Winsun 3d printed building

Shanghai-based WinSun 3D Prints 6-Story Apartment Building and an Incredible Home - 3DPrint.com

The 3D printed home is an accomplishment which many architects and designers have at least been contemplating for a few years now. We have seen numerous companies as well as individuals jump into the space recently, with design concepts which take home building well into the 21st century. Although China has been lagging behind the U.S and Europe in terms of consumer and manufacturing-based 3D printing, one China-based company seems to be leading globally when it comes to the 3D printing of large-scale structures such as homes.

Back in April of last year, Shanghai, China-based WinSun Decoration Design Engineering Co. revealed what many believed was a hoax initially; 10 homes which were almost entirely 3D printed with a recycled concrete material. The company seemingly emerged from nowhere and surprised us all.

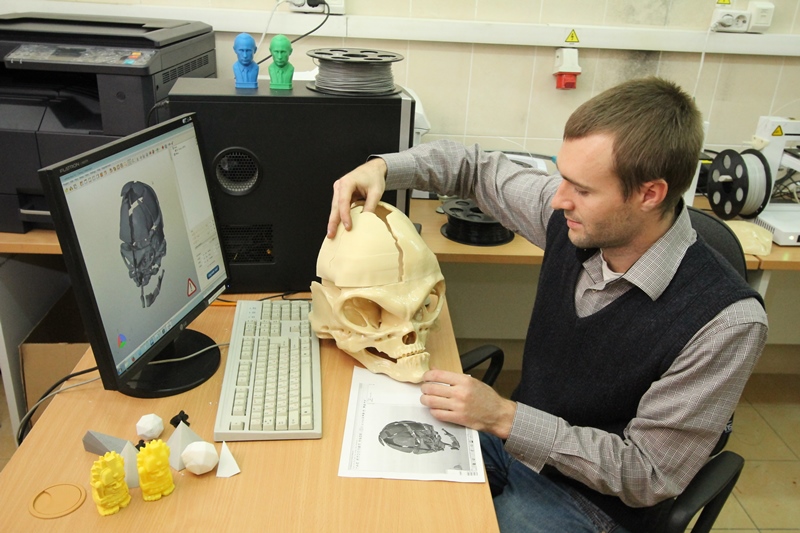

Well, today it was revealed that WinSun has made significant progress in their drive to 3D print livable homes and other structures. They have managed to 3D print an entire apartment building, consisting of 6 stories, as well as an impressive home, which certainly doesn’t appear to be 3D printed by any means. These structures were unveiled at the Suzhou Industrial Park, of east China’s Jiangsu Province, and the apartment building alone features a structure which is approximately 1,100 square meters in size.

