Joel 3d printing nerd

3D Printing Nerd – Educational / Inspirational / Exception High Fiver

-

Finally, I can show your this AMAZING 3d printing project I did with Neil Patrick Harris! It’s the LARGEST 3D PRINTING PROJECT I’ve ever done! 87 DAYS of 3D PRINTING! I printed 3 MASSIVE ornate frames that Neil finished and added custom canvas prints to! Also, WHAT WAS THAT AT THE END?!?!?

Read More

-

Read More

-

Sovol has the SV06 PLUS, a larger sized version of their very popular SV06. Let’s get it out of the box and a first print done! https://sovol3d.com/products/sovol-sv06-plus Early bird price $299/300 units $329/500units normal price: $399.

Read More

-

Read More

-

Is @markforgedworth it? Let’s get an answer to that question! I designed and printed a bracket for my @VarlaScooter Eagle scooter! #3dprinting #practicalprinting #additivemanufacturing

Read More

-

Read More

-

Read More

-

Read More

-

The @Nexa3D XiP can print with xFLEX 475, a flexible resin, and it can do it VERY fast.

The process to wash and cure IS different than I’ve seen before, so let me take you through the process.

Read More

-

This @Clockspring3D phone stand needed a part fixed. Used some super glue and the @BambuLab X1 Carbon!

Read More

-

SUPPORT! 😍 ETSY! ▶ https://www.etsy.com/shop/3DPrintingNerd MERCH! ▶ https://the3dprintingnerd.com/merch Patreon ▶ https://3d.pn/patreon FloatPlane ▶ https://www.floatplane.com/channel/3dprintingnerd BuyMeACoffee ▶ https://buymeacoff.ee/3dprintingnerd KoFi ▶ https://www.ko-fi.com/joeltelling

Read More

-

SUPPORT! 😍 ETSY! ▶ https://www.etsy.com/shop/3DPrintingNerd MERCH! ▶ https://the3dprintingnerd.com/merch Patreon ▶ https://3d.pn/patreon FloatPlane ▶ https://www.

floatplane.com/channel/3dprintingnerd BuyMeACoffee ▶ https://buymeacoff.ee/3dprintingnerd KoFi ▶ https://www.ko-fi.com/joeltelling

Read More

-

SUPPORT! 😍 ETSY! ▶ https://www.etsy.com/shop/3DPrintingNerd MERCH! ▶ https://the3dprintingnerd.com/merch Patreon ▶ https://3d.pn/patreon FloatPlane ▶ https://www.floatplane.com/channel/3dprintingnerd BuyMeACoffee ▶ https://buymeacoff.ee/3dprintingnerd KoFi ▶ https://www.ko-fi.com/joeltelling

Read More

3D PRINTING NERD Trademark of Joel Telling - Registration Number 5054398

3D PRINTING NERD - Trademark Details

Status: 700 - Registered

Serial Number

86921464

Registration Number

5054398

Word Mark

3D PRINTING NERD

Status

700 - Registered

Status Date

2016-10-04

Filing Date

2016-02-26

Registration Number

5054398

Registration Date

2016-10-04

Mark Drawing

4000 - Standard character mark Typeset

Published for Opposition Date

2016-07-19

Attorney Name

Courtney McNulty

Law Office Assigned Location Code

L10

Employee Name

RHIM, ANDREW

Classification Information

International Class

041 - Education; providing of training; entertainment; sporting and cultural activities. - Education; providing of training; entertainment; sporting and cultural activities.

US Class Codes

100, 101, 107

Class Status Code

6 - Active

Class Status Date

2016-03-02

Primary Code

041

First Use Anywhere Date

2015-04-03

First Use In Commerce Date

2015-04-03

Current Trademark Owners

Party Name

Joel Telling

Party Type

30 - Original Registrant

Legal Entity Type

01 - Individual

Address

Please log in with your Justia account to see this address.

Trademark Owner History

Party Name

Joel Telling

Party Type

30 - Original Registrant

Legal Entity Type

01 - Individual

Address

Please log in with your Justia account to see this address.

Party Name

Joel Telling

Party Type

20 - Owner at Publication

Legal Entity Type

01 - Individual

Address

Please log in with your Justia account to see this address.

Party Name

Joel Telling

Party Type

10 - Original Applicant

Legal Entity Type

01 - Individual

Address

Please log in with your Justia account to see this address.

Correspondences

Name

Courtney McNulty

Address

Please log in with your Justia account to see this address.

