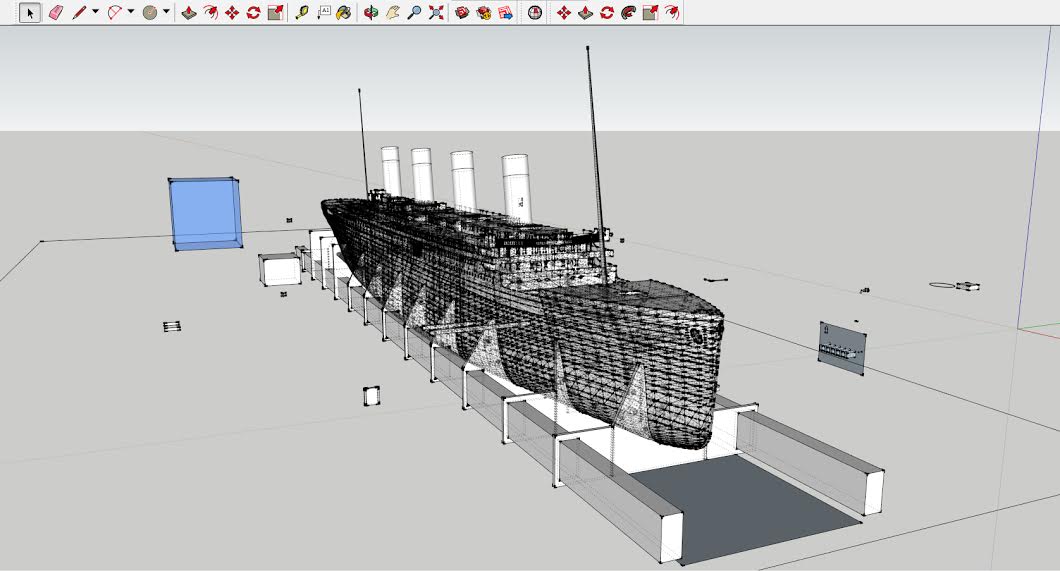

RMS TITANIC - scale 1/1000

Free

bathtub boat

Free

LEO the little fishing boat (visual benchy)

Free

Smoke for #3DBenchy boat

Free

JUN - the Jungle Queen

Free

Small fishing boat - floating toy for kids

Free

CAS - the modular xyz-cube cargo ship

Free

nine0008 Small compressed Titanic and scale example of the icebergFree

Mini RC Jet Boat 200 Mono

8 €

Container Ship

Free

The Endeavor

Free

Little bathtub tug boat (visual benchy)

Free

nine0008 FIN the little Trawler (visual benchy)Free

Paddle Boat

Free

The Trinidad

Free

Tug Boat

Free

Battleship - Recreated

Free

The Bao Chuan

Free

Sailboat Scale Model Esc: 1:43, based on Westerly Tiger 25

Free

EMMA - a Maersk Ship

Free

Motor Boat RC small (experimental)

Free

COS - the Container Ship

Free

nine0008 Toy BoatFree

The Sao Cristovao

Free

Sailboat

Free

Turbo-BOAT --> Print in Place / NO SUPPORTS / No assemble

Free

RS1: Cargo ship

Free

nine0008 ICE - the icebreakerFree

ship (battle)

Free

Cargo container for cargo ship Marauda

0,50 €

FERRY - the little transport miracle

Free

Impeller Boat RC - spiral vase printable

Free

Research Vessel

Free

VOS - the Supply Ship

Free

Sailboat

Free

Sailboat

Free

Speed Boat 2 RC

Free

nine0008 Two Hulled Impeller Boat RC (experimental)Free

Cruise Ship

Free

Antique boat

1 €

OLI - the little Ocean Liner

Free

Speed Boat RC (experimental)

Free

nine0008 titanic 5. 15 €

15 €

Sail Boat

Free

Speed Boat 3 RC

Free

#3DBenchy - fun 3D printing torture

#3DBenchy - fun 3D printing torture

RC Benchy

Mini RC Jet Boat 200 Mono

Here is our selection of best STL files of boats , all these beautiful boats from 3D file library Cults and are perfectly printable in 3D .