A stand-alone villa, which has been 3D printed

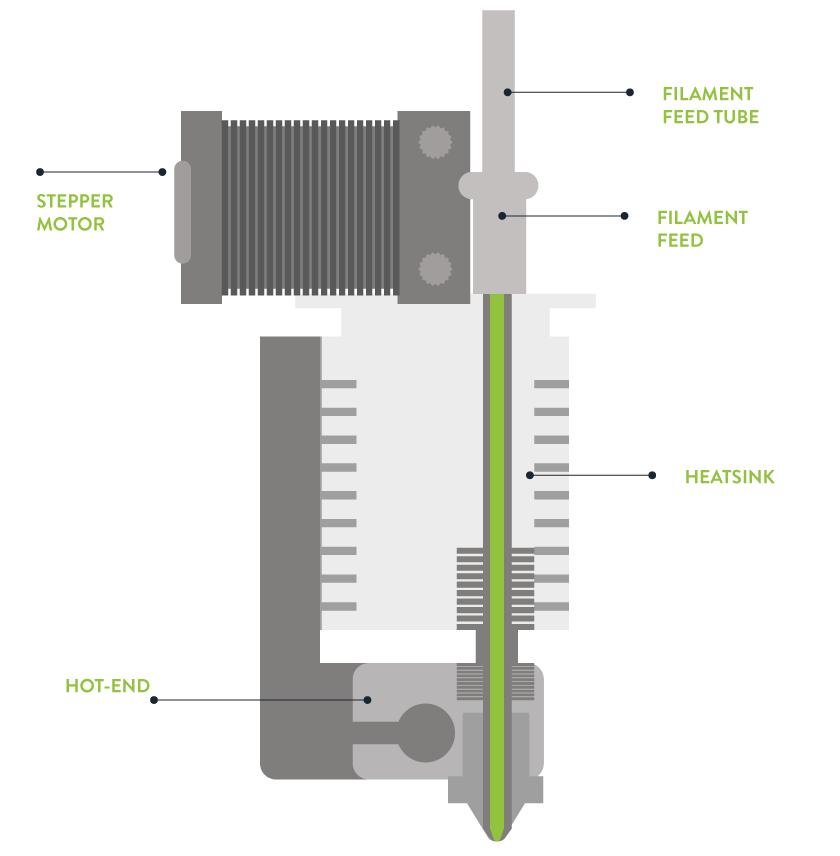

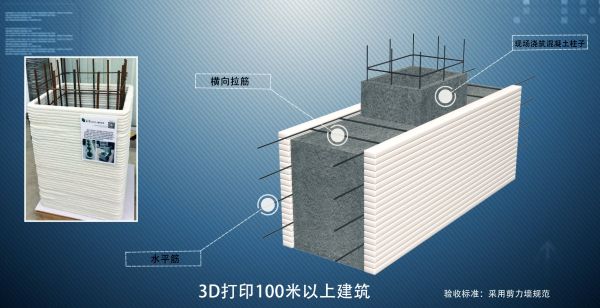

Using a machine which measures a staggering 20 feet tall, 33 feet wide and 132 feet long, the team at WinSun started with a basic CAD drawing which they fed to the massive 3D printer that was able to fabricate the structure piece-by-piece using a specially formulated and patented ‘ink’. The ink, which includes construction waste such as concrete, fiberglass, sand, and a special hardening agent, is an incredible way to recycle general construction materials — not to mention it is flexible, self-insulating, and resistant to strong earthquakes. The walls and other components of the structure were fabricated offsite with a diagonal reinforced print pattern and then shipped in and pieced together. The company then placed beam columns and steel rebar within the walls, along with insulation, reserving space for pipe lines, windows and doors.

The walls and other components of the structure were fabricated offsite with a diagonal reinforced print pattern and then shipped in and pieced together. The company then placed beam columns and steel rebar within the walls, along with insulation, reserving space for pipe lines, windows and doors.

A 6-story tall building which has been 3D printed by Winsun

The construction methods, according to the company, are able to save 60 percent of the materials typically needed to construct a home, and can be printed in a time span which equates to just 30 percent of that of traditional construction. In total, 80 percent less labor is needed, meaning more affordable construction, and less risk of injury to contractors.

Without a doubt, this is probably one of the the most exciting accomplishments within the 3D printing space we have covered. To be able to construct a 6-story building with 3D printed material is certainly a feat that’s guaranteed to garner further attention. WinSun is not done by any means. They will continue to further the technology behind this incredible 3D printer, and hope to eventually construct numerous homes at affordable prices within mainland China. Check out some additional photos below of the construction process and the structures themselves. Let’s hear your thoughts on this incredible accomplishment in the 3D Printed Apartment Building forum thread on 3DPB.com.

They will continue to further the technology behind this incredible 3D printer, and hope to eventually construct numerous homes at affordable prices within mainland China. Check out some additional photos below of the construction process and the structures themselves. Let’s hear your thoughts on this incredible accomplishment in the 3D Printed Apartment Building forum thread on 3DPB.com.

Front view of the 3D printed stand-alone villa

Stay up-to-date on all the latest news from the 3D printing industry and receive information and offers from third party vendors.

Tagged with: 3d printed apartment • 3d printed apartment building • 3d printed home • 3d printed homes • 3d printed house • 3d printing houses • winsun • winsun 3d print • winsun 3d printed homes • winsun 3d printing • winsun stock

Please enable JavaScript to view the comments powered by Disqus.

Chinese Company Constructs the World's Tallest 3D Printed Building

Chinese Company Constructs the World's Tallest 3D Printed Building

Image via australiandesignreview.com- Written by Rory Stott

Once again, Chinese company WinSun Decoration Design Engineering Co has expanded the capabilities of 3D printing. After constructing ten houses in under twenty-four hours last year, now they are back with both the world's tallest 3D printed building - a five-story apartment block - and a 1,100 square meter mansion with internal and external decoration to boot.

On display in Suzhou Industrial Park in Jiangsu province, the two buildings represent new frontiers for 3D printed construction, finally demonstrating its potential for creating more traditional building typologies and therefore its suitability for use by mainstream developers.

+ 2

Image via www. 3ders.org

3ders.orgThe buildings were created using the same 6.6 by 10 meter tall printer which builds up layers of an "ink" made from a mixture of glass fibre, steel, cement, hardening agents and recycled construction waste. With this technology, WinSun is able to print out large sections of a building, which are then assembled together much like prefabricated concrete designs to create the final building.

