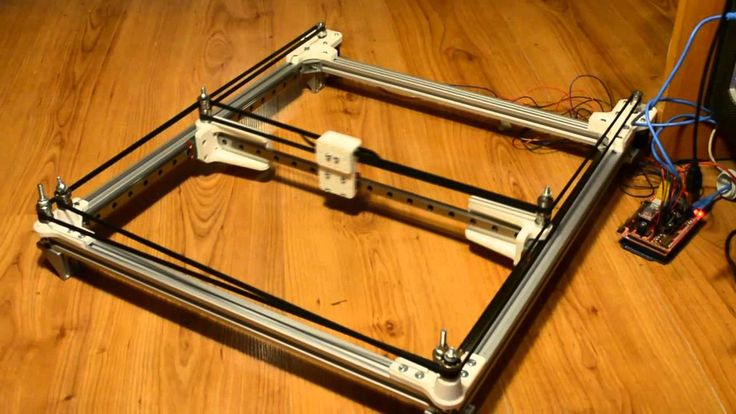

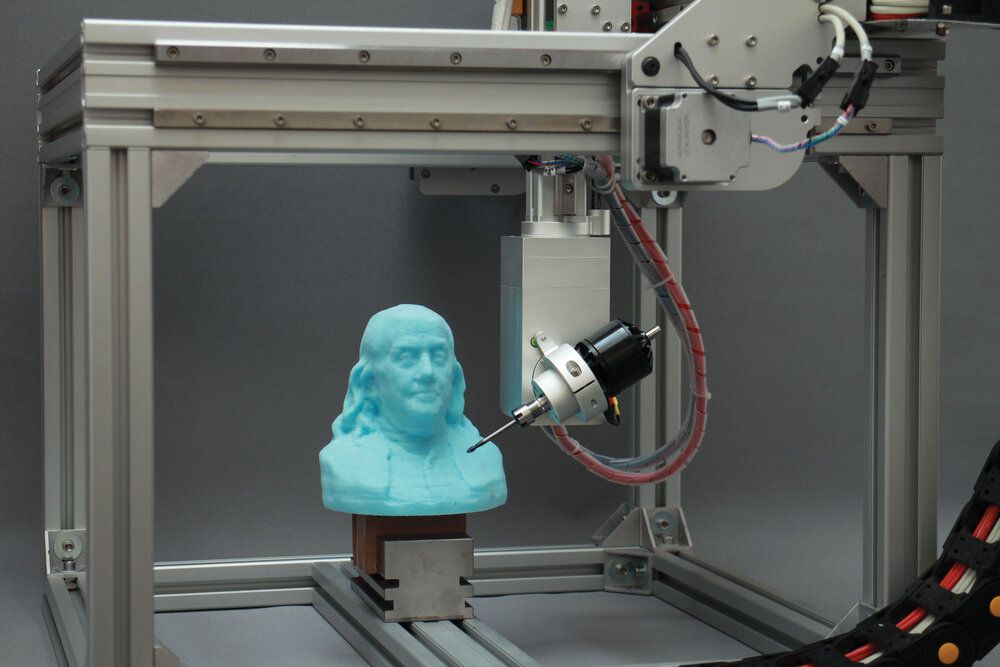

Hybrid 3d printer cnc

What's HYBRID? - 3D HYBRID: AM FOR CNC

"Hybrid Manufacturing" is an industry recognized term for combining both Additive Manufacturing and Subtractive Manufacturing processes.

Relevant Definitions from ASTM F2792 − 12a :

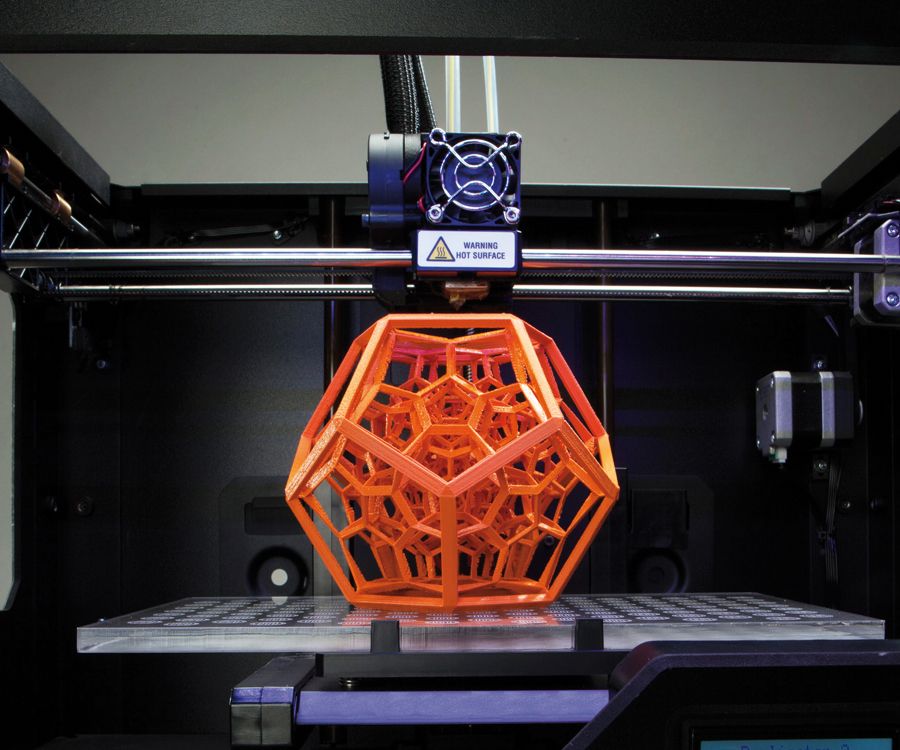

- additive manufacturing (AM), n--a process of joining materials to make objects from 3D model data, usually layer upon layer, as opposed to subtractive manufacturing methodologies. Synonyms: additive fabrication, additive processes, additive techniques, additive layer manufacturing, layer manufacturing, and freeform fabrication.

- subtractive manufacturing, n--making objects by removing of material (for example, milling, drilling, grinding, carving, etc.) from a bulk solid to leave a desired shape, as opposed to additive manufacturing.

- directed energy deposition, n--an additive manufacturing process in which focused thermal energy is used to fuse materials by melting as they are being deposited.

...But why combine the two?

After review of metal 3D printing technologies, one will learn that there are two main types of metal 3d printing, powder bed fusion (PBF) and directed energy deposition (DED).

When considering printing a part using either method it becomes abundantly clear that both are plagued by poor surface finish quality and require post machining. Therefore, CNC expense is inherent. DED technologies, ignore the goal of surface finish and precision, instead focus on speed and material quality. The CNC process provides the precision required. And DED lends itself quite easily as a tool to CNC machine through 3D-Hybrid. This is consolidation is Hybrid Manufacturing.

Hybrid Manufacturing History

Hybrid Manufacturing made its first commercial appearances in the early 2000’s via Laser-Powder Deposition in a CNC Machine. Some cases used a robot in a separate cell of the CNC machine with a pallet pool change mechanism. Hybrid Manufacturing didn’t quite catch on at that time. Lasers were still large capital expenditures and were typically produced for small spot sizes (i.e. cutting and engraving applications). With the onset of the metal 3D Printing or Additive Manufacturing growth in the 2010’s hybrid manufacturing made a resurgence. At this time the cost of Lasers had dropped to around $100,000 for a couple kilowatts, making it possible to couple with a large CNC machine tool purchase. Also at this time the metal powder bed machines were being delivered for $800,000 to $1,500,000 making Hybrid manufacturing an ideal alternative, especially for larger parts.

Hybrid Manufacturing didn’t quite catch on at that time. Lasers were still large capital expenditures and were typically produced for small spot sizes (i.e. cutting and engraving applications). With the onset of the metal 3D Printing or Additive Manufacturing growth in the 2010’s hybrid manufacturing made a resurgence. At this time the cost of Lasers had dropped to around $100,000 for a couple kilowatts, making it possible to couple with a large CNC machine tool purchase. Also at this time the metal powder bed machines were being delivered for $800,000 to $1,500,000 making Hybrid manufacturing an ideal alternative, especially for larger parts.