Trademark Events

| Event Date | Event Description |

| 2016-03-01 | NEW APPLICATION ENTERED IN TRAM |

| 2016-03-02 | NEW APPLICATION OFFICE SUPPLIED DATA ENTERED IN TRAM |

| 2016-03-03 | NOTICE OF PSEUDO MARK E-MAILED |

| 2016-06-10 | ASSIGNED TO EXAMINER |

| 2016-06-14 | APPROVED FOR PUB - PRINCIPAL REGISTER |

| 2016-06-21 | TEAS REVOKE/APP/CHANGE ADDR OF ATTY/DOM REP RECEIVED |

| 2016-06-21 | ATTORNEY/DOM. |

| 2016-06-29 | NOTIFICATION OF NOTICE OF PUBLICATION E-MAILED |

| 2016-07-19 | PUBLISHED FOR OPPOSITION |

| 2016-07-19 | OFFICIAL GAZETTE PUBLICATION CONFIRMATION E-MAILED |

| 2016-10-04 | REGISTERED-PRINCIPAL REGISTER |

| 2017-03-14 | TEAS CHANGE OF OWNER ADDRESS RECEIVED |

| 2017-03-14 | APPLICANT/CORRESPONDENCE CHANGES (NON-RESPONSIVE) ENTERED |

| 2021-10-04 | COURTESY REMINDER - SEC. 8 (6-YR) E-MAILED |

| 2021-10-19 | TEAS SECTION 8 RECEIVED |

REC Wiki » Taper Slicing as a More Efficient Method for 3D Printing Hanging Structures

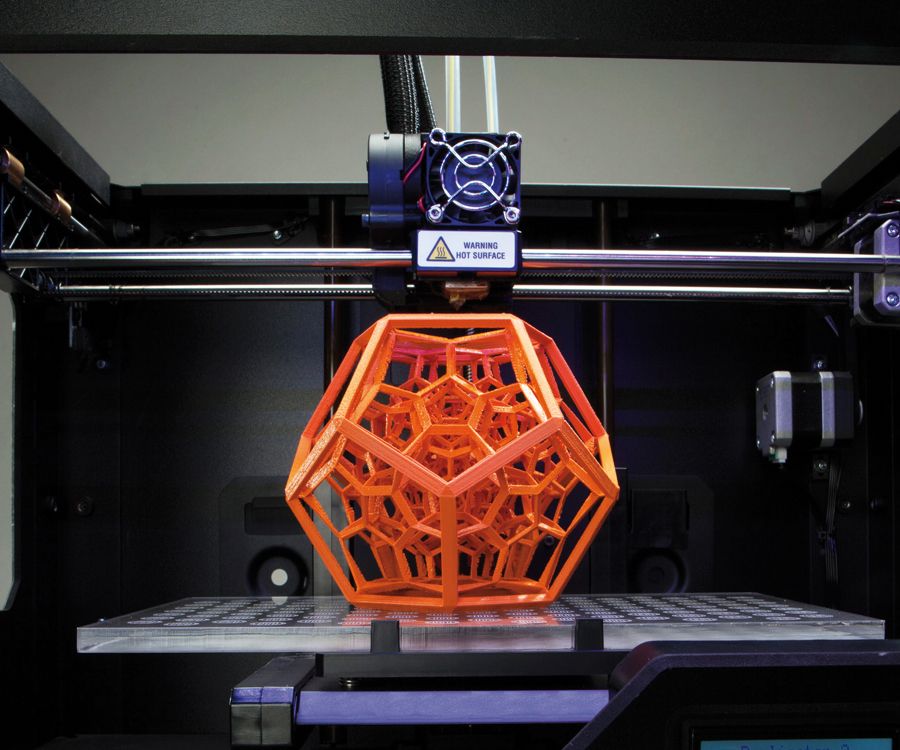

Standard slicers and FDM 3D printers slice 3D models horizontally, often requiring heavy use of support structures. Is it possible to do without supports and reduce material consumption? You can if you use the conical threading method.

In recent years, several non-planar cutting methods have emerged, although none of them has yet been widely adopted. One of the simplest and most interesting is the so-called conical threading. Such a scheme was implemented by scientists from the Zurich University of Applied Sciences (ZHAW), who assembled a four-axis 3D printer based on the Prusa i3. By mounting the hot end at a 45-degree angle on the rotating head, this system is able to print parts with large projections without building support structures. What is most interesting, the same approach can be used on conventional, unmodified FDM 3D printers with vertical hot ends and get very similar results.

Conventional and bevel cutting and stacking

Conventional 3D printers can print inclined surfaces, but only to a certain extent. At too large angles of inclination, the plastic will be extruded not so much on the already formed layers, but into the air, which means it will slide and sag. Hence the need to build supports that, after 3D printing, are separated from the model and turn into garbage. With conical cutting, the layers are slightly tilted so that when 3D printing hinged elements, only the edges of the layer line up “in the air”, and even then they maintain contact with neighboring perimeters. All this allows you to print parts of much more complex shapes without support structures.