Image via australiandesignreview.comIn a press conference attended by online 3D printing newspaper 3Ders.org, the Chief engineer of China Construction No.8 Engineering Bureau Ma Rongquan explained: "These two houses are in full compliance with the relevant national standards. It is safe, reliable, and features a good integration of architecture and decoration. But as there is no specific national standard for 3D printing architecture, we need to revise and improve such a standard for the future."

A close-up of the construction system. Image via www.3ders.orgThe company also announced a raft of signed contracts and future plans that will expand 3D printed buildings beyond the realm of construction experiments: the $160,000 mansion is the prototype for a set of ten that has been ordered by Taiwanese real estate company Tomson Group; a third house on display at Suzhou Industrial Park was just one of 20,000 ordered by the Egyptian Government; they also announced the creation of Winsun Global, a collaboration with an American firm that will seek to expand into countries around the world with the aim of providing cheap and efficient homes for low-income families, particularly in Africa and the Middle East.

Story via 3Ders.org and Australian Design Review

Image gallery

See allShow less

About this author

Rory Stott

Author

•••

Cite: Rory Stott. "Chinese Company Constructs the World's Tallest 3D Printed Building" 26 Jan 2015. ArchDaily. Accessed . <https://www.archdaily.com/591331/chinese-company-creates-the-world-s-tallest-3d-printed-building> ISSN 0719-8884

Top #TagsSave

世界上最受欢迎的建筑网站现已推出你的母语版本!

想浏览ArchDaily中国吗?

是否Did you know?

You'll now receive updates based on what you follow! Personalize your stream and start following your favorite authors, offices and users.

Go to my stream

Top #Tags

The world's first printed five-storey building and villa

As early as March 29, 2014, ten printed houses, each with an area of 200 square meters, appeared in Shanghai. The buildings were created from concrete using giant construction 3D printers. The cost of each house was $4800.

The buildings were created from concrete using giant construction 3D printers. The cost of each house was $4800.

On January 18, 10 months after the first project, Shanghai WinSun Decoration Design Engineering Co announced that they have taken 3D printing to a whole new level: they built the world's tallest 3D printed building, a 5-story residential building, and printed the first villa in the world. The area of the villa is 1100 square meters and is rented with internal and external finishing. nine0004

In 12 years of operation, WinSun has registered 98 national patents for building materials. The company started its innovative path in construction back in 2004, when it developed a 3D nozzle for automatic supply and spraying of building materials, and in 2008 the first wall was printed.

More than 300 representatives of construction and investment companies gathered at the press conference. WinSun's CEO said the company's success is due to the uniqueness of the presented method. Firstly, an exclusive building material, which is a mixture of recycled construction waste, fiberglass, steel, cement and special additives. Secondly, the construction 3D printer itself is 6.6 meters high, 10 meters wide and 150 meters long. Such dimensions make it possible to increase the efficiency of construction by 10 times. nine0004

Firstly, an exclusive building material, which is a mixture of recycled construction waste, fiberglass, steel, cement and special additives. Secondly, the construction 3D printer itself is 6.6 meters high, 10 meters wide and 150 meters long. Such dimensions make it possible to increase the efficiency of construction by 10 times. nine0004

The company believes that thanks to 3D printing technology, it is possible to save up to 60% of materials and reduce construction time by 50-70% while reducing labor costs by 50-80%. In the future, the company plans to build bridges and high-rise office buildings using a 3D printer.

Presented today, the villa was designed for the Taiwanese company Tomson Group, the largest real estate agent in Taiwan, and the total construction costs amounted to $161,000 and there are already 10 pre-orders. nine0004

The director of the company hopes that with their 3D technology they will be able to undermine the usual picture of a construction site where noise and dirt reign. The new construction method is more compact and efficient.

The new construction method is more compact and efficient.

The villa and the five-story house, which were printed by a giant 3D printer, comply with local construction standards, while the company notes that in addition to developing the method itself, it is necessary to carry out comprehensive work to introduce new standards, taking into account modern realities. nine0004

The presentation also featured a one-story house, an order for which was placed by the Egyptian government. The house was printed in one day and is part of an overall production plan for 20,000 units.

Today's display site also featured a one-story house pre-ordered by the Egyptian government, which will soon be shipped to Egypt. As Ma explained, "This house was printed in one day, and is part of a total order of 20,000 units." nine0004

WinSun announced the start of cooperation with the Egyptian company Nile Sand Material Technology Co. Ltd. Within two years, the companies together plan to set up 12 factories in the desert. Solutions are currently being sought for the use of sand for printing. Already, they have discovered that sand is great for creating walls that prevent the spread of the desert.