Hybrid Manufacturing is now a common, industry recognized term for combined additive and subtractive manufacturing. Since 2013, the number of machine tool builders offering hybrid manufactring machines has gone from zero to double digits. 3D-Hybrid is the only hybrid manufacturing tool integrator offering multiple metal deposition technologies for virtually any CNC machine.

Hybrid 3D printers available on the market

Published on September 3, 2020 by Aysha M.

Hybrid machining combines additive and subtractive manufacturing methods in one single solution. The concept was around since 1990’s but it was not commercially popular until recently. Today, more and more manufacturers are developing hybrid 3D printers as the demand for such machines keeps growing. Some manufacturers are offering even more functions than 3D printing and CNC – laser engraving and cutting and paste extrusion are often added to offer a versatile solution for the customer. Therefore, such hybrid printers are also known as “All-in-one printer” or “3-in-1 printer”. We have prepared a list of 14 hybrid 3D printers available on the market, divided into desktop and industrial categories and ranked in alphabetical order.

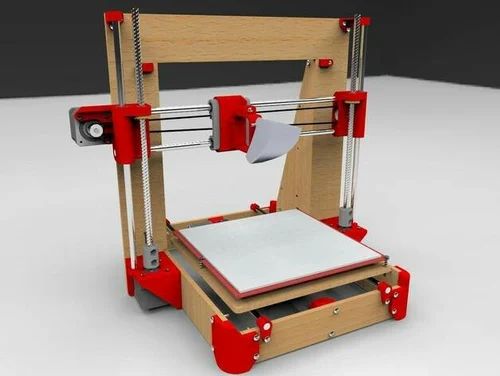

Desktop hybrid 3D printers

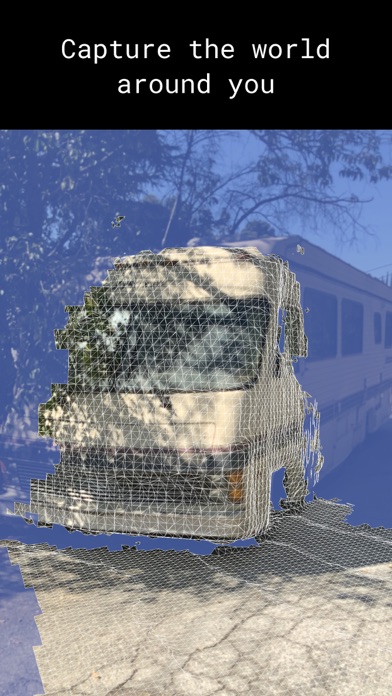

5axismaker

The 5AXISMAKER solution was launched in 2015 by UK-based manufacturer 5AXISWORKS. This machine is available in two versions, the 5xm400 and 5xm600 according to the maximum manufacturing size. Both support any CAD/CAM software (provided a post processor is available) and include a one-year commercial subscription to Autodesk® Fusion 360 TM Ultimate. They include a set of tools including a 5-axis CNC router, touch probe, 3D printer, 3D scanning and measurement, and hot wire cutter, plus the potential to add more items via their adapter. As we have said they have a printing volume of 400mm3 or 600mm3 depending on the version, and are compatible with engineering thermoplastics, such as nylon, PC, etc. You can purchase one of these hybrid multifunction 3D printers for $6,500 on the manufacturer’s website.

This machine is available in two versions, the 5xm400 and 5xm600 according to the maximum manufacturing size. Both support any CAD/CAM software (provided a post processor is available) and include a one-year commercial subscription to Autodesk® Fusion 360 TM Ultimate. They include a set of tools including a 5-axis CNC router, touch probe, 3D printer, 3D scanning and measurement, and hot wire cutter, plus the potential to add more items via their adapter. As we have said they have a printing volume of 400mm3 or 600mm3 depending on the version, and are compatible with engineering thermoplastics, such as nylon, PC, etc. You can purchase one of these hybrid multifunction 3D printers for $6,500 on the manufacturer’s website.

Creality CP-01

Creality 3D, a low-cost 3D printer manufacturer, has unveiled its Creality CP-01, a hybrid printer that can be used as a 3D printer, CNC milling machine, and laser engraving machine. The integrated FDM-based 3D printer prints with ABS, PLA, PVA, TPU and wood components at a maximum print speed of 80 mm/sec. The heating plate can be heated up to 100°C. The maximum volume is 200 x 200 x 200 mm and it must not be exceeded even for components that are milled or engraved. The integrated laser can engrave wood, plastic and paper with a laser power of 500mW. The same materials extended by printed circuit boards can also be milled with a maximum spindle speed of 4,800 rpm. The three individual modules of the hybrid printer (extruder, CNC milling and laser engraving unit) can be easily exchanged as required. By combining three units in one, the CP-01 saves not only space but also costs. However, the CNC milling and laser engraving units are entry-level models, so they do not provide above-average performance. In summary, the CP-01 is a good option for makers and hobbyists, but it is not at an industrial level.

The heating plate can be heated up to 100°C. The maximum volume is 200 x 200 x 200 mm and it must not be exceeded even for components that are milled or engraved. The integrated laser can engrave wood, plastic and paper with a laser power of 500mW. The same materials extended by printed circuit boards can also be milled with a maximum spindle speed of 4,800 rpm. The three individual modules of the hybrid printer (extruder, CNC milling and laser engraving unit) can be easily exchanged as required. By combining three units in one, the CP-01 saves not only space but also costs. However, the CNC milling and laser engraving units are entry-level models, so they do not provide above-average performance. In summary, the CP-01 is a good option for makers and hobbyists, but it is not at an industrial level.

da Vinci 1.0 Pro 3-in-1

Taiwanese manufacturer, XYZPrinting, entered the global 3D printing market with easy-to-use FDM desktop 3D printers. Today, the company is known for its da Vinci line of products for their value for money. The da Vinci 1.0 Pro 3 in 1 is a hybrid printer that integrates both a 3D printer based on FDM technology and a 3D scanner. If that’s not enough, a laser engraving unit can be added. The 3D printer prints parts from PLA, ABS, PETG, HIPS and wood PLA at a maximum print speed of 120 mm/sec. Because the da Vinci 1.0 Pro 3 in 1 has an open filament system, the materials do not necessarily have to be purchased from XYZPrinting, but can be purchased from third-party suppliers. The heating plate can be heated up to 90°C and the maximum construction volume is 200 x 200 x 190 mm. The 3D scans can have a maximum size of 15 x 15 cm with an accuracy of 0.25 mm. The optional laser engraving unit has an engraving area of 20 x 20 cm with a laser power of 350 mW. Due to its features, the da Vinci1.0 Pro 3 in 1 is suitable for professionals.

The da Vinci 1.0 Pro 3 in 1 is a hybrid printer that integrates both a 3D printer based on FDM technology and a 3D scanner. If that’s not enough, a laser engraving unit can be added. The 3D printer prints parts from PLA, ABS, PETG, HIPS and wood PLA at a maximum print speed of 120 mm/sec. Because the da Vinci 1.0 Pro 3 in 1 has an open filament system, the materials do not necessarily have to be purchased from XYZPrinting, but can be purchased from third-party suppliers. The heating plate can be heated up to 90°C and the maximum construction volume is 200 x 200 x 190 mm. The 3D scans can have a maximum size of 15 x 15 cm with an accuracy of 0.25 mm. The optional laser engraving unit has an engraving area of 20 x 20 cm with a laser power of 350 mW. Due to its features, the da Vinci1.0 Pro 3 in 1 is suitable for professionals.