One of the key considerations when using this method on conventional FDM 3D printers is the nozzle length. The nozzle must be long enough (that is, high) so that the rest of the head structure does not touch the laid material, because now the printer prints not strictly horizontal, but inclined layers. A lot here depends on the design of the head: in most cases, the fans and blower pipes leave a very small gap, which seriously limits the slope of the layers. The longer the nozzle, the higher the clearance and the possible angles of inclination of the layers. For example, in the Prusa Mini 3D printer, the cooling system is located quite high, which allows you to tilt the layers at angles of more than twenty degrees. On the other hand, when using the popular Ender-3 3D printers or their many imitations, the easiest solution is to install a nozzle with a long tip. At the same time, it is highly desirable to dismantle the calibration sensors from the head, since they are likely to interfere.

Artillery Hornet 3D printer with extended Airbrush nozzle

The problem is that the higher the cooling systems are, the worse the airflow will be. In some cases, depending on the material, this moment will have to be compensated by a reduction in the paving speed.

The main question is in which slicer to generate machine code? Fortunately, you can use almost any program, but you have to cheat a little. Simply checking the box and switching to the conical cutting mode will not work, since there is no such option yet in any popular slicer, however, any slicer can be fooled and forced to generate the desired G-code using a couple of scripts written in Python. The first script deforms the 3D model in the STL file into the shape of an inverse cone, moving the points of the polygon mesh up by a distance depending on the distance of the point from the central axis. The resulting 3D model is cut in almost any slicer - Cura, PrusaSlicer, Simplify3D or some other. Then the second script converts the machine code back so that the 3D printer prints an undistorted, original model, but with an inclined stacking instead of a horizontal one.

The necessary scripts were developed by the Swiss researchers from ZHAW mentioned above, then modified by Stefan Hermann, the author of the CNC Kitchen Youtube channel, for conventional FDM 3D printers and made available to the public. At the same time, Stefan shared a good example. This example uses SuperSlicer, a variant of PrusaSlicer with some additional and very useful features, such as the ability to export G-code with empty layers.

The STL file is loaded into the slicer with a slightly modified 3D printer profile, where the origin is in the center of the table. The model is placed on the table so that the global Z axis is aligned with the axis of the future cone, and saved.

Then the first script comes into play: you need to specify the angle of inclination in it, after which the script transforms the part into a pre-deformed, “conical” model.

The part is then sliced in the slicer as usual and saved as a G-code.

At the final stage, the name of the file with the machine code is inserted into the second script, which converts the code for building the deformed model into the code for building the original part. The whole process takes just a couple of minutes.

It must be understood that this method is not ideal: not only does it add work, albeit a little, but in some cases it can be less practical than conventional horizontal 3D printing. Please note that the illustrations above show examples with external tabs. If tapered threading is applied to 3D models with internal hinged structures, an even larger volume of support structures will be required than after horizontal slicing. Keep this in mind and choose the most appropriate method according to the circumstances.

Best files for 3D printers The%20last%20of%20us・Cults

Pendant of the star of David 133

10 €

Fat Lord with bell

10 €

Advanced Combat Weapon "ACW-20" - World War Z Game "Inspired Prop"

94. 81 €

Headphone holder under the table

Free

Batman Robert Pattinson

5 €

Fat virus lord

7 €

Mantis from Guardians of the Galaxy

5 €

Yorkist polygonal beam

Free

smoker - X files

Free

Pendant P089

7.48 €

Pendant P083

7.48 €

baby groot

2 €

Dark Saber Wielders Nameplates

Free

9th century Play accessory

2 €

40 mm 2x2 Shooting tray

0. 50 €

PLATE 50x100MM 3X1 or 25MM 6x4

0,50 €

40 mm 3x3 tray

0.50 €

Tray 40 mm 3x2

0.50 €

Tray 25 mm 8x5

0.50 €

25MM 8X4 TRAY

0.50 €

Tray 25 mm 6x5

0.50 €

Tray 25 mm 5x5

0.50 €

Tray 25 mm 5x4

0.50 €

Tray 25 mm 5x3

0.50 €

Tray 25 mm 5x2

0.50 €

TRAY 25 MM 5X1

0.50 €

Tray 20 mm 6x3

0. 50 €

Tray 20 mm 5x5

0.50 €

Tray 20 mm 5x4

0.50 €

Tray 20 mm 5x3

0.50 €

Tray 20 mm 5x2

0.50 €

TRAY 20 MM 5X1

0,50 €

Base 50x75 mm

0.50 €

Base 50x50 mm

0.50 €

Deathwing

3 €

Handle for lathe Mira VGX-21

5 €

FHW: Missile Bunker v1

Free

HEADPHONE STAND THE LAST OF US 2

4,55 €

PS4 PS5 THEME THE LAST OF US SUPPORT CONTROLS

6.