This collection includes many free and paid 3D files of that will allow you to 3D print at home many variations of boats. Each Cults 3D designer has their own vision of a boat, so you will find incredibly realistic boats created as models, but also more childish boats to play in the bathtub. Obviously, it's impossible to talk about 3D printing and boats without mentioning the famous Benchy , this boat that floats and is an excellent calibration test for your 3D printer.

Obviously, it's impossible to talk about 3D printing and boats without mentioning the famous Benchy , this boat that floats and is an excellent calibration test for your 3D printer.

Then, of course, there are purely decorative boats that can be neatly shelved, then 3D printed boats that float and can go on an adventure, and finally remote RC 3D printed boats . Some 3D designers of have even created boats with a 3D printed motor that works great ! In terms of format, there is everything you can imagine: large cargo ships, catamarans, sailboats, fishing boats...

Homemade submarine with a surface wi-fi antenna / Sudo Null IT News

How it all began

I welcome everyone. I am Maxim and I want to share information about how I assembled a radio-controlled submarine without any knowledge of electronics at the beginning of my journey.

I myself am an animation and computer graphics artist by education - I have never dealt with programming or electronics. I had only a small stock of knowledge about soldering, which was passed on to me by my grandfather when I was still a primary school student. nine0007

All my life I have been interested in the topic of underwater research, it all started at the same time, in childhood, with Zh.I. Cousteau, and ended with the development of a game about the subglacial oceans of Europe. But, however, now is not about that.

Deciding that it was time to turn my passion into practice, I went to Youtube. I received a handful of the most basic knowledge, and then my path lay already on AliExpress, like many others. It all ended with the purchase of 27 items of various modules and other components.

The post office worker was very unhappy when he was looking for 27 parcels…

The beginning of work on the submarine and the first failures

Spoiler

At the end there is a video with an overview of the project, and in the article itself I will talk about interesting problems which I encountered and which I did not mention in the video.

First, I found a man who knew firsthand about submarines, he helped me with theory and tests. nine0007

Next, I immediately started writing my first Arduino code. It was the code to control the submarine's two engines. Two potentiometers: the left one controls the total power of the engines, and the right one controls the rotation of the submarine (reduces the power of one of the engines, depending on the position of the potentiometer). I displayed all this on an inexpensive display, as I planned to make a separate control panel (as a result, the submarine is controlled via a smartphone).

Considering that a week ago I did not know how potentiometers work, my delight was indescribable. Without stopping there, I went to a hardware store and a pharmacy. In the construction shop I got different polypropylene pipes, couplings and clamps, and in the pharmacy I took several Janet syringes. nine0007

Pipes, respectively, went to the hull of the submarine, and syringes to the buoyancy change module. It was the buoyancy change module that turned out to be the most problematic part for me.

It was the buoyancy change module that turned out to be the most problematic part for me.

Buoyancy module

The tasks of this module are quite simple, to collect water and squeeze it back on command. And the question arose - how to push the syringe piston, having a handful of servos, motors and a set of gears? That's exactly how you should not push:

This was the first experience of interacting with gears and other little things. By the way, I was able to remake the sg9 servo0 for 360 ° rotation: I grinded off the lock on the main gear, which turned the potentiometer, and glued the potentiometer shaft itself in the zero position so that it would not accidentally rotate even with a beveled limiter.

Gear photo

This still did not help solve the problem - I could not securely fix the gear interacting with the rack. The engineering experience gained helped me master the buoyancy change module the second time: I took a more powerful servo, a thick threaded stud and a nut, which I fixed on the piston. This time I didn't bother with modifying the servo, I decided that it was easier to use an external driver and connect directly to the servo motor. nine0007

This time I didn't bother with modifying the servo, I decided that it was easier to use an external driver and connect directly to the servo motor. nine0007

I'm an engineer at my mom's

Vasyansky flexible coupling

Aluminum frame for rigidity 9026 9026 9026 9026 9026 9026 9026 A laser rangefinder was placed on the piston so that I could determine in real time what position it was now. Well, based on this distance data, I prescribed the piston lock when it is in extreme positions. Perhaps there are simpler methods for determining the position of the piston, but I accidentally found a very cheap module from the Chinese - a rangefinder VL53L0X and decided to use it. As a result, I was very pleased, the library is simple, it works as it should, I advise. The accuracy in the enclosed space of the syringe is about 5 mm, in principle, this was enough for me.