DOBOT MOOZ 2 PLUS

Shenzhen Yuejiang Technology Co. (DOBOT) is a leading global provider of intelligent robotics solutions. DOBOT’s product line includes the MOOZ 2 PLUS. The DOBOT MOOZ 2 PLUS is a hybrid printer that combines 3D printing, CNC milling and laser engraving to print parts made ofPLA, TPU, PETG and flexible materials at a maximum print speed of 80 mm/sec. The heating plate can be heated up to 80°C. The maximum construction volume is 200 x 200 x 190 mm and this volume must not be exceeded even for components that are to be milled or engraved. The integrated laser can engrave wood, bamboo, leather, paper, plastic, fabric and opaque acrylic with a laser power of 1.6 W. The CNC milling machine mills wood, bamboo, acrylic, PCB, carbon fiber boards, plastic, etc. with a maximum spindle speed of 8,000 rpm. The DOBOT MOOZ 2 Plus is a desktop printer that is ideal for makers.

The DOBOT MOOZ 2 PLUS is a hybrid printer that combines 3D printing, CNC milling and laser engraving to print parts made ofPLA, TPU, PETG and flexible materials at a maximum print speed of 80 mm/sec. The heating plate can be heated up to 80°C. The maximum construction volume is 200 x 200 x 190 mm and this volume must not be exceeded even for components that are to be milled or engraved. The integrated laser can engrave wood, bamboo, leather, paper, plastic, fabric and opaque acrylic with a laser power of 1.6 W. The CNC milling machine mills wood, bamboo, acrylic, PCB, carbon fiber boards, plastic, etc. with a maximum spindle speed of 8,000 rpm. The DOBOT MOOZ 2 Plus is a desktop printer that is ideal for makers.

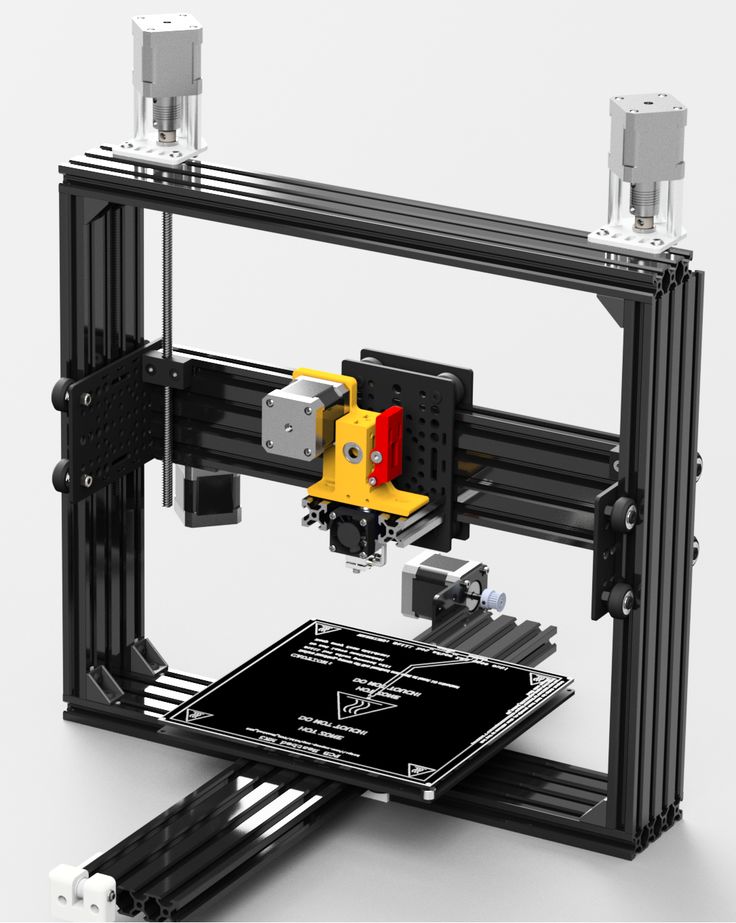

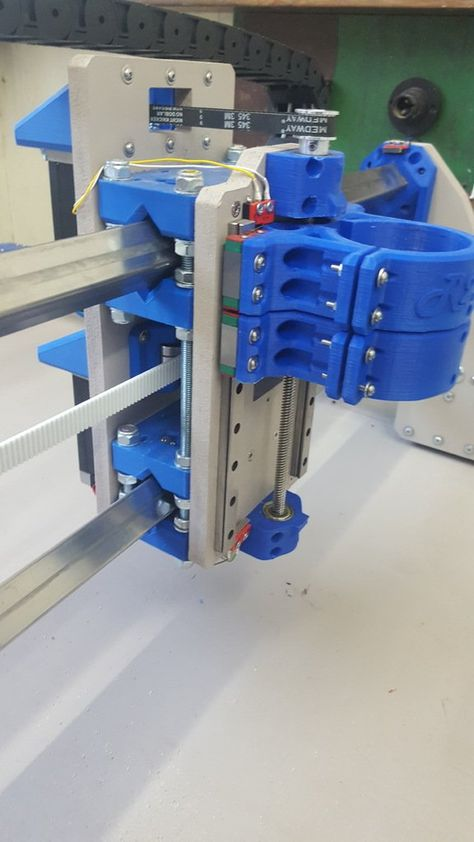

H-Series by Diabase Engineering

The H-Series from Diabase Engineering is a hybrid machine that offers CNC machining and 3D printing in a single interface. The machine has been carefully engineered to solve real problems in the desktop manufacturing toolchain. It is a machine that enables the manufacture of functional products with high accuracy and a professional finish. Depending on the number of axes you decide to go for, whether 3, 4 or 5, the machine offers different build volumes. The build volume on the 3-axis machine is 416mm x 186mm x 210mm. On the 3D printing side, you can print a range of engineering-grade thermoplastics such as ABS, PLA, NYLON, PETG, TPU, water-soluble materials and more. The machine is equipped with an active nozzle cleaning system, a heated filament cabinet, a changeable heated build platform and various subtrative tool heads for milling, engraving and surfacing. As mentioned you can also go for a rotary modular axis for 4th and 5th axis printing and milling.

It is a machine that enables the manufacture of functional products with high accuracy and a professional finish. Depending on the number of axes you decide to go for, whether 3, 4 or 5, the machine offers different build volumes. The build volume on the 3-axis machine is 416mm x 186mm x 210mm. On the 3D printing side, you can print a range of engineering-grade thermoplastics such as ABS, PLA, NYLON, PETG, TPU, water-soluble materials and more. The machine is equipped with an active nozzle cleaning system, a heated filament cabinet, a changeable heated build platform and various subtrative tool heads for milling, engraving and surfacing. As mentioned you can also go for a rotary modular axis for 4th and 5th axis printing and milling.

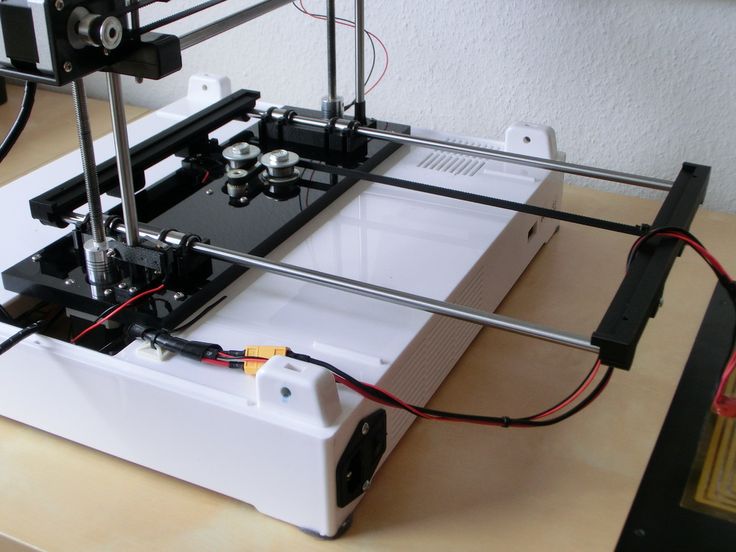

Snapmaker 2.0

Snapmaker 2.0, is a 3-in-1 machine that enables 3D printing, laser engraving and cutting, and CNC carving. It supports several 3D printing materials such PLS, ABS, wood, etc. For CNC carving you would be able to use carbon fiber sheet, PCB, platane wood, and more. You can also perform laser engraving and cutting on a diverse range of materials including plywood, fabric, leather, and acrylic. Snapmaker 2.0 comes with a smart touchscreen that simplifies the workflow of your projects, letting you manage the most-used tasks directly from the touchscreen. This desktop hybrid 3D printer retails for $1,039.