Solutions are currently being sought for the use of sand for printing. Already, they have discovered that sand is great for creating walls that prevent the spread of the desert.

Contracts have also been signed with Winsun Global, a joint venture between American and Chinese companies. Over the next three years, factories will be established in Saudi Arabia, the United Arab Emirates, Qatar, Morocco, Tunisia and the United States, as well as in more than 20 countries. In particular, the program is aimed at developing the countries of the Middle East and Africa - providing low-income people with cheap housing. The first batch of 3D printers is ready to ship. nine0004

Finally, Winsun announced a joint venture with China Railway 24th Bureau Group. Construction of 5 factories in Shanghai, a high-tech park in Hebei and Heilongjian provinces, as well as in Mexico and Russia.

The enterprises will produce building materials for 3D construction and components of the construction printers themselves.

It can be added that there are cooperation agreements with designers from all over the world who will be able to submit their 3D projects for printing houses. nine0004

By increasing efficiency, reducing waste, creating safer and quieter construction sites, new opportunities are opening up for humanity, and this is just the beginning of the 3D printing era. The day is getting closer when settlements on other planets will cease to be pictures from the screens, but will move into the category of “downloaded and built”.

Below are photos of the world's first printed villa and high-rise building.

Shanghai WinSun printed a five-story house and mansion

3D printing

Subscribe author

Subscribe

Don't want

13

3D printing of architectural structures has occupied the minds of specialists for several years. In recent years, we have seen several attempts to develop 3D construction printers, both by companies and individual designers. One thing is clear: 3D printing may very well become the mainstream construction method. Although most of the research on this topic is being carried out in Europe and the United States, Chinese engineers are also making an effort, and this time the designers from the Middle Kingdom managed to pull ahead. nine0004

One thing is clear: 3D printing may very well become the mainstream construction method. Although most of the research on this topic is being carried out in Europe and the United States, Chinese engineers are also making an effort, and this time the designers from the Middle Kingdom managed to pull ahead. nine0004

Last April, the Chinese company WinSun made a statement that was seen by many as a belated April Fool's joke: the company reported successfully 3D printing ten houses within a day. When the company's representatives posted photos of finished objects, there was no laughing matter: a small, unknown Chinese company managed to equalize with the world's best developers. Each house was 200 square meters and cost only $4,800, and although those ten houses turned out to be rather simple "boxes", a start was made. nine0004

Now, just six months later, WinSun has announced the completion of a much more complex pilot project. During the last demonstration, the company's specialists printed a five-story residential building and quite a pretty mansion, and these buildings are full-fledged architectural structures. Both buildings were erected on the territory of an industrial park in Suzhou. The mansion alone has an area of 1,100 square meters.

During the last demonstration, the company's specialists printed a five-story residential building and quite a pretty mansion, and these buildings are full-fledged architectural structures. Both buildings were erected on the territory of an industrial park in Suzhou. The mansion alone has an area of 1,100 square meters.

nine0004

A giant 3D printer six meters high, ten meters wide and forty meters long was used for printing. Specialists settled on the production of building blocks with subsequent assembly into a solid structure. The material used was a mixture of cement, fiberglass, sand and a special hardener. It is noteworthy that construction and industrial wastes were widely used for the production of such concrete. The finished material turned out to be strong enough for the construction of buildings that are resistant to earthquakes. nine0004

The blocks were printed on a separate site and transported to the construction site for the next stage, which includes the installation of fittings, thermal insulation, pipes, window and door frames. According to representatives of the company, during the experiment, significant savings in building materials were achieved, about 60%. In terms of time savings, building a house using 3D printing took about 30% of the time needed to build a similar object using traditional methods. At the same time, the staff of the construction crew was reduced by five times, which in itself means excellent cost savings and a reduced risk of work injuries. nine0004

According to representatives of the company, during the experiment, significant savings in building materials were achieved, about 60%. In terms of time savings, building a house using 3D printing took about 30% of the time needed to build a similar object using traditional methods. At the same time, the staff of the construction crew was reduced by five times, which in itself means excellent cost savings and a reduced risk of work injuries. nine0004

Of course, WinSun is not going to stop there. The company plans to continue improving the technology and hopes to win massive affordable housing contracts. So far, the company has 98 patents, including its own design spray nozzle and automatic material supply system. The company itself is twelve years old, and the first experiment on 3D printing of the wall of a building was carried out only seven years ago. nine0004

Now WinSun is printing full-fledged mansions with a meager cost of $161,000 for such a project.