During testing, another problem arose - the piston strongly sticks to the walls of the syringe. I don’t know what it is connected with, but to start the piston movement, you need to apply considerable effort, after the initial jam it goes on normally. We tried almost all types of lubricants - many of them only made it worse. It is for this reason that an aluminum frame for the module had to be added. nine0007

Motors

With the propulsion system, I settled on the simplest solution and took ready-made underwater motors. Before that, I tried the option with a motor inside the case. I ordered a stern tube in a set with a shaft and screws, but as I studied the issue, it turned out that a whole system was needed for my purposes: a complex stuffing box, flanges, etc. Otherwise it will leak anyway. I have plans for the future to throw the submarine somewhere on Ladoga and control it via a 3G network, sitting on the couch at home, which means that any possible leaks will lead to a small autonomy of the device. nine0007

nine0007

In the future I plan to use only underwater motors, most likely brushless ones. At the moment, these are used, collector:

I control them using PWM. The seller says that they are at a maximum depth of 8 meters, which, again, imposes some restrictions immediately.

Housing

There was an interesting task with the case - to make a tight connection that would be easy to disassemble. The task was not completed, I had to glue everything tightly. When the syringe draws water, pressure is created inside the body and all our fasteners were simply squeezed out. As a result, all the important wires were brought to a sealed connector, through which you can charge the device, flash the onboard Arduino, and connect the antenna. nine0007

Yes, our antenna is connected with a cable and is in the surface position, guaranteeing a reliable connection. But about the antenna a little later.

Additional photos

The body consists of 50mm polypropylene pipes and couplings. The joints are smeared with hermetic paste, and on top, for strength, are filled with hot melt adhesive. A syringe spout, a sealed connector, a power switch and two wires for spotlights were brought to the end. Searchlights are fixed on the bow of the flooded part, this design made it possible to shift the center of gravity closer to the center of the submarine. nine0007

The joints are smeared with hermetic paste, and on top, for strength, are filled with hot melt adhesive. A syringe spout, a sealed connector, a power switch and two wires for spotlights were brought to the end. Searchlights are fixed on the bow of the flooded part, this design made it possible to shift the center of gravity closer to the center of the submarine. nine0007

Submarine brains

This is the most interesting part for me. When I started to work out the circuit, I still did not know how, for example, capacitors work and what they are for. I was very happy when, when the power was turned off, the LED on the Arduino slowly dimmed due to the capacitive capacitor.

In fact, they were useful in the circuit to smooth out the peaks that arise in the circuit due to the operation of the collector motors. They are also needed to connect a voltage stabilizer.

We have a battery of two cells, respectively, 8.4 V voltage goes to the motors, and 5 V after the stabilizer goes to the Arduino and other sensors. full size scheme (clickable):

full size scheme (clickable):

At first, a lot of things did not work out just for the reason that I assembled everything on a prototyping board. I could not understand why this or that part of the circuit does not work. As a result, everything began to solder and positive test results were not long in coming.

One of the interesting problems arose with the rangefinder. His library is good, but if you set the accuracy mode to medium or high, then the entire sketch will slow down and control will come out with a ping of at least 2000 ms. Because of this, the rangefinder is in FAST mode, but its accuracy is still enough for our tasks. nine0007

The next thing I ran into was cable management. Case diameter 50 mm. It seems like a lot until you start trying to fit everything inside. I used really overly fat cables designed for audio, which let me down a lot. I wanted exactly copper ones, since it is convenient to solder them, and so that they do not break, like, for example, aluminum ones. Next time I'll spend more time looking for good wires.

Next time I'll spend more time looking for good wires.

Further difficulties arose only with the antenna. nine0007

Antenna

As an antenna, I decided to use esp8266 and control the submarine via a smartphone via Wi-Fi. Only now the Chinese have a wide variety of modules based on ESP8266, I purchased three different ones, but I was able to connect and flash only one of them - ESP-01 .