You can also perform laser engraving and cutting on a diverse range of materials including plywood, fabric, leather, and acrylic. Snapmaker 2.0 comes with a smart touchscreen that simplifies the workflow of your projects, letting you manage the most-used tasks directly from the touchscreen. This desktop hybrid 3D printer retails for $1,039.

ZMorph VX

ZMorph VX is considered by many to be one of the best desktop hybrid 3D printers currently available on the market. This versatile solution supports single and dual extrusion, CNC milling, laser engraving and cutting, and paste extrusion. ZMorph VX works with virtually all 3D printing materials on the market, so the users can take advantage of 3D printing with advanced materials like nylon, HIPS, PC/ ABS, and more. Silent X and Y steppers reduce noise by 50%. The paste extrusion function works with chocolate, dough, cream cheese, frosting, and more. To ensure a smooth workflow process for the users, the Polish company also released a designated software Voxeliser 2.

Industrial hybrid 3D printers

Aconity

MIDIThe 3D printer AconityMIDI was launched by the German manufacturer Aconity3D in 2018 with the intention of providing a flexible production system to users. AconityMIDI is equipped with an optional second camera that allows for parallel setup times while the main system is still in production. It has a maximum production volume of Ø 170 mm x H 200 mm and a layer thickness of up to 10 μm. In addition, the system integrates process monitoring or high temperature preheating (up to 1200°C). This hybrid 3D printer is also available as a DUAL-Laser system that allows for maximizing productivity. Weighing 1450kg, AconityMIDI can be equipped with the unique vacuum option and Micro-LBM configuration. This is certainly an advanced solution for professionals in the 3D industry.

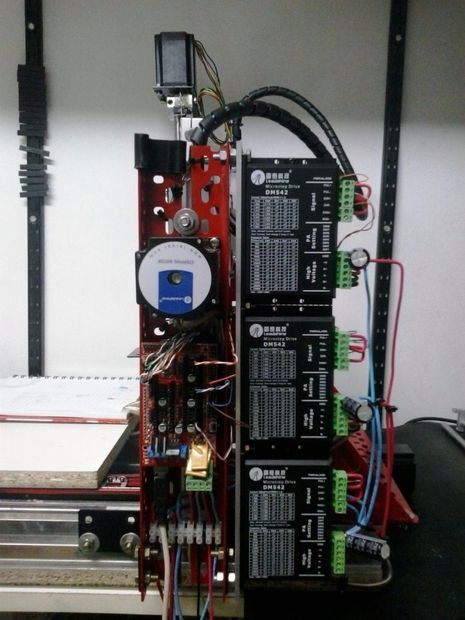

AMBIT Series 7

The new multitasking system AMBIT Series 7 has been developed by the company Hybrid Manufacturing Technologies with the aim of opening up new opportunities in the production of metal parts. It provides a perfect integration of 7 production technologies in the same tool without precedents. This new multitasking system integrates DED technology heads with a robust performance to deposit metal from 0.5 to 3mm thickness. It also features a column that functions as a universal docking station to monitor and control manufacturing processes to ensure quality parts. Its main novelty is the subsequent verification of manufacturing quality thanks to the eddy current inspection head, which allows the detection of surface and subway cracks. The AMBIT Series 7 solution is undoubtedly an innovative way to integrate additives in conventional manufacturing!

It provides a perfect integration of 7 production technologies in the same tool without precedents. This new multitasking system integrates DED technology heads with a robust performance to deposit metal from 0.5 to 3mm thickness. It also features a column that functions as a universal docking station to monitor and control manufacturing processes to ensure quality parts. Its main novelty is the subsequent verification of manufacturing quality thanks to the eddy current inspection head, which allows the detection of surface and subway cracks. The AMBIT Series 7 solution is undoubtedly an innovative way to integrate additives in conventional manufacturing!

INTEGREX i-400 AM by MAZAK

Manufactured by the Japanese company MAZAK, the INTEGREX i-400 AM is a hybrid multi-tasking machine that provides additive manufacturing technology and high-precision finish machining operations for large format manufacturing. The AM technology is based on Directed Energy Deposition (DED) process. The nozzle deposits the molten metal layer by layer to build the part. DED is interesting for repair applications of worn or damaged components such as aerospace turbine blades. In terms of its Multi-Tasking capabilities, the INTEGREX i-400 AM provides full 5-axis machining to process prismatic parts from solid billets or castings, round parts, highly contoured parts and AM manufactured parts.

The nozzle deposits the molten metal layer by layer to build the part. DED is interesting for repair applications of worn or damaged components such as aerospace turbine blades. In terms of its Multi-Tasking capabilities, the INTEGREX i-400 AM provides full 5-axis machining to process prismatic parts from solid billets or castings, round parts, highly contoured parts and AM manufactured parts.

Kraken hybrid 3D printer

The KRAKEN project is a European project that was launched to bring an all-in-one hybrid manufacturing machine to the market at an affordable price. Therefore, the KRAKEN system provides 3D printing technologies, robotics and subtractive technologies. It has been developed for the production of end-use parts and large customized functional parts, measuring up to 20 meters long with 0.1mm precision. The creators claim that the system is 40% faster than competing methods thanks to high deposition rates during the AM process and a seamless switch to milling and finishing operations (with an interchangeable manufacturing head). KRAKEN is also said to be 25% more productive and take up to 90% less floor space. On the 3D printing side, it integrates multiple technologies too: wire arc AM, resin 3D printing, and a thermal spray process to allow metal 3D printing on top of a polymer part. This is a very complete solution to say the least!

KRAKEN is also said to be 25% more productive and take up to 90% less floor space. On the 3D printing side, it integrates multiple technologies too: wire arc AM, resin 3D printing, and a thermal spray process to allow metal 3D printing on top of a polymer part. This is a very complete solution to say the least!

LASERTEC 65 3D Hybrid by DMG Mori

The German-Japanese manufacturer DMG Mori, the result of the merger between the German company DMG and the Japanese company Mori Seiki, offers industrial manufacturing solutions for all industries. Its product range includes hybrid manufacturing machines that can both print and machine parts. Among them is the LASERTEC 65 3D Hybrid, a machine with a spray nozzle that offers additive metal fabrication and milling capabilities. It can create parts up to a maximum size of 735 x 650 x 560 mm and is based on the DED process. Equipped with 5 axes, it can change its laser head to mill the designed part. The LASERTEC 65 3D Hybrid integrates Siemens software solutions to maximize your design and control your manufacturing process.

LENS 860 hybrid 3D printer by Optomec

The LENS 860 has been designed by Optomec to provide industrial companies with large metal parts: it combines a DED process and a milling spindle for finishing work. Its maximum printing volume is 860 x 600 x 610 mm and its laser reaches a maximum power of 3kW. Four versions are now available, with or without milling, and with or without controlled atmosphere. Depending on the configuration you choose, you will be able to print non-reactive metals such as steel or flap, or metals such as titanium.

LUMEX Avance -25 by Matsuura

Released in 2002, LUMEX Avance-25 is a hybrid 3D printer developed by a Japanese manufacturer Matsuura. It combines metal 3D printing technology with conventional milling, CNC. This hybrid solution uses a 400 W Yb fiber laser and can store up to 20 tools, as well as 3D print parts at a speed of 7 cubic cm per hour, for a maximum part weight of 90 kg. An interesting advantage of this machine is its APR System (Automatic Powder Recovery System), which means that powder supply, collection and reuse can be fully automated without the need for the operator to directly touch the powder. Excess powder that remains after sintering is automatically sieved and reused for subsequent sintering.

Excess powder that remains after sintering is automatically sieved and reused for subsequent sintering.

Did this list of hybrid 3D printers help you? Let us know what you think of these hybrid 3D printers. Leave a comment below or on our Facebook and Twitter pages! Don’t forget to sign up for our free weekly Newsletter, with all the latest news in 3D printing delivered straight to your inbox!

Hybrid 5-axis milling machine and metal 3D printer

Plastic 3D printing has become quite a mass and fun phenomenon, but experts believe that metal 3D printers are machines that are going to really challenge traditional manufacturing techniques . And in this regard, the MPA 40 machining center, which has just been introduced to the German machine tool manufacturer Hermle, could be a game-changer. The new center is not only a large and very efficient milling machine; he can also 3D print metal in a rather unusual way.

Hermle is one of the world's leading manufacturers of milling machines, headquartered in a tiny village in southern Germany and known for developing cutting-edge metalworking technology. The new hybrid machining center is the result of a seven year development at the Ottobrunn R&D center with at least twenty of the company's engineers, and is quite different from most 3D printers we've come across.

The new hybrid machining center is the result of a seven year development at the Ottobrunn R&D center with at least twenty of the company's engineers, and is quite different from most 3D printers we've come across.

So we have a 5-axis machine that combines 3D printing with milling. But perhaps the most interesting is the printing technology. Most metal 3D printers are based on laser sintering or laser cladding technology, the MPA 40 3D prints metal objects using a more sophisticated technology sometimes referred to as "micro-forging". In essence, the proposed technology relies on a thermal spray process that provides a low kinetic energy seal and can be seen as a significant advance in industrial manufacturing technology.

Like a conventional 3D printer, the MPA 40 processes CAD files, but 3D printing is done with metal powders suspended in a nitrogen atmosphere. The task is set and the machine begins to print objects, blowing these metal powders through jets of superheated steam onto the substrate at a mind-blowing speed, three times the speed of sound. High speed creates a huge pressure of the order of 10 GPa, and the temperature reaches 1000 ° C. The result? The metal powder is compressed in a process of localized super-plastic deformation. Completed layers are then further processed in milling mode to ensure high quality dense levels before the MPA 40 continues with the 3D printing process. The technological process can be completed by heat treatment and water quenching.

High speed creates a huge pressure of the order of 10 GPa, and the temperature reaches 1000 ° C. The result? The metal powder is compressed in a process of localized super-plastic deformation. Completed layers are then further processed in milling mode to ensure high quality dense levels before the MPA 40 continues with the 3D printing process. The technological process can be completed by heat treatment and water quenching.

This process is distinguished not only by high precision, but also by the ability to mix different materials, placing one layer on top of another, with sharp or smooth transitions between them; if you want, you can create smooth objects with up to six different metals. The following powders are currently used in the MPA 40 for 3D printing: several types of steel, including stainless steel, copper, bronze, titanium and aluminum. Powder particles have a size between 25 and 75 microns.

The dimensions of the new machine mean that it can create quite large objects: up to 550 mm in diameter, up to 460 mm in height, weighing up to 600 kg. The speed of 3D printing is also quite high - up to 5 cm3 per minute, in the case of using steel powders. Optionally, you can use a filler made of a water-soluble material to build the internal elements of the part, for example, to create cooling channels.

The speed of 3D printing is also quite high - up to 5 cm3 per minute, in the case of using steel powders. Optionally, you can use a filler made of a water-soluble material to build the internal elements of the part, for example, to create cooling channels.

Of course, the new technology requires special software and Hermle has already developed its own CAM package. It currently provides layer analysis, machining calculation and process simulation.

Clearly far beyond the reach of today's 3D printing consumers, the 3D printer/CNC machine looks like a truly revolutionary device capable of rocking the foundations of mechanical engineering. The MPA 40 is not yet for sale, but Hermle is already actively consulting with potential customers to better understand the applications of this hybrid technology and make the machine as practical as possible.

Source: http://www.3ders.org/articles/20150224-hermle-unveils-giant-hybrid-5-axis-metal-3d-printer-cnc-mill-mpa-40. html

html

Comments (1)

| Like0 TechnoLab March 30, 2015 00:22:40 |

| To be honest, this Hermle machine was already shown at home 2 years ago. Rather marketing... |

| Name Quote Like0 |

Leave a comment

Log in or Register to leave a comment.

5 best 3 in 1 3D printers of 2022 (with laser engraving and CNC!)