In theory, if you order now, they will already have the correct firmware. It is controlled via RemoteXY, and it needs a specific firmware version for AT commands. The problem with finding the right firmware for control via AT commands was solved only with the help of a guide from RemoteXY. By the way, not advertising, I just liked the interface, and only then I found more convenient and well-developed interface designers for all kinds of IoT. nine0007

After a successful firmware, I hung the module with the necessary components for operation and soldered a USB connector to it for easy connection. I integrated the USB mate into a cork from a regular bottle and got a simple wired antenna with the ability to change the case (bottle replacement).

There were other problems besides the firmware.

The ESP-01 board must operate from 3.3 V, not from 5 V. Both logic and power. If I set up the logic through a level converter, then I was too lazy to mess around with the power supply and I just glued a small radiator child onto the chip. From five volts it works fine, but it gets very hot. Radiatorchik as a result helps not to burn the chip. nine0007

Another problem - I picked the perfect cable for a sealed connector, but it's only 2 shielded pins, while the antenna needs 4 (power and RX and TX for communication between the antenna and the Arduino on board).

It turned out that it would not be possible to simply power our antenna separately, since for the ESP + Arduino to work, it is necessary to have a common ground. I had to use shielding as ground at the cable, and add a separate battery to the antenna itself. Inconvenient, but works. It’s easier, of course, to find a 4-core cable and feed the antenna with batteries from the submarine. nine0007

Inconvenient, but works. It’s easier, of course, to find a 4-core cable and feed the antenna with batteries from the submarine. nine0007

The photo shows a good match between the diameters of the cable, silicone tube and crimp hole at the sealed connector.

Control and firmware

Management is carried out through the interface from a smartphone. The interface was compiled from ready-made modules directly on the site, received the source code of the interface, and then it remains just to bind various interface elements to actions inside the firmware.

Before getting the source code for the interface, you need to specify in the settings the type of wireless module that the Arduino will interact with. We flash only the Arduino itself - with the Wi-Fi module, further communication goes automatically through AT commands. An access point is created, connected to it from a smartphone and controlled through a pre-installed application. The interface comes from Arduino, it is hardwired into the firmware and is already recognized by the application itself in the smartphone. nine0007

The interface comes from Arduino, it is hardwired into the firmware and is already recognized by the application itself in the smartphone. nine0007

This was my very first code, I won't post it right here as it only uses basic programming skills and basic math. There were also difficult moments for me - I could not do the usual logical operation the first time - so that the syringe servo would be blocked for movement in one direction at certain values.

For example, when it reaches the maximum set of water, the piston should stop on the reverse movement, but should not be blocked on the forward movement. And vice versa, when all the water is squeezed out, the piston should not go forward, but without problems carry out commands to reverse. nine0007

if ((RemoteXY.button_1 == 1) && (RemoteXY.button_2 == 0) && (val_f < 100)) { pwm_UP = 1; pwm_DOWN = 0; } else if ((RemoteXY.button_1 == 0) && (RemoteXY.button_2 == 1) && (val_f > 25)) { pwm_UP = 0; pwm_DOWN = 1; } else { pwm_UP = 0; pwm_DOWN = 0; } Here is such a logical structure in the end, where RemoteXY. button_# are buttons in the interface for diving or surfacing.

button_# are buttons in the interface for diving or surfacing.

Also, from the code that is difficult for me, this is a rangefinder value filter (I took one of the simplest ones on the network), and, well, setting values for a voltmeter. The filter was needed because of the aforementioned FAST mode in the rangefinder, the incoming values jumped a lot and the filter just helped to cope with this. But the voltmeter came in handy to indicate the discharge of batteries. The Arduino has a reference pin, and if you apply no more than 1.1 volts to it, then the Arduino will be able to accurately determine the voltage applied to this pin. 8.4 V after the voltage divider is converted to 1.1 V. And this conversion turned out to be inaccurate, I had to experimentally correct the voltage value by adding a variable to the firmware. nine0007

Testing

Testing was carried out in an abandoned quarry with relatively clean water. For tests, it was necessary to fix the camera and adjust the trim of the submarine (along with basic neutral buoyancy).