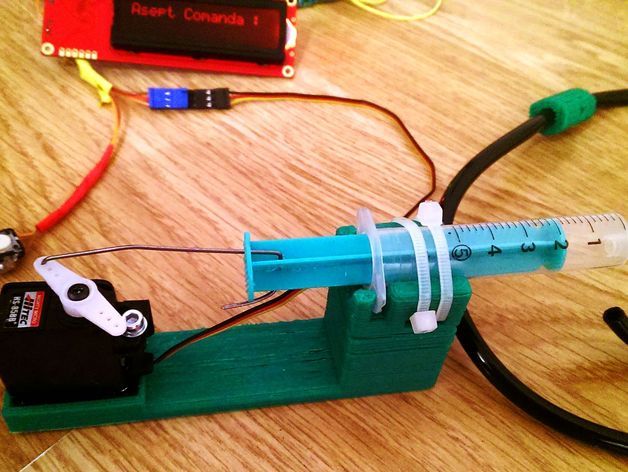

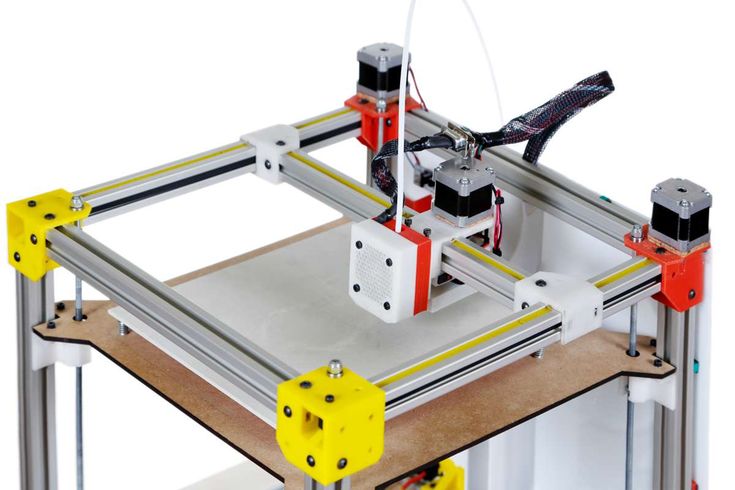

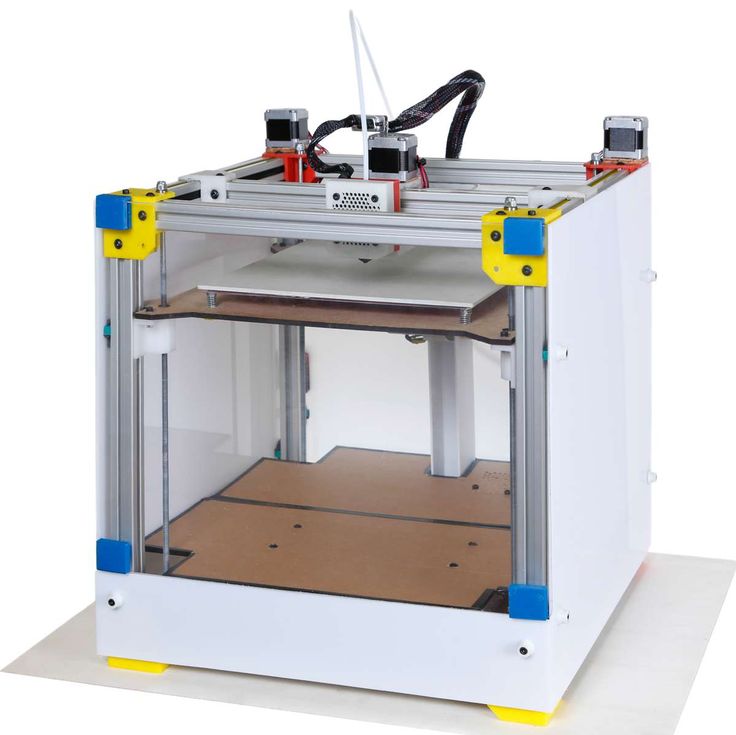

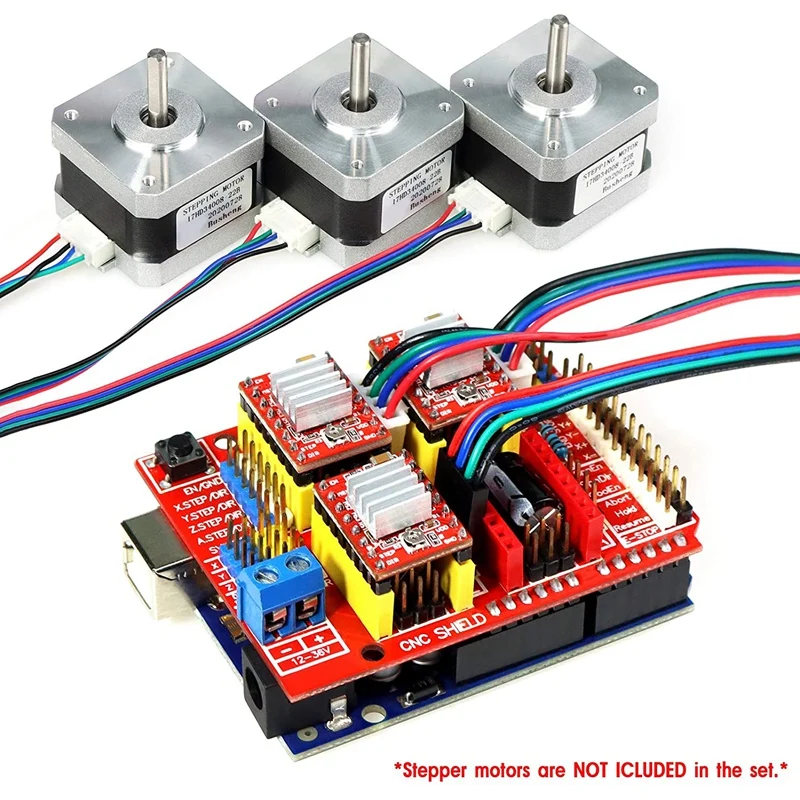

Ideally, we should all have one machine that could perform all the necessary production tasks - a laser 3D printer that would printed, laser cut, CNC engraved and much more. 3-in-1 3D printers aren't perfect yet, but they offer versatility in 3D printing, CNC machining, and laser engraving - at different levels.

These printers, sometimes referred to as multifunction 3D printers or AIO 3D printers, feature removable tool heads that can be swapped to change their functions. If you want to prototype and cut out a wooden model first, use a CNC machine and then switch to a 3D printer extruder to create the final plastic prototype.

If you want to prototype and cut out a wooden model first, use a CNC machine and then switch to a 3D printer extruder to create the final plastic prototype.

After testing dozens of 3D printers over the years, including our top pick, the Snapmaker 2.0, we've compiled our findings into our top 3-in-1 3D printer recommendations to help you make the best choice for you.

Contents

- How good are all-in-one 3D printers?

- The criteria we used to rate the best 3-in-1 3D printers

- When ranking the 3-in-1 3D printers we recommend below, we compared:

- The best all-in-one 3D printers

- Snapmaker 2.0 - Available in 3 shapes: A150, A250 & A350

- Snapmaker Original - A good starter laser engraver 3D printer

- ZMorph Fab - 4 in 1 3D printer

- Creality CP-01

- 5axismaker - Great CNC 3D Printer

- Diabase H-Series - Powerful CNC Milling 3D Printer

- Ecubmaker TOYDIY - 4 in 1 3D Printer

all in one"?

Naturally, focusing on being good enough at everything means losing quality in some areas. Elite athletes can't compete at the top of the NBA, NFL, and NHL at the same time - not even Michael Jordan could beat baseball - and the same is true for less specialized all-in-one 3D printers.

Elite athletes can't compete at the top of the NBA, NFL, and NHL at the same time - not even Michael Jordan could beat baseball - and the same is true for less specialized all-in-one 3D printers.

This is not to say that the 3D printer/laser hybrids we recommend don't work well. For hobby projects, laser 3D printers are great, but we don't recommend starting a full-service manufacturing company after purchasing a desktop 3D laser printer and CNC laser engraver.

The criteria we used to rate the best 3 in 1 3D printers

When ranking the 3 in 1 3D printers we recommend below, we compared:

- 3D Printer Quality: Most of these 3-in-1 3D printers are made by 3D printer companies and are mainly focused on additive manufacturing. Therefore, the quality of a 3D printer is a key factor.

- CNC Router Power: Some CNC machines cannot fully mill, only engrave. More powerful CNC machines rotate faster, can engrave harder materials, work more accurately and last longer.

- Laser engraver power: As with CNC machine, some all-in-one 3D printers can only engrave while others can cut materials.

- How easy it is to change heads: It's good to have powerful heads that work great, but if they're too hard or difficult to change, they can only do one thing.

- Software Efficiency: most of our recommendations contain specialized software that allows you to cut models for 3D printing, prepare designs for CNC and laser. The best software is easy to use, yet effective and reliable in all functions.

Best All-in-One 3D Printers

Snapmaker 2.0 - Available in 3 shapes: A150, A250 & A350

- Price: $1,199 to $1,799

- Assembly volumes: A150 = 160 x 160 x 145 mm / A250 = 230 x 250 x 235 mm / A350 = 320 x 350 x 350 mm

- Type: 3D in 1 3D printer: 3D printing, CNC and laser engraving

The original Snapmaker has already made a splash with over $2. 2 million on Kickstarter, but Snapmaker 2.0 has completely surpassed all expectations, becoming the most funded tech project in Kickstarter history, raising an astounding $7.85 million. Thousands of enthusiastic fans who love Snapmaker Original , are back to support the new version, and it has remained the most popular all-in-one 3D printer since its full release.

2 million on Kickstarter, but Snapmaker 2.0 has completely surpassed all expectations, becoming the most funded tech project in Kickstarter history, raising an astounding $7.85 million. Thousands of enthusiastic fans who love Snapmaker Original , are back to support the new version, and it has remained the most popular all-in-one 3D printer since its full release.

We've tested and reviewed Snapmaker 2.0 and talked about how great it is. It is undoubtedly the best 3-in-1 3D printer, offering fantastic 3D printing experience as well as excellent CNC carving and laser processing. You could even call it a 4-in-1 3D printer, as you can purchase an optional 4-axis rotary module that turns the laser and CNC heads into 4-axis versions with a 360-degree field of view. We've carved cylindrical chess pieces, engraved cylindrical gift boxes, and more with this add-on.

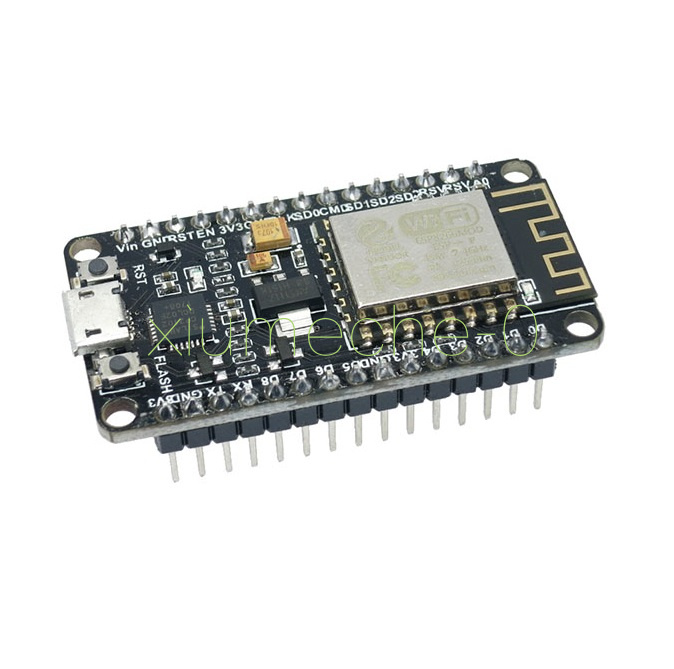

The 3D printer can print with PLA, ABS and flexible filaments such as TPU, and with WiFi and USB connectivity, you can print remotely online or offline using USB. The portable and movable touch screen used to control the printer looks and acts like a smartphone, simplifying workflow and making it easier to control and manage projects.

The portable and movable touch screen used to control the printer looks and acts like a smartphone, simplifying workflow and making it easier to control and manage projects.

What's more, the low filament sensor automatically pauses printing when it runs out, giving you time to load more filament and resume printing without ruining it, and if you purchase an extra housing, you can print ABS more easily to prevent warping - and save money. CNC from dust, and laser brightness from your eyes.

Snapmaker 2.0 3D printed vase

A vase that we 3D printed with Snapmaker 2.0.

The laser engraver creates high contrast images on fabrics, leather, plywood and acrylic materials. The built-in camera allows you to monitor the design remotely and make sure everything runs smoothly. This is an efficient low cost laser 3D printer. We also tested it as a laser cutter and were able to cut and assemble a gift box from a 1.5mm thin sheet of softwood.

Snapmaker 2. 0 laser 3d printer with laser cutter

0 laser 3d printer with laser cutter

Snapmaker 2.0 also works as a laser cutter as well as a 3D printer.

The CNC machine can carve designs on walnut, PCB wood, as well as carbon fiber sheets, acrylic and hard wood. A key enhancement to Model 2.0 is increased speed, which means that large projects can be created in record time.

Overall, we highly recommend the Snapmaker 2.0 models, of which we tested the largest version, the Snapmaker 2.0 A350. You can optionally purchase a body, a 4-axis rotary module, and a powerful new 10W laser head, but we haven't tried the 10W laser head.

We recommend purchasing a housing for safer and more consistent manufacturing, as well as replacement CNC bits.

Snapmaker Original is a good starter laser engraver 3D printer

- Price: $719

- Assembly volume: 125 x 125 x 125 mm

- Type: 3 in 1 3D printer: 3D printing, CNC and laser engraving

Snapmaker went public and made headlines when it raised an incredible $2. 2 million on Kickstarter for its first all-in-one 3D printer, the Snapmaker Original. Functioning as a small 3D printer, as well as being able to carve wood and engrave images into phone cases and other materials, the Snapmaker Original captured the hearts of many crafters around the world and became a wild success.

2 million on Kickstarter for its first all-in-one 3D printer, the Snapmaker Original. Functioning as a small 3D printer, as well as being able to carve wood and engrave images into phone cases and other materials, the Snapmaker Original captured the hearts of many crafters around the world and became a wild success.

The heated bed of the 3D printer can reach 80C, allowing both ABS and PLA to be printed. It is accurate, with layer resolution down to 50 microns. The heavy metal frame secures the printer and improves stability and durability, while the heavier frame is less prone to vibrations that can affect print quality and surface quality.

The CNC cutter can create intricate parts up to 90 x 90 x 50mm and the laser engraver works up to 125 x 125mm.

Snapmaker's 3-in-1 software, Snapmaker Luban, allows you to do 3D printing, CNC and laser engraving on the same platform and seamlessly switch between each tool head.

Snapmaker claims that a 3D printer can be assembled in just 10 minutes, and switching between tool heads to change the functions of an all-in-one 3D printer is very easy. Highly acclaimed by manufacturers as one of the best 3-in-1 3D printers in its price range, Snapmaker recently upgraded the Original with the Snapmaker 2.0, with a higher build volume and higher price tag.

Highly acclaimed by manufacturers as one of the best 3-in-1 3D printers in its price range, Snapmaker recently upgraded the Original with the Snapmaker 2.0, with a higher build volume and higher price tag.

A selection of wood and other materials cut with the Snapmaker Original CNC tool head. Source: snapmaker.com

ZMorph Fab 4 in 1 3D Printer

- Price: $3,999 for a complete set of

- Assembly volume: 250 x 235 x 165 mm

- Type: 4 in 1 3D printer with CNC milling, laser cutting and engraving and thick paste extruder.

- Home country: Poland

Polish company ZMorph makes some of the most versatile all-in-one 3D printers: Fab can print, CNC, engrave and laser cut, and can even turn into a food 3D printer with ZMorph's thick paste extruder . This edible material can print chocolate as well as other similar materials such as icing and pastry.

ZMorph 3D printers are renowned for their reliability and workhorse quality, and the Fab is no exception. This is a great 3D printer with a high quality heated bed that can comfortably print ABS, HIPS and other stiffer materials like nylon. The printer can automatically align and easily transform from a 3D printer to a laser engraver or CNC router.

This is a great 3D printer with a high quality heated bed that can comfortably print ABS, HIPS and other stiffer materials like nylon. The printer can automatically align and easily transform from a 3D printer to a laser engraver or CNC router.

Also, with the dual head option, the ZMorph works well as a dual extruder 3D printer, capable of printing multiple colors or soluble support materials such as HIPS and PVA, and even mixing two colors together to produce multiple different shades in one details. The hybrid CNC laser 3D printer can be configured to print with both 1.75mm and 3mm 3D printer filaments, and has a large enough build area to print even the largest projects.

When used with a CNC tool head, the ZMorph becomes a powerful 3D printer with a CNC router that can mill and engrave almost any type of wood, as well as other materials such as acrylic glass and EVA foam. The 300W power allows you to mill at speeds up to 120mm/s, while ZMorph recommends a cutting depth of up to 0. 5mm.

5mm.

The Laser PRO attachment turns the Fab into a 3D laser engraver capable of burning and engraving plywood and many other types of wood, cardboard, leather and acrylic glass with a powerful yet compact 2.8W blue laser. Although the default speed is 15mm/s, the laser can run up to 120mm/s for faster engraving.

ZMorph's Voxelizer 2 software works as a 3D slicer for 3D printing parts, and offers the features of CAD CAM software for CNC and laser cutting models, all in one. All in all, this is a fantastic and extremely versatile all-in-one 3D printer and the closest thing to a machine with a complete manufacturing facility.

zmorph vx cnc wood carving printer

ZMorph CNC tool head creates design from wood. Source: ZMorph on Medium.

Creality CP-01

- Price: $819

- Assembly volume: 200 x 200 x 200 mm

- Type: 3 in 1 3D printer: 3D printer, CNC and laser engraving

Creality makes the world's most popular affordable 3D printers today, including the Ender 3, Ender 5 and CR-10 series. The Creality CP-01 is their all-in-one 3D printer venture offering CNC engraving and laser engraving along with a 3D printer.

The Creality CP-01 is their all-in-one 3D printer venture offering CNC engraving and laser engraving along with a 3D printer.

As a 3D printer, it has a good print volume of 200 x 200 x 200mm and comes with a heated bed that can reach 100C. Such temperatures mean that 3D printing on ABS, HIPS and TPU shouldn't be a problem, and in theory you could even try printing on materials like polycarbonate and carbon fiber.

The textured glass plate should promote adhesion and reduce warping, and the direct drive extruder also makes flex filament 3D printing easier in most cases.

As a laser engraver, the Creality CP-01 3-in-1 3D printer is equipped with a 0.5W laser tool that can engrave areas up to 100 x 90mm. The engraver can create contrasting halftone patterns on paper, plastic and wood.

As a CNC cutter, the CP-01 is equipped with a 4800 rpm CNC rotating spindle, capable of cutting plastic, wood and circuit boards. It can cut sections of the same size as a 3D printer - 200 x 200mm.

The CP-01 comes with Creality Workshop's own 3D printer software that supports engraving and CNC functions. The offline Creality Slicer software is well suited for 3D printing.

Overall, it's similar to the Snapmaker and seems to offer similar specs and features, so it remains to be seen if the kings of cheap 3D printers can compete in the all-in-one 3D printer sector.

Each of Creality CP-01 tool heads for 3D printing, CNC cutting and laser engraving.

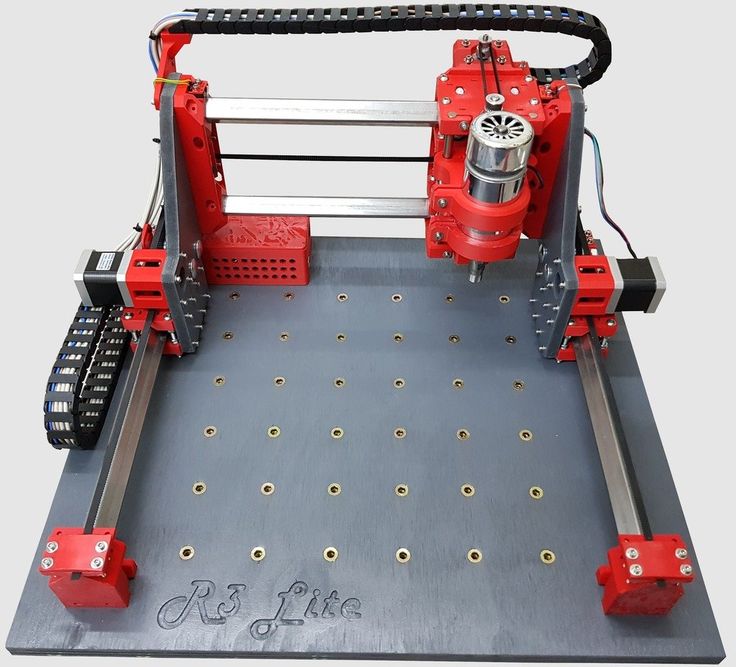

5axismaker - great CNC 3D printer

- Price: £5,500 / £6,800 depending on size

- Assembly volume: 5xm400 = 400 x 400 x 400 mm / 5xm600 = 600 x 600 x 400 mm

- Type: 2 in 1 CNC 3D printer

London-based 5axismaker has developed a great multi-function CNC 3D printer that comes in two main sizes to meet your production needs:

- 5axismaker 5xm400 model: 400 x 400 x 400mm building volume

- model 5axismaker 5xm600: 600 x 600 x 400 mm

As a 3D printer, the 5axismaker comes with a default 0. 6mm nozzle - although you can go to 0.4mm if you're used to smaller nozzles, and up to 1.2mm nozzles if speed is important to you and you are willing to sacrifice some precision. 5axismaker can print to PLA or ABS.

6mm nozzle - although you can go to 0.4mm if you're used to smaller nozzles, and up to 1.2mm nozzles if speed is important to you and you are willing to sacrifice some precision. 5axismaker can print to PLA or ABS.

As a CNC machine, 5axismaker offers a fast spindle speed of 10,000-15,000 RPM on a powerful 500-1000W brushless motor capable of milling foam, hardwood, carbon fiber, engineering plastics, processable wax, etc. .d. There is also a touch sensor option - but for this head and any other custom tools you need to contact 5axismaker directly.

5axismaker has also developed its own CAM software to support CNC milling and NC code generation called 5xmonkey. 5axismaker focuses primarily on CNC machining, preferring not to offer laser engraving with a 3D printer, but it is well suited as a 2 in 1 3D printer.

- Price: from $9,750

- Assembly volume: depends on the number of axles

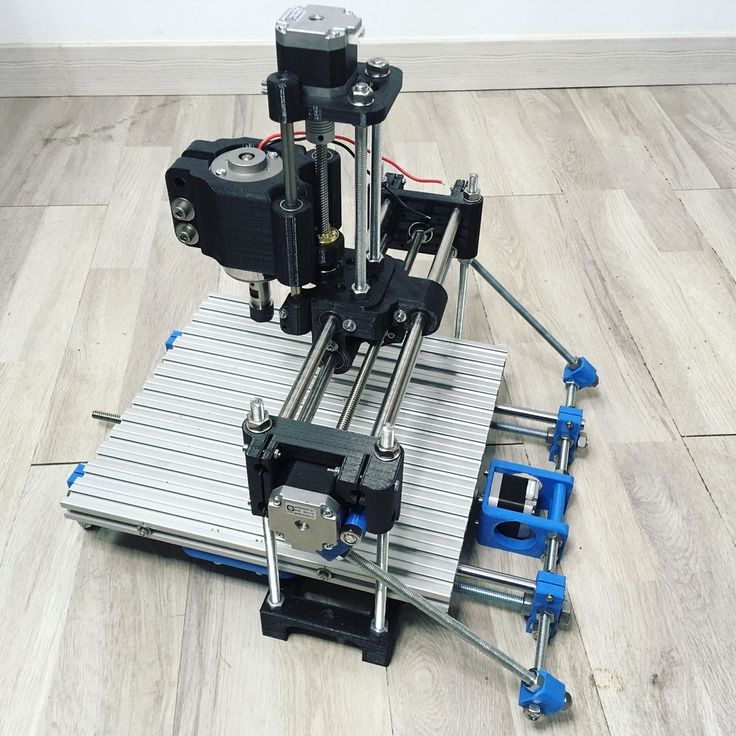

Another 2-in-1 3D printer focused on 3D printing and CNC milling, Diabase offers three different H-series options:

H5-400A Hybrid: no tool plate, 5 or 4 axis upgradeable , but can mill printed parts.

H5-400A CNC Lite: offers 4 and 5 axis upgrades.

H5-400B CNC Full: offers 4 material printing, 14 tool changes and a powerful spindle.

Diabase is already well known for its excellent 3D printer extruders focused on making 3D printing as reliable as possible with flexible filaments that were previously considered difficult to print - especially on Bowden extruders.

Now they offer a complete manufacturing solution: their multifunctional 3D printers can print and mill parts in a single workflow with each tool head.

h-series diabase CNC 3D printer

H-series hybrid 3D printer with CNC cutter offers 5-axis CNC production and 12,000 RPM rotation speed to create very complex and intricate parts. As a 3D printer, it allows 3D printing in multiple materials such as TPU and PVA, with PVA's solubility making it ideal for later easy removal of PVA supports. The CNC milling part can machine soft metals up to 75 HRB hardness, truly a full service solution.

Diabase H-series rotary axes provide fantastic detail complexity and complex geometries for production.

Ecubmaker TOYDIY - 4 in 1 3D Printer

- Price: $549

- Case volume: 180 x 180 x 180 mm

- Type: 4 in 1 3D printer: FDM, dual color, CNC engraving and laser engraving

- Country of manufacture China

Although it calls itself a 4 in 1 3D printer, this statement implies the division of the 3D printing part into standard FDM 3D printing and two-color 3D printing, which both belong to 3D printing. In reality Ecubmaker TOYDIY is a 3 in 1 3D printer but with four easily interchangeable tool heads for 3D printing, CNC engraving or laser engraving.

For 3D printing, the extruder can reach up to 240C and the heated bed up to 50C. Therefore, printing with higher temperature materials such as ABS and HIPS is not possible and you are limited to using the Ecubmaker TOYDIY as a PLA 3D printer only. (Testing has been done to use a dual extruder for PVA printing as a support, although the company does not recommend this). So when using the dual extruder 3D printing option, you can only print two different colors of PLA, not soluble support materials.

So when using the dual extruder 3D printing option, you can only print two different colors of PLA, not soluble support materials.

ecubmaker toydiy 4 in 1 3d printer

Each of the four modes of Ecubmaker TOYDIY.

For a laser 3D printer that doesn't specialize in any one measurement, it's surprisingly accurate - with layer thicknesses down to 0.05mm. The foldable three-layer plate also makes it easier to remove finished prints and helps reduce buckling, although PLA rarely warps.

As a laser engraver, TOYDIY 3D printer is equipped with a 1500MW violet laser, which can engrave wood, plastic, leather, cardboard and some other materials. However, this is purely a laser engraver and cannot cut materials.

The CNC tool head is equipped with a 385DC motor that rotates at 8,000 to 10,000 rpm. The CNC printer can engrave and cut wood, plastic, acrylic and most non-metal materials, but cannot be used with transparent materials such as glass.